Electro-catalytic oxidation material for wastewater treatment, preparation method and application

An electrocatalytic oxidation and wastewater treatment technology, applied in water/sewage treatment, chemical instruments and methods, oxidized water/sewage treatment, etc., can solve problems such as high COD value, many types of pollutants, strong acidity and alkalinity, and achieve Fast mold release, good ventilation and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] a. Ingredients: 30 kg of iron powder with a particle size of 250-400 mesh, 2 kg of alumina with a particle size of ≤100 nm, 2 kg of nickel oxide with a particle size of ≤100 nm, 4 kg of titanium oxide with a particle size of ≤100 nm, and aluminum silicate 4 kg, water glass 5 kg, activated carbon powder 30 kg, polyvinyl alcohol 3 kg, graphite powder 20 kg;

[0047] b. Grind 30kg of activated carbon powder and 20kg of graphite powder and pass through a 250-300 mesh screen;

[0048] c. Mix 30 kg of activated carbon powder, 20 kg of graphite powder, 30 kg of iron powder, 2 kg of aluminum oxide, 2 kg of nickel oxide, 4 kg of titanium oxide, and 4 kg of aluminum silicate in the reaction kettle, and then add water glass 5kg, 3kg of polyvinyl alcohol and a certain amount of water, adjusted to a thick substance with a moisture content of 10-20%;

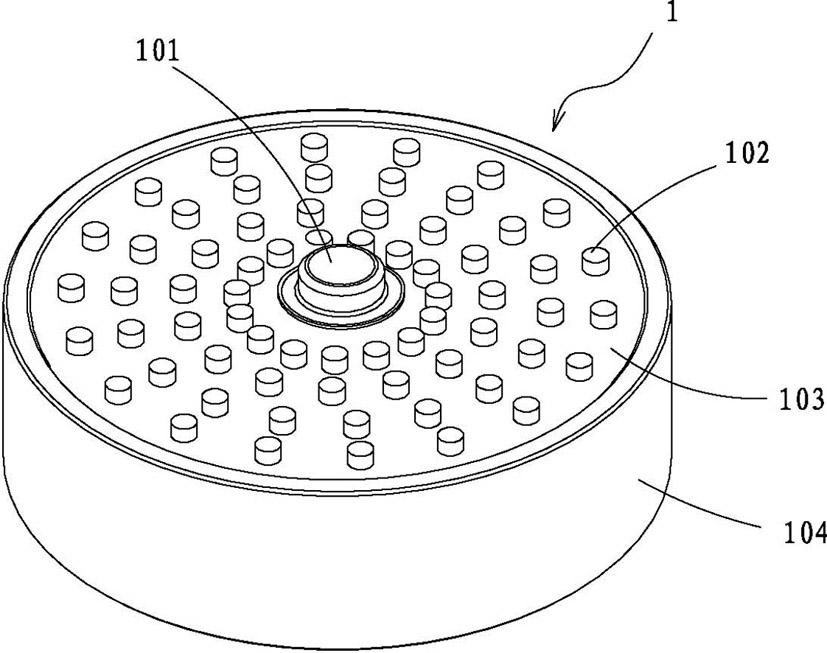

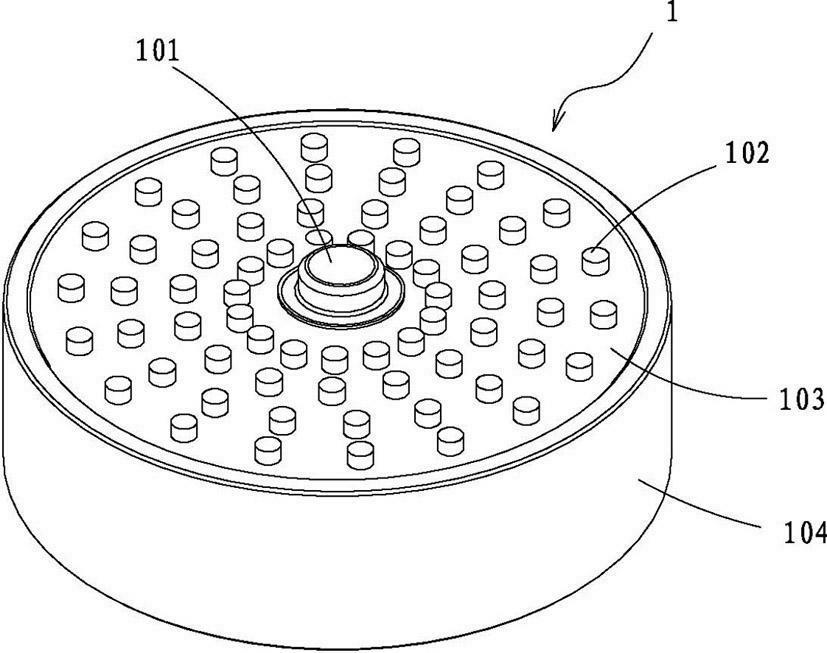

[0049] d. The thick material obtained in step c is granulated into granules by a granulator or pressed into a block or disc in a mol...

Embodiment 2

[0051] a. Ingredients: 60 kg of iron powder with a particle size of 250-400 mesh, 1 kg of alumina with a particle size of ≤100 nm, 1 kg of nickel oxide with a particle size of ≤100 nm, 2 kg of titanium oxide with a particle size of ≤100 nm, and aluminum silicate 2 kg, water glass 3 kg, activated carbon powder 20 kg, polyvinyl alcohol 1 kg, graphite powder 10 kg;

[0052] b. Grind 20kg of activated carbon powder and 10kg of graphite powder and pass through a 250-300 mesh screen;

[0053] c. Put 20kg of milled activated carbon powder, 10kg of graphite powder, 60kg of iron powder, 1kg of aluminum oxide, 1kg of nickel oxide, 2kg of titanium oxide, and 2kg of aluminum silicate into the reaction kettle and mix well, then add 3kg of water glass, poly Vinyl alcohol 1kg and a certain amount of water, adjusted to a thick substance with a moisture content of 10-20%;

[0054] d. The thick material obtained in step c is granulated into granules by a granulator or pressed into a block or d...

Embodiment 3

[0056] a. Ingredients: 45 kg of iron powder with a particle size of 250-400 mesh, 1.5 kg of alumina with a particle size of ≤100 nm, 1.5 kg of nickel oxide with a particle size of ≤100 nm, 3 kg of titanium oxide with a particle size of ≤100 nm, silicon Acid aluminum 3kg, water glass 4kg, activated carbon powder 30kg, polyvinyl alcohol 2kg, graphite powder 10kg;

[0057] b. Grind 30kg of activated carbon powder and 10kg of graphite powder and pass through a 250-300 mesh screen;

[0058] c. Put 30kg of milled activated carbon powder, 10 kg of graphite powder, 45kg of iron powder, 1.5kg of aluminum oxide, 1.5kg of nickel oxide, 3kg of titanium oxide, and 3kg of aluminum silicate into the reaction kettle and mix well, then add water 4kg of glass, 2kg of polyvinyl alcohol and a certain amount of water, adjusted to a thick substance with a moisture content of 10-20%;

[0059] d. Use the granulator to granulate the thick product obtained in step c to form granules or press it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com