Patents

Literature

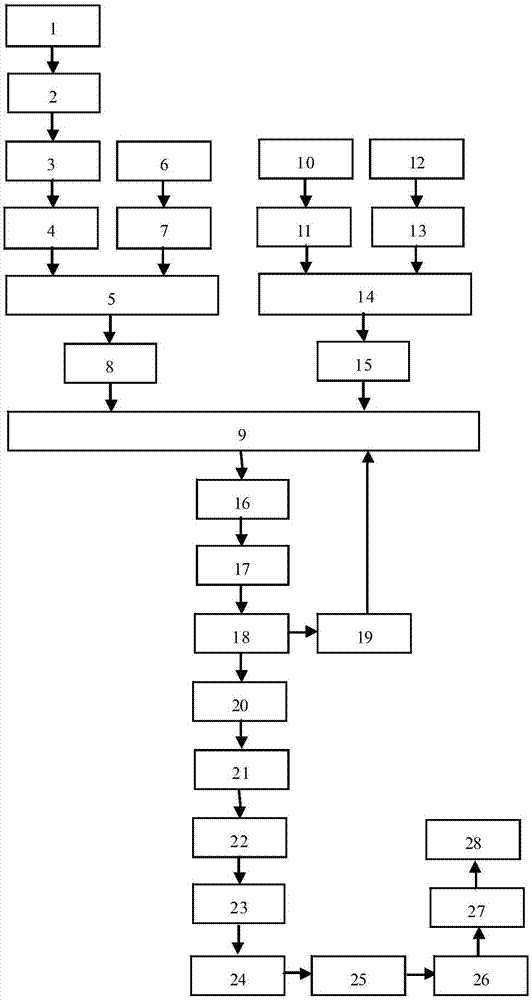

680 results about "Activated charcoal powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Capture of mercury from a gaseous mixture containing mercury

InactiveUS20070104631A1Increase concentrationGas treatmentUsing liquid separation agentChemistryActivated carbon

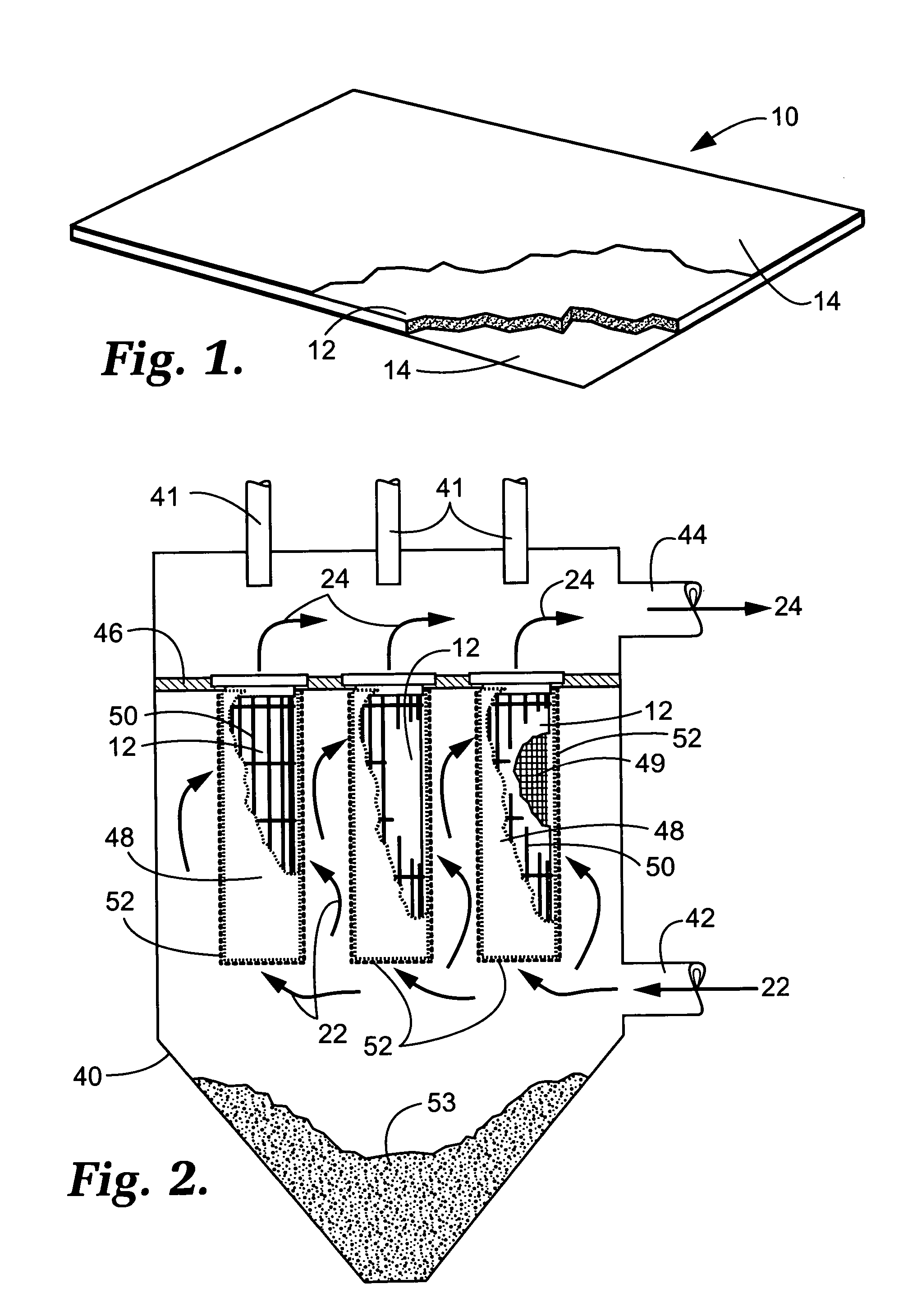

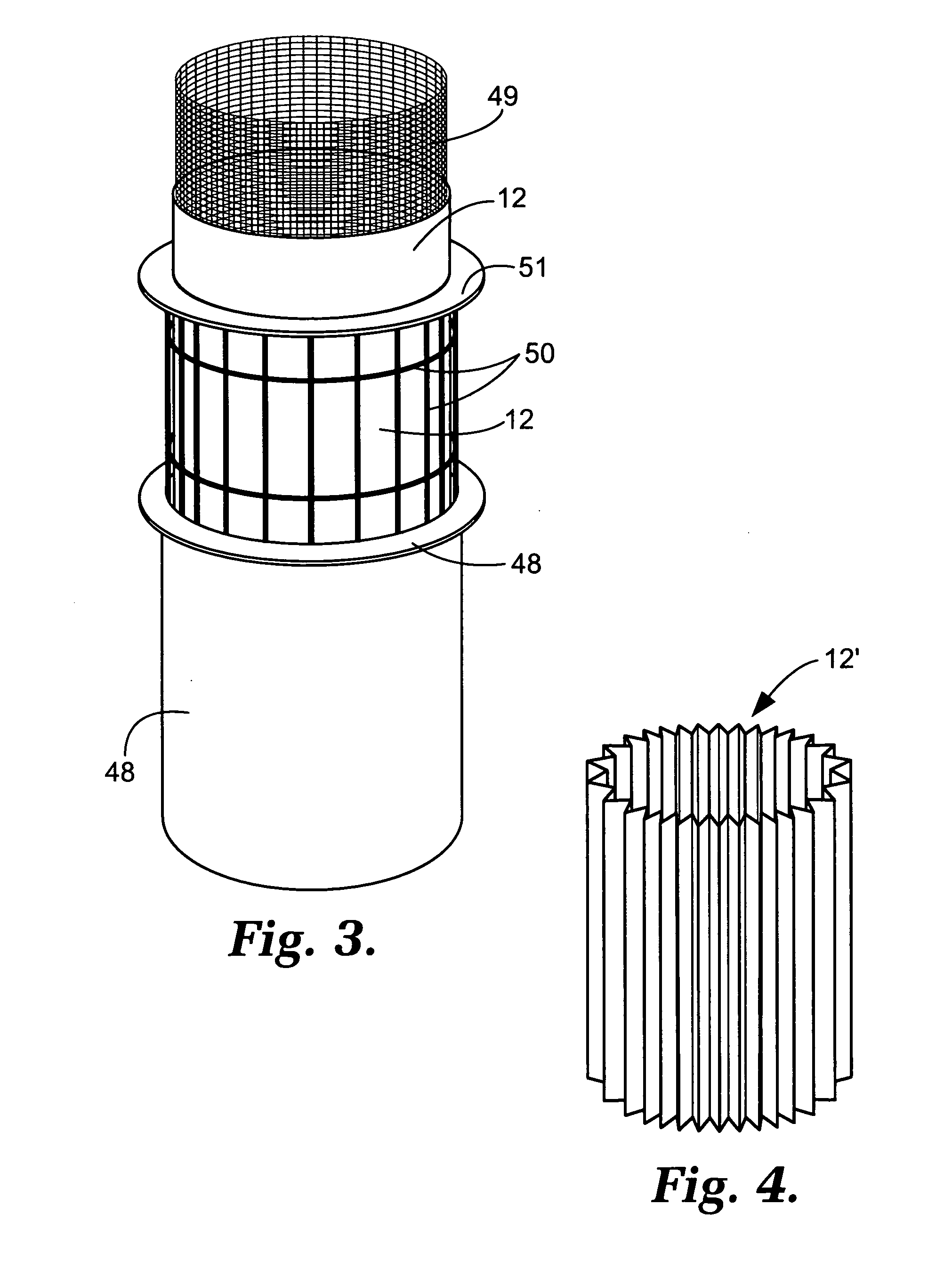

Compositions are provided, derived from chemical treatment of carbonaceous fiber felt forms or other carbonaceous substrates, that exhibit both high efficiency and capacity for mercury capture from flue gases and the like. These compositions are superior to known compositions, particularly with regard to their performance under severely deactivating conditions. The compositions result from the pyrolysis of certain specific sulfur bearing compounds while in contact with activated carbon powders, activated carbon fibers, or with other carbonized forms. Precursor compounds to these novel mercury-binding compositions contain structural moieties that may be represented as: where X, Y are individual atoms or are functional groups consisting of several atoms, such that the atom bonding to sulfur is not hydrogen. X and Y can be linked in cyclic structures, either directly or through other atoms.

Owner:WL GORE & ASSOC INC

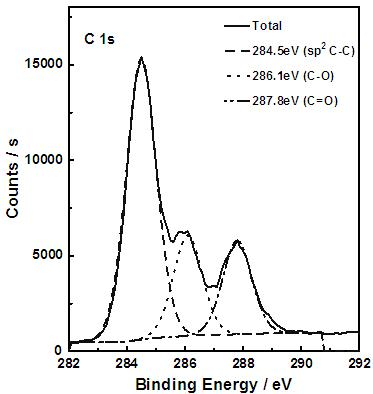

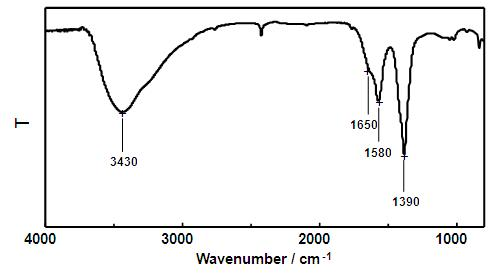

Method for extracting carbon quantum dots from activated carbon

ActiveCN101973541AUniform particle sizeImprove photoelectric performanceNanostructure manufactureLuminescent compositionsActivated charcoal powderCarboxyl radical

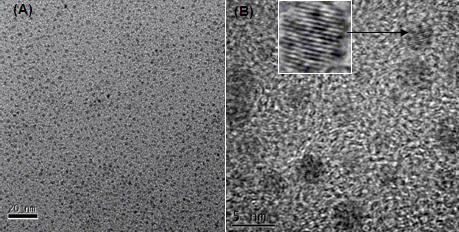

The invention provides a method for extracting carbon quantum dots from activated carbon, which comprises the following steps of: adding dry activated carbon powder to salpeter solution and stirring for backflow; performing reduced pressure distillation for evaporating suspension obtained by backflow to dryness; dispersing obtained black solids in water, and neutralizing obtained solution with sodium hydroxide; and finally, centrifugating neutralized black suspension for removing precipitation, separating supernatant fluid by using an ultrafiltration centrifugal tube or an ultrafiltration membrane, collecting filtrate, and drying the filtrate to obtain carbon quantum dots. The method uses cheap and available activated carbon as carbon sources, and can obtain a large number of carbon quantum dots by simple chemical oxidation process and simple subsequent processes of evaporation, saturation, centrifugation and ultrafiltration. The carbon quantum dots are graphite structure nanocrystals with the grain diameter of 3 to 5 nm, the surfaces of which have a large amount of hydroxide radicals. The carbon quantum dots have good fluorescence and electrochemiluminescence.

Owner:FUZHOU UNIV

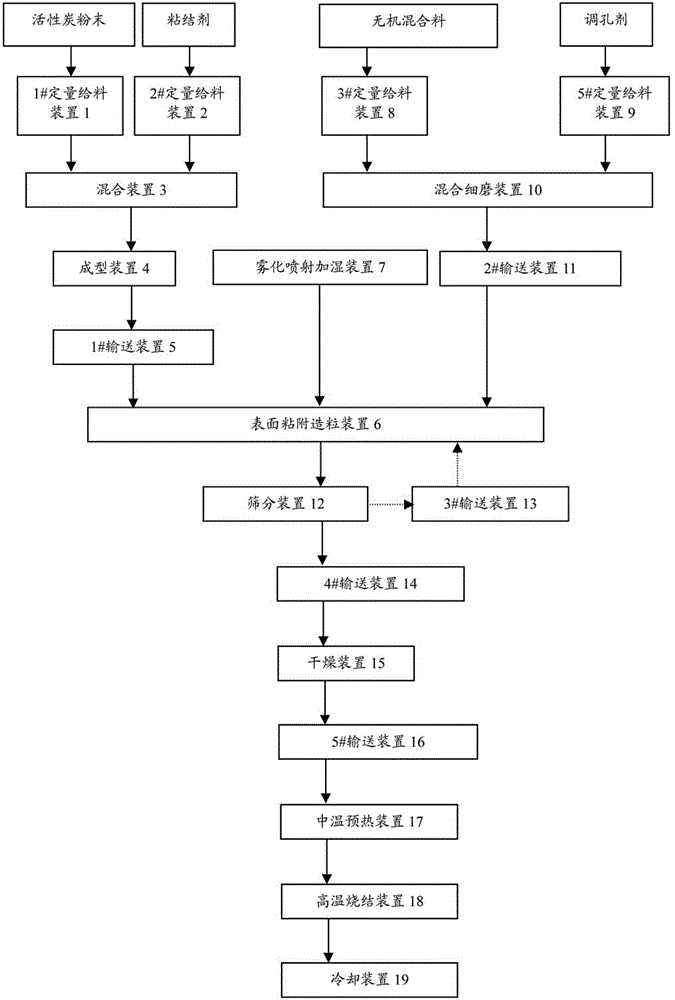

Method and device for preparing surface-vitrified carbon adsorption material

ActiveCN104941579AHas comprehensive adsorption propertiesExtended AdsorptionOther chemical processesActivated charcoal powderVitrification

The invention discloses a method and a device for preparing the surface-vitrified carbon adsorption material. Activated carbon powders are mixed with a binder to be shaped up to prepare activated carbon core granules. After that, an inorganic mixture is mixed with pore-adjusting agent to be ground to prepare the vitrification material. The activated carbon core granules are adopted as mother balls and the ceramic material is uniformly adhered onto the surfaces of the carbon core granules. In this way, carbon granules coated by a ceramic raw-material shell are obtained. The carbon granules are dried, preheated at a medium temperature and sintered at a high temperature. After the introducing of nitrogen, the carbon granules are cooled to the room temperature and then discharged. In this way, surface-vitrified activated carbon granules can be obtained. The surface-vitrified carbon adsorption material has the comprehensive adsorption properties of activated carbon and porous ceramic materials and can absorb polar or non-polar pollutants, especially the combined pollutants of heavy metal pollutants, organic contaminants and the like. Meanwhile, PM 2.5 composite pollutants in the flue gas can be purified. The surface-vitrified carbon adsorption material can be further expanded and applied to the cyclic adsorption and removal of the combined pollutants of heavy metal pollutes, N, P, organics and the like in the waste water. The method is simple and practical in technique, small in investment, low in cost, and good in economic and environmental benefits.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

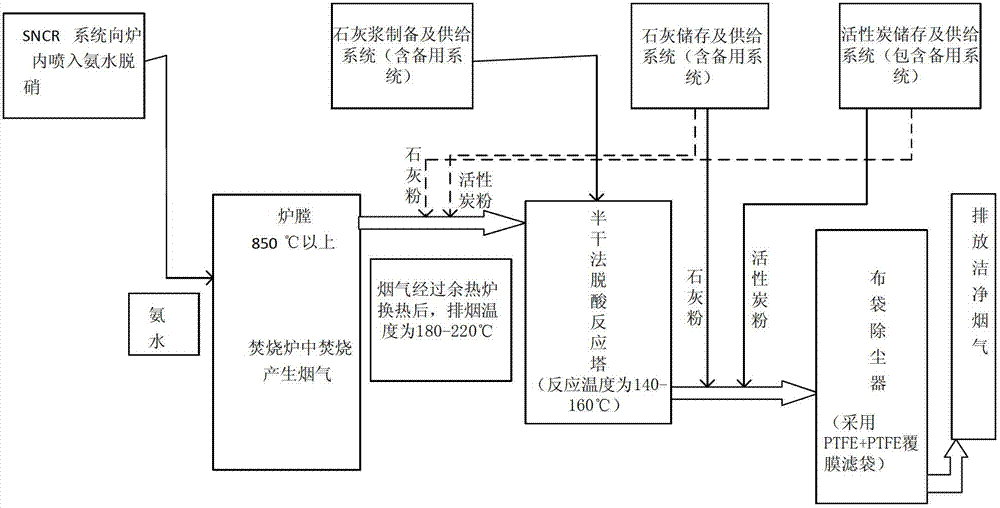

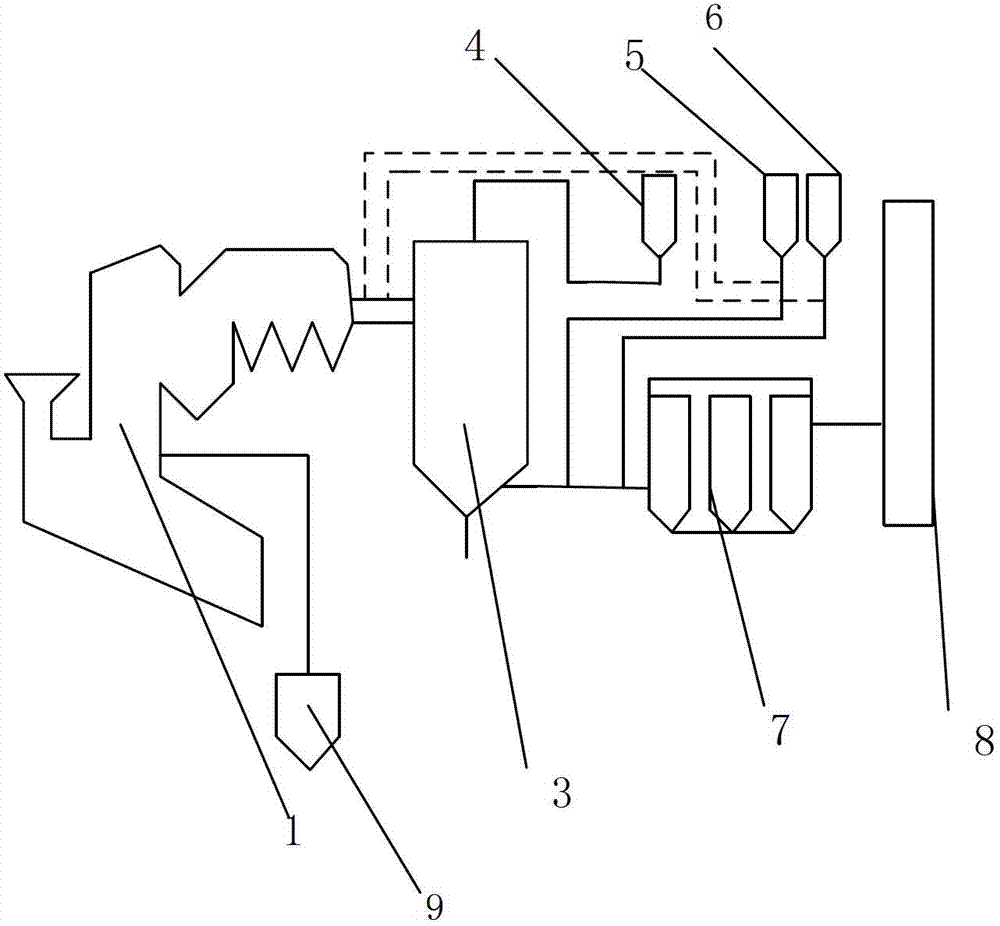

Method and device for fume purification treatment in waste incineration

InactiveCN102728194AControllable investment costControllable operating costsDispersed particle filtrationActivated carbonOperational costs

The invention relates to a method and a device for fume purification treatment in waste incineration. The method comprises steps of denitration, semidry-method deacidification, dry-method deacidification, activated carbon adsorption and cloth-bag dust removing; in the semidry-method deacidification step, a temperature reducing water system which is independent from lime slurry is adopted to control the deacidification reaction temperature to be 140-160 DEG C; and the dry lime powder for the dry-method deacidification and the activated carbon powder for the activated carbon absorption can be injected prior to the semidry-method deacidification or injected after the semidry-method deacidification. The device aims at analyzing and improving the prior art and further inspecting after the improvement; indexes in fume discharge can reach the standard 2000 of the European Union continuously and stably; furthermore, the investment and operation cost are controllable and lower; the process is simple; the operation management is convenient; and no secondary liquid pollution is caused.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECHCAL DEV BEIJING +3

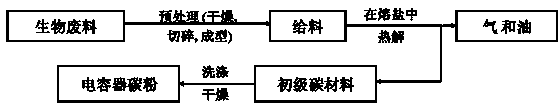

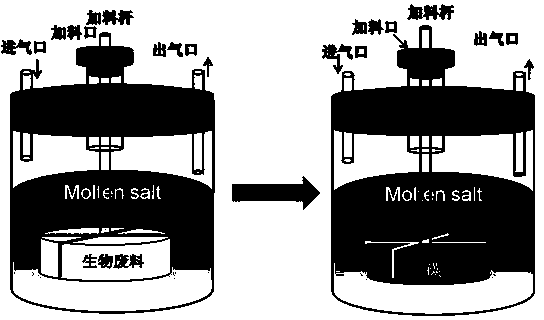

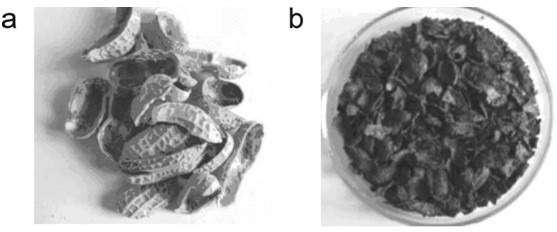

Method for preparing capacitive active carbon powder through biomaterial treated by fused salt

The invention relates to a method for preparing capacitive active carbon powder through a biomaterial treated by fused salt, and belongs to the field of carbon materials. The method comprises the following steps: washing, drying and mincing a waste biomaterial, and preparing the waste biomaterial into a feed material in a definite shape; wrapping the prepared feed material by using a mesh bag made from high-temperature resistant materials or a basket, and fixing on an operating rod made from the high-temperature resistant materials; heating the fused salt to 750-850 DEG C, then immersing the feed material into the fused salt for cracking, and lifting to the upper part of a reactor after 1 hour, and cooling in an inert atmosphere; finally washing a small amount of salt contained in a product by using water so as to prepare active carbon. The method disclosed by the invention can not only be used for recycling the waste biomaterial, but also be used for preparing the active carbon, and changing wastes into valuables.

Owner:WUHAN UNIV

Electro-catalytic oxidation material for wastewater treatment, preparation method and application

ActiveCN102659221AAchieve the purpose of processingQuick releaseWater/sewage treatment by oxidationChemical oxygen demandPolyvinyl alcohol

The invention discloses an electro-catalytic oxidation material for wastewater treatment. The material comprises 30 to 60 percent of iron powder, 1 to 2 percent of aluminum oxide, 1 to 2 percent of nickel oxide, 2 to 4 percent of titanium oxide, 2 to 4 percent of aluminum silicate, 3 to 5 percent of water glass, 20 to 30 percent of active carbon powder, 1 to 3 percent of polyvinyl alcohol, and 10to 20 percent of graphite powder. The material is prepared by the following steps of: adding water into raw materials to form a thick material, pressing the thick material into granules, blocks or discs through a forming machine, demoulding, drying in an oven, and calcining in a high-temperature furnace to obtain a porous carbon electrode material of which the yield reaches 95 percent. The porouscarbon electrode material is put into a reactor; the pH value of the wastewater is regulated and aeration is performed when the water is added, and Fenton reaction is produced when hydrogen peroxide is added for cooperative work; in high-concentration organic wastewater treatment indexes of nano-filtration (NF) or reverse osmosis (RO) membrane concentrate of purified garbage leachate and the like, good technical effects on chemical oxygen demand (COD), ammonia nitrogen concentration and chromaticity are achieved; and the aim of discharging the industrial wastewater with standards is fulfilled.

Owner:深圳市地大东江环境研究院

Carbon/nickel-cobalt layered double hydroxide composite material and preparation method and application thereof

InactiveCN105489389AObvious cost advantageImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureActivated charcoal powderCapacitance

The invention provides a carbon / nickel-cobalt layered double hydroxide composite material which is prepared according to the following method that carbonization treatment is performed on raw material wood powder under the atmosphere of nitrogen; then the carbonized product is uniformly mixed with alkali and water, and most of the water of the mixture is heated and evaporated and then activation treatment is performed so that alkali activated charcoal powder is prepared; the alkali activated charcoal powder is added in a nitrogen doped solution, and hydrothermal reaction is performed ultrasonic uniform mixing so that nitrogen doped activated charcoal powder is prepared; the nitrogen doped activated charcoal powder is added in deionized water, and the mixed solution of nickel salt and cobalt salt is added after dispersion; an alkali solution is added after temperature rising and stirring, and heat preservation and stirring reaction is continued; and then the reaction solution is post-treated so that the finished product is obtained. Low-cost, environment-friendly, renewable and easily obtaining wood material acts as the raw material to prepare carbon material used for manufacturing of the carbon / nickel-cobalt layered double hydroxide composite material used for a supercapacitor so that the cost advantage is obvious. Besides, stability of the composite material can be enhanced by the nitrogen doped feature of the carbon material in the composite material so that capacitance output capability of the composite material can be enhanced.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Pd/TiO2/C composite nano-catalyst, and preparation method and application thereof

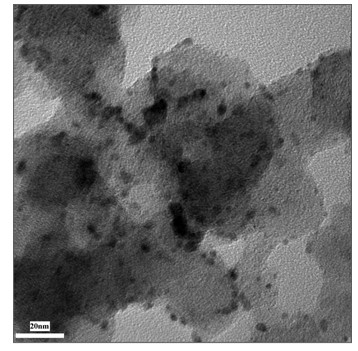

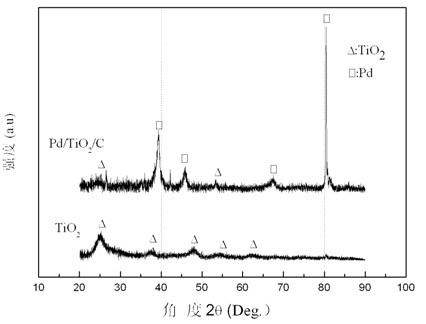

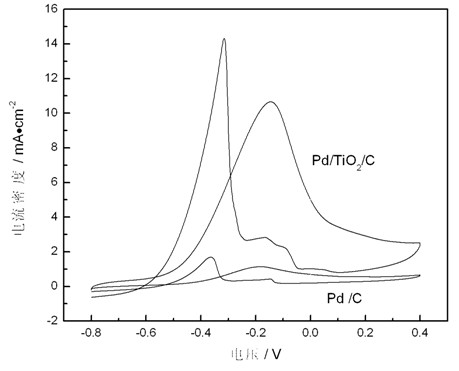

InactiveCN102544531AHigh catalytic activityImprove catalytic stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsNano catalystActivated charcoal powder

The invention discloses a Pd / TiO2 / C composite nano-catalyst and a preparation method thereof. The Pd / TiO2 / C composite nano-catalyst consists of nano-Pd, nano-TiO2 and active carbon powder, wherein the mass ratio of the nano-Pd to the nano-TiO2 to the active carbon powder is preferably 1:2:2. The preparation method comprises the steps of preparing nano-TiO2 powder by a hydrothermal synthesis method, preparing a mixed solution of a carrier consisting of active carbon and TiO2, loading Pd nanoparticles on the carrier consisting of the active carbon and the TiO2 by a liquid phase reducing method and the like. The nano-TiO2 with high stability in acid and alkaline solution and the treated active carbon form the composite carrier, so compared with the traditional carrier only comprising the active carbon, the Pd / TiO2 / C composite nano-catalyst has higher catalytic activity on ethanol and stability.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Preparation method of non-woven fabric for shoe linings

InactiveCN105019143AEasy extractionIncrease relative volatilityInsolesNon-woven fabricsActivated charcoal powderAfter treatment

The invention relates to the field of preparation of non-woven fabrics for shoe linings and discloses a preparation method of non-woven fabric for shoe linings. The preparation method comprises following steps of: (1) taking and adding natural perfume to water, adding sea-foam stone powder to a solution, allowing mixed liquor to stand and obtaining sea-foam stone powder loaded with natural perfume by centrifugal and drying treatment; (2) additionally taking activated charcoal powder, aluminum chloride, polyoxyethylene, carboxymethylcellulose, dispersants, silane coupling agents and sea-foam stone powder loaded with natural perfume in order to obtain a mixture; (3) fusing isotatic polypropylene slices and the mixture and performing spinning, drawing, web-forming and hot-rolling operation in order to obtain base cloth of the non-woven fabric; (4) utilizing finishing liquor to process one of surfaces of the base cloth of the non-woven fabric and performing roll-pressing operation on the base cloth after treatment; (5) drying the base cloth of the non-woven fabric subjected to roll-pressing operation and thus obtaining the non-woven fabric for shoe linings. The preparation method of non-woven fabric for shoes is good in deodorization function and breathability and high in hardness so that the shape of a vamp can be kept for a long time.

Owner:LANXI YIMING WEAVING

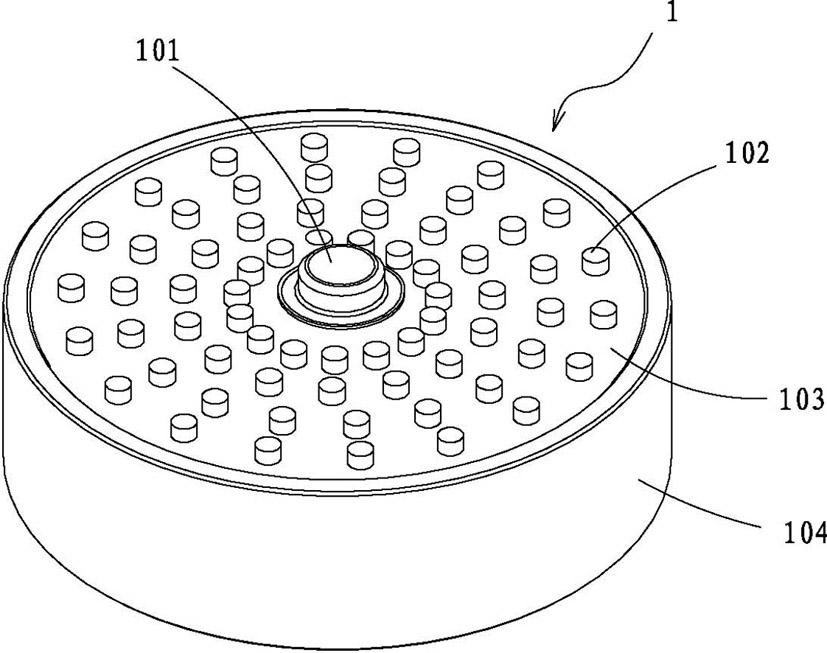

Preparation method of special activated-carbon electrode block for capacitive deionizing equipment

ActiveCN106395814AReduce manufacturing costEase of mass productionCarbon compoundsDispersed particle separationActivated charcoal powderFiber

The invention provides a preparation method of a special activated-carbon electrode block for capacitive deionizing equipment. Activated carbon powder, a binding agent, a carbon fiber, expanded graphite powder and conducting carbon black are loaded in a material box to be mixed; an obtained first mixture is agitated and mixed uniformly; the agitated and mixed first mixture is kneaded to be paste with plasticity; the well mixed paste is molded into a green compact in a fixed shape in molding equipment. The green compact is loaded in a heating furnace to be subjected to high-temperature calcination under the protection of a filling material; a primary product of the electric block is obtained. The primary product is made into an electrode according to the size, the shape and the precision needed by the electrode by adopting cutting machining. Finally, the activation treatment is carried out on the electrode; the electrode is made into a final product of the electrode. The method is low in preparation cost, and is easy for large-scale production. No binding agent resides in the electrode; the conductivity is good; the electrode is good in integrality and high in mechanical strength; the electrode can be cut to be in various needed shapes. The electrode can be used for preparing a capacitive deionizing device, and is used for the desalting treatment of water or the removal of harmful ions such as heavy metal ions, hardness, fluorine ions and the like in the water.

Owner:ZHEJIANG DOWAY ADVANCED TECH CO LTD

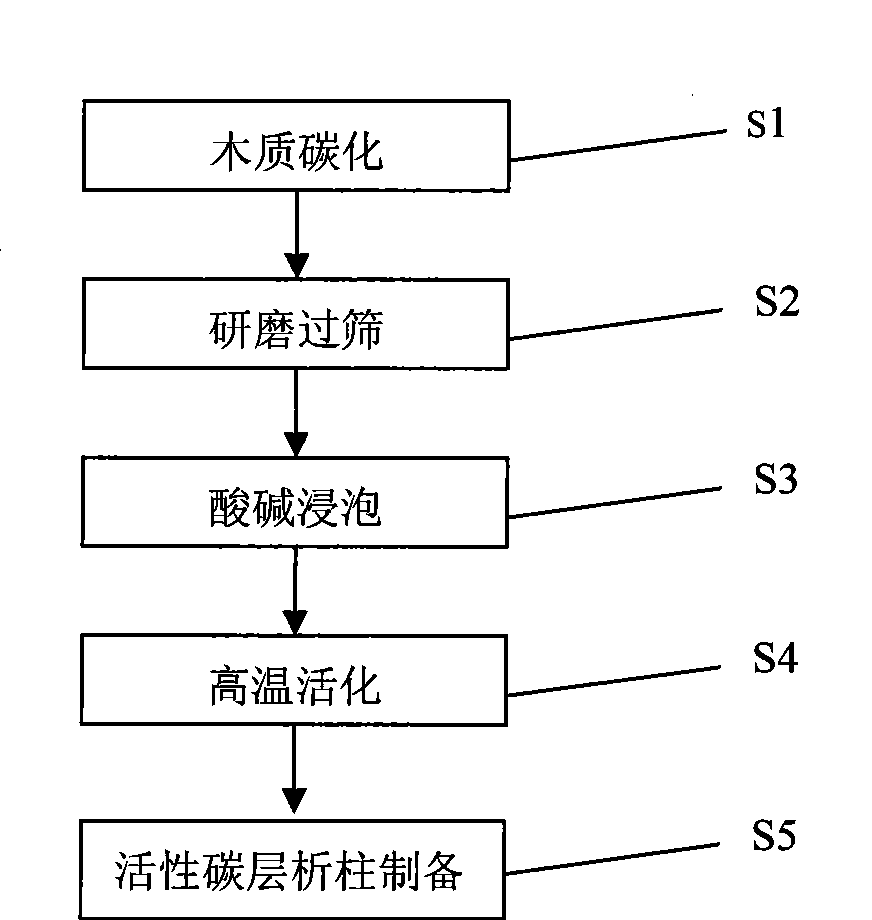

Preparation of modified active carbon

The invention discloses a method for preparing modified activated charcoal. The method comprises the following process steps that: a woody material is dried, thermally decomposed and carbonized at a high temperature; charcoal blocks after carbonization are crushed, ground and sieved so as to obtain charcoal powder; the charcoal powder which is ground and sieved is adequately soaked in a hydrochloric acid solution and a sodium hydroxide solution in turn; the charcoal powder which is soaked in the hydrochloric acid solution and the sodium hydroxide solution and dried is activated in a high-temperature furnace; and the activated charcoal powder after high-temperature activation and anhydrous sodium sulfate are put into a glass chromatography column containing acetone in turn so as to prepare an activated charcoal glass chromatography column. The method for preparing the modified activated charcoal has the advantages of low cost, easy operation and applicability to the separation of sixteen types of organic chloride pesticides and ten types of polychlorinated biphenyls in marine environmental samples (marine organisms, marine sediments and seawater).

Owner:NATIONAL MARINE ENVIRONMENTAL MONITORING CENTRE

Preparation method of environment-friendly and health-care type artificial stone board for interior home

InactiveCN103588434ARaw materials are cheap and easy to getReduce manufacturing costActivated charcoal powderPolymer modified

The invention discloses a preparation method of an environment-friendly and health-care type artificial stone board for interior home. Dry powder of polymer-modified cement mortar is adopted as an adhesive, a activated carbon powder material with high adsorbability and an tourmaline powder material with anion generating capability are added as fillers, under assistance of other artificial stone base layer materials and auxiliaries, the mixture is subjected to vacuumizing, high-frequency vibration, vacuum lamination and moderate-temperature curing in sequence in a mold to produce a square stock or a rough board, and finally the environment-friendly and health-care type artificial stone board for interior home is produced after cutting, thickness setting, grinding and polishing. According to the method, raw materials for the production are cheap and available, artificial stone production equipment used in the prior art can still serve as production equipment, and the production cost is low; and from production, processing to finished product processing, the produced artificial stone is nontoxic, free from contamination and environmental-friendly, and has functions of absorbing toxic gas in air, purifying the air and releasing anion which is beneficial to human body and mind, and further, the living environment of people is improved.

Owner:佛山市欧泊石业有限公司

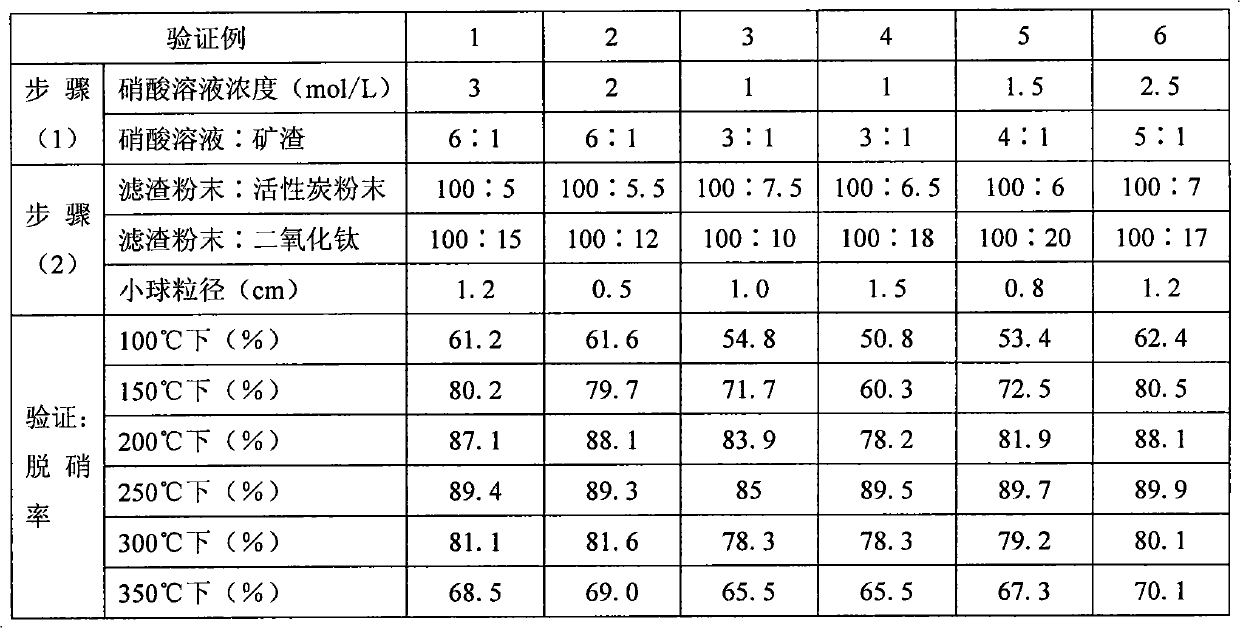

Method for preparing SCR (Selective Catalytic Reduction) denitration catalyst by slag and catalyst thereof

InactiveCN102000563ALow raw material costHigh low temperature activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActivated charcoal powderPtru catalyst

The invention relates to a method for preparing SCR (Selective Catalytic Reduction) denitration catalyst by slag and a catalyst thereof. The catalyst uses slag remained after potassium manganate is extracted as a main raw material. The preparation method comprises the following steps of: washing slag by a nitric acid solution, filtering the slag, drying and pulverizing; fully mixing filter slag powder with active carbon powder; then after adding titanium dioxide sol and deionized water for being adjusted into proper slurry, rubbing into strips and preparing small balls; and drying and roasting in sequence for activating. Compared with the prior art, the SCR denitration catalyst has catalytic activity in the range of smoke temperature of 150-350 DEG C and higher catalytic activity compared with the prior art within 200 DEG C and 300 DEG C (particularly 250 DEG C or so); and by applying the catalyst of the invention for carrying out SCR denitration, the denitration rate is high. The invention also has the advantages of raw material cost saving, elimination of pollution of high-valence manganese-contained wastes on environment and simple preparation process.

Owner:CHONGQING UNIV

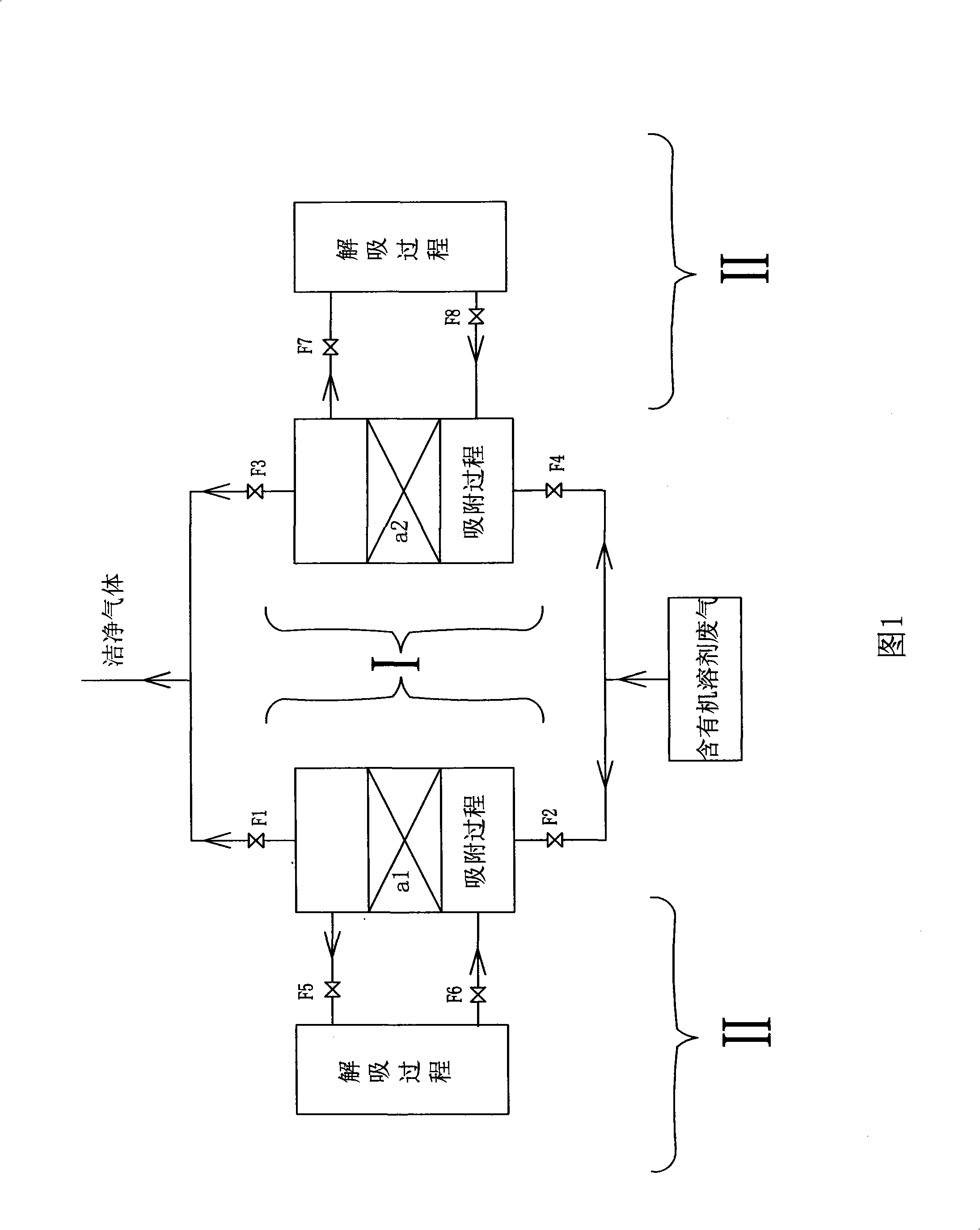

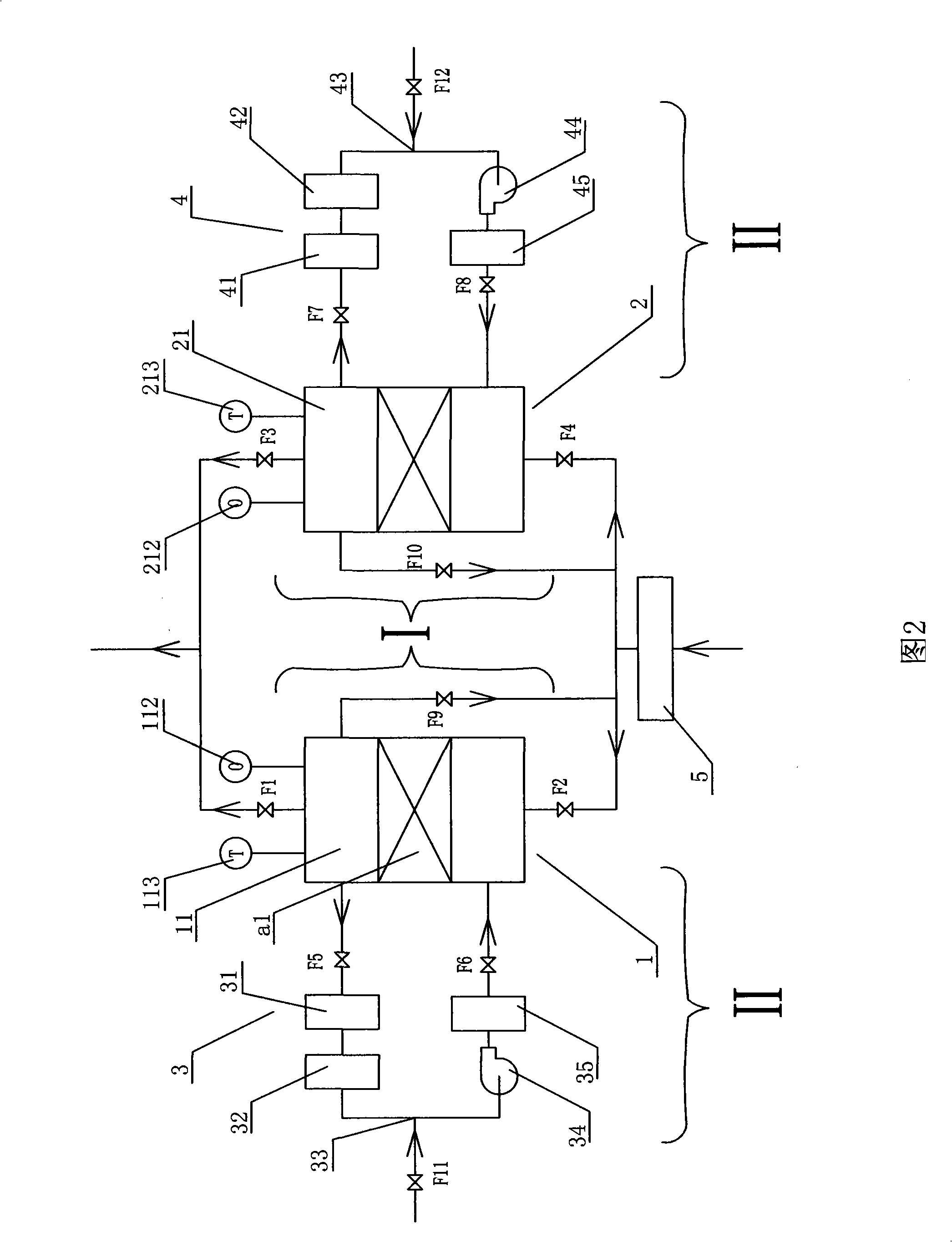

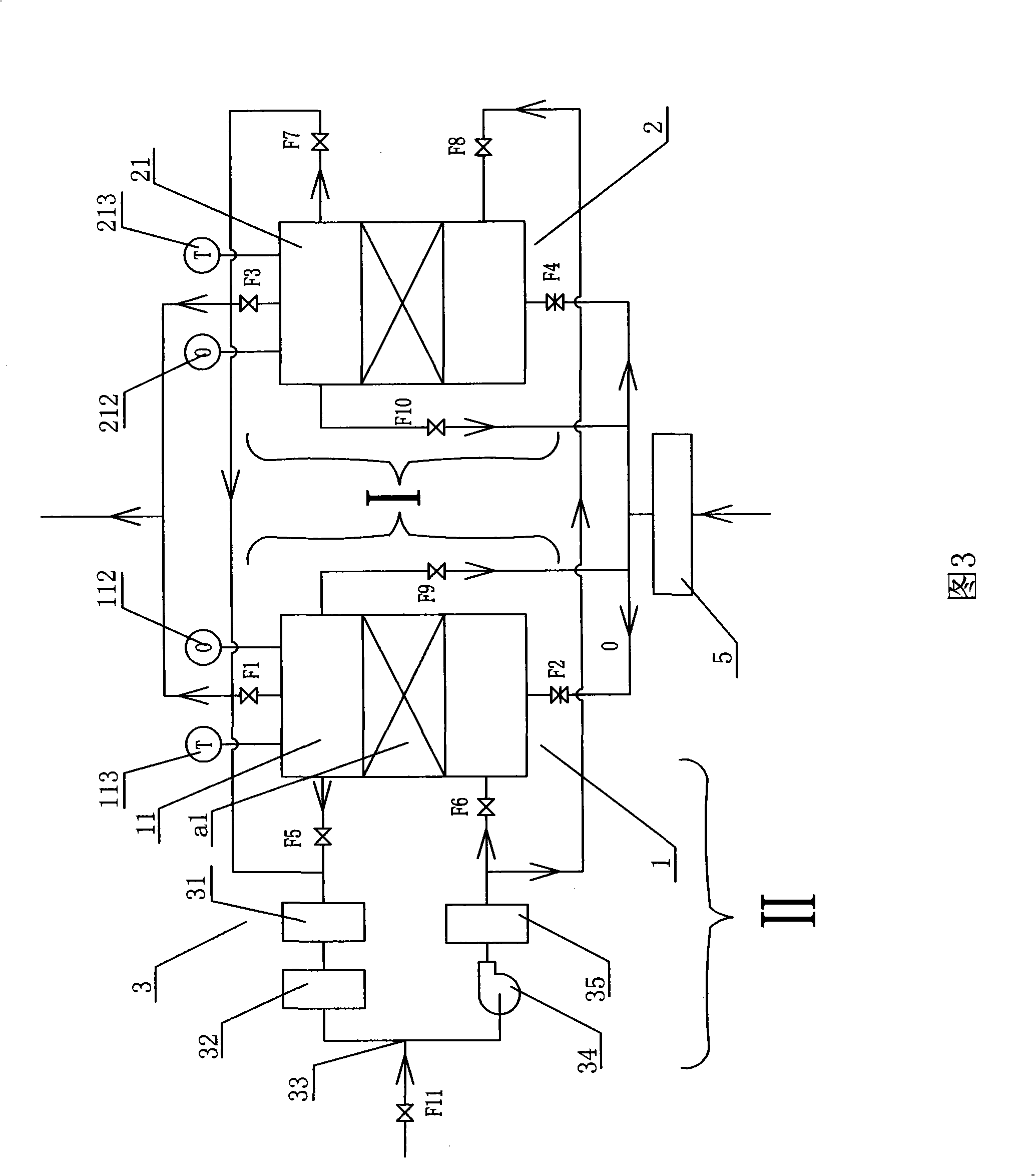

Organic gas withdrawal processing technique and device thereof

ActiveCN101310825AImprove adsorption capacityReduce manufacturing costDispersed particle separationActivated carbonMolecular sieve

The invention relates to an organic waste gas recycling and processing technique and a device thereof, absorption materials are adopted to absorb organic solvents in waste gas, the waste gas can be changed into clean gas after the absorption to be directly exhausted to atmosphere, when the absorption materials absorb a certain amount of the organic solvents, the absorption materials are carried out the desorption, thus desorbing the absorbed organic solvents, the absorption capacity of the absorption materials is recovered, then the absorption materials are re-input the absorption operation for the sequential circulating operation; at least two groups of absorption materials are adopted for alternate operation, when one group of the absorption materials are in the absorption process, the other group of the absorption materials are in the desorption process; the absorption materials take superfine molecular sieve powder or activated carbon powder as raw materials and are prepared by adding inorganic fibers or activated carbon fibers and inorganic binders, and the structure thereof is a cellular structure. The device can not only maintain the durable absorption capacity of the absorption materials, but can also have strong absorption capacity, low production cost and long service life.

Owner:马军

Manganese oxide coated activated carbon catalyst and preparation method and application thereof

InactiveCN106807362AAvoid uneven loadHigh load rateWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsAdhesiveSolid particle

The invention belongs to the technical field of ozone catalysts, and discloses a manganese oxide coated activated carbon catalyst and a preparation method and application thereof. The method comprises the following steps: (1) uniformly mixing some activated carbon powder, an adhesive and a pore-forming agent; preparing a raw material core through a sugar-coating preparation machine; roasting the raw material core under the inert gas protection; and cooling to obtain an activated carbon carrier core; (2) uniformly mixing potassium permanganate solid particles, a manganese sulfate aqueous solution and the rest activated carbon powder; then transferring into the activated carbon carrier core; and preparing activated carbon particles through the sugar-coating preparation machine; and (3) sintering the activated carbon particles under nitrogen or carbon dioxide atmosphere to obtain the manganese oxide coated activated carbon ozone catalyst. According to the catalyst, the catalyzing active components are high in coating rate and uniform to disperse; the ozone oxidation performance and the reaction efficiency can be increased; organic matters which are hardly degraded in wastewater can be efficiently removed; meanwhile, the method is simple and applicable to ozone oxidation sewage treatment.

Owner:GUANGZHOU HUALYU ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

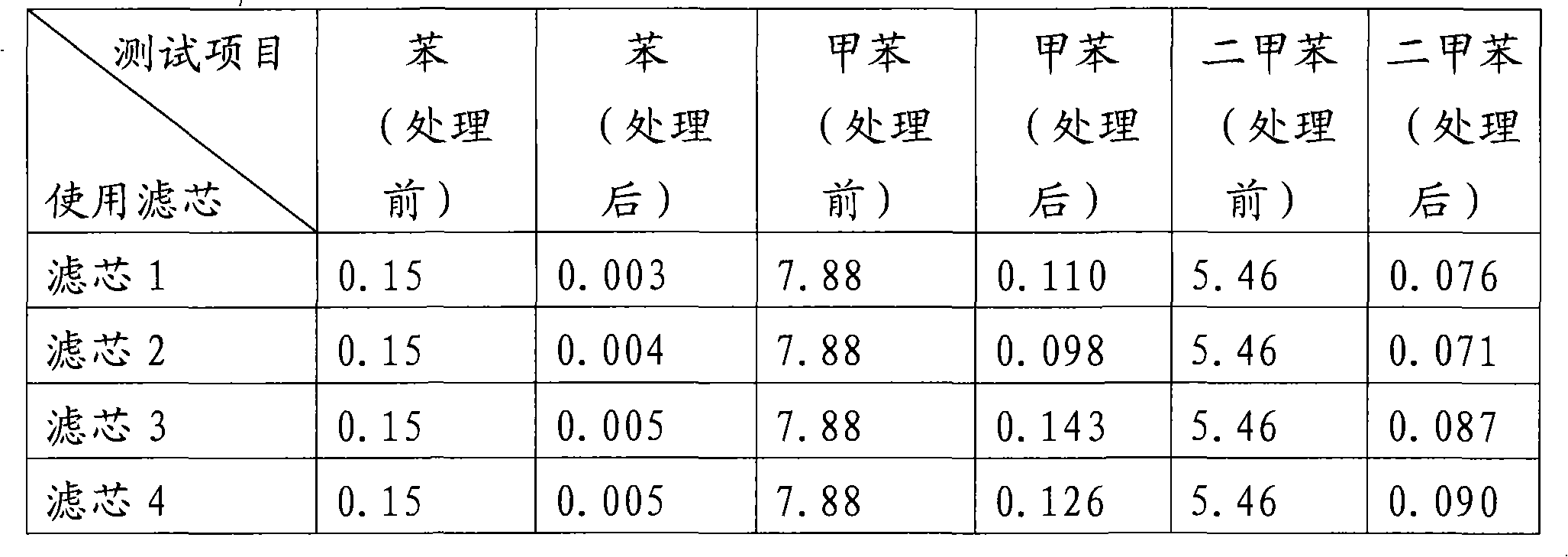

Filter medium for removing benzene and homologous compounds thereof from drinking water and preparation method thereof

InactiveCN101844005AEliminate damageHigh removal rateOther chemical processesFiltration separationHuman bodyActivated carbon

The invention discloses a filter medium for removing benzene and homologous compounds thereof from drinking water and a preparation method thereof, and also relates to a filter element, a water purifying plant and a water dispenser using the filter medium. The preparation method for the filter medium comprises the following steps of: a) mixing raw materials, namely powered activated carbon, zeolite powder, ultra-high molecular weight polyethylene powder, diatomite powder and a foaming agent in a weight ratio of 60-200:50-200:200-300:50-200:50-150; and b) performing mold pressing, sintering and cooling on the mixture obtained by the step a). The filter medium has the advantages that: the prepared filter medium has high removal rate for the benzene and homologous compounds thereof in the drinking water, so the benzene and homologous compounds thereof are prevented from harming human bodies; and the filter medium is simple and convenient to use, and is suitable for treating the drinking water at a home terminal. Through detection, the filter medium has the removal rate of 95 to 99 percent for the benzene and homologous compounds thereof in the drinking water.

Owner:QIDI ELECTRIC GROUP

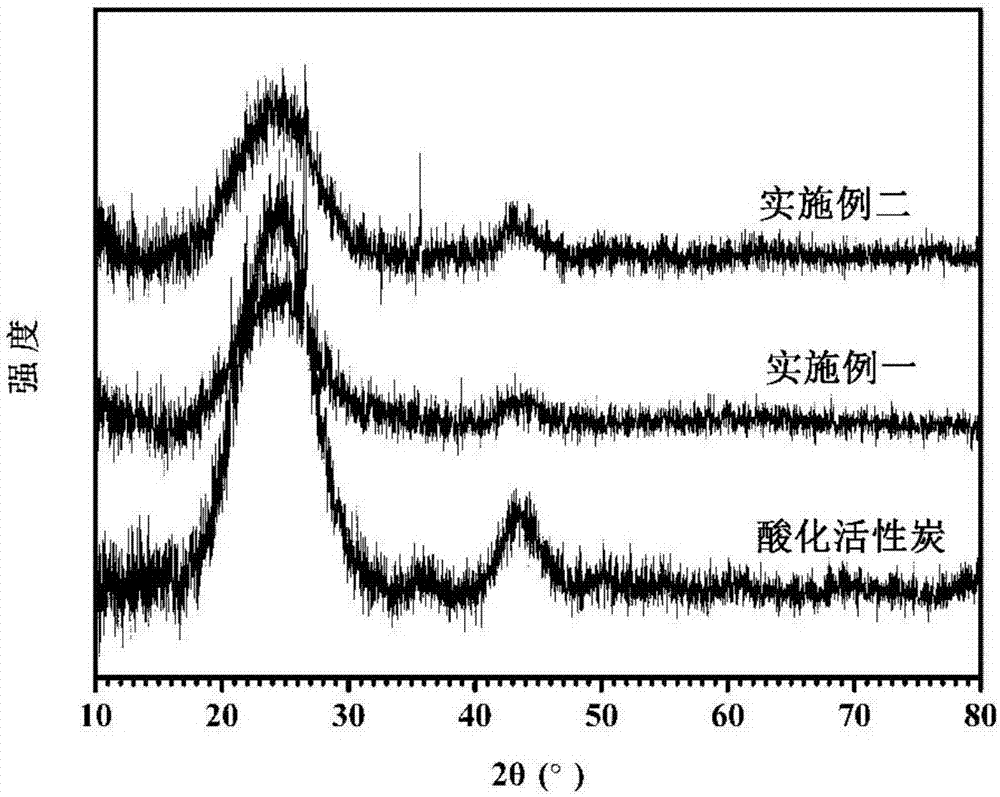

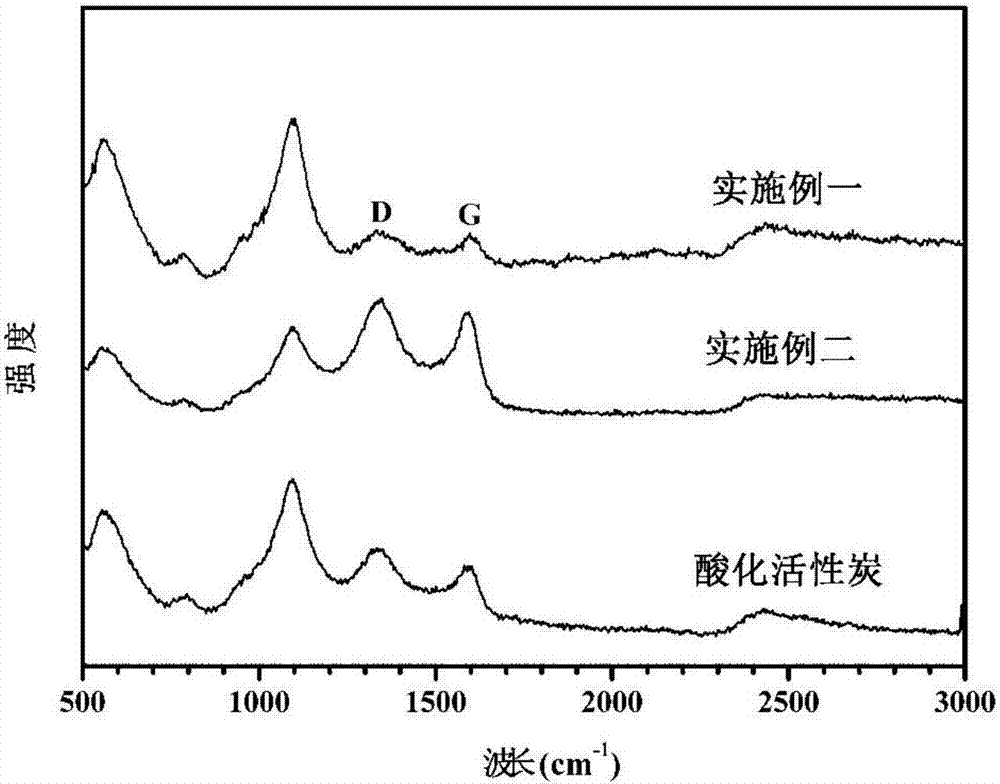

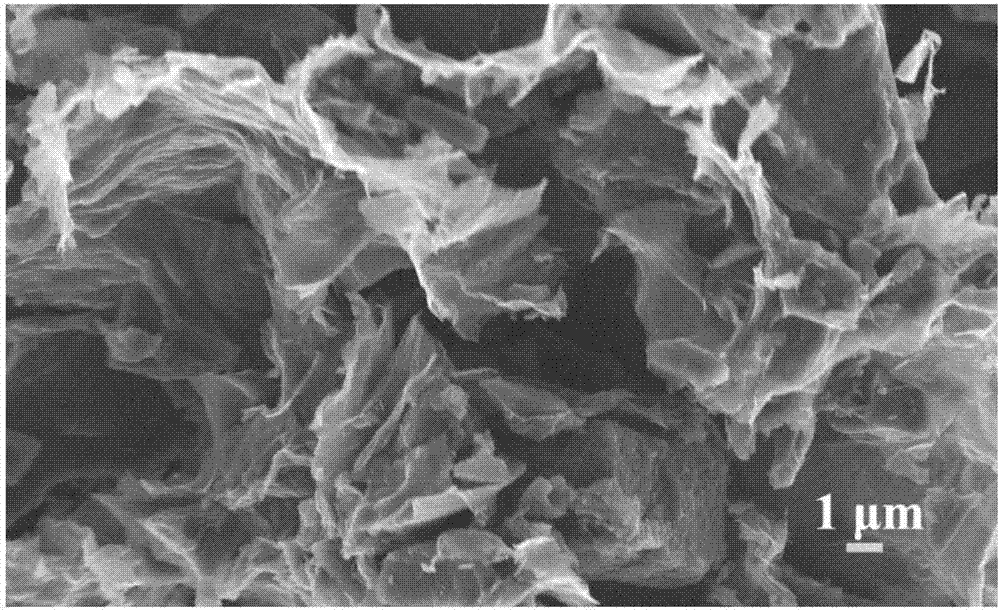

Graphene-loaded activated carbon composite material and preparation method thereof

ActiveCN107055532ALow commercial valueImprove conductivityHybrid capacitor electrodesGrapheneWater bathsActivated carbon

The invention relates to a graphene-loaded activated carbon composite material and a preparation method thereof. The preparation process of the material comprises the following steps of crushing activated carbon to be 1,000 meshes, carrying out acidification treatment on the activated carbon, and then cleanly washing and drying the activated carbon; carrying out ultrasonic treatment on a graphene oxide solution, so as to form a homogeneous solution; afterwards, immerging the acidified activated carbon into the solution, sufficiently agitating an obtained first mixture, then adding an ethylenediamine solution into the obtained first mixture, making an obtained second mixture react at a temperature of 80 DEG C in a water bath, and after a reaction is terminated, subjecting graphene loaded activated carbon to dialysis treatment; finally, washing and filtering the graphene-loaded activated carbon, and subjecting the graphene-loaded activated carbon to vacuum drying, so that the material is made. The method provided by the invention is simple in technique, and is simple and convenient to operate; by utilizing the excellent electric conduction performance of graphene, the graphene-loaded activated carbon composite material which is higher in conductivity and lower in cost is prepared; not only is the agglomeration phenomenon, which is generated due to surface electrostatic action, of the graphene overcome, but also the self electric conduction performance of the activated carbon is promoted; the conductivity of the composite material is increased by approximately 100 times.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

Bentonite clay particles and preparation method thereof

InactiveCN105727884ALarge specific surface areaImprove adsorption capacityOther chemical processesAlkali metal oxides/hydroxidesActivated carbonCarbonate

The invention discloses bentonite clay particles and a preparation method thereof.The bentonite clay particles are prepared from bentonite powder, activated carbon, carbonate and silicate, wherein the activated carbon accounts for 8-20% of the bentonite powder by mass, the carbonate accounts for 0.02-0.05% of the bentonite powder by mass, and the silicate accounts for 0.02-0.05% of the bentonite powder.The bentonite clay particles include activated carbon; due to addition of the activated carbon, multiple holes can appear in the bentonite clay particles, the specific surface area of the particles is increased, and the good adsorption capacity is achieved.

Owner:张兴华

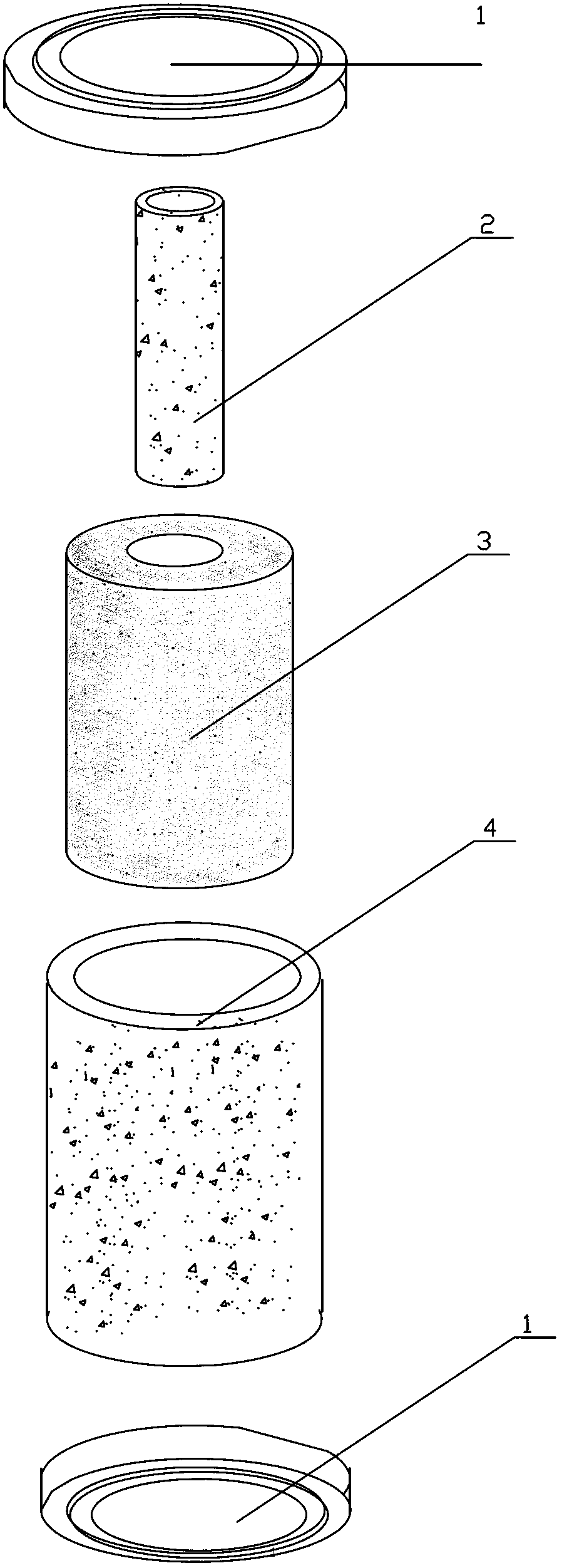

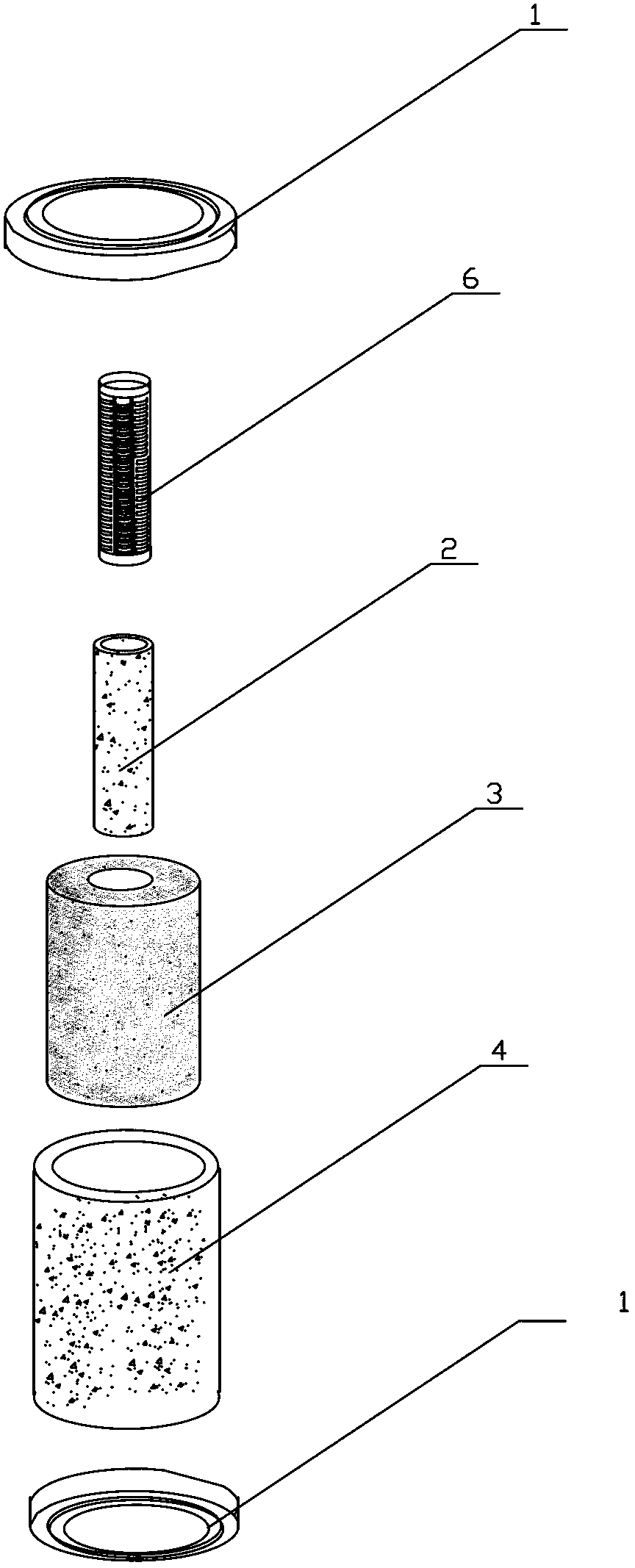

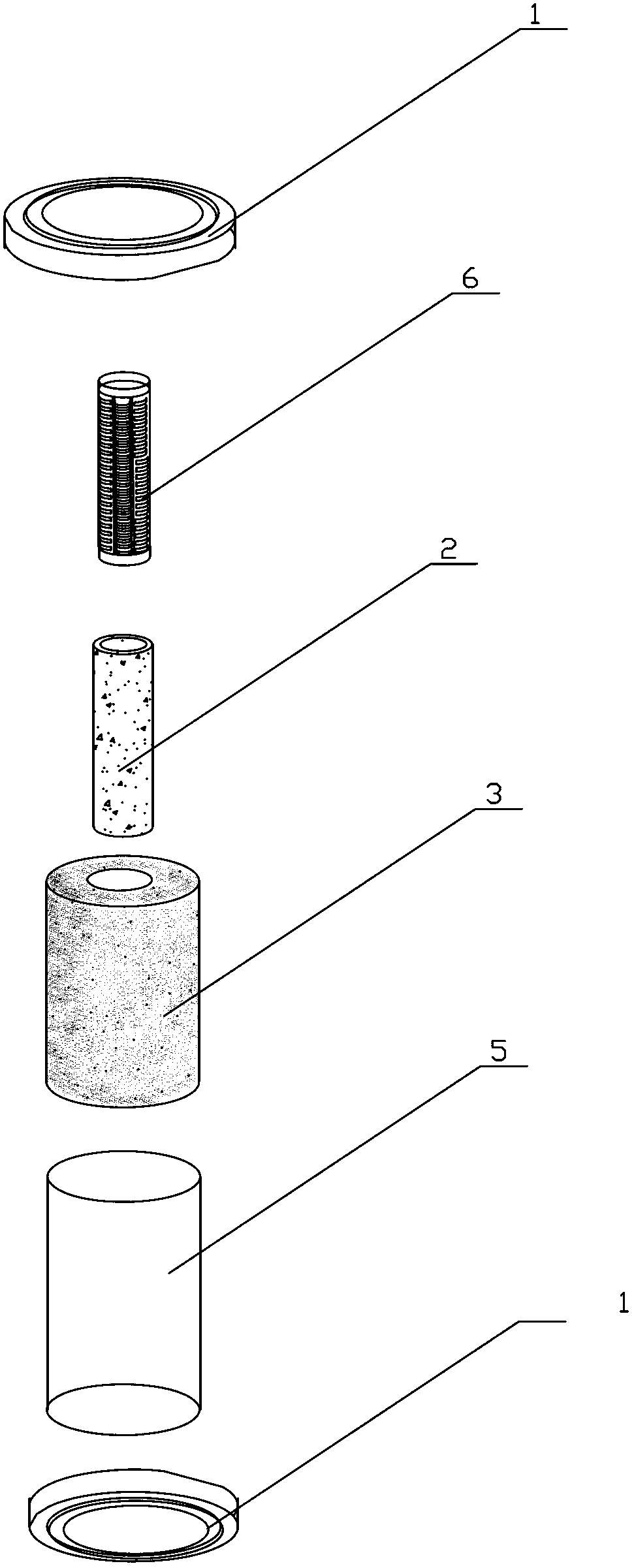

Two-in-one paper fiber powder activated carbon filter element and preparation method thereof

InactiveCN102698506AImprove adsorption capacityOvercome the disadvantages of impermanent bubblesOther chemical processesMembrane filtersFiberActivated charcoal powder

A two-in-one paper fiber powder activated charcoal filter element comprises at least three filtering layers which are in sleeve joint coaxially and tightly, the three layers sequentially comprise an inner layer, namely a PP (Propene Polymer) filter element which is tubular, an intermediate layer, namely a two-in-one paper fiber powder activated charcoal kryptol which is tubular and sleeved outside the PP filter element, an outer layer, namely a fixed protective layer sleeved outside the two-in-one paper fiber powder activated charcoal kryptol, as well as an end cover which is used for sealing the two ends of each filtering layer of two-in-one paper fiber powder activated charcoal filter element, from inside out. According to the invention, paper fiber is taken as main raw material, activated charcoal powder is added, the advantage of strong adsorbability of activated charcoal powder and the character of branching and tangling of the paper fiber are utilized in a combined manner, and the defects of reeled winding form and incapability of resisting long time soaking in the prior art can be overcome.

Owner:李昆洋

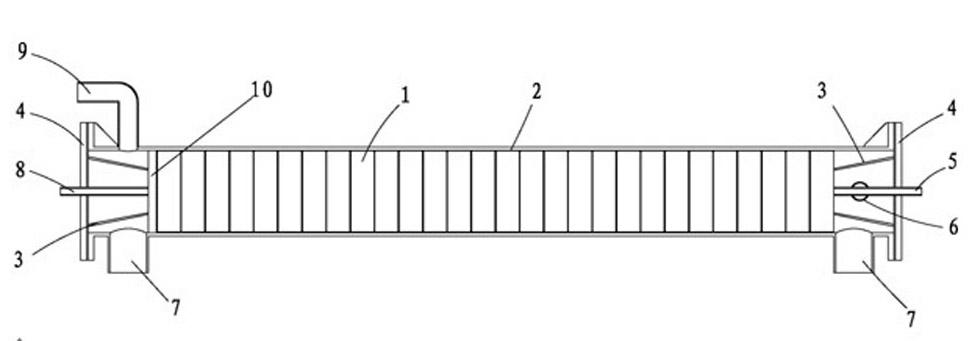

Method for preparing active carbon loaded with manganese oxide by hydrothermal method and device thereof

ActiveCN107352540AImprove conversion rateImprove loading efficiencyGas treatmentCarbon compoundsActivated charcoal powderActivated carbon

The invention relates to a method for preparing active carbon loaded with manganese oxide by a hydrothermal method and a device thereof. The method comprises the following steps: firstly carrying out equivalent-volume impregnation on vacuumdryingactive carbon and potassium permanganate solution, then putting the active carbon, the potassium permanganate solution and mixed solution of manganese nitrate and nitric acid together into a hydrothermal crystallization device for reaction, cooling and separating obtained solid-liquid mixture, washing and drying solid-phase products, calcining in inertial gas to obtain modified active carbon powder loaded with the manganese oxide; and the modified active carbon powder has good property in low-temperature NO catalytic oxidation, and the conversion rate is 48.5%-58.3%. The invention also discloses the device for implementing the method for preparing the active carbon loaded with the manganese oxide by the hydrothermal method. The equipment is high in automation degree, clean in production process, simple in process and low in cost.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

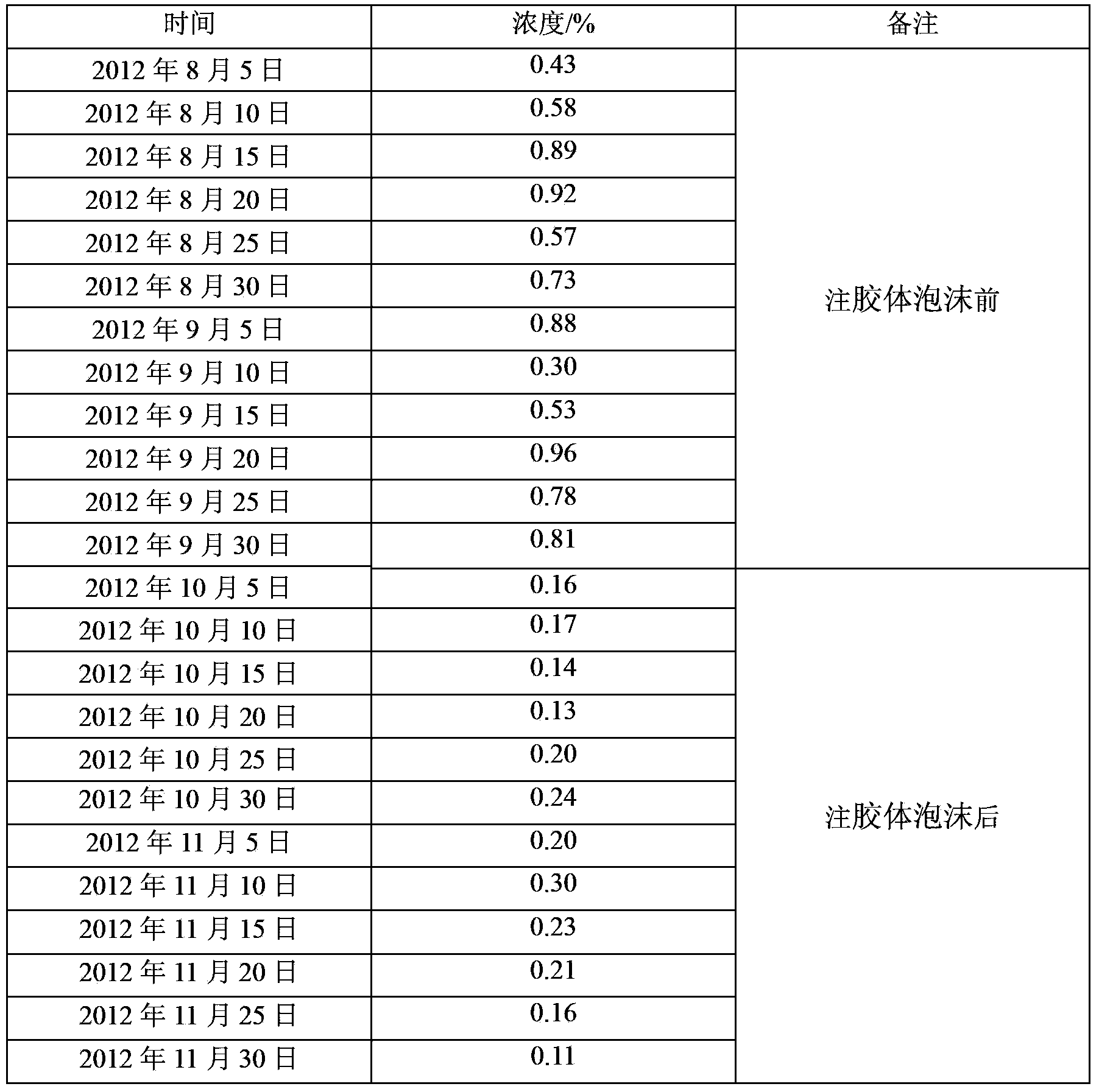

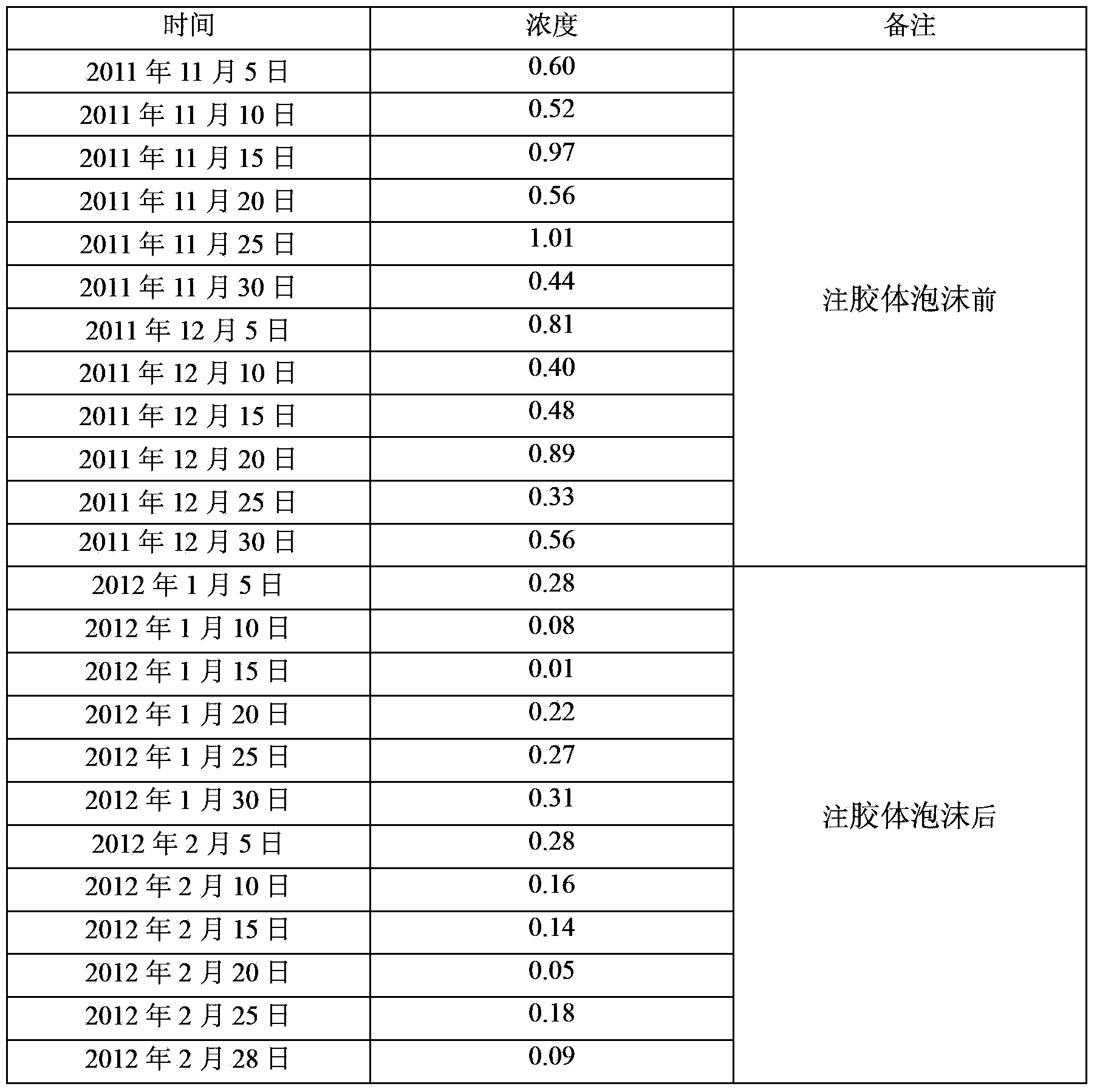

Method for preparing active-carbon-containing colloid gas foam for preventing gas emission in gob

InactiveCN103362532AIncrease in sizeGood shear thinning propertiesDust removalFire preventionActivated charcoal powderCross-link

Active-carbon-containing colloid gas foam for preventing gas emission in a gob is provided, wherein active carbon powder is dispersed into water and is added with certain amount of thickener to prepare an active-carbon-containing thick solution at a certain concentration, and small amount of cross linking agent and foaming agent are added into the solution and is physically and mechanically stirred and foamed under the action of air to prepare the active-carbon-containing colloid gas foam. After the colloid gas foam is injected into the gob through a slip casting pipeline of a mine, a large area of float coal in the gob can be covered and the coal crack can be blocked, the active carbon is used to fully adsorb the free gas in the gob, and meanwhile, a film-shaped colloid covering material like cloth is formed on the surface of the coal to achieve the purpose of long-lasting effective inhibition of emission of the coal gas. The effect of the active-carbon-containing colloid gas foam on preventing gas emission in the gob is remarkable, the cost is low, and the prospect of application is wide.

Owner:CHINA UNIV OF MINING & TECH

Iron catalyst for slurry reactor hydrogenation, preparation, design method, and applications thereof

InactiveCN104826662ALarge specific surface areaStrong specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSlurry reactorCoal blending

The invention discloses an iron catalyst for slurry reactor hydrogenation, preparation, a design method, and applications thereof. The iron catalyst comprises the following components: iron main catalyst (FeOOH), an active auxiliary agent (ammonium molybdate), and a carrier (dry coal powder or active carbon powder); wherein the mass ratio of metal center (Mo) to Fe is 1:350 to 1:175, and the mass ratio of metal center (Fe) to carrier is 1:30 to 1:3. The preparation method comprises the following steps: dissolving FeOOH into distilled water, evenly stirring to obtain FeOOH slurry; adding an ammonium molybdate water solution into the FeOOH slurry, evenly stirring to obtain FeOOH slurry with dispersed molybdenum; adding a carrier into the FeOOH slurry with dispersed molybdenum, evenly stirring, filtering to obtain filter cakes; drying the filter cakes in the atmosphere of N2, and grinding the filter cakes to a size of 10-200 [mu]m to obtain the iron catalyst for slurry reactor hydrogenation. The provided iron catalyst can be applied to residual oil hydrogenation, direct coal liquefaction, and oil-coal blending, the conversion rate and liquid yield are both very high, and the economic benefits are prominently improved.

Owner:CATECH TECH

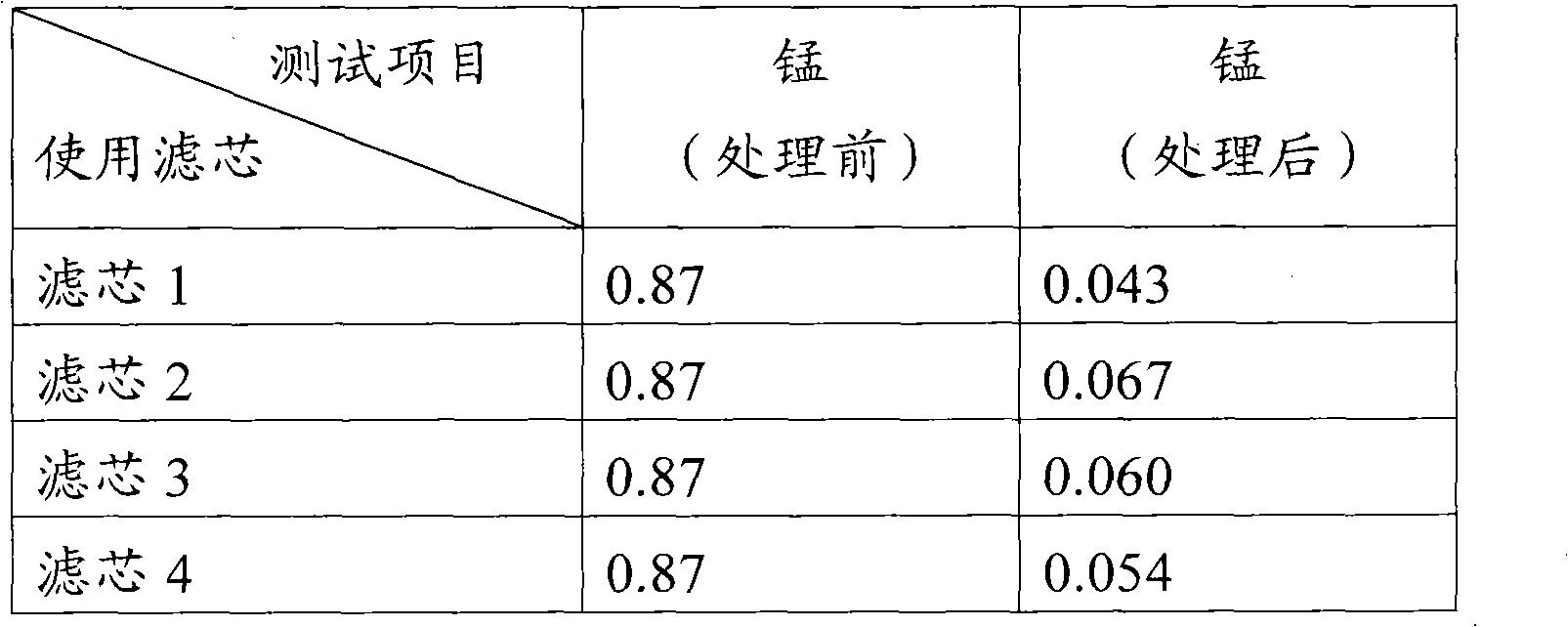

Filter medium for removing manganese in drinking water and preparation method thereof

InactiveCN101817582ALow impurity contentIncrease surface areaWater contaminantsWater/sewage treatment by sorptionMolecular sieveFilter media

The invention discloses a filter medium for removing manganese in drinking water and a preparation method thereof, and also relates to a filter core, a water purifying device and a water dispenser consisting of the filter medium. Preparation of the filter medium comprises the following steps of: a) mixing raw materials including zeolite molecular sieve powder, polyethylene powder with super-high molecular weight, active carbon powder and pore forming agent in a weight ratio of 100-300 to 200-400 to 50-150 to 50-150; and b) pressing, sintering and cooling the mixture obtained by the step a) in a mould. The filter medium provided by the invention has high removal rate of the manganese in the water, high removing speed, simple use and low cost, can prevent the manganese from causing injury to the human body without subsequent processing and is suitable for the treatment of the drinking water at the home terminal. Tests show that the filter medium has a removal rate of more than 90 percent of the manganese in the drinking water.

Owner:QIDI ELECTRIC GROUP

Air purification filter element material for efficiently releasing anion and preparation method

InactiveCN109331607AGood release effectImprove air purification efficiencyGas treatmentDispersed particle separationParticulatesAdhesive

The invention discloses an air purification filter element material for efficiently releasing anion and a preparation method. The preparation method comprises the following steps: mixing and ball-milling an anion release material, an excitation material and an energy conduction material, adding water and a dispersant, and grinding so as to obtain nano mixed powder; hydrolyzing the activated carbonpowder, nano titanium dioxide powder, sodium dodecyl sulfate and tetraethoxysilane with absolute ethyl alcohol so as to obtain a silica sol compound, and pelletizing so as to obtain granules; dispersing the mixed powder, an emulsifier and an adhesive into the absolute ethyl alcohol, spraying to the surfaces of the granules, and drying, thereby obtaining the air purification filter element material. According to the air purification filter element material disclosed by the invention, an anion release agent is solidly adhered to the surfaces of solid granules, so that the contact area with airis greatly increased, anion can be efficiently released into the air for a long time, meanwhile, other substances such as formaldehyde in the air can be adsorbed and degraded, and the purposes of degrading air pollutants and improving air quality can be achieved.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

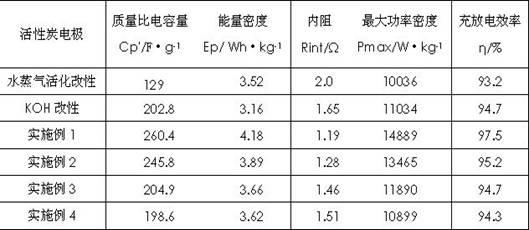

Preparation method of ionic-liquid modified active carbon electrode material

InactiveCN102602926AEasy to operateNo pollution in the processCarbon compoundsElectrolytic capacitorsCapacitanceActivated charcoal powder

The invention relates to a preparation method of an ionic-liquid modified active carbon electrode material, which comprises the following steps: mixing 1-methyl-3-butylimidazolium glutamic acid ionic liquid with carbohydrate compounds, uniformly stirring under a microwave action to obtain a brownish-black viscous substance, i.e. carbon spot ionic liquid; and then adding de-ionized water into the carbon spot ionic liquid to prepare a carbon spot ionic liquid solution, placing active carbon powder into the solution to be uniformly mixed, soaked, dispersed by ultrasonic waves, induced by microwaves and filtered to obtain a solid phase, and finally vacuum-drying the solid phase to obtain the ionic-liquid modified active carbon electrode material. The method is simple to operate, the adopted carbon spot ionic liquid is friendly to the environment, has no pollutant and can be recycled, and the prepared ionic liquid has excellent electrolyte wettability; and the modified active carbon has large specific surface area, is uniform in aperture distribution, and has multiple conductive active substances and small internal resistance. When the modified active carbon electrode material is used as an electrode material for a super-capacitor, the specific capacity, application efficiency, service life, specific capacitance and constant-current discharging-charging efficiency of the super-capacitor can be improved.

Owner:BOHAI UNIV

Method for treating water through Fenton oxidation of activated molecular oxygen by utilizing ultrasonic catalysis

InactiveCN104386866AReduce investmentImprove reaction efficiencyWater/sewage treatment with mechanical oscillationsTreatment involving filtrationActivated charcoal powderPtru catalyst

The invention relates to a method for treating water through Fenton oxidation of activated molecular oxygen by utilizing ultrasonic catalysis. The method comprises the following specific steps: (1) adding activated carbon powder into waste water, wherein the addition amount of the activated carbon powder is 0.7 weight percent of the weight of the waste water; (2) after the activated carbon powder adsorbs impurities, filtering the waste water, and then injecting the waste water into an ultrasonic reactor; (3) performing ultrasonic crushing reaction, wherein the sound energy density of an ultrasonic wave is 0.2 w / m<3>; (4) after the reaction is performed for 30 minutes, adding transition metal ions, transition metal or a transition metal oxide catalyst into the ultrasonic reactor, introducing air or oxygen, catalyzing the activated molecular oxygen at room temperature to generate a hydroxyl free radical, adjusting the PH value to be 4, and performing stirring; (5) after the stirring is performed for 2 hours, performing sedimentation and solid-liquid separation after the reaction is completed so as to treat the waste water. Sewage is purified by adding the transition metal ions, the transition metal or the transition metal oxide catalyst into the Fenton oxidation under an ultrasonic environment. The method has the advantages of wide oxygen source, low cost, high economy and high reaction rate.

Owner:SUZHOU FUQINUO WATER TREATMENT EQUIP

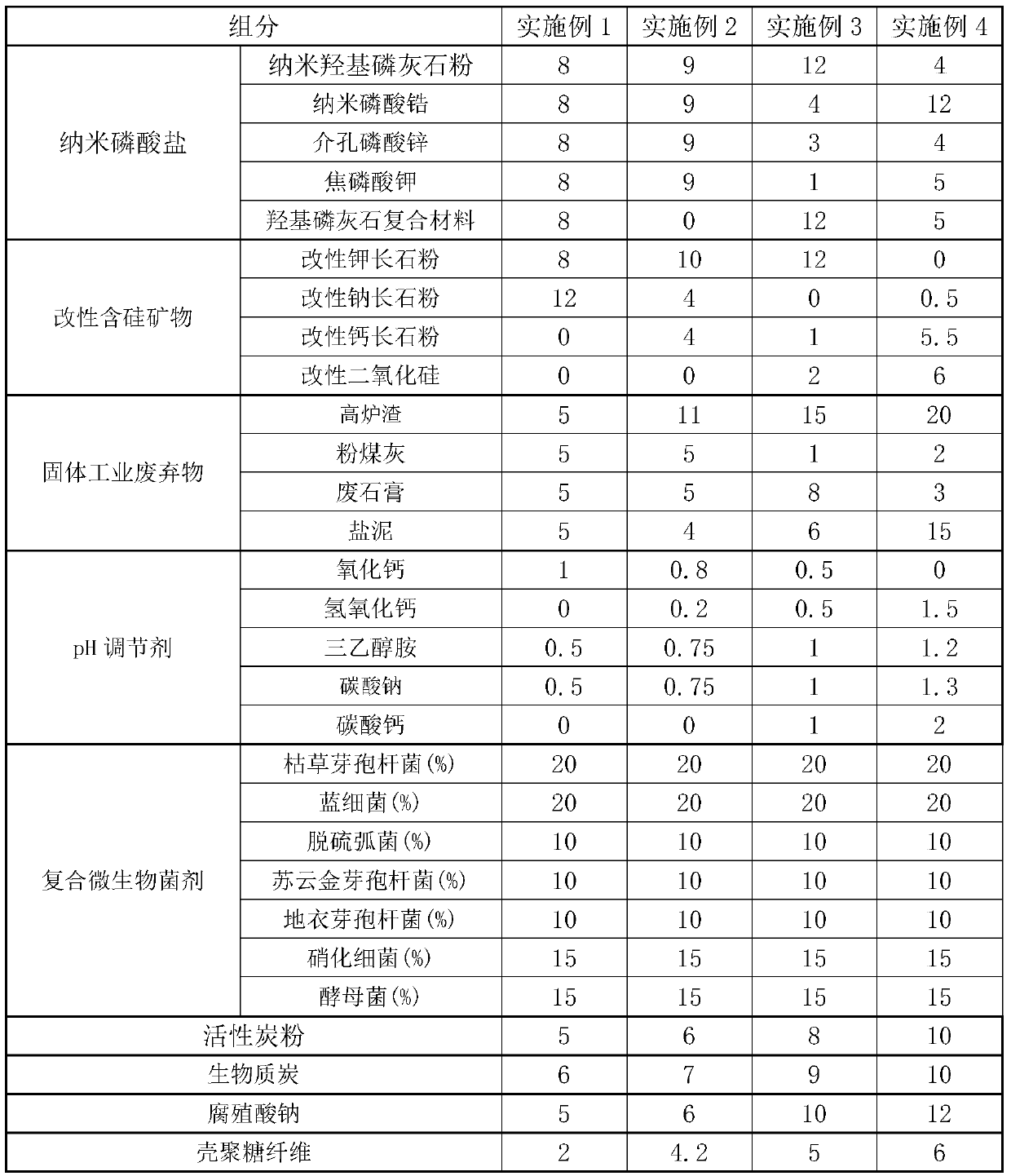

Soil bioremediation agent and soil remediation method based on soil bioremediation agent

InactiveCN111073660AIncrease fluffinessPrevent compactionBiocideOther chemical processesActivated charcoal powderPhosphate

The invention discloses a soil bioremediation agent and a soil remediation method based on the soil bioremediation agent. The soil remediation method based on the soil bioremediation agent mainly comprises the following steps: S1, soil turning: turning and airing contaminated soil to be remediated; S2, secondary soil turning: performing secondary soil turning and airing on the soil subjected to the step 1; S3, pesticide spraying: spraying a layer of soil bioremediation agent on the surface of the soil subjected to the step S2, standing for at least 3 hours, turning over the soil for at least one time, spraying a layer of soil bioremediation agent again, and then standing for 2-5 days; and S4, water spraying: spraying water to the surface of the soil obtained in the step S3, then ventilating and drying the soil obtained after water spraying is conducted and then completing remediation of the soil. Heavy metal ions such as lead, chromium, cadmium and cobalt in the soil are adsorbed or complexed through the nano phosphate so that the content of the heavy metal ions in the soil is reduced; and organic pollutants are adsorbed through activated carbon powder and chitosan, and the problemof soil pollution is solved.

Owner:广东中苗景观有限公司

Method for preparing activated carbon capable of absorbing electromagnetic waves

InactiveCN103887033AOptimum Permeability Characteristic ParametersImproved electromagnetic wave absorption characteristicsMagnetic/electric field screeningInorganic material magnetismMagnetite NanoparticlesUltra fine

The invention discloses a method for preparing activated carbon capable of absorbing electromagnetic waves, belongs to the technical field of functional carbon materials, and particularly relates to a preparation method through which the special activated carbon with the strong magnetism and the large surface area can be prepared. According to the method, ultra-fine grinding, chemical activation, magnetic nanoparticle and metal nanoparticle loading and the like are conducted on raw materials for preparing the activated carbon or universal activated carbon, and then the activated carbon is prepared. The prepared activated carbon powder material has high electromagnetic wave absorption efficiency within the frequency range from 6 GHz to 18 GHz. A sample with the thickness of 2 mm is prepared by mixing and solidifying 8% of fillers and phenolic resin. Within the frequency range of 2 GHz to 18 GHz, the frequency is measured to be 6.1 GHz through the NRL-arc method when the intensity of electromagnetic waves which can be absorbed reaches -5 dB, the frequency is larger than 3.4 GHz when the intensity of electromagnetic waves which can be absorbed is lower than -10 dB, and therefore the activated carbon is good electromagnetic attenuation functional materials and can be used for radar stealth of military equipment or electromagnetic pollution control of civil architecture.

Owner:CHANGZHOU ZHONGKE HAINA CARBON TECH

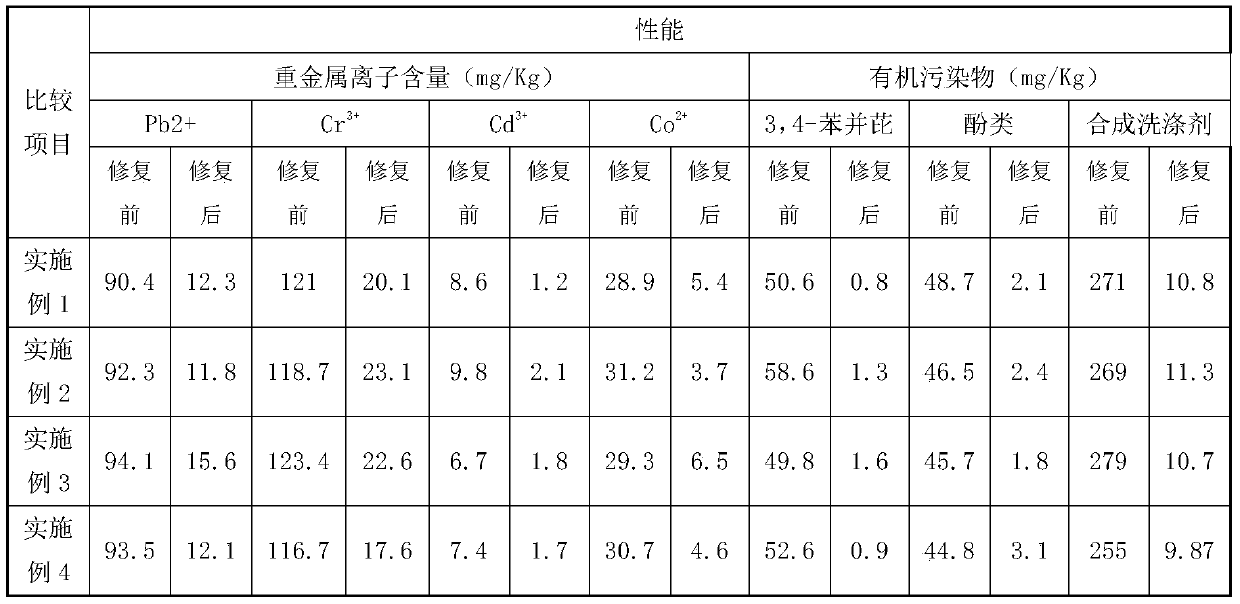

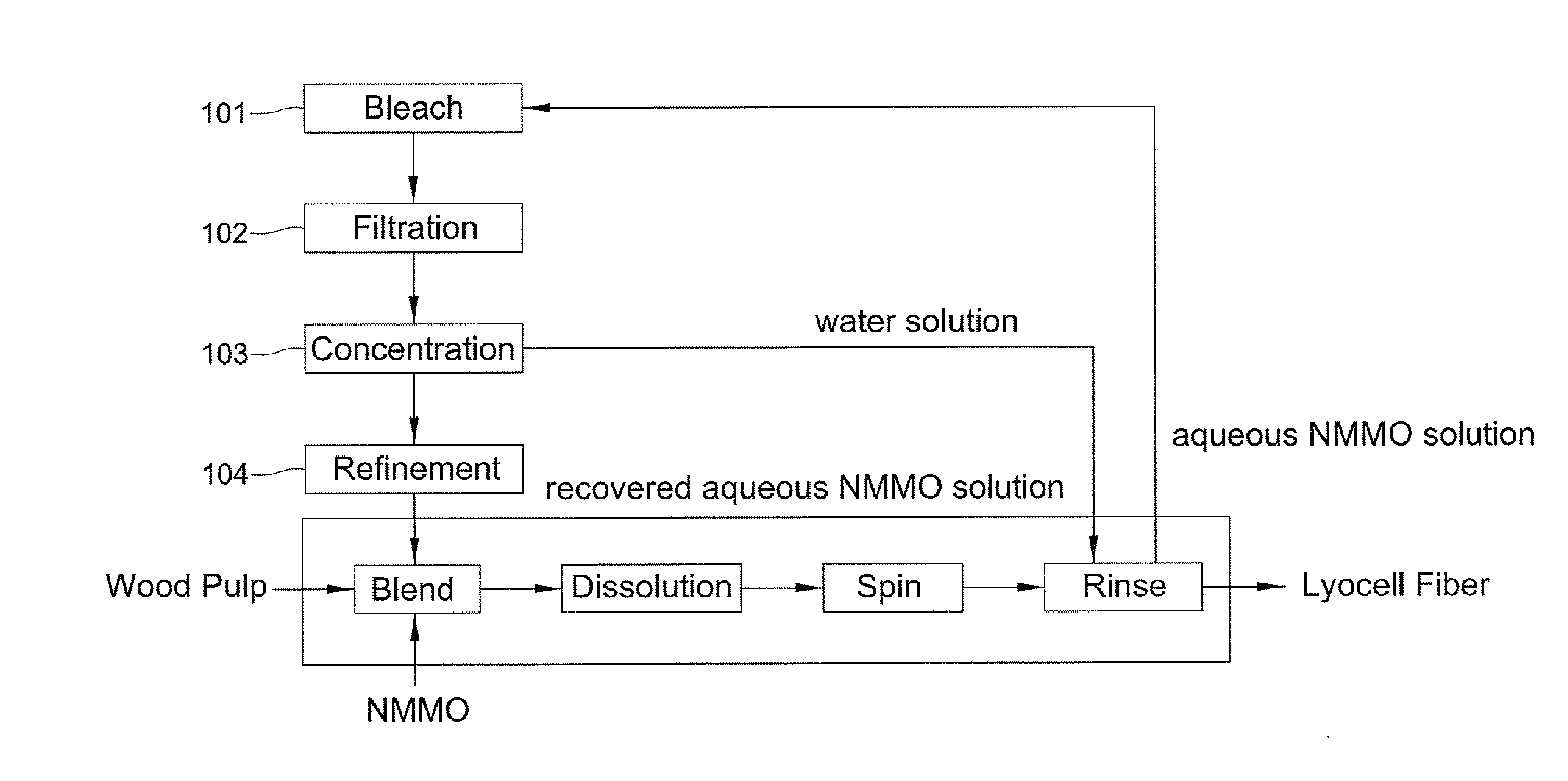

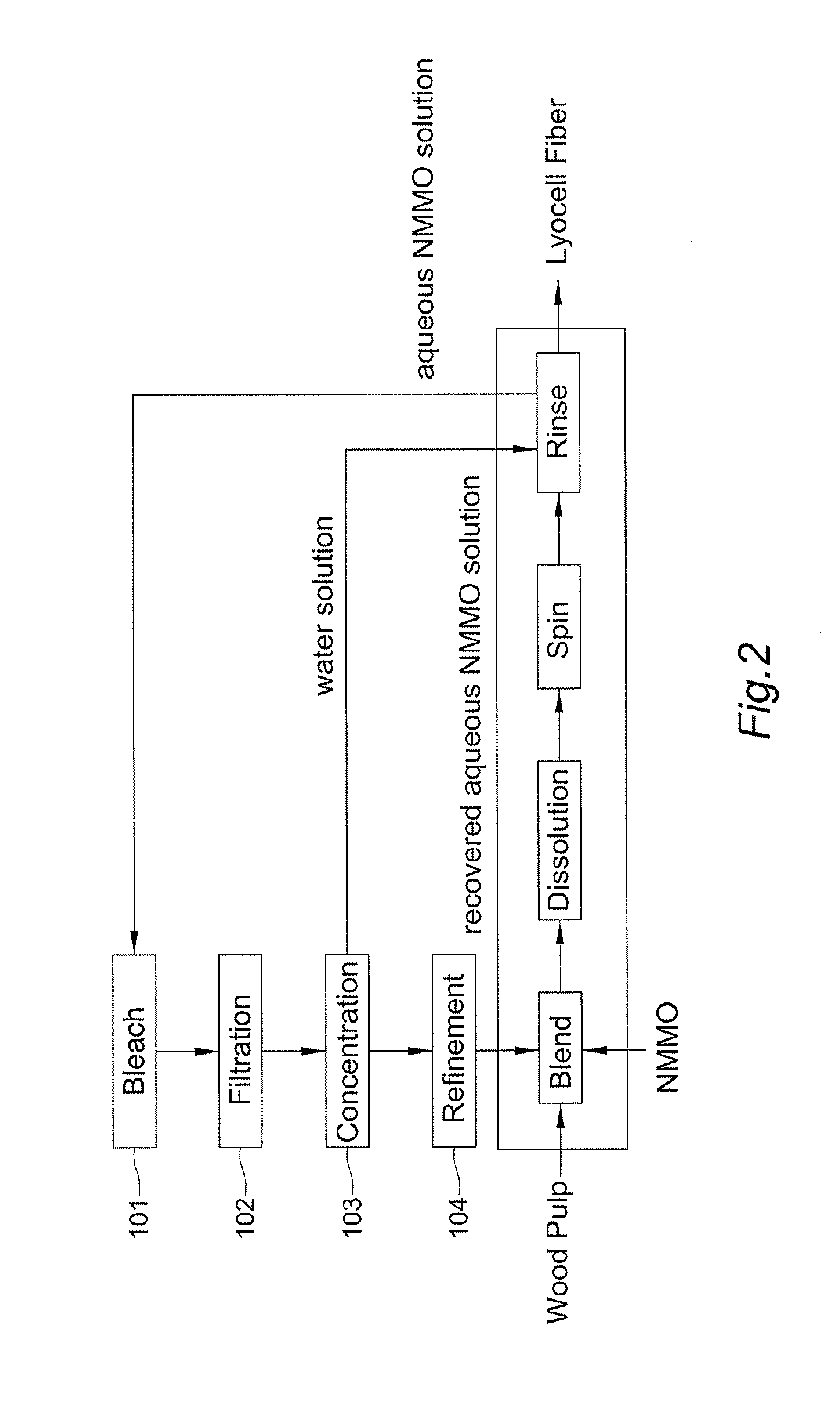

Method of Recovering Aqueous N-Methylmorpholine-N-Oxide Solution Used in Production of Lyocell Fiber

InactiveUS20140008577A1Facilitate purityReduce material costsArtificial filament recoveryTextile/flexible product manufactureFiberEnvironmental resistance

A method of recovering aqueous N-Methylmorpholine-N-Oxide solution used in production of Lyocell fiber comprises following steps. Bleach means for decoloring coloration in aqueous NMMO solution via alternate blow-mixing adsorption mode and static suspending adsorption mode reiteration. Filtration means for purifying the activated carbon powder and impurities by two filtering stages of first coarse filtering stage and second fine filtering stage. Concentration means for intensifying aqueous NMMO solution to obtain a condensed aqueous solution without NMMO solvent and a concentrated aqueous solution with NMMO solvent respectively by a sequential multi-stage evaporating system. Refinement means for purifying aqueous NMMO solution with promoting purity of concentrated aqueous solution to obtain required recovered aqueous solution by adding suitable agents in the redox reactions involved. Owing to streamlining and simplicity, the method not only has better competitiveness from promoted recovery cost, efficiency and quality but also meets regulations of environmental protection.

Owner:ACELON CHEM & FIBER

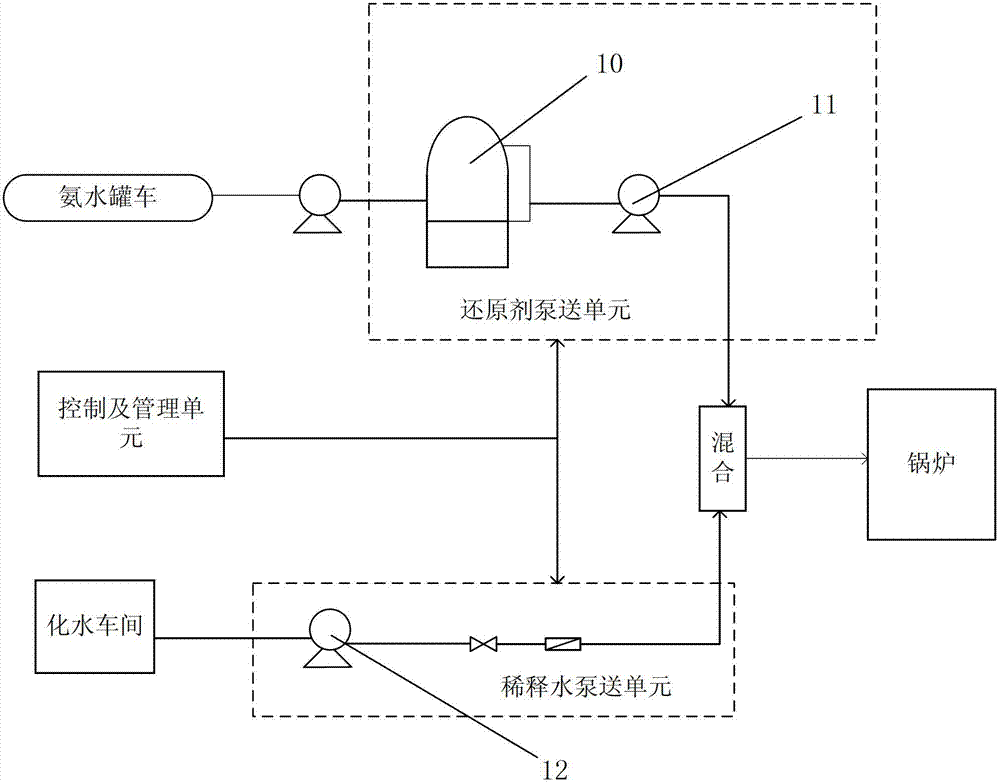

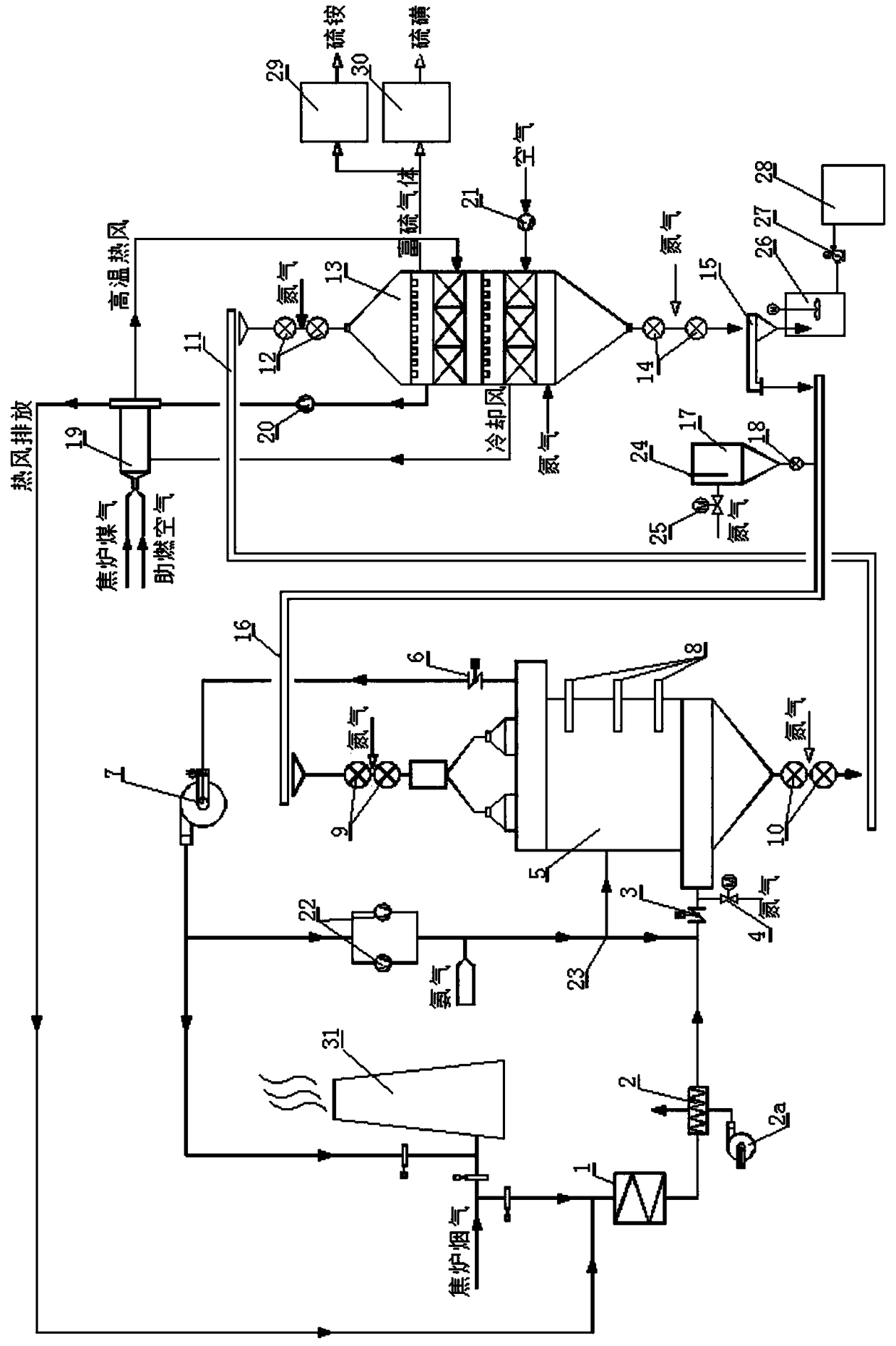

Process and system for activated-carbon desulfurization and denitration of coke oven flue gas and comprehensive utilization of byproducts

PendingCN109432980ASmall footprintNo potential hazardGas treatmentDispersed particle separationSorbentNitrogen gas

The invention relates to a process and a system for activated-carbon desulfurization and denitration of coke oven flue gas and comprehensive utilization of byproducts. The activated carbon is adoptedas a desulfurization adsorbent and a denitration catalyst of the coke oven flue gas, sulfur-rich gas generated by desulfurization is sent to a chemical production process of a coking plant for producing sulfur or ammonium sulfate, and powdered activated carbon which cannot be recycled is sent to a sewage treatment process of the coking plant as a high-efficiency adsorbent of coking wastewater, sothat the byproducts from activated-carbon desulfurization and denitration of the coke oven flue gas are recycled. Real desulfurization and denitration integration is realized, requirements of desulfurization and denitration indexes are met, and the activated carbon is environmentally friendly; the sulfur-rich gas generated by desulfurization is sent to the chemical production process of the cokingplant for producing sulfur or ammonium sulfate; ammonia is used as a reducing agent in activated carbon denitration, and the generated products are nitrogen and water, which can be directly discharged with flue gas; the worn powdered activated carbon is sent to the sewage treatment process of the coking plant as the high-efficiency adsorbent of the coking wastewater, and thus, comprehensive utilization of the desulfurization and denitration by-products of the coke oven flue gas is realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com