Patents

Literature

77results about How to "Large amount of steam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

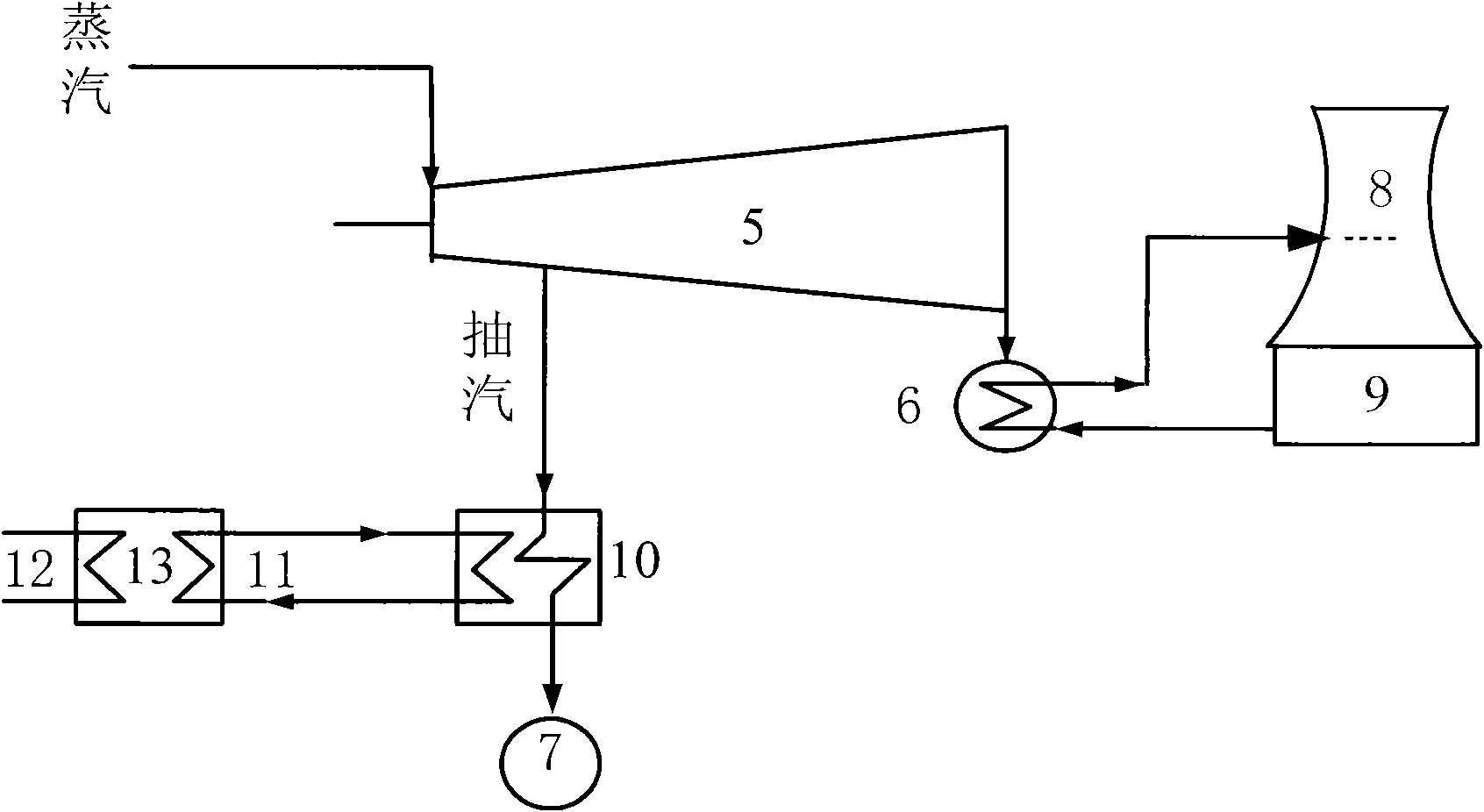

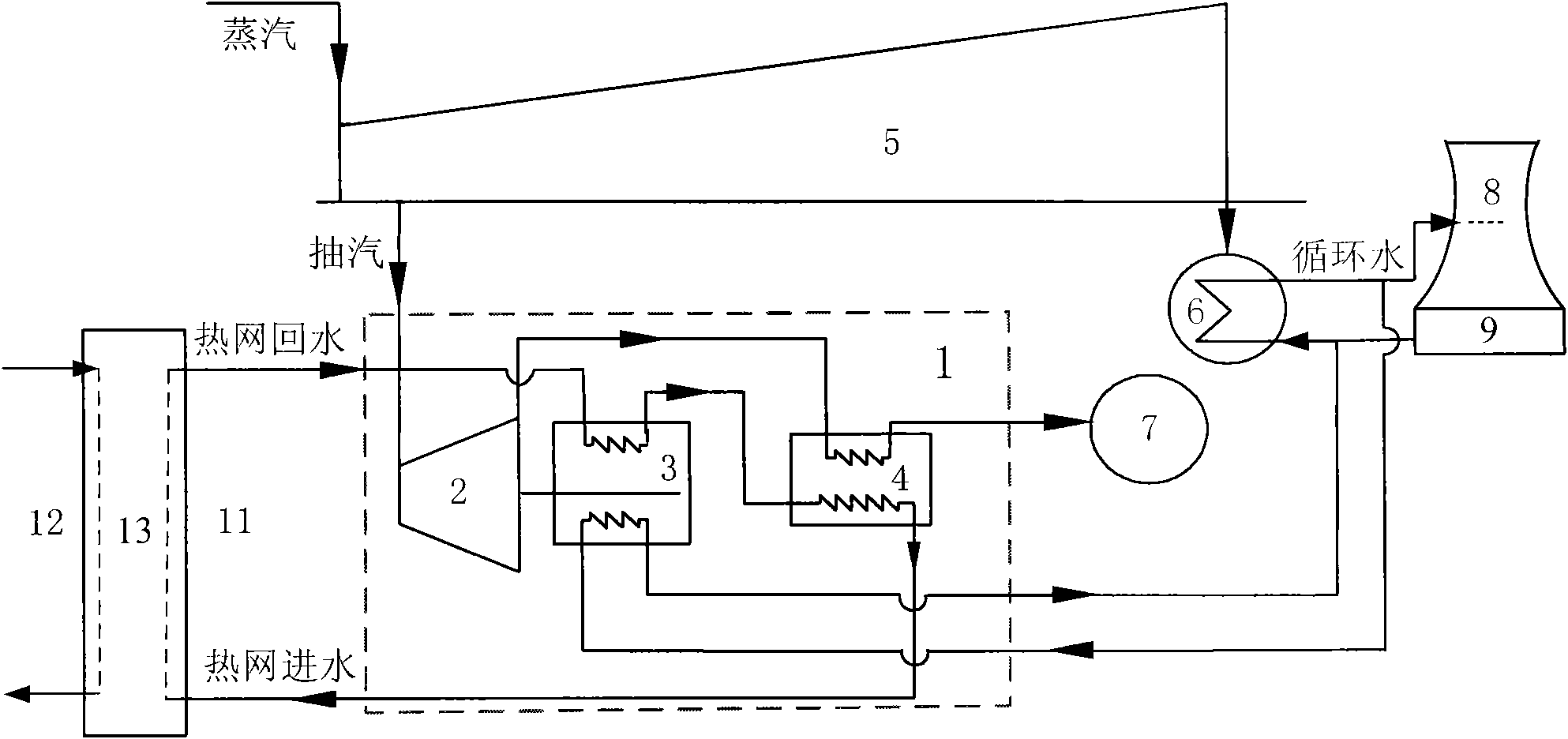

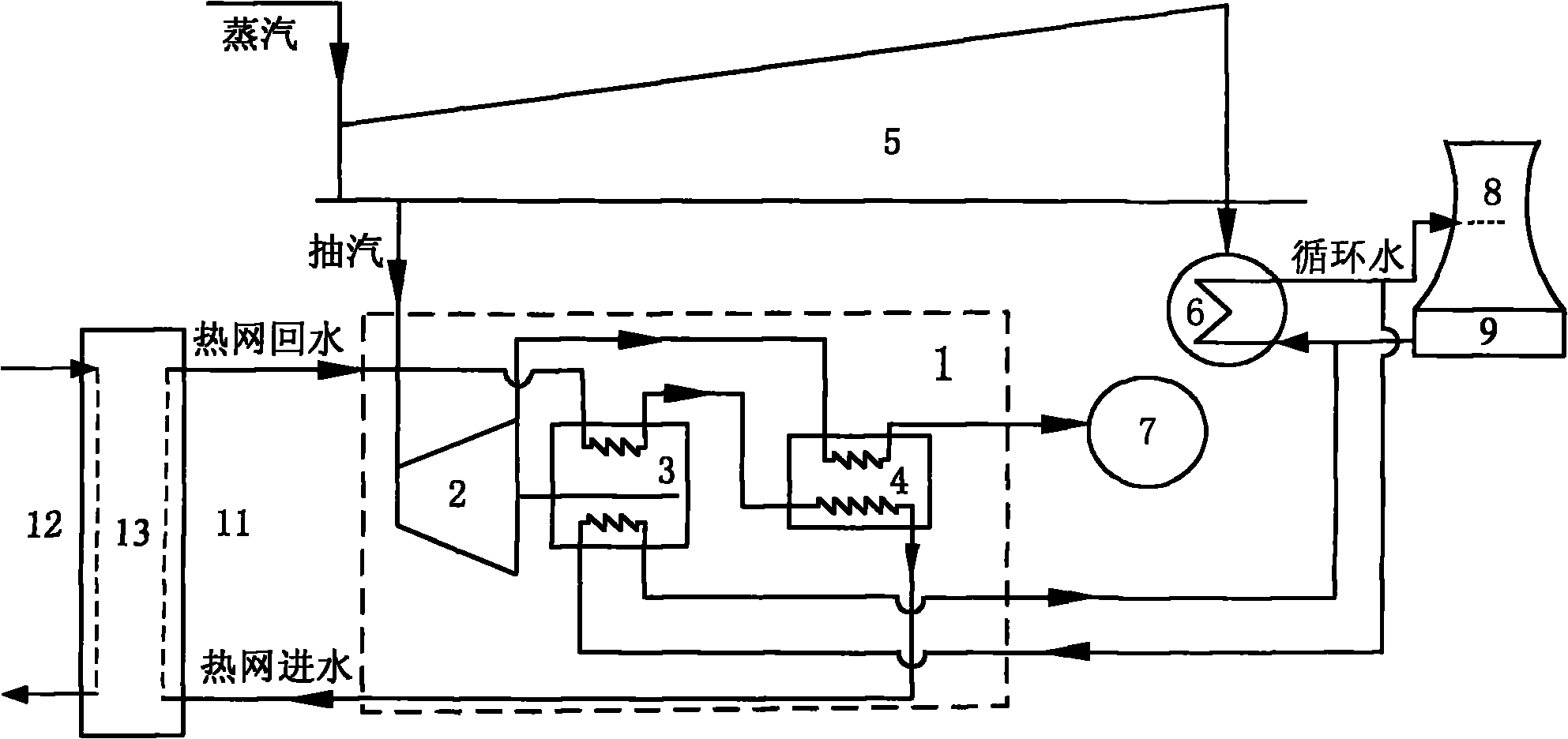

Combined heat and power generation energy saving device using afterheat to supply heat and energy saving method

InactiveCN101967999AIncrease small loopReduce heat transfer irreversible lossLighting and heating apparatusEnergy efficient heating/coolingCooling towerCogeneration

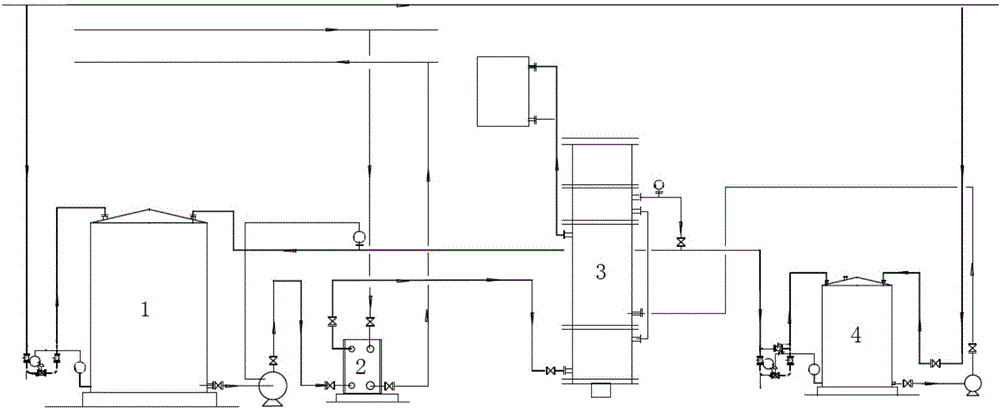

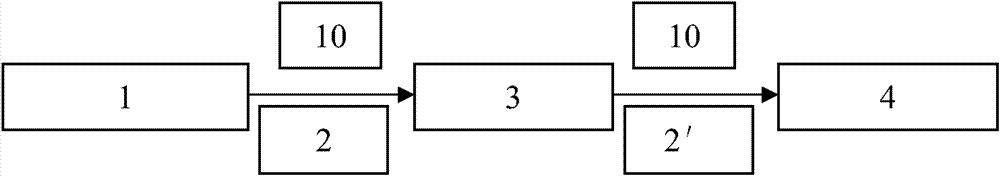

The invention relates to a combined heat and power generation energy saving device using afterheat to supply heat and an energy saving method. The combined heat and power generation energy saving device comprises a steam boiler, a steam extraction condensed type steam turbine, an electric generator, a condenser, a deaerator and a cooling tower, wherein the steam extraction condensed type steam turbine is connected with the condenser by an exhaust steam cylinder, and the condenser is connected with the cooling tower to form large waterway circulation; the combined heat and power generation energy saving device also comprises a backpressure turbine, a compression heat pump and a heat exchanger, wherein a steam inlet of the backpressure turbine is connected with a steam extraction hole of the steam extraction condensed type steam turbine, an exhaust steam hole is connected with a steam inlet of the heat exchanger, the compression heat pump is drawn by the backpressure turbine and is connected with the backwater end of a hot-water pipe network, the condenser and the compression heat pump are connected with the cooling tower to form small waterway circulation, the water inlet end of the heat exchanger is connected with the water outlet end of the compression heat pump, the water outlet end is connected with the water inlet end of the hot-water pipe network, and the drainage end is connected with the deaerator. The invention is capable of reducing cold source loss, increasing comprehensive heat efficiency and electrothermal proportion and reducing unit electric-generation coal consumption.

Owner:联合优发生物质能源徐州有限公司

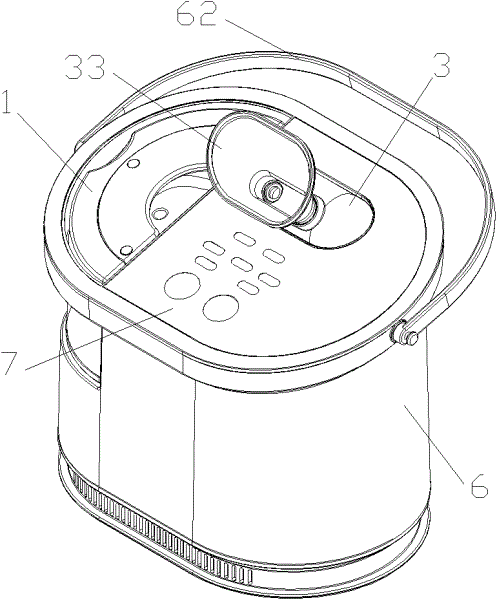

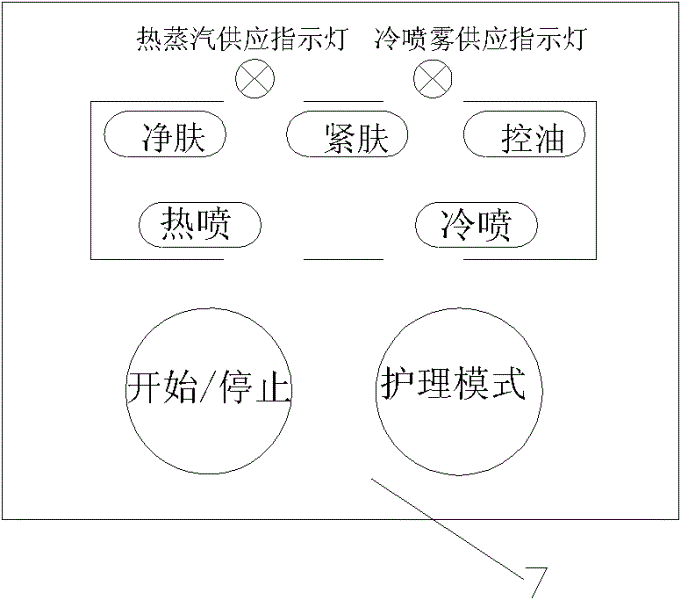

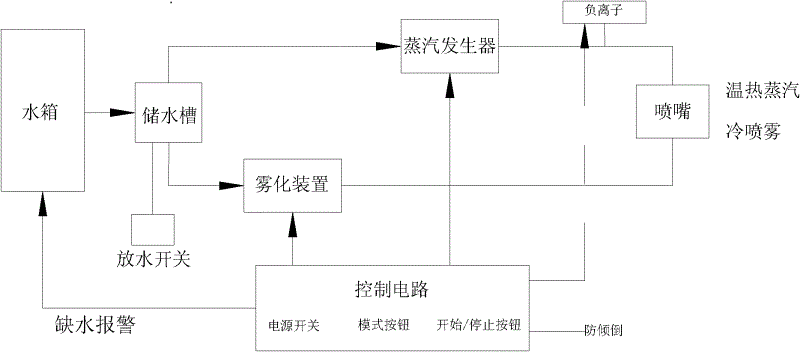

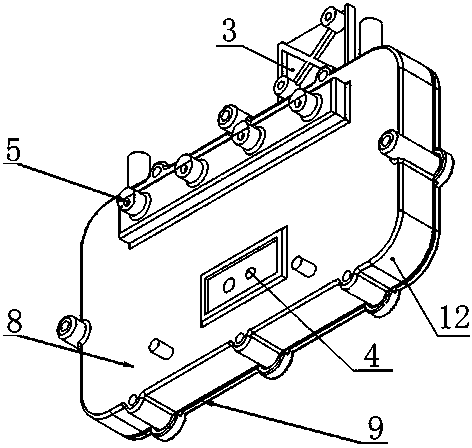

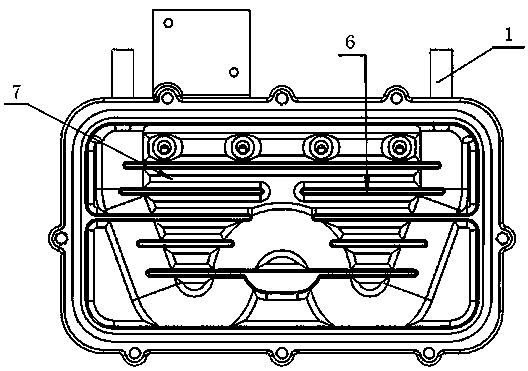

Ion steam cosmetic instrument and control method thereof

InactiveCN102614077AReduce the temperatureImprove insulation performanceElectrotherapyBathing devicesEngineeringMoisture

The invention discloses an ion steam cosmetic instrument and a control method thereof. The ion steam cosmetic instrument comprises a main machine which is provided with a water supply device, a steam generator, an atomization device and a nozzle, wherein the water supply device can continuously supply water for the steam generator and the atomization device, the steam generator can heat water to release steam, the atomization device atomizes water, a spray port is positioned on the nozzle, an ion generator is positioned in the nozzle, steam released by the steam generator and vapor atomized by the atomization device can be sprayed out from the nozzle, and the main machine is provided with a control device to control startup and shutdown of the steam generator and the atomization device. When the ion steam cosmetic instrument is in a cold spray mode, a hot spray device and a cold spray device can be simultaneously started (namely, cold and hot mixing) to spray from the single spray port. Thus, the sprayed steam is low in temperature, high in moisture and large in steam amount.

Owner:ZHEJIANG HUAGUANG ELECTRIC APPLIANCE GRP

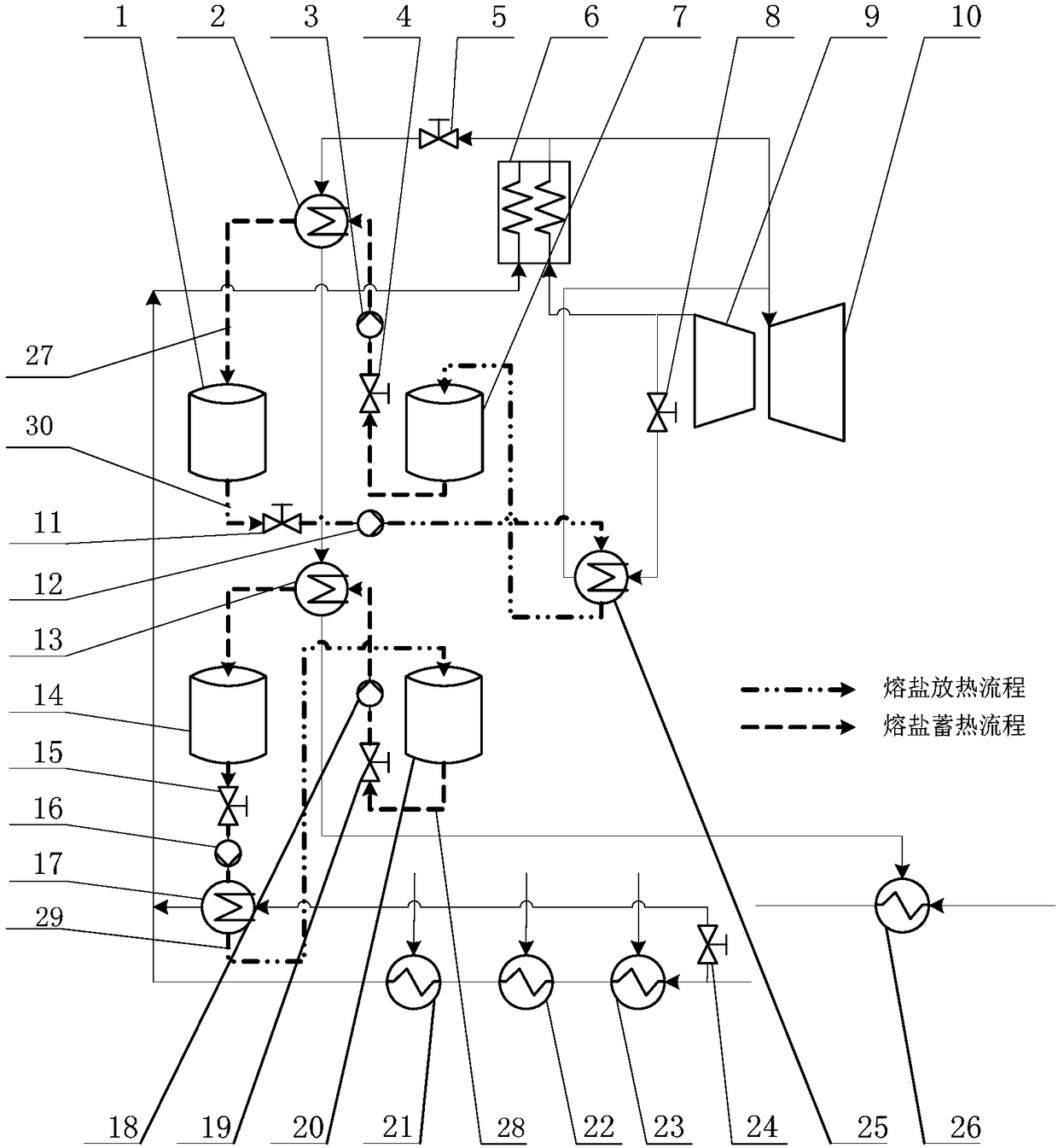

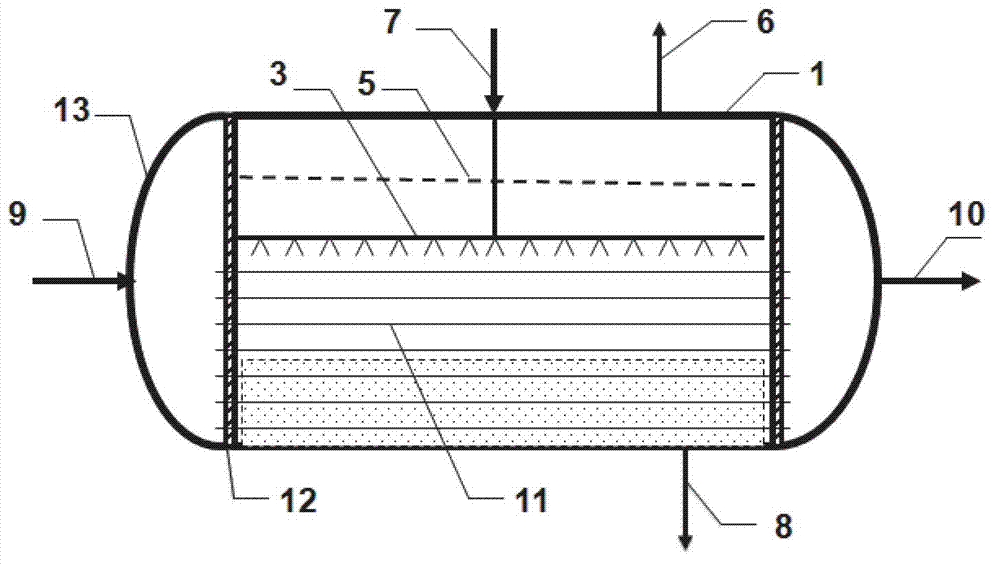

Fused salt heat storage and heat release peak load regulating system for thermal power generating unit

The invention discloses a fused salt heat storage and heat release peak load regulating system for a thermal power generating unit. According to the fused salt heat storage and heat release peak loadregulating system, a fused salt heat storage system, an I-stage fused salt low-temperature heat release system and a II-stage fused salt high-temperature heat release system are additionally arrangedon the basis of the original thermal power generating unit, and therefore peak load regulating of a power grid is realized through heat storage and heat release of fused salt; when the dispatching load of the power grid is decreased, part of high-temperature reheat steam is extracted from an outlet of a boiler reheater and exchanges heat with the fused salt in the fused salt heat storage system, and therefore consumption and utilization of the reheat steam in the electricity utilization off-peak season are completed; when the dispatching load of the power grid is increased, a part of high-pressure feedwater flowing to a high-pressure heater is divided into the I-stage fused salt low-temperature heat release system to exchange heat with the fused salt; and meanwhile, the steam discharge amount of a high-pressure cylinder is increased, part of increased exhaust steam of the high-pressure cylinder is fed into the II-stage fused salt high-temperature heat release system to exchange heat with the high-temperature fused salt, the heated steam enters an intermediate-pressure cylinder to apply work, the amount of the steam entering the intermediate-pressure cylinder and the output of a steam turbine can be increased, and the electric power of the thermal power generating unit can be rapidly increased.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

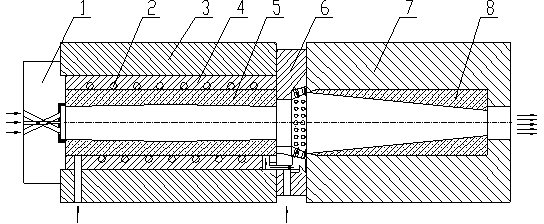

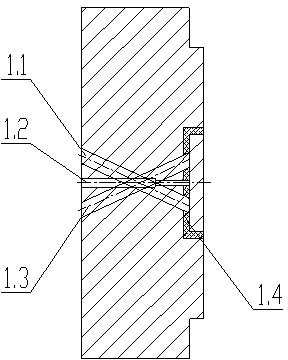

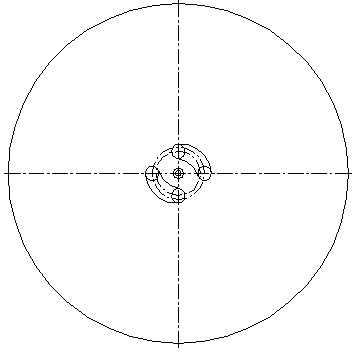

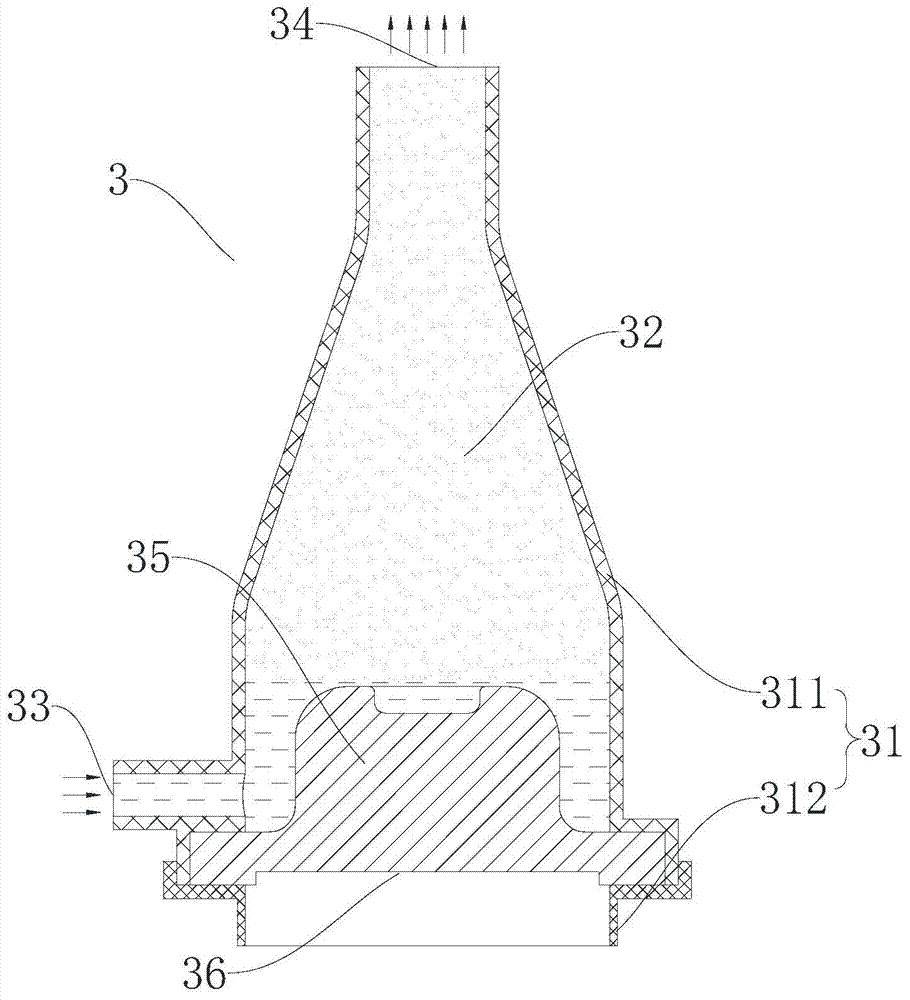

High-temperature high-pressure combustion structure of pure oxygen combined heat carrier generator

InactiveCN103452537AImprove combustion efficiencyImprove heat utilizationFluid removalHeat carrierCombustion chamber

The invention relates to a high-temperature high-pressure combustion structure of a pure oxygen combined heat carrier generator. The high-temperature high-pressure combustion structure comprises a generator fuel-pure oxygen combined supply and ignition structural part (1), a strength retainer shell (3), a main combustion chamber (4), an inflammable bin (5), a mix connector (6), a main gasification shell (7), and a gasification zone heat-resisting layer (8). The main gasification shell (7) is disposed behind the strength retainer shell (3). The strength retainer shell (3) is fixedly connected with the main gasification shell (7) through the mix connector (6). The inner wall of the strength retainer shell (3) is provided with the main combustion chamber (4). The inflammable bin (5) is formed inside the main combustion chamber (4). The gasification zone heat-resisting layer (8) is disposed inside the main gasification shell (7). The high-temperature high-pressure combustion structure has the advantages that operating pressure can meet the requirement for operational combustion reliability under the subcritical pressure when combustion temperature exceeds 3000 DEG C.

Owner:JIANGSU GREATRIVER OTECH

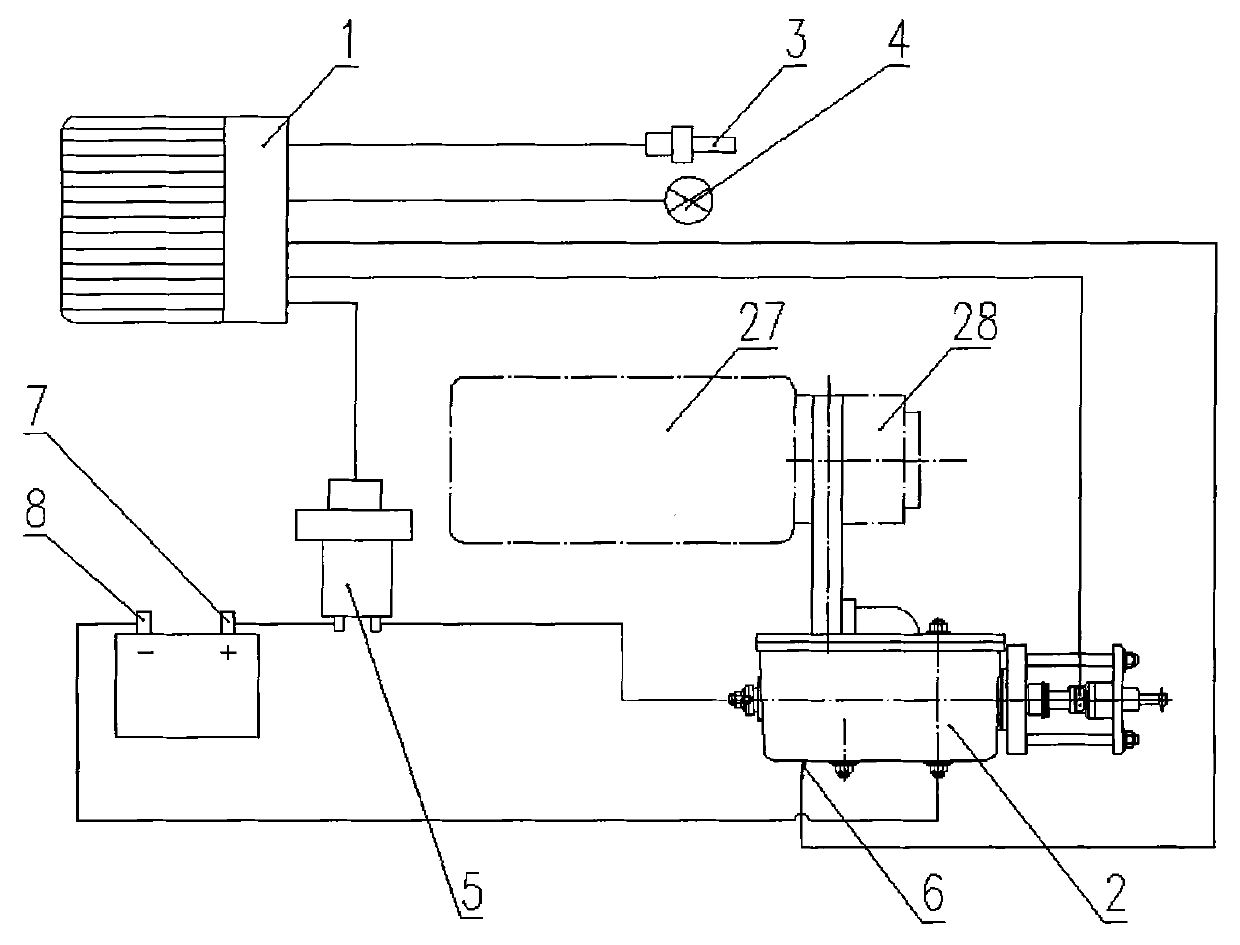

Cold start device and cold start method of M100 methanol engine

InactiveCN101949347ASolve the cold start problemImprove economyInternal combustion piston enginesGaseous engine fuelsStopped workThroat

The invention relates to a cold start device and a cold start method of an M100 methanol engine. The device comprises a controller, a methanol steam generator, a water temperature sensor, a DC contactor and a temperature sensor of the methanol steam generator. The method comprises the following steps: the controller detects the cooling water temperature of the engine through the water temperaturesensor of the engine; when the water temperature is lower than 16 DEG C, the DC contactor is switched on, and a PTC ceramic thermistor is used for heating; when the temperature in an evaporation cavity is higher than 180 DEG C, an electrically-controlled methanol spraying device sprays methanol into the evaporation cavity, the methanol sprayed on an annular evaporation column is heated and evaporated into methanol steam, and the methanol steam enters an intake manifold of the engine through a methanol steam channel and a throat opening on a connecting plate; and after cold start of the engineis performed, the cold start device stops working. In the invention, when the engine is in the cold start, the concentration of the combustible gas mixture entering a cylinder reaches the firing limit, and the engine is started, thereby solving the problem of the cold start of the methanol engine.

Owner:TAIYUAN UNIV OF TECH

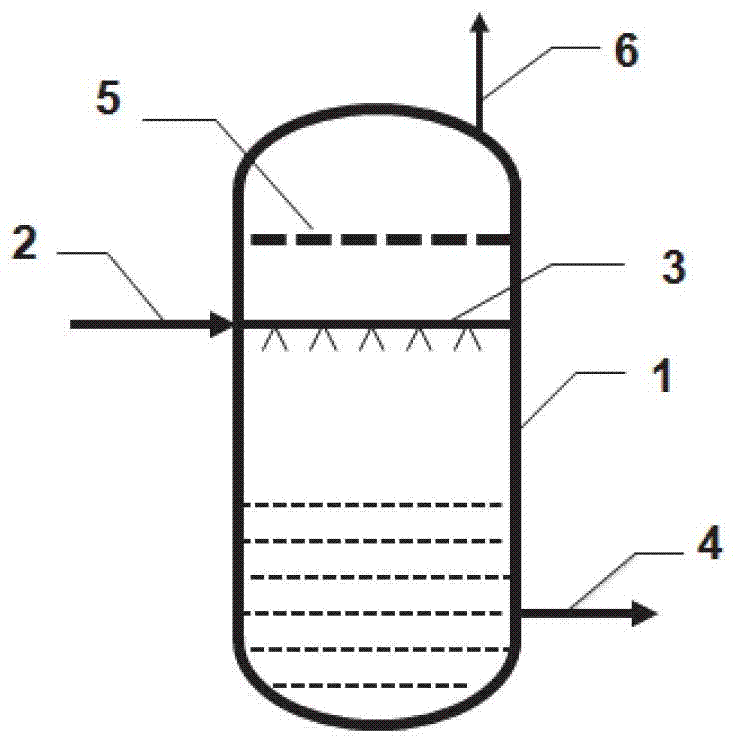

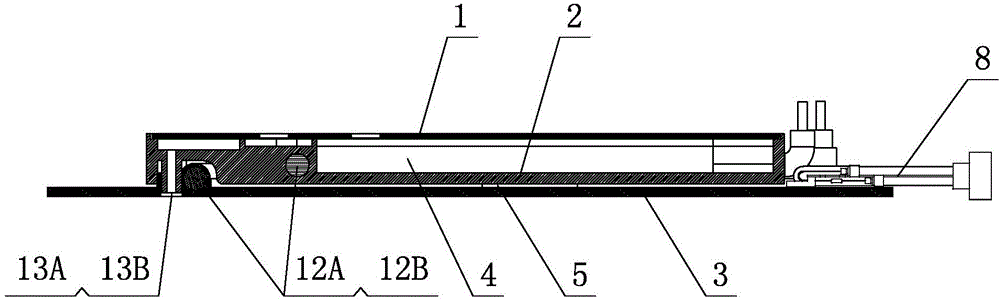

Method for recovering surplus heat source energy by using flash evaporator

InactiveCN102829460AEasy to operateSolution to short lifeSteam generation using hot heat carriersEvaporationEngineering

The invention relates to a method for recovering surplus heat source energy by using a flash evaporator and belongs to the field of the flash evaporator. The flash evaporator comprises a cylinder, a spraying pipe, a steam-liquid separator, a steam outlet, a surplus heat source inlet A, a surplus heat source outlet A, a surplus heat source inlet B, a surplus heat source outlet B, a heat exchange pipe, a pipe plate and end sockets, wherein the flash evaporator is horizontally arranged; the end sockets are arranged at the two ends of the cylinder; the cylinder and the end sockets are connected through the pipe plate; the steam-liquid separator, the spraying pipe and the heat exchange pipe are fixed on the pipe plate; the steam-liquid separator is located in an upper space of the flash evaporator; the spraying pipe is arranged in a middle space; the heat exchange pipe is arranged in a lower space; a part of the heat exchange pipe is soaked in surplus heat source liquid A; the surplus heat source inlet A is arranged on the upper part of the cylinder; the surplus heat source outlet A is arranged on the lower part of the cylinder; the surplus heat source inlet A is connected with the spraying pipe; the surplus heat source inlet B is arranged at one end of the cylinder; and the surplus heat source outlet B is arranged at the other end of the cylinder. The flash evaporator can simultaneously recover the surplus heat source energy and can obviously increase the flashing evaporation effect.

Owner:BEIJING UNIV OF TECH

Converter smoke radiation type waste heat boiler recovery system

InactiveCN102321779AReduce power consumptionReduce water consumptionManufacturing convertersSteam generation using hot heat carriersPressure stabilizationEngineering

The invention discloses a converter smoke radiation type waste heat boiler recovery system, comprising a three-way valve, a settling chamber, a water-spraying cooling device, a radiation type waste hat boiler and a heat accumulator. When oxygen content of smoke reaches the standard, the three-way valve opens a gate communicated with the settling chamber, high temperature smoke after being subjected to dust removal by virtue of the settling chamber is fed into the radiation type waste heat boiler, heat exchange is carried out by virtue of a smoke flow equalizing chamber, a water-cooling radiation heat exchange chamber, an intermediate settling chamber of a boiler and a convection heat exchange chamber, dust content and temperature of the smoke are greatly reduced, then the smoke is fed into a dust remover to remove dust and then is recovered; when the oxygen content of the smoke exceeds standard, the high-temperature smoke is directly subjected to water spraying and cooling by virtue of the water-spraying cooling device, the smoke is fed into the dust remover to remove dust and then is directly discharged. Clearance type steam generated by the waste heat boiler enters into the heat accumulator to be subjected to pressure stabilization, so as to be changed into continuous steam, and the continuous steam is applicable to production and power generation. The converter smoke radiation type waste heat boiler recovery system disclosed by the invention can fully recover heat of converter smoke, the recovered steam quantity is increased by more than 25%, dust removal water consumption is greatly reduced, and the system disclosed by the invention can run stably and reliably.

Owner:孙慕文

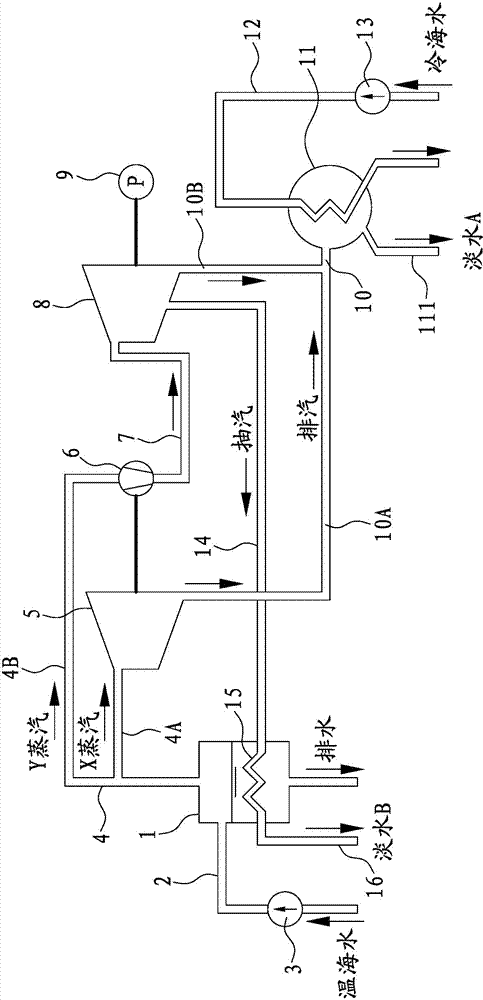

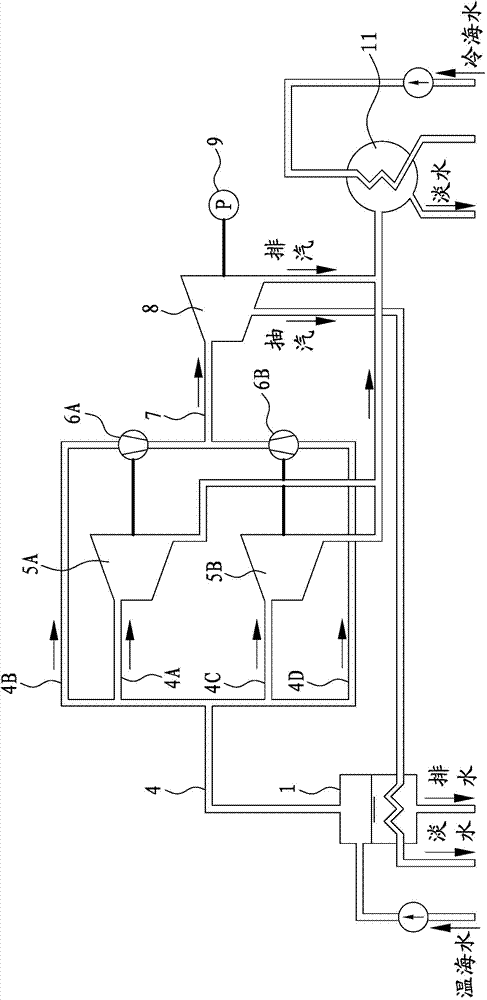

Ocean heat energy open circulation power generation system

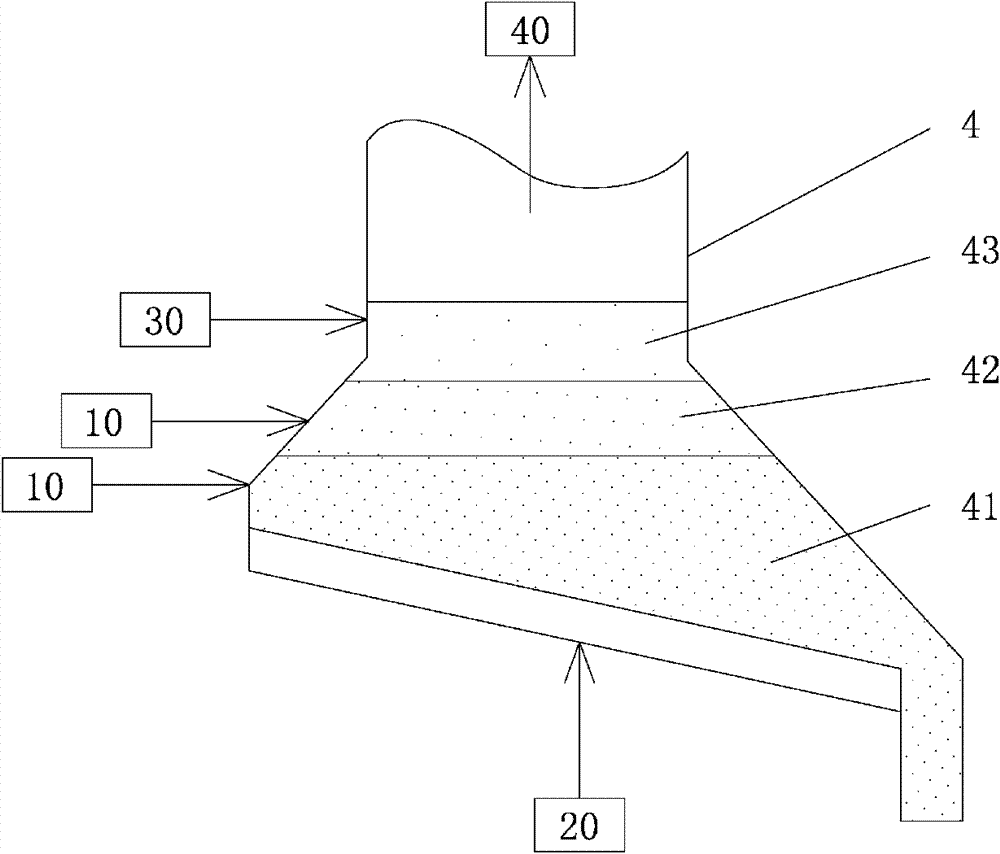

InactiveCN103790793AReduce volumeBreak through the problem of limited capacityMachines/enginesMechanical power devicesExhaust pipeSeawater

The invention discloses an ocean heat energy open circulation power generation system which comprises a flash evaporator, a warm seawater pipe, a warm seawater pump, a low-pressure steam pipe, a front-arranged small steam turbine, a steam compressor, a high-pressure steam pipe, a main steam turbine, a power generator, a steam exhaust pipe, a surface type condenser, a cold seawater pipe, a cold seawater pump, a steam pumping pipe and a heat exchange pipe bundle. Low-pressure steam is divided into two channels, one channel of low-pressure steam enters the front-arranged small steam turbine to do work to drive the steam compressor to work, the other channel of low-pressure steam is compressed by the steam compressor to become high-temperature high-pressure steam, the high-temperature high-pressure steam then enters the main steam turbine to do work to drive the power generator to generate power, part of steam is pumped from the main steam turbine to be used for heating seawater in the flash evaporator, and the amount of the steam generated by the flash evaporator is increased. According to the ocean heat energy open circulation power generation system, the size of the steam turbine in existing open circulation is effectively reduced, and the problem that the unit capacity is limited is solved; the ocean heat energy open circulation power generation system has the advantages of being high in system heat efficiency, high in water power utilizing rate, high in net power generated power and the like.

Owner:JIMEI UNIV

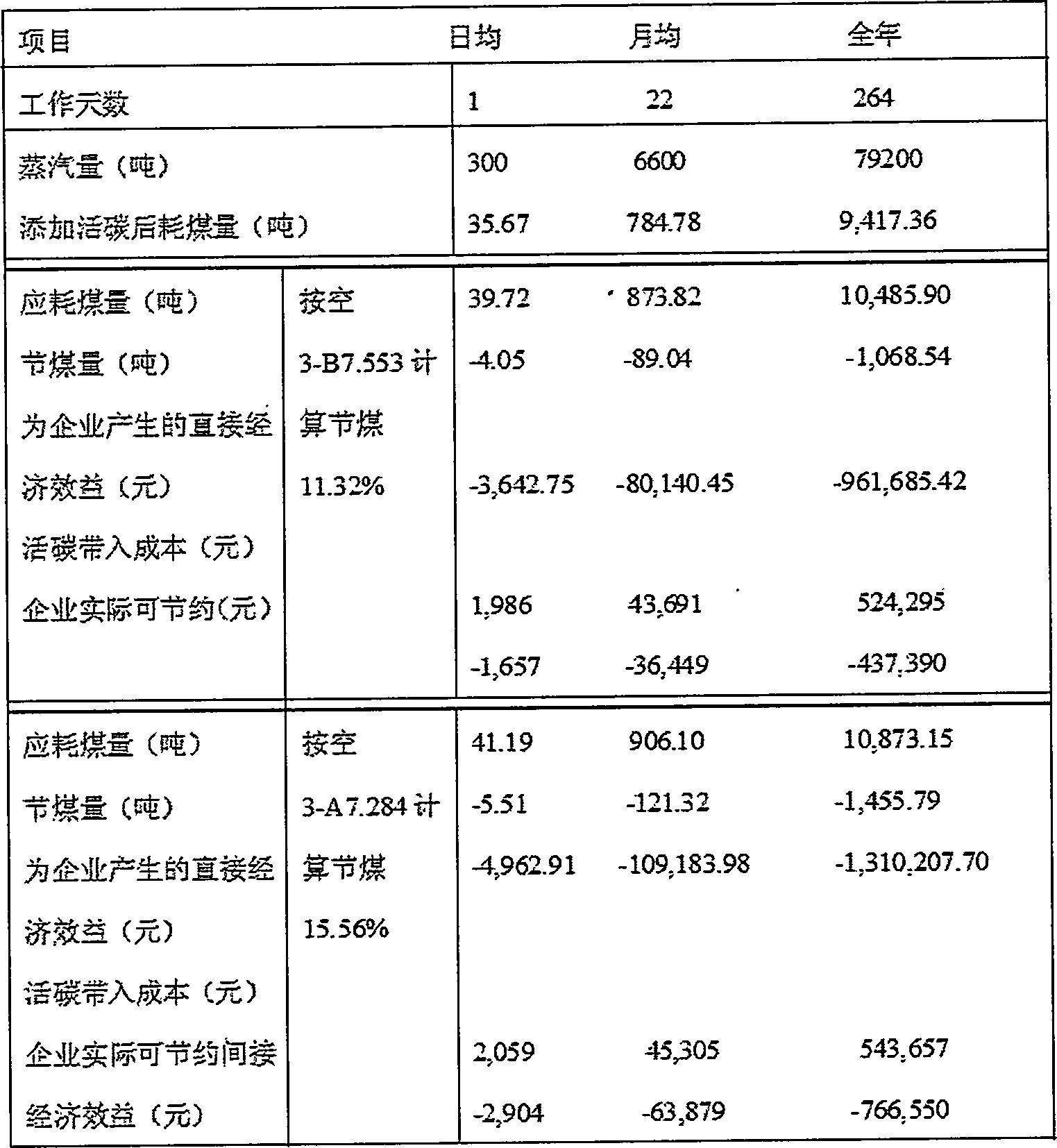

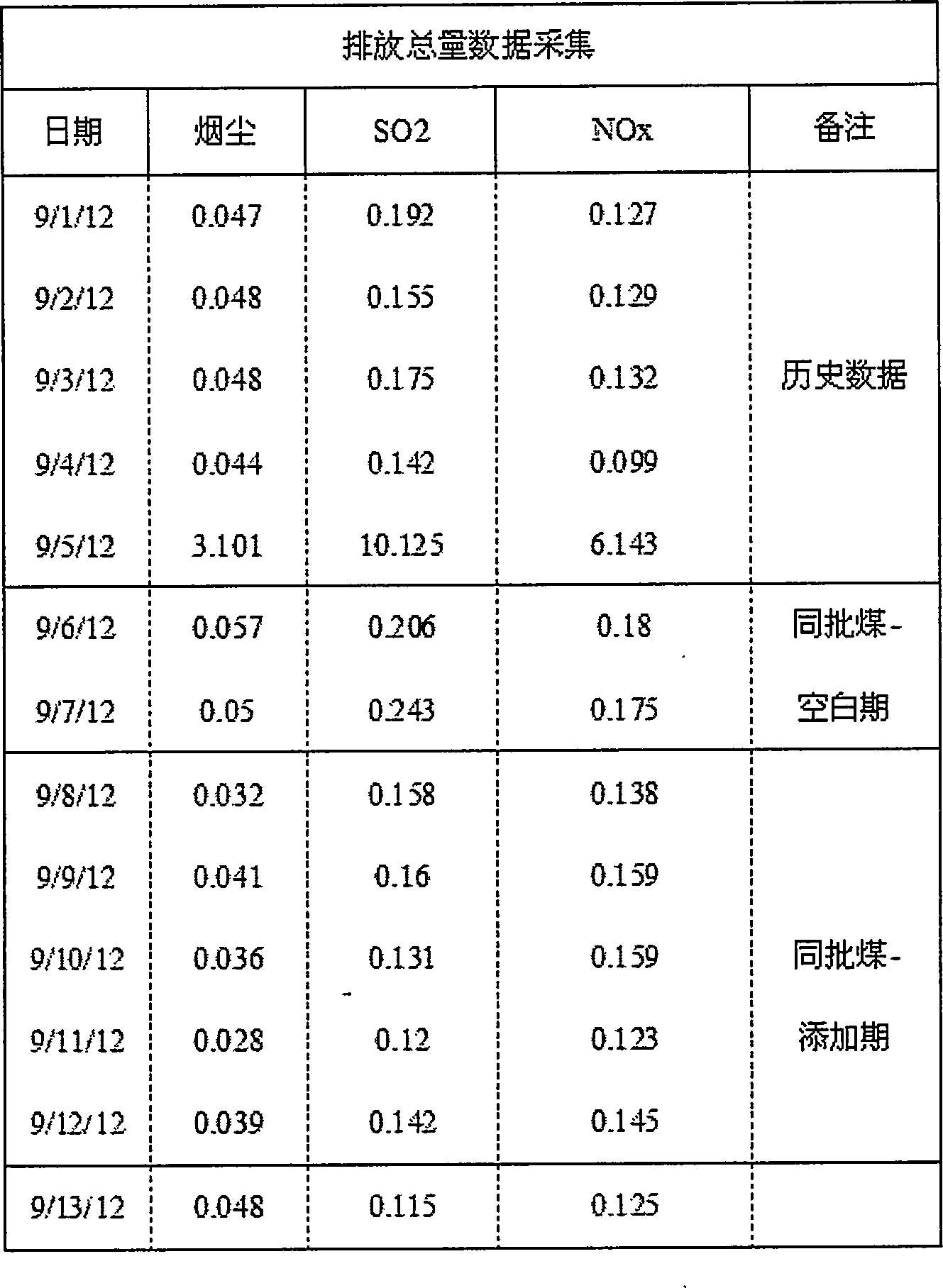

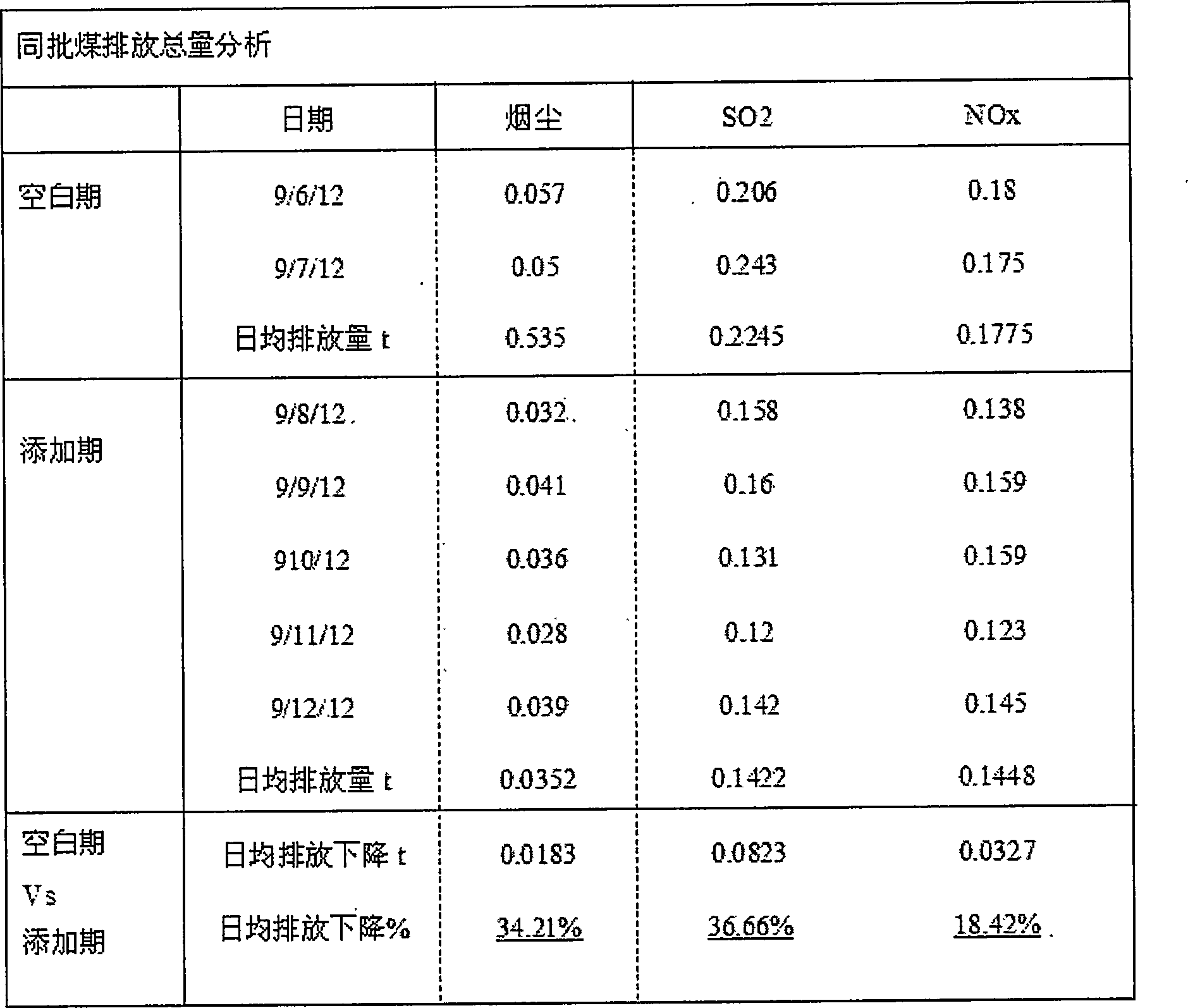

Coal additive

ActiveCN103320195APlay a catalytic roleLower the ignition temperatureSolid fuelsRare-earth elementCombustion

The invention provides a coal additive. The coal additive comprises an emulsifier, a dispersant, a corrosion inhibitor and a penetrant. The coal additive contains O, Mg, Al, Si, S, Ca, Ba and Mn. The coal additive has the advantages that the emulsifier, the dispersant, the corrosion inhibitor and the penetrant are used and the rare earth elements improve catalyst activity so that a traditional exterior-to-interior combustion mode is changed into an interior-exterior synchronous combustion mode and thus a coal complete-combustion degree is improved and a heat loss caused by chemical incomplete combustion and mechanical incomplete combustion of coal in a furnace is reduced; and through composite carriers having mesoporous structures, catalyst activity is improved, a hydrodesulfurization process is finished and discharge amounts of flue dust and harmful gas in exhaust gas are reduced so that coal saving and sulfur fixation are realized.

Owner:甘肃泰聚环保科技有限公司

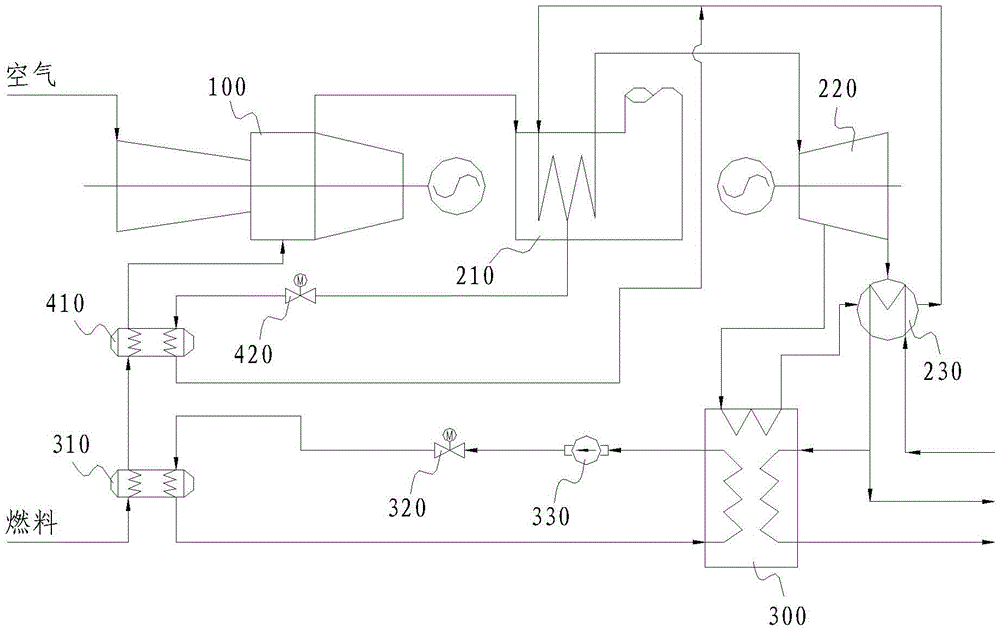

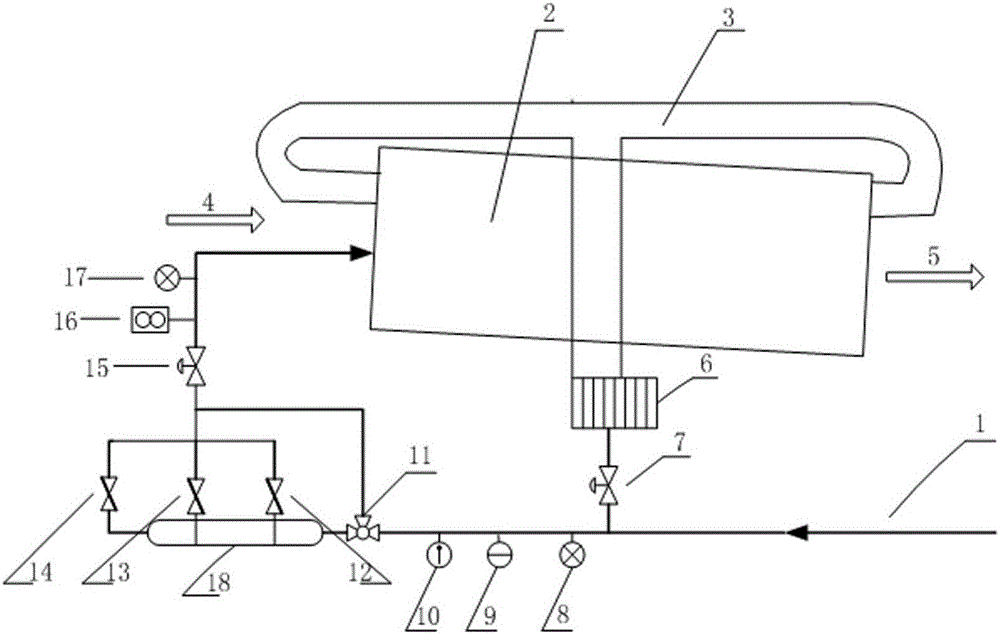

Fuel gas and steam combination system and running control method thereof

ActiveCN105484816AImprove cycle thermal efficiencyEco friendlyTurbine/propulsion fuel heatingGas turbine plantsPlate heat exchangerWater vapor

The invention relates to a fuel gas and steam combination system and a running control method thereof. The fuel gas and steam combination system comprises a gas turbine, a steam circulating loop, an absorption type heat pump and a preheating heat exchanger, wherein a residual heat boiler, a steam turbine and a condenser are arranged on the steam circulating loop, and a steam extraction opening is formed in the steam turbine; the absorption type heat pump is provided with a first heat exchange channel, a second heat exchange channel and a driving heat source channel, which are matched; and the preheating heat exchanger is provided with a third heat exchange channel and a fourth heat exchange channel which are matched. Part of steam in the steam turbine enters the driving heat source channel from the steam extraction opening and is used as the driving force of the absorption type heat pump, so that circulating work medium is heated in the second heat exchange channel, and cooling water is cooled in the first heat exchange channel. The heated circulating work medium heats air or fuel flowing across the fourth heat exchange channel, so that the temperature of the air or fuel entering the gas turbine is raised.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

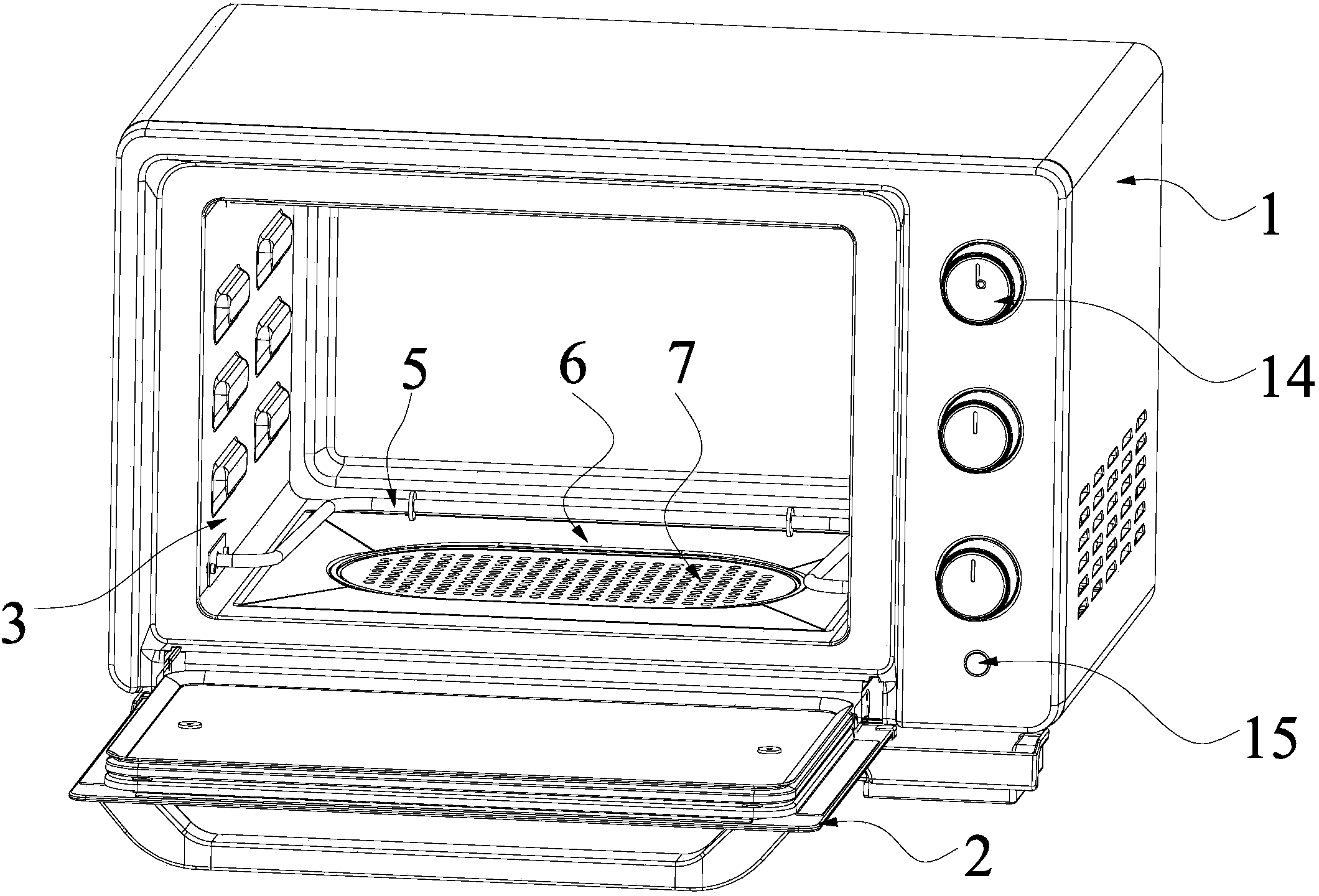

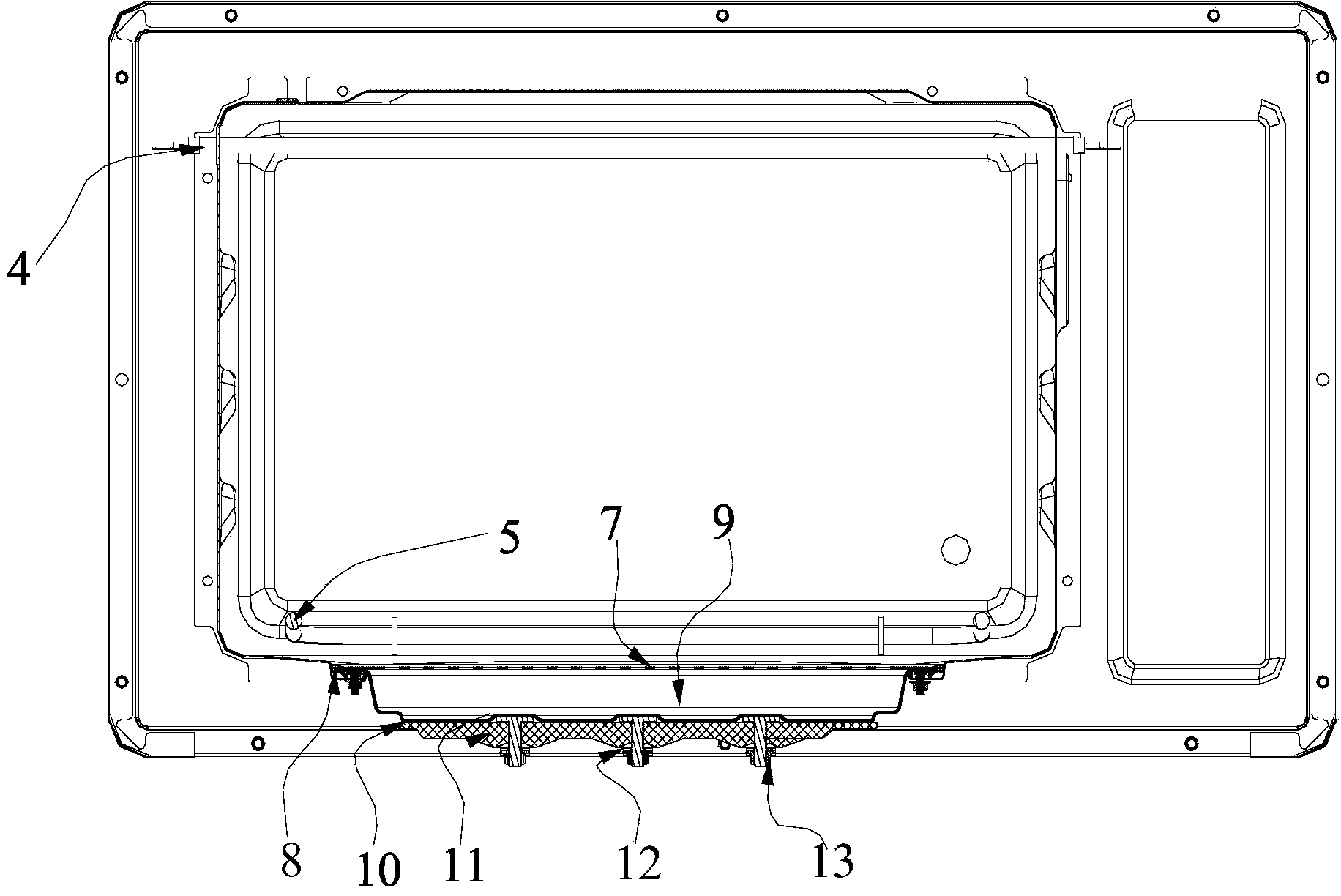

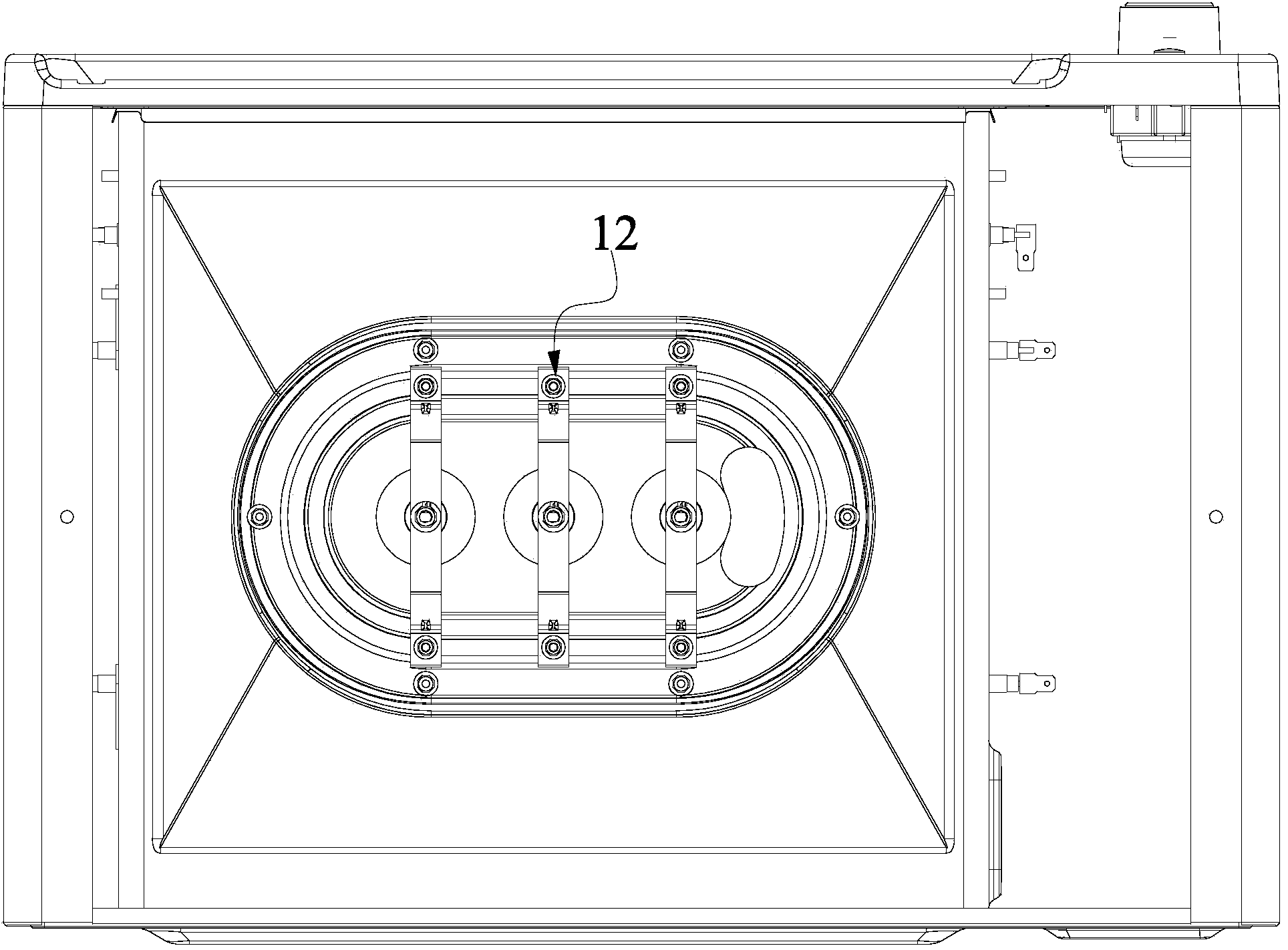

Steaming oven without water tank

InactiveCN103876613AReduce water consumptionThe overall structure is simpleSteam cooking vesselsWarming devicesEngineeringPositive temperature

The invention relates to the technical field of ovens, in particular to a steaming oven without a water tank. The steaming oven comprises a shell, a door subassembly and a heating cavity, wherein dry-burning pipes for barbecuing food are arranged in the heating cavity; an evaporating plate for storing and evaporating water is arranged on the bottom of the heating cavity; and a PTC (positive temperature coefficient) heating element is arranged at the lower end of the evaporating plate. The steaming oven is simple in structure, high in efficiency and obvious in energy conservation, and is convenient to clean.

Owner:聂国顺

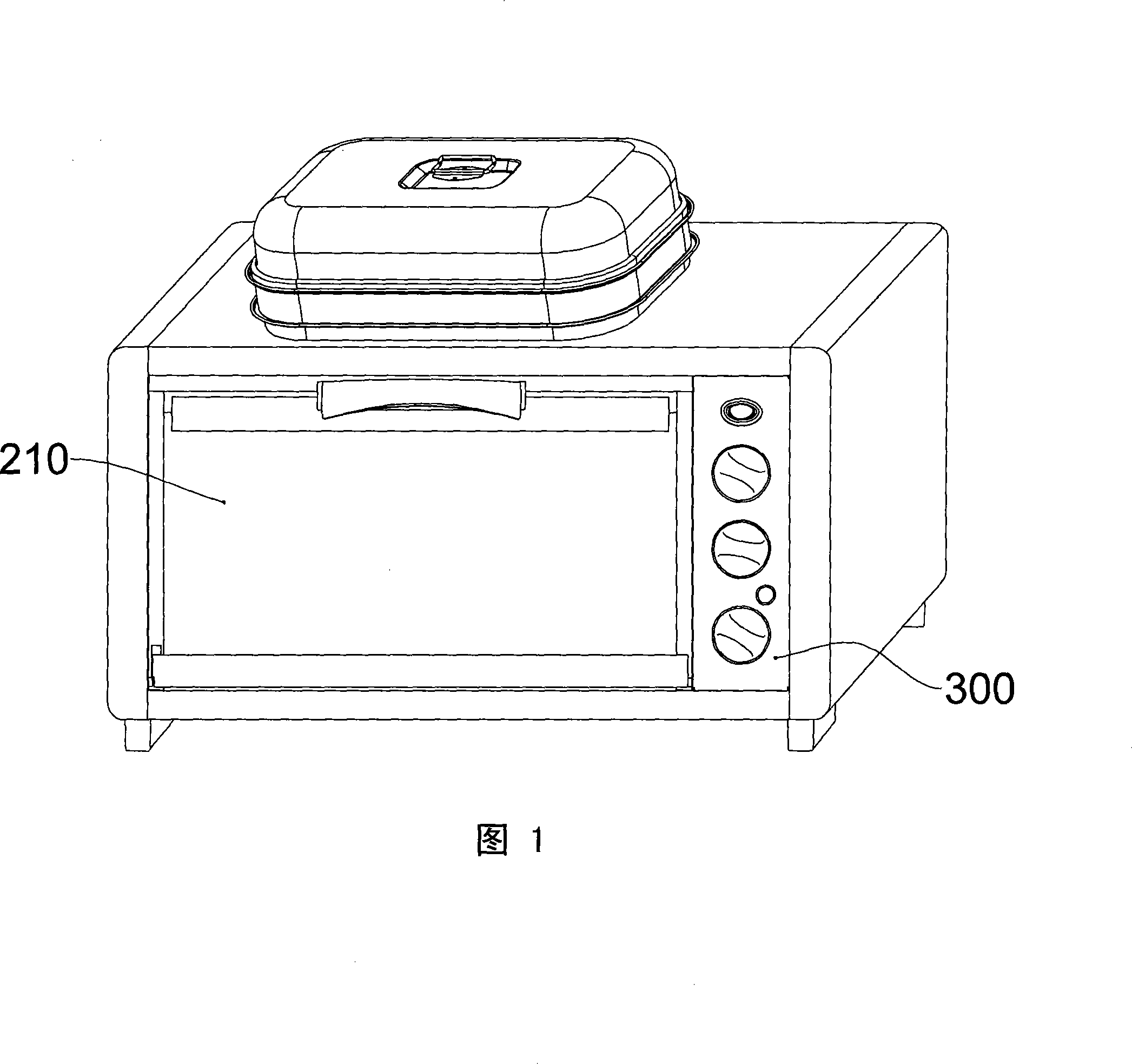

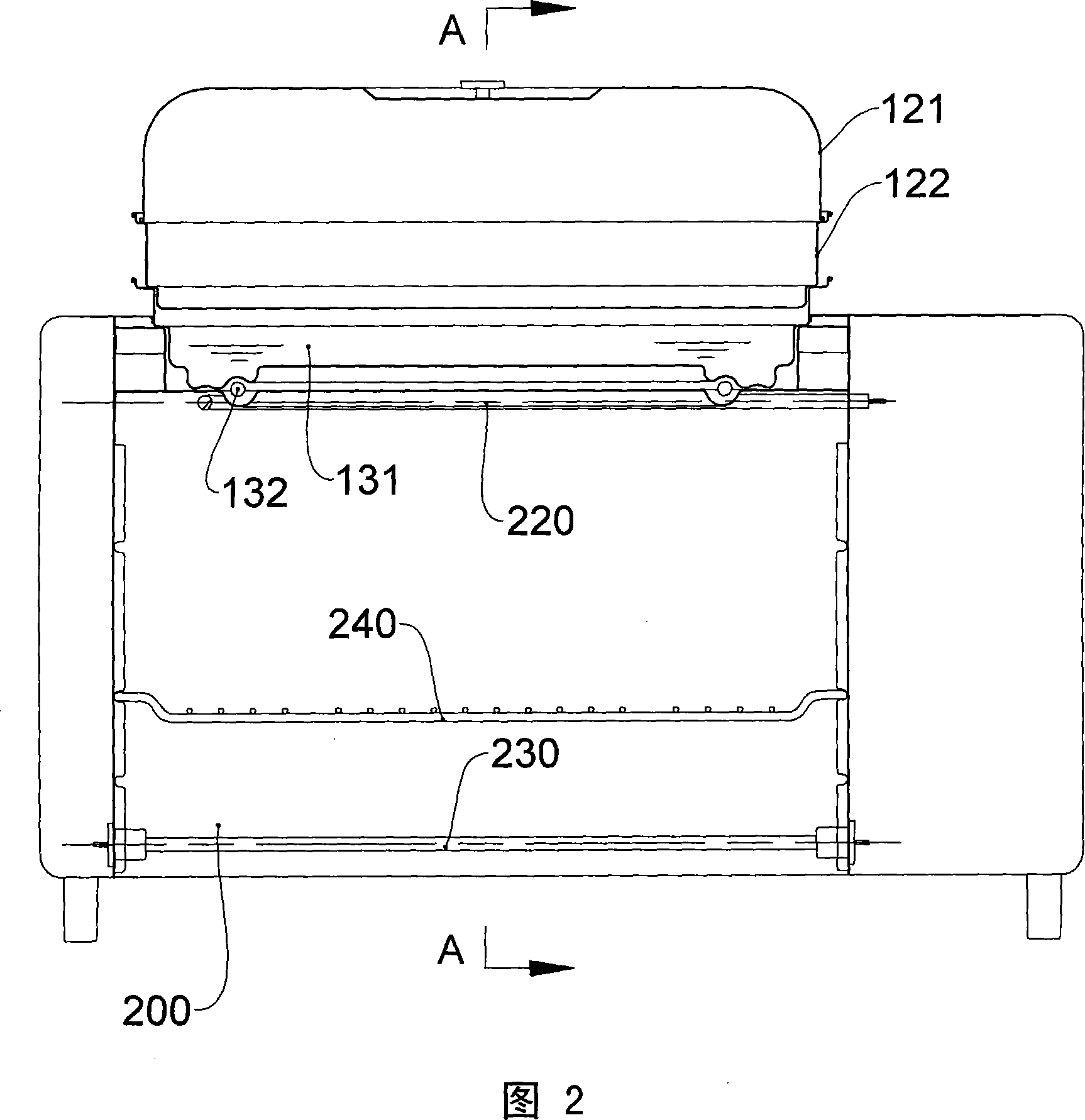

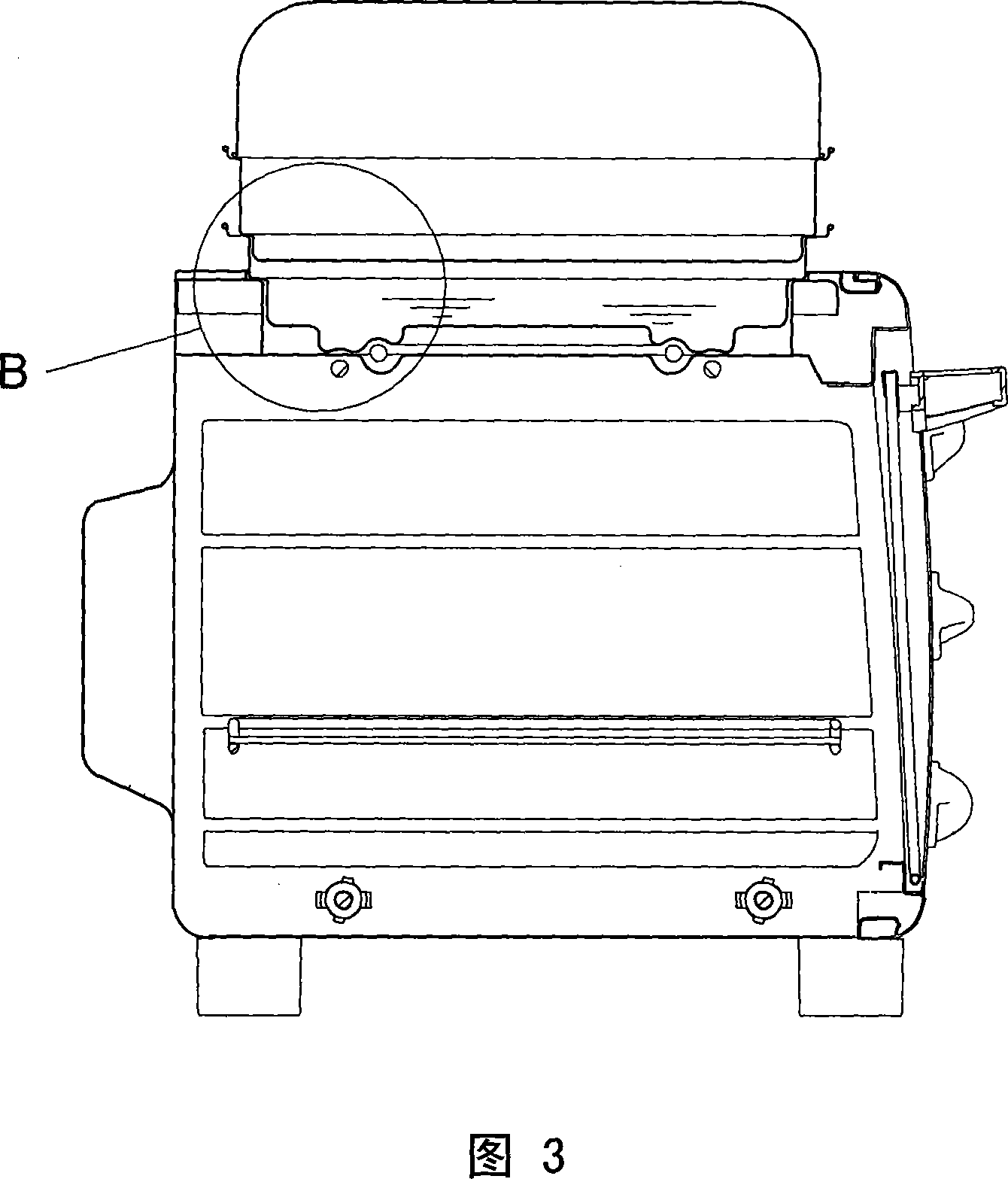

Multifunctional electronic oven

InactiveCN101181140AAvoid wastingImprove efficiencyCooking vesselsRoasters/grillsHeat conductingEngineering

The invention discloses a multifunctional electric oven with the advantages of fast heating, convenient usage, low energy consumption and saving energy. The multifunctional food electric oven can do the operation of a plurality of cooking methods such as steaming, boiling, frying, pan-frying, sauting, stewing, etc., when in baking. The invention includes an oven body, an on-off door (210) and a control panel (300). The oven body and the on-off door (210) enclose a heating chamber (200) which is internally provided with a first electric-heat tube (230), the control panel (300) is arranged on the oven body, the top part of the heating chamber (200) is provided with a heat conducting clapboard (400), the clapboard (400) is provided with a heat conducting vessel (131), and the vessel (131) is provided with an upper cover (121). The invention can be widely applied to the food-processing field.

Owner:黄朝龙

Method for recycling heat energy in low-temperature smoke containing SO3 and dust

InactiveCN104197309AAvoid cloggingReduce work stressFluid heatersSulfur compoundsCorrosionThermal energy

The invention discloses a method for recycling heat energy in low-temperature smoke containing SO3 and dust. According to the method, electric precipitation is carried out on the low-temperature smoke containing the SO3 and the dust, and the smoke temperature after electric precipitation ranges from 290 DEG C to 310 DEG C; the smoke is fed into an acid and high temperature resisting heat exchange device, heat exchange is carried out on the smoke and soft water used in a waste heat boiler, and the temperature of the smoke obtained after heat exchange is 140 DEG C to 160 DEG C, the soft water obtained after heat exchange is used for the waste heat boiler, and the smoke obtained after the heat exchange passes through a smoke power wave purification device and a padding tower and then is discharged after the SO3 is absorbed, wherein the acid and high temperature resisting heat exchange device continuously operates for 12 hours to 36 hours and then is cleaned once by circulating dilute acid washing liquid of the smoke power wave purification device. According to the method, comprehensive recycling of the smoke heat energy can be achieved, the blocking and corrosion problems are solved, the cooling water evaporation capacity is reduced, the production cost is reduced, economic benefits are improved, and the method is suitable for being applied and popularized in the field.

Owner:攀枝花圣地元科技有限责任公司

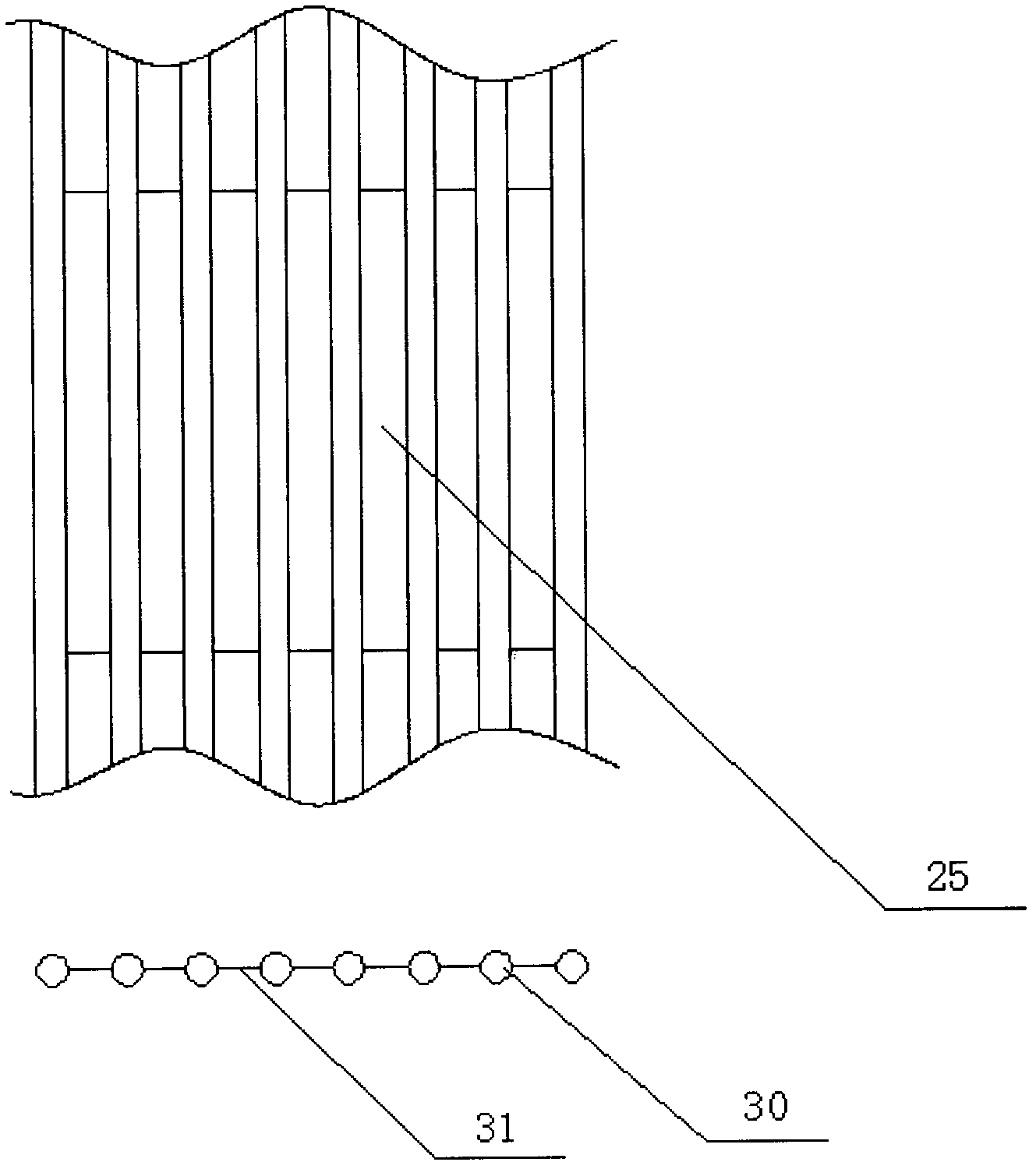

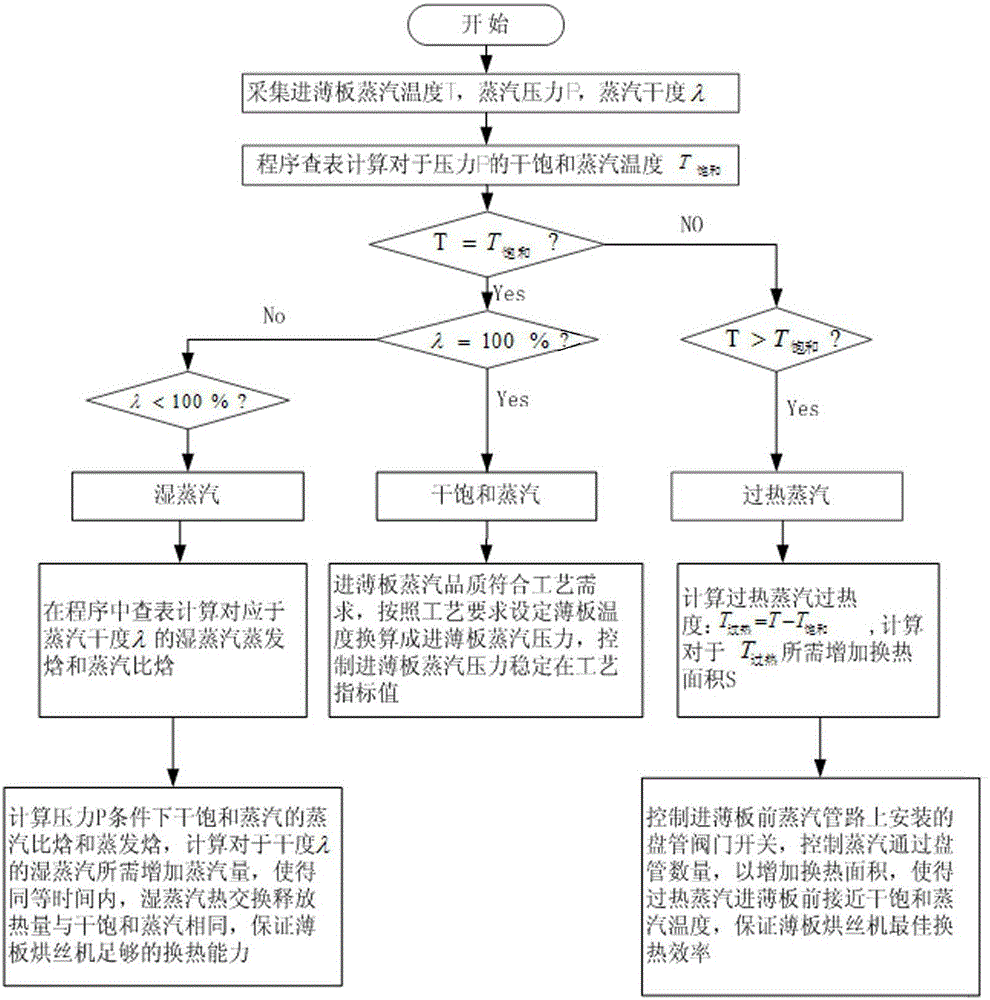

Method for stabilizing heat exchange efficiency and capacity of thin plate of cut-tobacco drier

ActiveCN105686040AGuaranteed heat exchange effectStable dehydration abilityTobacco preparationTobacco treatmentWet steamEngineering

A method for stabilizing heat exchange efficiency and capacity of a thin plate of a cut-tobacco drier is characterized by including the first step of a method for judging the quality of steam entering the thin plate, the second step of a method for processing overheated steam entering the thin plate, and the third step of a method for processing wet steam entering the thin plate. The method has the advantages that the steam, under different quality conditions, entering the thin plate can reach the tobacco dewatering capacity meeting the process requirement, the heat exchange efficiency and capacity of the thin plate of the cut-tobacco drier are stabilized, and the homogenized processing quality of cut tobacco is ensured.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

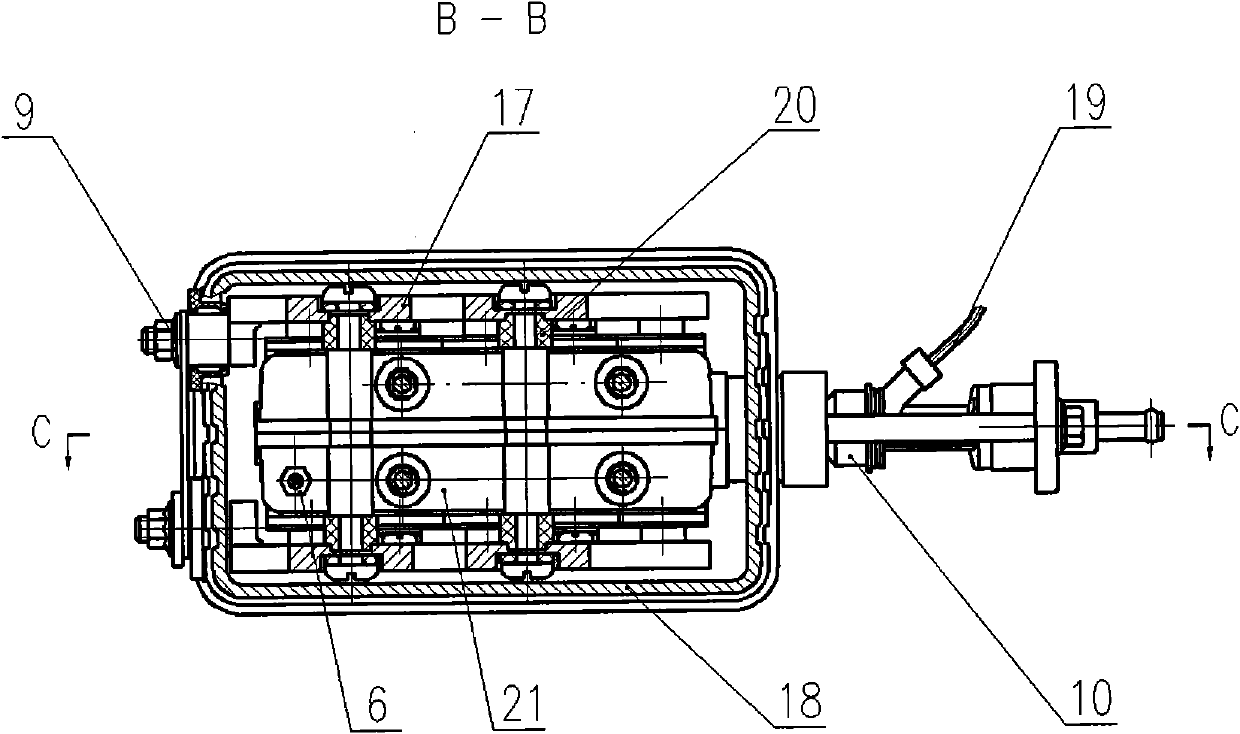

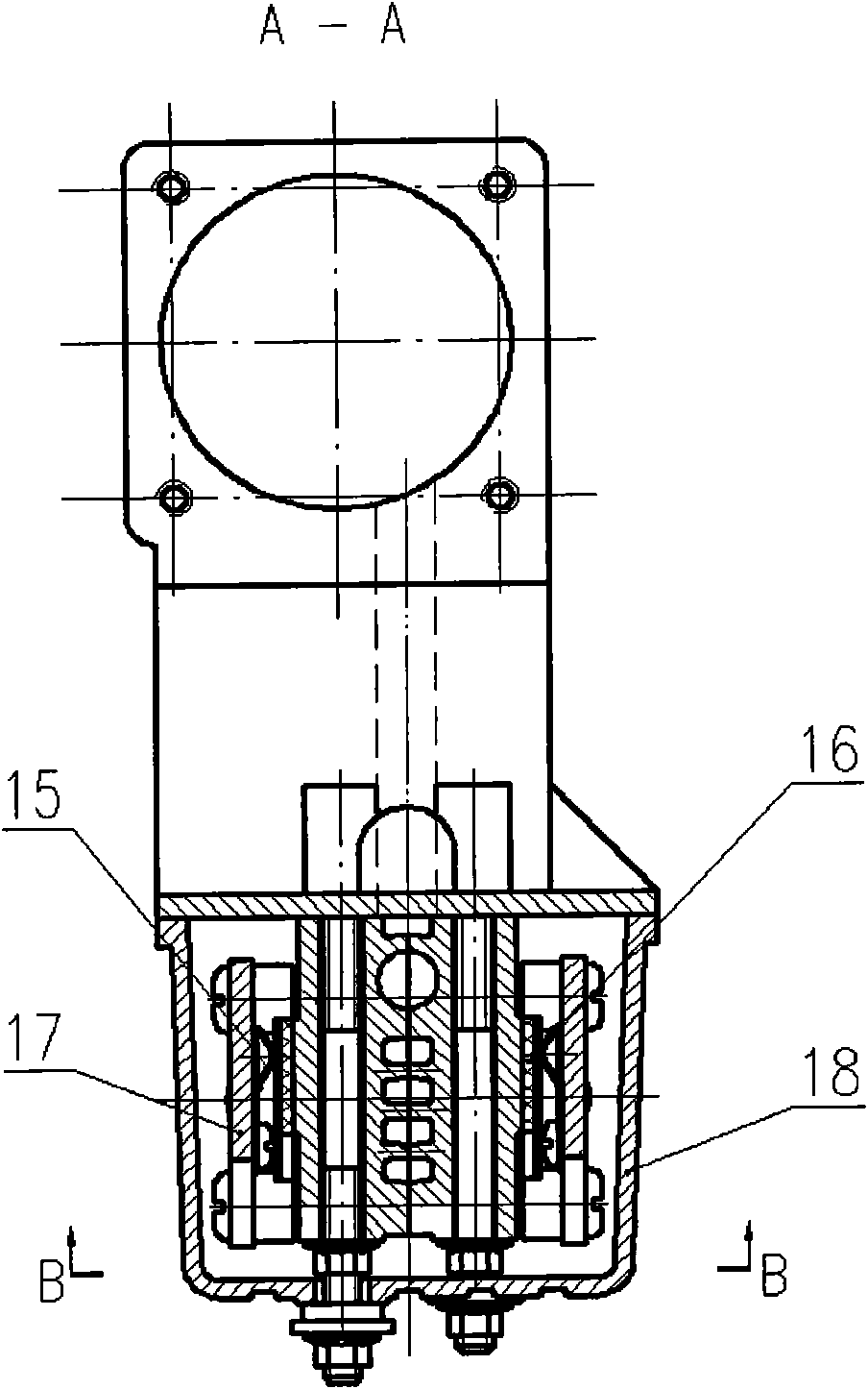

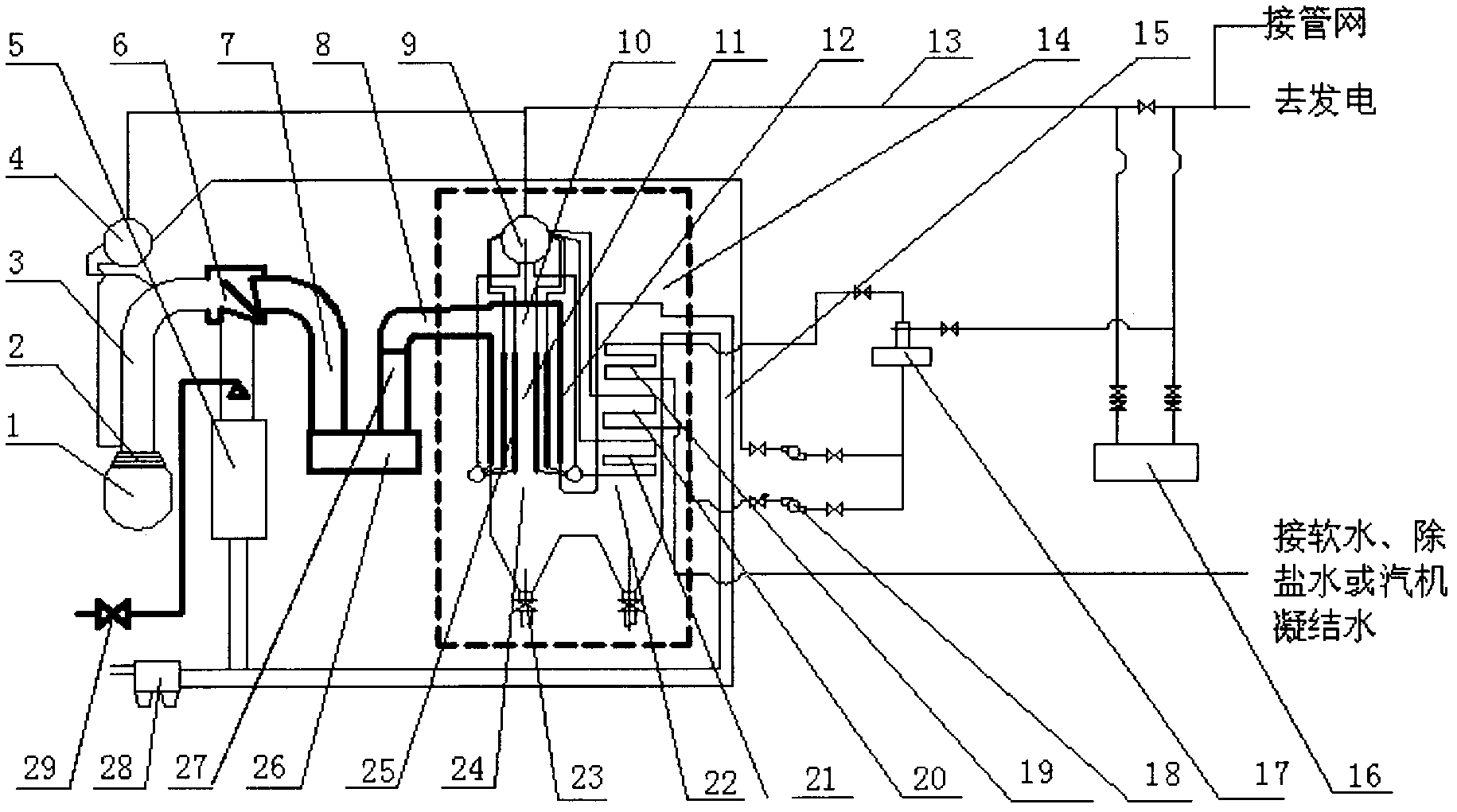

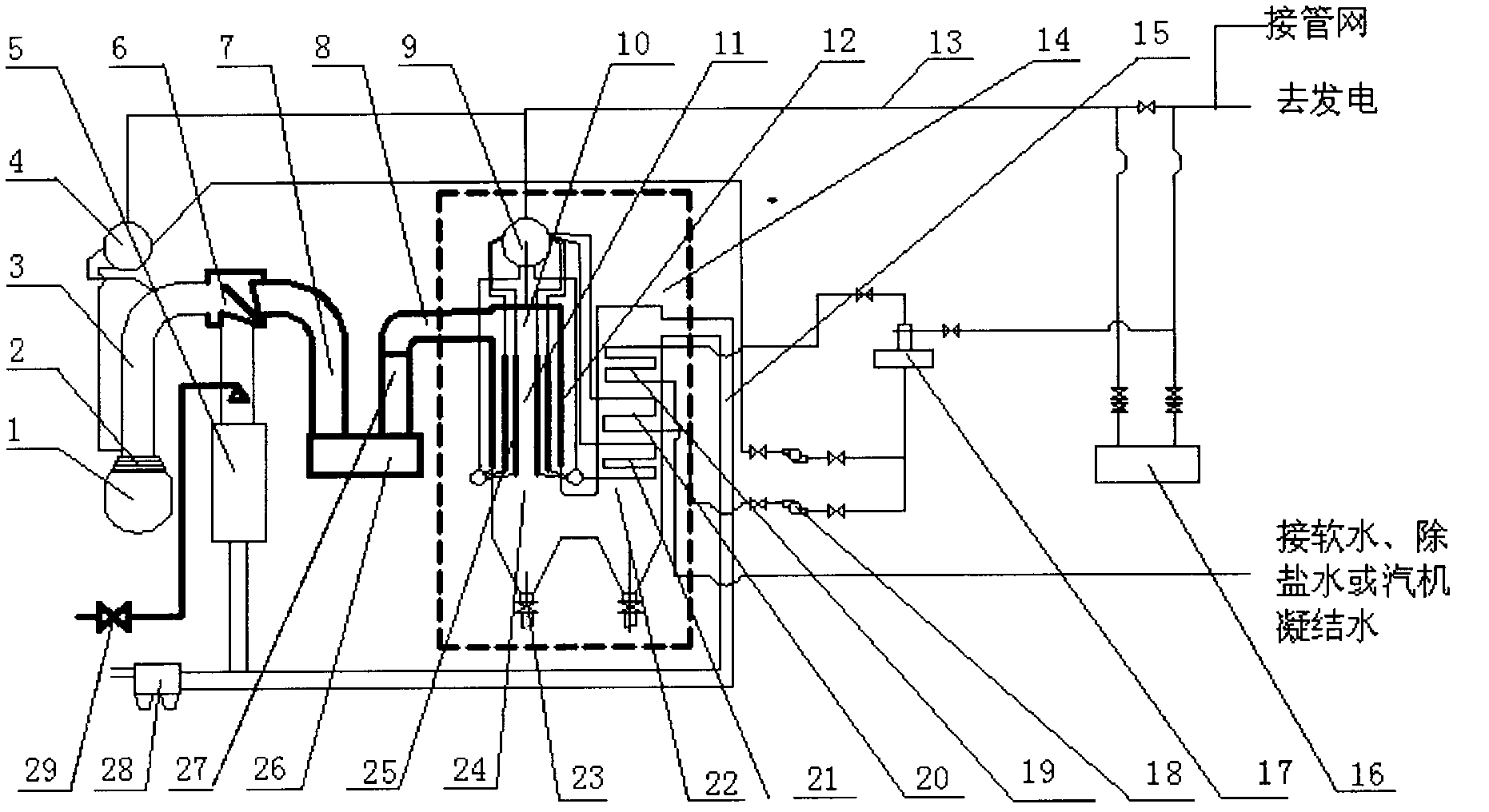

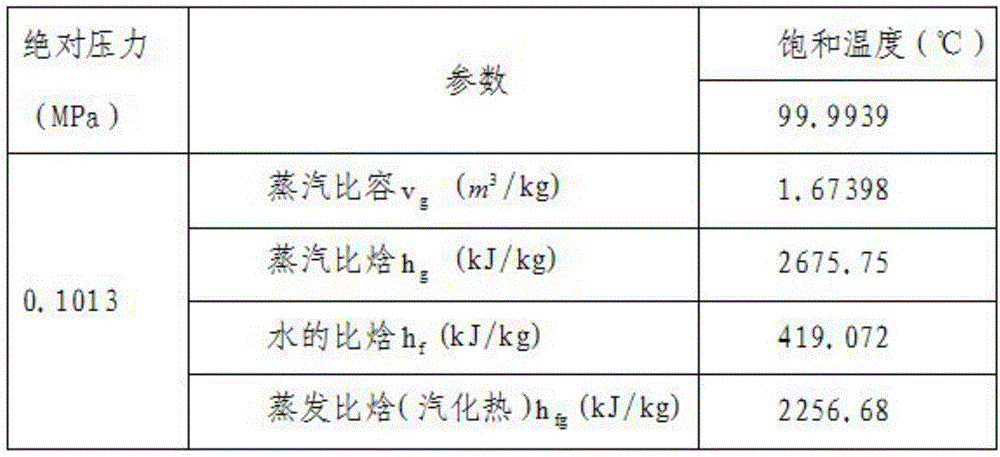

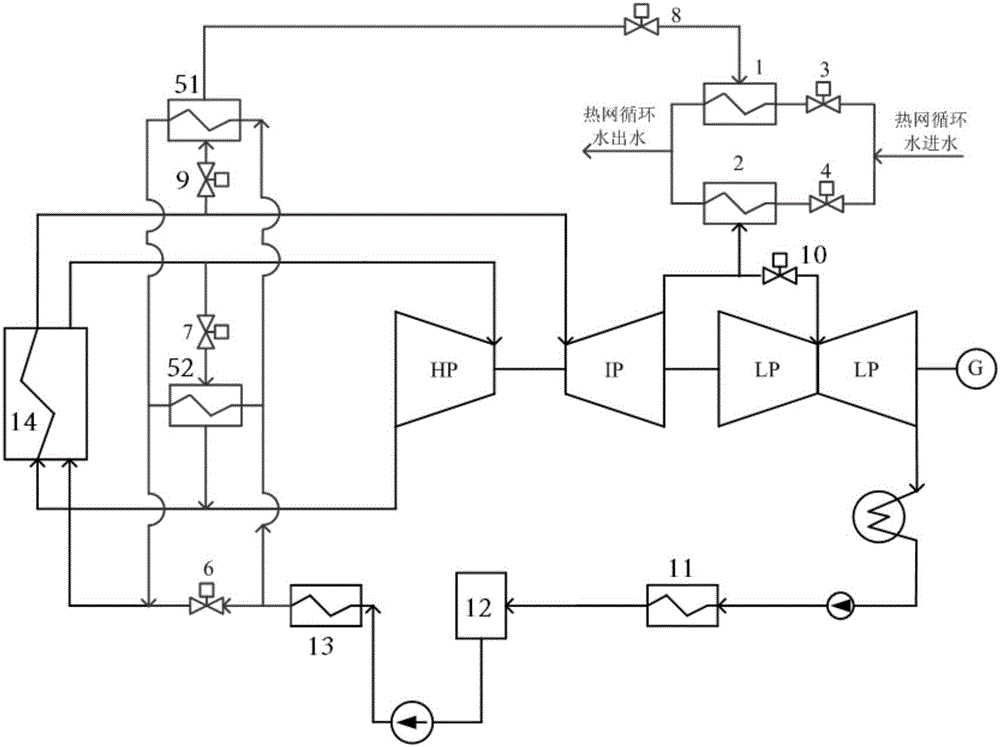

Thermoelectric decoupling system capable of improving energy utilization quality of thermoelectricity plant

ActiveCN107178398ALarge amount of steamIncrease the amount of steamSteam engine plantsThermodynamicsLow voltage

The invention discloses a thermoelectric decoupling system capable of improving energy utilization quality of a thermoelectricity plant. The system comprises a boiler, a high voltage cylinder, a primary bypass adjusting valve, a first additional high voltage heater, a medium voltage cylinder, a second additional high voltage heater, a secondary bypass adjusting valve, a hot net circulating water system, a low voltage cylinder and a water feeding adjusting valve. According to the system disclosed by the invention, decoupling operation of power production and thermal production can be realized, so that heat supply peak shaving ability of a thermoelectric unit can be obviously improved.

Owner:XIAN XIRE ENERGY SAVING TECH

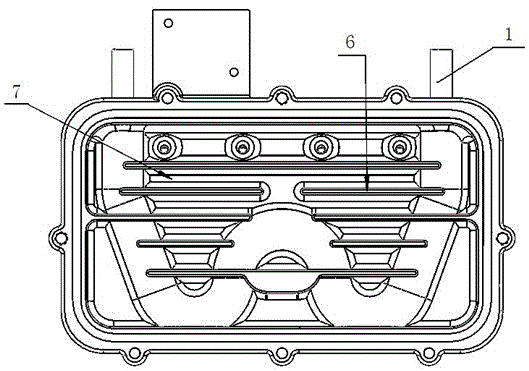

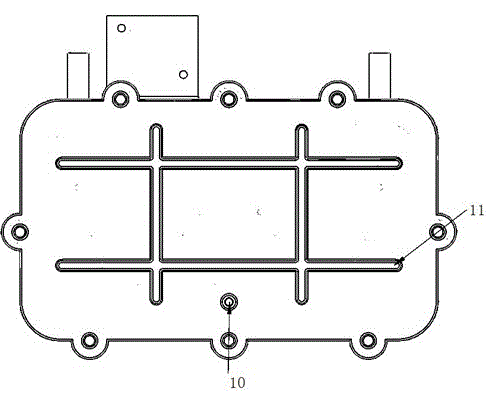

Novel steam generator

ActiveCN103776006AUnobstructed pathLarge amount of steamSteam generation heating methodsSteam boilersEngineeringThermal efficiency

The invention provides a novel steam generator. The novel steam generator comprises a heating shell, a water inlet and a steam outlet are formed in the heating shell, the steam outlet is arranged to be an inclined hole which is axially inclined for 20 degrees, a W-shaped heating tube is arranged in the cavity of the heating shell, a steam flow guide baffle is arranged on the inner wall of the heating shell, and the W-shaped heating tube and the steam flow guide baffle are arranged in an overlapped way. The novel steam generator has the advantages that the path becomes smoother and resistance-free during steam jetting, the quantity of steam is increased and the jetting distance is increased; since the W-shaped heating tube and the steam flow guide baffle are arranged in the overlapped way, the internal part is uniformly heated and the thermal efficiency is effectively improved; the steam circulating path of the cavity is further prolonged, the surrounding flow is formed and is in full contact with the heating tube, and the goals of steam overheating and steam-liquid separation are completed more effectively; the thermal conversion efficiency is high, the output steam temperature is high, the quantity of the steam is large, the jetting distance is long and the flowing passage structure is reasonable.

Owner:QINGDAO YUNLU ENERGY TECH

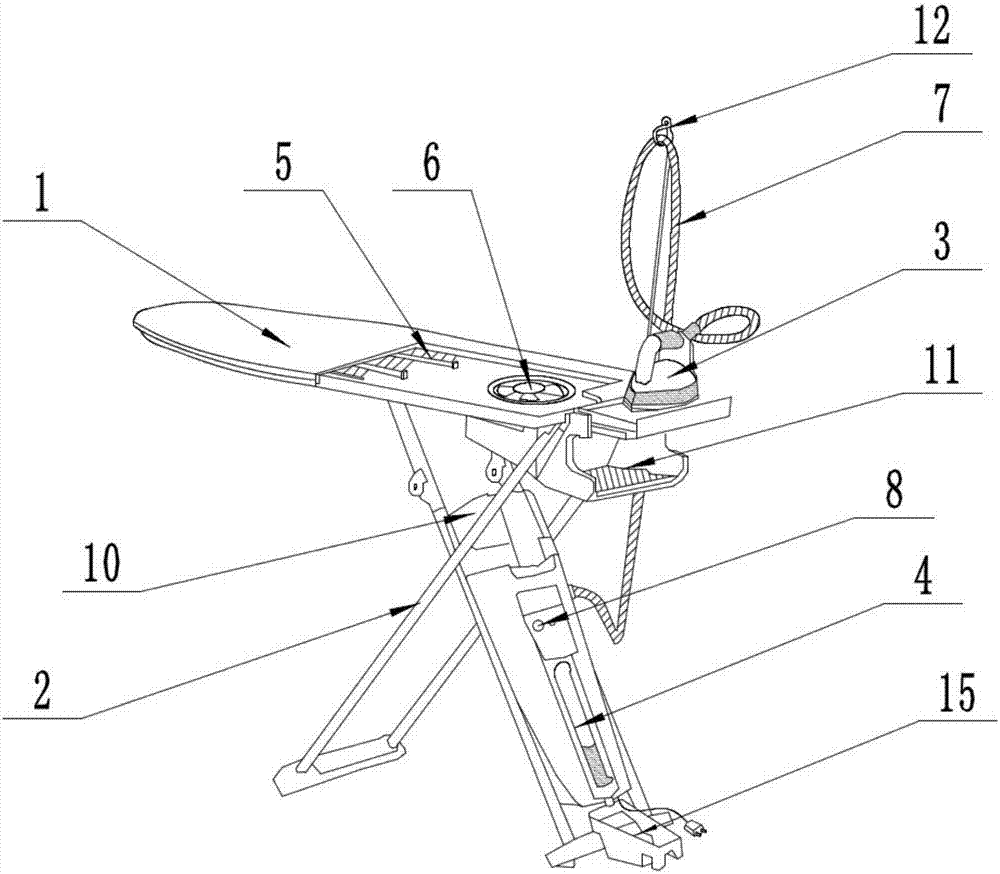

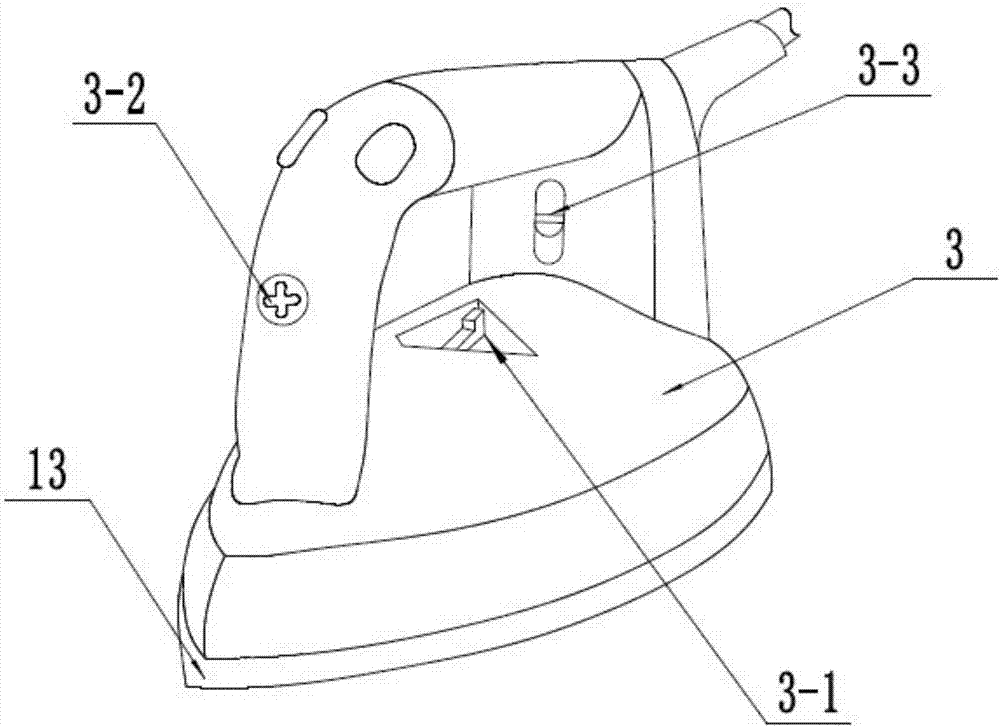

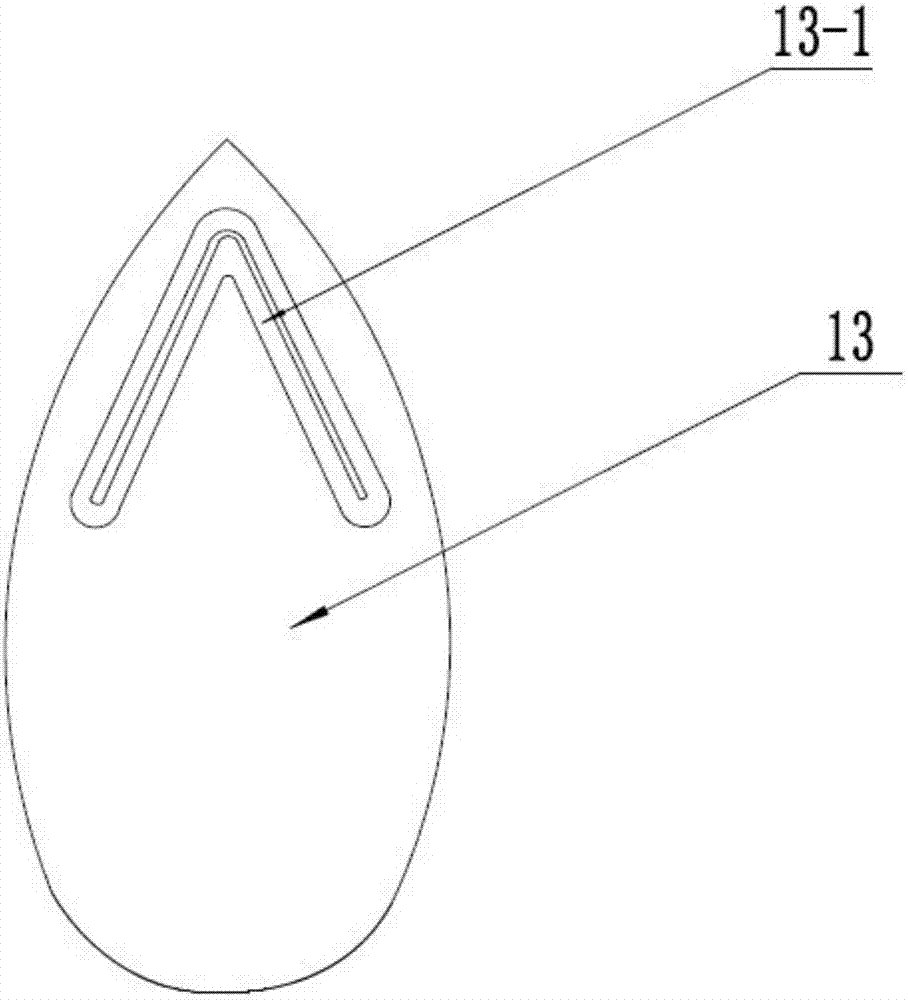

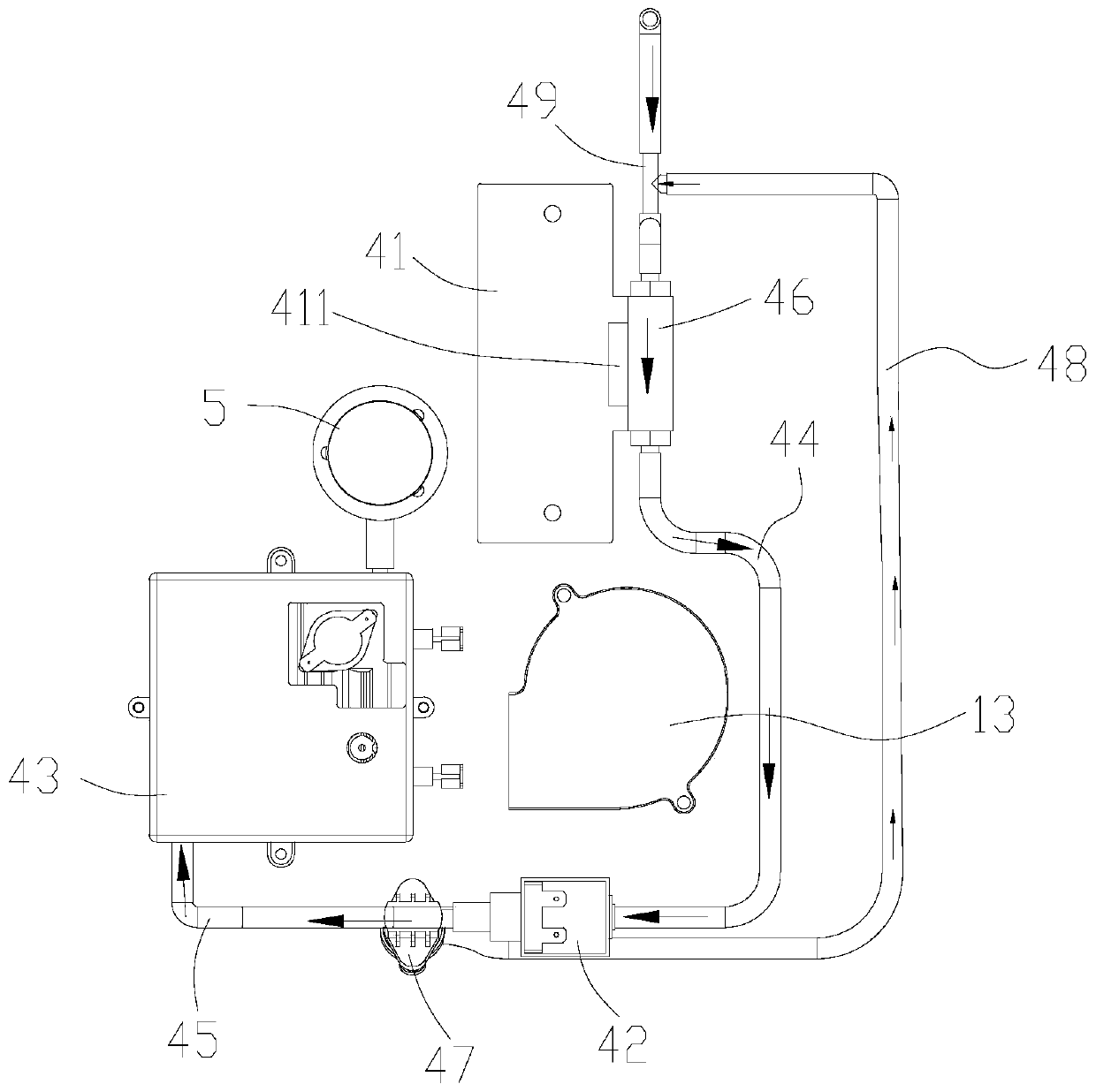

Folding electric iron

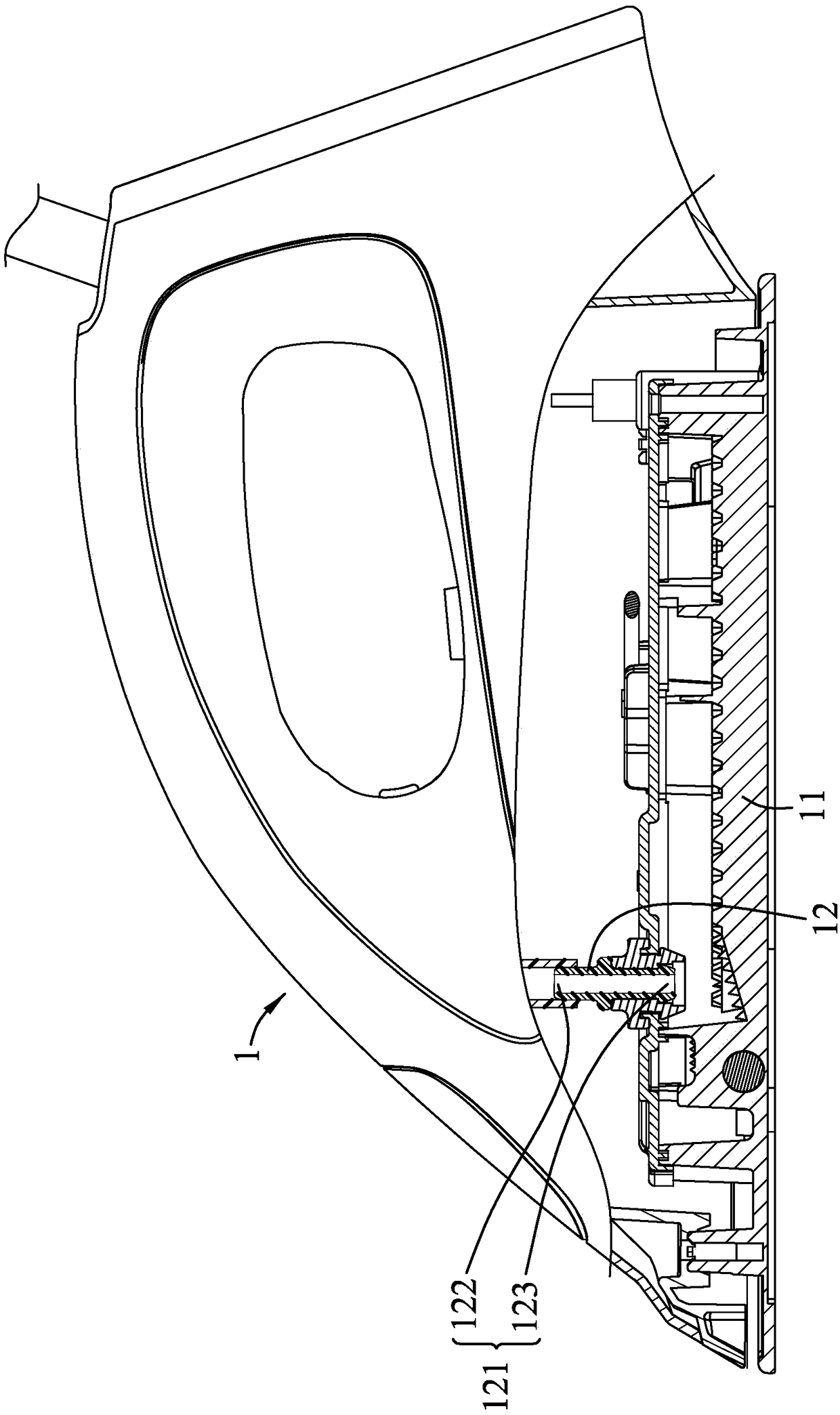

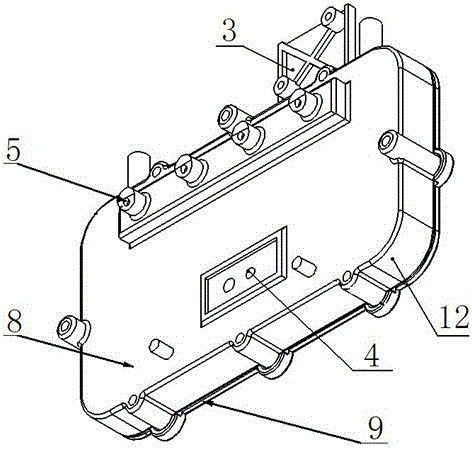

PendingCN107476031ASolve the lack of steamSolving the problem of water coming out of the soleplate of the ironIroning boardsHand ironEngineeringMechanical engineering

The invention discloses a folding electric iron. The electric iron comprises an iron body, an ironing plate and a support, the bottom of the ironing plate is supported by the support, a storage box is arranged on the side portion of the ironing plate, a steam stove is arranged on the support, and the iron body is communicated with the steam stove through a steam hose; a holding part of the iron body is provided with a fan switch, a temperature knob is arranged on the surface of the iron body, and a shift button is arranged on the inner side portion of the iron body; a first V-shaped groove is formed in an iron body bottom plate of the iron body, a 3D bottom plate is installed on the iron body bottom plate, a second V-shaped groove corresponding to the iron body bottom plate is formed in the 3D bottom plate, and a plurality of even holes are formed in the 3D bottom plate. According to the folding electric iron, the iron body and the ironing plate are arranged together, so that use is convenient, and the support below the ironing plate can be folded, so that space is saved after use; the 3D bottom plate is additionally arranged for the first time, double heating is conducted through the iron body bottom plate, the steam amount is increased, no water drop is formed, the problems of insufficient steam and water leakage of the iron body bottom plate do not occur, ironing of clothes is faster, and the effect is higher.

Owner:王录强

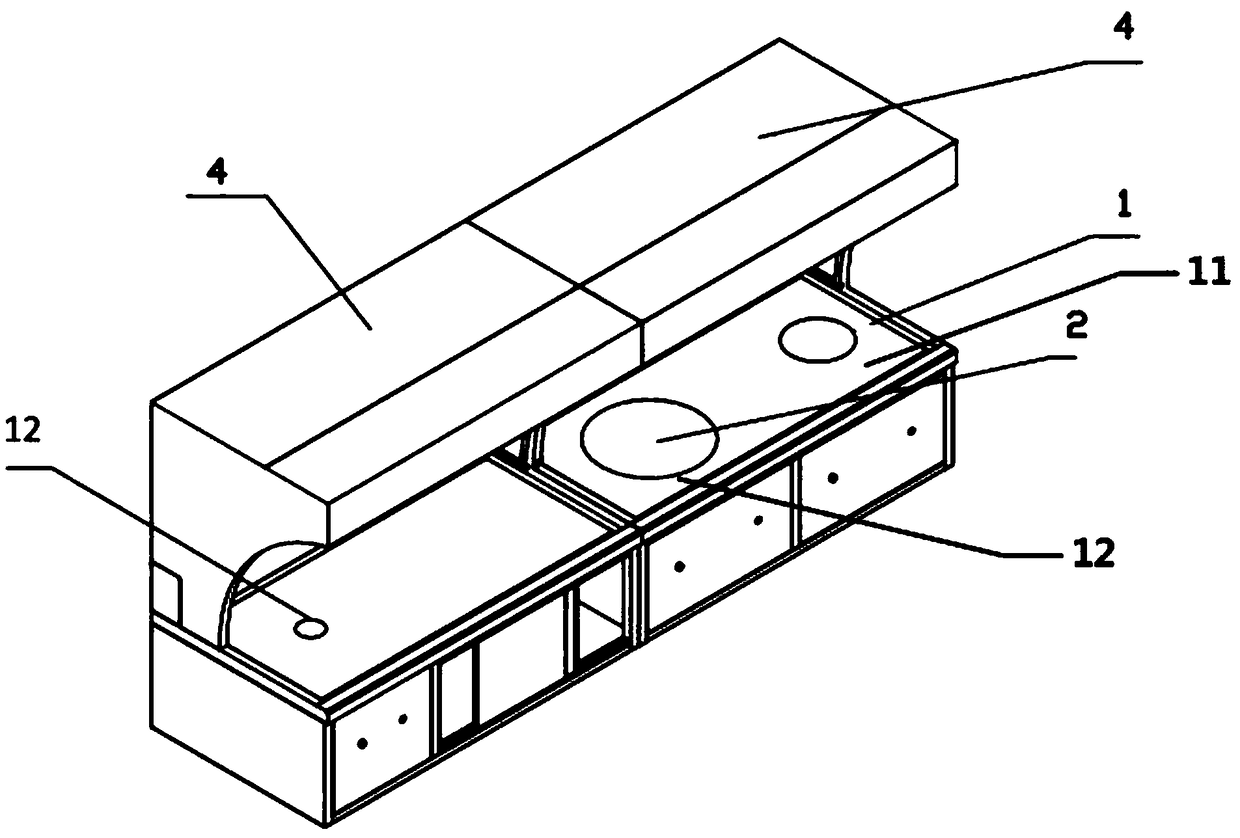

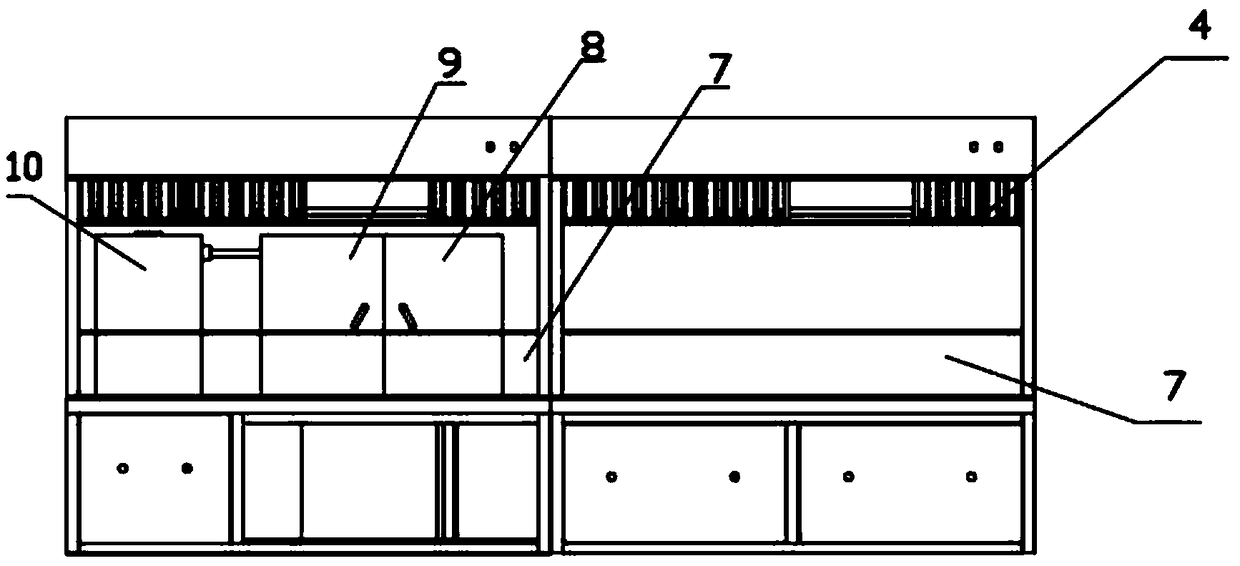

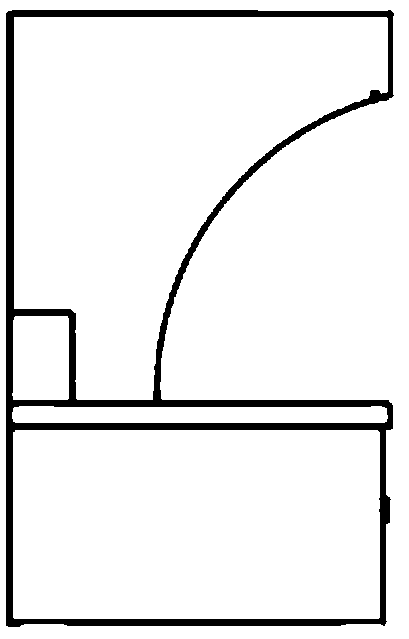

Commercial integrated oven

PendingCN108826387AIncrease profitImprove conversion efficiencyLighting and heating apparatusWater heating stoves/rangesCombustionThermal insulation

The invention discloses a commercial integrated stove. The commercial integrated stove comprises a stove body and at least one furnace, and a combustion burner is arranged under the furnace. The combustion burner is connected to an air-inducing system; the stove body comprises a frame, a pan position and a waste heat energy-saving system; the waste heat energy-saving system comprises an insulatedsandwich water-storage tank, an evaporator, a steam pipe and a flue gas pipe. The thermal insulation interlayer and the flue gas pipe respectively realize the comprehensive utilization of the residualheat of the furnace and the residual heat of the flue gas of the furnace combustion. The integrated and compact design not only improves space utilization, but also systematically reduces equipment heat loss, and greatly improves thermal efficiency.

Owner:湖南万家供热发展有限公司

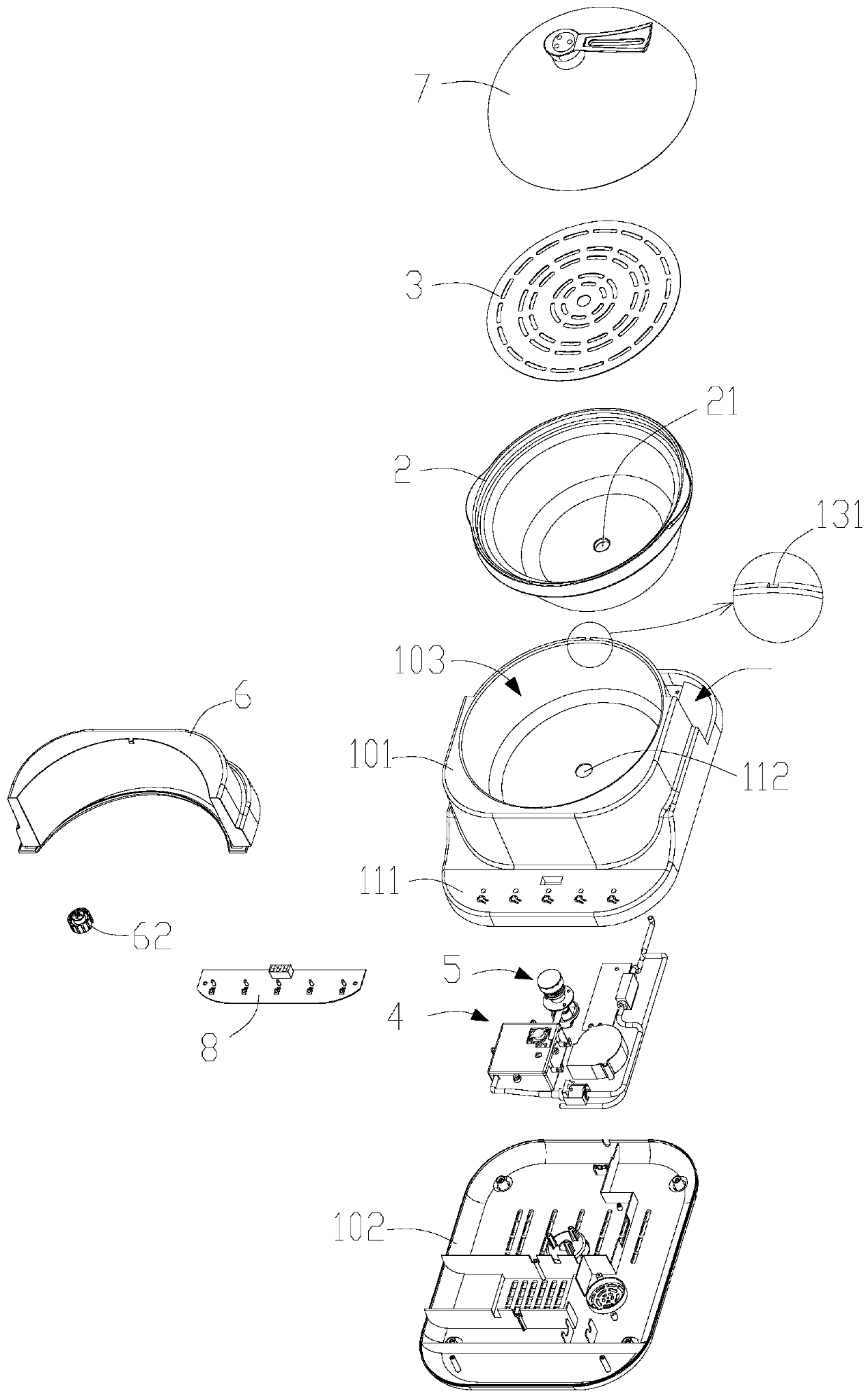

Electric steaming pot

The invention provides an electric steaming pot. The electric steaming pot comprises a shell, a pot body, a water tank, a steam component and a nozzle component, wherein a pot groove with an opened upper side is formed in the shell; the pot body is mounted in the pot groove; the steam component and the nozzle component are arranged inside the shell; the water tank is arranged on the outer side ofthe shell; the steam component comprises a power plate, a water pump and a steam generator; the water pump and the steam generator are electrically connected with the power plate; a water inlet of thewater pump is connected with the water tank through a first pipe body; a water outlet of the water pump is connected with a water inlet of the steam generator through a second pipe body; a steam outlet of the steam generator is connected with a steam inlet of the nozzle component; a steam outlet end of the nozzle component is arranged at the bottom of an inner cavity of the pot body; power of thesteam generator and flow of the water pump can be adjusted by the power plate. Compared with the prior art, the power of the steam generator and the flow of the water pump can be adjusted, so that the water can be rapidly converted into steam when flowing through the pipeline; the steam generation speed is rapid; the amount of the steam generated instantaneously is great.

Owner:BEAR ELECTRICAL APPLIANCE CO LTD

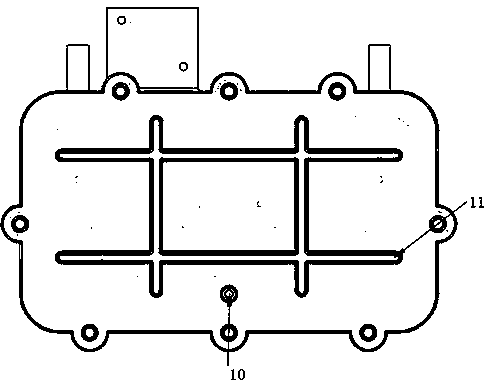

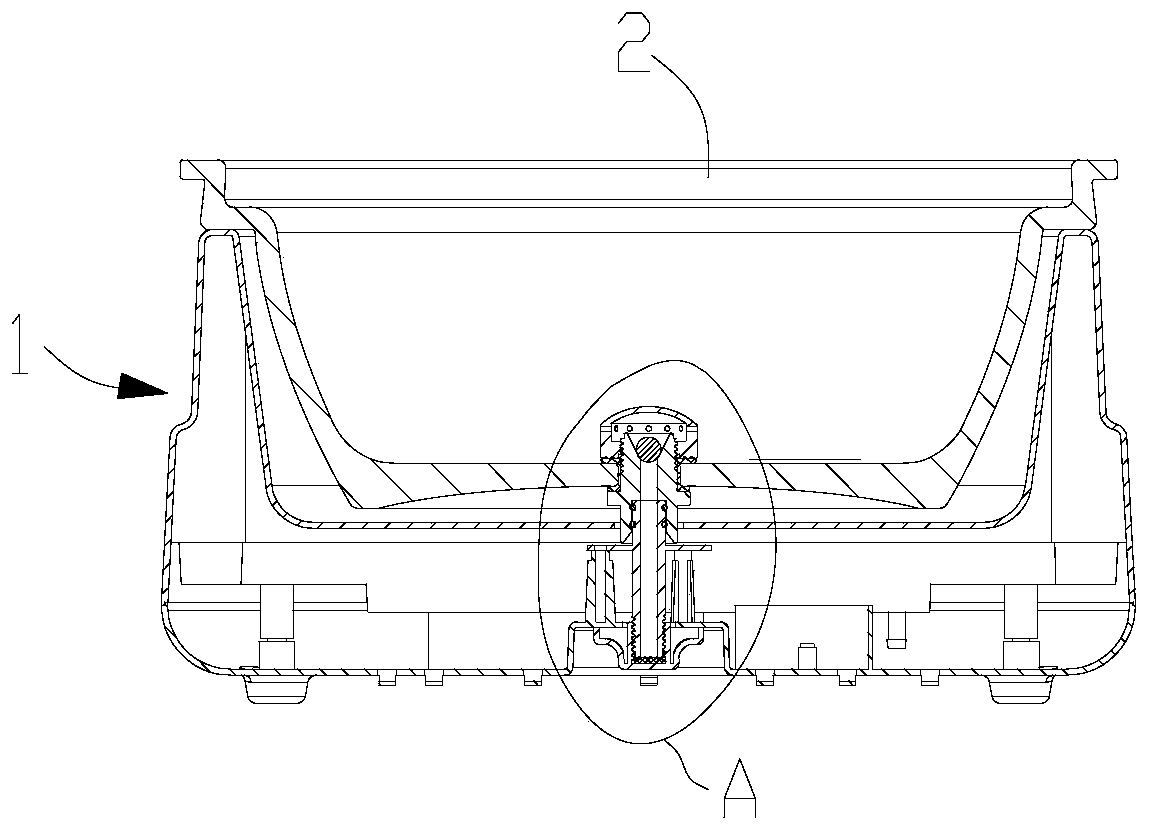

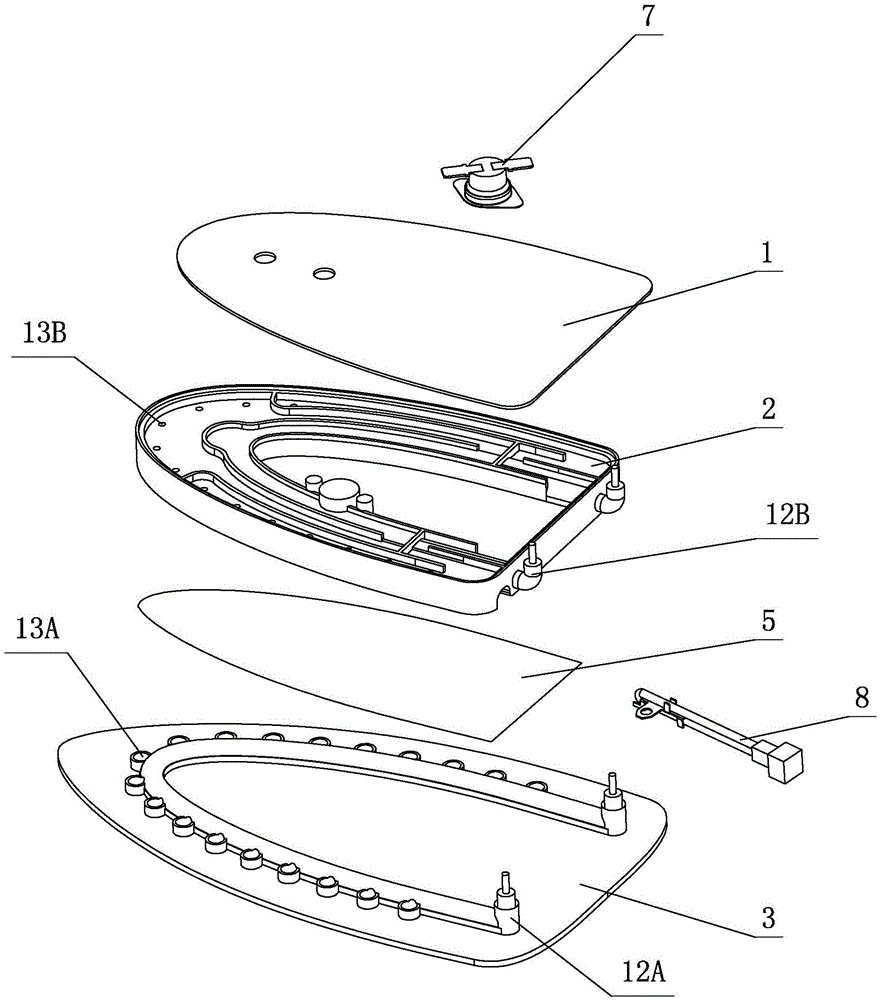

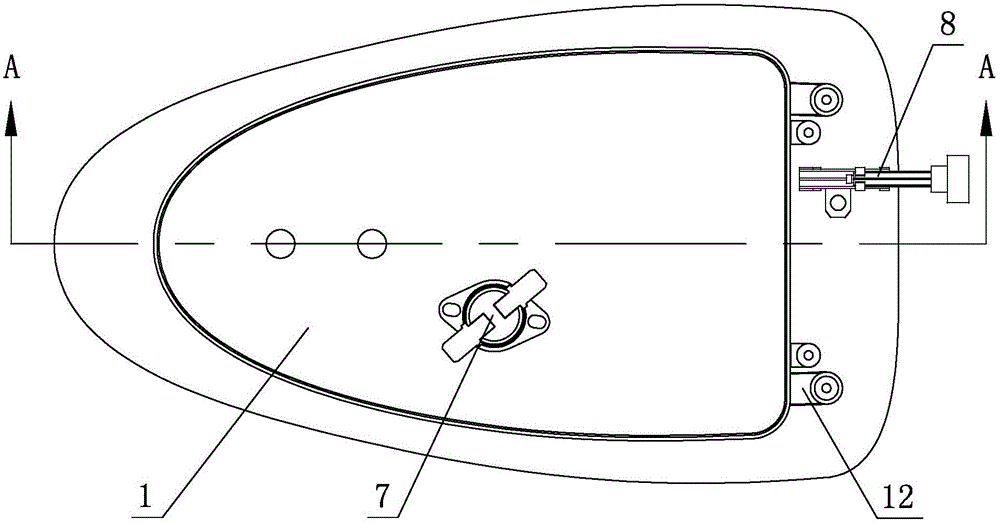

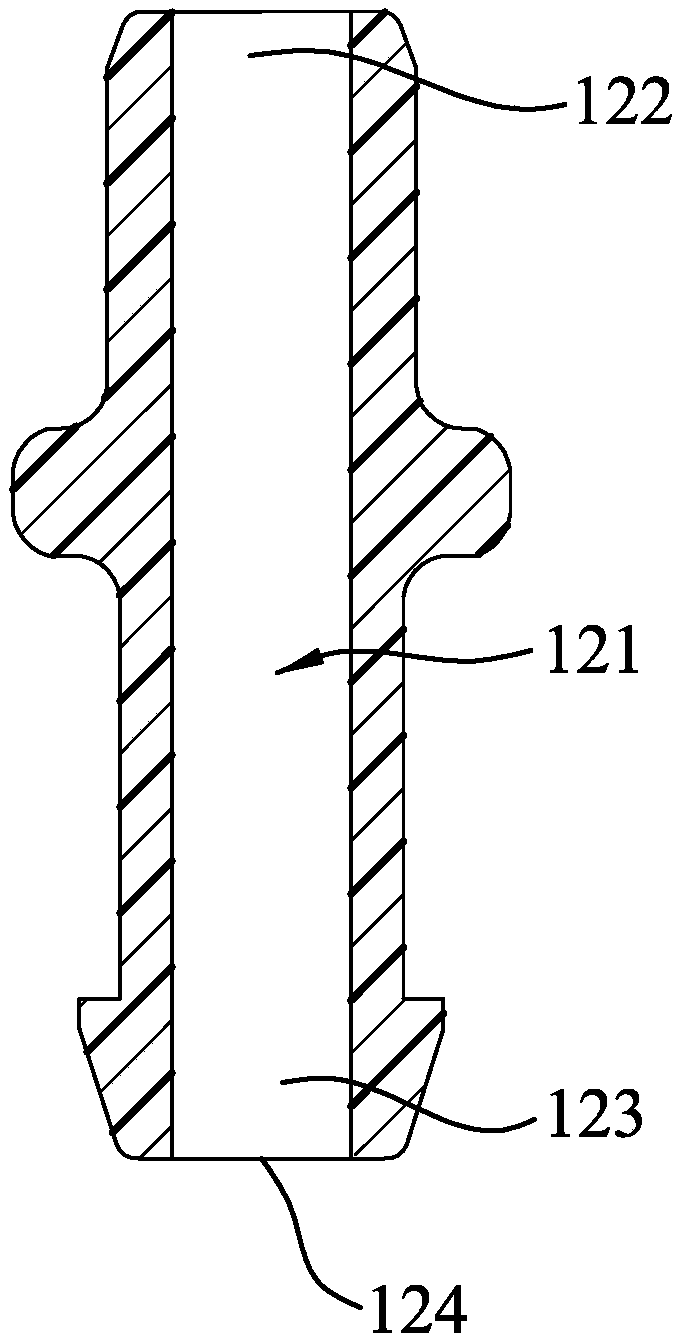

Bottom plate structure of steam-powered ironing device

InactiveCN104088125AImprove featuresImprove securityHand ironTextiles and paperTemperature controlEvaporation

A bottom plate structure of a steam-powered ironing device comprises a first bottom plate and a second bottom. The first bottom plate comprises a first heating device and an evaporation cavity and meanwhile comprises at least one first steam outlet. The first bottom plate is provided with a first temperature control device. The second bottom plate comprises a second heating device and at least one second steam outlet. The second bottom plate is provided with a second temperature control device. The temperature of the first bottom and the temperature of the second bottom are separate through a heat isolation device, the first temperature control device controls the first bottom plate to heat, and the second temperature control device controls the second bottom plate to heat. According to the steam-powered ironing device, an independent double-layer aluminum bottom plate temperature control technology is adopted, the evaporation cavity is separated from the bottom plate, independent heating and temperature control are achieved, the ironing temperature is not affected when an ironing bucket releases steam, even though under a low-temperature state, the ironing steam quantity is not affected, the steam of the ironing bucket is more even, the steam quantity is larger, the cloth ironing effect is obvious, and the operation of ironing the cloth is more convenient and fast and high in practicability.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

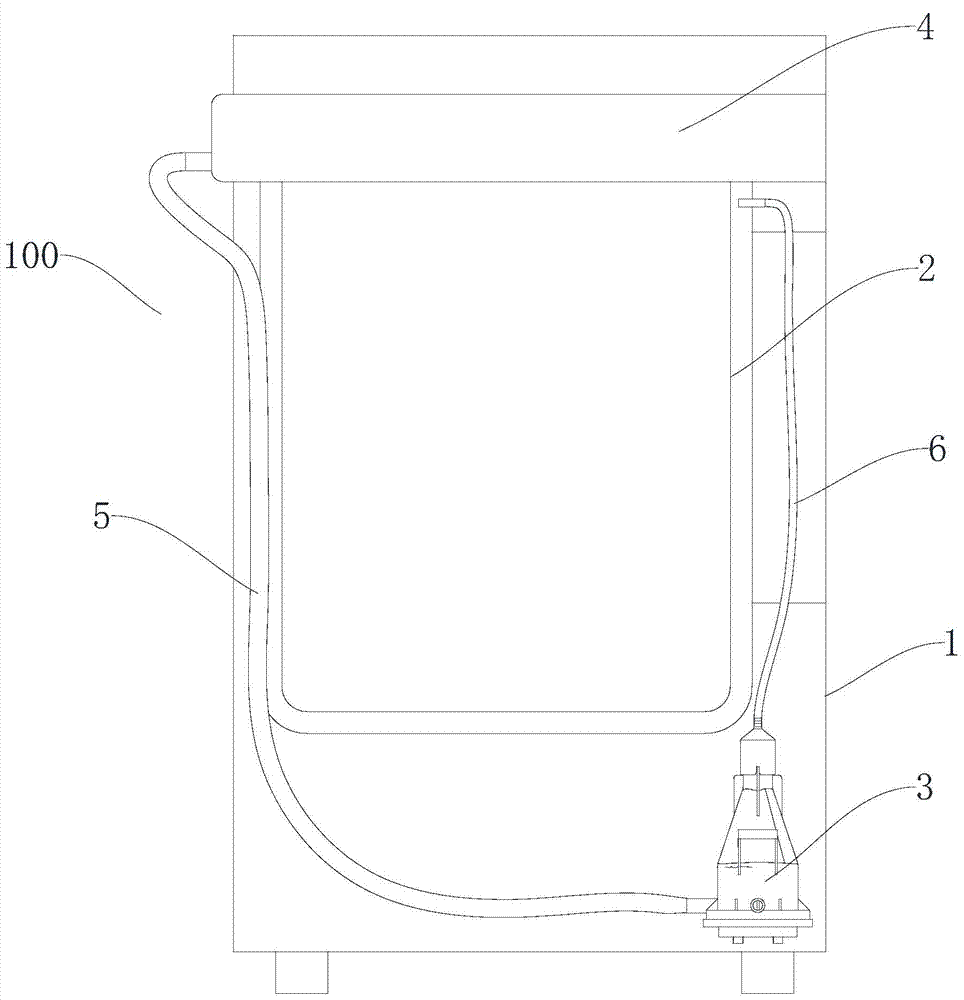

Clothes treating equipment

PendingCN104846611ATo achieve the effect of wrinkle ironingImprove anti-wrinkle effectIroning machinesTextiles and paperEngineeringElectromagnetic pump

The invention discloses clothes treating equipment. The clothes treating equipment comprises a shell, an inner barrel and a steam generator, wherein the inner barrel is arranged in the shell; a cavity is defined in the inner barrel; the steam generator is arranged in the shell and comprises a shell and a heater; a cavity is defined in the shell; a water inlet and a steam outlet which are respectively connected with the cavity are formed in the shell; the water inlet is connected with a water supply device; the steam outlet is connected with the cavity; and the heater is arranged on the bottom of the cavity and heats water in the cavity so as to generate steam. The steam generator is connected with the cavity of the inner barrel, high-temperature steam is provided for the cavity, clothes in the cavity can be ironed so that wrinkles on the clothes can be removed, an electromagnetic pump and an inner pipe of the steam generator can be omitted, the steam generator directly generates the steam, the amount of the steam is large, a wrinkle removing effect of clothes is high, and the service life is long.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

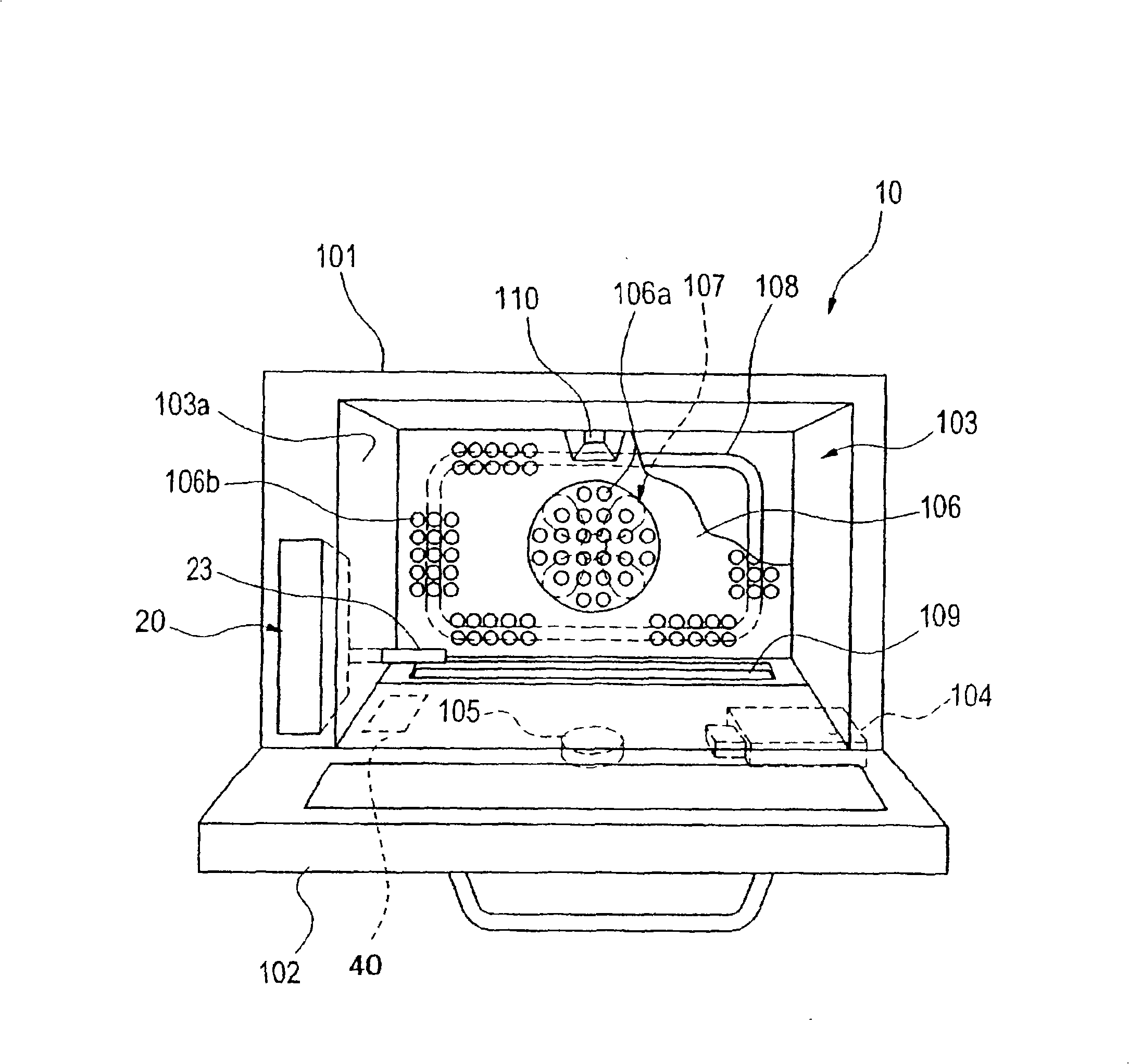

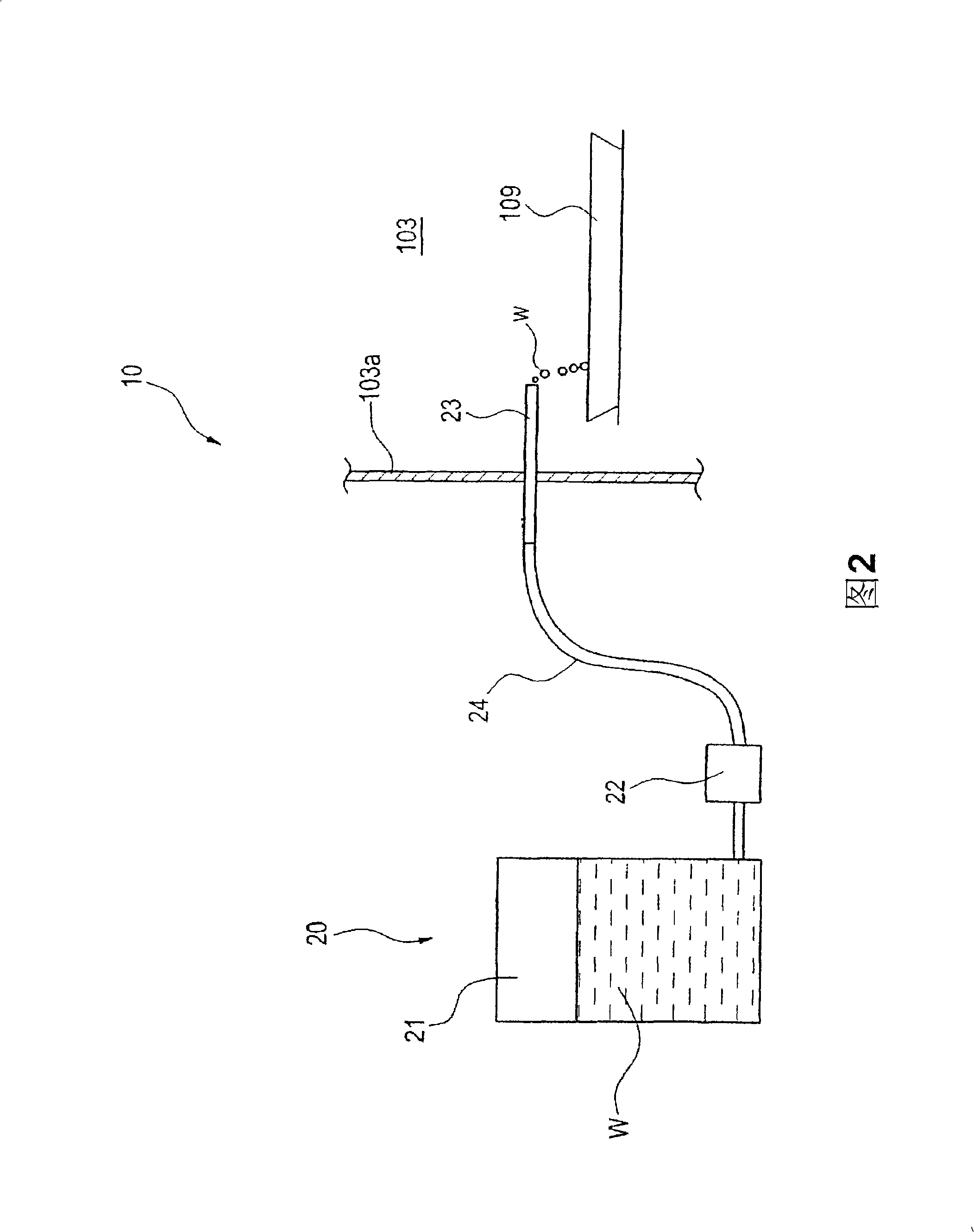

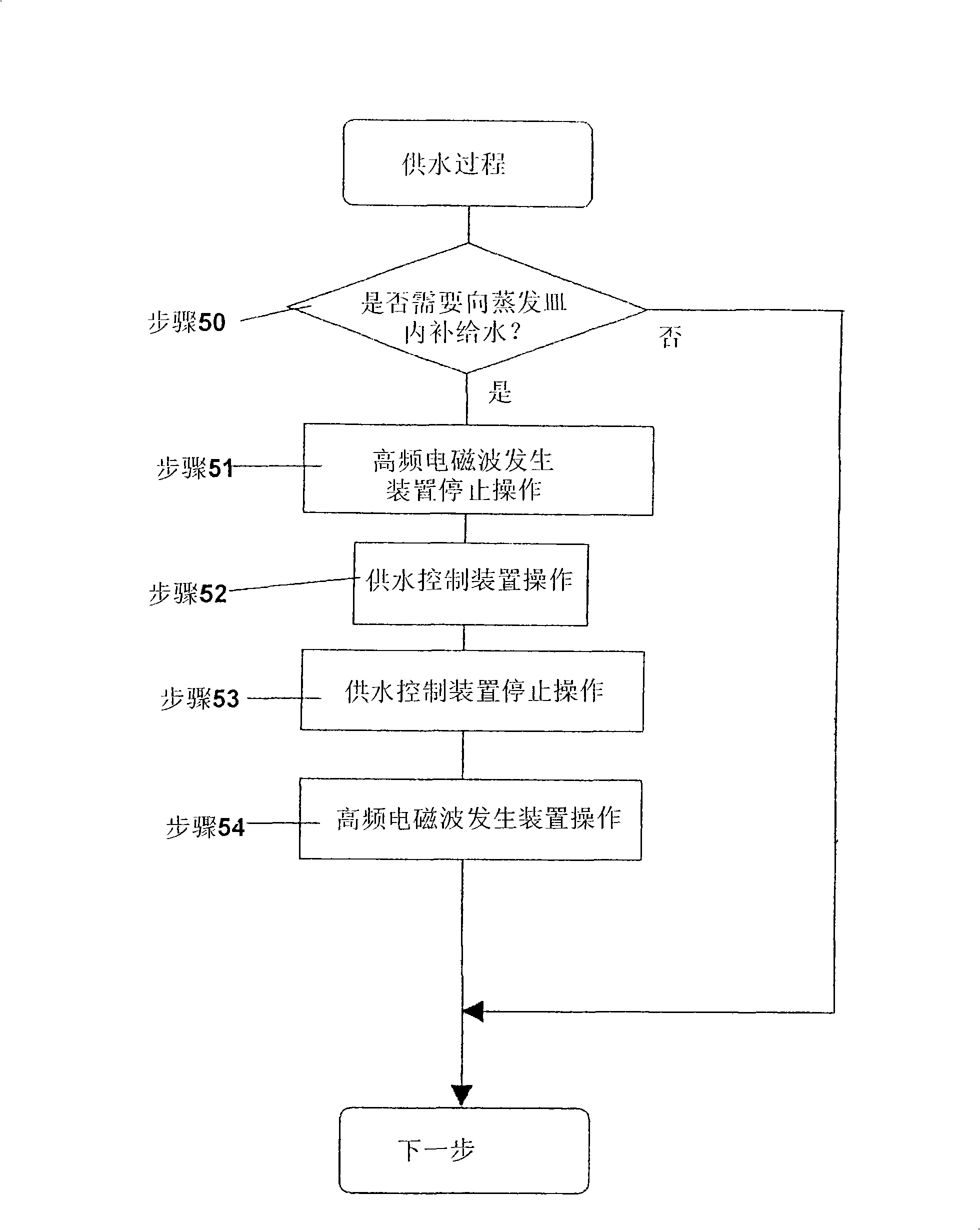

High-frequency electromagnetic wave cooking appliance with steam generation function

InactiveCN101270888APrevent high-frequency electromagnetic wave leakageEasy to useDomestic stoves or rangesSteam generation heating methodsEngineeringSteam generation

The invention provides a high frequency electromagnetic wave cooking apparatus with steam generating function without high frequency electromagnetic wave leakage when using the steam and high frequency electromagnetic wave to cook, including an evaporating utensil (109) arranged in a heating chamber (103), a water supply pipe (23) that supplies water to the evaporating utensil by penetrating a heating chamber wall, a water supply control device (22) that controls water supply to the evaporating utensil, a high frequency electromagnetic wave generating device (104) that provides high frequency electromagnetic wave to the heating chamber, a control unit (40) that controls the water supply control device and the high frequency electromagnetic wave generating device. The control unit stops operating the high frequency electromagnetic wave generating device when using the water supply control device to supply water to the evaporating utensil. Therefore, if the water supply penetrating the heating chamber wall is filled with water when supplying water to the evaporating utensil, the high frequency electromagnetic wave leakage does not occur because there is no high frequency electromagnetic wave , which generates a lot of steam and prevents the electromagnetic wave from leakage.

Owner:PANASONIC CORP

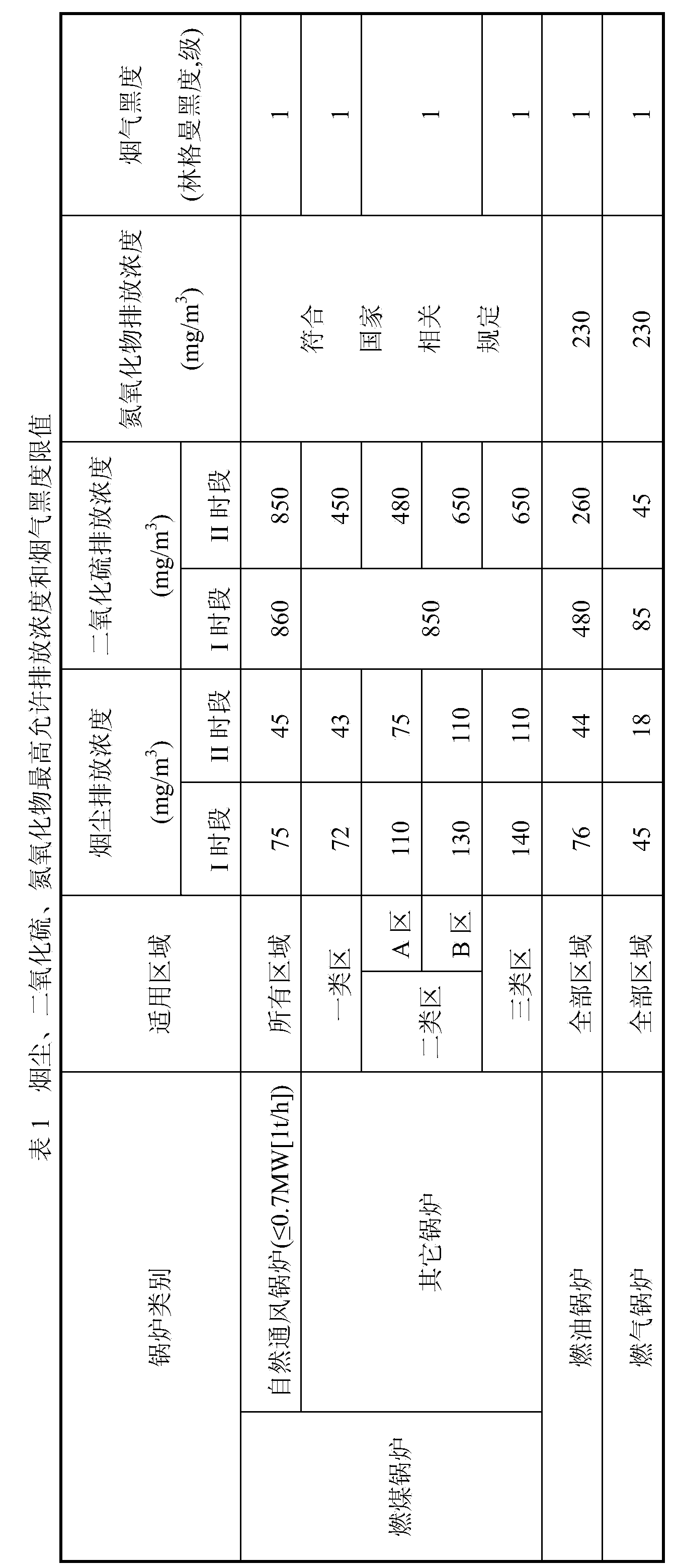

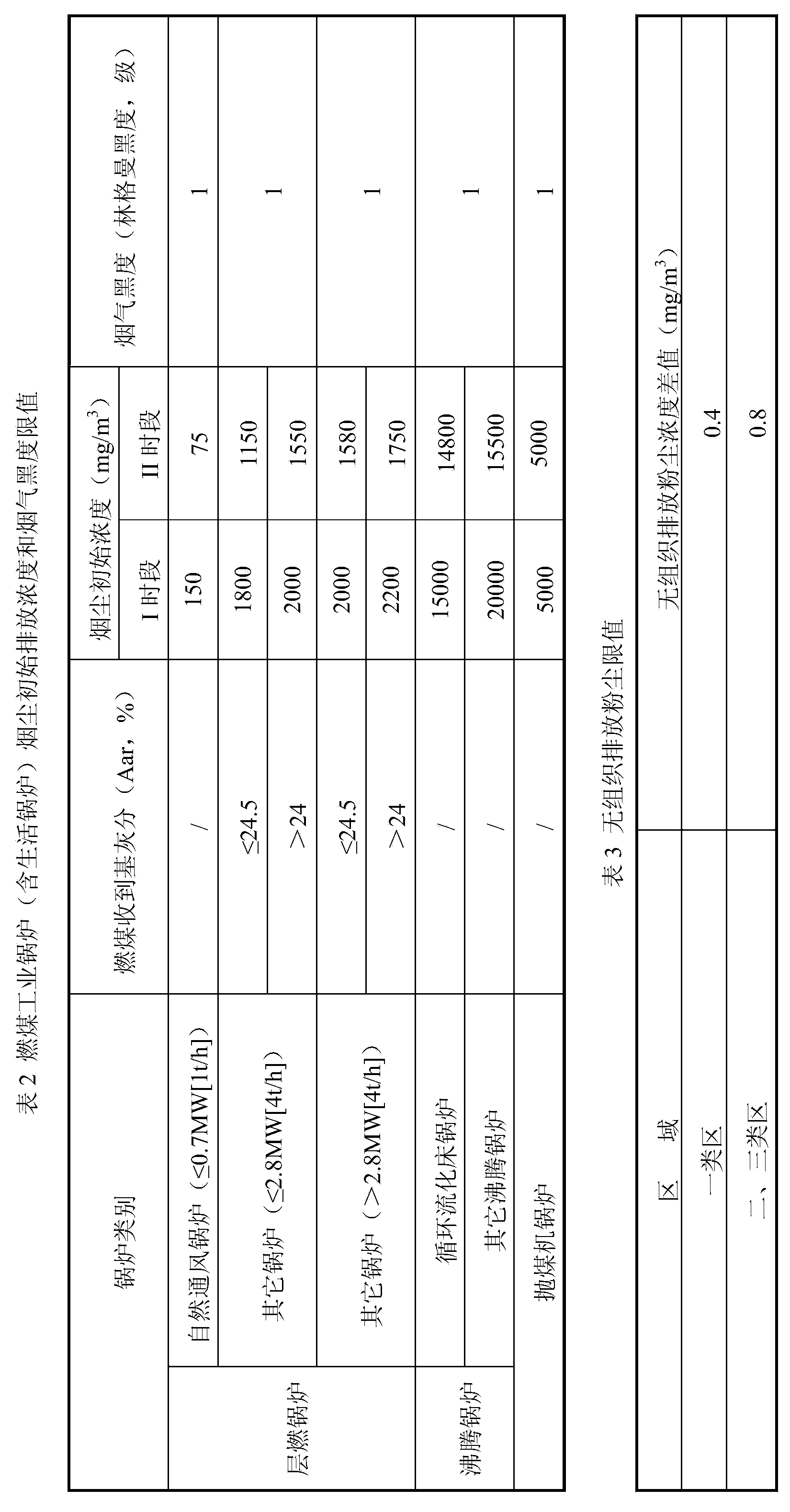

Combustion improver for boiler and preparation method and application thereof

The invention provides a combustion improver for a boiler. The combustion improver is prepared from the following raw materials in parts by weight: 4 parts of sulfuric acid, 4 parts of hydrochloric acid, 4 parts of iron oxide, 4 parts of zinc oxide, 4 parts of copper oxide, 4 parts of calcium oxide, 4 parts of magnesium oxide, 4 parts of aluminum oxide, 16 parts of selenium dioxide, 16 parts of strontium oxide, 16 parts of difluorine monoxide, 16 parts of No. 97 gasoline, 16 parts of No. -20 diesel oil, 16 parts of ethanol, 16 parts of kerosene, 10 parts of paraffin, 10 parts of n-octane, 10 parts of nonane, 10 parts of decane, 10 parts of undecane, 10 parts of dodecane, 10 parts of eicosane, 10 parts of triacontane and 10 parts of tetracontane. The combustion improver provided by the invention can reduce pollution, improve combustion efficiency and prolong the service life of the boiler. The invention further provides a preparation method and application of the combustion improver.

Owner:上海悦和科技有限公司

Water drop type mining transformer circulating refrigeration device

InactiveCN113838632ATo achieve the effect of circulating coolingAchieve water-locking effectTransformers/reacts mounting/support/suspensionTransformers/inductances coolingThermal dilatationTransformer

The invention discloses a water drop type mining transformer circulating refrigeration device, which belongs to the technical field of transformer heat dissipation, and can cool a transformer through heat dissipation liquid when the transformer works normally, and when the temperature of the transformer is too high, a plurality of thermal expansion hemispheres in contact with a heated block are heated to expand. Water in the adsorption sponge is extruded and then flows onto the refrigeration ball, the water cooled by the refrigeration ball continuously drips, the refrigeration effect is achieved, part of steam generated by the heat dissipation liquid is attached to the surfaces of the mesh film and the condensation mechanism due to heat of the transformer, and meanwhile the steam is condensed into large and small water drops after encountering the water drop cone cylinder refrigerated by the refrigeration ball to be dropped back along a guiding thin pipe to achieve a circulating cooling effect. When the temperature of the transformer drops, the thermal expansion hemisphere gradually recovers to the shape, the thermal expansion hemisphere pulls the adsorption sponge to adsorb moisture on the surface of the mesh film, and after water drops stop dropping, the saltpeter powder gradually crystallizes for next use.

Owner:李明

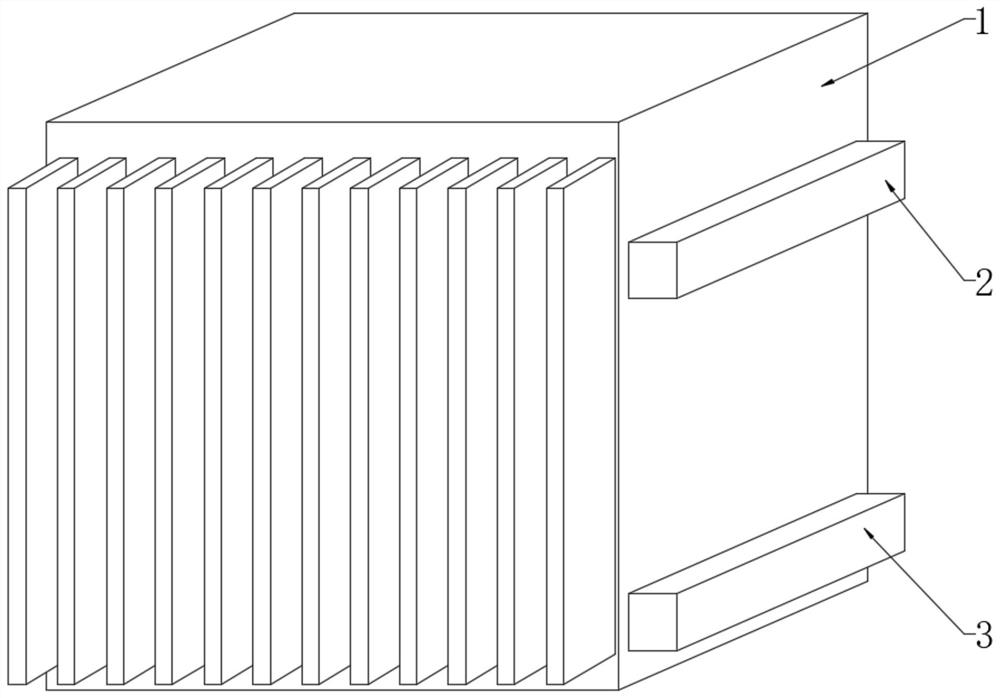

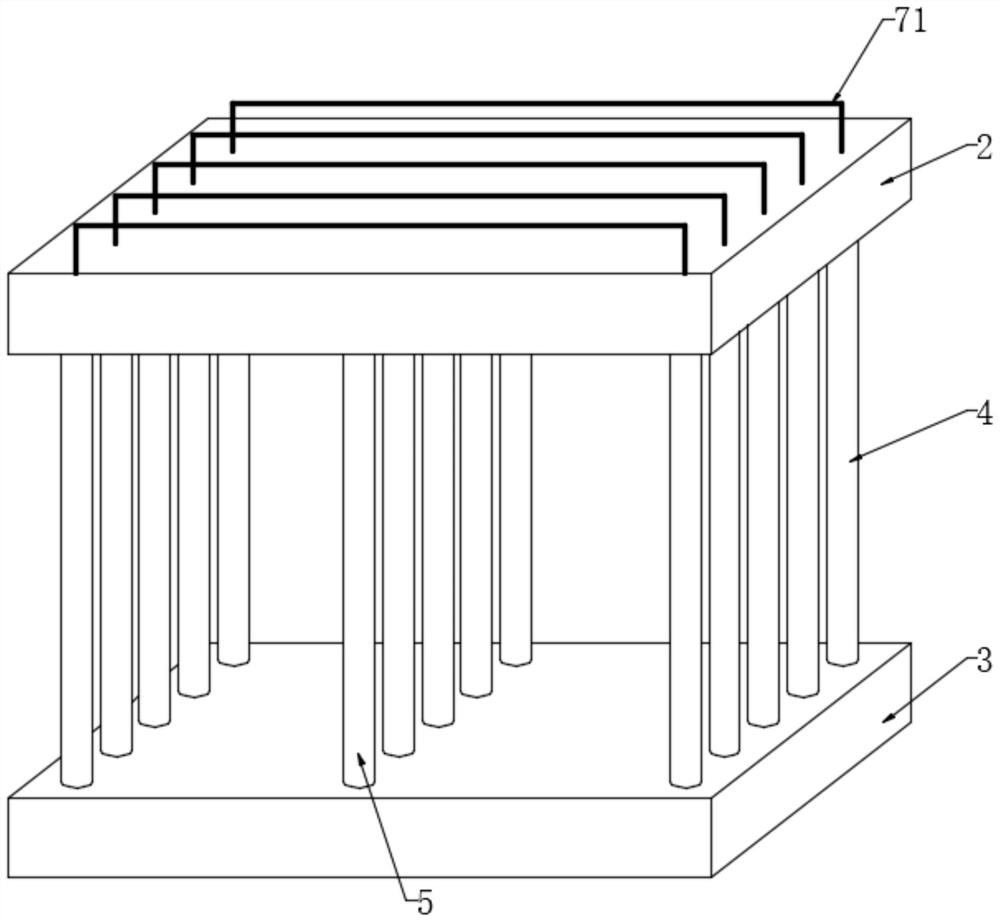

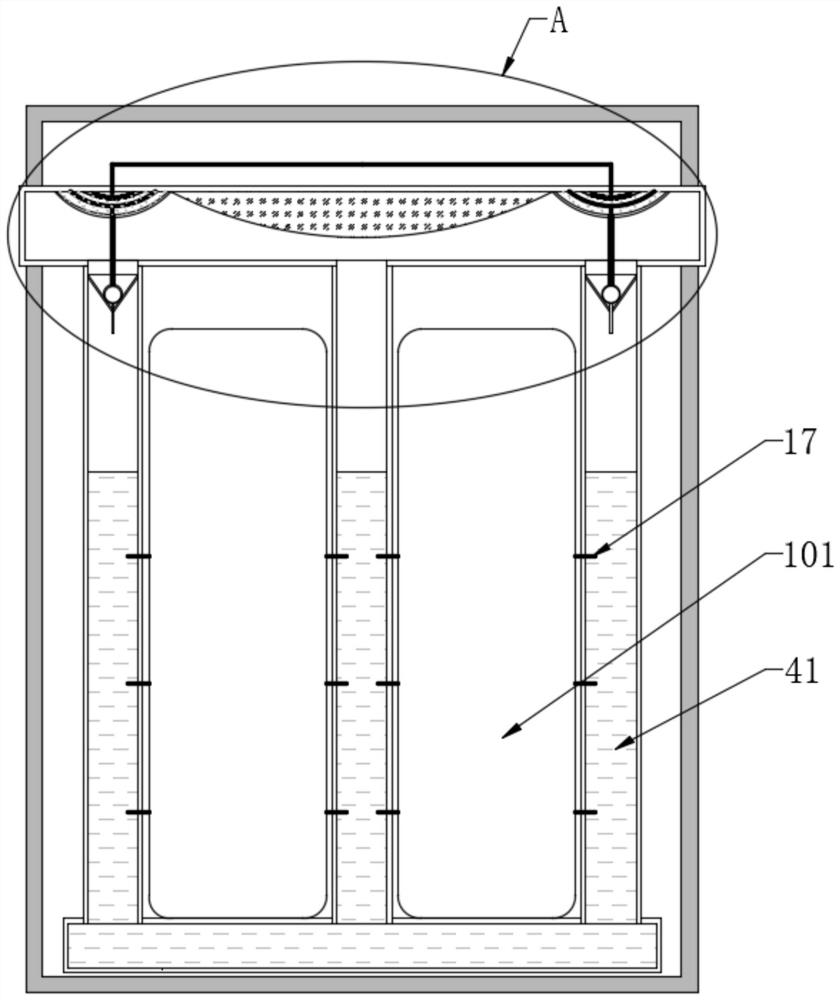

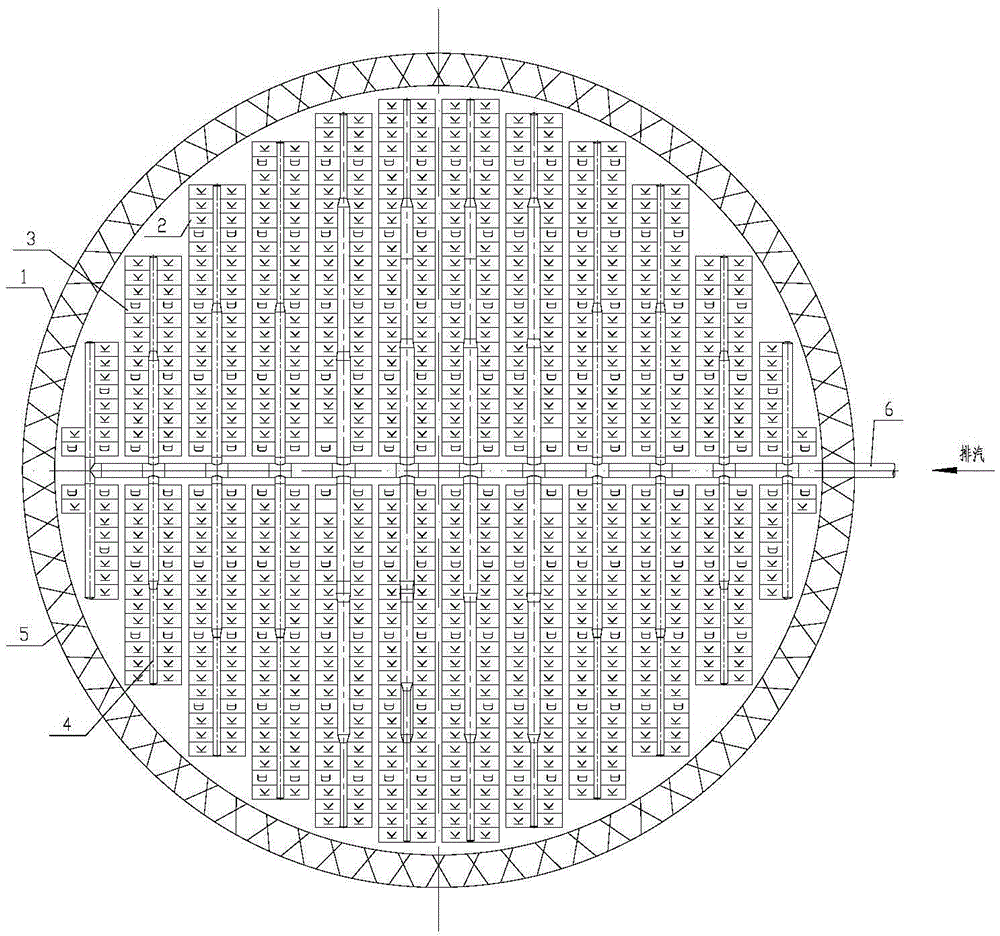

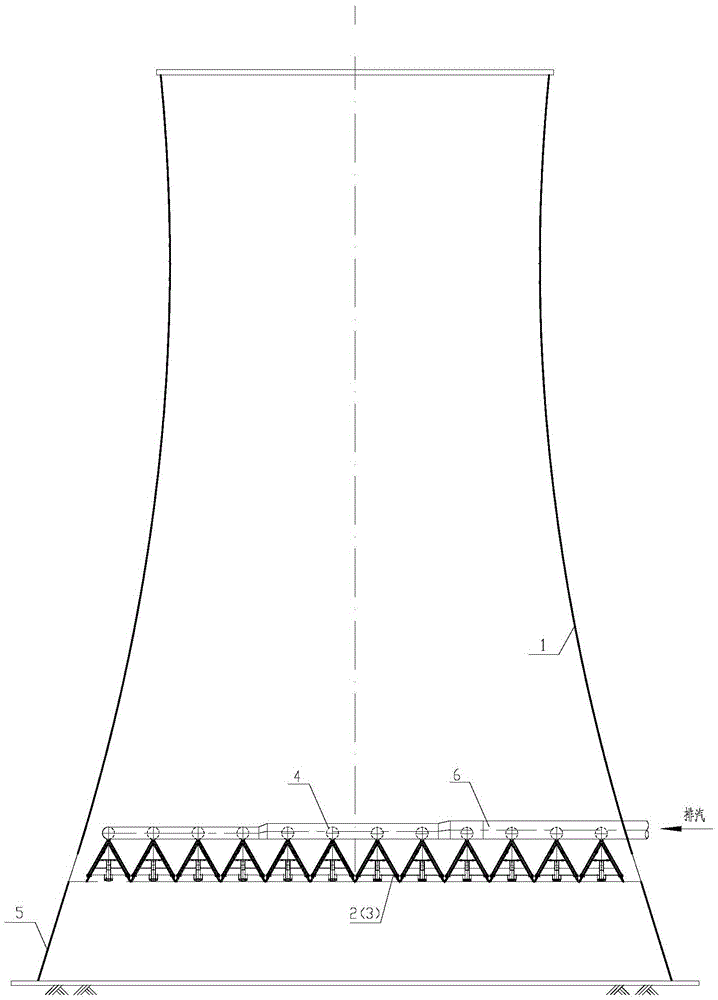

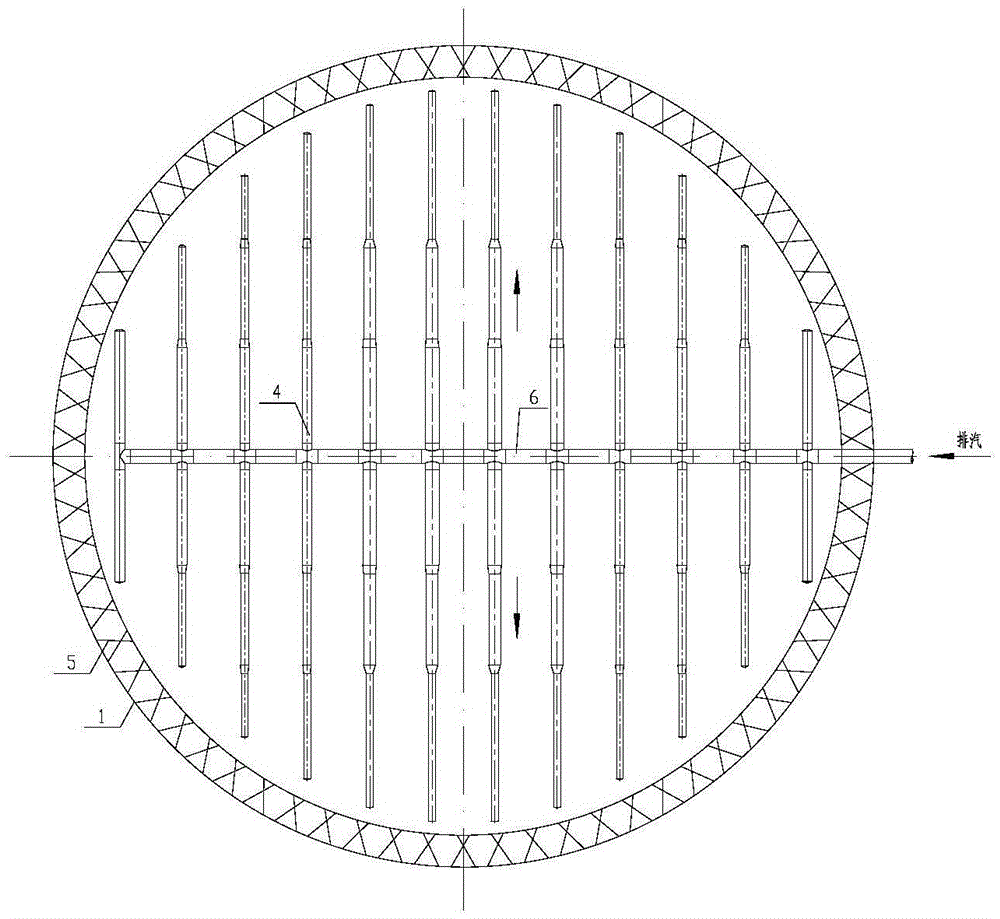

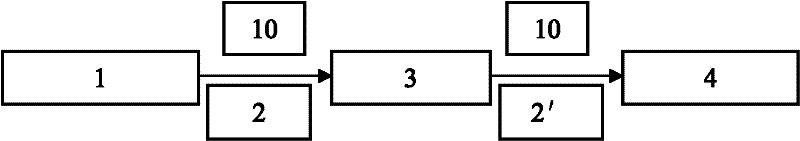

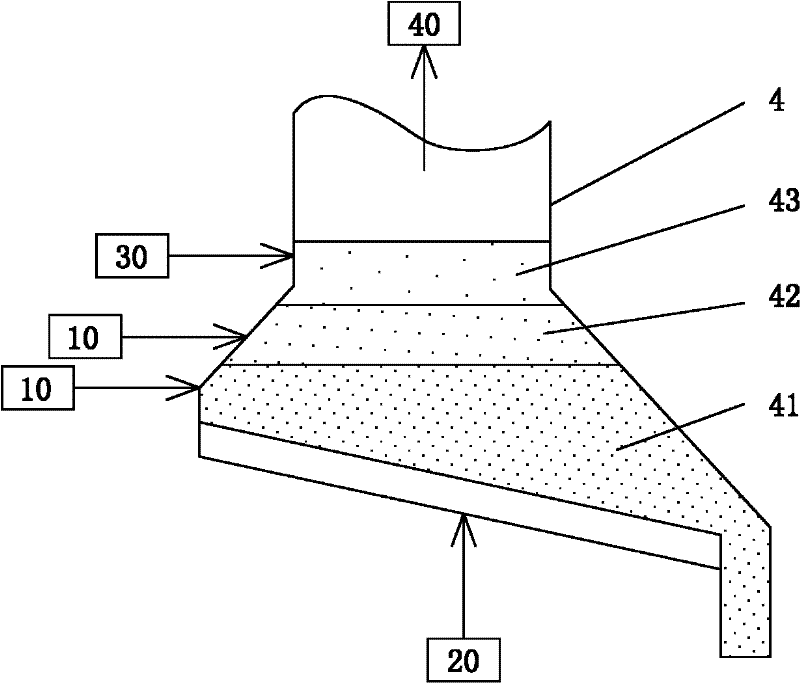

Direct dry cooling system of natural draft cooling tower

InactiveCN105466235AShorten the lengthSmall pressure dropSteam/vapor condensersNatural ventilationCooling tower

The invention discloses a direct dry cooling system of a natural draft cooling tower. Air cooling radiators are arranged in rows and an array on a cross section at a certain height within the tower in a direction parallel to a diameter of the section; the radiators of each row share one steam distribution pipe; from the center to the periphery of the tower, the lengths and diameters of the steam distribution pipes are orderly reduced; such a unique form of row arrangement of the radiators within the tower is conductive to effectively reduce the length of each steam distribution pipe in the system, and therefore, steam exhaust pressure drop in the pipe can be well controlled. The direct dry cooling system of the natural draft cooling tower is scientific, tidy and simple in overall arrangement form; further, the pressure drop of a steam exhaust pipeline is reduced and the electric energy production of a unit is increased.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Method and treatment system for reducing nitrogen oxides by using incineration of refuse landfill gas

InactiveCN102252333AEfficient collectionNo pollution in the processIncinerator apparatusPower stationNitrogen oxides

The invention relates to a refuse landfill gas burning and re-burning technology, and in particular relates to a method and a treatment system for reducing nitrogen oxides by using incineration of refuse landfill gas. The treatment system mainly consists of a refuse landfill, an air pipe, a fan, the other air pipe and an incinerator connected sequentially; during working, the landfill gas of the refuse landfill is led out by the fan through the air pipe, delivered to the incinerator through the other air pipe, and burnt and re-burnt by the incinerator; and the landfill gas is used for reducing NOx in the incinerator, so that the NOx content of the flue gas exhausted by the incinerator is effectively reduced. The method and the system solve the problem of air pollution caused by stench of the refuse landfill and the problem of NOx concentration in the flue gas exhausted by the refuse incinerator, and are particularly suitable for a newly built refuse power plant, particularly a refuse burning power plant which is built nearby the refuse landfill and can provide the landfill gas more conveniently and effectively.

Owner:福建省丰泉环保控股有限公司

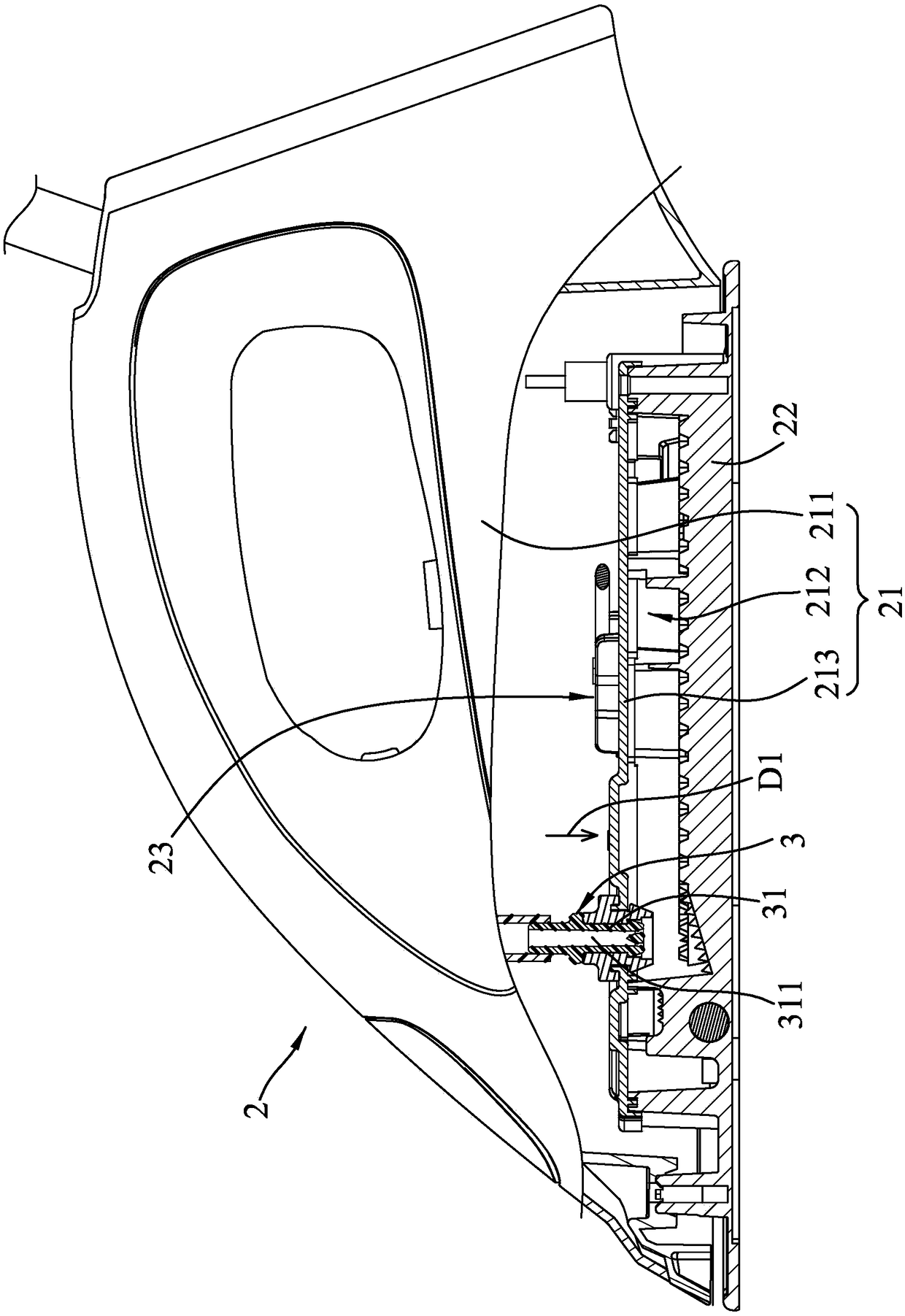

Water injection component and ironing device

ActiveCN109082869AImprove evaporation efficiencyIncrease the amount of waterHand ironTextiles and paperEvaporationWater flow

The invention discloses a water injection component and an ironing device. The water injection component is applicable to a steam cavity for injecting water into the ironing device so that water can fall into a heating disc of the ironing device. The water injection component comprises a water injection pipe forming a pipe channel. The pipe channel comprises an inlet portion in which water is allowed to flow in the water injection direction and an outlet portion opposite to the inlet portion and used for water outflowing. The water injection component further comprises a center stop block forblocking the outlet portion, and a plurality of stop ribs extending out from the center stop block to be connected with the water injection pipe. A plurality of water dispersing holes are formed by partitioning the outlet portion through the stop ribs. The water dispersing holes are used for enabling water flowing in from the inlet portion to flow out from the outlet portion and be dispersed on the heating disc. The water injection component is provided with the water dispersing holes, so that the contact area between water and the heating disc can be increased, the water evaporation efficiency is improved, the water injection amount can be increased while the evaporation efficiency can be improved, the steam amount is increased, and the clothes ironing effect is improved.

Owner:TSANN KUEN ZHANGZHOU ENTERPRISE CO LTD

System and method for improving heat exchange effects of graphite blocks in HCl synthetic furnace with byproduct steam

The invention relates to a system and method for improving the heat exchange effects of graphite blocks in an HCl synthetic furnace with byproduct steam. The method comprises the steps that water in a first water tank enters the lower end of a circulating water section of a synthetic furnace after undergoing heat exchange in a heat exchanger, then comes out from the upper end of the circulating water section of the synthetic furnace and returns to the first water tank; hot water in the middle of the circulating water section of the synthetic furnace enters a second water tank, and the hot water in the second water tank returns to the synthetic furnace and generates low-pressure steam under the pressurization action of a first water pump. The system and the method have the beneficial technical effects that the water in the second water tank comes from the middle section of the circulating water in the synthetic furnace and has higher temperature, and the hot water enters the synthetic furnace to generate steam under the pressure of the first water pump, thus effectively utilizing the heat in the circulating water and saving the extra heating cost; pure water is used instead of original industrial water and contains little calcium and magnesium ions and silt, so that scaling and blockage are avoided, thus prolonging the service life of equipment and then greatly reducing the accident danger coefficient and reducing the installation and maintenance costs of the equipment.

Owner:DEZHOU SHIHUA CHEM

Method and treatment system for reducing nitrogen oxides by using incineration of refuse landfill gas

InactiveCN102252333BEfficient collectionWill not affect lifeIncinerator apparatusPower stationNitrogen oxides

Owner:福建省丰泉环保控股有限公司

new steam generator

ActiveCN103776006BUnobstructed pathLarge amount of steamSteam generation heating methodsSteam boilersSeparated stateEngineering

The invention provides a novel steam generator. The novel steam generator comprises a heating shell, a water inlet and a steam outlet are formed in the heating shell, the steam outlet is arranged to be an inclined hole which is axially inclined for 20 degrees, a W-shaped heating tube is arranged in the cavity of the heating shell, a steam flow guide baffle is arranged on the inner wall of the heating shell, and the W-shaped heating tube and the steam flow guide baffle are arranged in an overlapped way. The novel steam generator has the advantages that the path becomes smoother and resistance-free during steam jetting, the quantity of steam is increased and the jetting distance is increased; since the W-shaped heating tube and the steam flow guide baffle are arranged in the overlapped way, the internal part is uniformly heated and the thermal efficiency is effectively improved; the steam circulating path of the cavity is further prolonged, the surrounding flow is formed and is in full contact with the heating tube, and the goals of steam overheating and steam-liquid separation are completed more effectively; the thermal conversion efficiency is high, the output steam temperature is high, the quantity of the steam is large, the jetting distance is long and the flowing passage structure is reasonable.

Owner:QINGDAO YUNLU ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com