Device for testing cryogenic mechanical properties of material

A testing device and material testing machine technology, applied in measurement devices, analytical materials, scientific instruments, etc., can solve the problems of helium resource waste, complicated operation, high cost, meet the temperature requirements and avoid a lot of waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

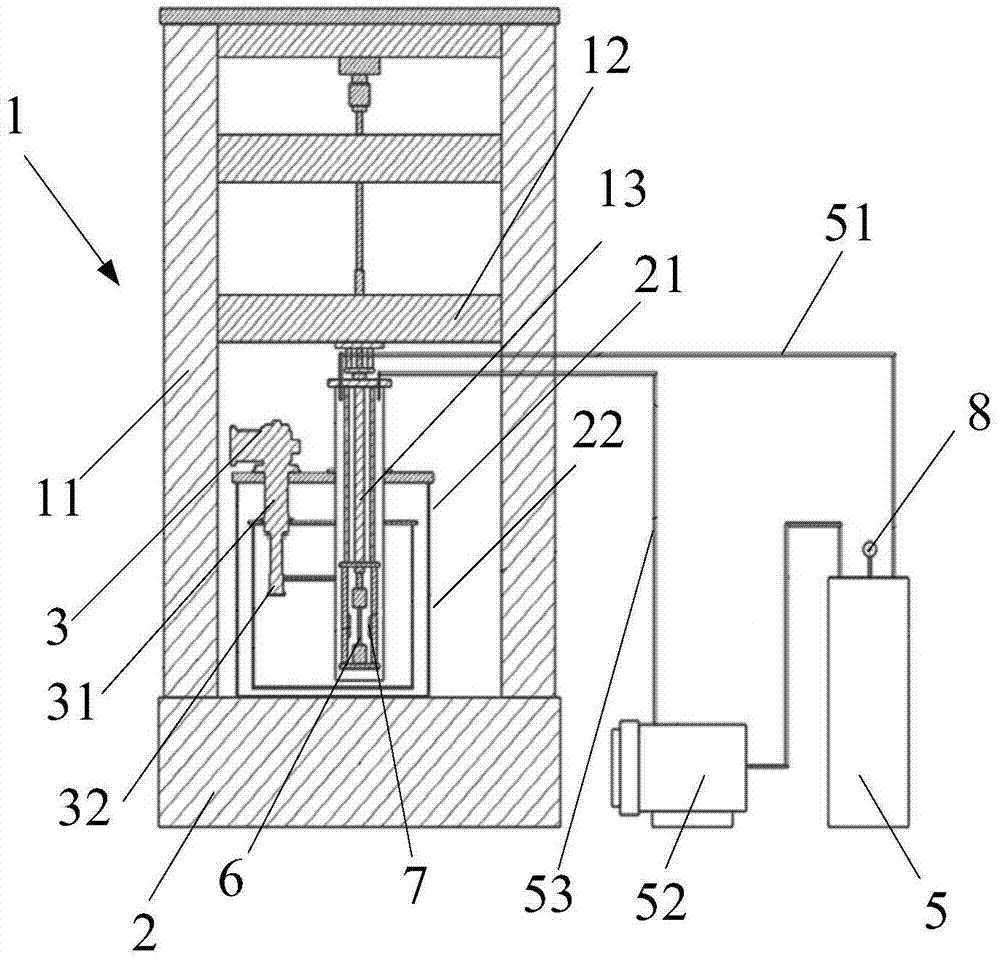

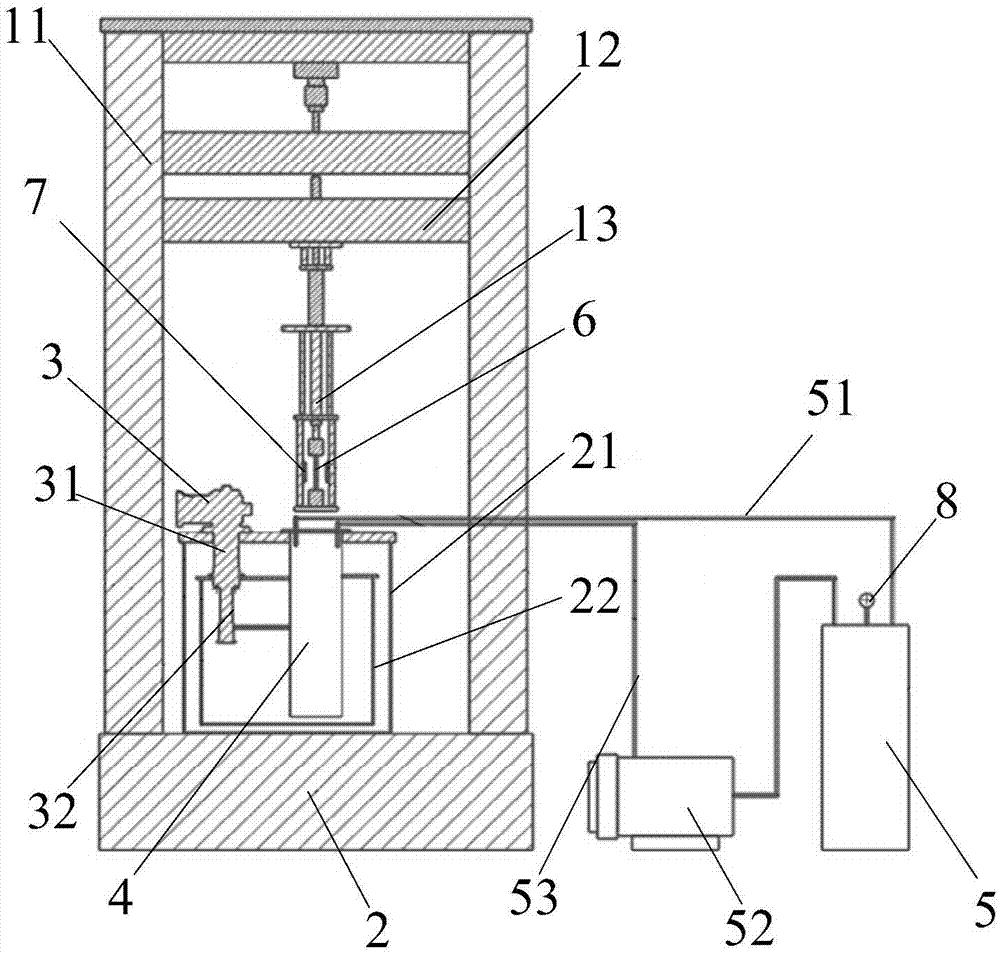

[0029] Such as figure 1 with figure 2 As shown, the material low-temperature mechanical performance testing device includes: a universal material testing machine, a mechanical support 13, a low-temperature refrigerator 3, a vacuum insulation barrel 21, a heat-resistant radiation barrel 22, a sample chamber 4, and a temperature controller 7; The universal material testing machine provides a mechanical power source (i.e. loading force) for the sample 6 to be tested. The universal material testing machine includes a base 2 and a support frame 1 arranged on the base 2, and the vacuum insulation barrel 21 is arranged on the base 2 Above, the support frame 1 is provided with a mechanical support 13 for rigid connection with the sample 6 to be tested, wherein the support frame 1 includes two parallel support rods 11 vertically arranged on the base 2, the The lower ends of the support rods 11 are connected to the base 2, and at least one crossbeam 12 is also provided between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com