Shaft seal electric heater system and method preventing steam seal journal sticking of 1000MW ultra supercritical turbine

An electric heater, ultra-supercritical technology, applied in the direction of leakage prevention, machines/engines, mechanical equipment, etc., can solve problems such as low auxiliary steam temperature, rotor lock, large shaft bending, etc., to meet the requirements of shaft seal temperature, Prevent the steam seal from holding the shaft and avoid dry burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

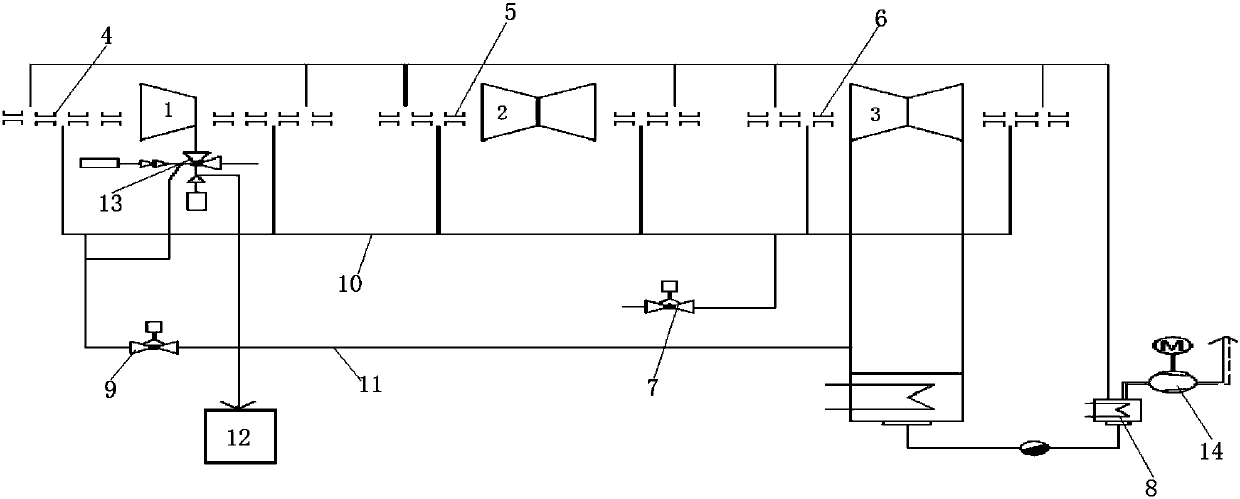

[0038] Such as figure 1As shown, the present application provides an electric heater system for preventing 1000MW ultra-supercritical steam turbine steam seal from holding the shaft, the system includes a supercritical steam turbine shaft seal system, and the ultra-supercritical steam turbine shaft seal system includes 1, the high-pressure cylinder shaft seal 4 at both ends, the medium-pressure cylinder shaft seal 5 disposed at both ends of the medium-pressure steam turbine 2, and the low-pressure cylinder shaft seal 6 disposed at both ends of the low-pressure steam turbine 3, the high-pressure cylinder shaft seal 4, the medium-pressure cylinder shaft seal 5 and the low-pressure cylinder shaft seal 6 communicate with the shaft seal steam supply main pipe 10 respectively through the shaft seal steam pipeline, and the steam supply regulating valve 7 is arranged on the pipeline connecting the shaft seal steam supply main pipe 10 and the auxiliary steam system; The critical steam ...

Embodiment 2

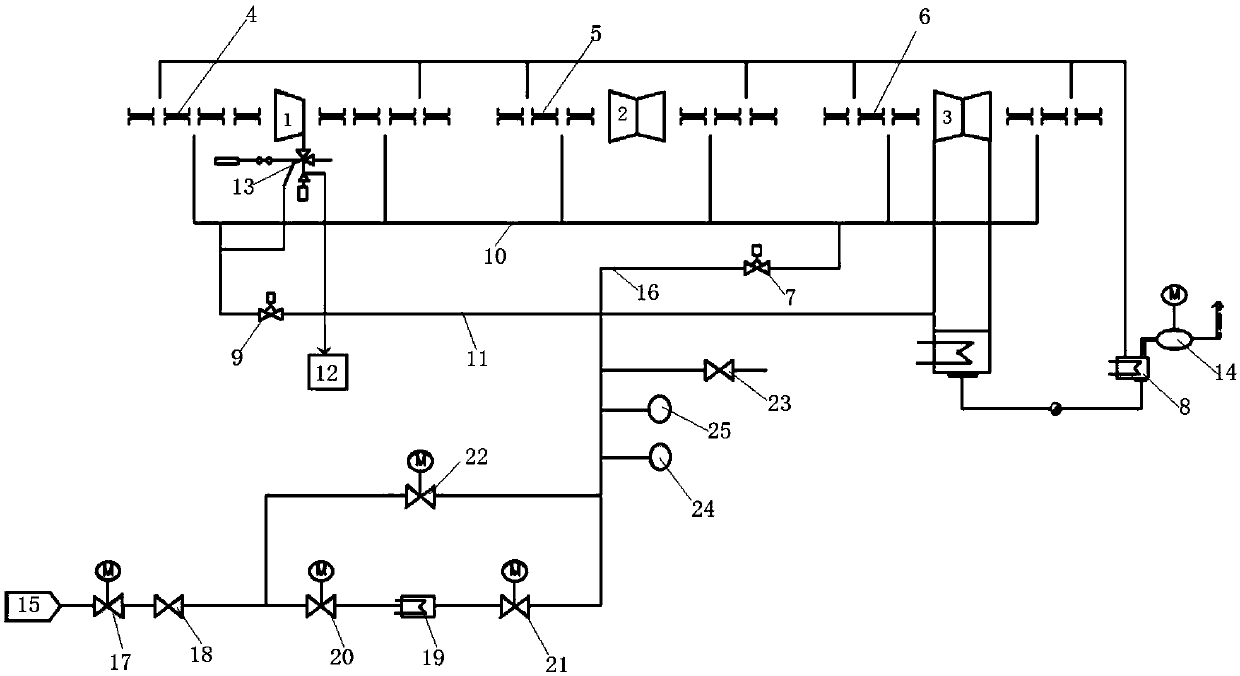

[0044] Such as figure 2 As shown, this embodiment provides a shaft seal electric heater system for preventing 1000MW supercritical steam turbine seal, including a supercritical steam turbine shaft seal system and a shaft seal electric heater system, and the ultra-supercritical steam turbine shaft seal system It includes a high-pressure cylinder shaft seal 4 arranged at both ends of the high-pressure steam turbine 1, an intermediate-pressure cylinder shaft seal 5 arranged at both ends of the medium-pressure steam turbine 2, and a low-pressure cylinder shaft seal 6 arranged at both ends of the low-pressure steam turbine 3. The high-pressure cylinder shaft seal 4, The medium-pressure cylinder shaft seal 5 and the low-pressure cylinder shaft seal 6 communicate with the shaft seal steam supply main pipe 10 through the shaft seal steam pipe respectively, and the shaft seal steam supply main pipe is connected to the auxiliary steam system 15 through the auxiliary steam pipe 16. A st...

Embodiment 3

[0052] This embodiment proposes a working method for preventing a 1000MW supercritical steam turbine steam seal shaft-hugging shaft seal electric heater system, including the following steps:

[0053] When the steam turbine starts and the load is low, if the shaft seal steam does not meet the temperature requirements, the electric heater system is put into operation, and the shaft seal steam electric door and the shaft seal electric heater bypass door are opened;

[0054] Open the front electric door of the shaft seal electric heater and the rear electric door of the shaft seal electric heater, and keep the drain valve normally open;

[0055] Put in the electric shaft seal heater and close the bypass door of the shaft seal electric heater;

[0056] Adjust the shaft seal steam temperature to 240°C to 300°C according to the shaft seal temperature limit curve.

[0057] The above-mentioned working method for preventing the 1000MW ultra-supercritical steam turbine steam seal shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com