Filter medium for removing manganese in drinking water and preparation method thereof

A technology for filtering media and drinking water, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of low removal rate, complex manganese removal process, long processing time, etc. Low cost and fast removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

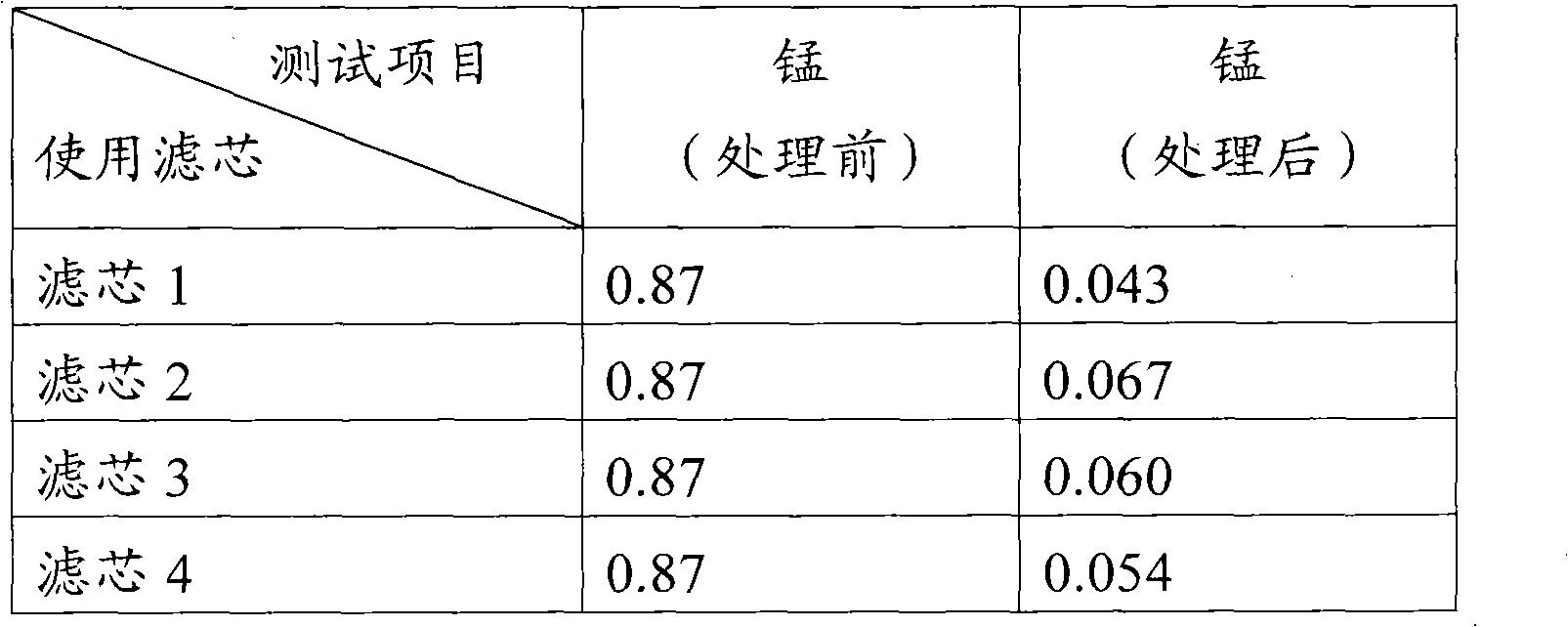

Examples

Embodiment 1

[0028] (1) Weighing 110g of 13X zeolite molecular sieve powder, the particle diameter of said 13X zeolite molecular sieve powder is 74~89 microns;

[0029] (2) Take ultra-high molecular weight polyethylene powder 250g, described ultra-high molecular weight polyethylene is the M-II type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 2.5 million;

[0030] (3) Take by weighing 55g of medical activated carbon powder, the particle diameter of described medical activated carbon is 74~89 microns;

[0031] (4) Take 70 grams of food-grade ammonium bicarbonate, and the purity reaches more than 99.99%;

[0032] (5) Put the above four powders into a mechanical stirrer and stir for 10 minutes to mix evenly;

[0033] (6) Fill the mixed powder into a tubular mold, press under a hydraulic pressure of 0.9MPa, and sinter at a temperature of 250° C. for 140 minutes;

[0034] (7) Naturally cool to 50°C and then release the mold, that is,...

Embodiment 2

[0037] (1) Take 150g of 13X zeolite molecular sieve powder, the particle diameter of the 13X zeolite molecular sieve powder is 74~89 microns;

[0038] (2) Take ultra-high molecular weight polyethylene powder 300g, said ultra-high molecular weight polyethylene is the M-III type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 3.5 million;

[0039] (3) Take medical active carbon powder 70g, the particle diameter of described medical active carbon is 74~89 microns;

[0040] (4) Take 115 grams of food-grade ammonium bicarbonate, and the purity reaches more than 99.99%;

[0041] (5) Put the above four powders into a mechanical stirrer and stir for 10 minutes to mix evenly;

[0042] (6) Fill the mixed powder into a tubular mold, press under a hydraulic pressure of 0.8 MPa, and sinter at a temperature of 280° C. for 130 minutes;

[0043] (7) Naturally cool to 60°C and then demold, that is, a tubular filter element with many fi...

Embodiment 3

[0046] (1) Take 200g of 13X zeolite molecular sieve powder, the particle diameter of the 13X zeolite molecular sieve powder is 74~89 microns;

[0047] (2) Take ultra-high molecular weight polyethylene powder 320g, described ultra-high molecular weight polyethylene is the M-II type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary Second Factory, and its molecular weight is 2,500,000;

[0048] (3) Take medical active carbon powder 100g, the particle diameter of described medical active carbon is 74~89 microns;

[0049] (4) Weigh 130 grams of azodicarbonamide, with a purity of more than 99.99%;

[0050] (5) Put the above four powders into a mechanical stirrer and stir for 10 minutes to mix evenly;

[0051] (6) Fill the mixed powder into a tubular mold, press under a hydraulic pressure of 0.6MPa, and sinter at a temperature of 220° C. for 150 minutes;

[0052] (7) Natural cooling to 40°C and then demoulding, that is, a tubular filter element with many fine pores.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com