Batch experimental device of water-rock reaction in CO2 geological storage

A technology of geological storage and experimental equipment, applied in the direction of measuring equipment, test sample preparation, instruments, etc., can solve the problems of small reaction chamber volume, reaction pressure reduction, device temperature, pressure range reaction mismatch, etc., to achieve simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

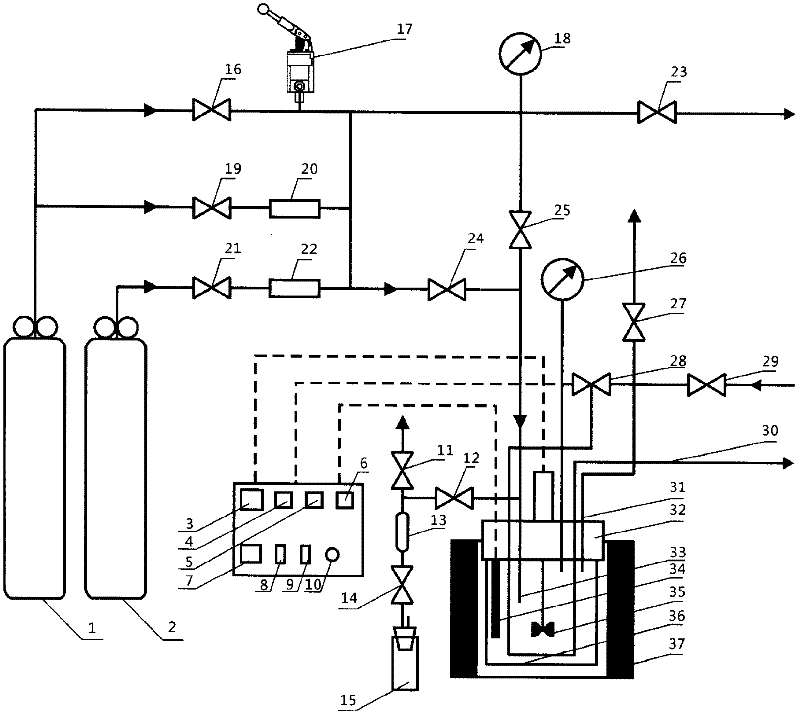

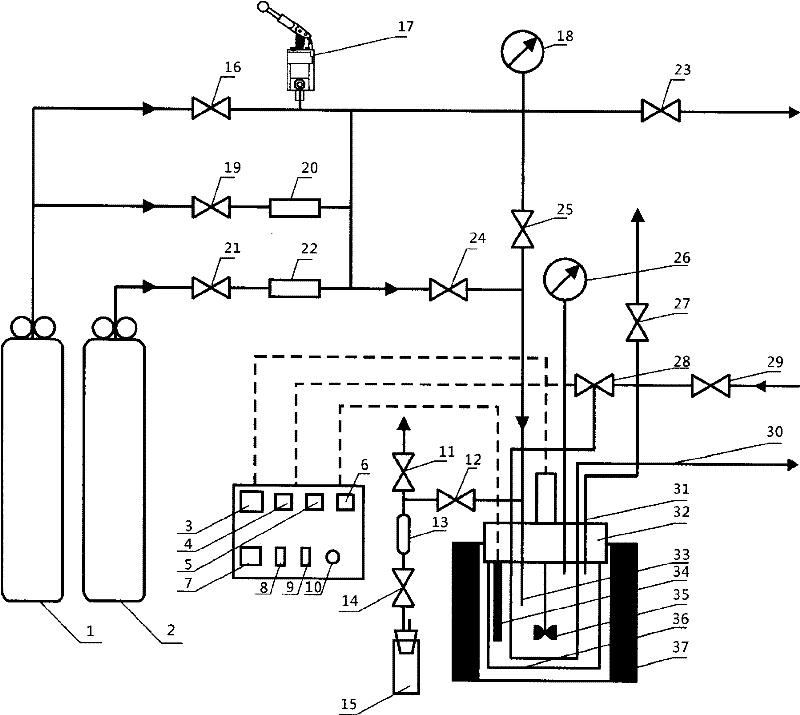

[0031] see figure 1 , is a schematic diagram of the device of the present invention. A reactor 36 is arranged in the device of the present invention, and the still head of the reactor is connected with the still body of the reactor with a detachable ring seal 32, and the still head and the still body interface are provided with a flexible graphite sealing gasket (not shown in the figure) . The still body is placed in the electromagnetic heater 37, and water and ground rock samples are housed in the still body, and a magnetic stirrer 35 is installed in the still body, and the reaction between the water and the rock sample port is enhanced by stirring. Through the ring seal 32, the reactor body of the reaction kettle 36 is respectively connected to the CO through the first air valve. 2 The gas cylinder is also connected to the still body by the water inlet valve 29, and the first exhaust valve 27 is also installed to be connected to the still body. In the device of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com