Cold start device and cold start method of M100 methanol engine

A methanol engine and engine cooling technology, which is applied to engine starting, engine components, combustion engines, etc., can solve problems such as cold starting of methanol engines, and achieve the effect of improving economy and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

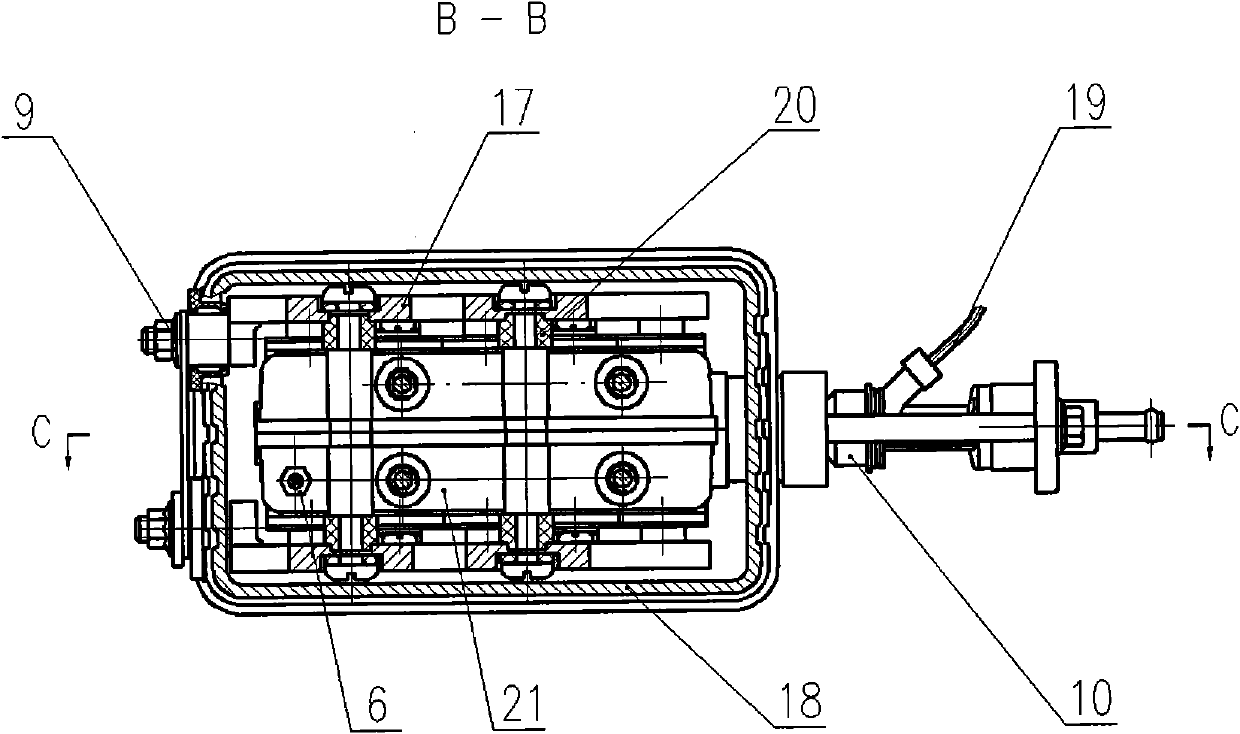

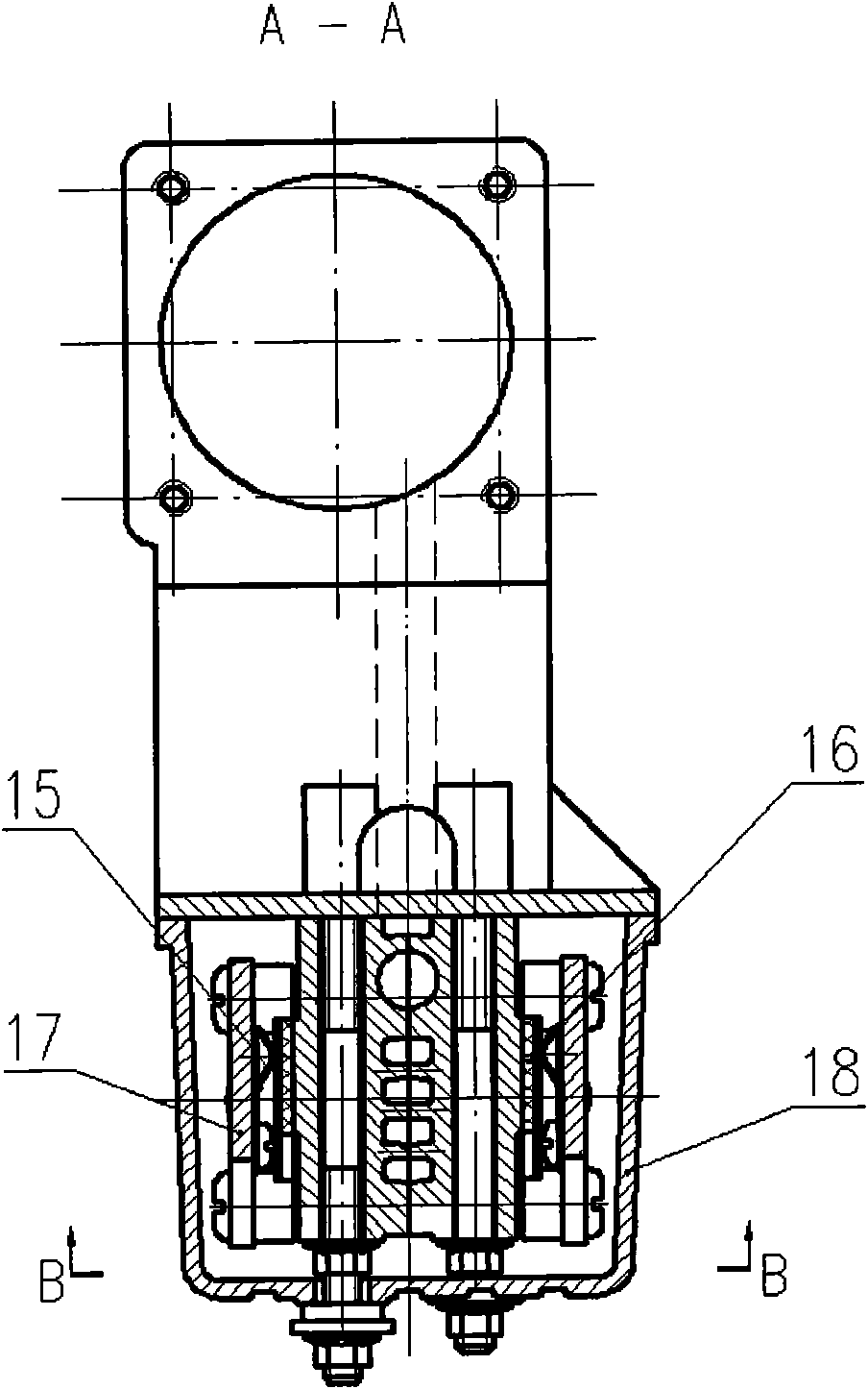

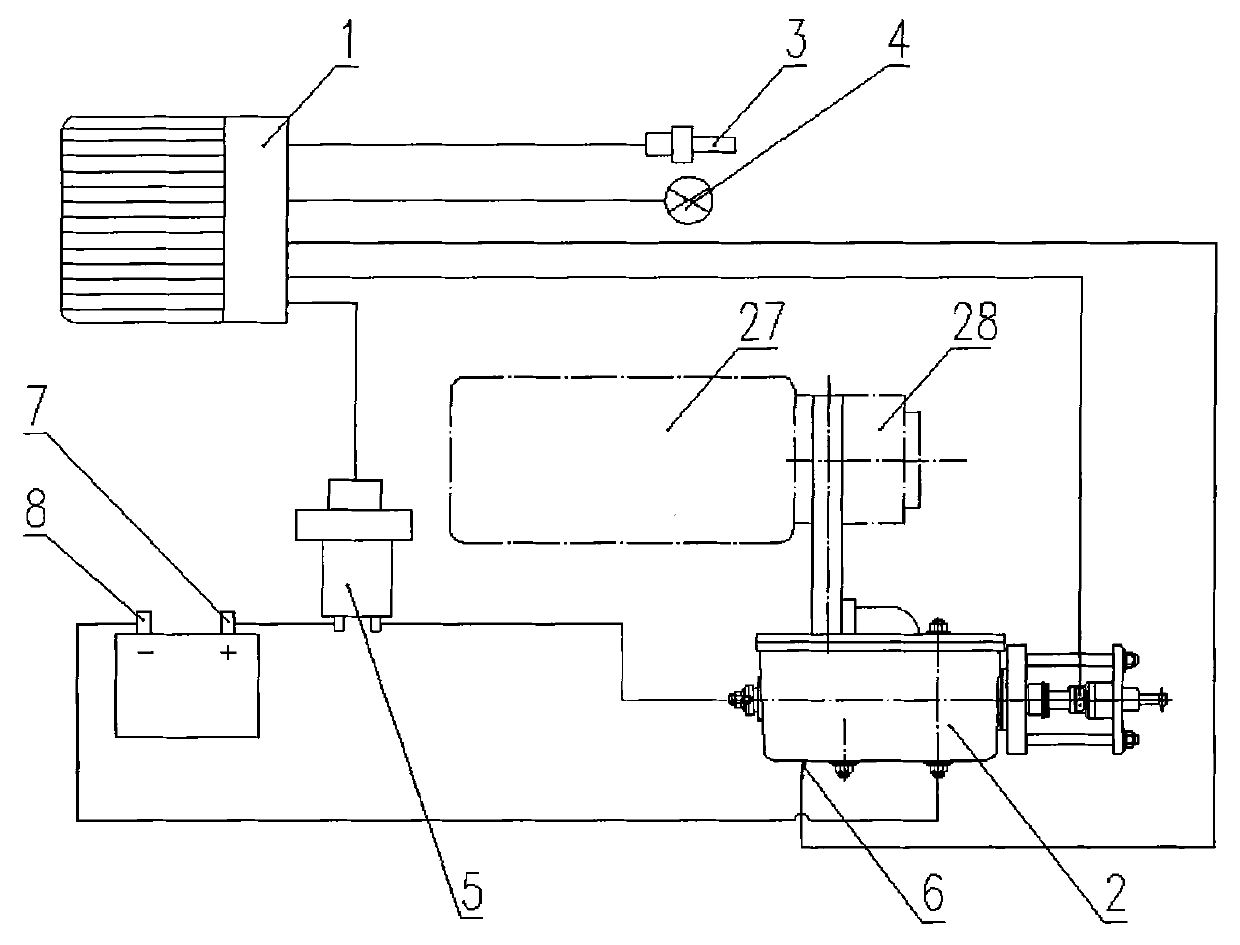

[0017] as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As described above, a kind of M100 methanol engine cold start device claimed by the present invention includes a controller 1, a methanol steam generator 2, a water temperature sensor 3, an indicator light 4, a DC contactor 5, a methanol steam generator temperature sensor 6, and a storage battery Positive pole 7, battery negative pole 8, positive pole terminal 9, electronically controlled alcohol injector 10, alcohol injector seat 11, negative pole power cord 12, negative pole pole pole 13, positive pole power cord 14, spring leaf 15, PTC ceramic thermistor 16 , Electrode 17, shell 18, electronically controlled alcohol injector signal line 19, insulating block 20, evaporation chamber 21, connecting plate 22, throat 23, methanol vapor channel 24, annular evaporation column 25, signal line 26, intake manifold 27, throttle valve 28.

[0018] The methanol steam generator 2 is fixed betw...

specific Embodiment approach 2

[0021] as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4Said, implement the above-mentioned cold start method of a kind of M100 methanol engine cold start device of the present invention, this method is when the methanol engine starts, controller 1 detects engine cooling water temperature by engine water temperature sensor 3, and controller 1 passes water temperature sensor The temperature feedback signal of 3 judges whether the engine cooling water temperature is higher than the set value of 16°C. If the engine cooling water temperature is higher than 16°C, the methanol steam generator 2 does not work; otherwise, if the engine cooling water temperature is lower than 16°C, the controller 1 sends a signal, The DC contactor 5 connects the positive power line 14 and the battery positive circuit, and the current flows from the positive power line 14 of the battery through the positive power line 14, the terminal post 9, the electrode 17, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com