Method for preparing active carbon loaded with manganese oxide by hydrothermal method and device thereof

A manganese oxide and activated carbon technology is applied in the field of hydrothermal preparation of supported manganese oxide activated carbon, which can solve the problems of high cost, complex manufacturing process, influence on large-scale application, etc., and achieves a high degree of automation, simple operation and good economic benefits. effect on environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

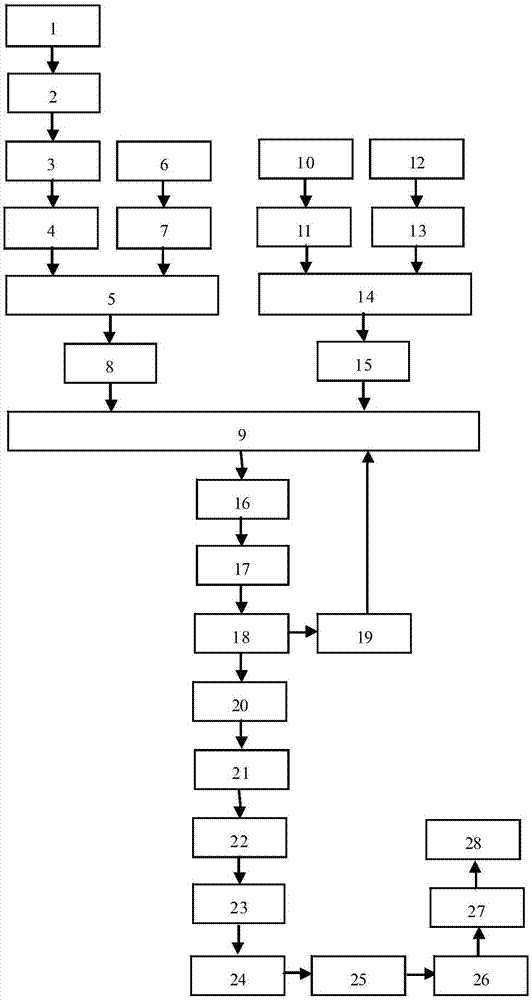

Method used

Image

Examples

Embodiment 1

[0038] Prepare modified activated carbon according to the following steps:

[0039] (a) impregnate vacuum-dried activated carbon with a particle size of 2 / g, the molar concentration of potassium permanganate solution is 0.010mol / L, after ultrasonic vibration, obtain the activated carbon impregnated and adsorbed potassium permanganate;

[0040] (b) Add the activated carbon impregnated and adsorbed potassium permanganate in the same volume in the previous step, and join the mixed solution of manganese nitrate and nitric acid into the hydrothermal crystallization device, and react the quality of the activated carbon impregnated and adsorbed potassium permanganate in a medium volume: nitric acid The quality of the mixed solution of manganese and nitric acid is 1:3. The mixed solution of manganese nitrate and nitric acid is mixed with manganese nitrate solution and nitric acid solution according to the volume ratio of 3:4, wherein the molar concentration of manganese nitrate soluti...

Embodiment 2

[0045] (a) impregnating activated carbon with vacuum-dried particle size2 / g, the molar concentration of potassium permanganate solution is 0.1mol / L, after ultrasonic vibration, obtain the activated carbon impregnated and adsorbed potassium permanganate;

[0046](b) The activated carbon impregnated and adsorbed potassium permanganate in the previous step is added to the hydrothermal crystallization device together with the mixed solution of manganese nitrate and nitric acid, and the mass of the activated carbon impregnated and adsorbed potassium permanganate in the reaction medium volume is: manganese nitrate and The quality of the mixed solution of nitric acid is 1:4. The mixed solution of manganese nitrate and nitric acid is mixed with manganese nitrate solution and nitric acid solution according to the volume ratio of 3:4, wherein the molar concentration of manganese nitrate solution is 0.1mol / L , the molar concentration of the nitric acid solution is 7.75mol / L; the temperat...

Embodiment 3

[0051] (a) Vacuum-dried activated carbon with a particle size of 2 / g, the molar concentration of potassium permanganate solution is 0.05mol / L, after ultrasonic vibration, obtain the activated carbon impregnated and adsorbed potassium permanganate;

[0052] (b) The activated carbon impregnated and adsorbed potassium permanganate in the previous step is added to the hydrothermal crystallization device together with the mixed solution of manganese nitrate and nitric acid, and the mass of the activated carbon impregnated and adsorbed potassium permanganate in the reaction medium volume is: manganese nitrate and The quality of the mixed solution of nitric acid is 1:5, and the mixed solution of manganese nitrate and nitric acid is mixed with manganese nitrate solution and nitric acid solution according to the volume ratio of 3:4, wherein the molar concentration of manganese nitrate solution is 0.05mol / L , the molar concentration of the nitric acid solution is 7.75mol / L; the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com