Patents

Literature

715results about How to "Meet temperature requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

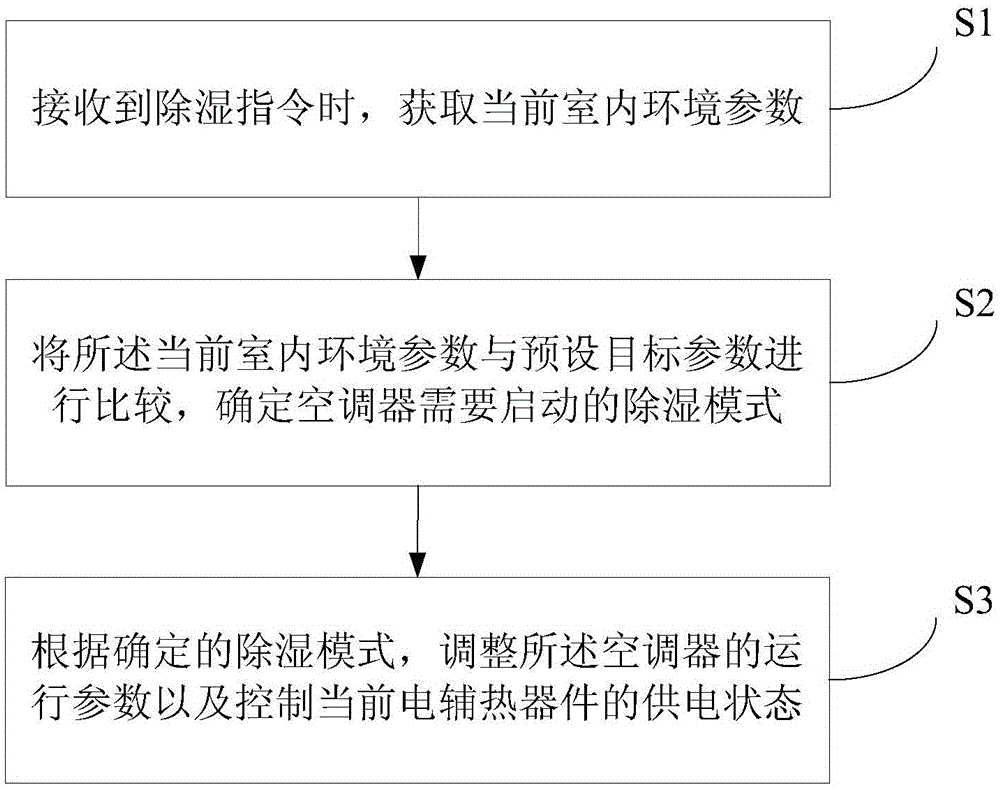

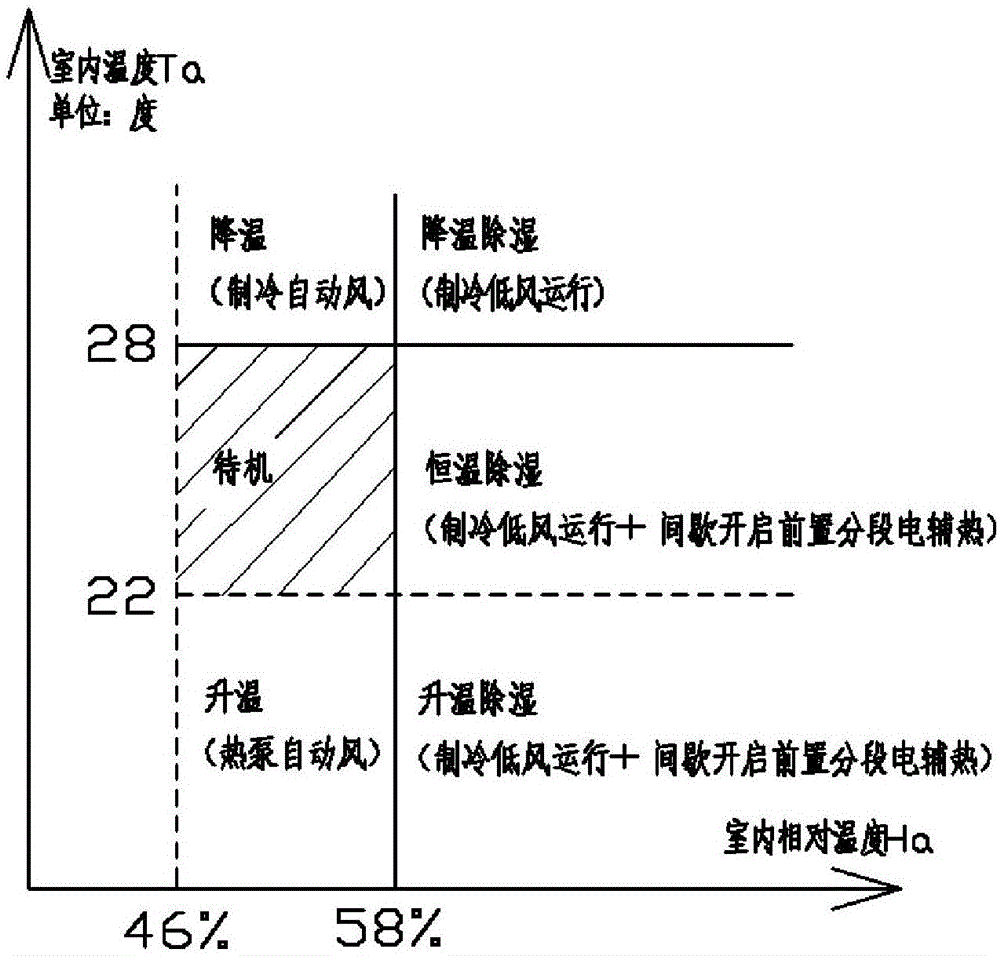

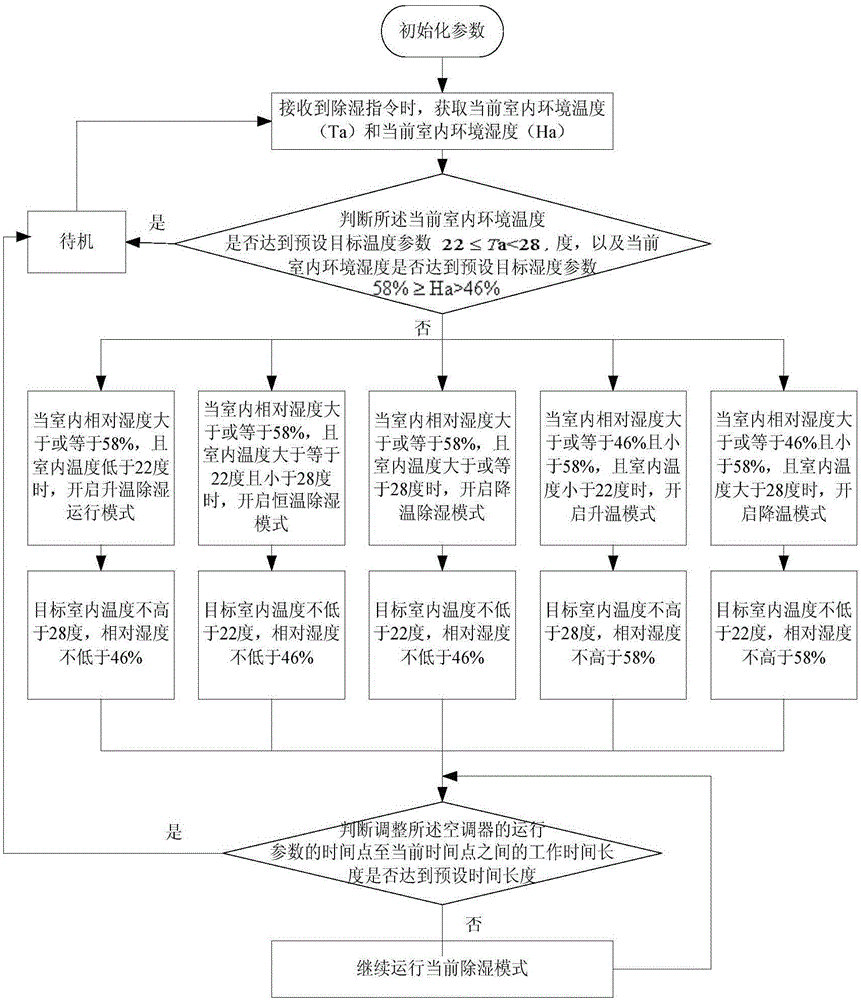

Dehumidification control method for air conditioner, controller and air conditioner

ActiveCN105157168AMeet temperature requirementsImprove experienceSpace heating and ventilation safety systemsLighting and heating apparatusControl theoryHeat exchanger

The invention provides a dehumidification control method for an air conditioner, a controller and the air conditioner. The dehumidification control method includes the steps that when a dehumidification command is received, a current indoor environment parameter is obtained; the current indoor environment parameter is compared with a preset target parameter, and a dehumidification manner required to be enabled for the air conditioner is determined; according to the determined dehumidification manner, the operation parameter of the air conditioner is adjusted, and the power supply state of current auxiliary electric heaters is controlled; the auxiliary electric heaters are arranged at the front end and / or rear end of fin type heat exchangers of a wind pipe machine of the air conditioner. By means of the dehumidification control method for the air conditioner, the controller and the air conditioner, quick dehumidification of a unit can be achieved while the appropriateness of the indoor temperature is guaranteed, and use experience is improved effectively.

Owner:HEFEI MIDEA HEATING & VENTILATING EQUIP

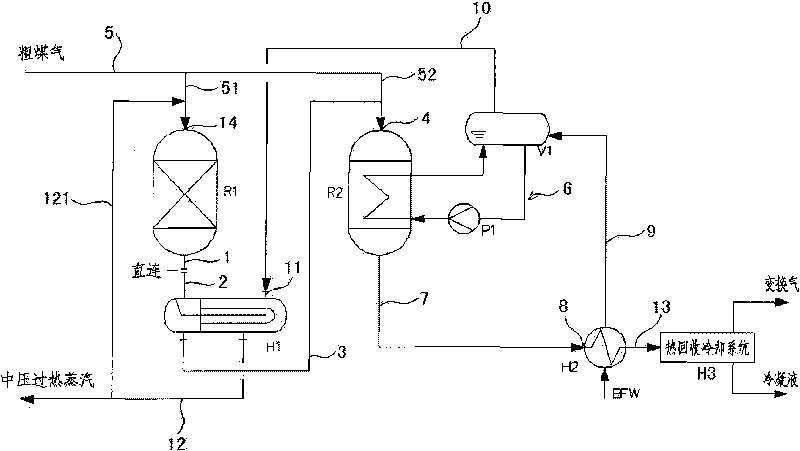

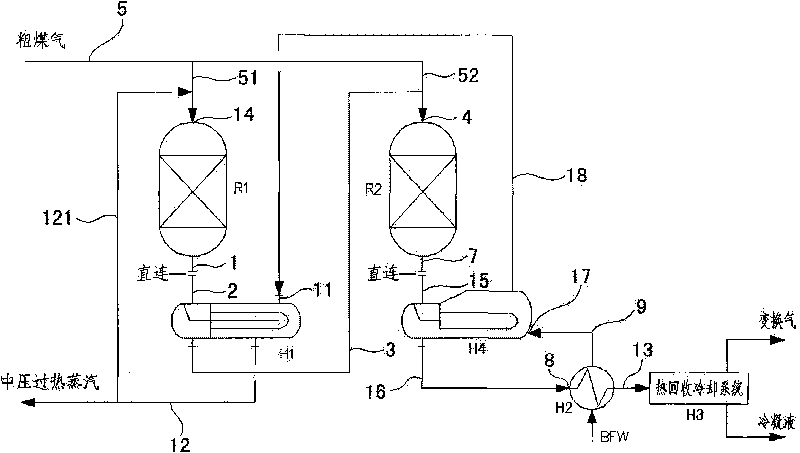

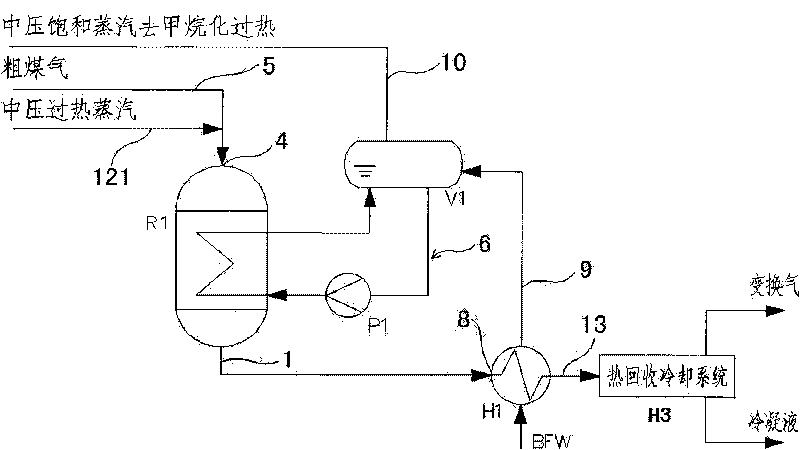

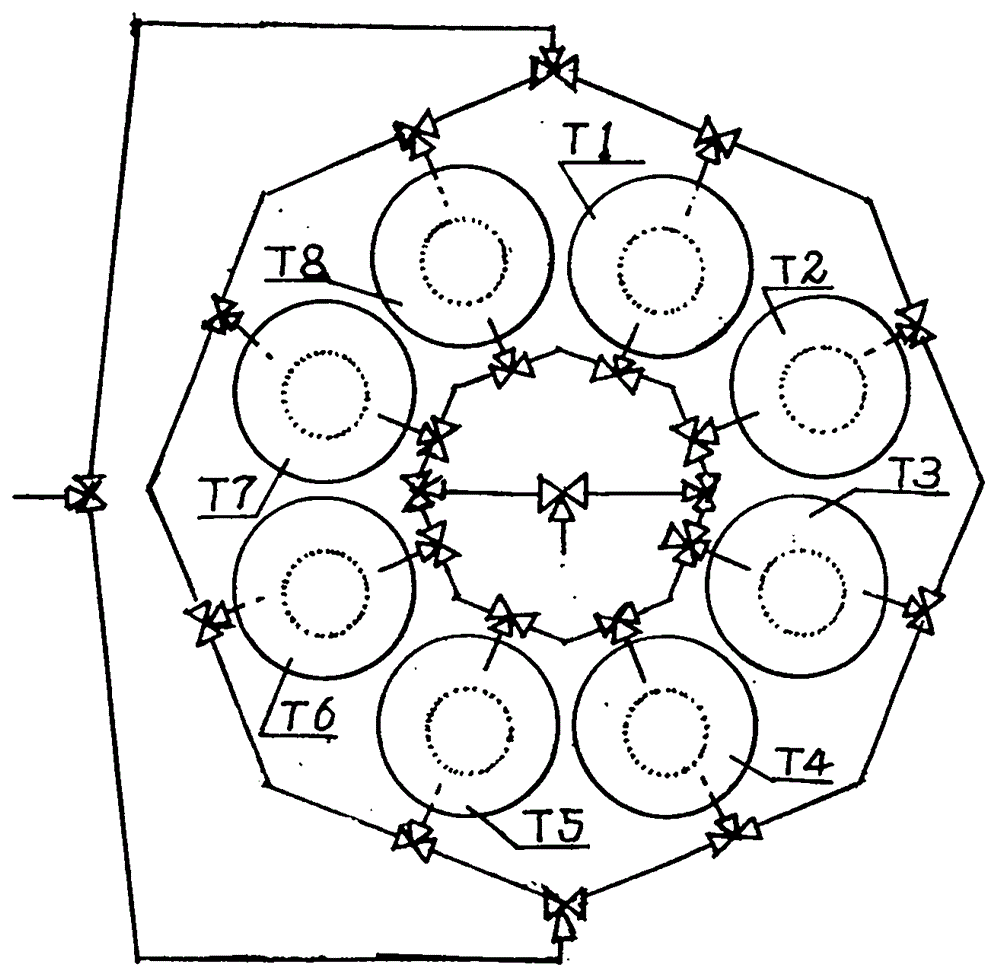

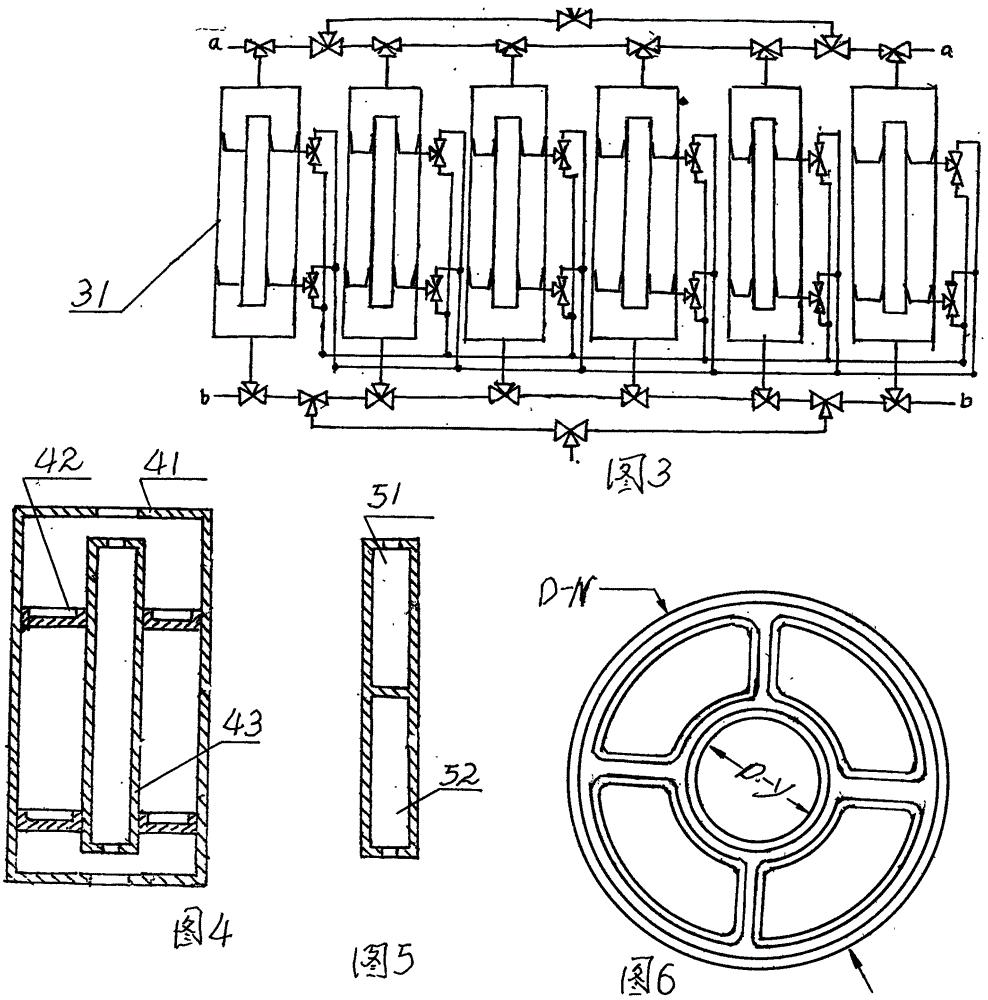

Shunting-type isothermal sulfur-tolerant conversion process and equipment thereof

ActiveCN101704513ASatisfy conversion rate requirementsMeet the requirements of adiabatic conversion control temperature riseHydrogenChemical industryShunt typesSulfur

The invention discloses a shunting-type isothermal sulfur-tolerant conversion process. The process comprises the following steps: shunting raw coal gas from exterior into at least two parts; leading overheat stream in the first part of the raw coal gas to increase the temperature to 200-300 DEG C; and then entering a first-stage conversion reaction step to carry out a conversion reaction and generate first conversion gas; and conveying the other part of the raw coal gas to next-stage conversion reaction step to carry out a conversion reaction. The catalyst bed of a shift converter has the advantages of stable temperature, simple control, convenient operation and low output CO content. The invention has the advantages of short conversion flows, few equipment, reduced resistance, great byproduct stream amount, high overheat temperature, stream pressure and heat recovery rate, and the like, thereby achieving the aims of reducing conversion stages, equipment number and resistance fall, decreasing investment, having great byproduct stream amount and high overheat temperature, stream pressure and heat recovery rate, reducing conversion stream consumption and outward wastewater discharge, protecting the environment and easily maximizing the device equipment. The invention also discloses shunting-type isothermal sulfur-tolerant conversion equipment used by the process.

Owner:SHANGHAI INT ENG CONSULTING

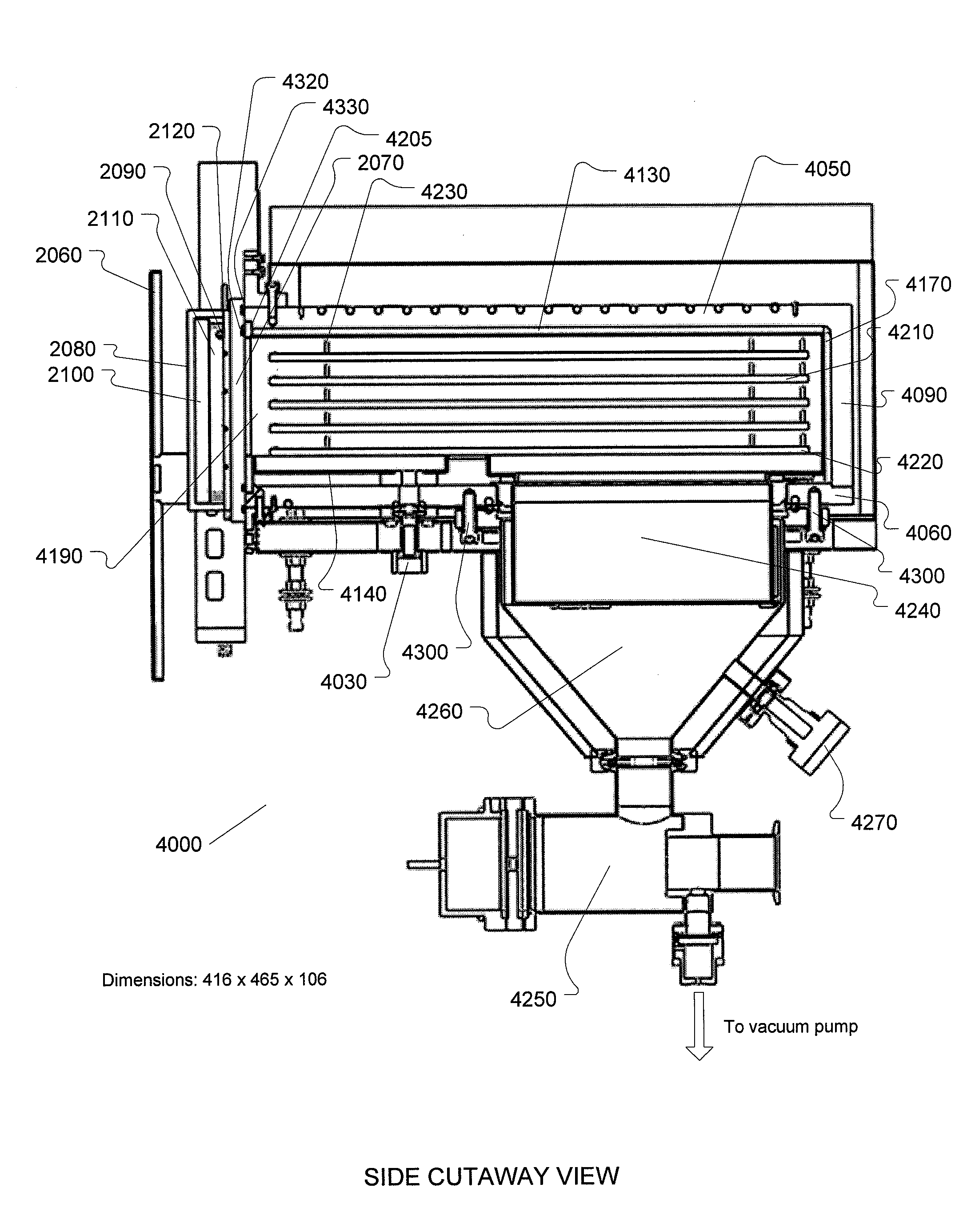

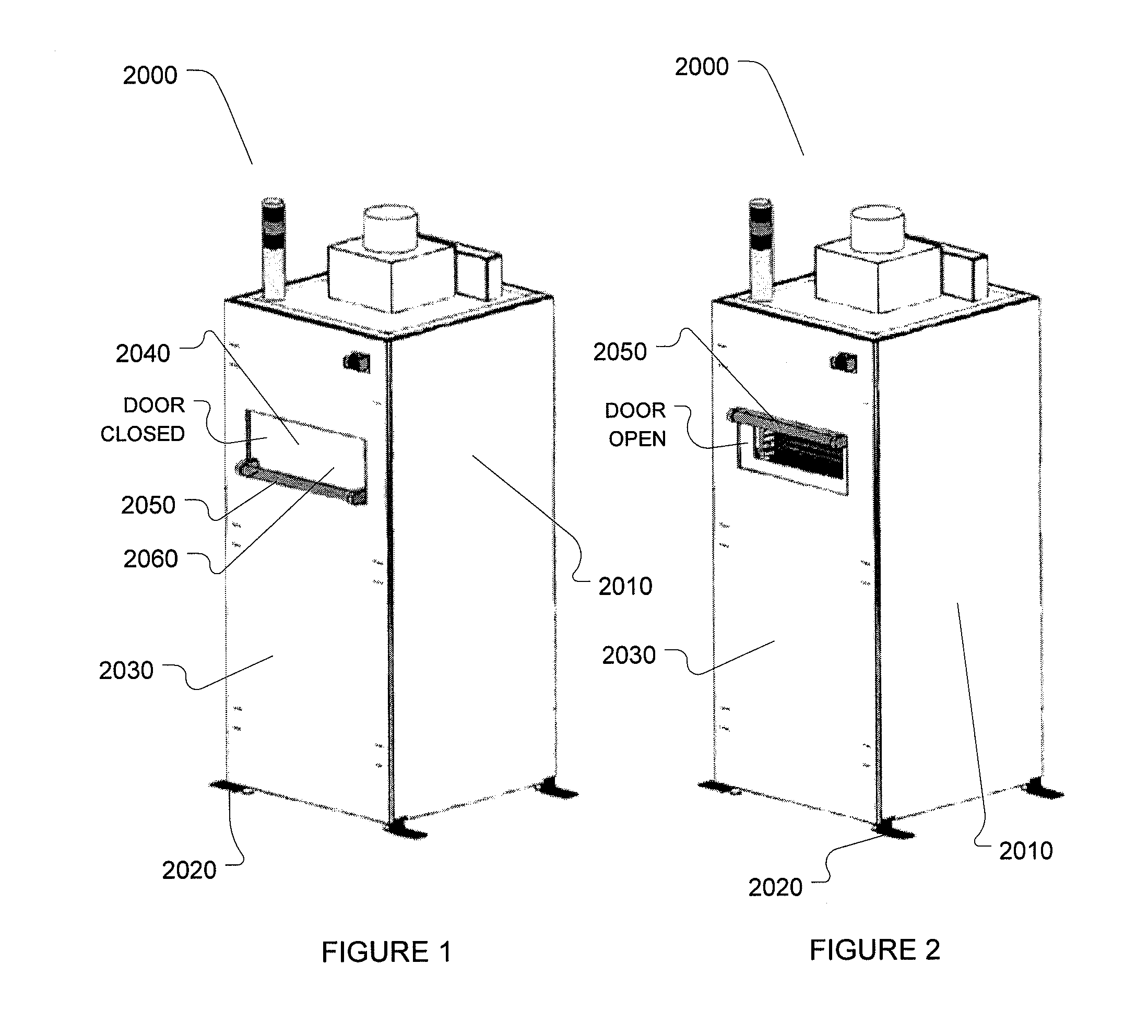

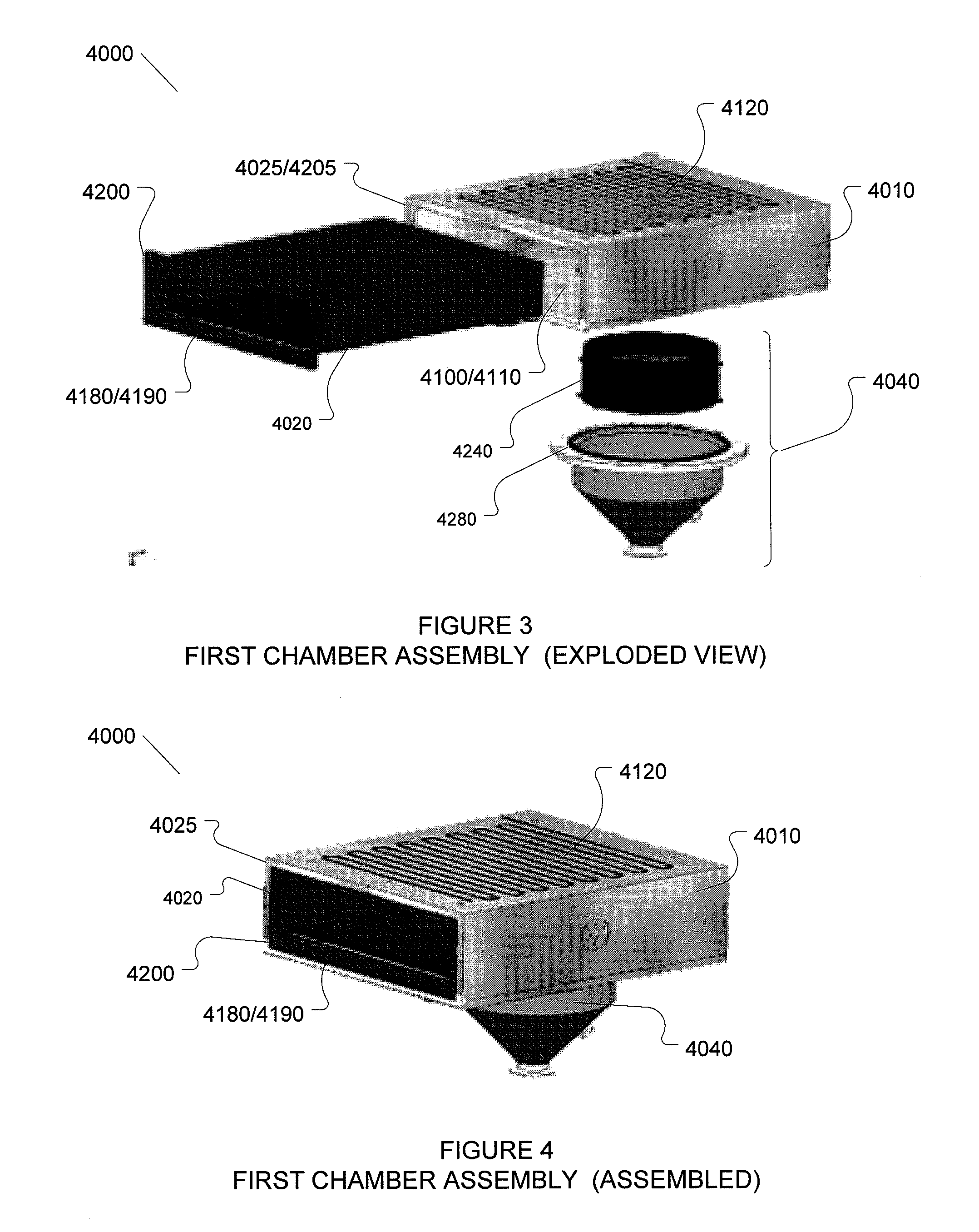

Reaction chamber with removable liner

ActiveUS20100247763A1Lower the volumeMaterial is undesirableChemical vapor deposition coatingAbrasive blastingEngineering

A reaction chamber assembly for thin film deposition processes or the like includes an outer wall assembly for enclosing an outer volume and a removable liner installed into the outer volume through an outer aperture for preventing precursors or reactants from coming into contact with internal surfaces of the outer wall assembly and forming thin film layers thereon. The removable liner encloses a reaction chamber and includes substrate support trays or the like for supporting substrates being coated. Thin film layers are formed onto internal surfaces of the removable liner instead of onto surfaces of the outer wall assembly. The removable liner may be disposable or may comprise stainless steel, which can be removed when contaminated, cleaned by abrasive blasting such as bead blasting, and replaced. Two removable liners can be used to periodically swap removable liners and clean one of the liners while the other is in service with minimal disruption to production coating schedules. Other removable cleanable elements such as input and output plenums, door liners and conduits comprising stainless steel can be periodically removed and cleaned by abrasive blasting.

Owner:VEECO INSTR

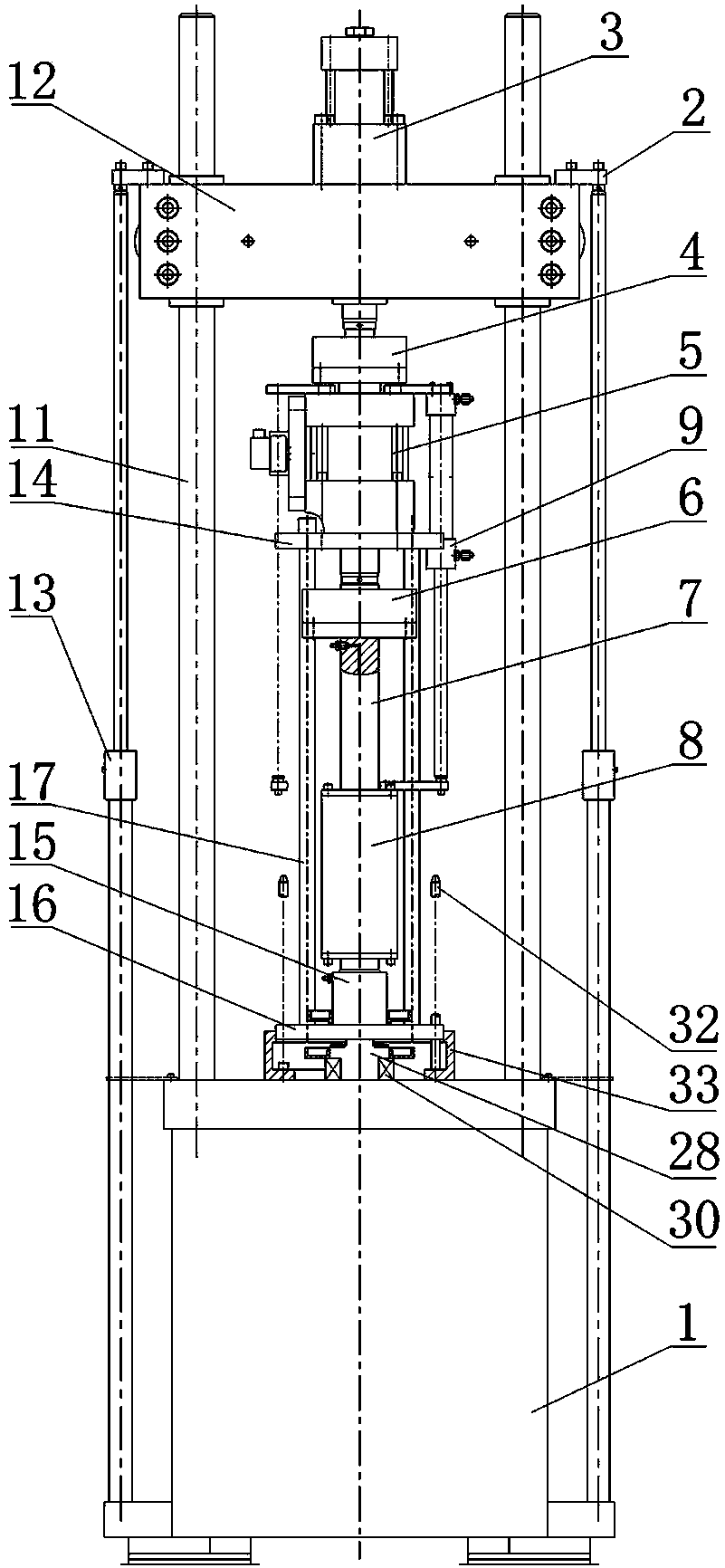

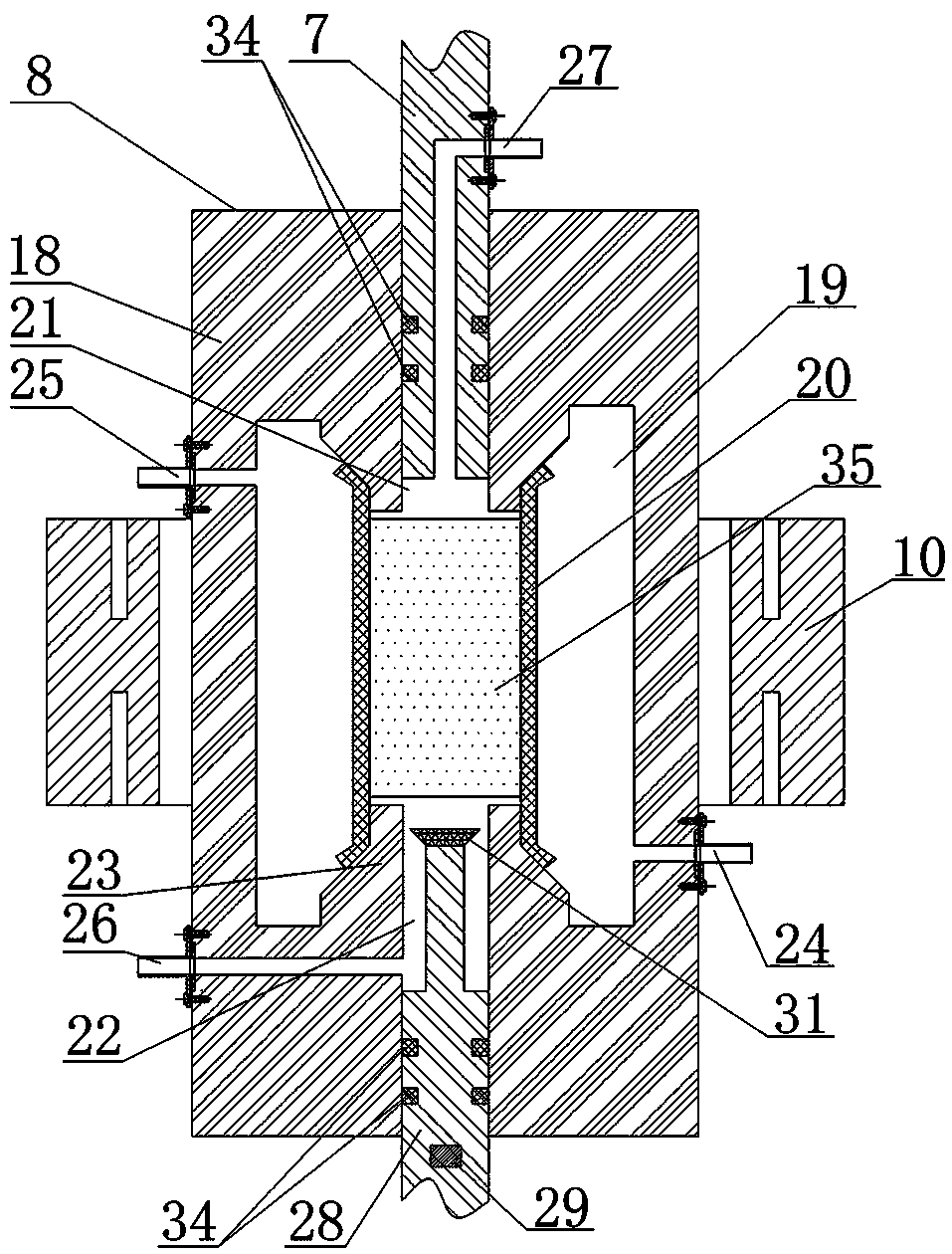

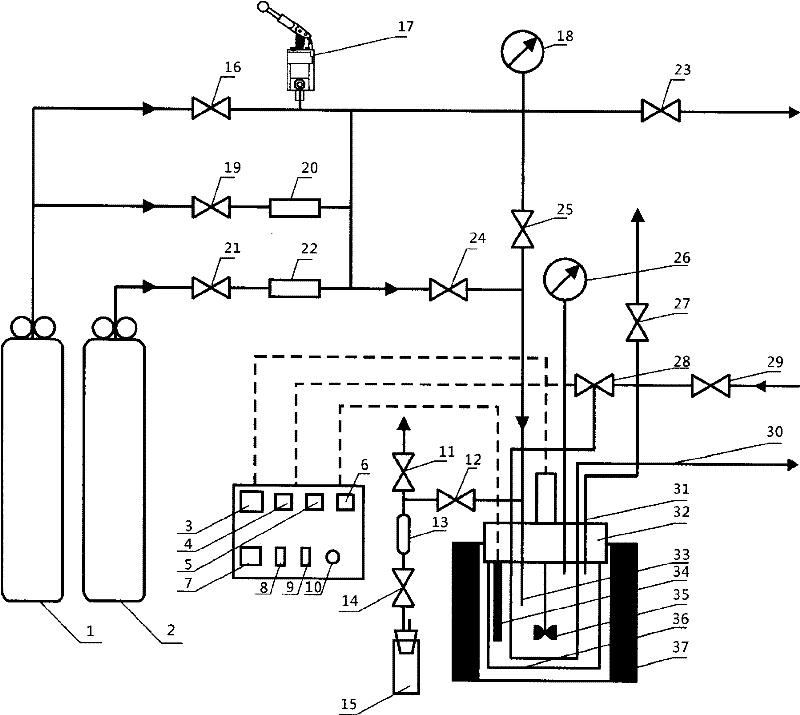

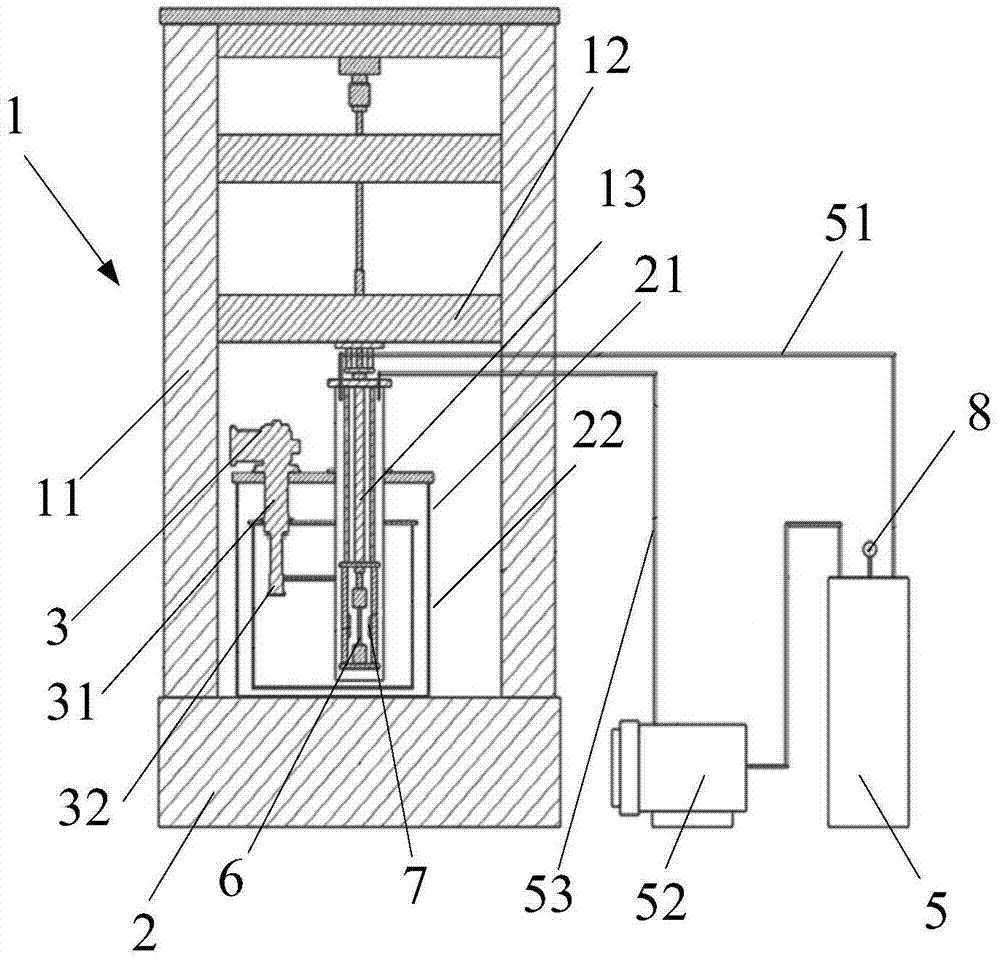

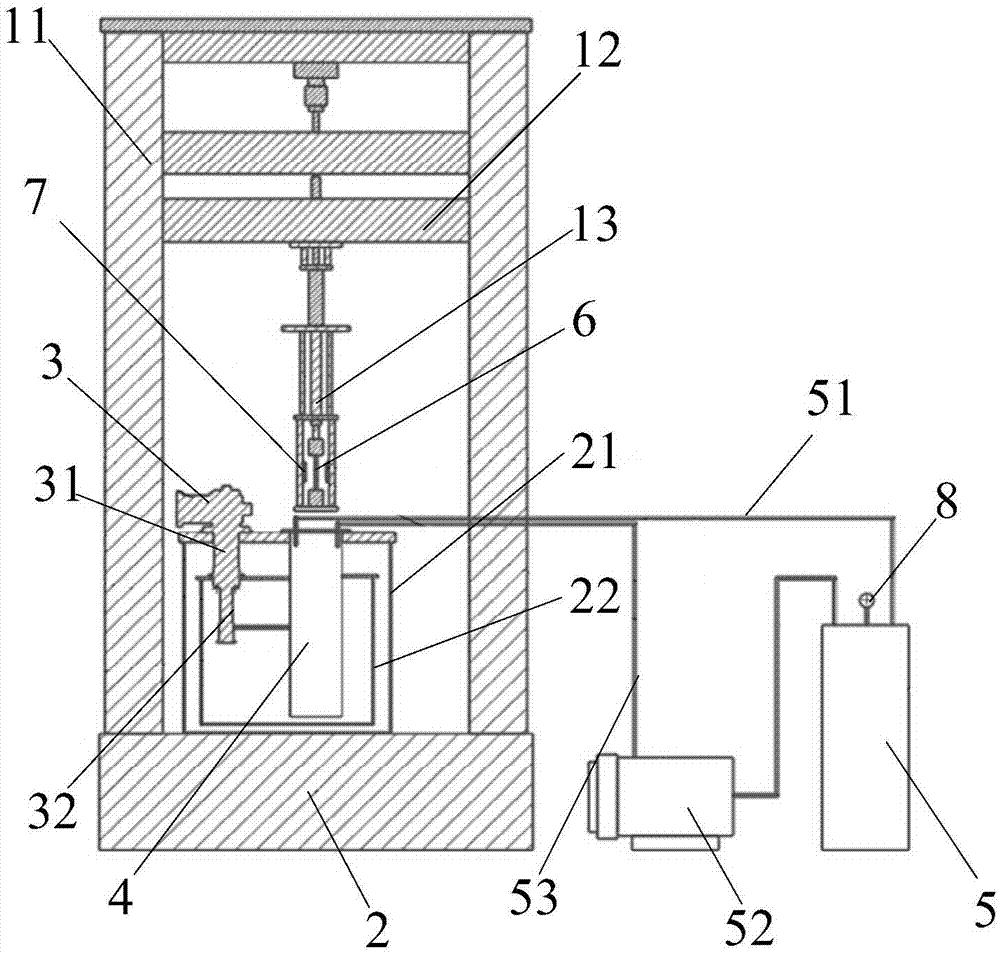

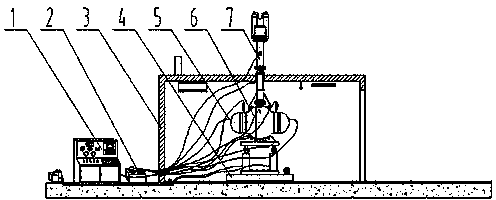

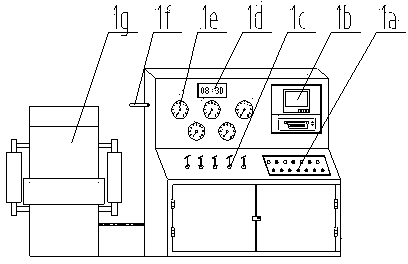

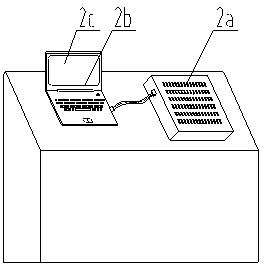

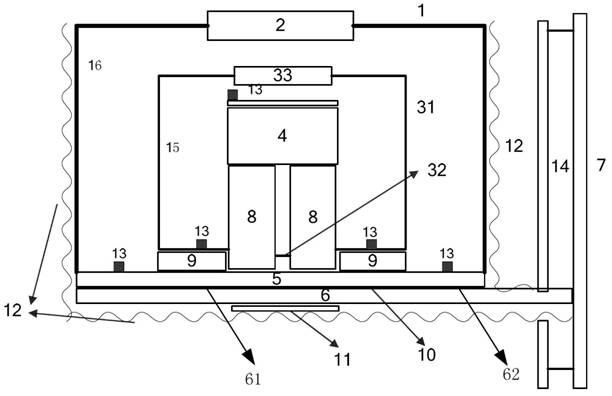

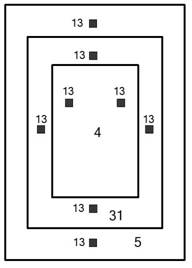

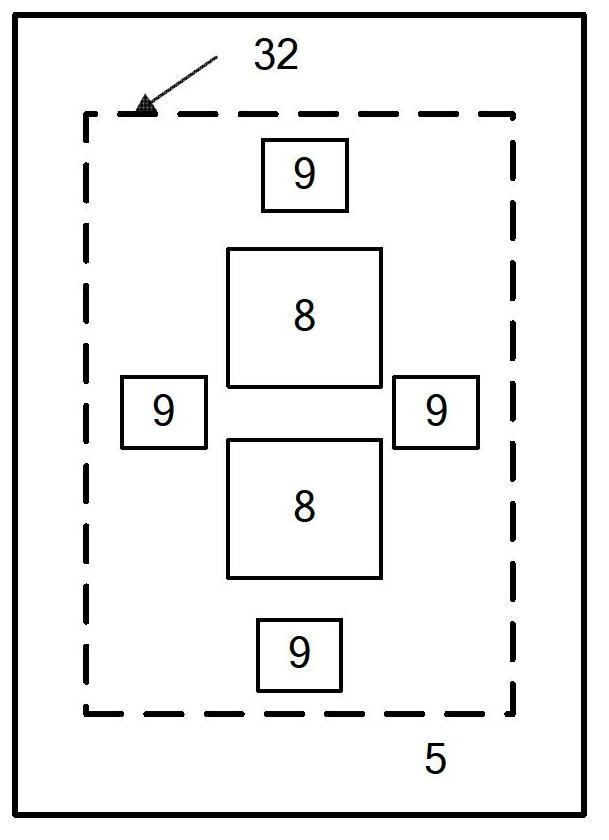

Method and device for testing rock drillability of deep well drilling and extra-deep well drilling

ActiveCN103806907AMeet temperature requirementsMeet pressure requirementsBorehole/well accessoriesExperimental testingWell drilling

The invention discloses a method and device for testing rock drillability of deep well drilling and extra-deep well drilling. The device comprises a machine frame (1), a high temperature and high pressure loading mechanism and a micro drill bit rock breaking drilling depth measurement mechanism, wherein the high temperature and high pressure loading mechanism and the micro drill bit rock breaking drilling depth measurement mechanism are arranged on the machine frame (1). The device exerts confining pressure, pore pressure and fluid column pressure on rock samples in cavities in three axes, overburden pressure is exerted on the rock samples through a hydraulic pump, and therefore the high pressure environment of the stratum of the bottom of a well can be simulated, the relation between the drilling depth and the time is tested through a displacement sensor at the position of a micro drill bit, optimization of the drilling pressure, the rotating speed and the drilling fluid type and drilling machinery drilling speed prediction are achieved. The method and the device have the advantages that the requirements for the bottom hole temperature and the pressure can be met in the deep well drilling process and the ultra-deep well drilling process, the function of testing multiple sets of rock drillability values through a single time of experimental testing of deep well drilling is achieved, the efficiency of the single time of experimental testing is greatly improved, and experimental cost is reduced.

Owner:SOUTHWEST PETROLEUM UNIV

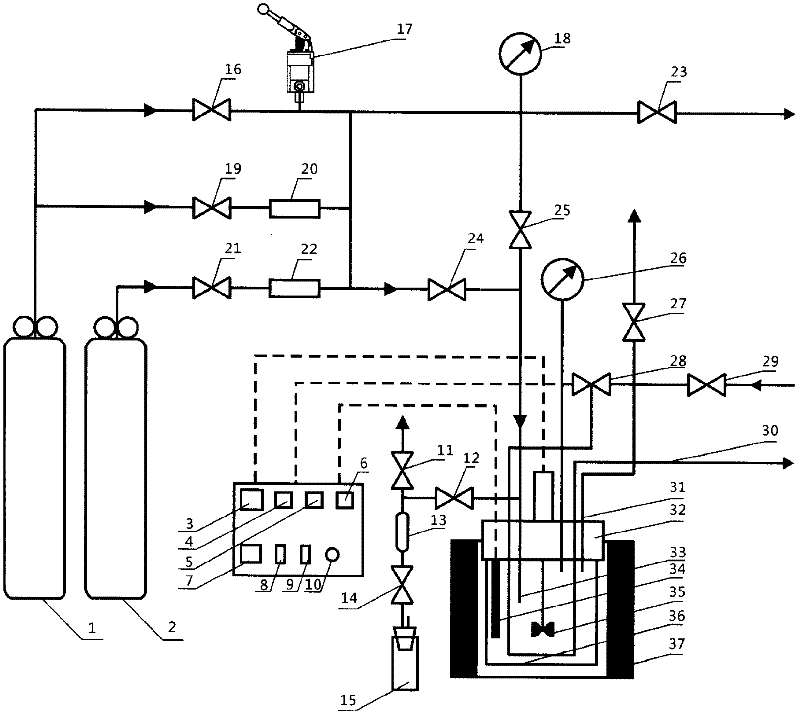

Batch experimental device of water-rock reaction in CO2 geological storage

InactiveCN102565273AMeet temperature requirementsMeet pressure requirementsPreparing sample for investigationChemical methods analysisProcess engineeringExhaust valve

The invention relates to a batch experimental device of water-rock reaction in CO2 geological storage. The batch experimental device comprises a reaction kettle, a CO2 gas cylinder, a water inlet pipe and a first exhaust valve, wherein a kettle head and a kettle body of the reaction kettle are connected by a detachable ring seal, the kettle body is arranged in a heater, and water and rock samples are arranged in the kettle body; the CO2 gas cylinder is connected into the kettle body through a first gas valve; the water inlet pipe is connected into the kettle body through a water inlet valve; and the first exhaust valve is connected into the kettle body. The batch experimental device can meet the temperature and pressure requirements of CO2-water-rock reaction, enable a CO2-water-rock reaction experiment to add sufficient water, rock and gas samples, prevent bringing air during the process of adding gas and maintain constant pressure during the reaction process, and further has the characteristics of simple operation and more economic property.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

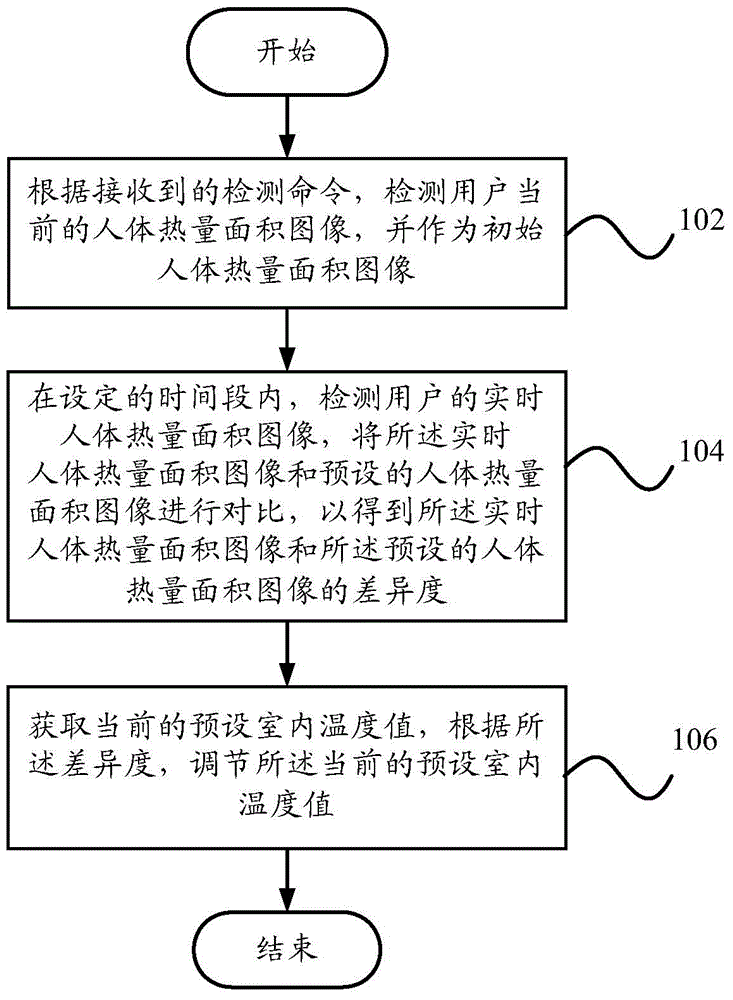

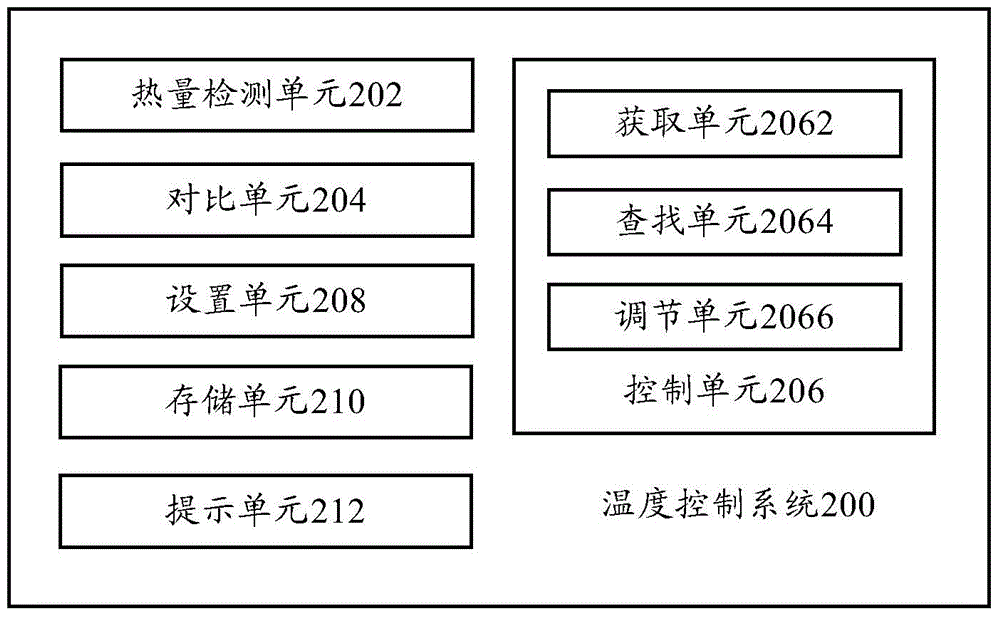

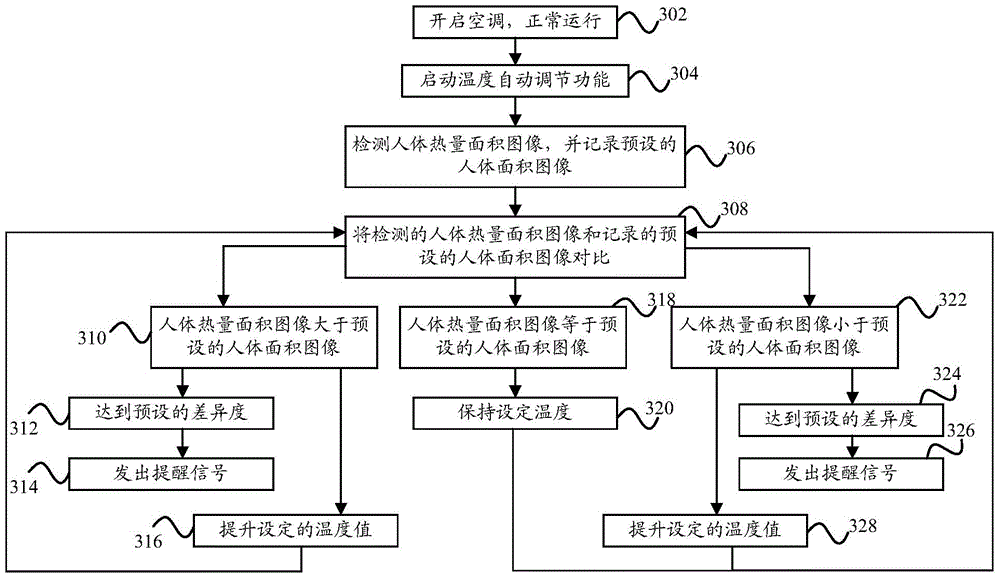

Temperature control method, temperature control system and air conditioner

ActiveCN103954005AMeet temperature requirementsSpace heating and ventilation safety systemsLighting and heating apparatusTemperature controlControl system

The invention provides a temperature control method, a temperature control system and an air conditioner. The temperature control method comprises the following steps of according to a received detection command, detecting a current human body heat area image of a user, and using as an initial human body heat area image; within a set time period, detecting a real-time human body heat area image of the user, comparing the real-time human body heat area image with the initial human body heat area image, and obtaining the different degree between the real-time human body heat area image to the initial human body heat area image; acquiring a current preset indoor temperature value, and adjusting the current preset indoor temperature value according to the different degree. Through the technical scheme of the invention, the setting temperature of the air conditioner can be automatically adjusted according to the needs of the user, so that the occurrence of the problems that the user easily catches a cold since the user kicks a quilt at night, and the like are avoided.

Owner:GUANGDONG MIDEA GRP WUHU REFRIGERATING EQUIP CO LTD +1

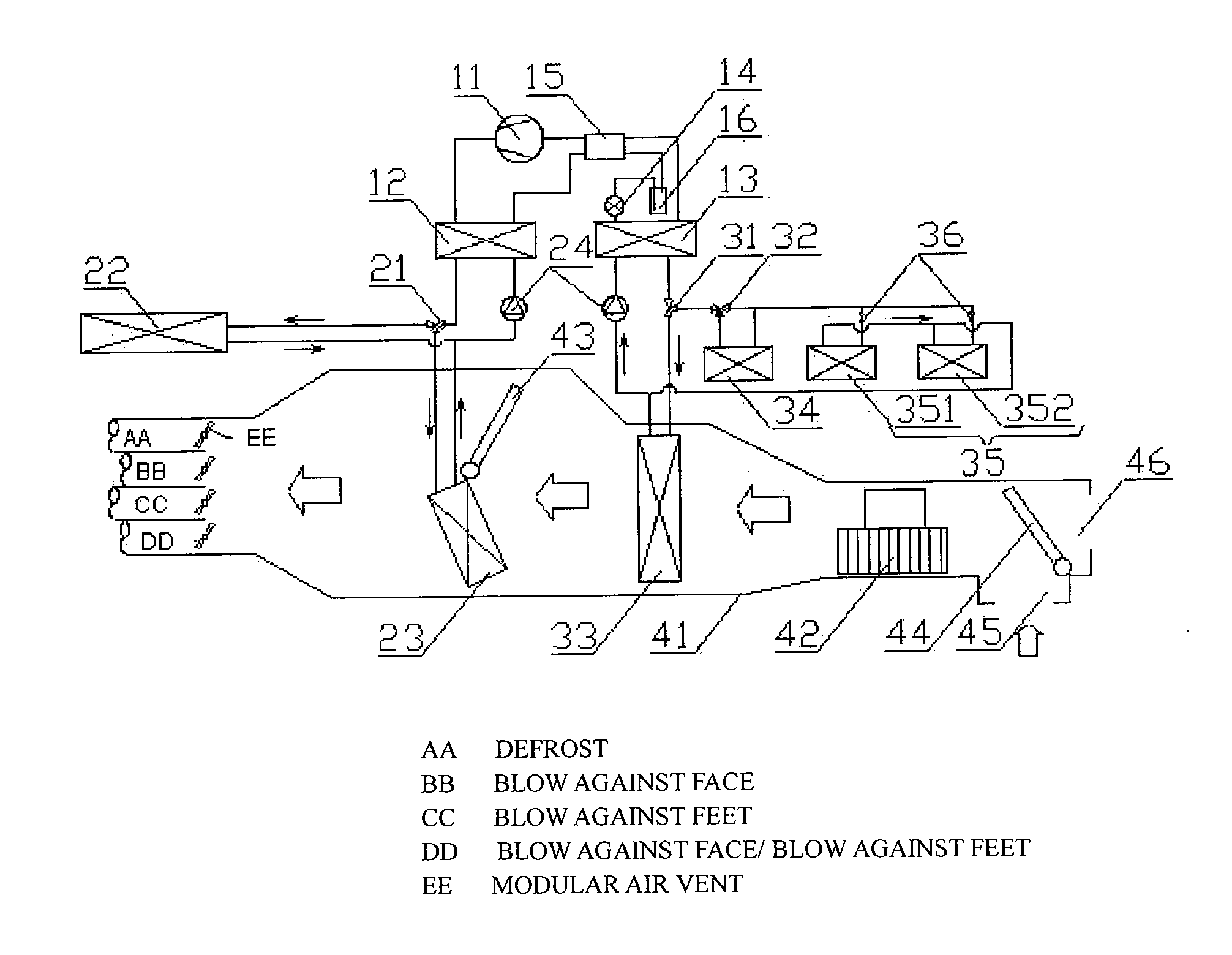

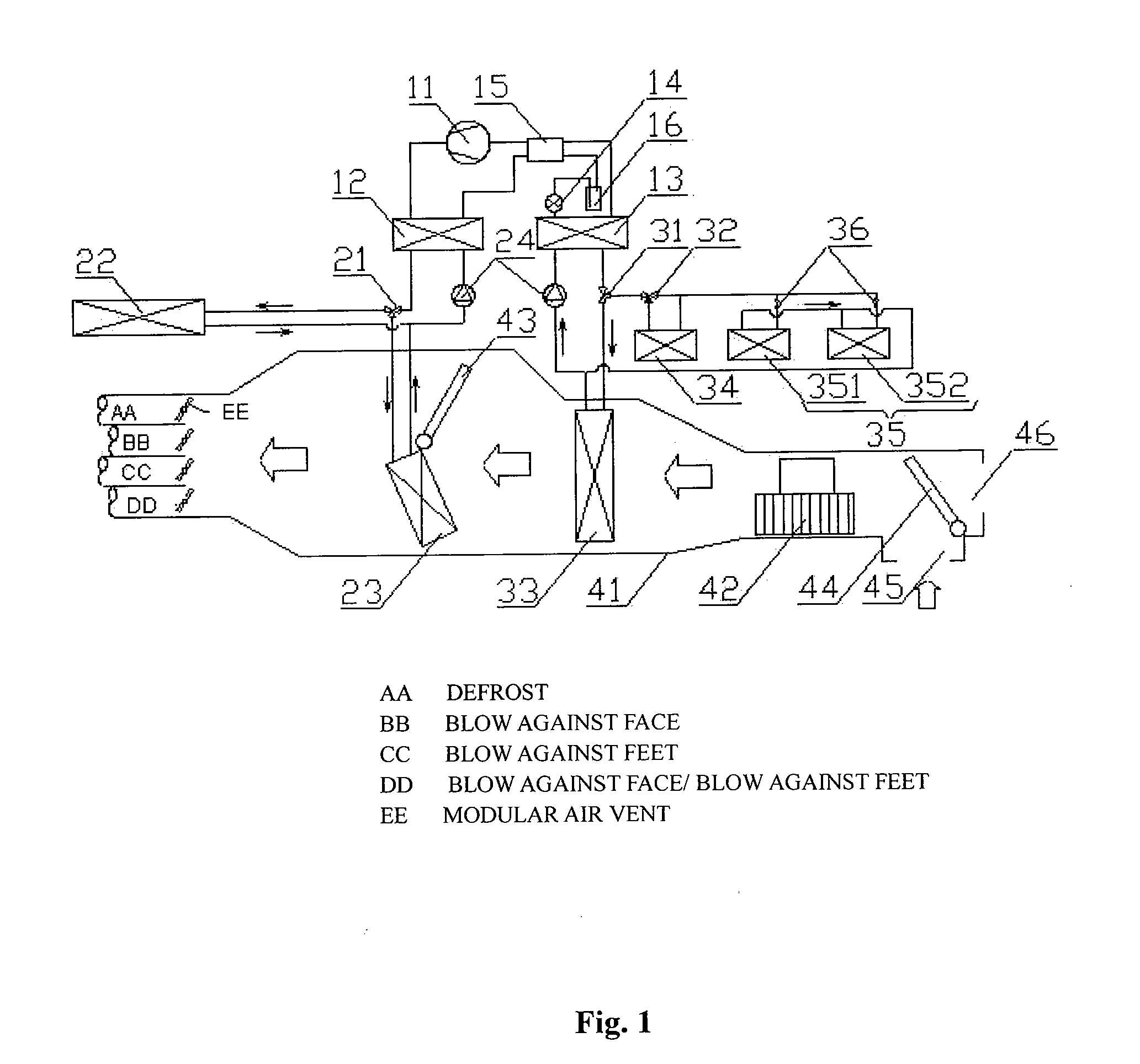

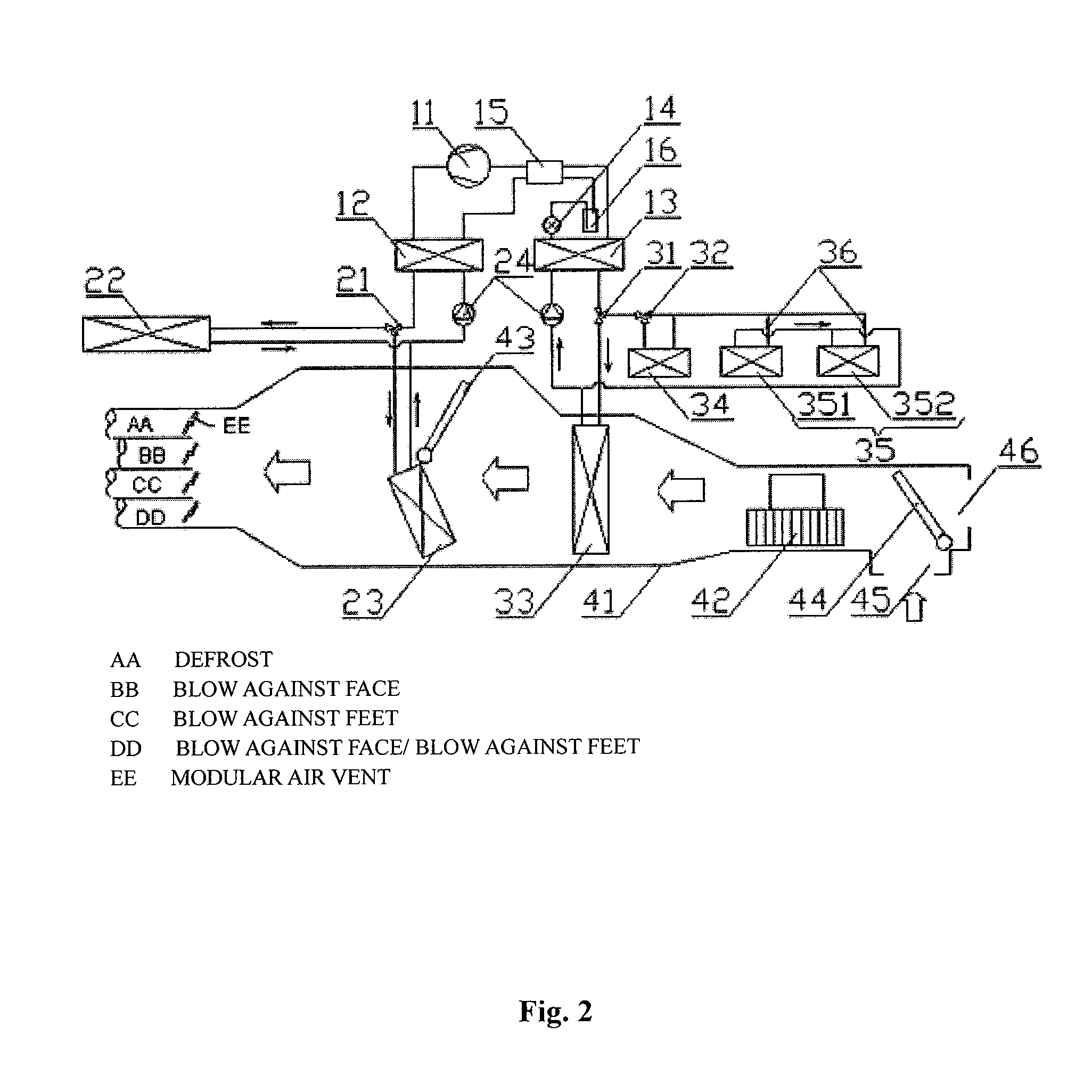

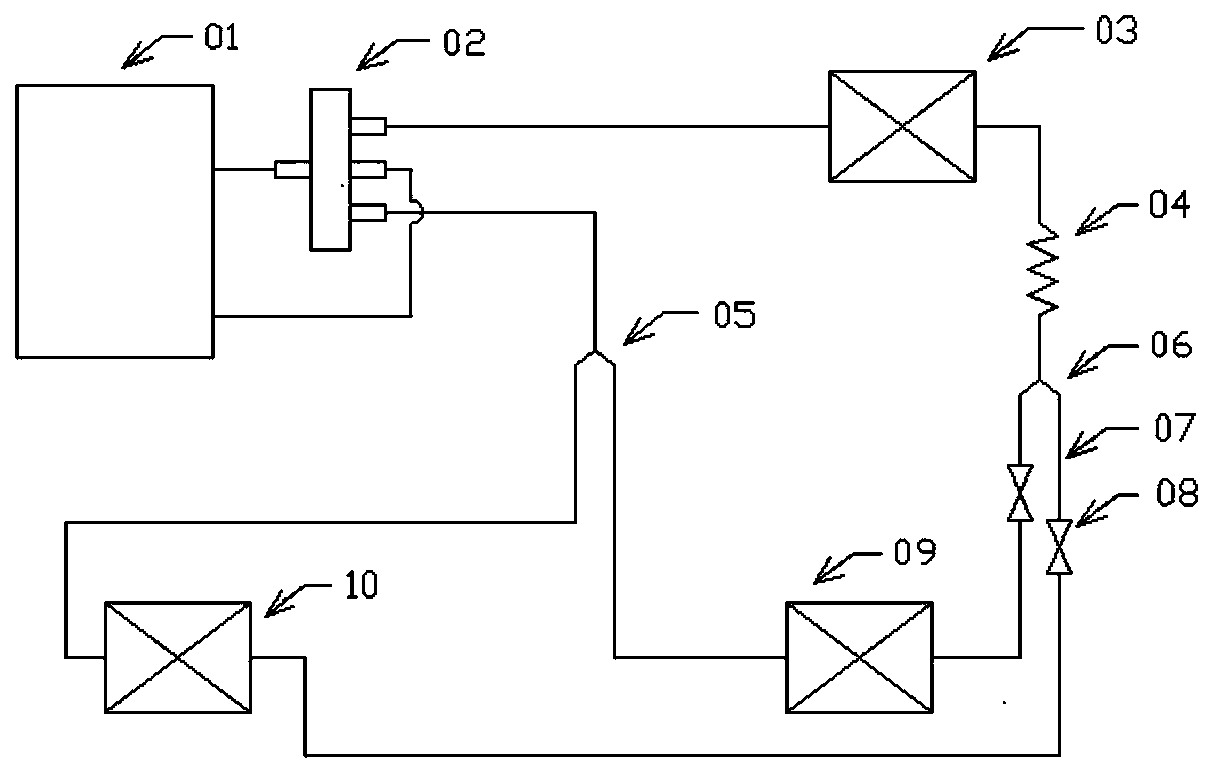

Electric Vehicle and Thermal Management System Therefor

ActiveUS20130206360A1Reduce wasteGood effectAir-treating devicesRailway heating/coolingCooling effectThermal management system

An electric vehicle and a thermal management system are provided, a cooling device thereof comprises a condenser (12), a throttling element (14) and an evaporator (13); a heat exchange device thereof comprises a first air cooled heat exchanger (22) and a heater (23); a heat recovery cooling device thereof comprises a heat emission component heat exchanger (35), a second air cooled heat exchanger (34) and a cooler (33); a passenger compartment temperature regulating device thereof comprises the heater (23) and a cooler (33). The first air cooled heat exchanger (22) and the heater (23) are in communication with the condenser (12) through a first flow regulating valve (21). The cooler (33) and the heat emission component heat exchanger (35) are in communication with the evaporator (13) through a second flow regulating valve (31). The second air cooled heat exchanger (34) is selectively connected in series to the heat emission component heat exchanger (35). The thermal management system ensures full utilization of heat, improves the cooling effect and the comfort level of the passenger compartment, reduces the amount of the charged coolant, and prevents the coolant from entering the passenger compartment.

Owner:HANGZHOU SANHUA RES INST CO LTD

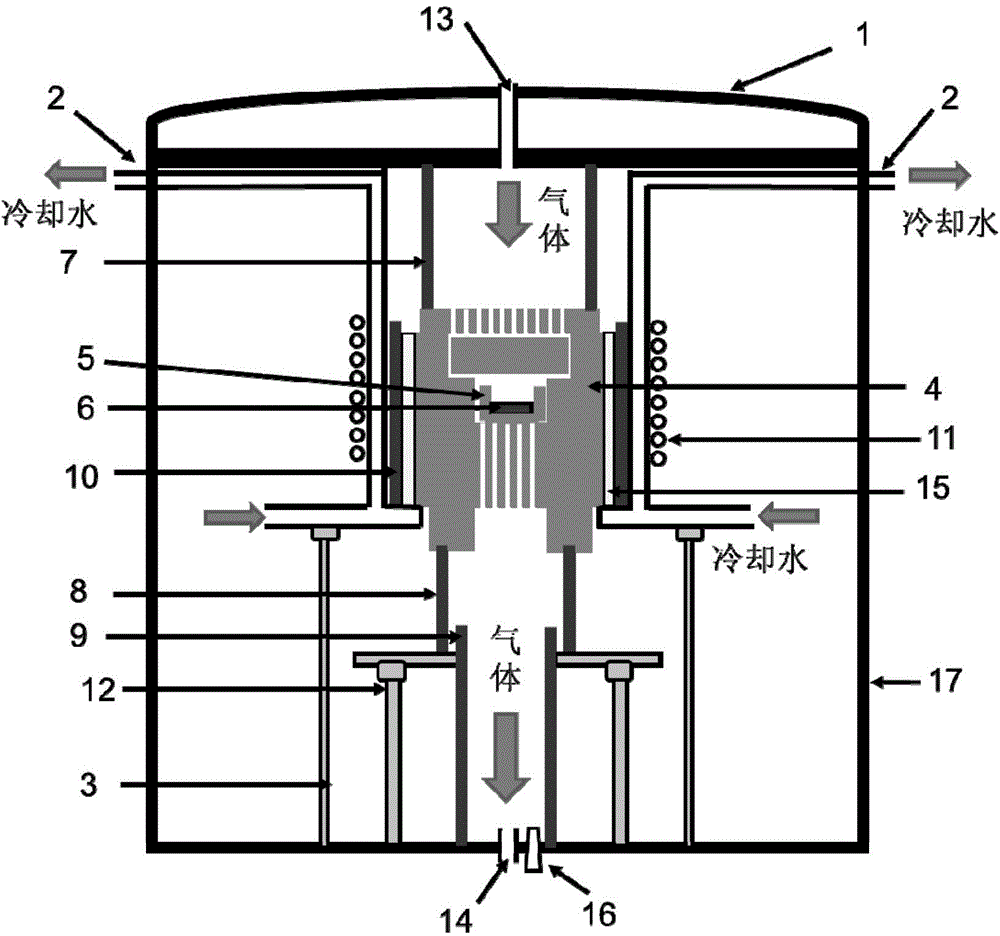

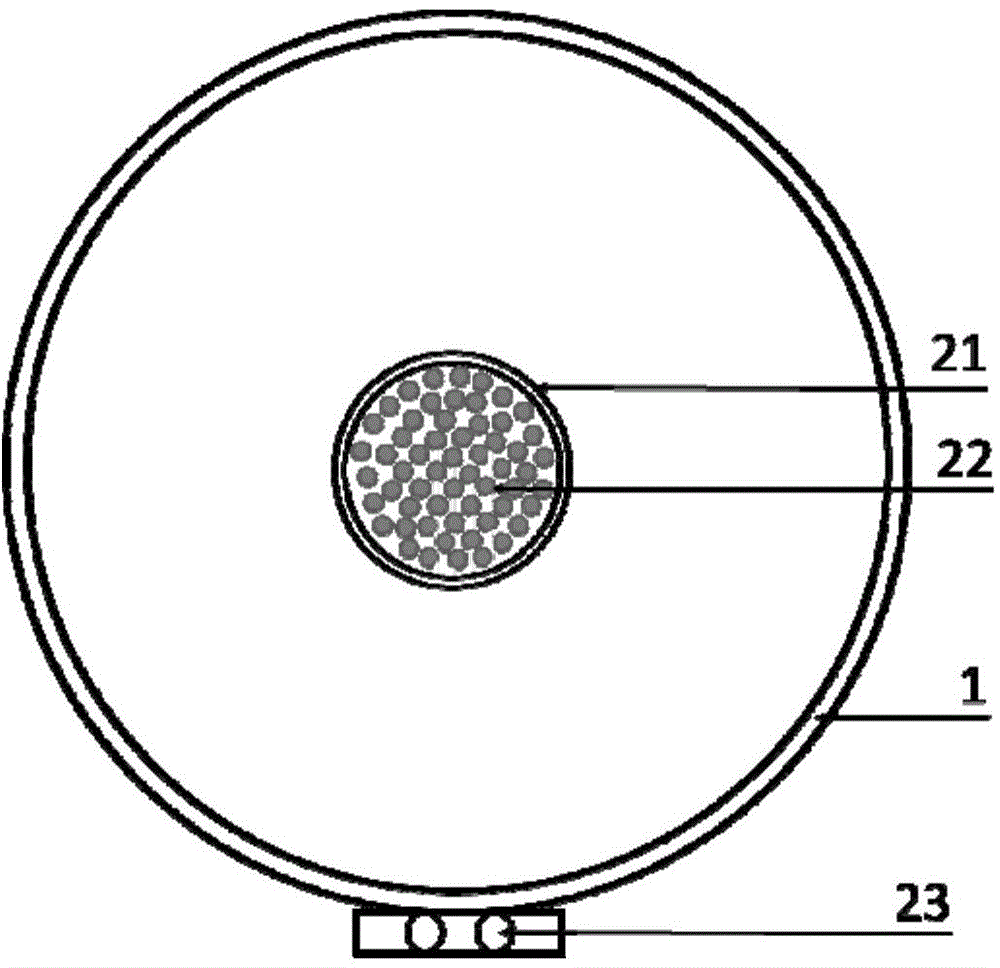

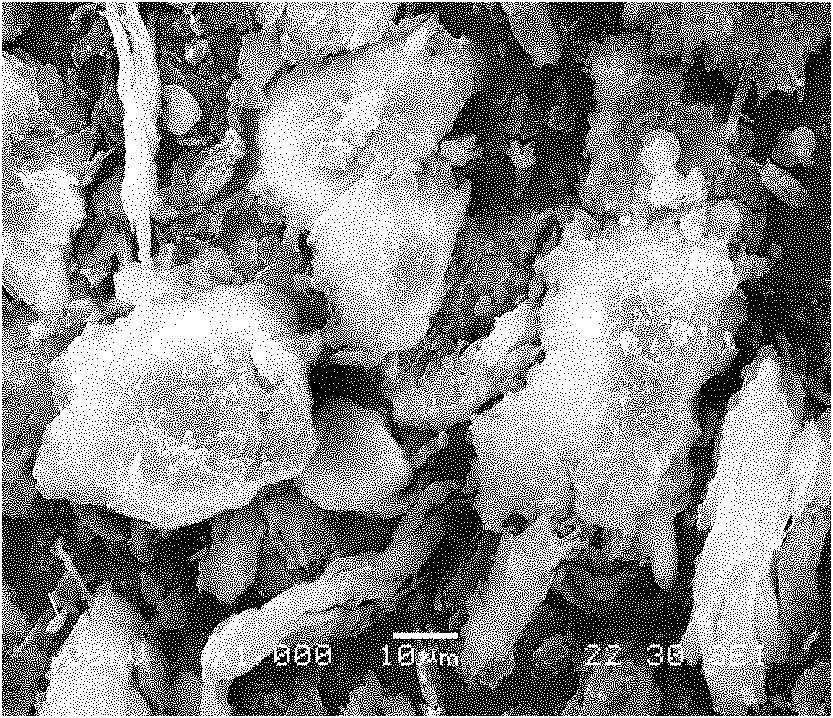

Device and method for preparing large-size high-quality graphene single crystal

ActiveCN104695012AFast heating and cooling rateIncrease working temperaturePolycrystalline material growthFrom chemically reactive gasesIntermediate frequencySingle crystal

The invention relates to a device and method for preparing a large-size high-quality graphene single crystal. The device comprises a shell and a top cover. The top cover is internally provided with a gas spray head with a gas distributing pipe so that inlet high-purity gas can enter a reaction cavity in an evenly-distributed mode. The reaction cavity is composed of sealed silica pipes, a graphite heating element connected between the two sealed silica pipes in an inserted mode and a graphite crucible placed in the graphite heating element. The graphite crucible is used for containing a SiC wafer substrate. A cooling water system and an intermediate frequency coil are arranged outside the graphite heating element. A gas outlet is formed in the bottom of the shell. The invention further provides the method for preparing the large-size high-quality graphene single crystal on the SiC substrate. By means of the device and method, the migration rate of the high-quality graphene crystal prepared on the SiC substrate is higher than that of graphene prepared through a SiC high-temperature pyrolysis method by 1-2 orders of magnitudes.

Owner:SHANDONG UNIV

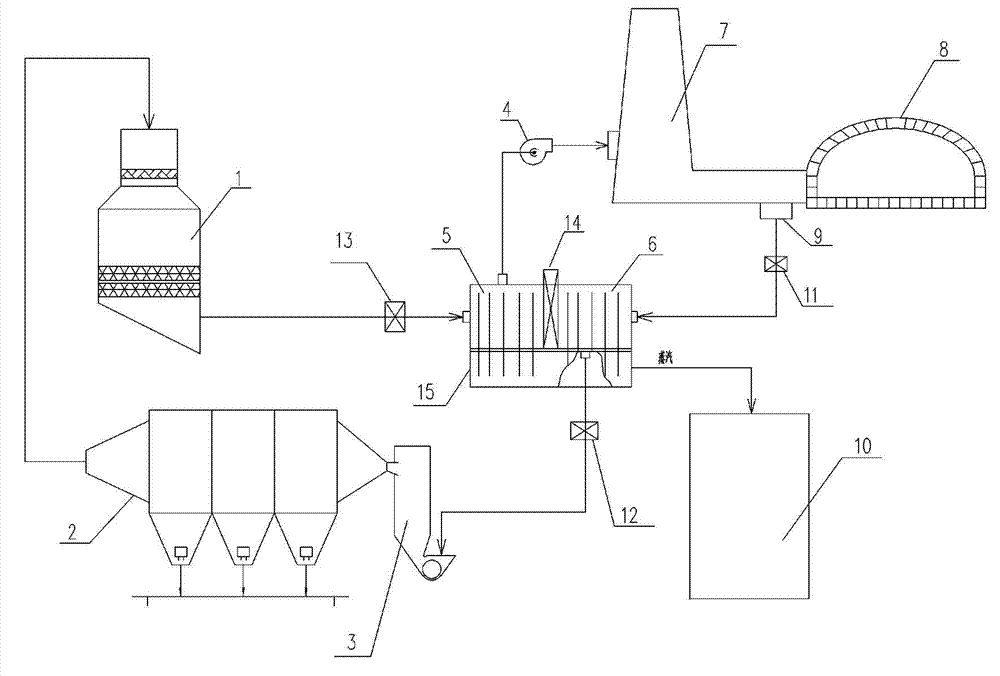

Desulfurization and denitrification afterheat power generation systematization device of glass melter flue gas

InactiveCN102735070AAvoid heat lossReduce electrode costDispersed particle separationIncreasing energy efficiencyChemistryElectrostatic precipitator

The invention discloses a desulfurization and denitrification afterheat power generation systematization device of glass melter flue gas. The desulfurization and denitrification afterheat power generation systematization device comprises the process that: a. a fourth flashboard (14) is arranged in an afterheat boiler (15), a high-temperature section (6) and a low-temperature section (5) are formed, a bypass flue (9) of a chimney (7) is connected with the high-temperature section (6), and an exhaust pipeline of the low-temperature section (5) is connected with the chimney (7); b. the high-temperature section (6) is provided with a bypass pipeline and connected with a dry desulfurization reactor (3), a high-temperature electric dust remover (2) and a denitrification reactor (1), and c. the denitrification reactor is connected with the low-temperature section (5) through the pipeline. The desulfurization and denitrification afterheat power generation systematization device has the beneficial effects that: high-temperature flue gas firstly passes through the high-temperature section of the afterheat boiler, and the temperature of the flue gas is reduced, so that electrode material of an ESP (electrostatic precipitator) does not need to adapt to over-high temperature, and the requirements of an SCR (selective catalytic reductor) denitrification system on the temperature can be met. The flue gas enters the low-temperature section of the afterheat boiler again after being desulfurized and dedusted, so that the afterheat of the flue gas is fully and effectively recovered.

Owner:JIANGSU CTIEC ENVIRONMENTAL PROTECTION RES INST +2

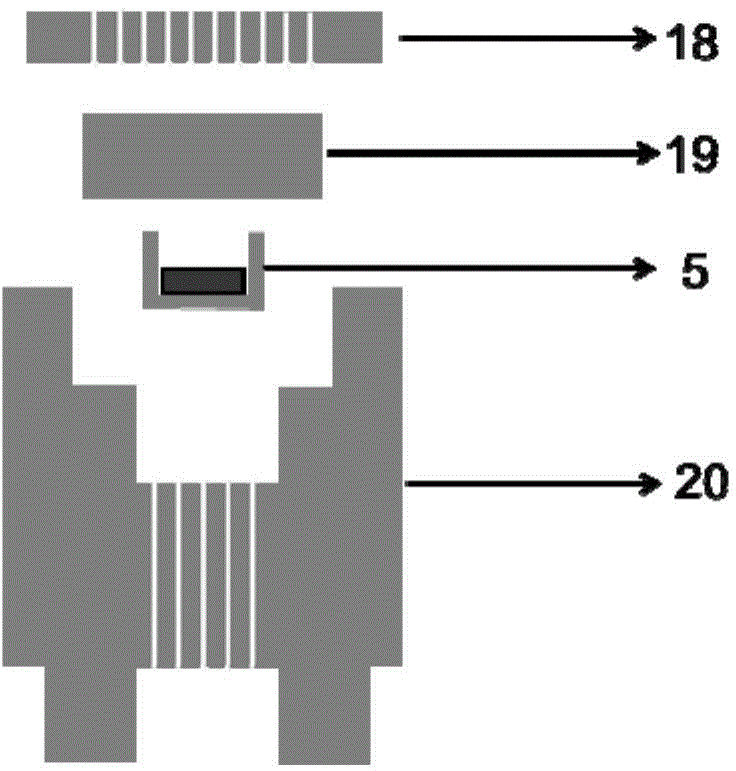

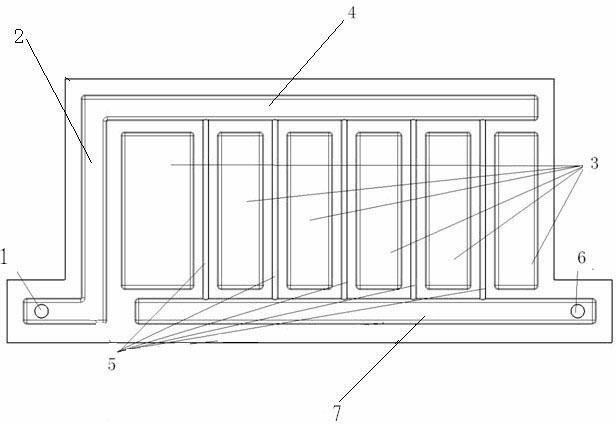

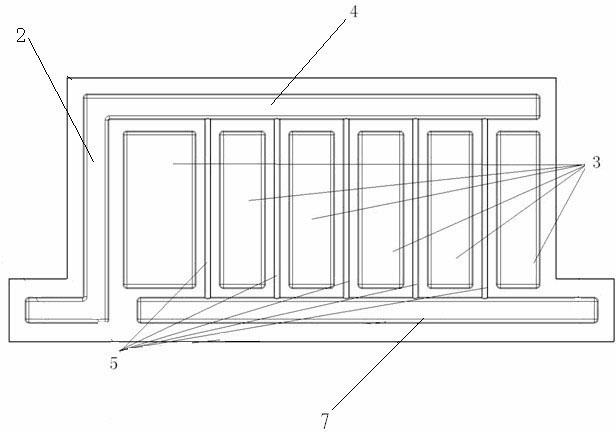

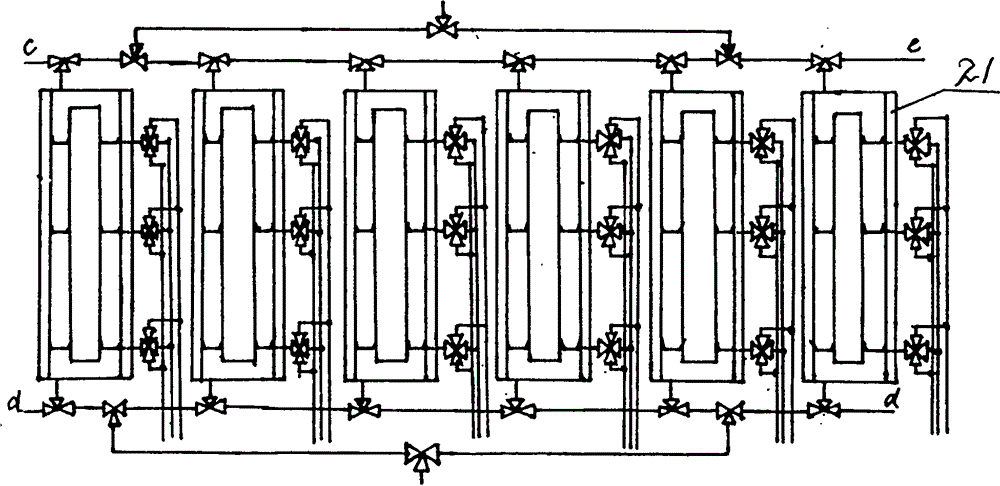

Battery cooling plate structure

ActiveCN102623771AImprove stabilityExtended service lifeSecondary cellsPower batteryElectrical battery

The invention discloses a battery cooling plate structure, which comprises an upper plate and a lower plate, wherein the upper plate and the lower plate are welded into a whole to constitute a cooling plate; the upper plate and the lower plate are respectively provided with protrusions in opposite directions, a cooling channel and a plurality of heat-radiating cavities are formed among the protrusions, and the upper plate is provided with a water inlet and a water outlet, which are communicated with the cooling channel; the cooling channel is used for allowing cooling liquid to flow through and comprises a main channel and a plurality of branch channels communicated with the main channel; and the heat-radiating cavities and the branch channels are parallel mutually and are arranged at interval in a staggered manner. The battery cooling plate structure is simple in structure, low in manufacturing cost and simple in process and is good in controllability as a flow field structure inside the cooling plate can be distributed according to actual needs. By means of integrating the cooling plate into a power battery system of an electric vehicle, the requirement of a power battery assembly of the electric vehicle for the temperature can be better met, so that the stability of a battery system is increased and the service life of the battery system is prolonged.

Owner:深蓝汽车科技有限公司

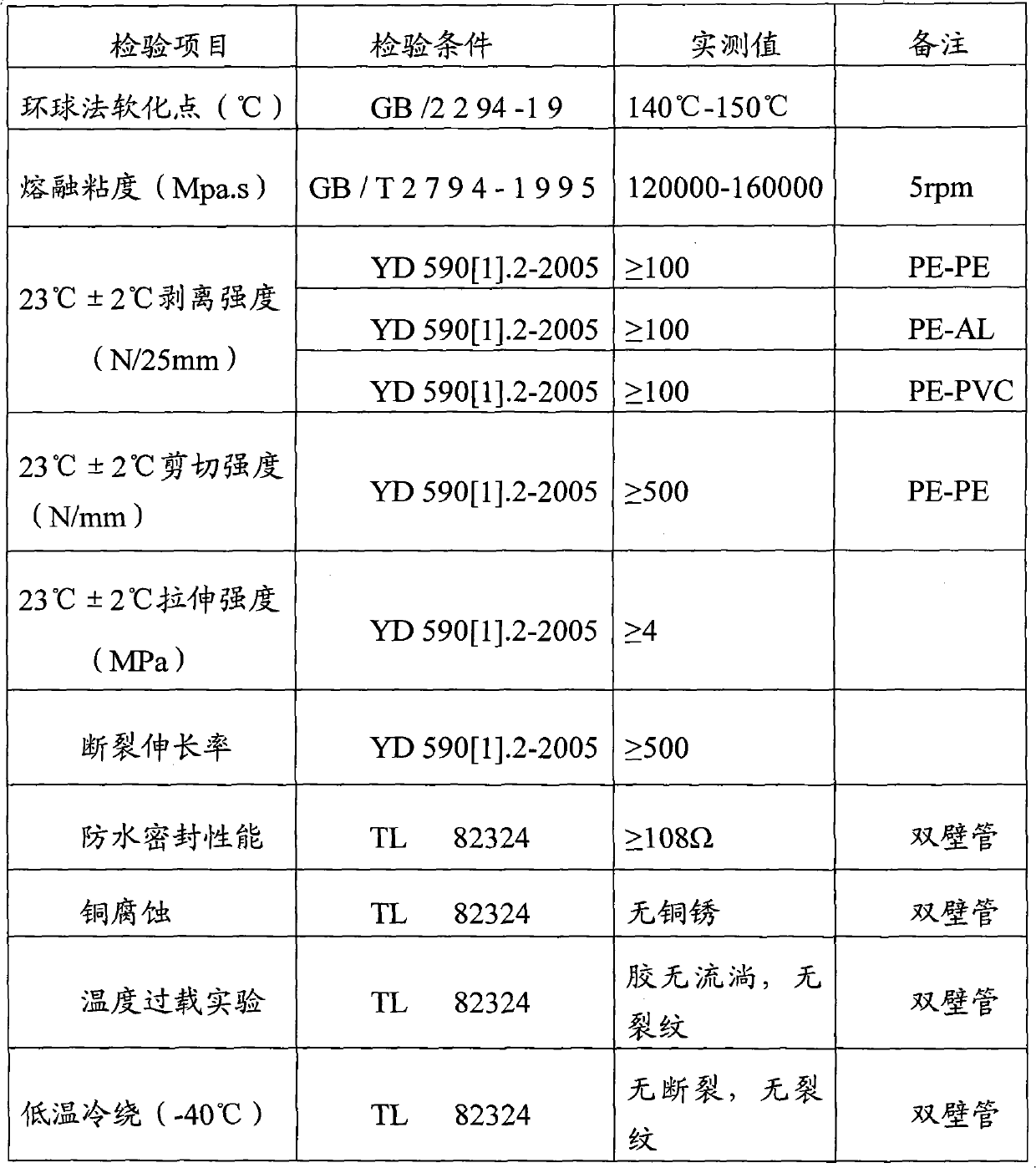

High temperature resistant hot melt adhesive and processing process thereof

The invention provides a formula of a high temperature resistant hot melt adhesive and a processing process of the hot melt adhesive. The formula comprises the following components: polyamide, an ethylene-ethyl acrylate copolymer, an ethylene-vinyl acetate copolymer, a tackifier, an antioxidant and a modifier. The high temperature resistant hot melt adhesive is high in bonding strength, resistant to high temperature, excellent in insulating and sealing performance, resistant to a low temperature, environment-friendly, non-toxic, simple in production process and good in repeatability.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

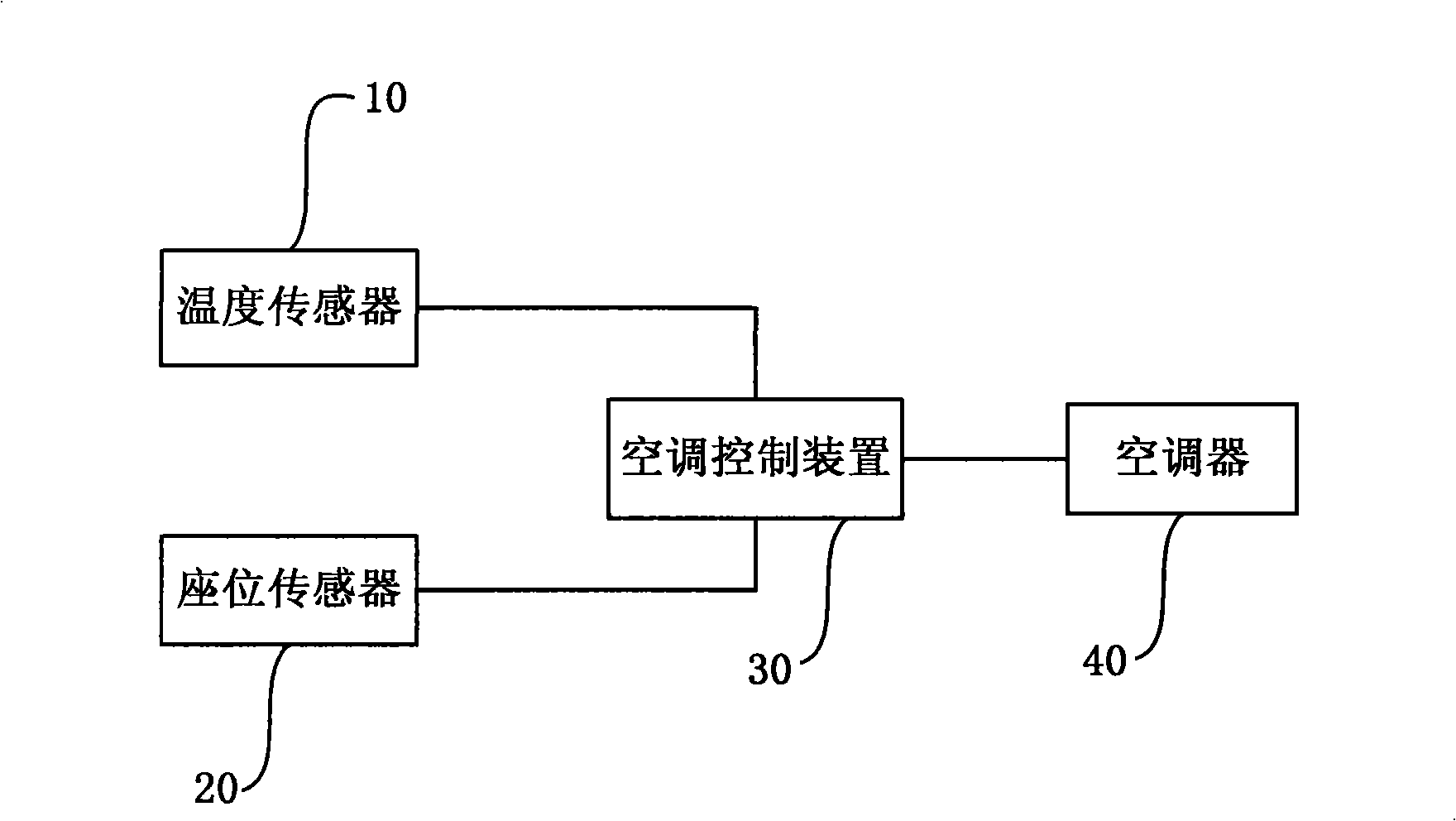

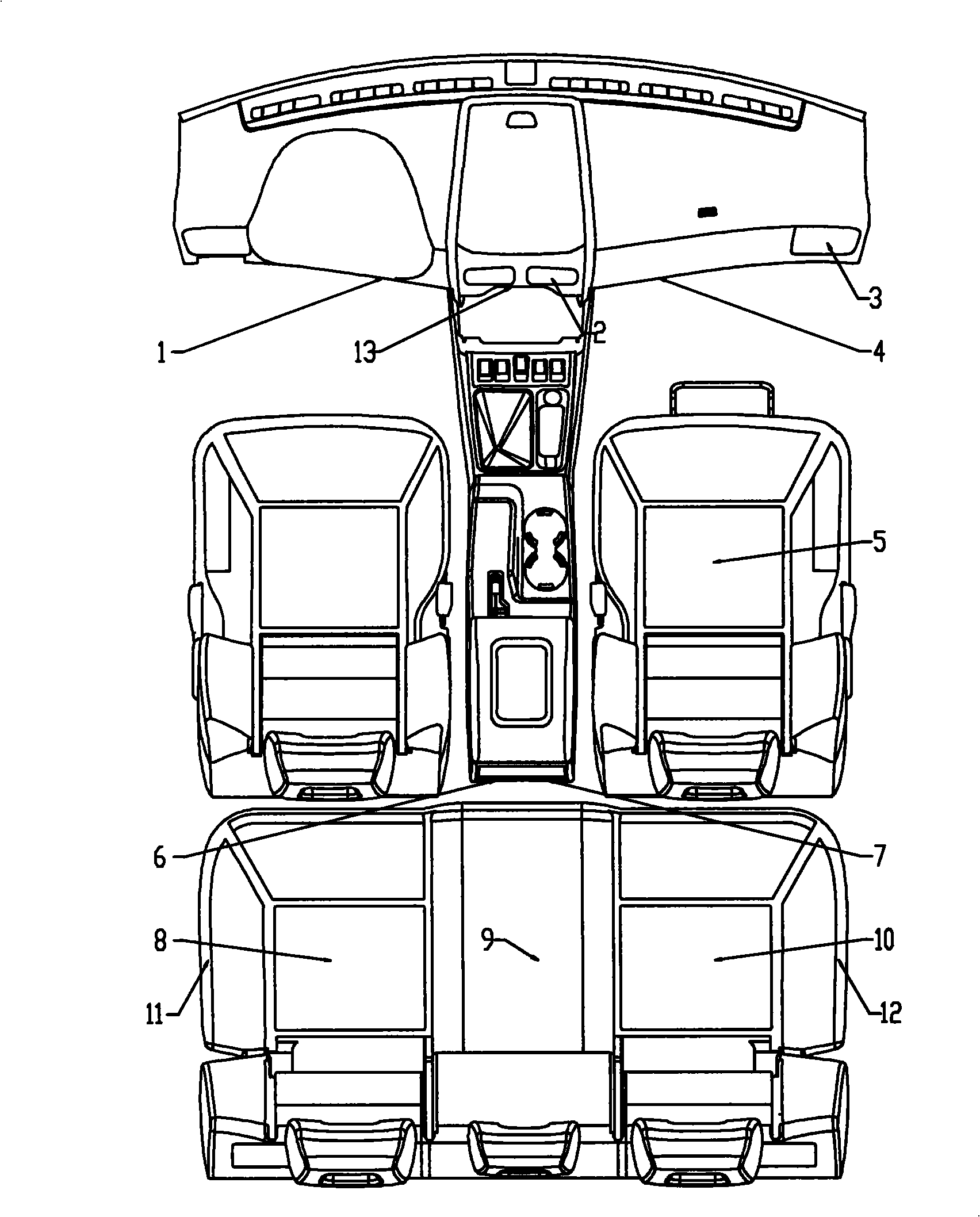

Intelligent air-conditioning system

InactiveCN101259824AReduce unnecessary wasteMeet temperature requirementsAir-treating devicesSpace heating and ventilation safety systemsControl signalProcess Measures

The invention discloses an intelligent air conditioning system comprising an air conditioner with an air outlet, a temperature sensor, a seat sensor which can sense the situation of the passenger load and an air conditioner controlling device. The air conditioner controlling device receives and processes measuring data provided by the temperature sensor and the seat sensor, and output control signals for adjusting the air conditioning power and the air outlet direction of the air outlet. The intelligent air conditioning system can automatically adjust the air conditioning power and the air outlet direction of the air outlet according to the situation of the passenger load and temperature in the automobile so as to reduce the meaningless waste of the power of the air conditioner while the requirement for inside temperature by passenger is met, thus saving energy resources.

Owner:CHERY AUTOMOBILE CO LTD

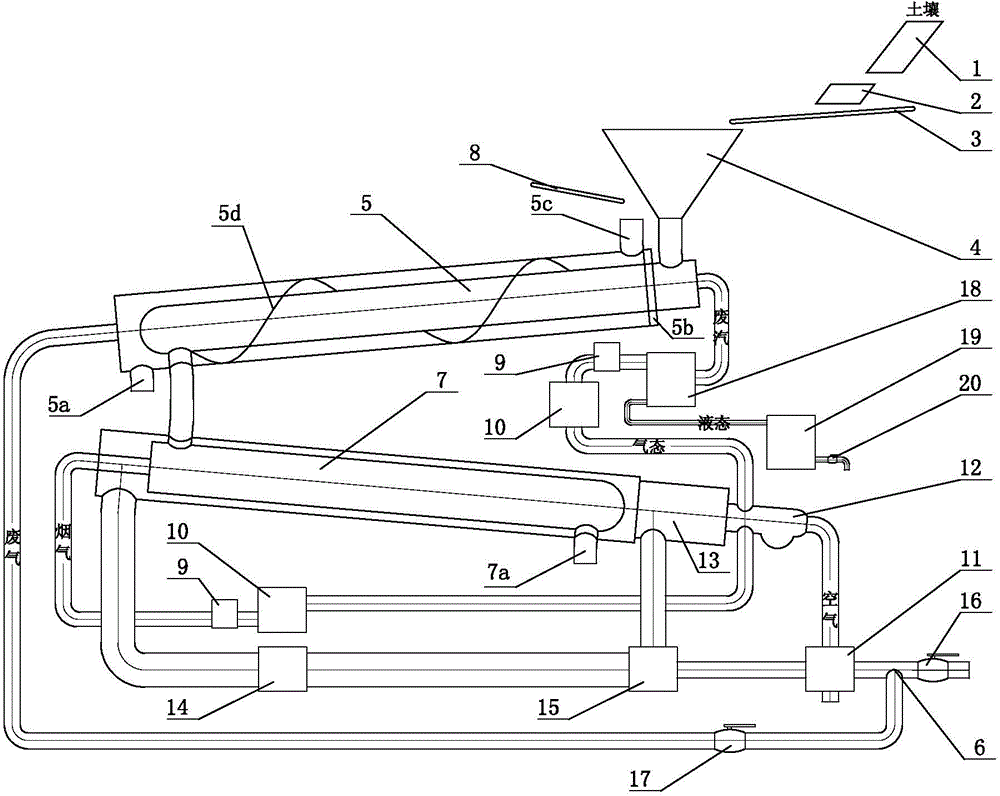

Contaminated soil remediation system

ActiveCN104785512AImpact emissionsNo pollution problemContaminated soil reclamationCombustion chamberCombustor

The invention discloses a contaminated soil remediation system. Soil is sequentially fed into the inner container of a waste heat rotary kiln through a feeding cabin, the inner container of a heat desorption rotary kiln, and the interlayer of the waste heat rotary kiln through a first conveyer belt, and is finally discharged out through a first soil outlet; air is fed into a combustion chamber for combustion through a combustor; generated fume is fed into the interlayer of the heat desorption rotary kiln to make straight line movement, is further accessed to the interlayer of the waste heat rotary kiln through a pipeline to make spiral movement, and is finally discharged out through a fume outlet formed in the shell of the waste heat rotary kiln; the waste gas generated in the inner container of the heat desorption rotary kiln is accessed to the combustor for incineration; the waste gas generated in the inner container of the waste heat rotary kiln is accessed to a condensation separator through a pipeline; the gas separated in the condensation separator is accessed to the combustion for incineration through another pipeline; a liquid separated in the condensation separator is discharged out through another pipeline. The contaminated soil remediation system has the characteristics of low energy consumption, high efficiency, low manufacturing cost, high easiness to implement, good remediation effect and the like, and has wide market prospect.

Owner:重庆化医太湖锅炉股份有限公司 +1

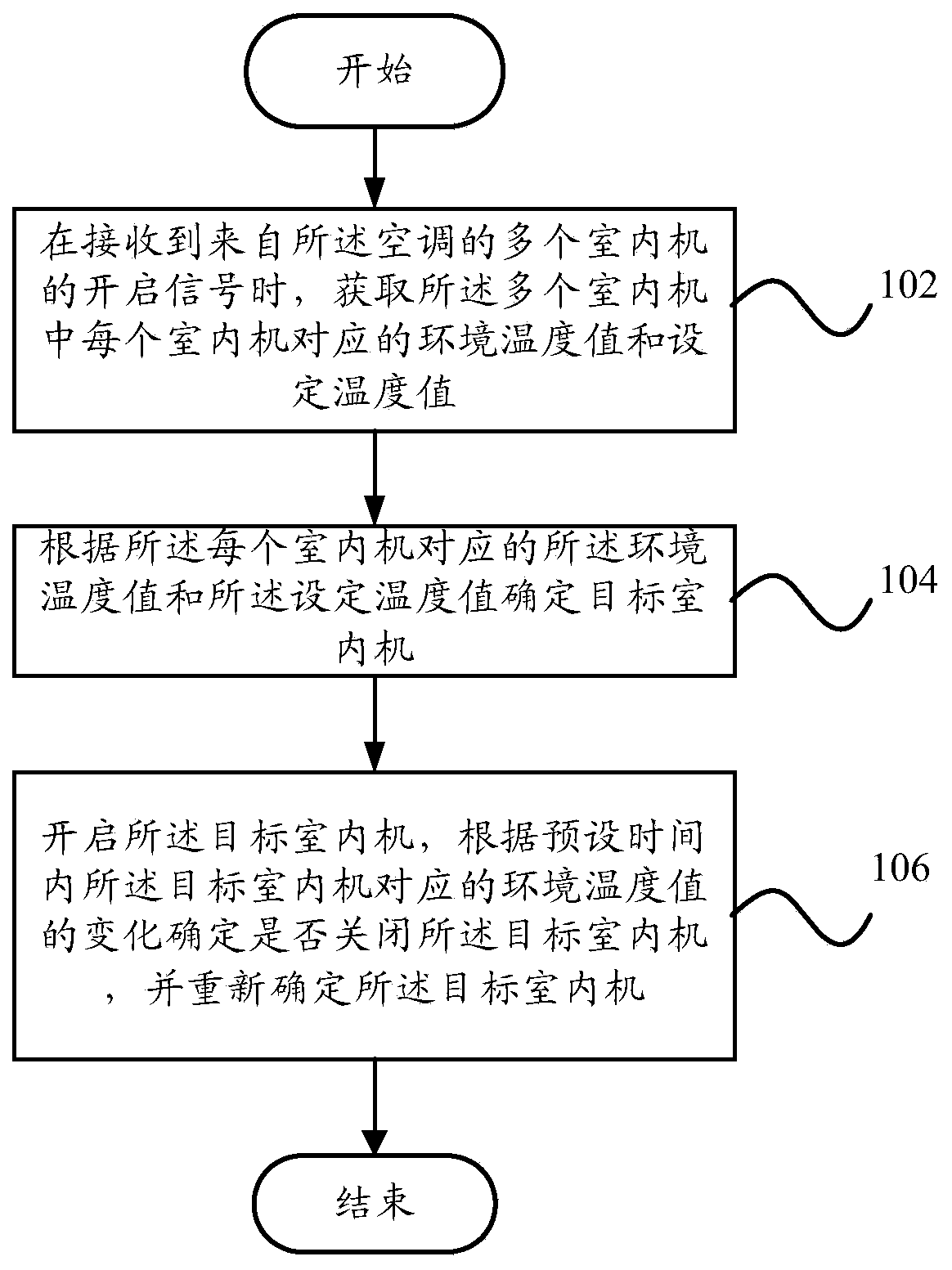

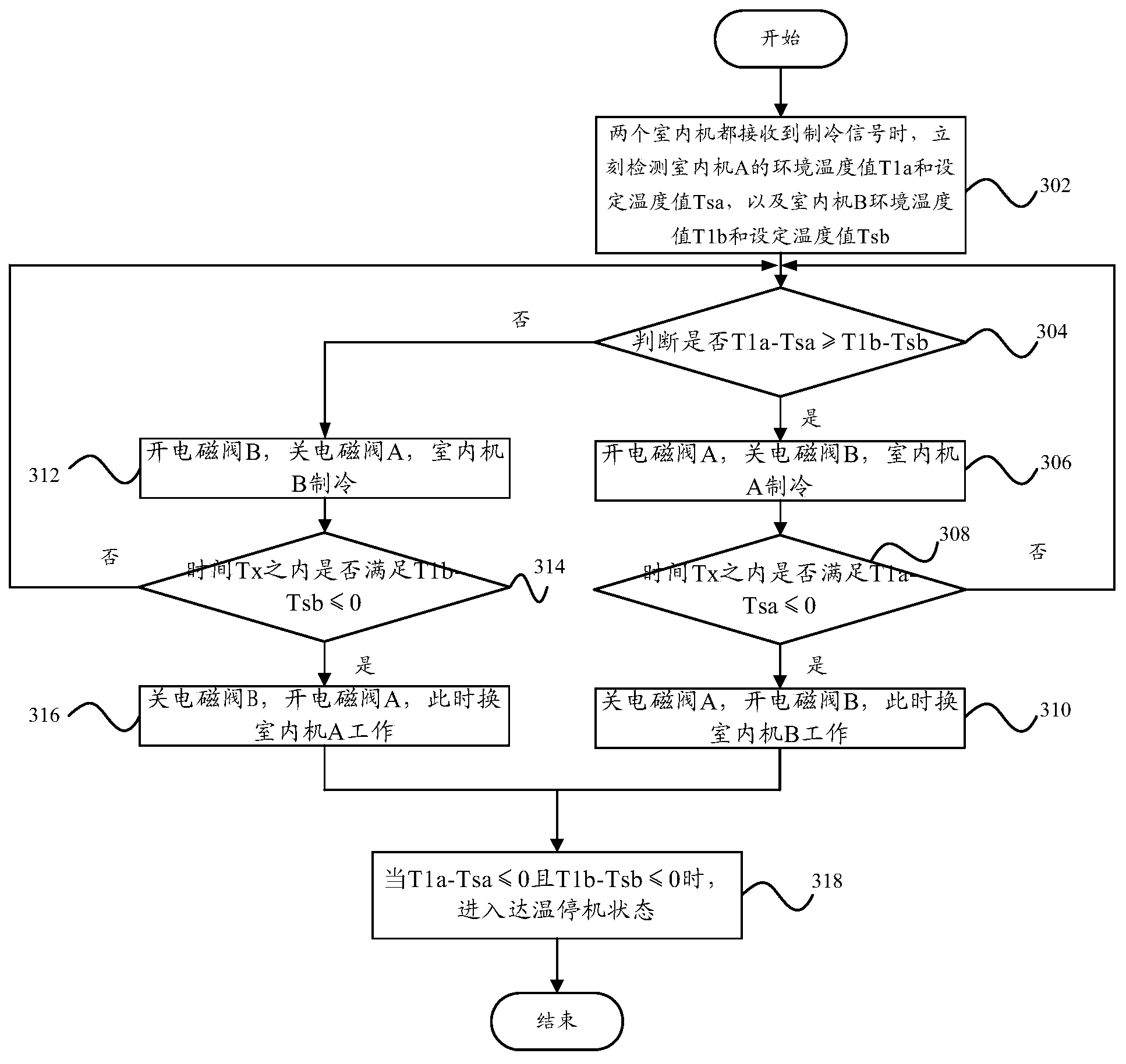

Control method and control device of constant frequency multi-split air conditioner

ActiveCN104214893AMeet temperature requirementsReduce use costSpace heating and ventilation safety systemsLighting and heating apparatusConstant frequencyEngineering

The invention provides a control method of a constant frequency multi-split air conditioner. The method comprises the following steps of acquiring step, during receiving starting signals of multiple indoor units from the air conditioner, acquiring an environment temperature value and a set temperature value corresponding to each indoor unit in the multiple indoor units; determining step, determining a target indoor unit according to the environment temperature value and the set temperature value corresponding to each indoor unit; and processing step, starting the target indoor unit, determining whether turning off the target indoor unit according to the change of the environment temperature value corresponding to the target indoor unit in the preset time, and determining the target indoor unit again. Correspondingly, the invention provides a control device of the constant frequency multi-split air conditioner. By adopting the technical scheme, the cost is reduced, and the temperature adjusting requirements of users on multiple rooms can be improved.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD

Device for testing cryogenic mechanical properties of material

The invention relates to the field of materials' mechanical properties testing technology, especially to a device for testing cryogenic mechanical properties of a material. According to the device for testing cryogenic mechanical properties of a material, a refrigerating machine is used as a cold source, and helium in a sample chamber is used as a heat transfer medium but will not generate heat itself and can be recycled. Therefore, helium is hardly lost, and huge waste of helium resources is avoided. In addition, a vacuum pump is arranged between the sample chamber and a gas storage tank. The helium inside the sample chamber can be recovered into the gas storage tank through the vacuum pump. As temperature in the sample chamber cannot be reduced to 4.2 K only by the use of the refrigerating machine, pressure intensity in the sample chamber is reduced by the vacuum pump so as to further reduce the temperature in the sample chamber to meet the requirement on temperature.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

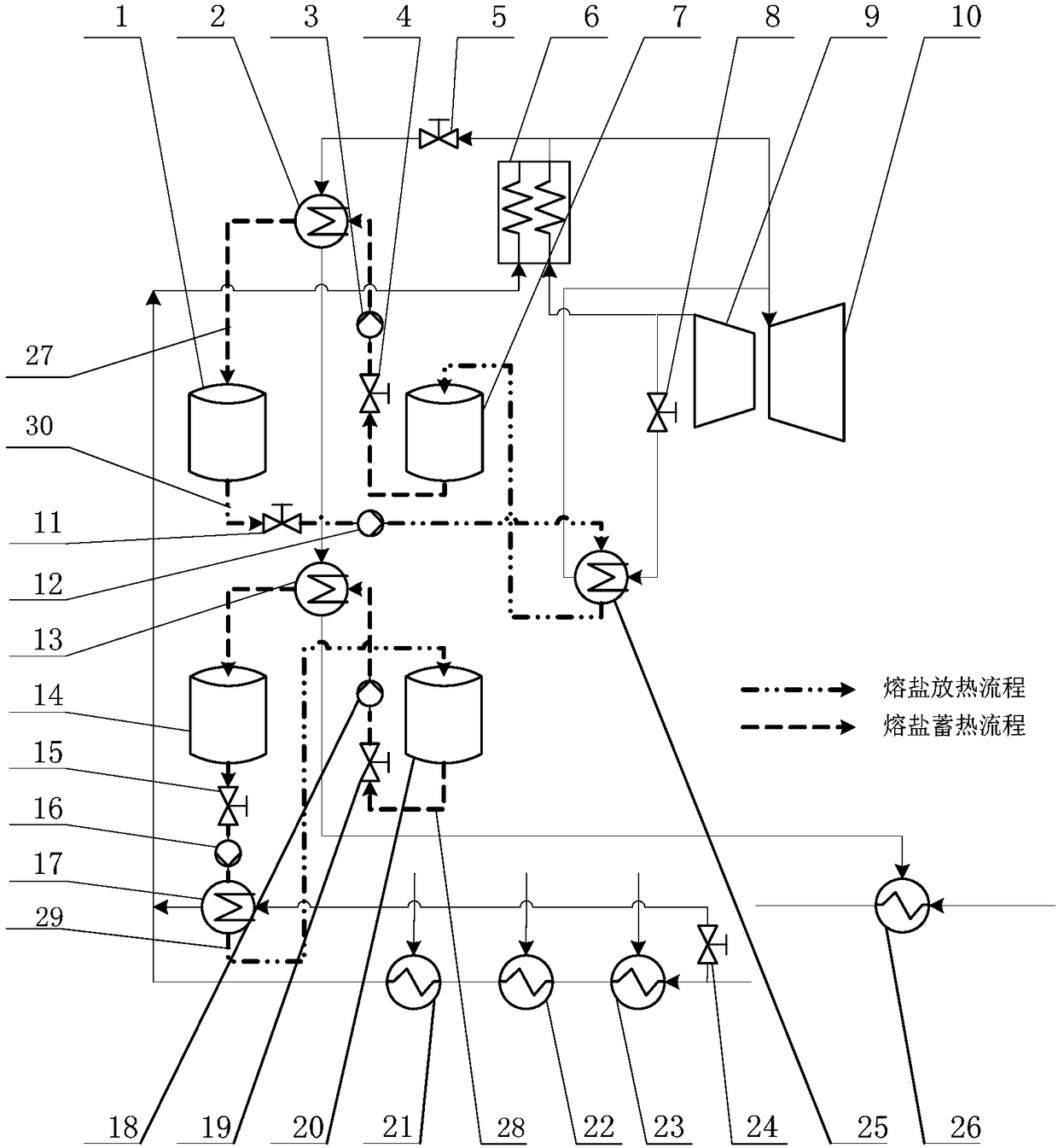

Fused salt heat storage and heat release peak load regulating system for thermal power generating unit

The invention discloses a fused salt heat storage and heat release peak load regulating system for a thermal power generating unit. According to the fused salt heat storage and heat release peak loadregulating system, a fused salt heat storage system, an I-stage fused salt low-temperature heat release system and a II-stage fused salt high-temperature heat release system are additionally arrangedon the basis of the original thermal power generating unit, and therefore peak load regulating of a power grid is realized through heat storage and heat release of fused salt; when the dispatching load of the power grid is decreased, part of high-temperature reheat steam is extracted from an outlet of a boiler reheater and exchanges heat with the fused salt in the fused salt heat storage system, and therefore consumption and utilization of the reheat steam in the electricity utilization off-peak season are completed; when the dispatching load of the power grid is increased, a part of high-pressure feedwater flowing to a high-pressure heater is divided into the I-stage fused salt low-temperature heat release system to exchange heat with the fused salt; and meanwhile, the steam discharge amount of a high-pressure cylinder is increased, part of increased exhaust steam of the high-pressure cylinder is fed into the II-stage fused salt high-temperature heat release system to exchange heat with the high-temperature fused salt, the heated steam enters an intermediate-pressure cylinder to apply work, the amount of the steam entering the intermediate-pressure cylinder and the output of a steam turbine can be increased, and the electric power of the thermal power generating unit can be rapidly increased.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

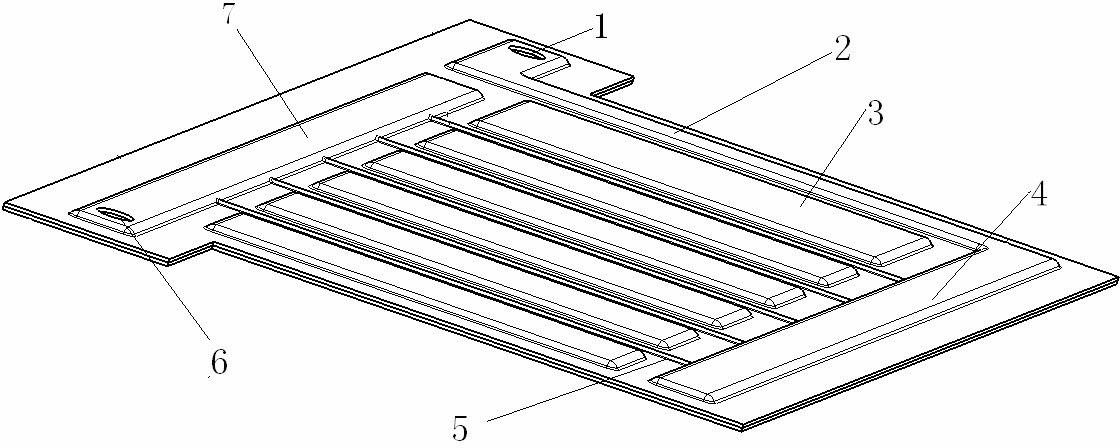

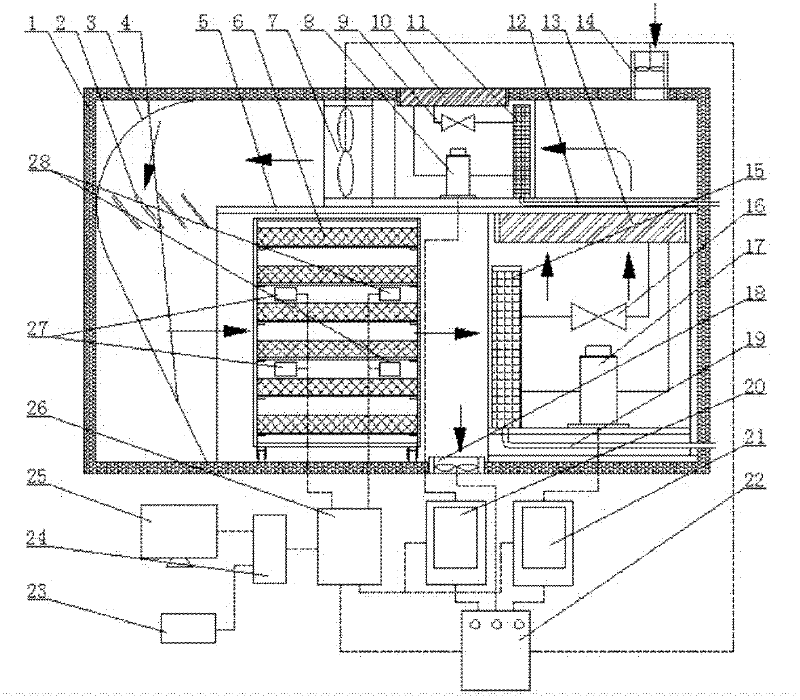

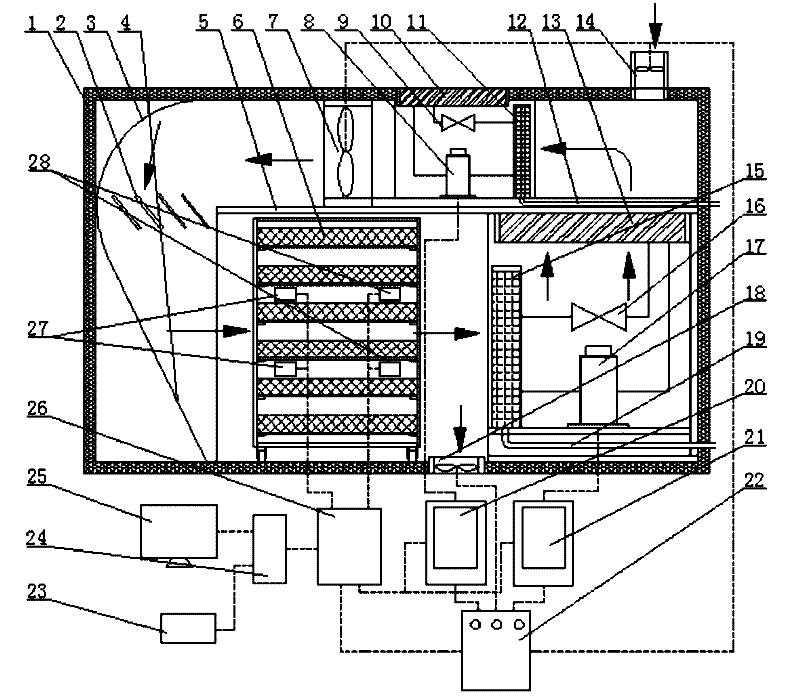

Heat pump drying device

InactiveCN102410709AFast high temperature dryingHigh quality low temperature dryingDrying gas arrangementsDrying solid materialsControl systemProcess engineering

The invention discloses a heat pump drying device, which comprises a drying box and a control system, wherein the drying box comprises a shell and an air inlet fan, a dehumidifying heat pump, a main fan, a material shelf, an air outlet fan and a heating heat pump which are arranged in the shell; when an air inlet and an air outlet are closed, the dehumidifying heat pump, the main fan, the material shelf, the heating heat pump and the dehumidifying pump are communicated in sequence, and a circulating path of a drying medium is formed in the shell; when the air inlet and the air outlet are opened, the air outlet, the dehumidifying heat pump, the main fan, the material shelf and the air outlet are communicated in sequence to form a one-way circulating path of the drying medium; and an air path between the main fan and the material shelf is arc-shaped, and an inclined air deflector is arranged in the air path. The heat pump drying device can not only realize high-temperature drying but also realize low-temperature drying and can meet temperature and humidify requirements of the same product at different drying stages; and the air path for communicating the main fan with the material shelf and the air deflector is improved, therefore airflow vortex is reduced, and drying quality and speed are increased.

Owner:SOUTH CHINA UNIV OF TECH

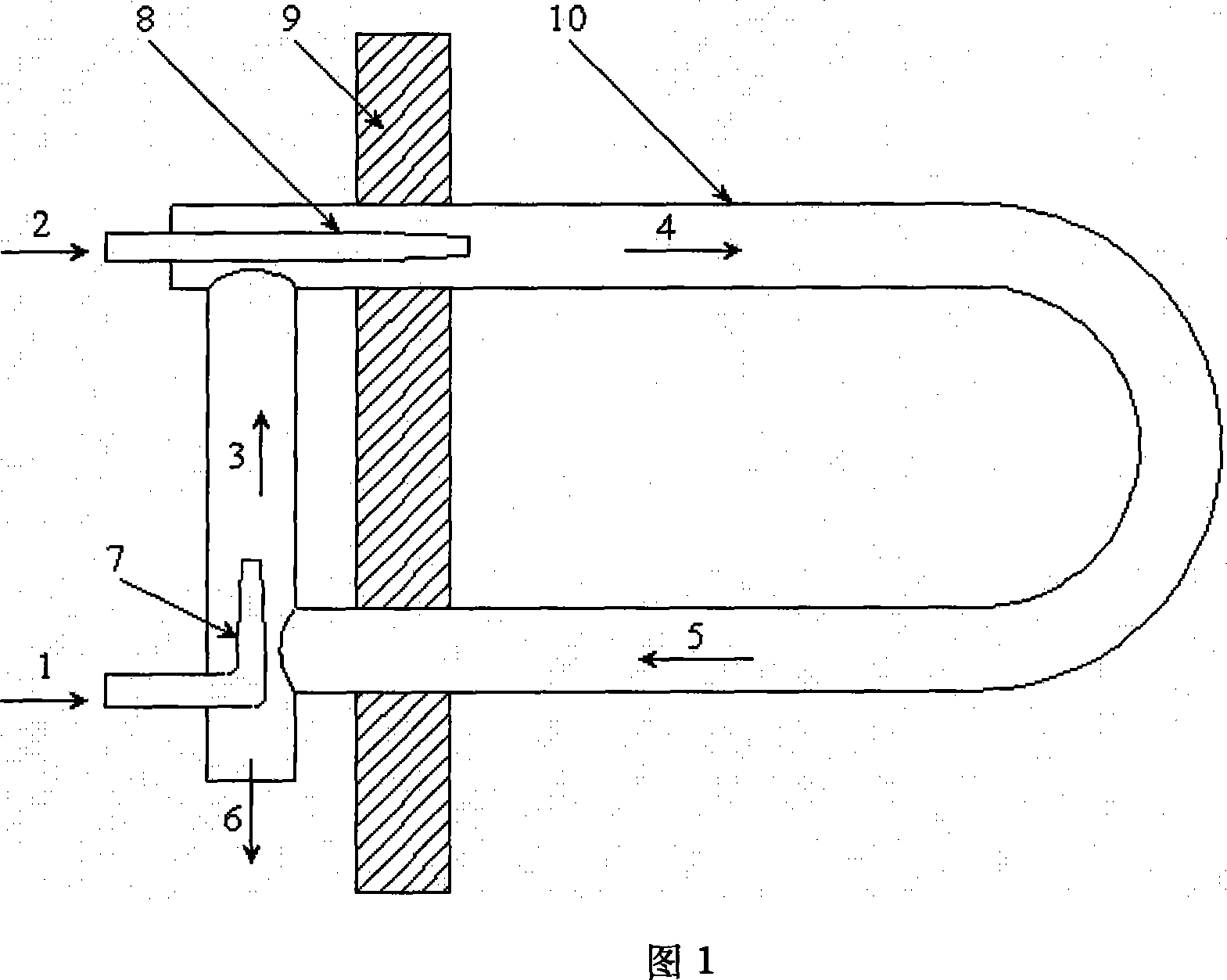

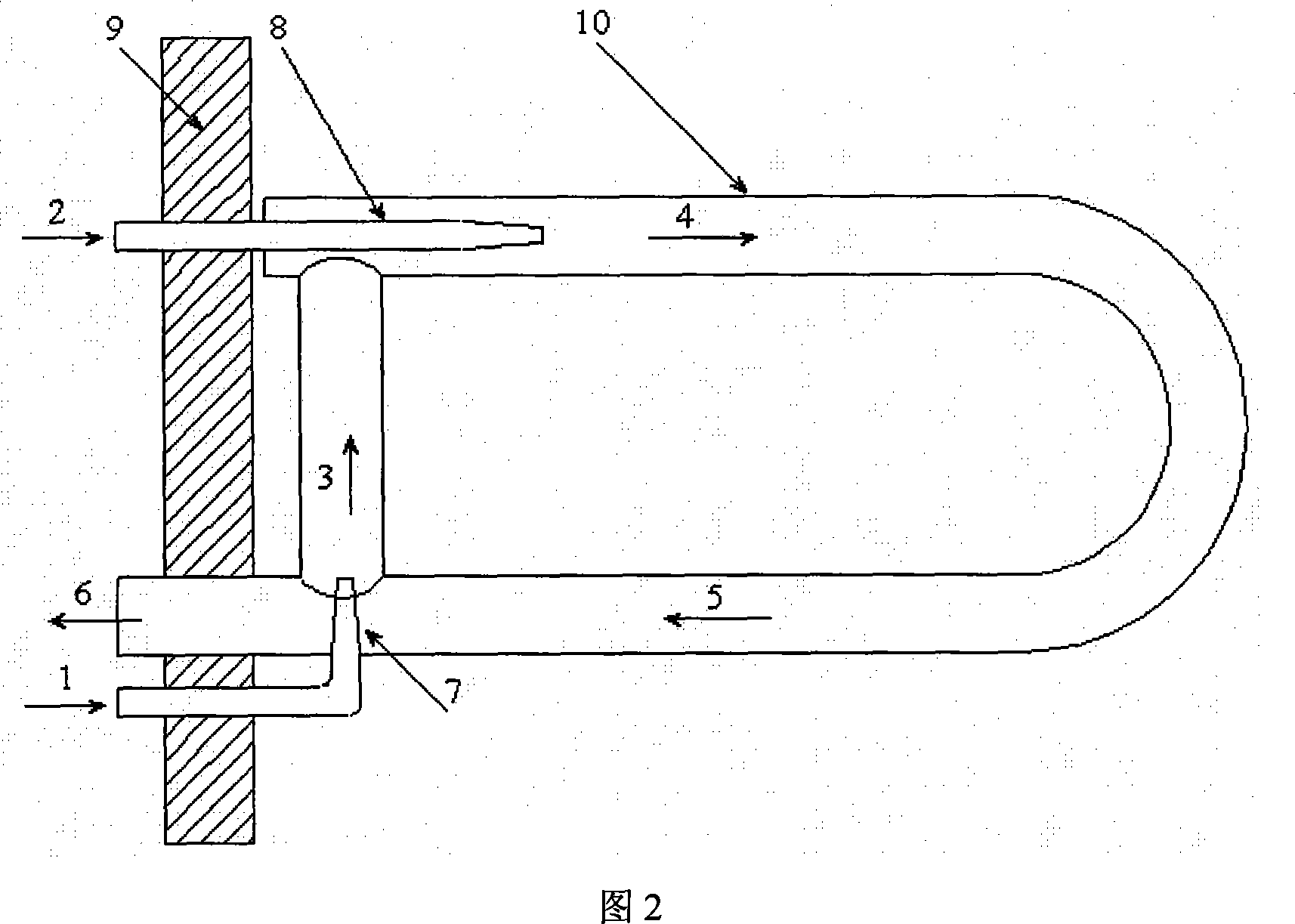

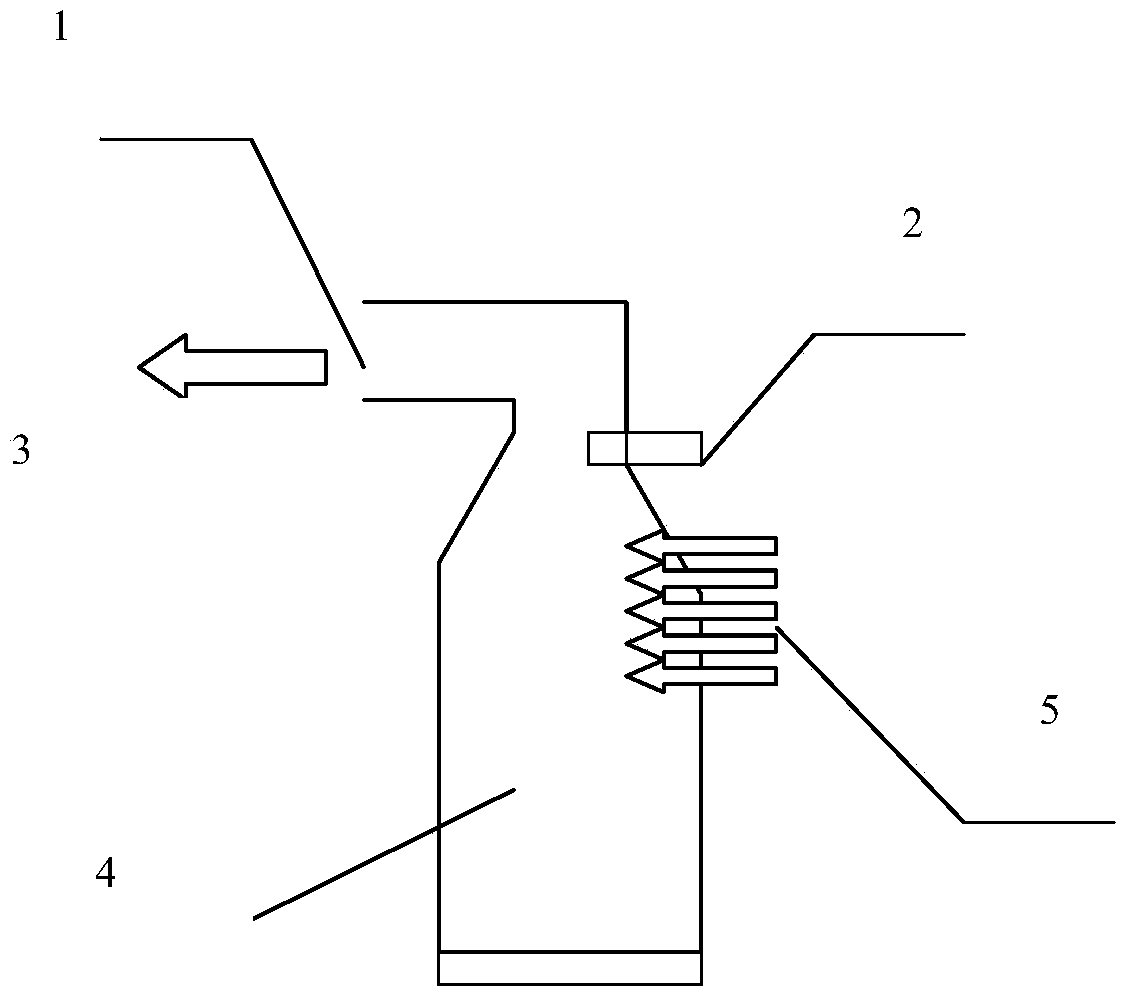

Oxygen-enriched combustion radiant tube heaters

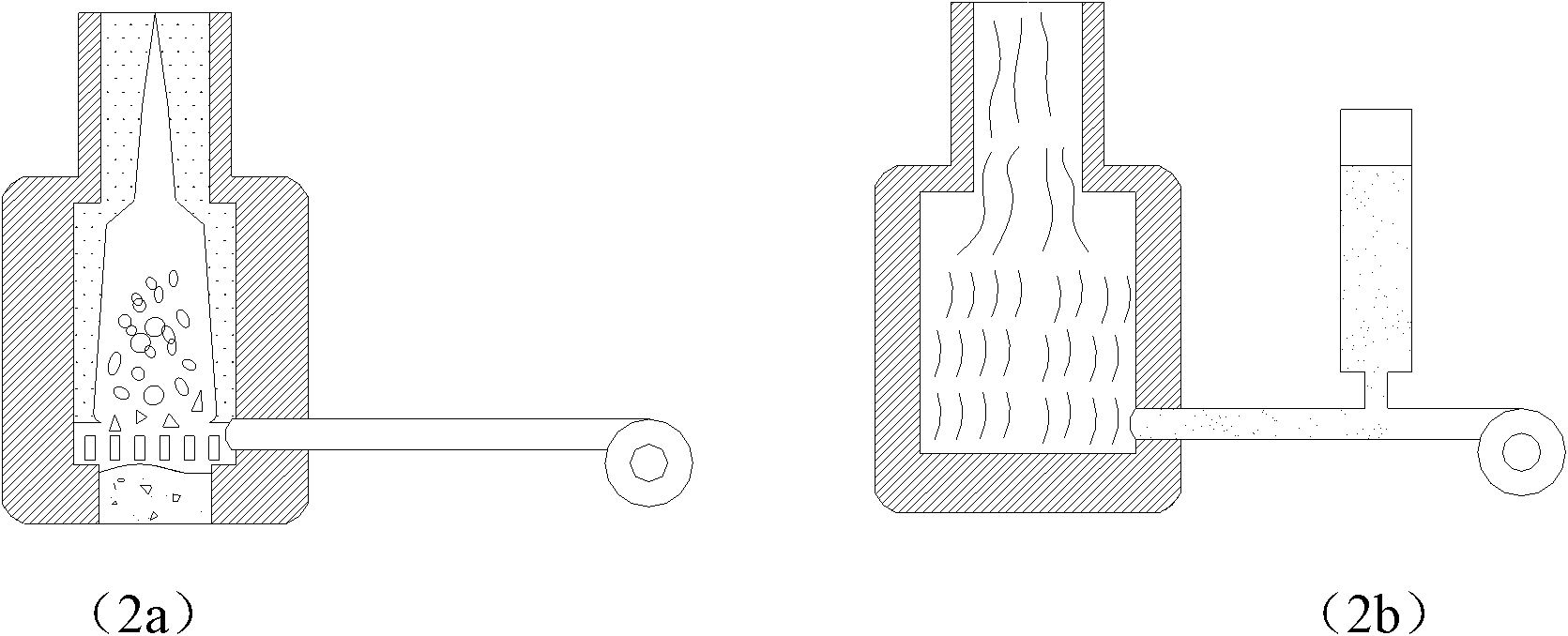

InactiveCN101063525ALower combustion temperatureEnhanced heat transferFurnace typesIndirect carbon-dioxide mitigationInjectorProcess engineering

A radiant-tube heater of oxygen-enriched combustion belonging to the field of environmental protection relates to a new method of oxygen-enriched combustion technology applicable to radiant-tube heater, to develop a combustion system of novel industrial radiant tube that combusts the low-calorific value gas (or other fuel gas) to increase the heat utilization, which is characterized in that the heater comprises oxygen or oxygen-enriched air (1), fuel (2), mixed gas (3) of oxygen or oxygen-enriched air and smoke gas, fuel gas (4), smoke gas (5) in the radiant tube, smoke gas (6) discharged from the radiant tube, a smoke gas injector (7), a combustor (8), a boiler wall (9) and a radiant tube (10). The heater has low combusting temperature, low content of harmful gas like NOx in the smoke gas and high heat efficiency, and is good for collecting the smoke, in particular to CO2 and increases the stability and reliability of the system.

Owner:UNIV OF SCI & TECH BEIJING

Large environment simulation test device for pipeline ball valve test

InactiveCN103411771AEnsure safetyMeet height adjustment requirementsMachine part testingFluid-tightness measurement using fluid/vacuumData processing systemLine tubing

The invention discloses a large outer load bending test device for pipeline ball valve test. The device comprises a pressure supply system, a data processing system, an environment simulation bin, a test lifting bench, a temperature sensor and a torque measuring device, wherein the test lifting bench is used for adjusting the height of a tested pipeline ball valve, and the temperature sensor is used for measuring high temperature and low temperature. The device has the advantages that the maximum pressure of the pressure supply system is 70Mpa; the maximum tension of a single double-function hydraulic fluid cylinder of the test lifting bench is 250T, the maximum travel is 2000mm, and the requirement of adjusting the heights of NPS2 to NPS60 pipeline ball valves is met; the environment simulation bin meets the temperature requirement of -50 DEG C to +93 DEG C, the size of a box is 210m<3>, and the test requirement of NPS2 to NPS60 and Class 150 to Class 2500 pipeline ball valves is met; the maximum measuring range of the torque measuring device is 600000N.m.

Owner:SHANGHAI KAIWEIXI GRP CO LTD

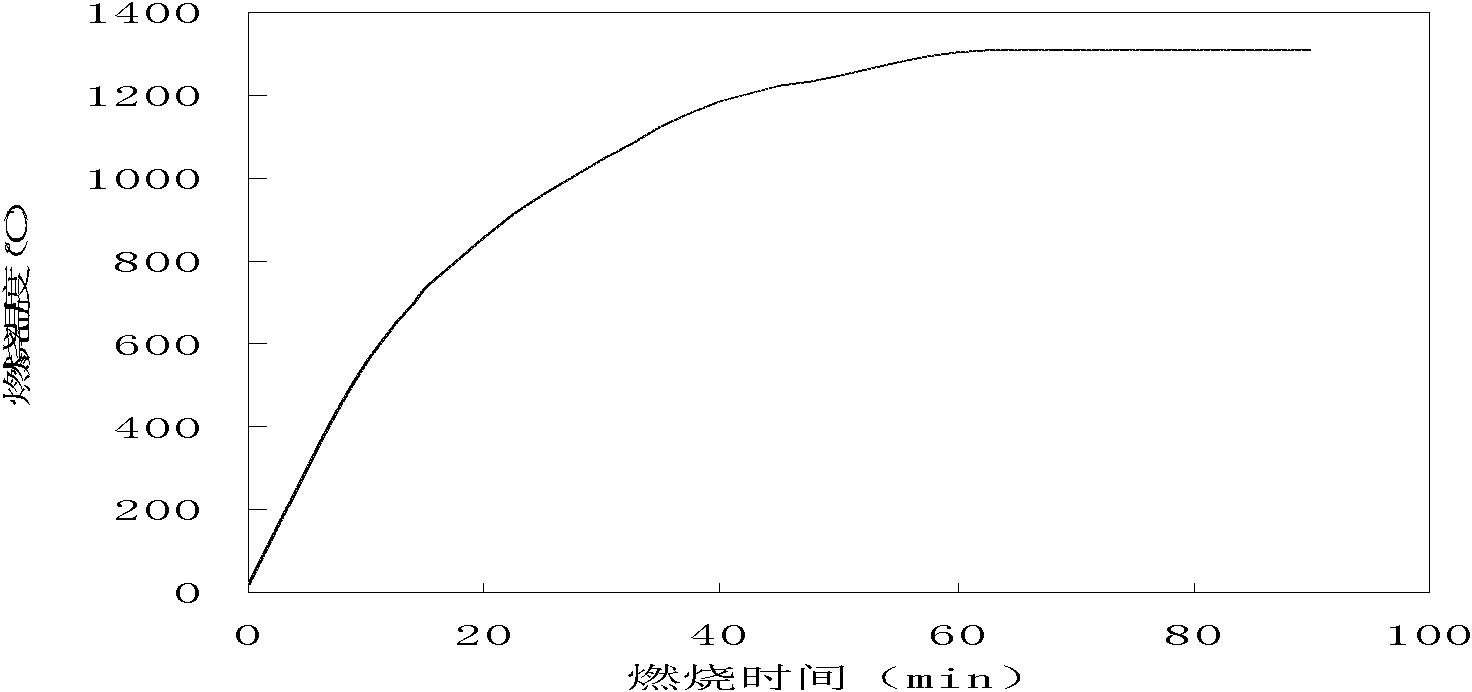

High-temperature biomass micron fuel

ActiveCN101935568ARaise the combustion temperatureEasy to control industriallyBiofuelsSolid fuelsVegetable fibersBiomass

The invention discloses a high-temperature biomass micron fuel. The high-temperature biomass micron fuel comprises 75 to 100 mass percent of vegetable fiber powder and the balance of additive, wherein the additive is at least one of coal powder, lime powder and red mud; and more than 70 percent of the vegetable fiber powder has the grain diameter of less than 250 mu m. Because the specific surface area of the biomass micron fuel is large, the biomass micron fuel can finish solid-gas conversion instantly under the action of the high temperature of a hearth and is decomposed to be combustible gases such as hydrogen (H2), carbon monoxide, methane and the like; the combustible gases combust with oxygen rapidly and vigorously; the energy is released in an explosive model; a high-temperature effect is formed; and the combustion temperature can reach over 1,300 DEG C and the fuel efficiency is over 96 percent. Compared with the traditional method, the method using the high-temperature biomass micron fuel has the advantages that the combustion temperature is increased by about one time and the combustion efficiency is increased by more than one time. The common biomass fiber material can perform fluidization transportation by a micron technique so as to form a high-grade fluid fuel near the grade of fuel oil and fuel gas. The high-temperature biomass micron fuel can be widely applied to thermal power generation, metal melting, the desalination of sea water, urban heating, lime burning, heating air conditioners, industrial heating and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

High efficiency biomass fuel and preparation method thereof

InactiveCN105238480ARaise the combustion temperatureImprove combustion efficiencyBiofuelsSolid fuelsDry weightAdhesive

The invention discloses a high efficiency biomass fuel and a preparation method thereof. The high efficiency biomass fuel comprises the following components by dry weight: 60-80 parts of agricultural and forestry waste, 5-15 parts of sludge, 25-35 parts of organosilicon waste, 1-15 parts of an adhesive, and 5-15 parts of a combustion supporting agent. The combustion supporting agent comprises the following components by weight: 80-100 parts of attapulgite clay, 10-20 parts of dolomite powder, 5-10 parts of heavy calcium carbonate powder, 1-8 parts of carbonyl diamine, 5-15 parts of potassium perchlorate, 2-8 parts of manganese oxide, 6-12 parts of potassium permanganate, and 1-8 parts of carboxymethyl cellulose. The biomass fuel has a high combustion temperature up to 1350-1400DEG C and combustion efficiency enhanced by about 32% compared to ordinary biomass fuels; the calorific value can reach 5100-5300kcal / kg, and per ton of biomass fuel is equivalent to 0.75 ton of standard coal; the combustion tail gas is accord with relevant provisions of the state, also the sulfur removal rate can reach 97.4%, and the nitrate removal rate is up to 93.2%.

Owner:DONGZHI COUNTY XINGNONG MUSHROOM PROCESSING

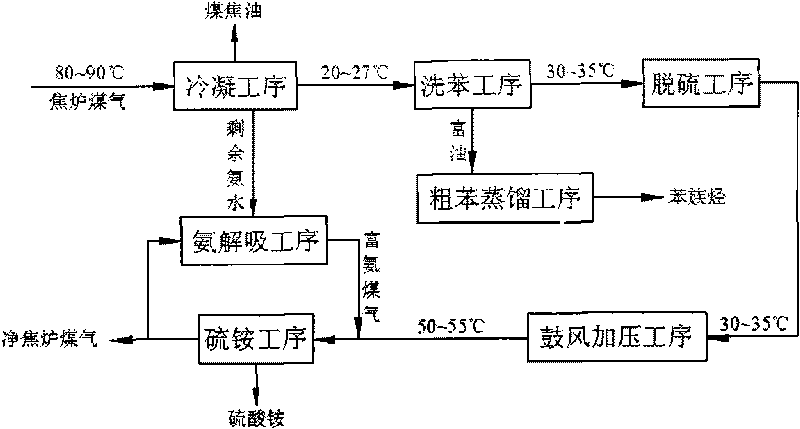

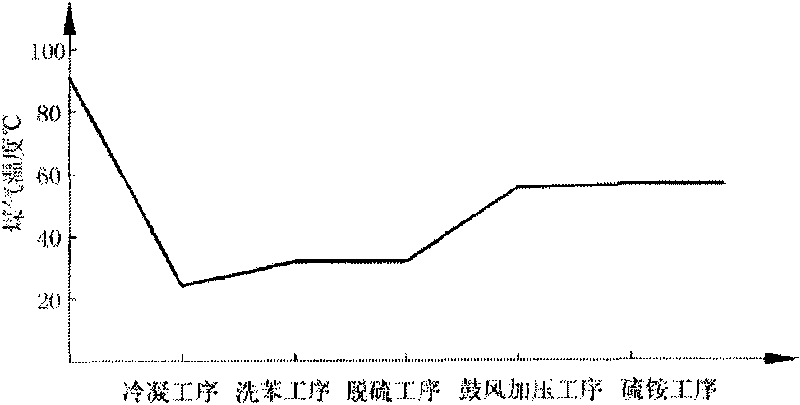

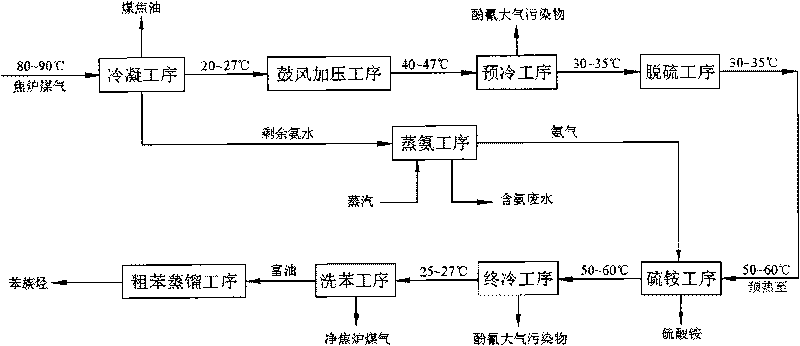

Method for purifying and recycling benzoid hydrocarbon, ammonia and coal tar from coke-oven gas

InactiveCN101724471AMeet temperature requirementsReduce energy consumptionLiquid hydrocarbon mixture recoveryGas purification by non-gaseous materials condensationBenzeneDesorption

The invention relates to a method for purifying and recycling benzoid hydrocarbon, ammonia and coal tar from coke-oven gas. The technical scheme of the method comprises the following steps of: cooling the 80-90 DEG C coke-oven gas through a condensation step to 20-27 DEG C, then directly carrying out a benzene washing step, absorbing benzoid hydrocarbon in the coke-oven gas to the wash oil to form rich oil, desulfurizing the coke-oven gas at 30-35 DEG C after the benzene washing step, air-blast pressurizing the desulfurized coke-oven gas at 30-35 DEG C, naturally raising the temperature of the coke-oven gas to 50-55 DEG C, carrying out an ammonium sulfate step on the coke-oven gas to recycle ammonia therein, and using the purified coke-oven gas after the ammonium sulfate step as high-grade fuel to be supplied to the outside. The remaining ammonia water generated in the condensation step goes into an ammonia desorption step so as to desorb ammonia and goes into the ammonium sulfate step to produce ammonium sulfate; and benzoid hydrocarbon is recycled from the rich oil produced in the benzene washing step through a crude benzene distilling step. The invention has the characteristics of orderly temperature change, smooth change of gradient, simple technical process, low energy consumption, low production cost, high purification efficiency and environmental friendliness.

Owner:WUHAN UNIV OF SCI & TECH

Mixed gas separation, mass storage, pressure rise and energy storage device and method and utility system

ActiveCN105299945AGuaranteed uptimeReduce emergency start timeCompression machinesSteam engine plantsBiomassMixed gas

The invention belongs to the field of energy storage, and discloses a mixed gas separation, mass storage, pressure rise and energy storage device and a method and a utility system, and a heat exchange pressure equalizer. The separation of mixed gas, the pressure rise, the energy storage, the heat exchange and the conversion of gas and liquid are finished in one device, so that the equipment is simplified, the efficiency is improved, and the heat energy is reduced; the cold energy is lost; the energy storage and the energy release can be separately or synchronously performed, so that the emission of carbon dioxide is reduced; and a nitrogen oxide, a sulfur oxide, heavy metal [pm 2.5] and the like are collected for storage and utilization to change harmful substances to useful substances. The invention discloses a gas (air and smoke) condensation, separation and energy storage power station, a wind-electricity plant air separation and energy storage power station, a photovoltaic power generation plant air separation and energy storage power station, a solar heat power air energy storage power station, a wind-electricity solar heat power complementary air energy storage power station, a nuclear power air separation and energy storage power station, a ire coal combustion biomass power generation plane smoke separation and energy storage power station, a gas power generation smoke separation and energy storage power station and an industrial kiln smoke separation and energy storage power station.

Owner:江洪泽

Precise thermal control mechanism of focal plane detector

InactiveCN102681568ATo achieve different working temperature requirementsFulfill heating needsTemperatue controlTemperature controlPhotovoltaic detectors

The invention relates to a precise thermal control mechanism of a focal plane detector, and the precise thermal control mechanism comprises a vacuum box body, a refrigerating assembly, a cold screen assembly, a heating assembly and a temperature collecting unit, and the precise thermal control mechanism also comprises a heat insulating layer which is arranged at the outer side of the vacuum box body and the outer side of the heating assembly, the refrigerating assembly comprises a refrigerator substrate, at least one detector refrigerator, at least one cold screen refrigerator, a heat tube assembly and a heat radiation plate. Due to the adoption of the precise thermal control mechanism, the technical problems that the quick variation of the temperature under the same working mode is difficult to realize because the temperature control of the traditional photoelectric detector thermal control mechanism mainly depends on the passive heat radiation way can be solved, a way combining the initiative refrigeration and the initiative heating is adopted, by the reasonable design of a thermal control system structure, not only is the quick variation of the temperature of the detector realized to meet the temperature requirement under different working modes, but also the temperature range can be precisely controlled, and the working reliability of the system is high.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

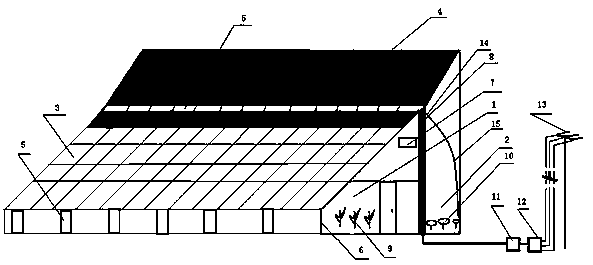

Photovoltaic solar greenhouse based on shade shed and sun shed integration and construction method thereof

InactiveCN103477908ARealize integrationMaximize utilizationClimate change adaptationRenewable energy machinesEngineeringAir exchange

Owner:ANHUI SCI ONE TECH CO LTD

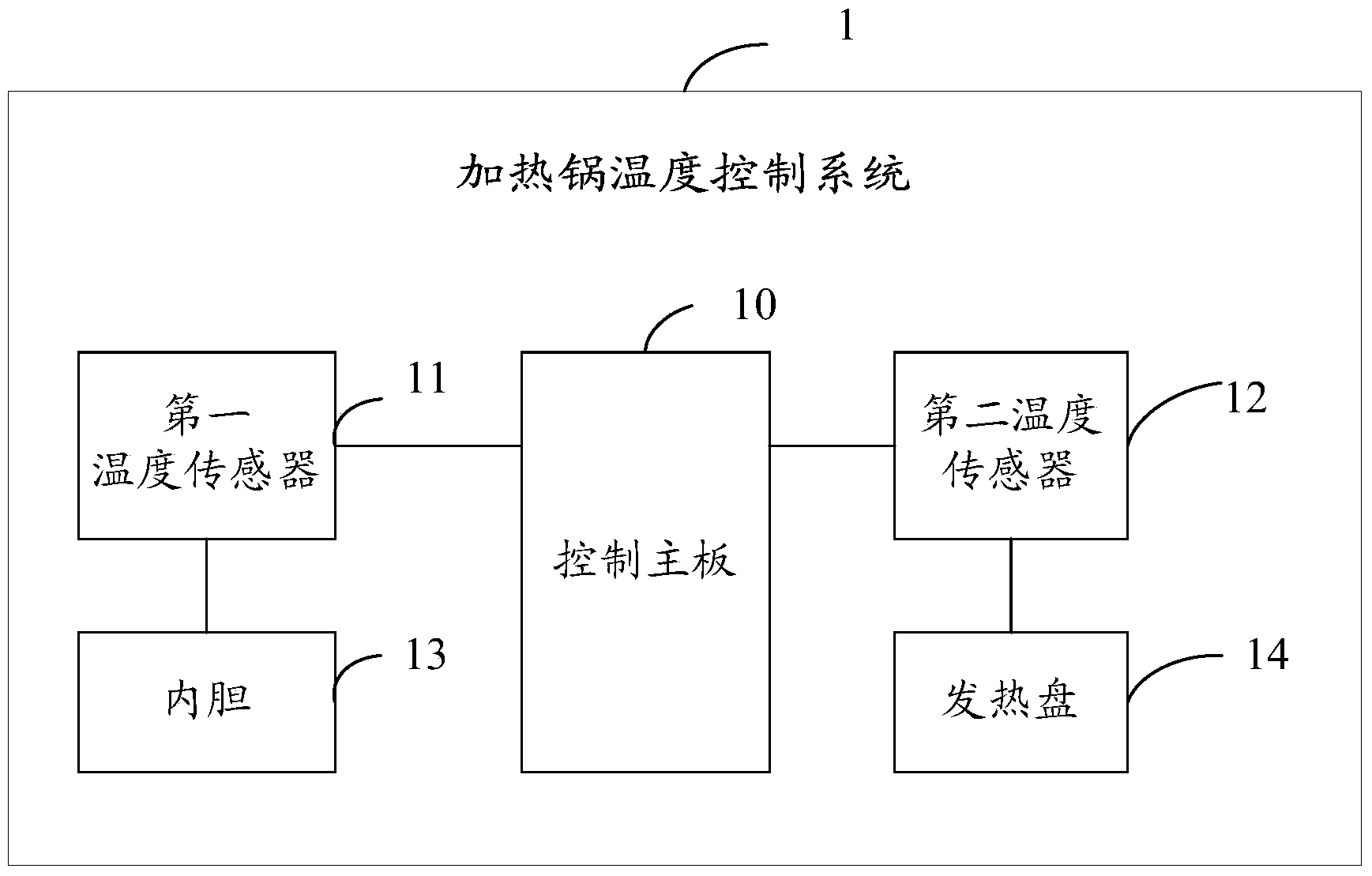

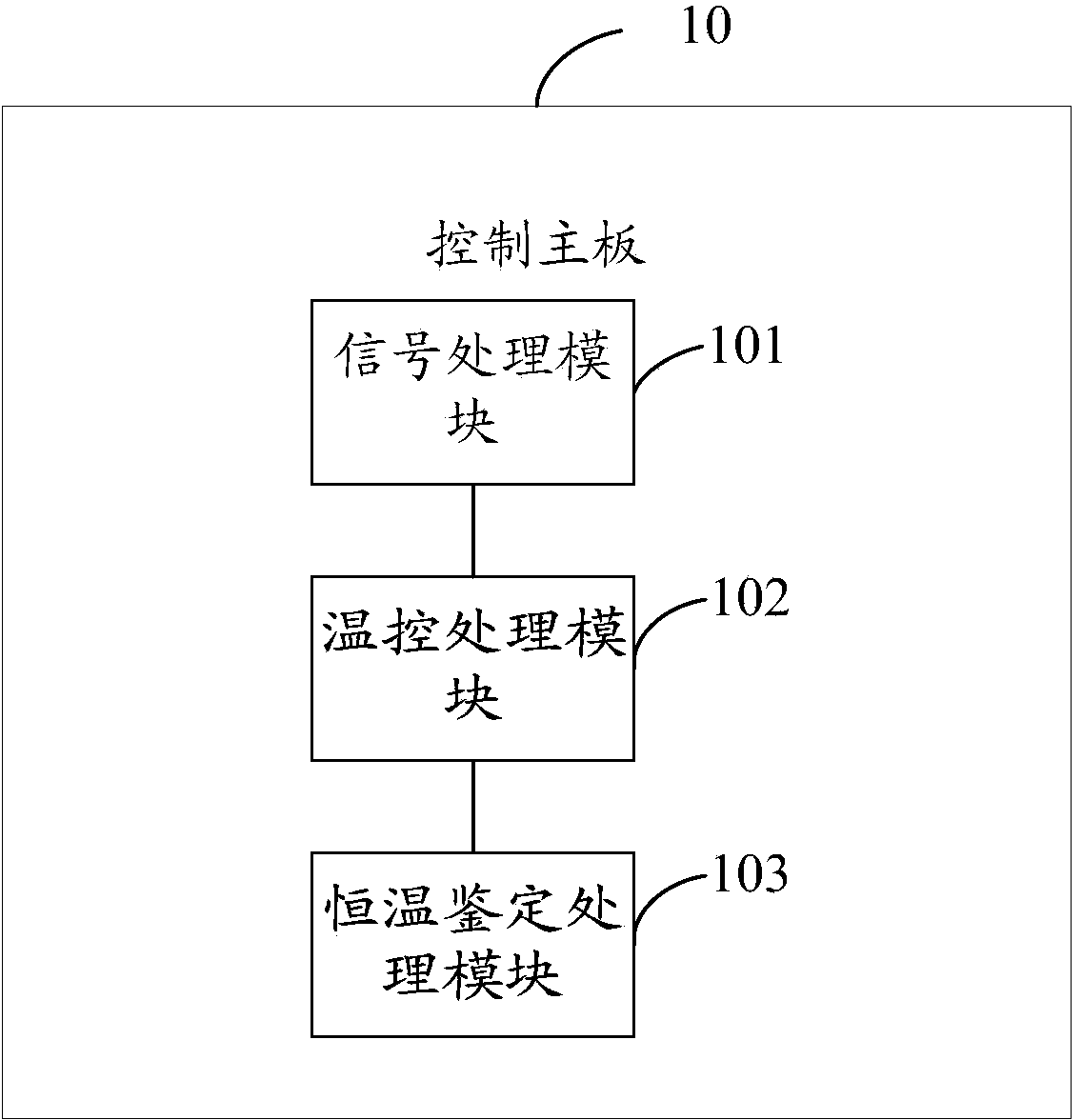

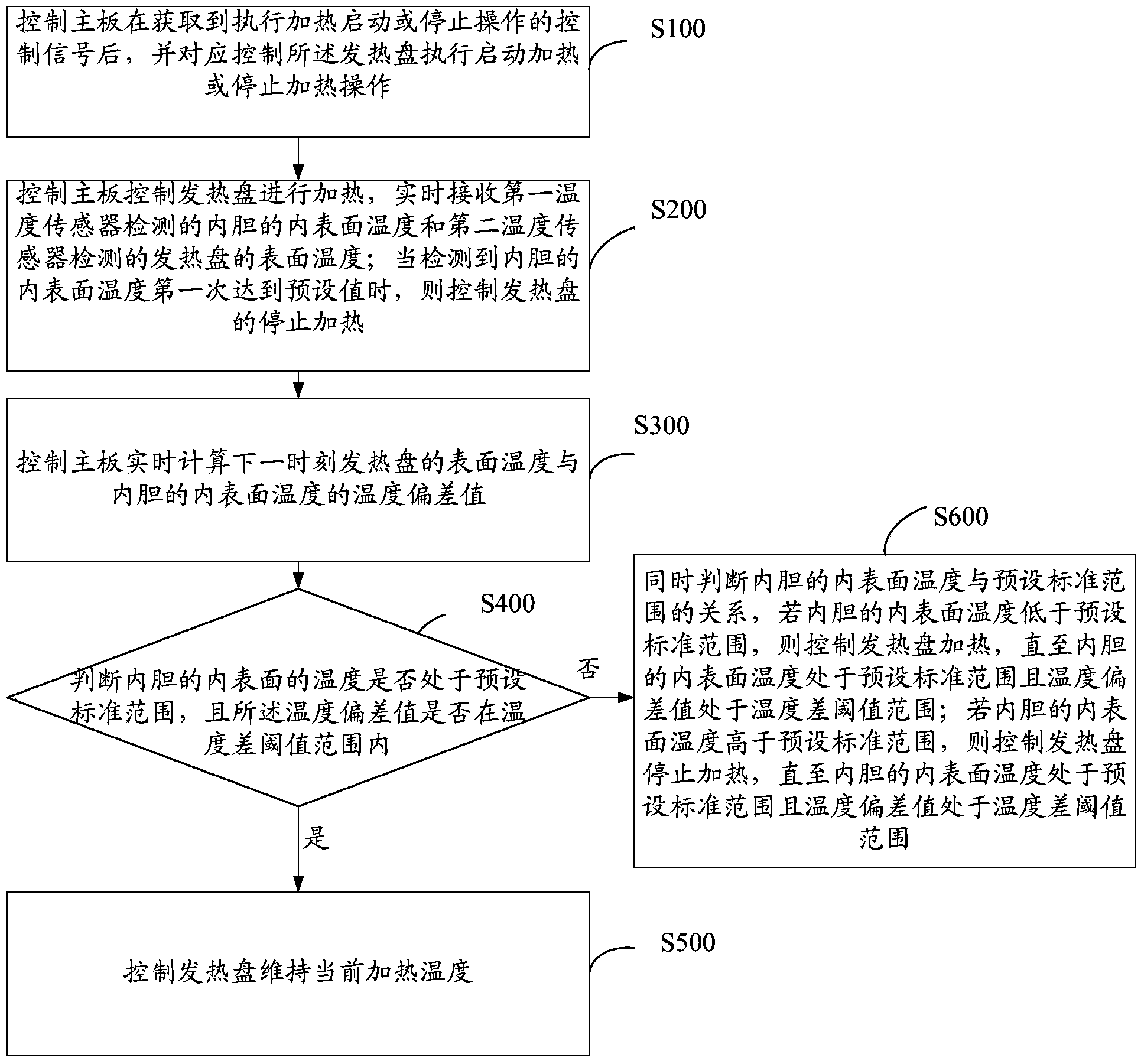

Heating boiler temperature control system and method

ActiveCN103645758ARealize the purpose of constant temperature controlReliable lockingTemperatue controlEngineeringEnergy consumption

The invention discloses a heating boiler temperature control system and method. The heating boiler temperature control method comprises the following steps of controlling a heating plate to perform heating through a control mainboard and receiving the inner surface temperature of an inner tank and the surface temperature of the heating plate timely, wherein the inner surface temperature of the inner tank is detected by a first temperature sensor and the surface temperature of the heating plate is detected by a second temperature sensor; controlling the heating plate to stop heating when the inner surface temperature of the inner tank is detected to reach a preset value for the first time; performing real-time calculation on a temperature deviation value of the surface temperature of the heating plate and the inner surface temperature of the inner tank at the next moment through the control mainboard and judging whether the inner surface temperature of the inner tank is located in the preset standard range or not and whether the temperature deviation value is within the temperature difference threshold range or not; controlling the heating plate to maintain the current heating temperature if yes. According to the heating boiler temperature control system and method, the temperature difference control is performed on the inner surface temperature of the inner tank, the surface temperature of the heating plate and the temperature deviation value and accordingly the accurate feedback control can be achieved, the locking of the temperature of the inner tank can be guaranteed, the inner tank can enter into the constant temperature state rapidly, and meanwhile the energy consumption is saved.

Owner:杨虎峰

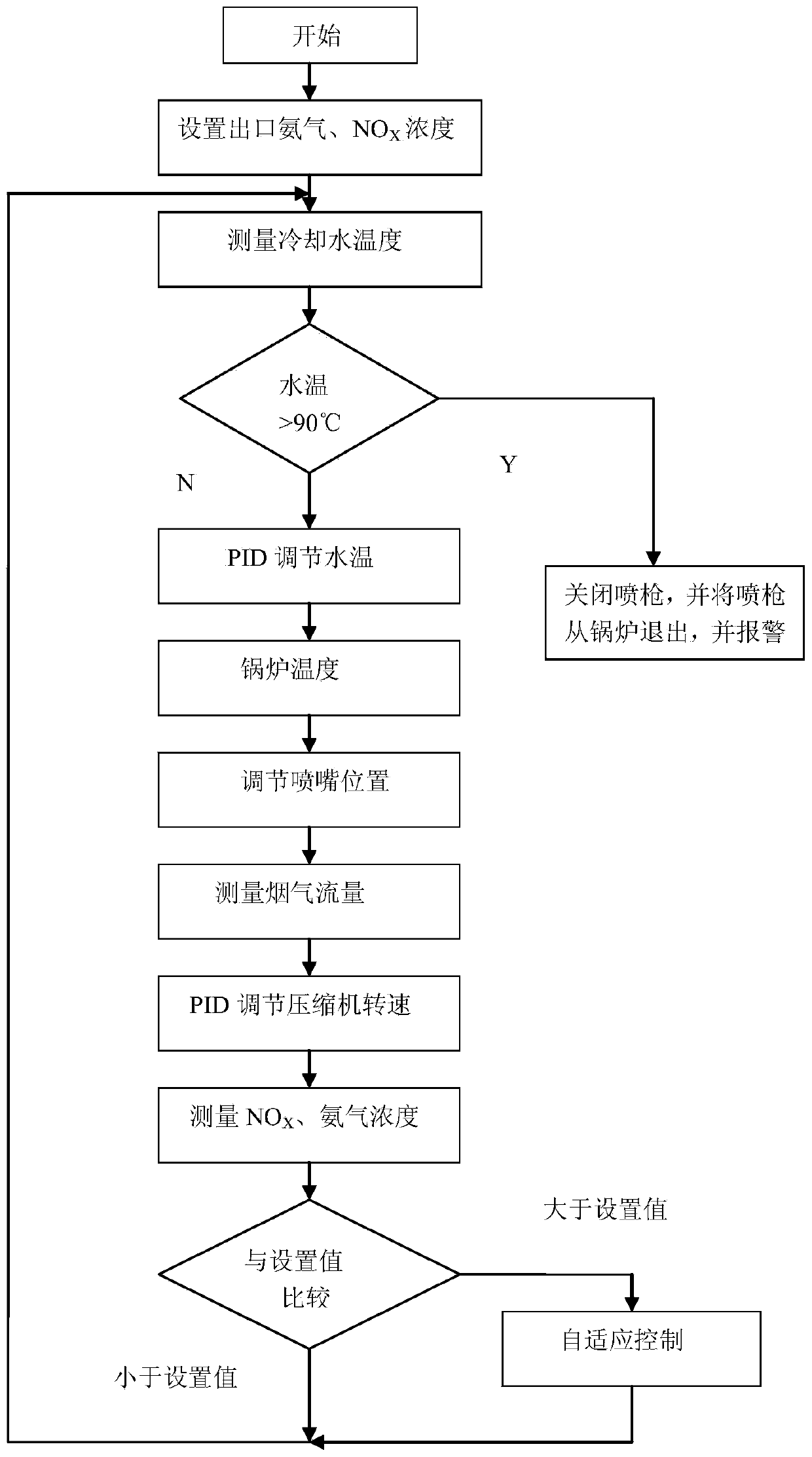

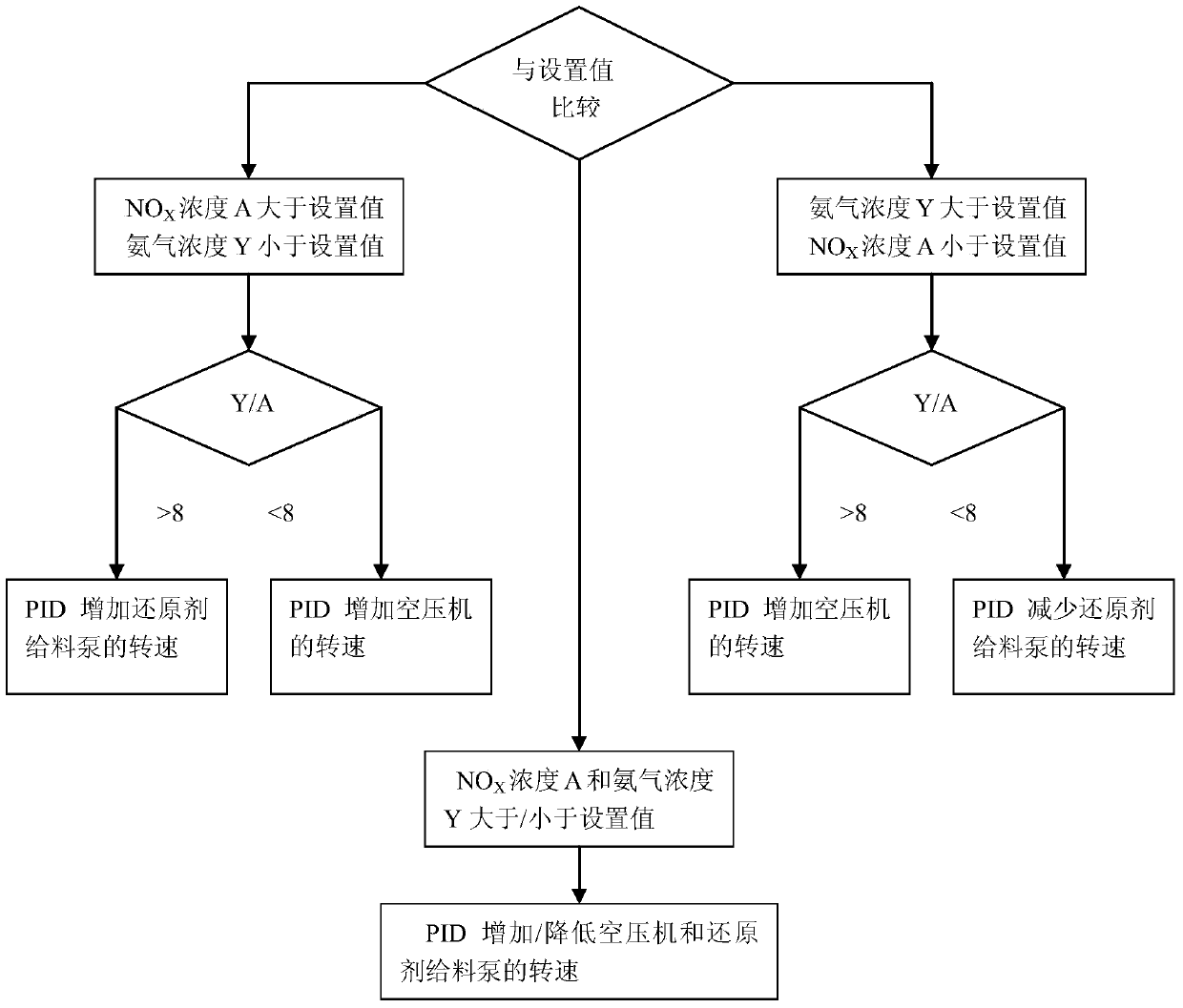

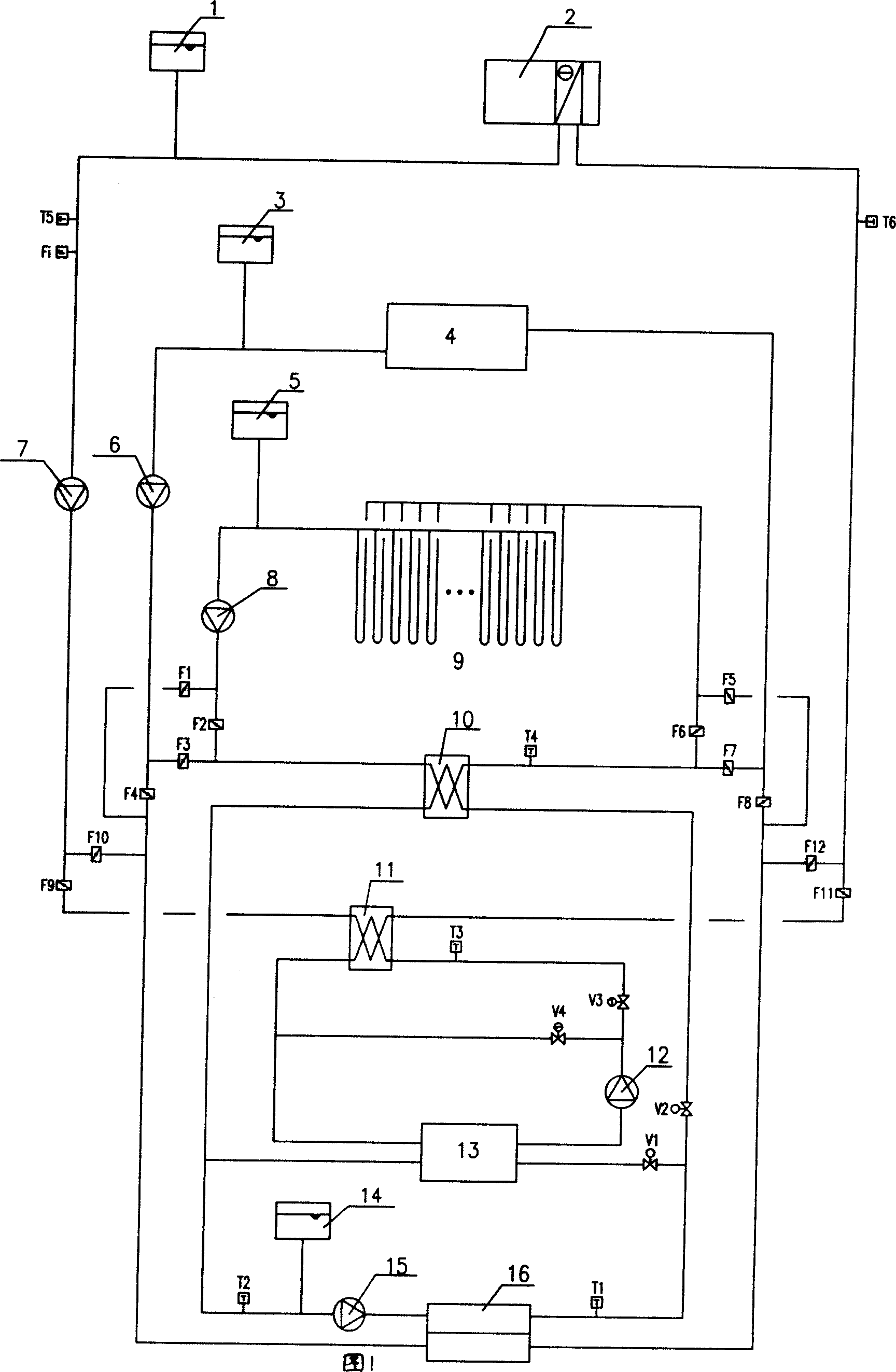

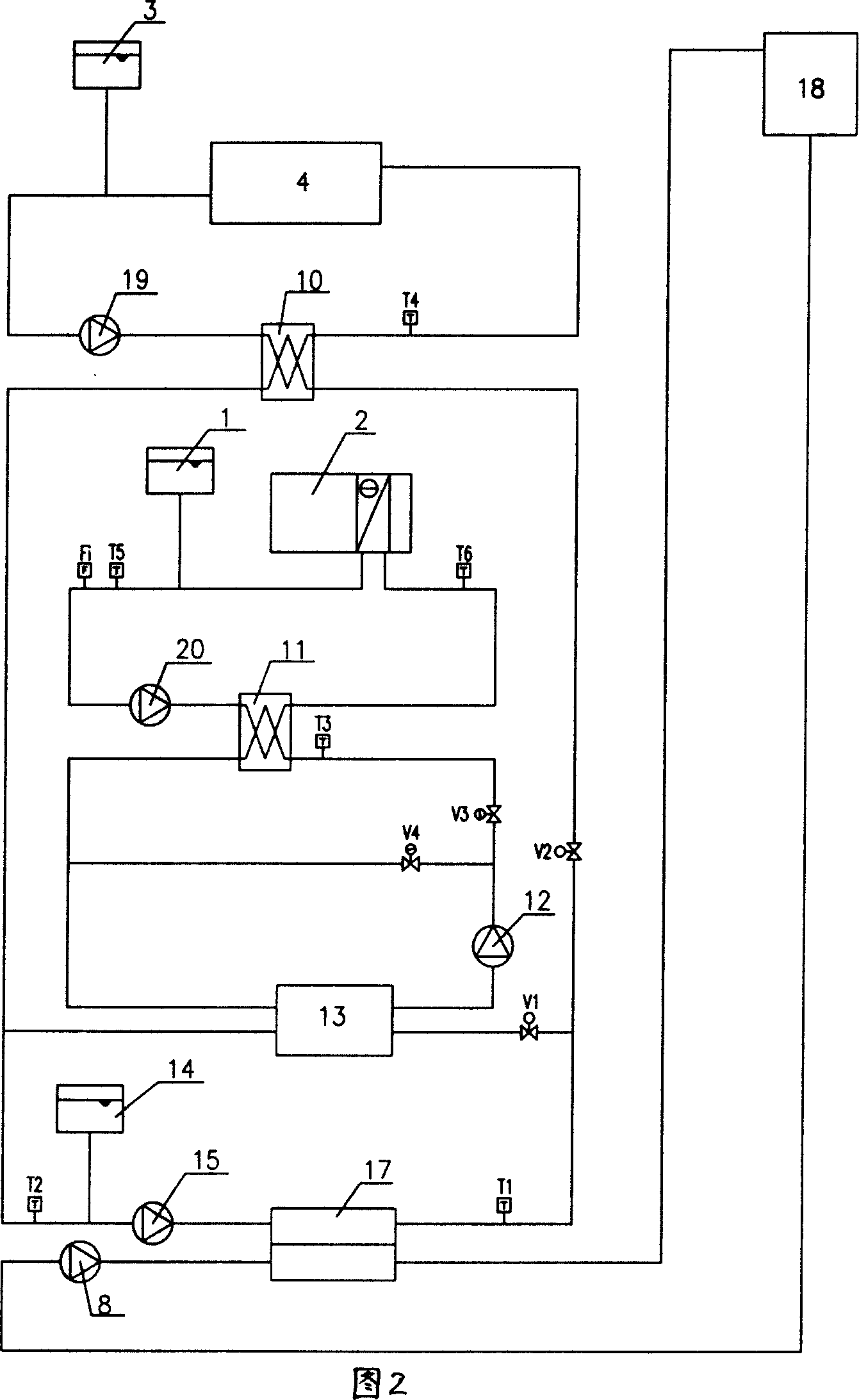

Flue gas SNCR (selective non-catalytic reduction) denitration control device and method

ActiveCN104001420AImprove efficiencyEasy to implementDispersed particle separationAdaptive controlFlue gas

The invention discloses a flue gas SNCR (selective non-catalytic reduction) denitration control method. A field detection module and an adaptive control module are adopted, wherein the field detection module is used for measuring the temperature T above a grate of a boiler, the nitrogen oxide concentration of tail gas of the boiler, the ammonia concentration of a reducing agent, the flow of flue gas and the temperature of cooling water of a spray gun by using sensors; the adaptive control module is used for transmitting values measured by the sensors to a PLC (programmable logic controller) unit to adaptively control the position of the spray gun, the amount of the supplied reducing agent and the spraying pressure of the reducing agent, and displaying the working condition of a whole device on a display module. The sensor is used for measuring the temperature T above the grate, and corresponding nozzles are opened according to the following relationships.

Owner:SHANDONG SHOUFENG ENVIRONMENTAL PROTECTION EQUIP CO LTD

Temperature and humidity individual control air conditioner system

InactiveCN1924473AMeet the requirements of off-peak operationImprove qualitySpace heating and ventilation safety systemsLighting and heating apparatusCooling towerEngineering

This invention relates to moisture independent control and memory air conditioning technique combination and to one system, which combines independent control air conditioning with outer melt and earth source pump technique, wherein, the hanging radiation board adopts cool water for 18 to 20 degrees to satisfy low temperature wind and cooling temperature requirements with better ice memory displacement peak to fill trough and with low cost and good air conditioning quality.

Owner:上海华电源牌环境工程有限公司

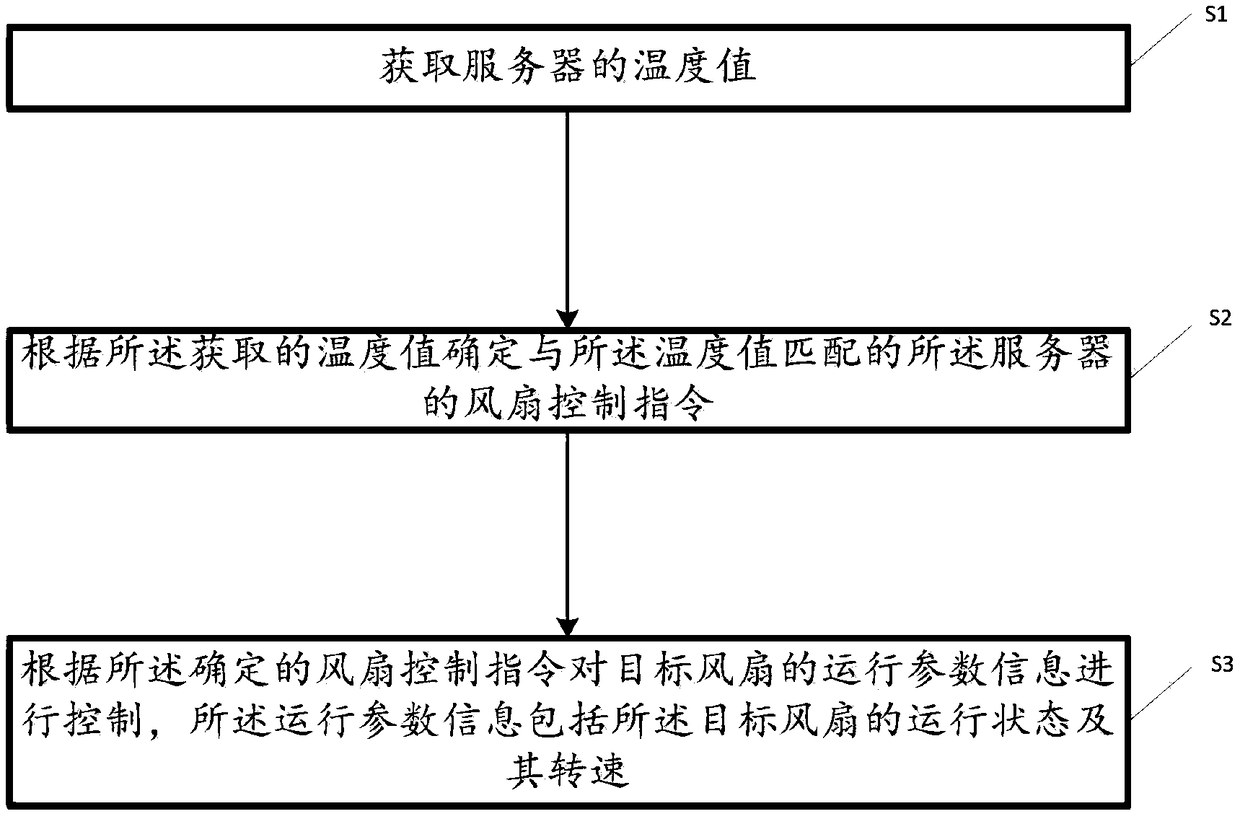

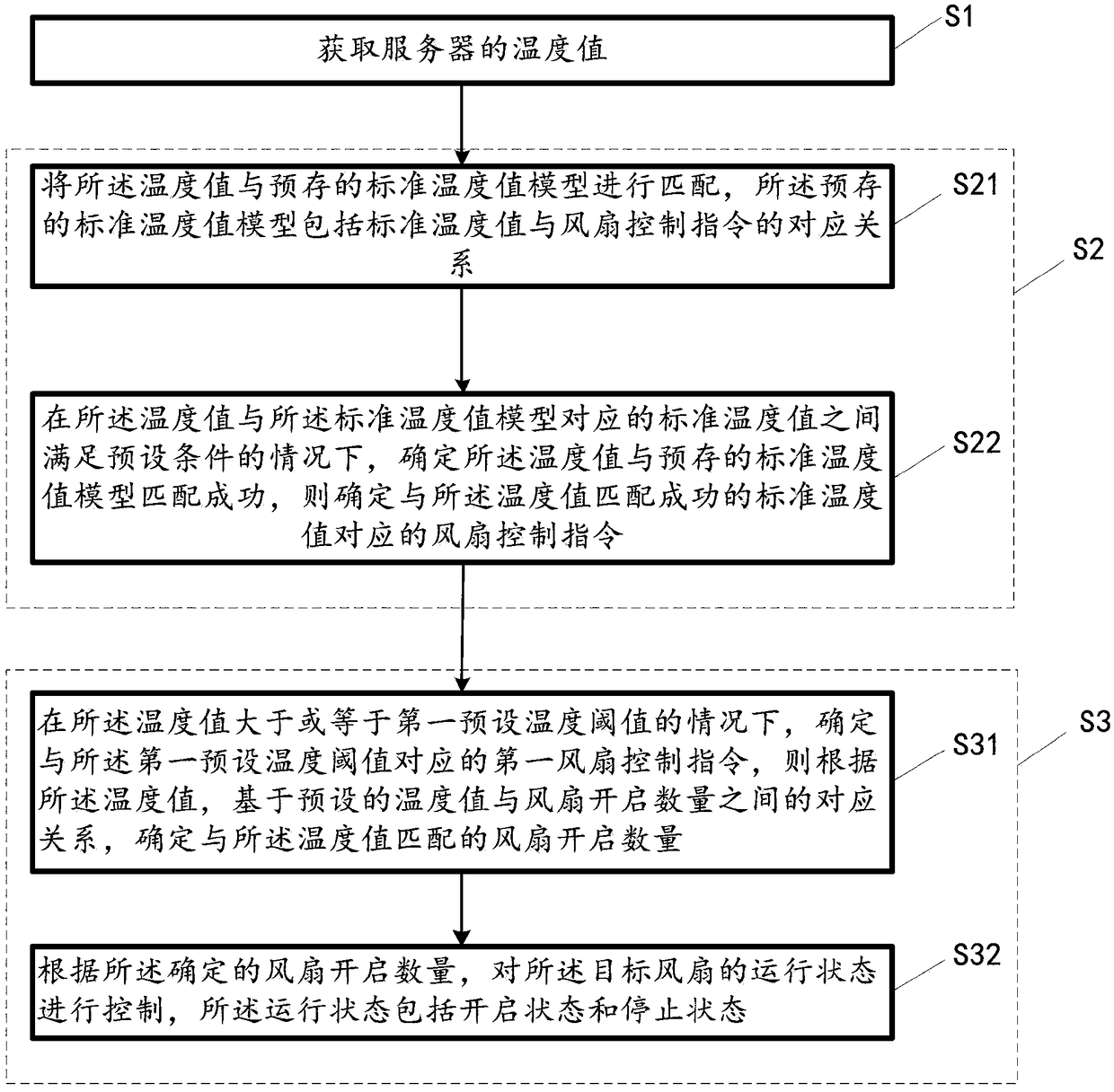

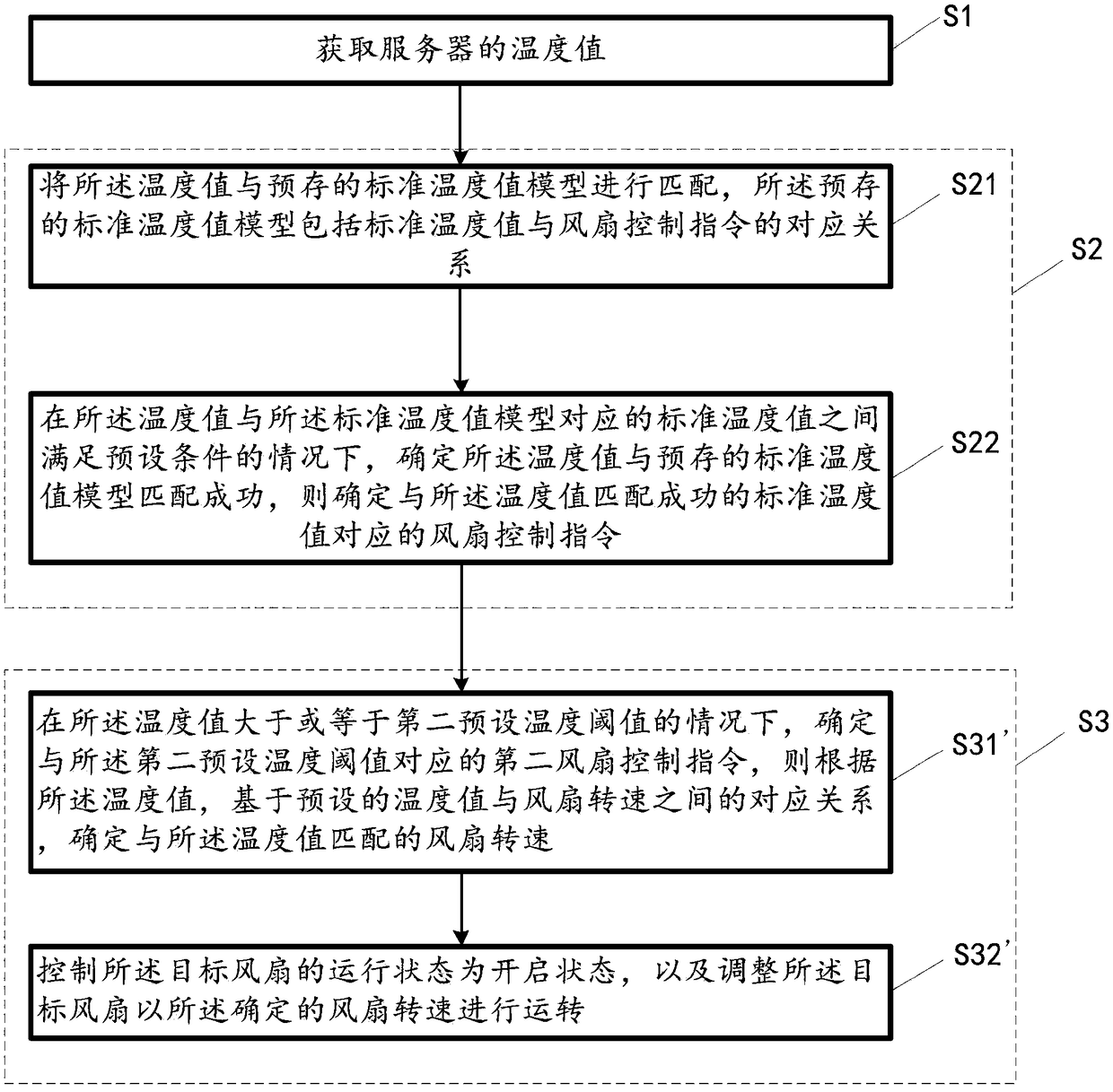

Server fan control method, device and equipment, and computer storage media

ActiveCN109441864AMeet temperature requirementsImprove the operating environmentDigital data processing detailsPump controlOperating environmentSmart control

Server fan control method, device and equipment, and computer storage media. The method includes acquiring a temperature value of a server; determining a fan control command matched with the acquiredtemperature value; and controlling the operation parameter information of the targeted fan according to the determined fan control command, the operation parameter information comprises an operating status and rotating speed of the targeted fan. The rise in the temperature of the server will impact the operation of the serer or even cause damages to the server. With adoption of the control method,the server fan is intelligently controlled, temperature requirement of the server is met, an excellent operating environment is provided for the server, the fault ratio of the server is reduced, andoperating safety of the server is guaranteed.

Owner:宝德计算机系统股份有限公司

Anti-tensile and wear-proof flame-retardant conveying belt covering rubber and preparation method thereof

ActiveCN103467802AHigh tensile strengthMeet temperature requirementsButadiene-styrene rubberFire retardant

The invention relates to conveying belt covering rubber and a preparation method thereof, in particular to anti-tensile and wear-proof flame-retardant conveying belt covering rubber and a preparation method thereof. The covering rubber comprises the following components in parts by weight: 60-90 parts of butadiene styrene rubber, 5-35 parts of natural rubber, 5-15 parts of butadiene rubber, 3.5-7.5 parts of activator, 2.5-6.5 parts of antiager, 50-70 parts of carbon black, 3.5-5.5 parts of dispersing agent, 0.5-3.5 parts of sulfur, 0.5-3.5 parts of vulcanization accelerator, 9.0-15.0 parts of C5 resin and 20-45 parts of fire retardant. By considering an anti-tensile property, a wear-proof property, processability and other aspects comprehensively, a selected formula system of the anti-tensile and wear-proof flame-retardant conveying belt covering rubber can achieve an excellent effect; the tensile strength is improved by 17.3% in comparison with the existing product; the wear-proof property is improved by 38%; requirements of material conveying on the temperature are met; the service life of a conveying belt is greatly prolonged; and very good economic benefits are realized.

Owner:QINGDAO HUIYANG MINING BELT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com