Process and system for activated-carbon desulfurization and denitration of coke oven flue gas and comprehensive utilization of byproducts

A desulfurization and denitrification, activated carbon technology, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of difficult by-product treatment, many operation and maintenance points, and long desulfurization and denitrification process, so as to save land occupation and system Effects of simplification and reduction of gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

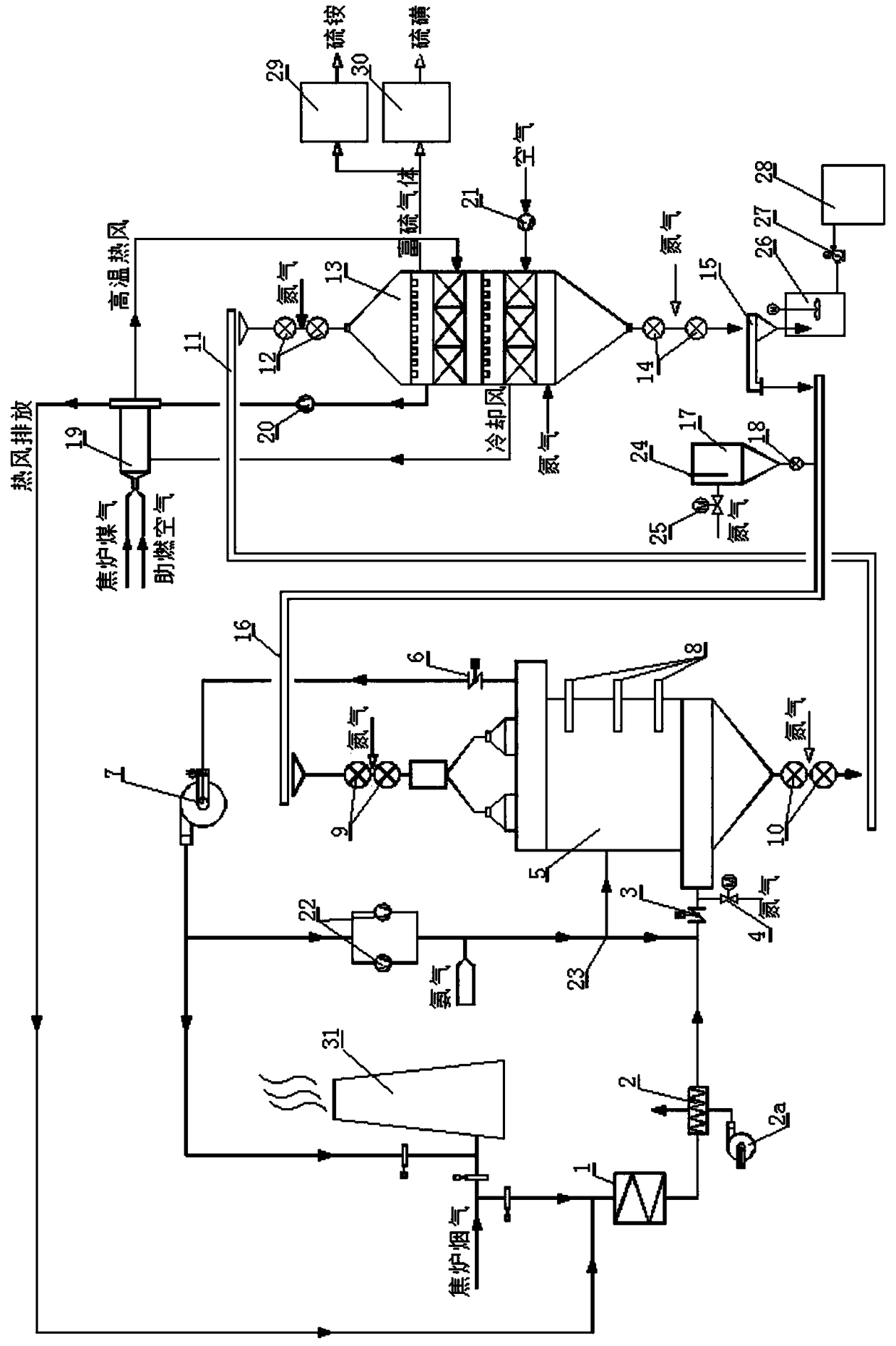

[0037] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0038] Such as figure 1 As shown, the coke oven flue gas activated carbon method desulfurization and denitrification and by-product comprehensive utilization process of the present invention adopts activated carbon as the desulfurization adsorbent and denitrification catalyst of coke oven flue gas, and the sulfur-rich gas generated by desulfurization is sent to the coking plant for chemical production process Used to produce sulfur or ammonium sulfate, the activated carbon powder that cannot be reused after wear and tear is sent to the coking plant sewage treatment process as an efficient adsorbent for coking wastewater, so as to realize the resource utilization of desulfurization and denitrification by-products of coke oven flue gas activated carbon method.

[0039] The coke oven flue gas desulfurization and denitrification by activated carbon me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com