Method and device for preparing surface-vitrified carbon adsorption material

A technology of carbon adsorption and surface adhesion, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effects of reducing costs, expanding the scope of application, and facilitating recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

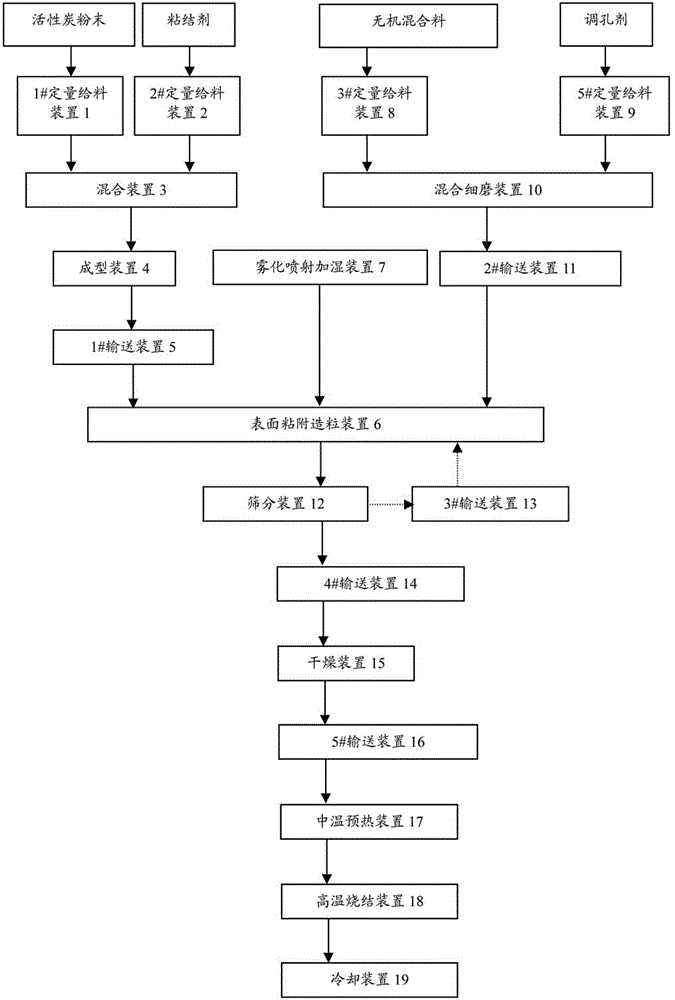

[0046] Example 1: Preparation of surface ceramic carbon adsorption material

[0047] The system equipment device of present embodiment is described as follows, and each following device all can be purchased directly in the market:

[0048] 1# quantitative feeding device 1, 2# quantitative feeding device 2, 3# quantitative feeding device 8, and 4# quantitative feeding device 9 can be screw scales, star feeders.

[0049] The mixing device 3 is a mill mixer, a ribbon mixer or a twin-shaft mixer;

[0050] The molding device 4 is a double-roll molding machine, a stamping molding machine or an extrusion molding machine;

[0051] 1# conveying device 5 is a belt conveyor or a bucket conveyor;

[0052] The surface adhesion granulation device 6 is a disc granulator or a drum granulator;

[0053] Atomized spray humidifier 7 is a conventional atomized water spray device;

[0054] The mixing fine grinding device 10 is a ball mill;

[0055] 2# conveying device 11 is buried scraper co...

Embodiment 2

[0070] Example 2: Preparation of surface ceramic carbon adsorption material

[0071] The system equipment of this embodiment is the same as that of Embodiment 1.

[0072] Preparation method: process reference figure 1 .

[0073] Preparation of activated carbon core particles: Powder activated carbon by wood physics method and then pass through the quantitative feeding device 1 and 2 respectively, enter the mixing device 3 and the molding device 4 to mix with the binder; the binder is sodium carboxymethyl cellulose (CMC), The weight addition ratio is 20% to make shaped activated carbon core particles with a particle size of 8mm;

[0074] Preparation of pottery material: the inorganic mixture is diatomite, fly ash, sludge from urban sewage plant, and the main chemical components after mixing are controlled within the following weight range: SiO 2 :60%; A1 2 o 3 :17%; Fe 2 o 3 :6%; CaO+MgO:7%; K 2 O+Na 2 O: 6%; C%: 4%,; Particle size control is below 100 orders; The po...

Embodiment 3

[0081] Example 3: Preparation of surface ceramic carbon adsorption material

[0082] The system equipment of this embodiment is the same as that of Embodiment 1.

[0083] Preparation method: process reference figure 1 .

[0084] Preparation of activated carbon core particles: Powder activated carbon by wood physics method and binder through quantitative feeding device 1 and 2 respectively, enter mixing device 3 and molding device 4 to mix; binder is modified phenolic resin, and the weight addition ratio is 29 % made into shaped activated carbon core particles, particle size is 10mm;

[0085] Preparation of pottery materials: the inorganic mixture is bentonite, shale, and river bed mud. After mixing, the main chemical components are controlled within the following weight range: SiO 2 :63%; A1 2 o 3 :16%; Fe 2 o 3 : 4%; CaO+MgO: 8%; K 2 O+Na 2 O: 4%; C%: 5%,; particle size is controlled to be below 100 orders; the pore-adjusting agent is selected as gelatin, and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption value | aaaaa | aaaaa |

| Adsorption value | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com