Coal additive

A technology for coal additives and coal, applied in the field of coal additives, can solve the problems of high cost, scarce sources, and cannot afford high-cost input, etc., and achieve the effects of improving output and efficiency, reducing reaction activation energy, and reducing pollutant emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Constituent elements and percentages of the coal additive of the present invention are:

[0038] the element

Proportion(%)

48.74

14.38

aluminum

4.6

4.6

2.4

16.09

7.8

1.39

[0039]

[0040] The catalyst is non-toxic, non-flammable and explosive

[0041] ·Coal-saving rate: 5%-25%, boiler thermal efficiency increased by 7%-10%.

[0042] ·SO content is reduced by about 40%-80%, and NO content is reduced by more than 80%.

[0043] Significantly reduce the carbon in the ash, reduce the corrosion of the coal combustion chamber, prolong the service life of the combustion chamber, reduce the time and frequency of downtime and maintenance, and reduce maintenance costs.

[0044] The additive of the invention can not only greatly reduce the discharge of sulfides and nitrogen oxides, improve the quality of the at...

Embodiment 2

[0047] The coal additive of the present invention is:

[0048] the element

Embodiment 3

[0050] Testing Unit: Liaocheng Energy Utilization Office of Shandong Province

[0051] Experimental unit: Shandong Liaocheng Guanhua Protein Group Co., Ltd.

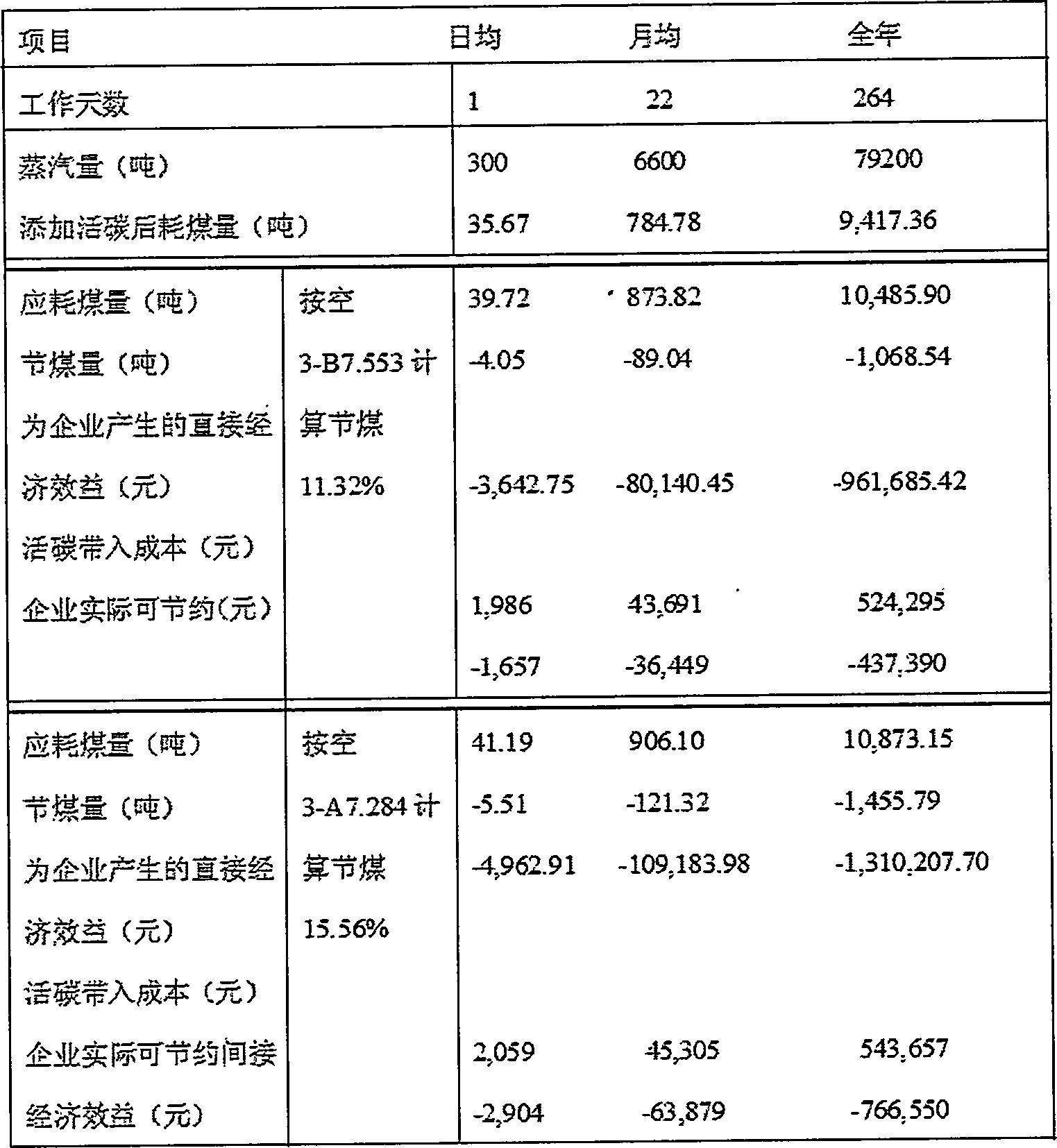

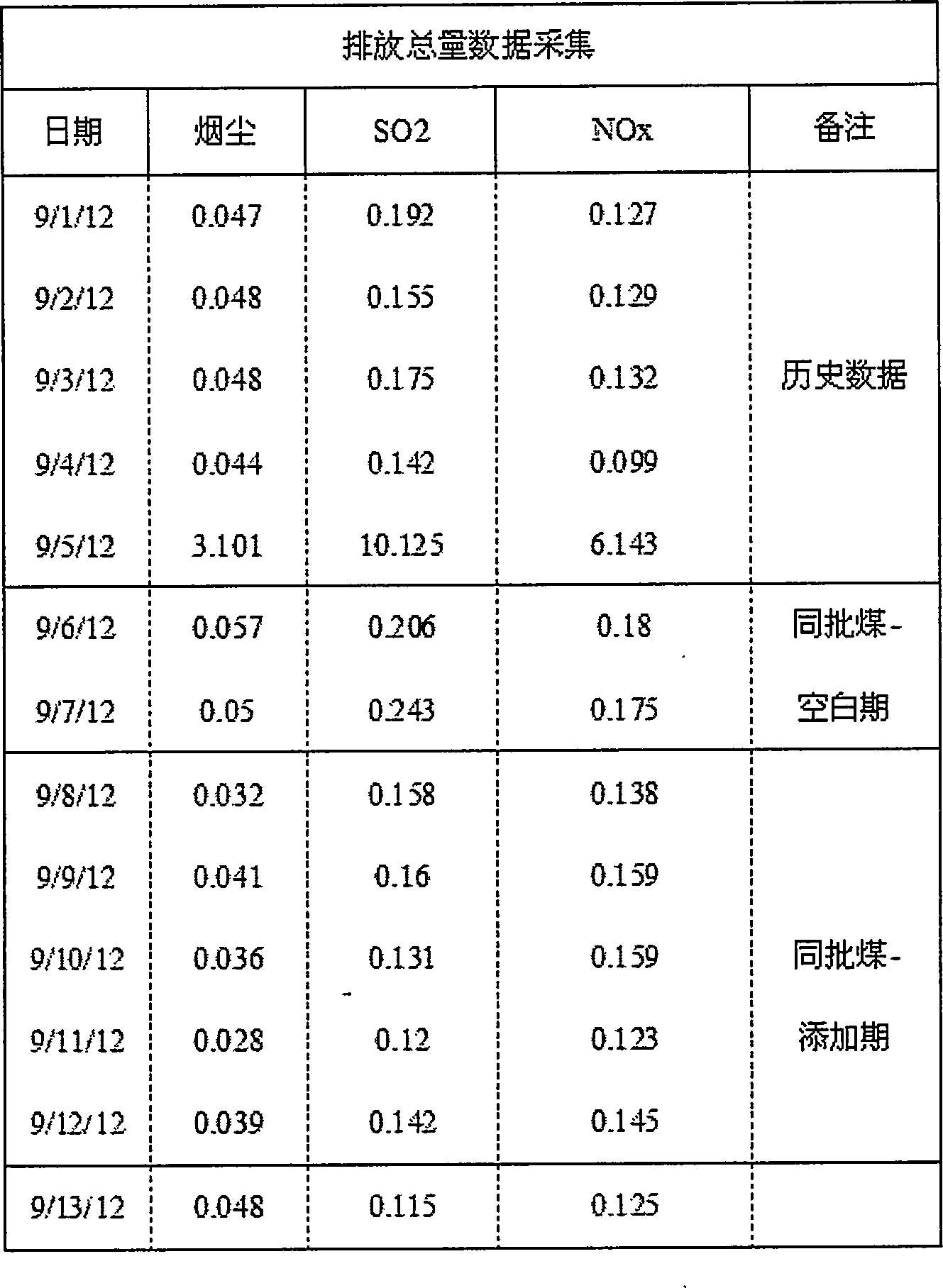

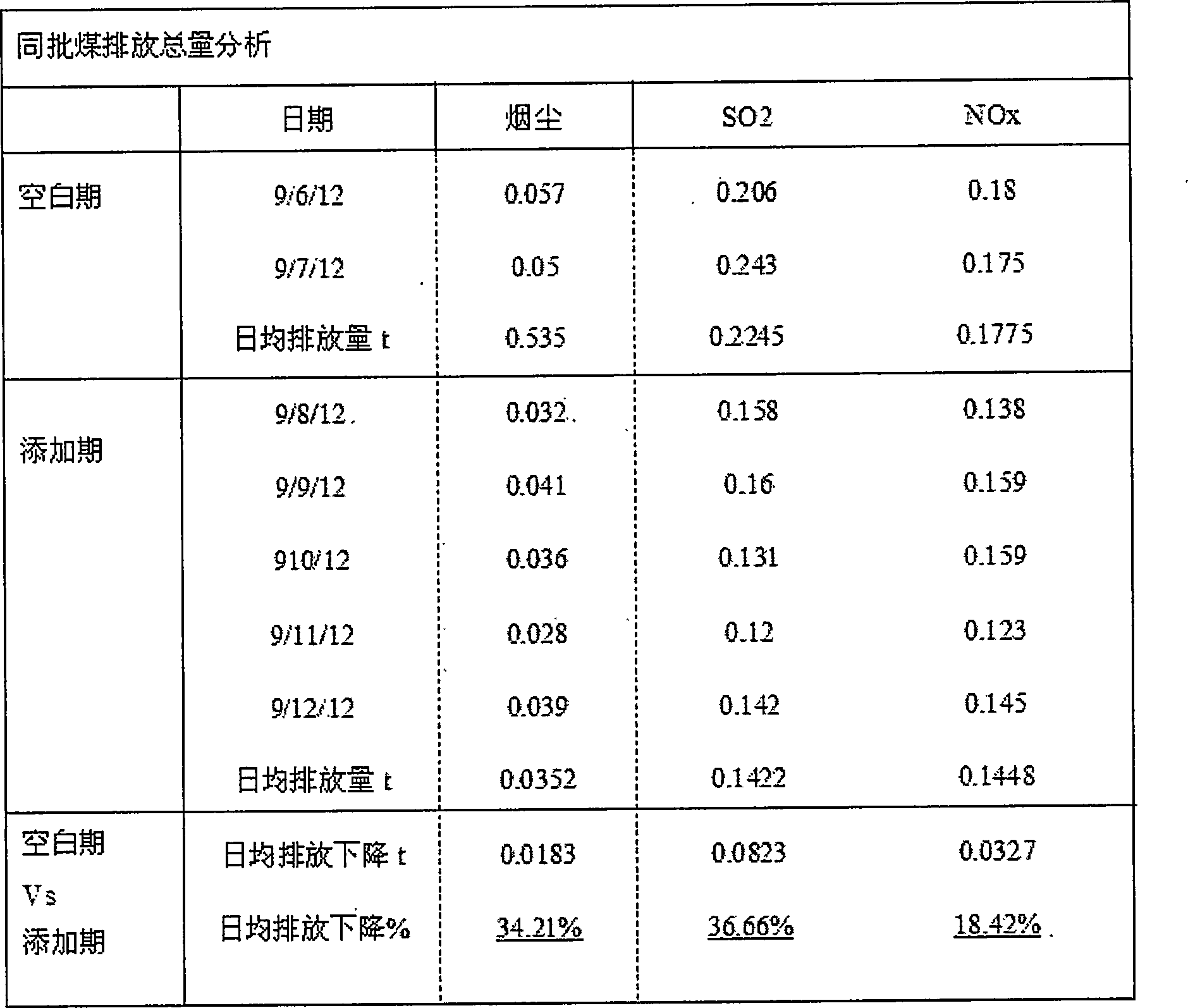

[0052] according to Figure 1-3As shown, the addition of active carbon can make the coal-fired fire zone advance after entering the furnace, and play a significant role in combustion.

[0053] During the addition period, the smoke dust and SO were greatly reduced 2 , NOx emission concentration, the reductions reached 34.21%; 36.66%; 18.42% respectively. Long-term use of live carbon brings immeasurable indirect economic benefits to enterprises, mainly including:

[0054] a. Reduce boiler maintenance times and related costs;

[0055] b. Extend the service life of the boiler;

[0056] c. Reduce boiler fouling, prolong the life of boiler accessories, reduce the number of replacement and cleaning.

[0057] d. After using activated carbon, SO can be greatly reduced x , NO x The emission is in line with the national emis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com