Treatment method of anchor rope within the range of foundation pit envelop enclosure

A technology of foundation pit enclosure and treatment method, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems that affect the construction quality of the enclosure structure, cannot guarantee the verticality of the hole, destroy the geological structure, etc., and shorten the construction period. The effect of construction period, ensuring safety and quality, and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Example 1 Hydraulic grab loading and unloading system

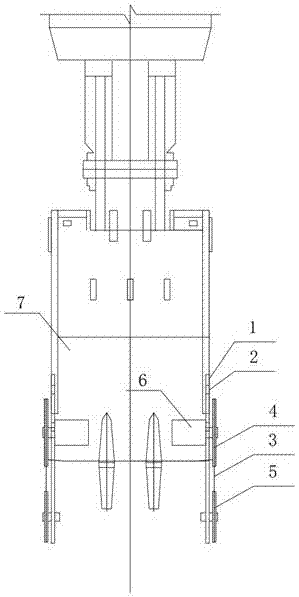

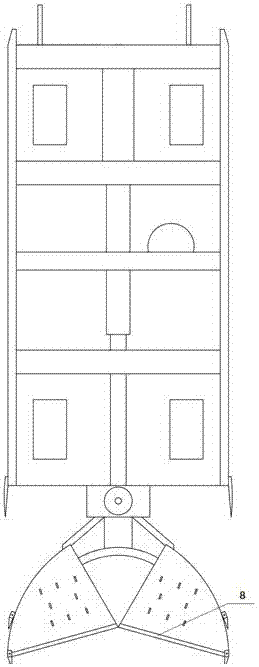

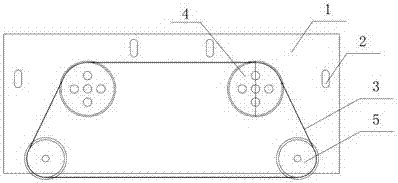

[0071] As attached to the manual Figure 1~6 As shown, the hydraulic grab loading and unloading system includes: a wire saw steel frame 1, a hydraulic grooving machine grab 7, and a wire saw. The wire saw includes: a wire saw chain 3 , a wire saw drive wheel 4 , a wire saw guide wheel 5 , and a wire saw hydraulic drive motor 6 .

[0072] Bolt holes are directly set on the wire saw steel plate frame 1 and the grab bucket 7 of the hydraulic grooving machine respectively. for circular holes. The wire saw steel frame 1 and the grab bucket 7 of the hydraulic grooving machine pass through the bolt holes and are connected with heavy-duty hexagonal bolts and nuts. The wire saw steel frame 1 is connected with the grab bucket 7 of the hydraulic grooving machine by bolts to realize fast disassembly and assembly.

[0073] The hydraulic grooving machine grab bucket 7 installs the wire saw at the wire saw installation posi...

Embodiment 2

[0075] Example 2 Hydraulic grab loading and unloading system

[0076] As attached to the manual Figure 1~6 As shown, the hydraulic grab loading and unloading system includes: a wire saw steel frame 1, a hydraulic grooving machine grab 7, and a wire saw. The wire saw includes: a wire saw chain 3 , a wire saw drive wheel 4 , a wire saw guide wheel 5 , and a wire saw hydraulic drive motor 6 .

[0077] Bolt holes are directly set on the wire saw steel plate frame 1 and the grab bucket 7 of the hydraulic grooving machine respectively. for circular holes. The wire saw steel plate frame 1 and the grab bucket 7 of the hydraulic grooving machine pass through the bolt holes and are connected with eyebolts and nuts.

[0078] The hydraulic grooving machine grab bucket 7 installs the wire saw at the wire saw installation position 8.

[0079] The connection mode of each component of the wire saw and the wire saw frame: the non-rotating part of the wire saw steel frame 1 and the wire ...

Embodiment 3

[0080] Example 3 Hydraulic grab loading and unloading system

[0081] As attached to the manual Figure 1~6 As shown, the hydraulic grab loading and unloading system includes: a wire saw steel frame 1, a hydraulic grooving machine grab 7, and a wire saw. The wire saw includes: a wire saw chain, a wire saw drive wheel 4, a wire saw guide wheel 5, a wire saw hydraulic drive motor 6, a wire saw steel plate frame 1 and a hydraulic grooving machine grab 7 are connected by bolts to realize fast disassembly and assembly. The hydraulic grooving machine grab bucket 7 installs the wire saw at the wire saw installation position 8.

[0082] Weld the connecting sheet with holes on the wire saw steel plate frame 1, and directly set the bolt holes on the grab bucket 7 of the hydraulic grooving machine. The hole on the connecting piece is an oval hole, and the bolt hole directly arranged on the grab bucket 7 of the hydraulic slotting machine is a circular hole. The wire saw steel plate f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com