Preparation method of ionic-liquid modified active carbon electrode material

An ionic liquid and electrode material technology, applied in chemical instruments and methods, circuits, capacitors, etc., can solve the problems of affecting the electrochemical performance of activated carbon-based electrode materials, high corrosion of equipment, polluting the environment, etc., to achieve good conductivity, improve Specific capacitance and effect of increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

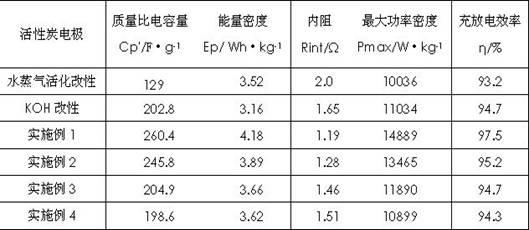

Examples

Embodiment 1

[0015] Mix 8g of 1-methyl-3-butylimidazole glutamic acid ionic liquid with 8g of glucose, stir evenly for 30min, and act under 500W microwave for 40min to obtain 13.6g of brown-black viscous substance, which is carbon dot ionic liquid; Add 77ml of deionized water to the obtained 13.6g carbon dot ionic liquid to form a carbon dot ionic liquid solution with a mass concentration of 15.01%, and add 53g of activated carbon powder to the solution, stir evenly, immerse for 40min, and 800W ultrasonic dispersion for 30min. Microwave was applied for 30 min, suction filtered, and the filtrate was recovered for modified activated carbon, and the solid phase was vacuum-dried at 80°C for 10 h to obtain a black powdery ionic liquid modified activated carbon electrode material.

[0016] The ionic liquid modified activated carbon electrode material with a mass ratio of 39:1:5:1:4, the dispersant quaternary ammonium salt surfactant, the conductive agent Ketjen black, the thickener sodium carboxy...

Embodiment 2

[0020] Mix 9g of 1-methyl-3-butylimidazole glutamic acid ionic liquid with 8g of fructose, stir evenly for 60min, and act under 800W microwave for 50min to obtain 14.4g of brown-black viscous substance, which is carbon dot ionic liquid; The obtained 14.4g carbon dot ionic liquid was added into 58ml deionized water to form a mass concentration of 19.89% carbon dot ionic liquid solution, and 40.1g of activated carbon powder was added to the solution, stirred evenly, soaked for 60min, and dispersed by 900W ultrasonic waves for 40min. Under 800W microwave for 40min, suction filtration, the filtrate was recovered for modified activated carbon, and the solid phase was vacuum-dried at 100°C for 12h to obtain a black powdery ionic liquid modified activated carbon electrode material.

[0021] The prepared ionic liquid modified activated carbon electrode material was assembled into a simulated ionic liquid modified activated carbon supercapacitor according to the same method as in Exampl...

Embodiment 3

[0023] Mix 10g of 1-methyl-3-butylimidazole glutamic acid ionic liquid with 8g of sucrose, stir evenly for 45min, and act under 600W microwave for 45min to obtain 15.2g of brown-black viscous substance, which is carbon dot ionic liquid; The obtained 15.2g carbon dot ionic liquid was added into 65ml deionized water to make a mass concentration of 18.95% carbon dot ionic liquid solution, and 44g of activated carbon powder was added to the solution, stirred evenly, immersed for 50min, and dispersed by 1000W ultrasonic wave for 35min. Microwave was applied for 35 min, suction filtered, and the filtrate was recovered for modified activated carbon, and the solid phase was vacuum-dried at 80°C for 11 h to obtain a black powdery ionic liquid modified activated carbon electrode material.

[0024] The prepared ionic liquid modified activated carbon electrode material was assembled into a simulated ionic liquid modified activated carbon supercapacitor according to the same method as in Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com