Patents

Literature

1178 results about "Weight range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Healthy Weight Ranges. Healthy weight ranges are determined by BMI. People with a BMI between 18.5 and 24.9 are considered a healthy weight. For a man who is 5 feet, 5 inches tall, a healthy weight ranges from 114 to 150 pounds, and a man who is 5 feet, 7 inches tall, the range is between 121 and 159 pounds.

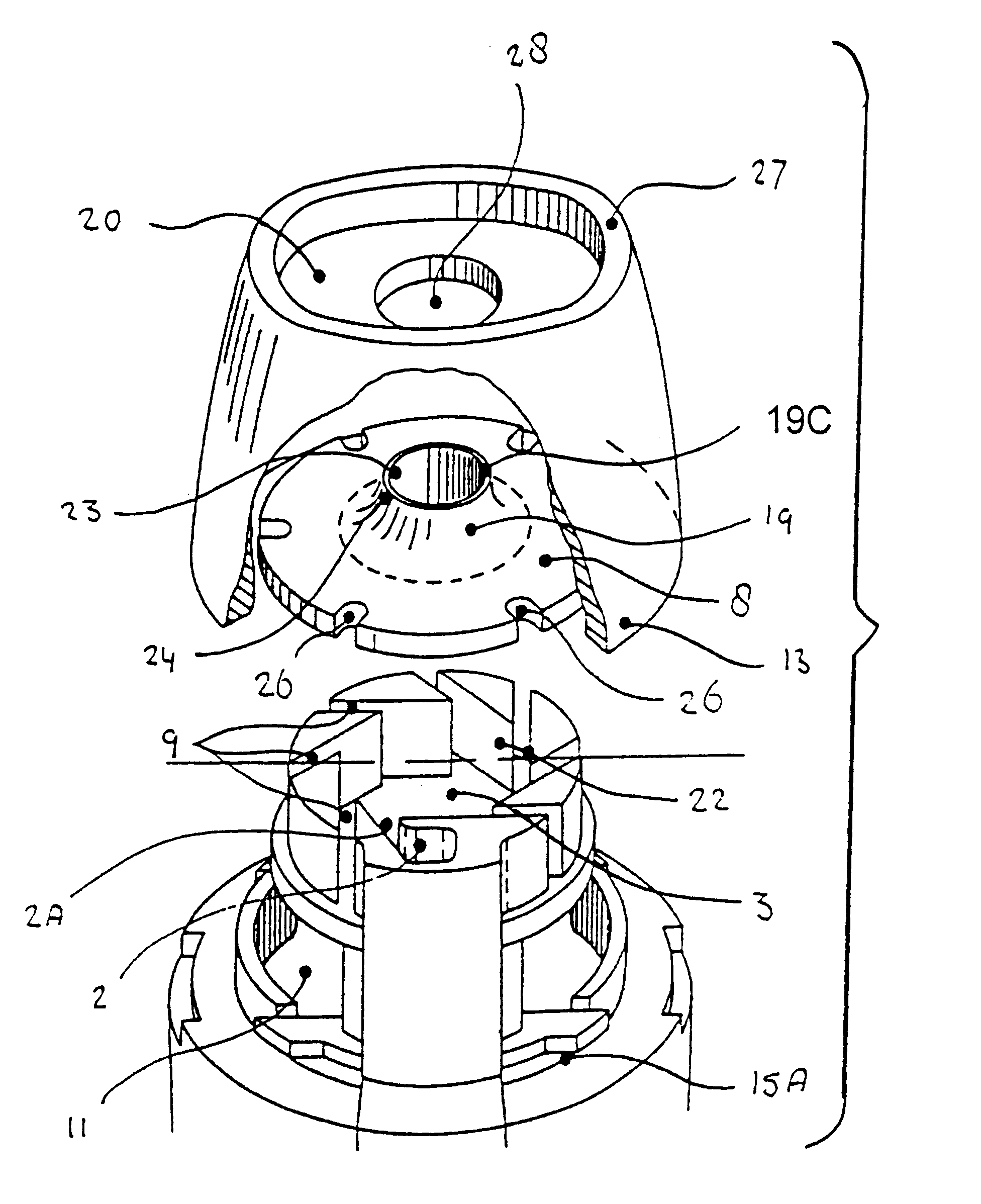

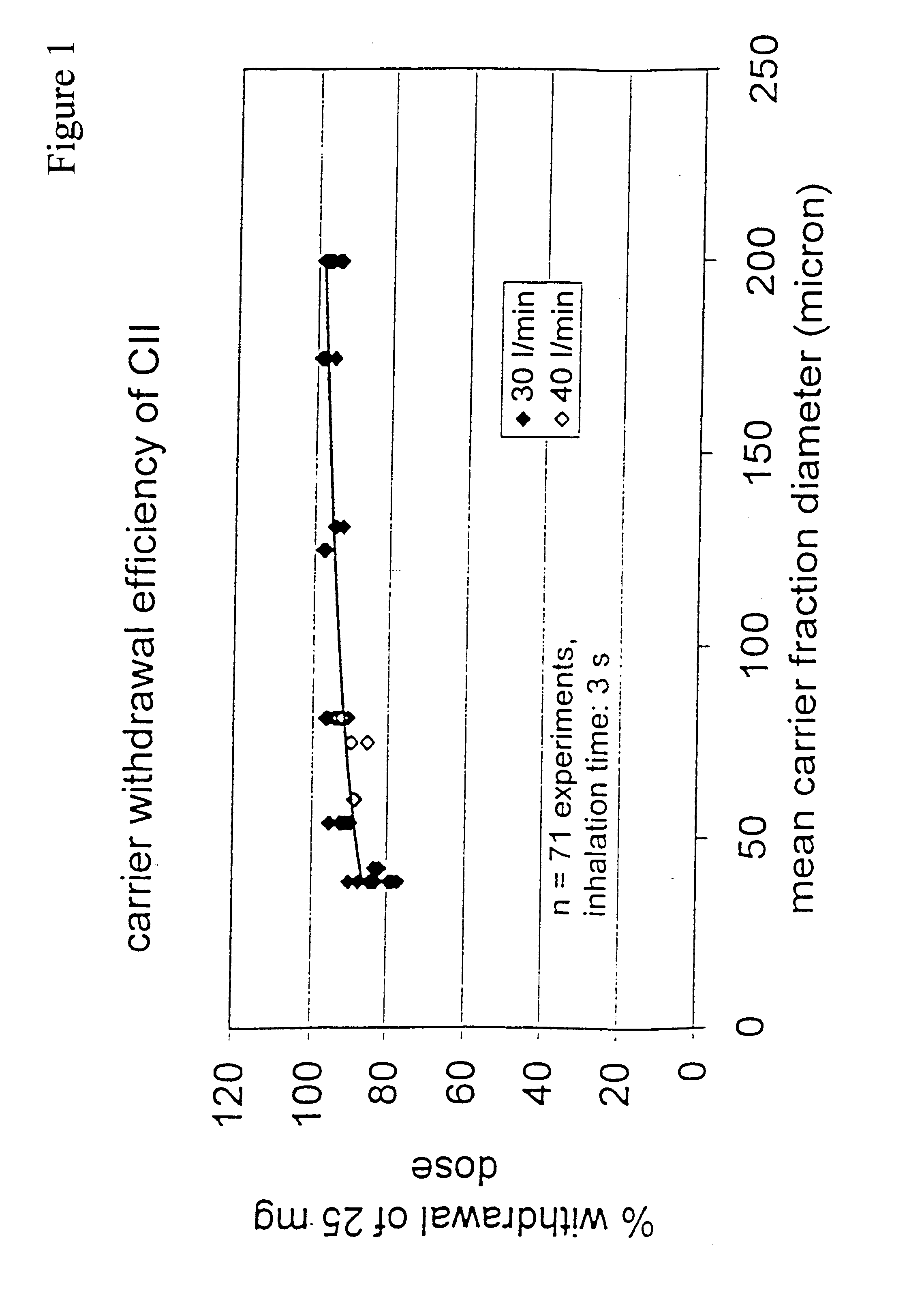

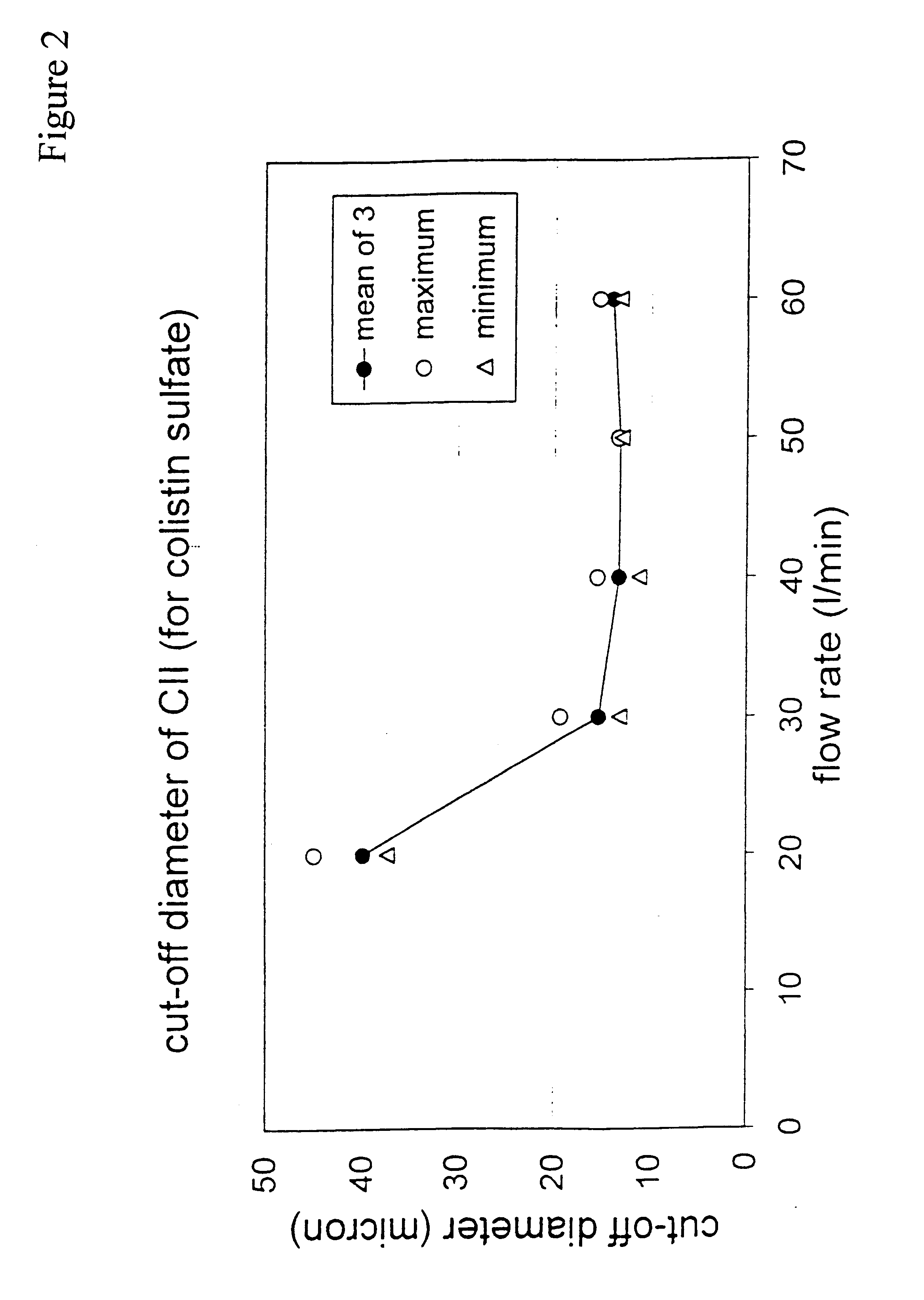

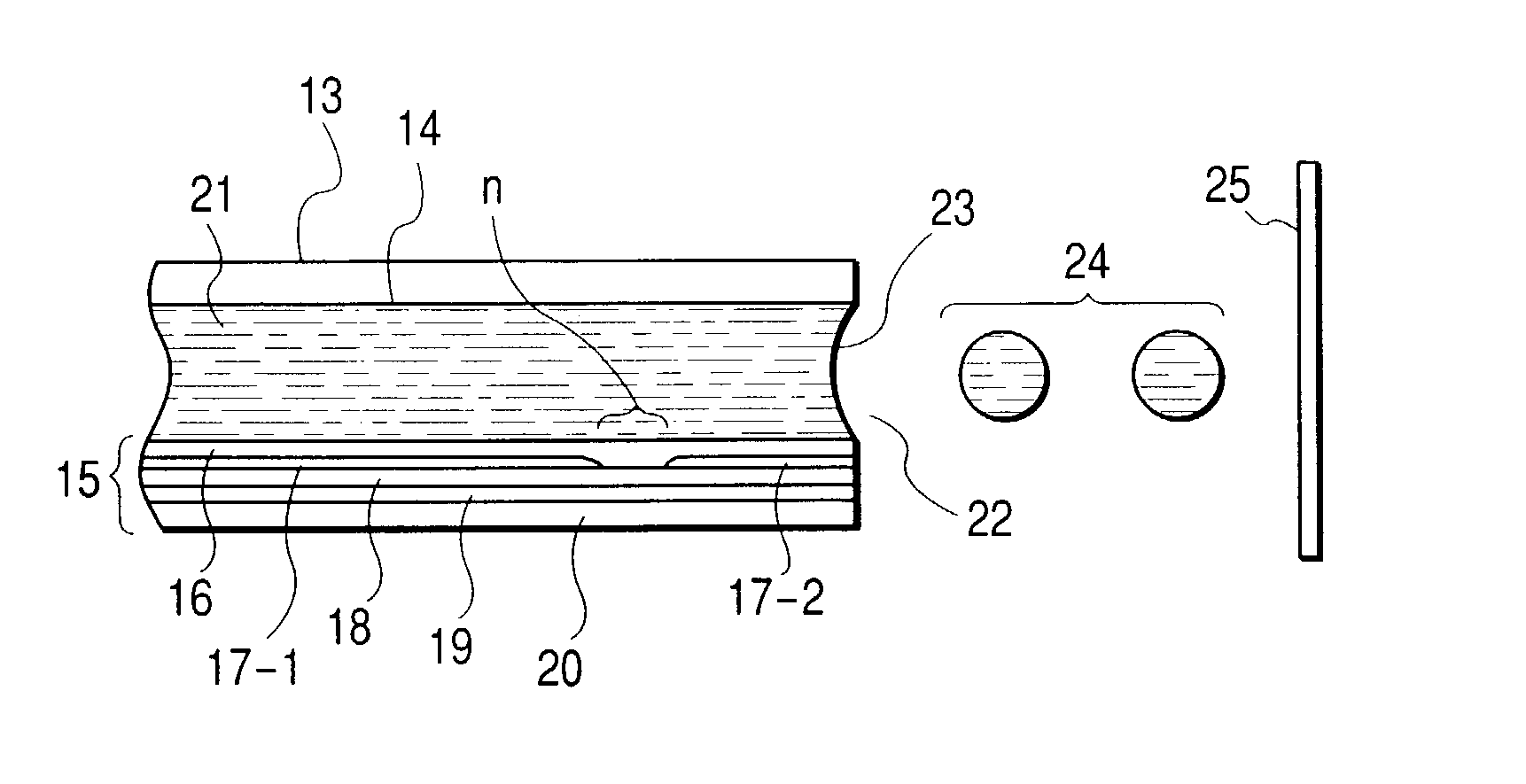

Powder formulation disintegrating system and method for dry powder inhalers

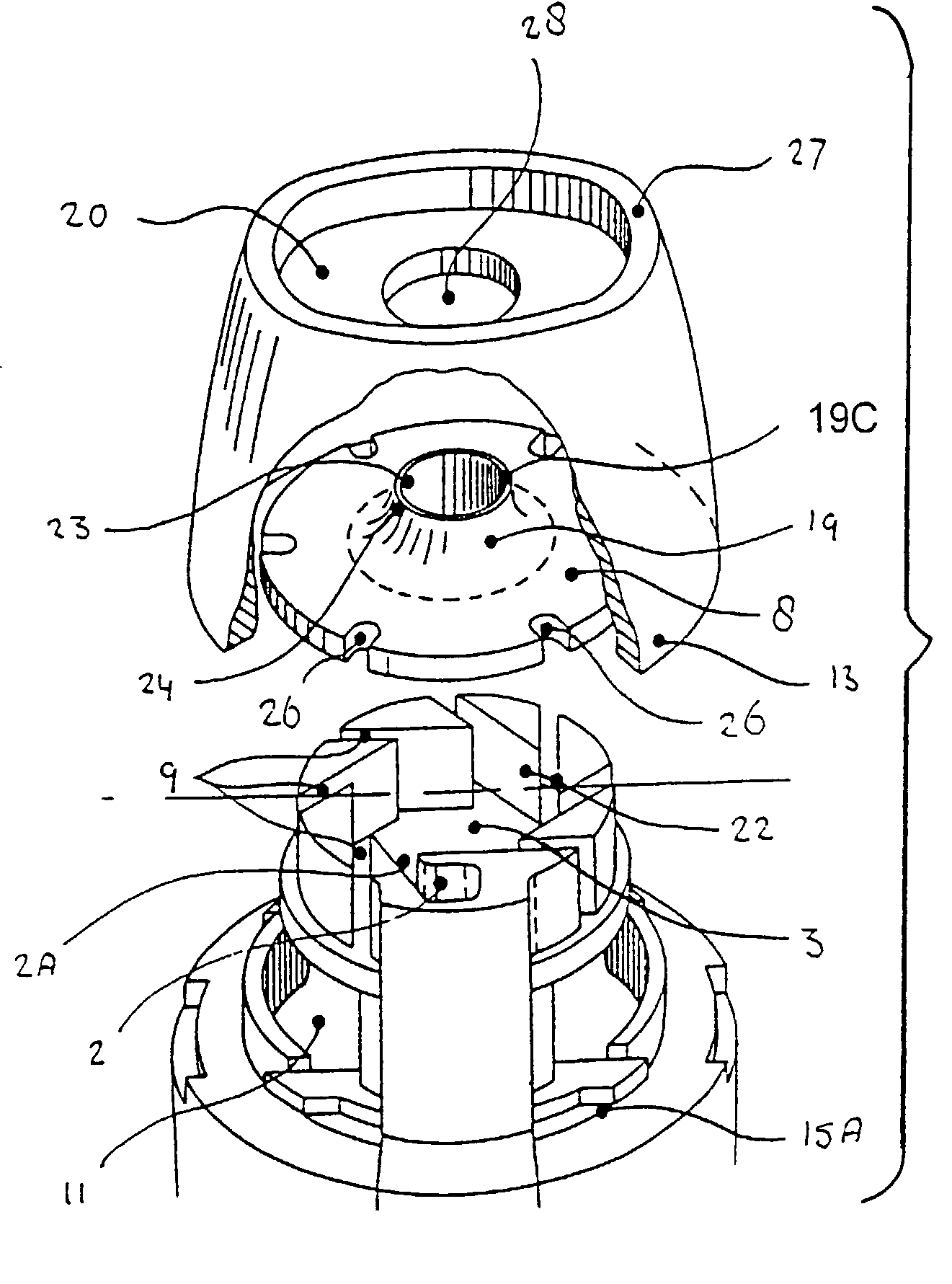

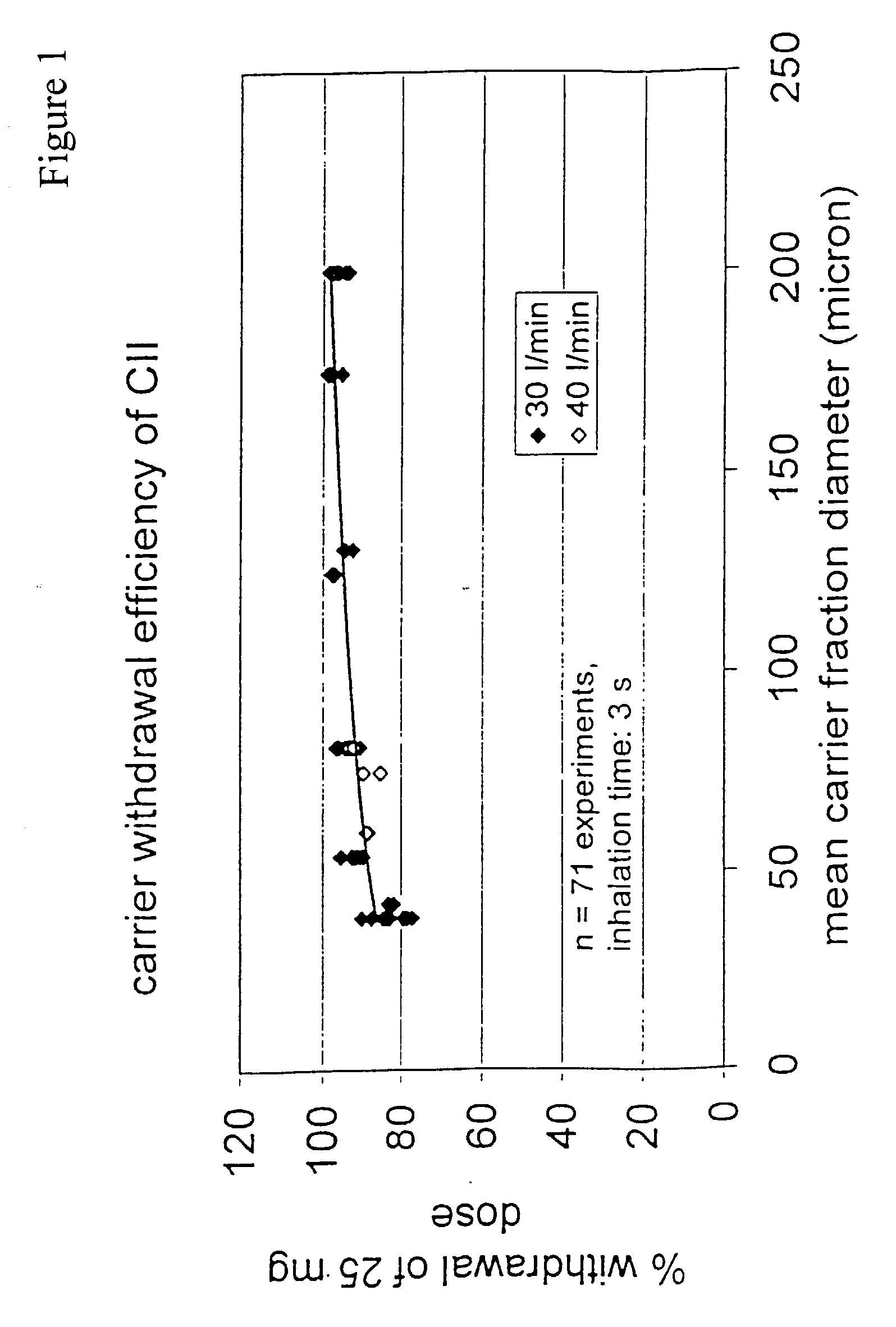

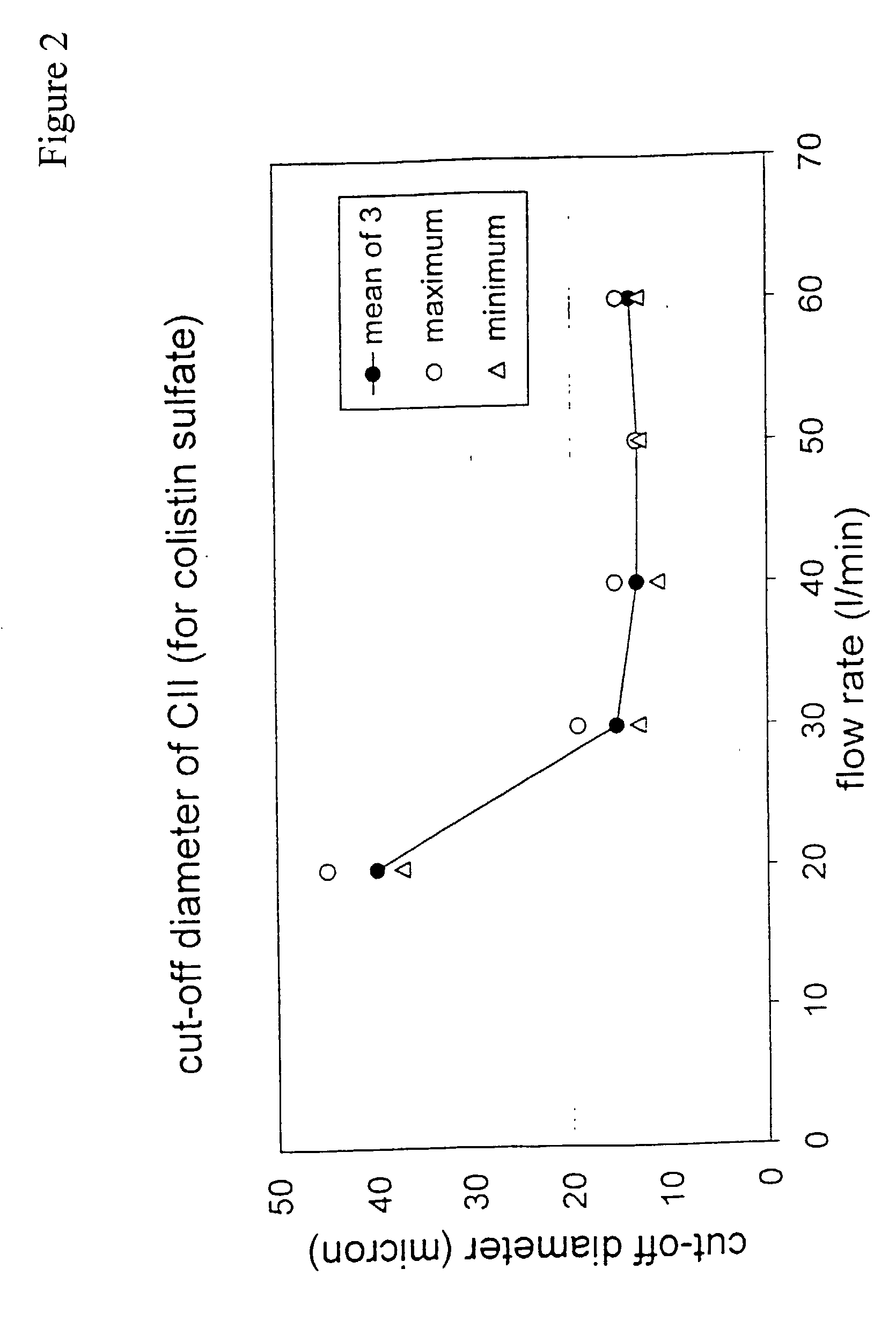

A disperser for dry powders which can be used with different dose systems, dose weights ranging from 2 to 25 mg and different types of powder formulation. In one embodiment, the disperser acts both as a de-agglomeration (disintegration; aerosolization) means and as an air classifier for especially adhesive mixtures. Only fine drug particles are emitted whereas the larger agglomerates and carrier crystals are retained by the disperser. Another embodiment enables time controlled release of carrier crystals in these mixtures. Yet another embodiment has optimized performance with spherical pellets, containing no carrier crystals. Other possible embodiments of the invention make it possible to control the total inhaler resistance and the powder deposition in the upper respiratory tract by means of the addition of a so-called sheath flow of clean air. Modifications also enable carrier retainment in the mouthpiece and elimination of the tangential flow component of the discharge cloud.

Owner:ASTRAZENECA AB

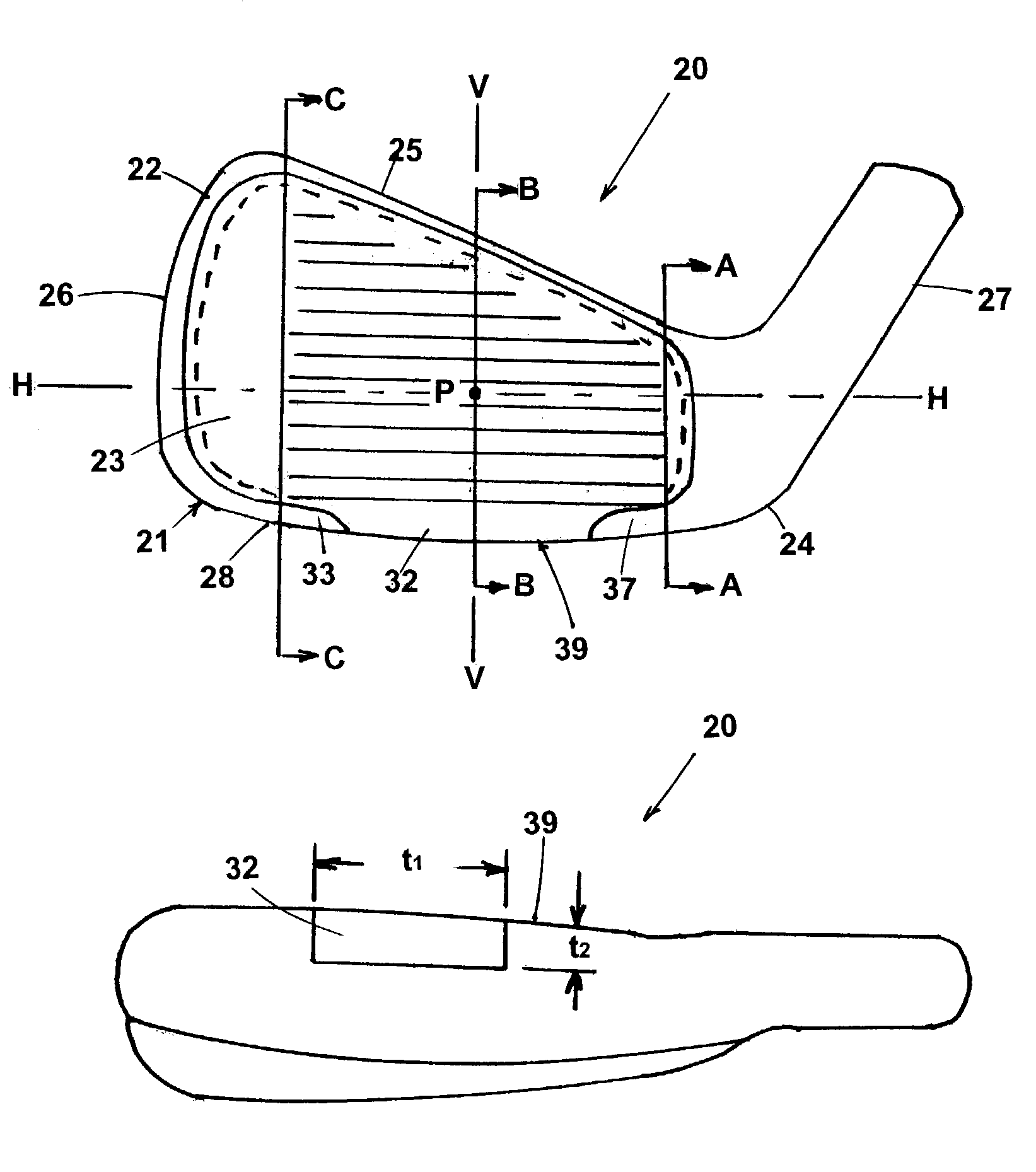

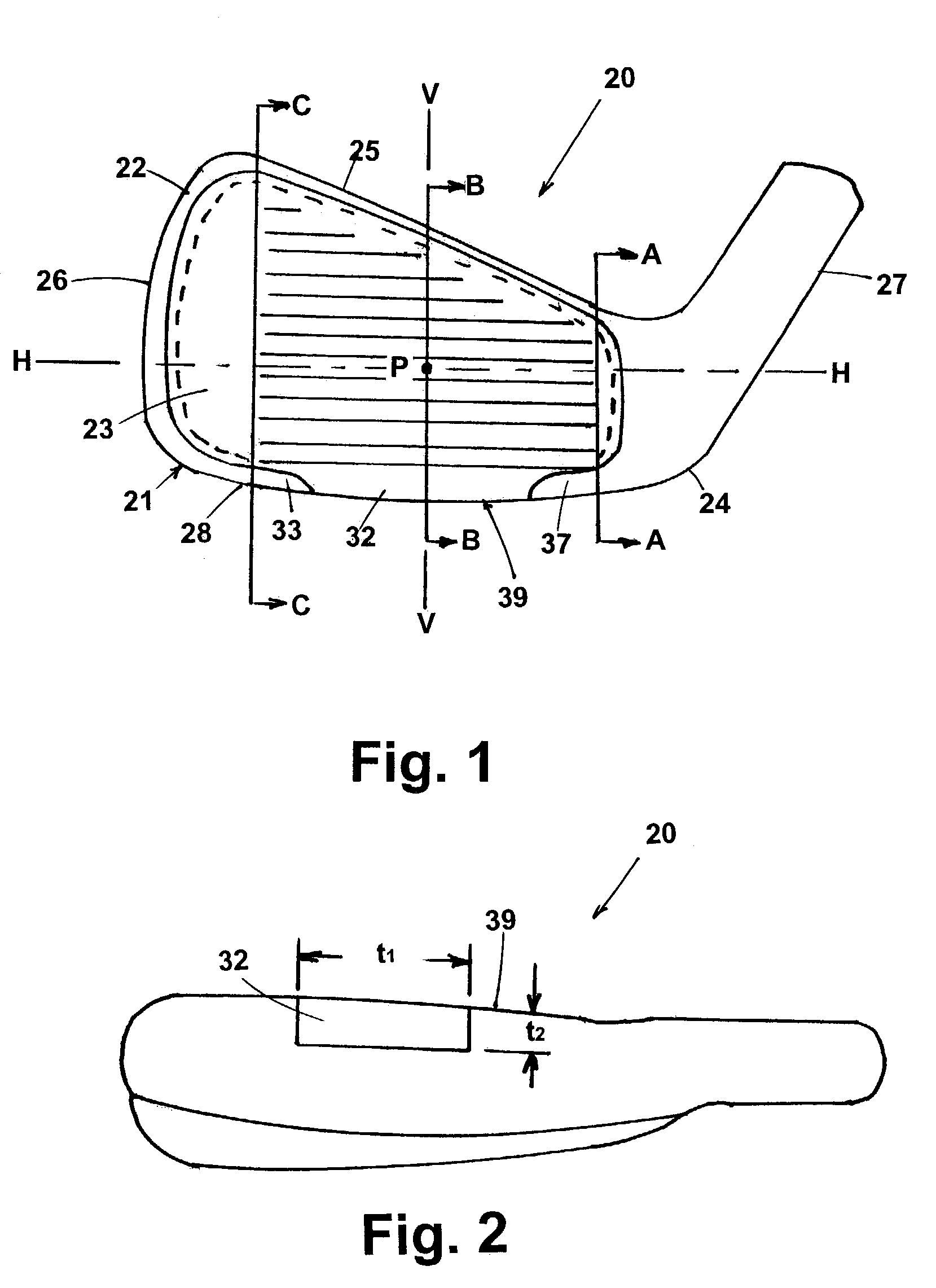

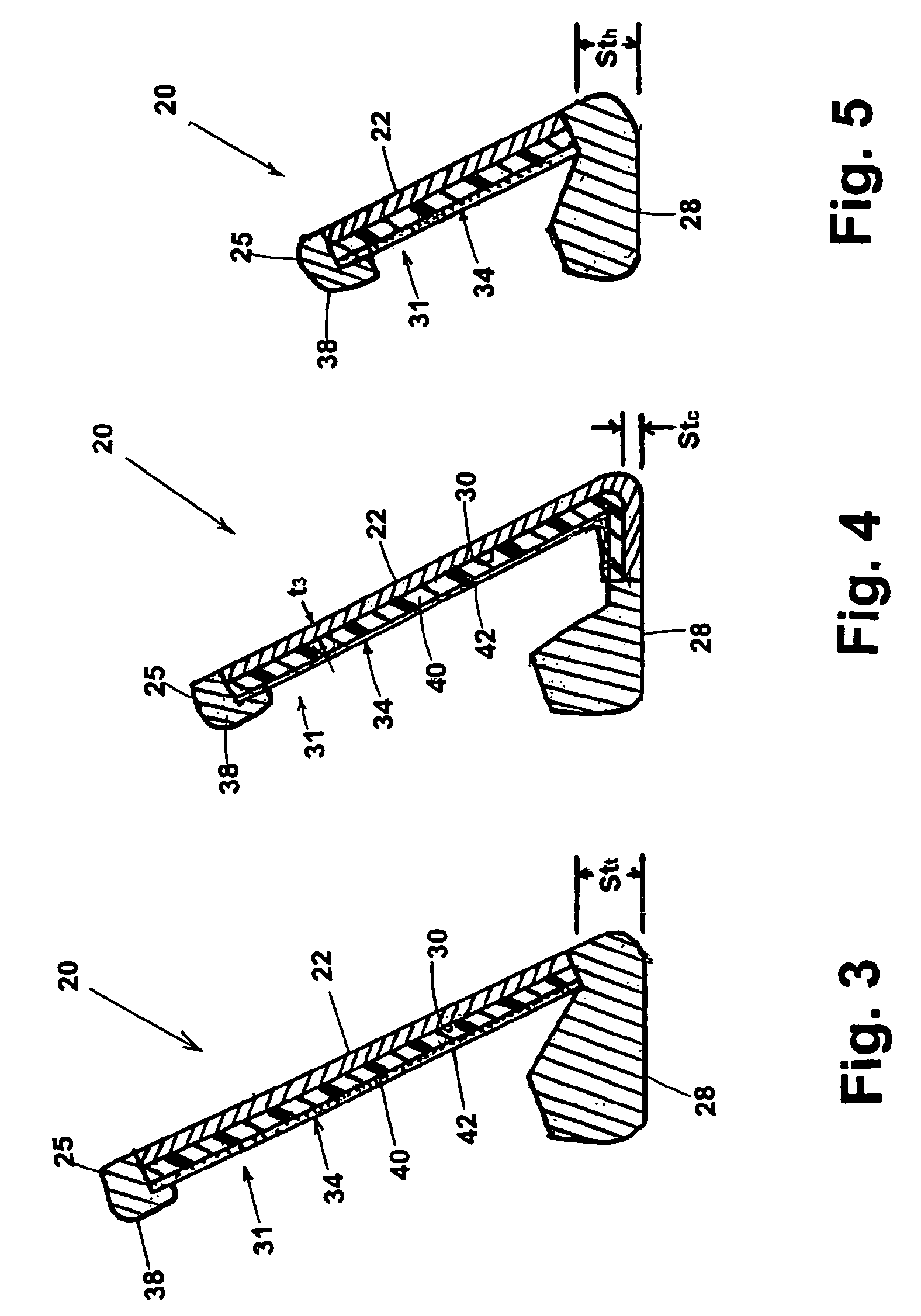

Golf club iron

An iron golf club head having a thin (less than 0.12 inches) first section that has an expanded unsupported front face region. The first section including a central portion forming part of a leading edge and wrapping around a sole section of the club, to create an increase the coefficient of restitution of the club head to greater than 0.8. The club head utilizes a rear insert that in addition to providing support for the front face, also allows for the fine tuning of swing weights with no change in geometry or size of the club head. This is accomplished this by the utilization of weight adjustment inserts that impregnate tungsten loaded plastic into sheets of carbon graphite and epoxy. The percentage of tungsten creating a weight range without any size change in the sheets.

Owner:ACUSHNET CO

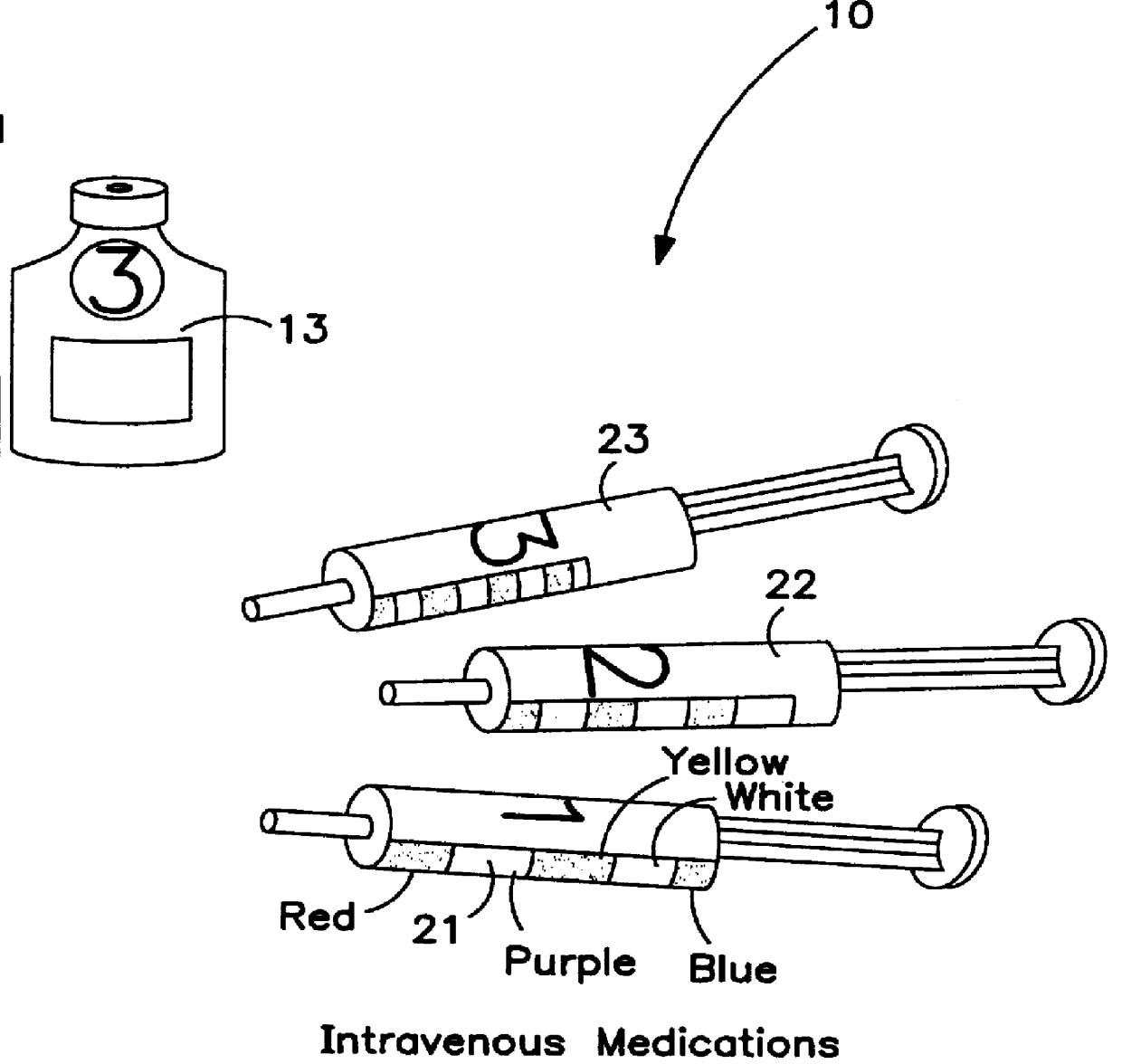

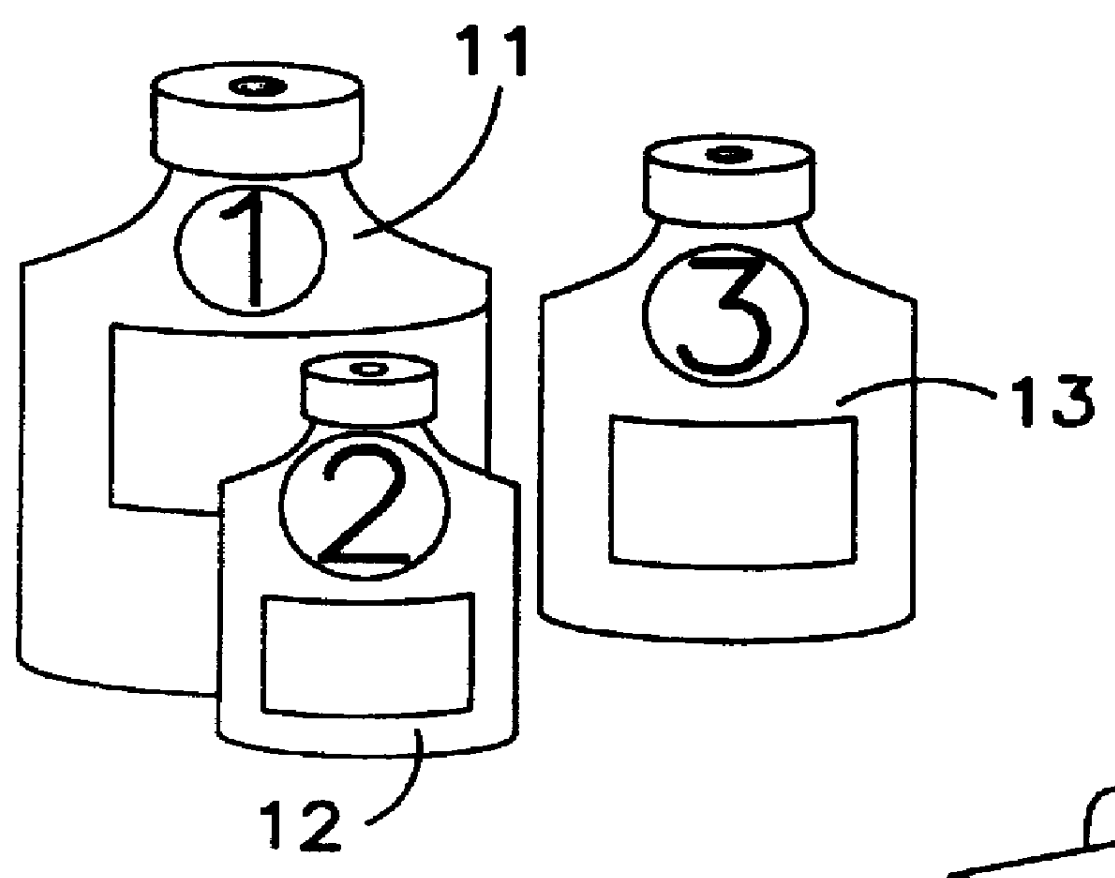

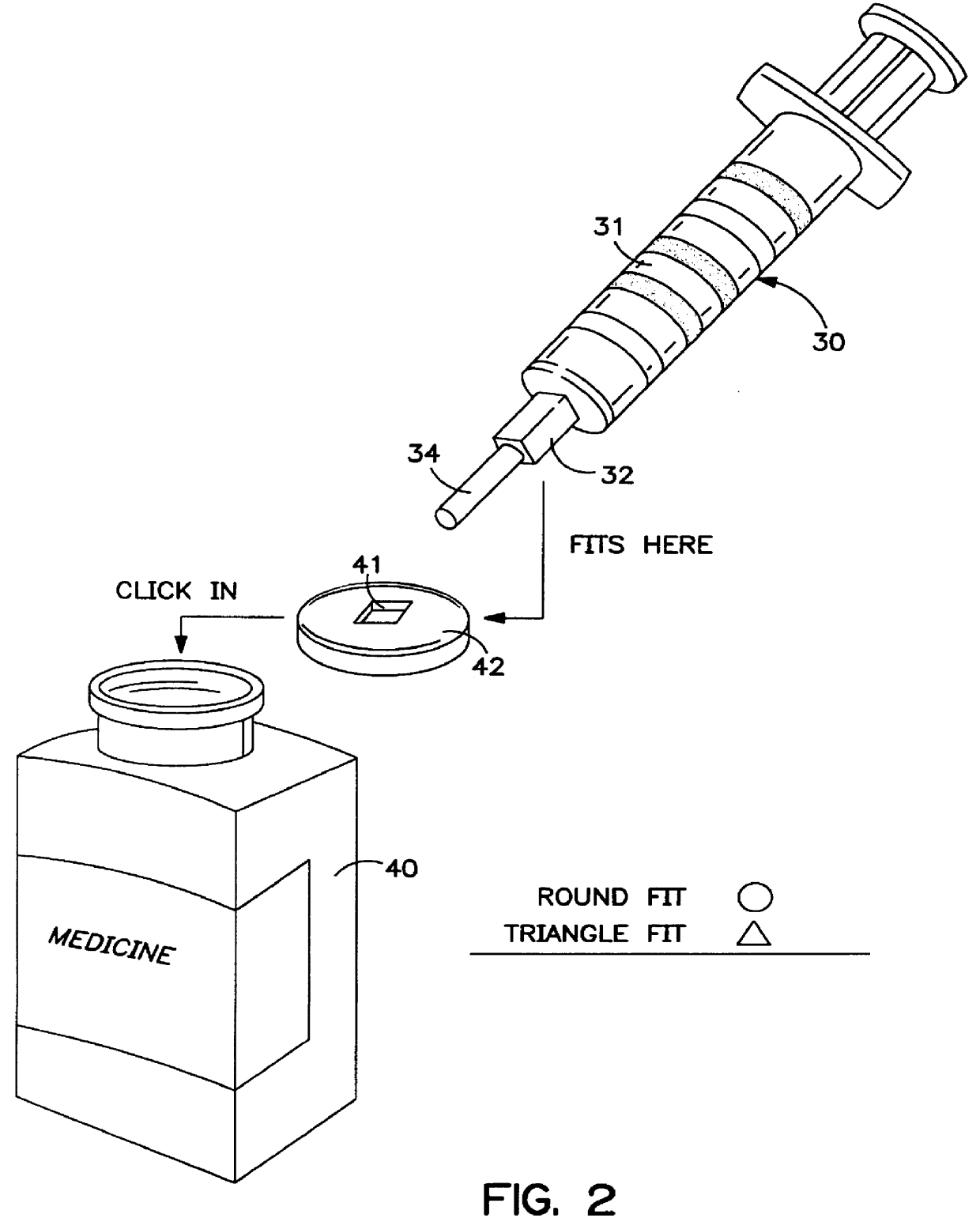

Universal medication dosing system

InactiveUS6132416AReduce the possibilityDosing becomes easy and reliableDiagnosticsSurgeryMedication doseWeight range

A method of determining the proper medication dosage for a patient, including the steps of correlating a plurality of dosages of a plurality of medications to respective weight-related values indicative of the proper dosage of each of the medications for a given patient weight range, assigning a color to each of the respective weight-related values within a predetermined, fixed sequence of colors collectively representing a dosage range for each of the medications, wherein each of the colors represents a proper dosage for each medication for a patient having a weight within the weight range to which the color is assigned, and providing a dosing system which correlates each of the dosages of the medications with the assigned color within the fixed sequence of colors without regard to the potency of said medication.

Owner:CERTA DOSE INC

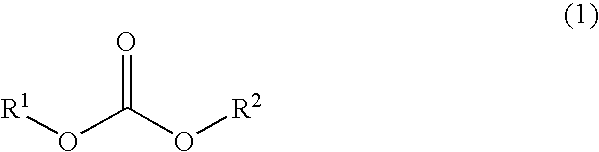

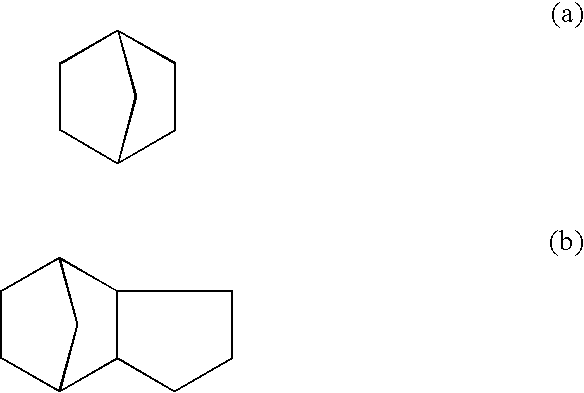

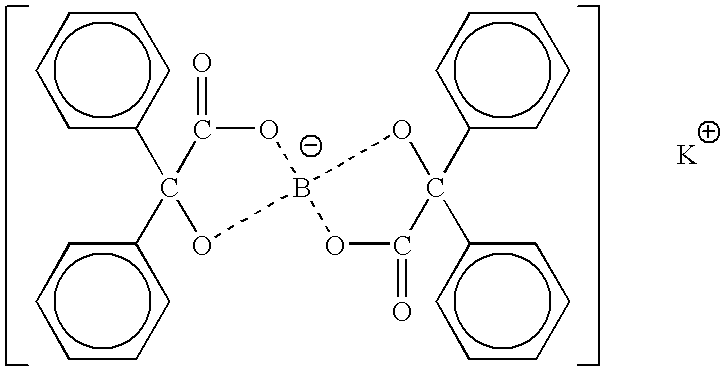

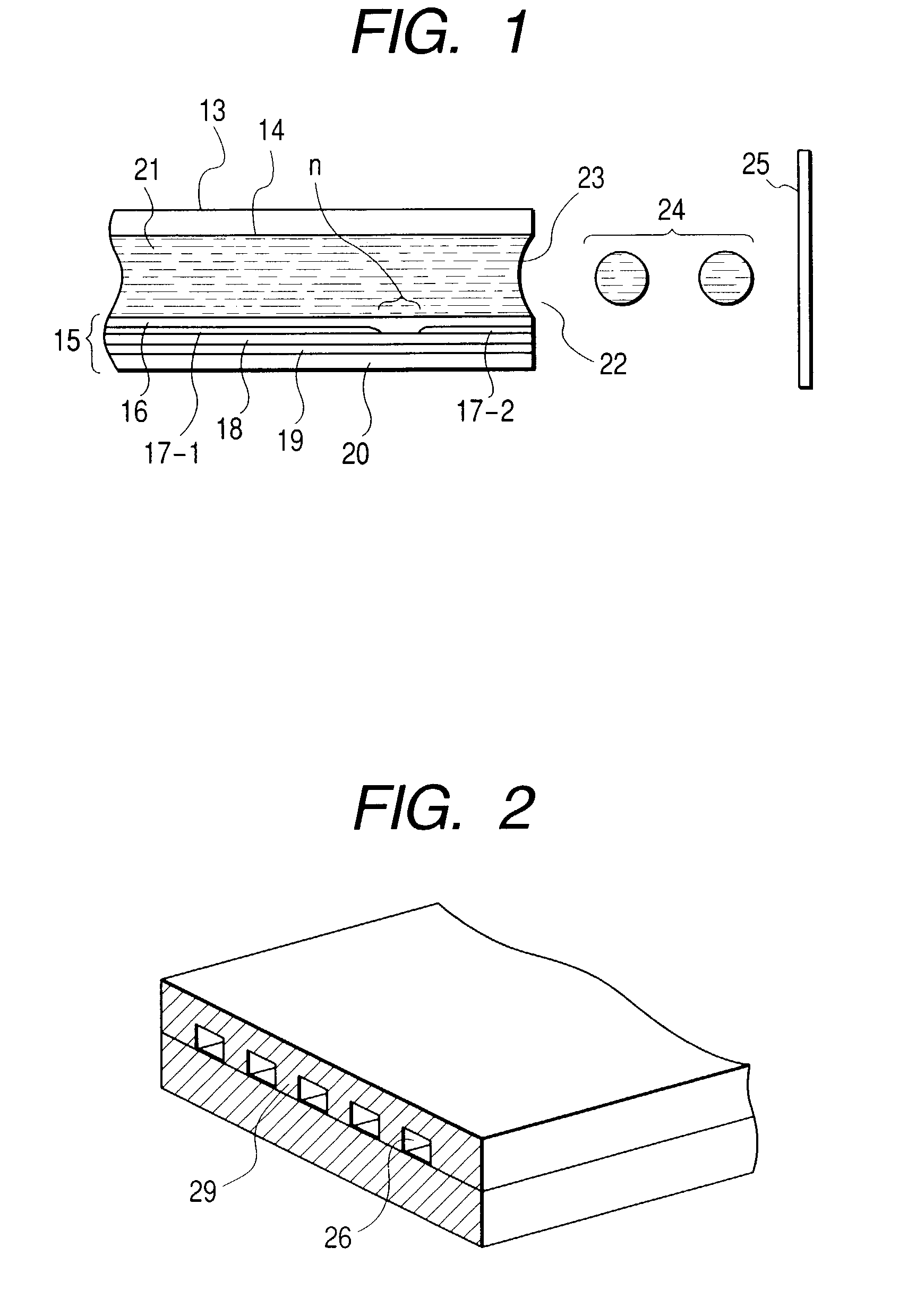

Magnetic recording medium

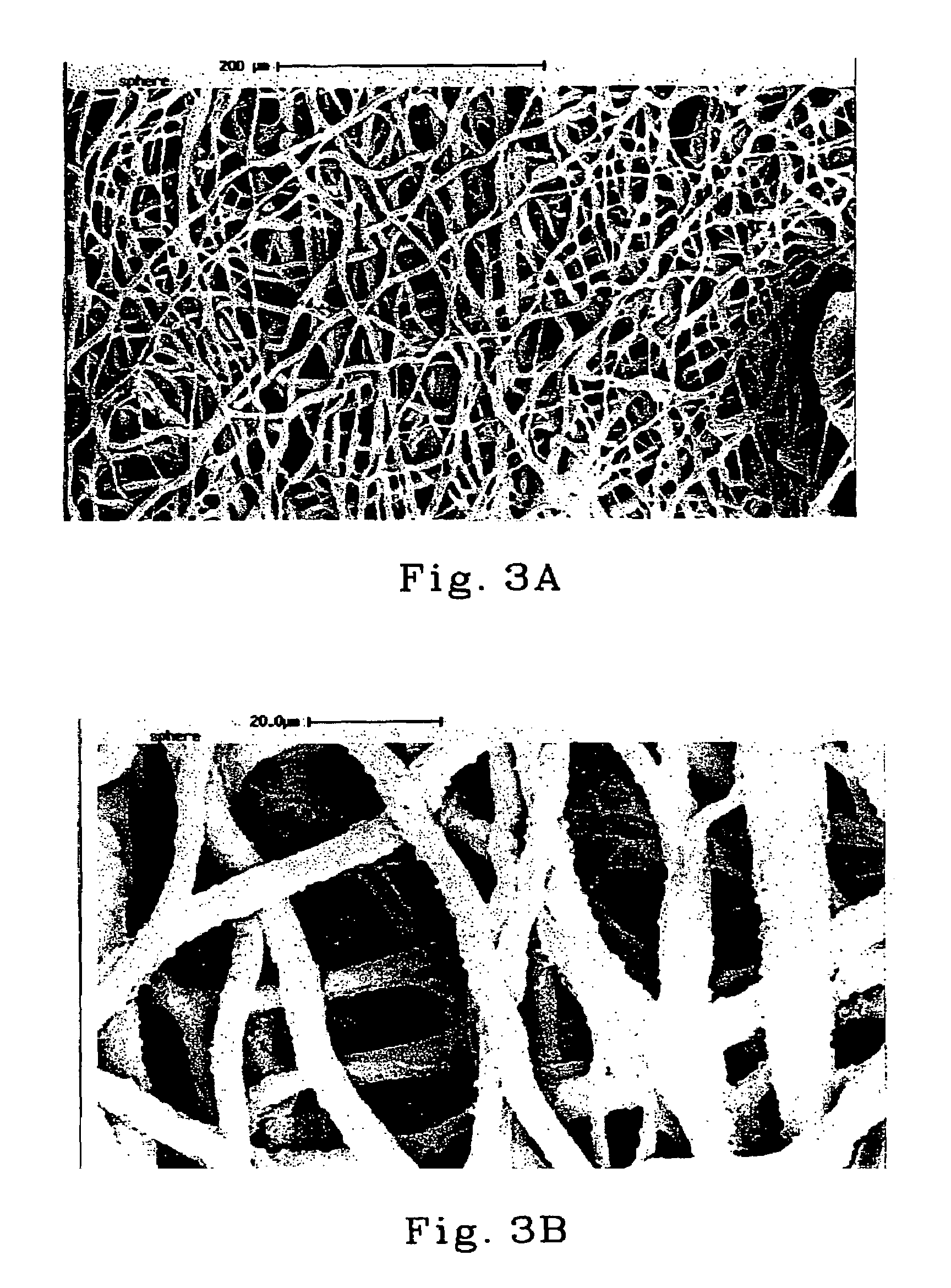

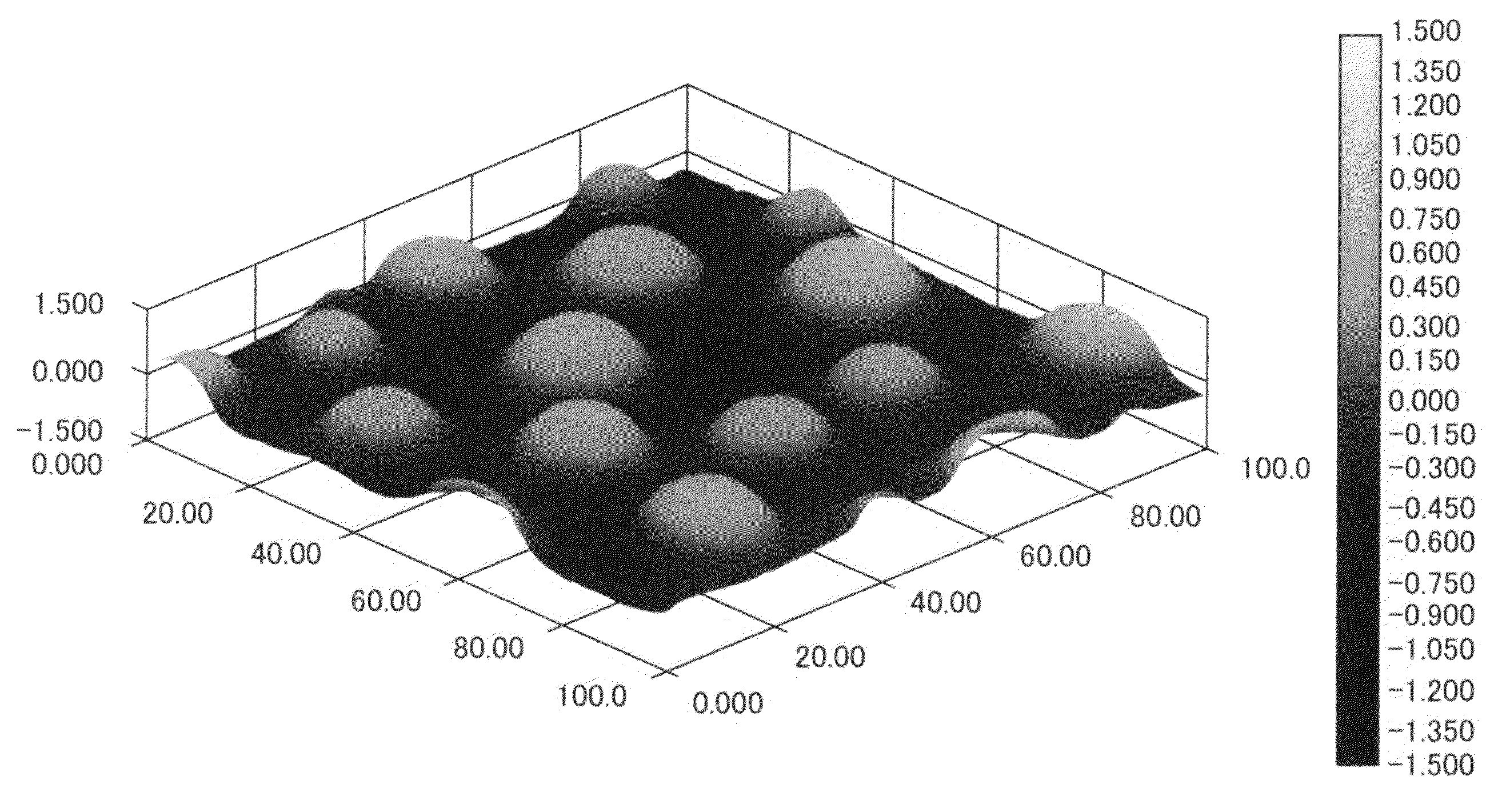

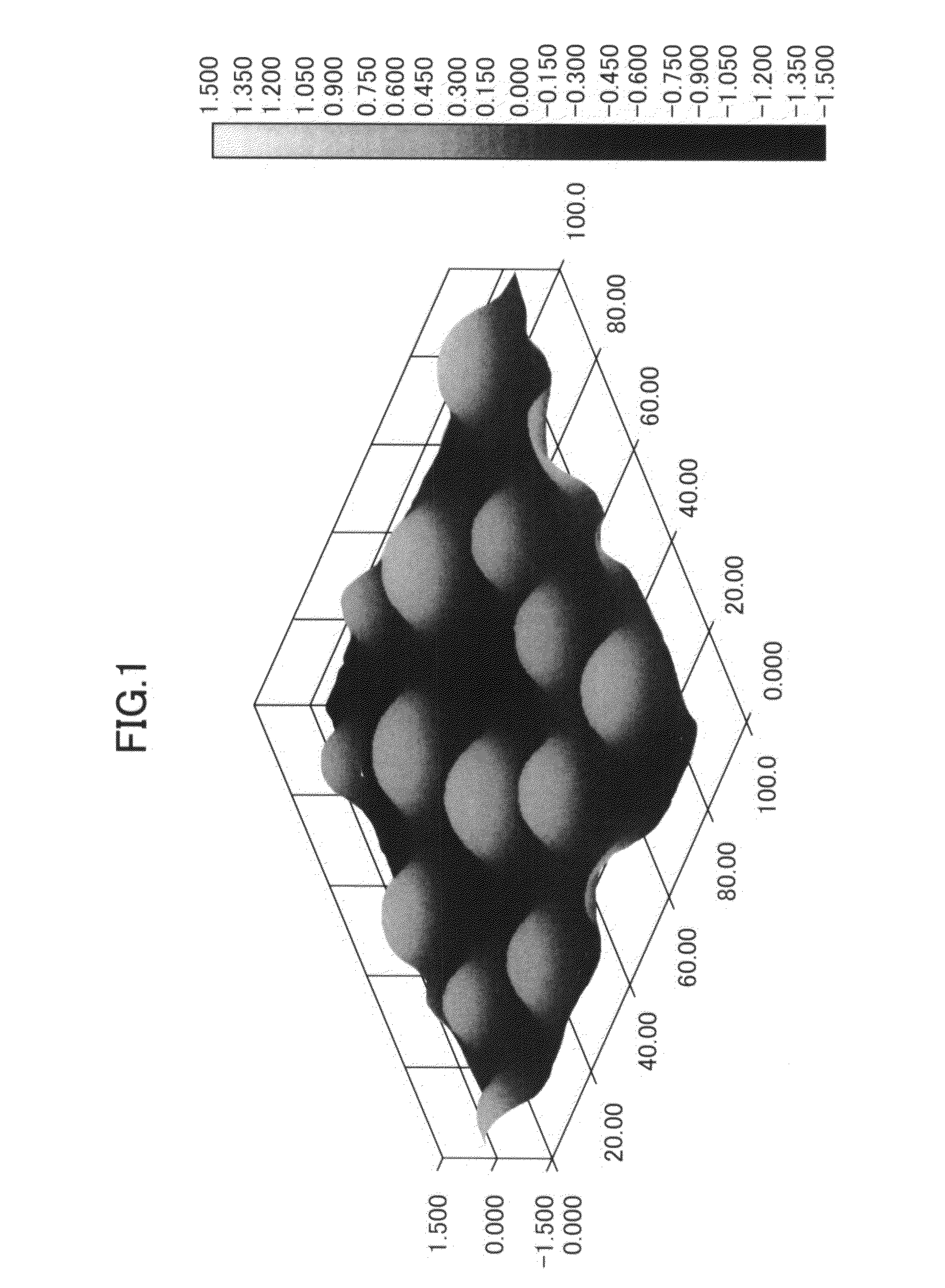

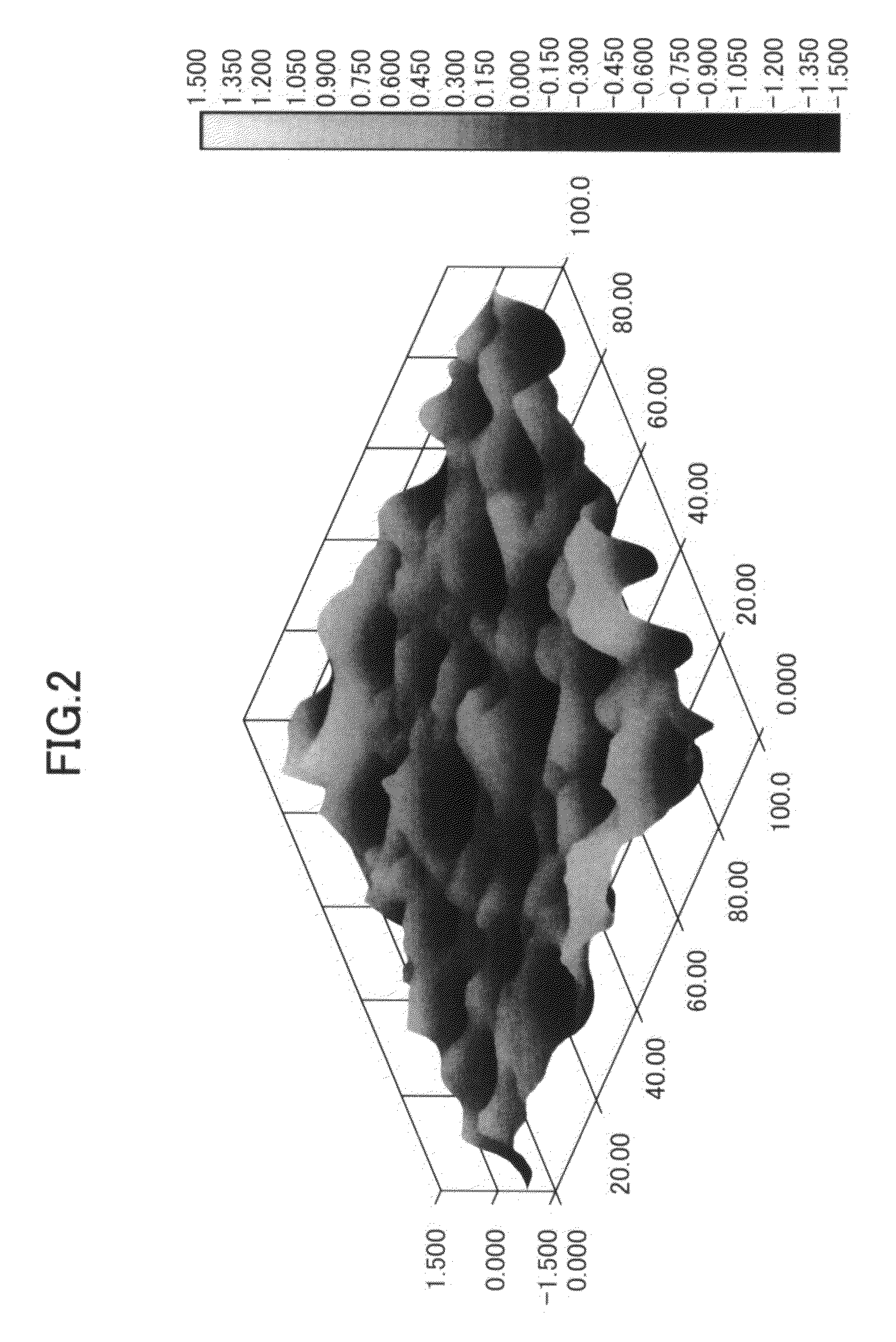

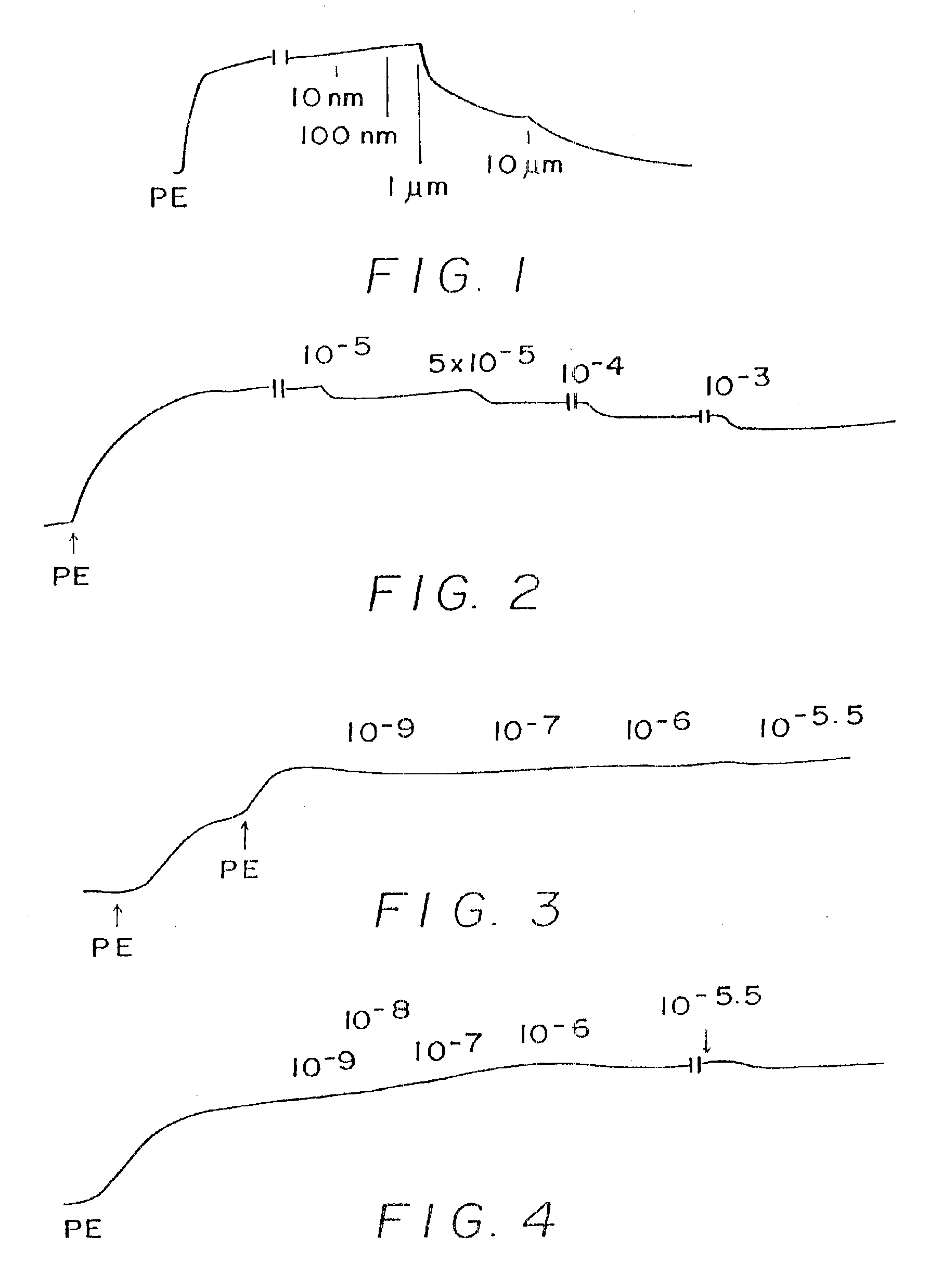

InactiveUS20090087689A1Improve high-speed running stabilityMaintain good propertiesMagnetic materials for record carriersRecord information storageAtomic force microscopyMagnetic force microscope

The magnetic recording medium comprises a magnetic layer comprising a ferromagnetic powder and a binder on a nonmagnetic support. In the magnetic recording medium, a number of protrusions equal to or greater than 10 nm in height on the magnetic layer surface, as measured by an atomic force microscope, ranges from 50 to 500 / 1,600 μm2, the binder comprises a polyurethane resin with a weight average molecular weight ranging from 100,000 to 200,000, and the magnetic layer further comprises a carbonic ester having a molecular weight ranging from 360 to 460.

Owner:FUJIFILM CORP

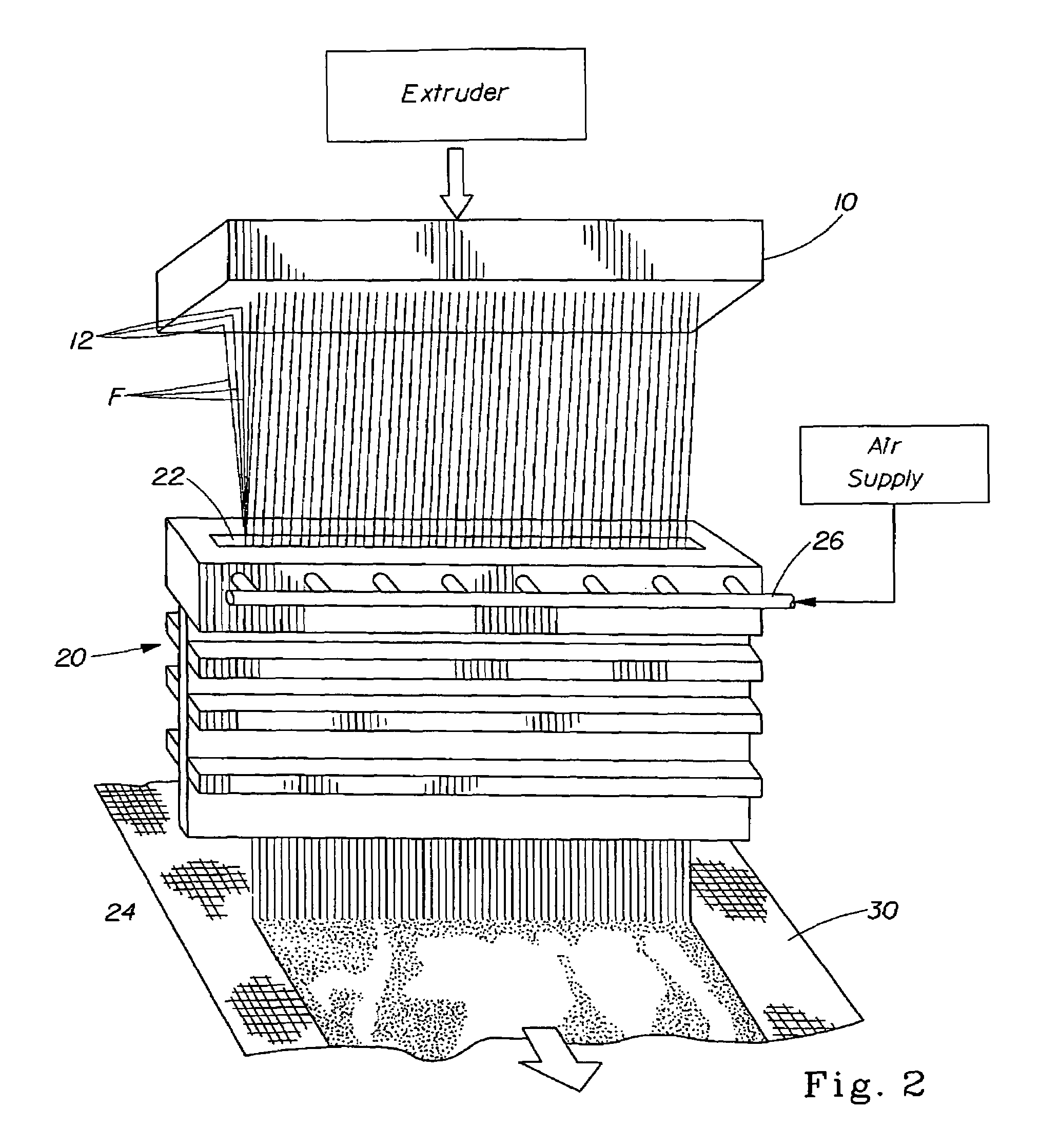

Powder formulation disintegrating system and method for dry powder inhalers

A disperser for dry powders which can be used with different dose systems, dose weights ranging from 2 to 25 mg and different types of powder formulation. In one embodiment, the disperser acts both as a de-agglomeration (disintegration; aerosolization) means and as an air classifier for especially adhesive mixtures. Only fine drug particles are emitted whereas the larger agglomerates and carrier crystals are retained by the disperser. Another embodiment enables time controlled release of carrier crystals in these mixtures. Yet another embodiment has optimized performance with spherical pellets, containing no carrier crystals. Other possible embodiments of the invention make it possible to control the total inhaler resistance and the powder deposition in the upper respiratory tract by means of the addition of a so-called sheath flow of clean air. Modifications also enable carrier retainment in the mouthpiece and elimination of the tangential flow component of the discharge cloud.

Owner:ASTRAZENECA AB

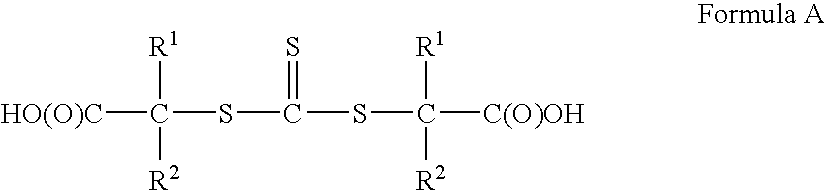

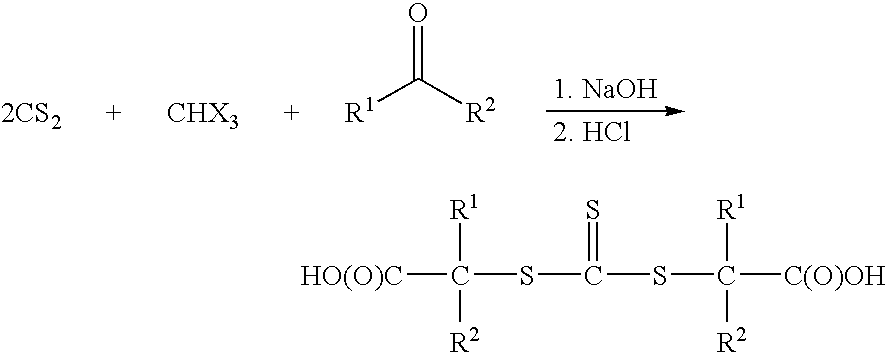

Fuel additives for treating internal deposits of fuel injectors

ActiveUS20120255512A1Avoid cloggingReduce the amount requiredNon-fuel substance addition to fuelInternal combustion piston enginesEnantiomerDiesel engine

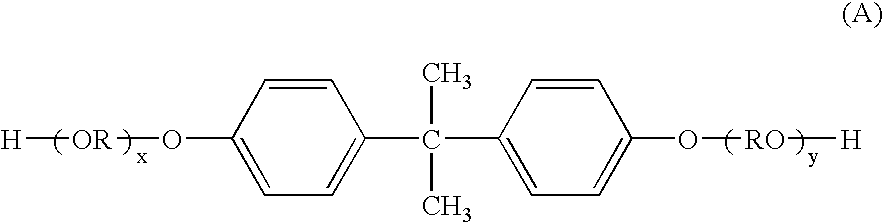

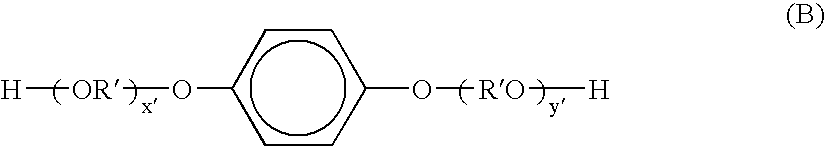

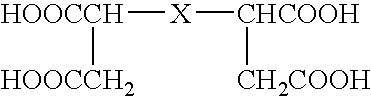

A method for cleaning internal components of a fuel injector for a diesel engine. The method includes operating a fuel injected diesel engine on a fuel composition comprising a major amount of fuel and from about 10 to about 100 ppm by weight based on the total weight of the fuel composition of (A) a compound of the formula:and tautomers and enantiomers thereof, wherein R2 is a hydrocarbyl group having a number average molecular weight ranging from 100 to 5000.

Owner:AFTON CHEMICAL

Melt processable starch composition

The present invention relates to starch compositions which contain starch and additives. The starch has a weight average molecular weight ranging from about 1,000 to about 2,000,000. The additives can be plasticizers or diluents. The composition containing the starch and the additive is formed by means of passing the composition through a die to produce fibers, foams or films. These compositions have an extensional viscosity in the range from about 50 to about 20,000 pascal seconds. The starch compositions preferably contain a polymer that is substantially compatible with starch and has a weight-average molecular weight of at least 500,000.

Owner:THE PROCTER & GAMBLE COMPANY

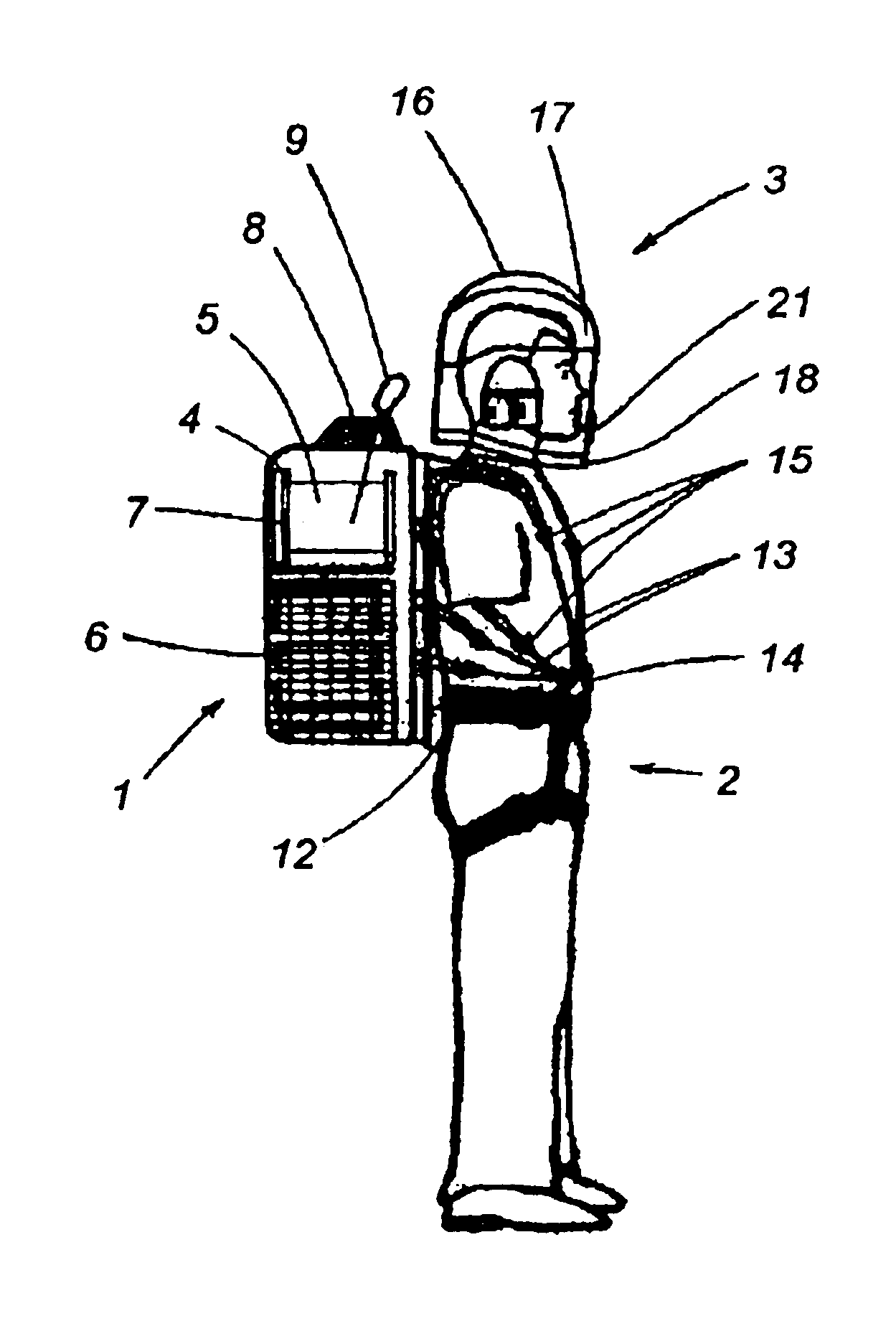

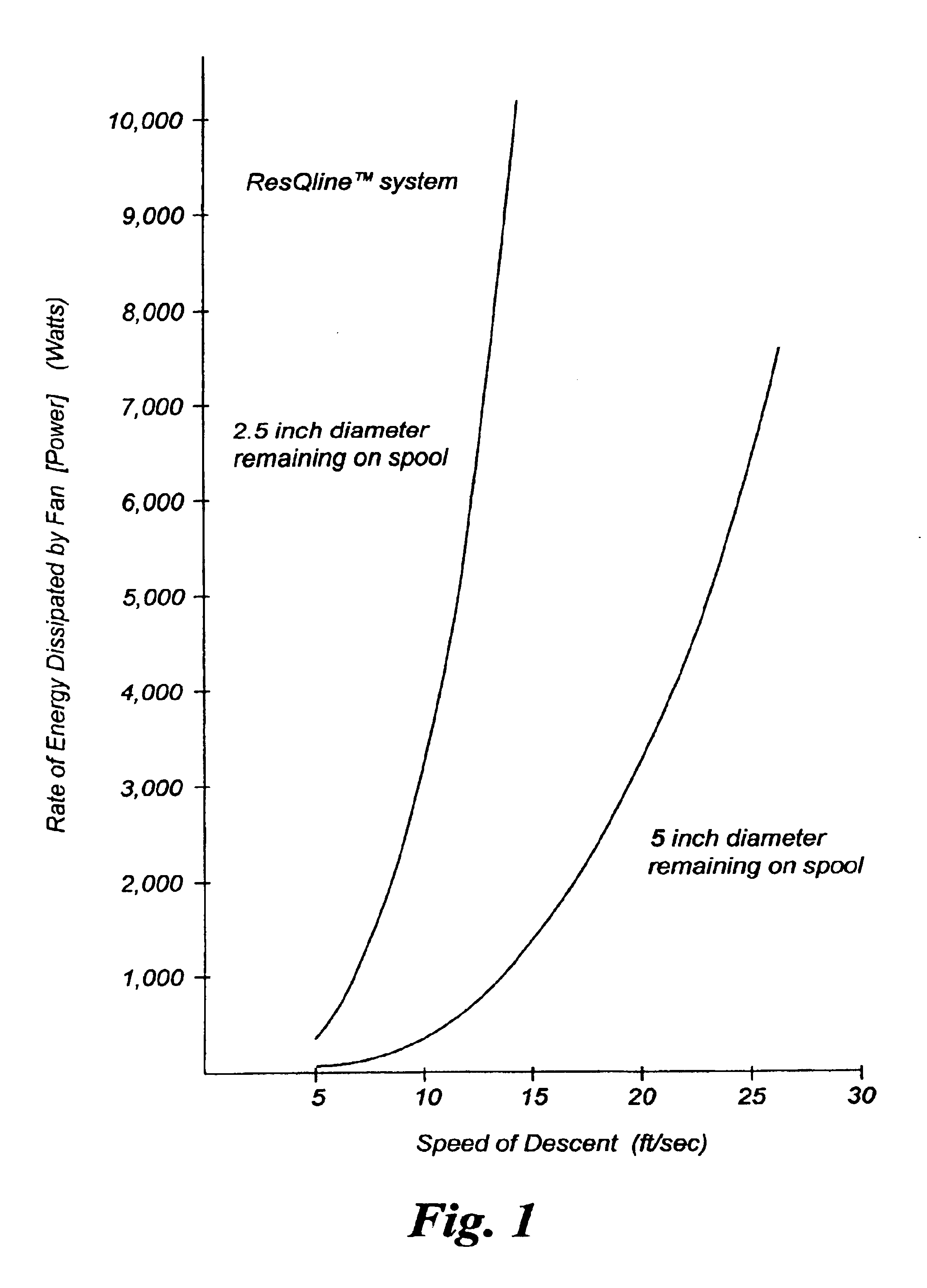

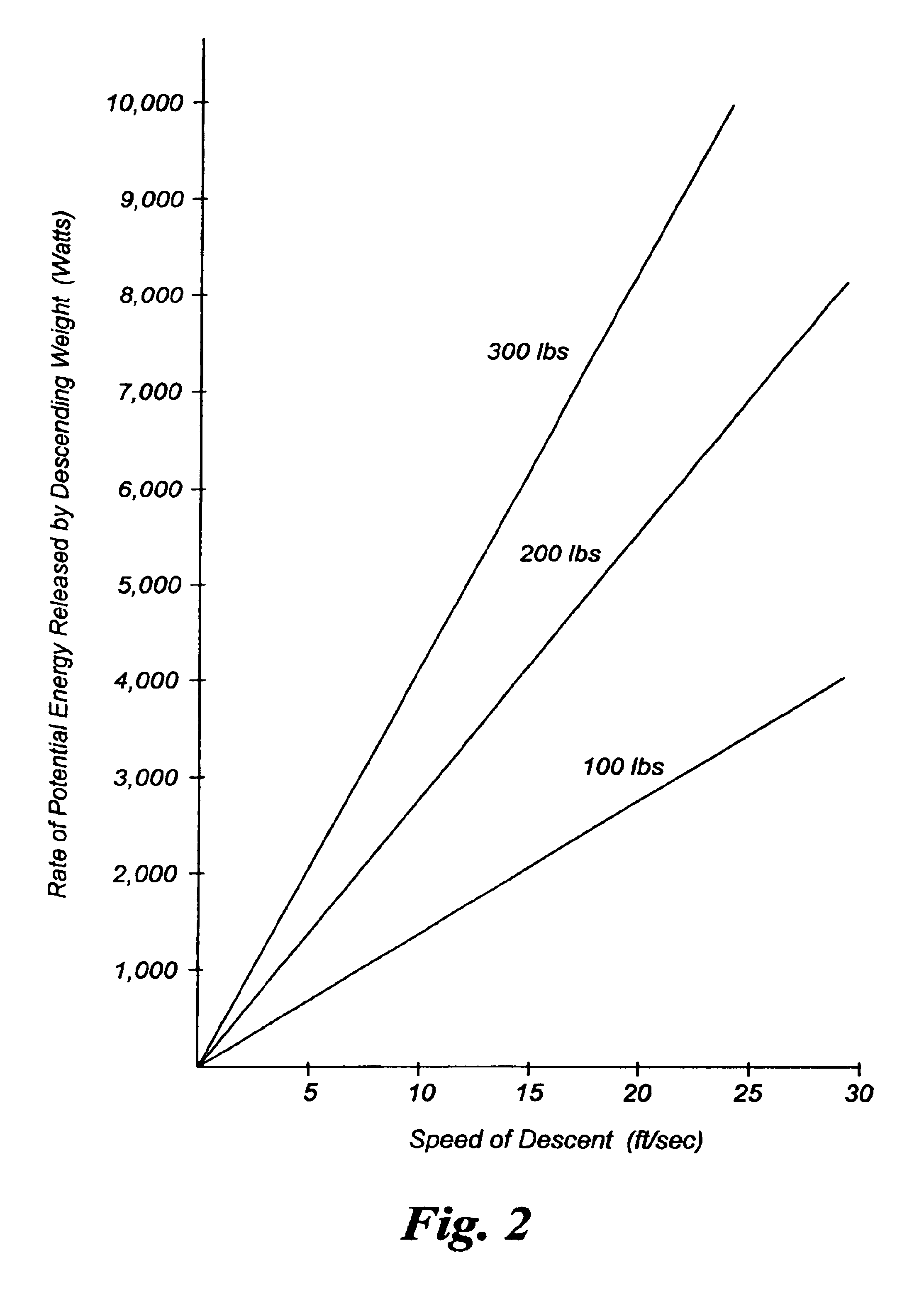

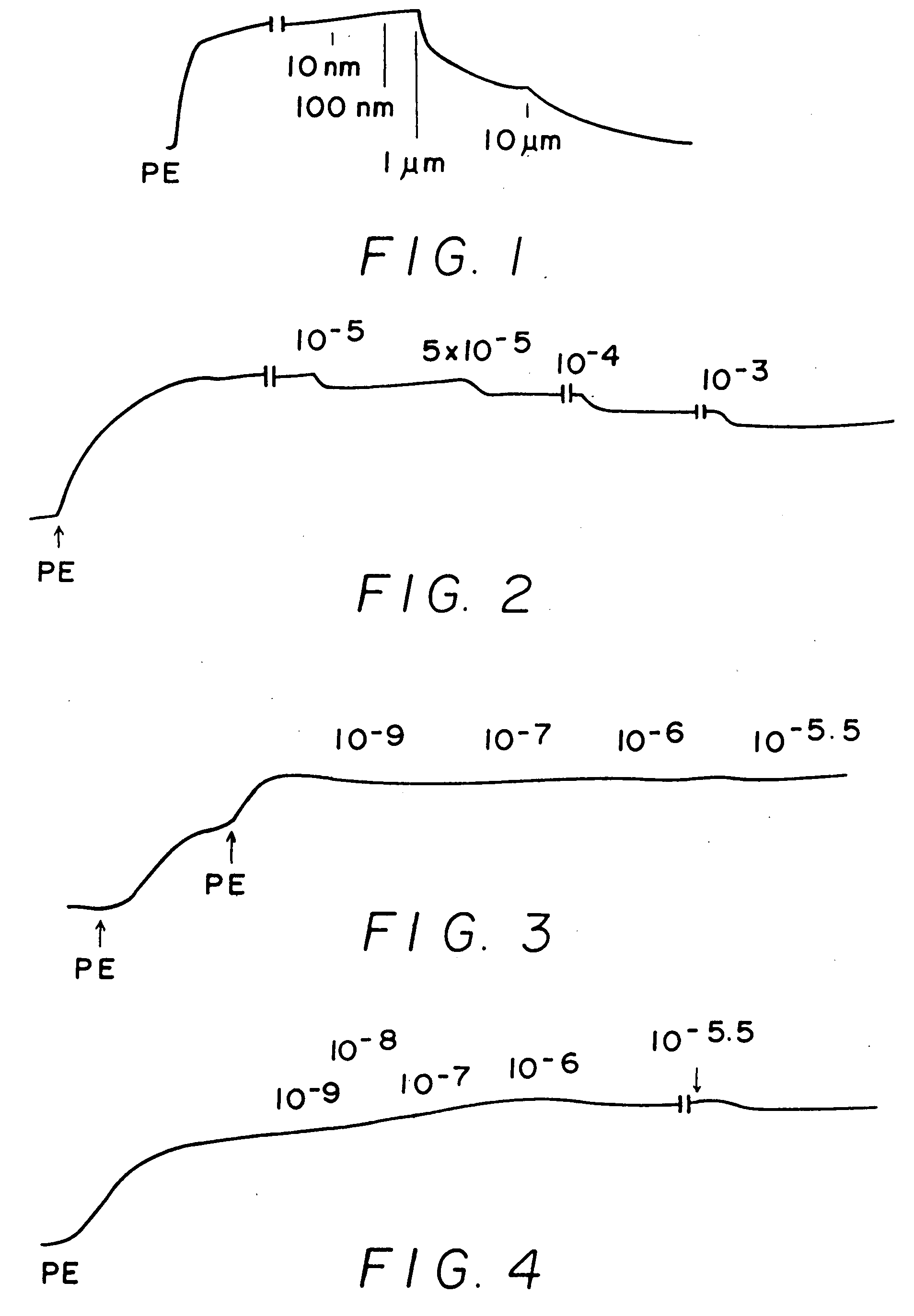

Apparatus for exterior evacuation from buildings

InactiveUS6962235B2Quick and safe evacuationQuick exitFilament handlingFire rescueFoot per secondEngineering

An apparatus for safely evacuating a person within a prescribed weight range from a multistory building by enabling the person to exit from the interior of the building to the outside very quickly and to descend to the ground or lower surface alongside the exterior of the building to attain a descent speed of less than four feet per second to land injury-free, the apparatus comprising a housing, a harness affixed to the housing for affixing the housing to the person, a cable of predetermined length within the housing, having a free-end with a securing member for affixing it to an anchorage proximate the descent point, and a descent slowing energy dissipating mechanism within the housing driven by the playout of the cable as the person descends, which enables the person to attain automatically within his descent a descent speed of less than four feet per second determined by the intersection of the graph of the curve that describes the rate of energy dissipated as a function of the descent speed and the graph of the line that describes the rate of potential energy released by the total descending weight as a function of descent speed where the slove of the graph of the rate of energy dissipated curve exceeds the slone of the graph of the rate of potential energy released line.

Owner:LIFE PACK TECH

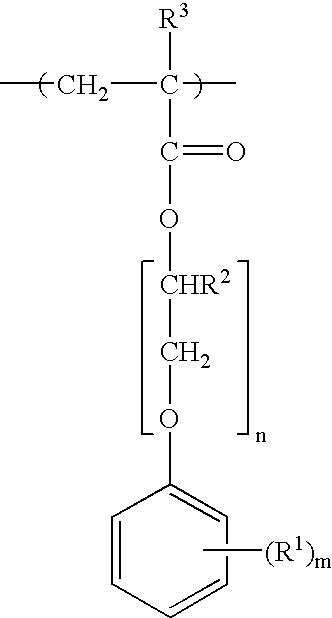

Anti-glare glass substrate

InactiveUS20070195419A1Improve visibilityWrite fluentlyLiquid crystal compositionsCoatingsArylPolymer science

An anti-glare glass substrate used for liquid crystal display devices is disclosed, which comprises a glass substrate; and a coating covering one side of said substrate, the coating having, on its surface, projection bodies which have round bottom surfaces and have an average bottom surface area ranging from 80 to 400 μm2, the projection bodies being randomly arranged on said coating at a density of 5 or more projection bodies per an area equivalent to one pixel of the liquid crystal display device, and the coating having a surface roughness from 0.1 to 0.4 μm. The anti-glare glass substrate can be prepared by the steps of (1) preparing a coating liquid by blending a silica sol (A) consisting of an oligomer whose crosslinks are formed from [SiO4 / 2] as crosslinking units and whose number average molecular weight ranges from 300 to 1000 (polystyrene conversion) and a silica sol (B) consisting of an oligomer in which silicon oxides having bonds between aryl groups and silicon atoms are formed as crosslinking units and whose number average molecular weight ranges from 500 to 1000 (polystyrene conversion); and (2) applying the resulting coating liquid onto the surface of a glass substrate according to the spin coating technique.

Owner:CENT GLASS CO LTD

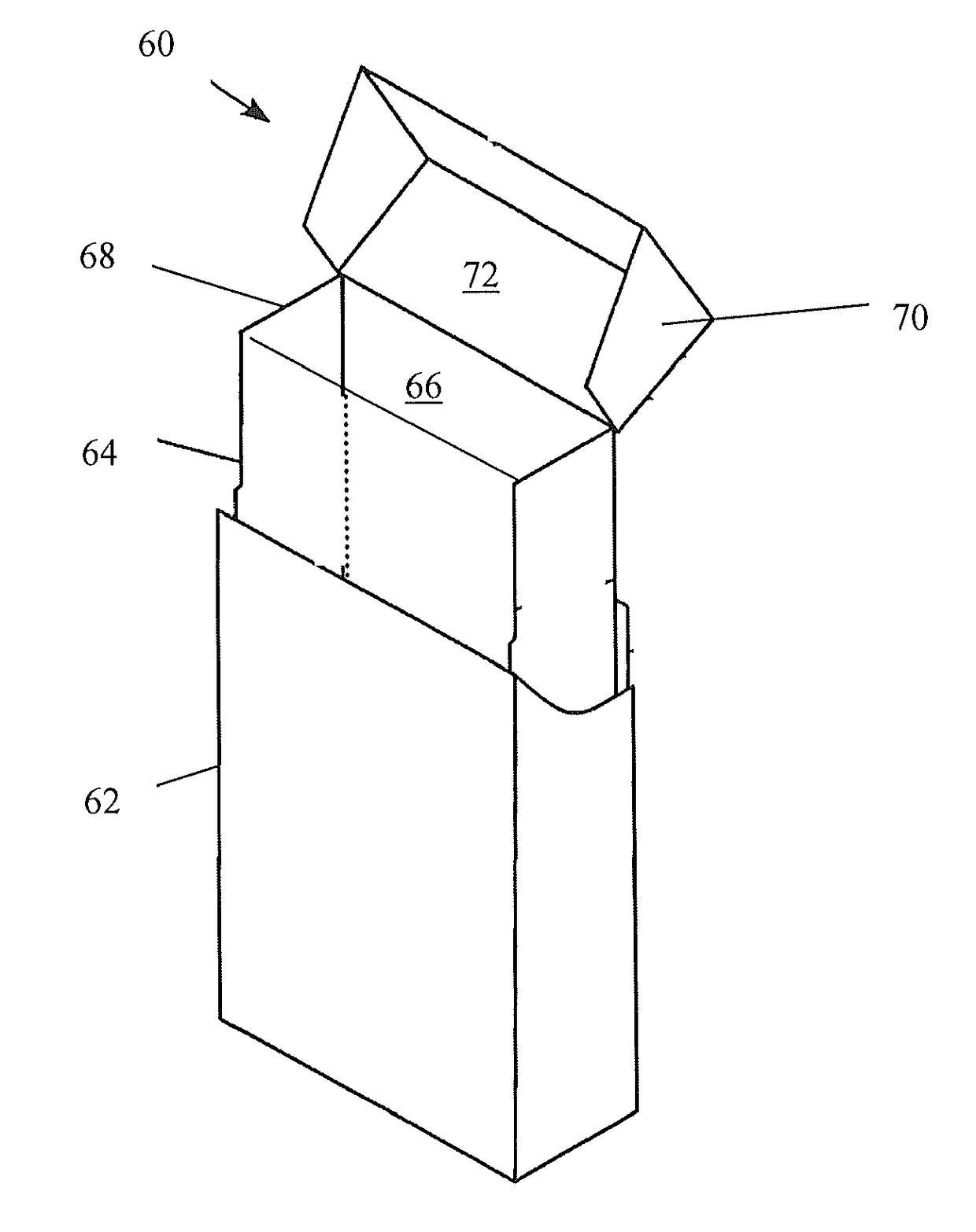

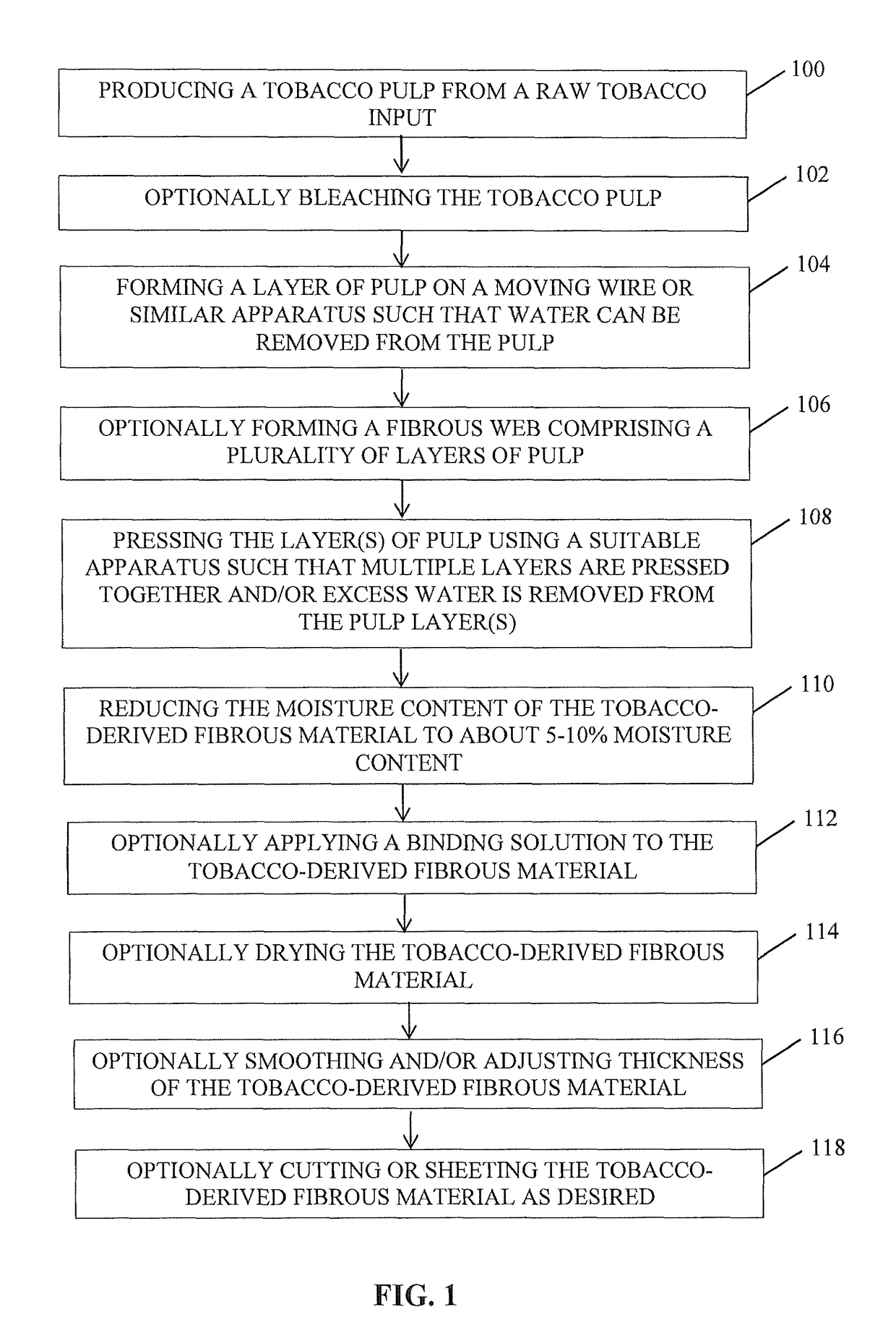

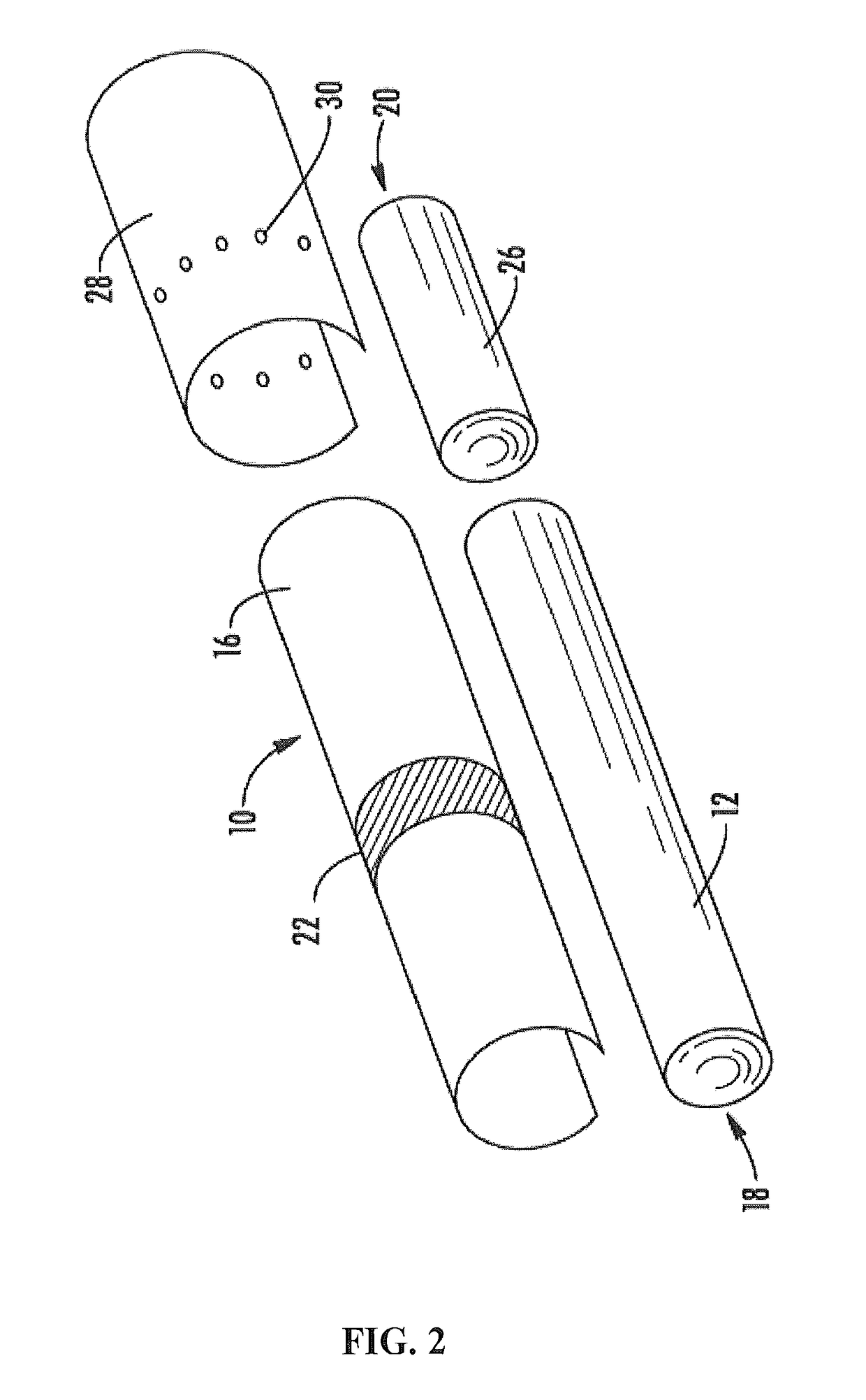

Tobacco-derived cellulose material and products formed thereof

A paper material is provided herein, wherein the paper material includes a fibrous material including at least 5 dry weight percent of fibers derived from a plant of the Nicotiana species; wherein the paper material has a basis weight ranging from about 5 g / m2 to about 450 g / m2; and wherein the paper material has a caliper ranging from about 0.01 mils to about 200 mils. The paper material can be suitable for use in a smoking article in the form of at least one of a tipping material, a plug wrap and a wrapping material. The paper material can be suitable for use in at least one of a soft carton container suitable to house smoking articles, a label, a paper substrate of a barrier layer, a hard carton suitable to house smoking articles and a container suitable to house smokeless tobacco products.

Owner:R J REYNOLDS TOBACCO COMPANY +1

Toner with hybrid binder resin

The invention is to provide a toner excellent in fixing property, high-temperature offset resistance and blocking resistance, and having an excellent developing property. The invention provides a toner including at least a binder resin and a colorant, wherein: the binder resin contains a hybrid resin which contains a polyester-type resin unit by 50 mass % or more and in which a polyester-type resin component and a vinyl-type resin component are chemically bonded; the toner contains 3 to 50 mass % of a tetrahydrofuran-insoluble matter derived from the binder resin; the tetrahydrofuran-insoluble matter contains a hybrid resin; and a tetrahydrofuran-soluble matter, obtained by hydrolyzing the tetrahydrofuran-insoluble matter and separating by filtration, has, in a GPC-measured molecular weight distribution, a main peak within a molecular weight range of 50,000 to 500,000.

Owner:CANON KK

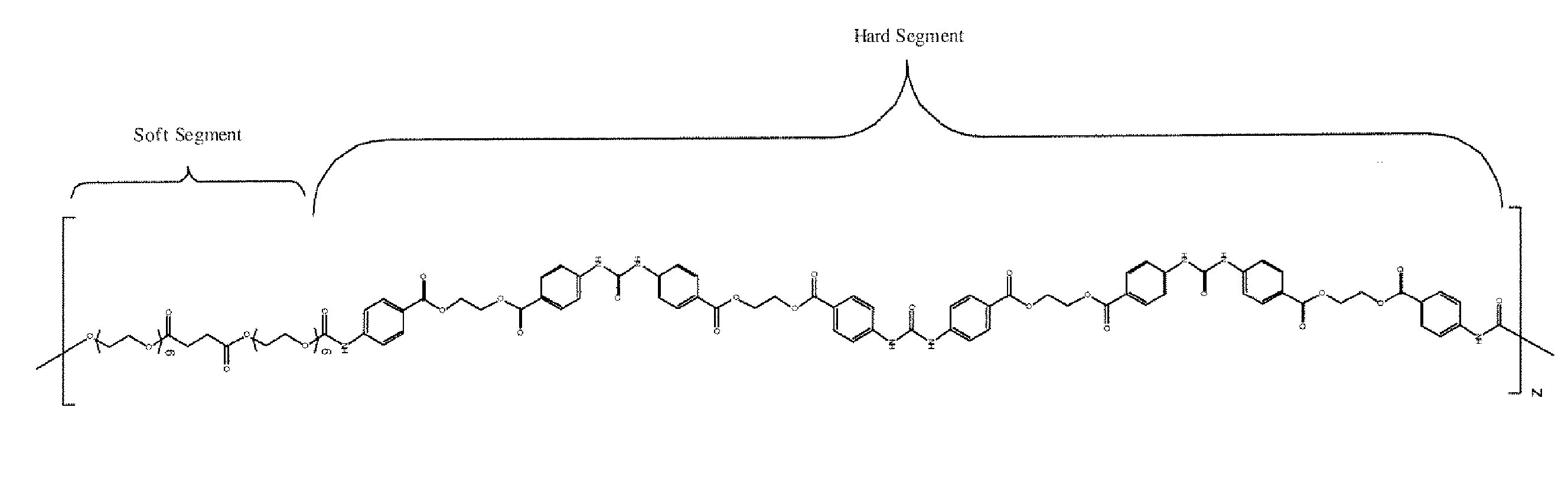

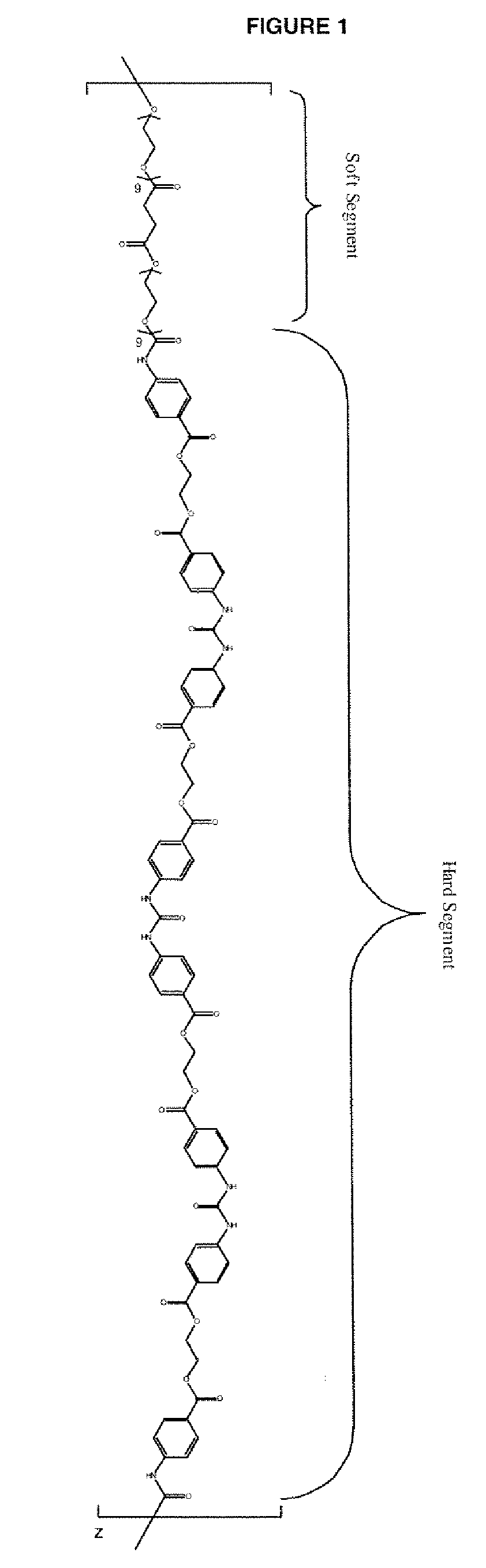

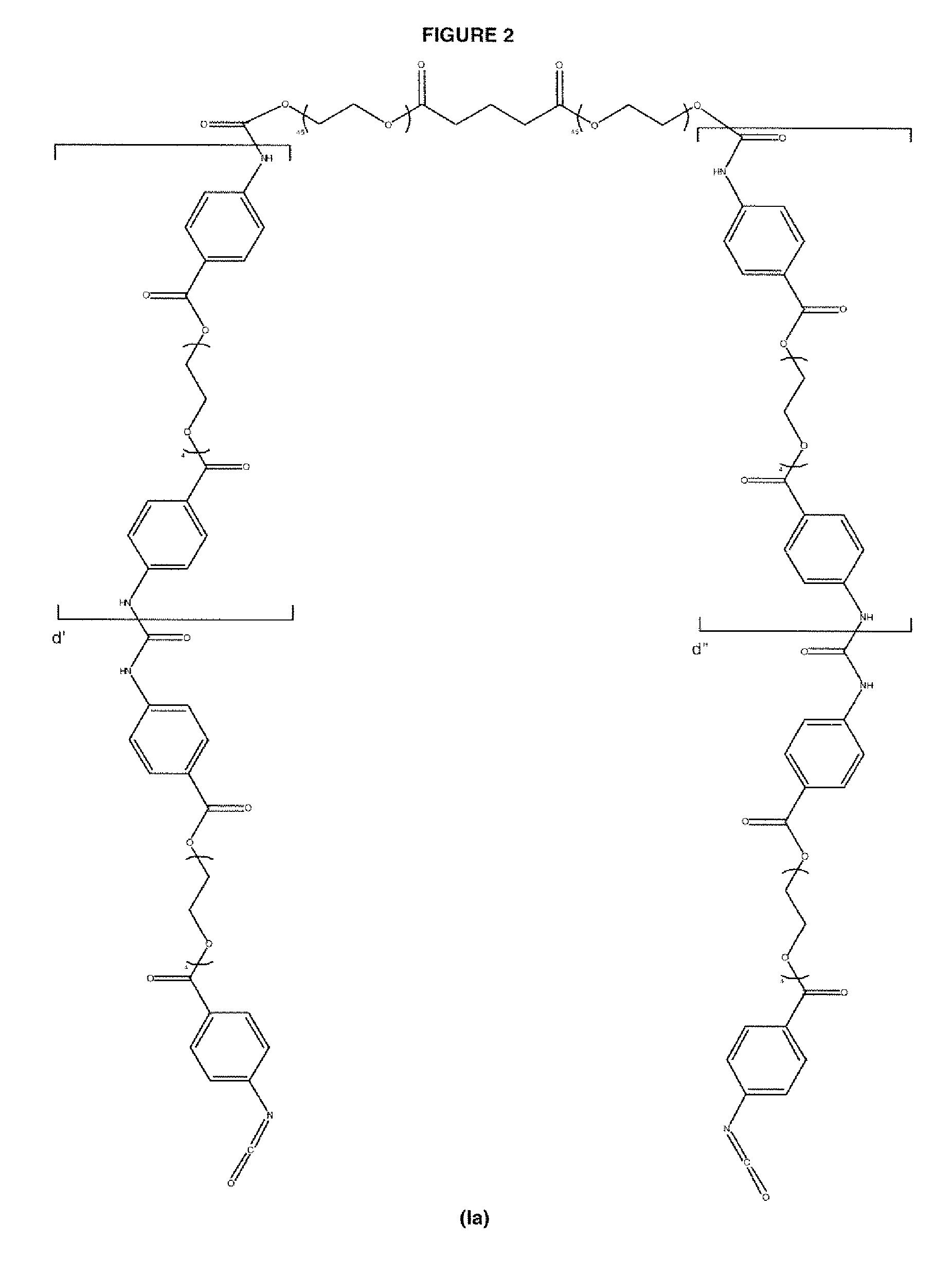

Diisocyanate terminated macromer and formulation thereof for use as an internal adhesive or sealant

A novel macromer or mixture thereof is described herein, comprising benzoyl isocyanate terminal moieties and at least two residues of a water-soluble polymer having a molecular weight ranging from 80 to 10,000 adjacent to the carbonyl group of the benzoyl isocyanate moieties, thereby forming at least two ester linkages in the macromer or mixture thereof. A method for making a polyisocyanate macromer is also described herein.

Owner:ETHICON INC

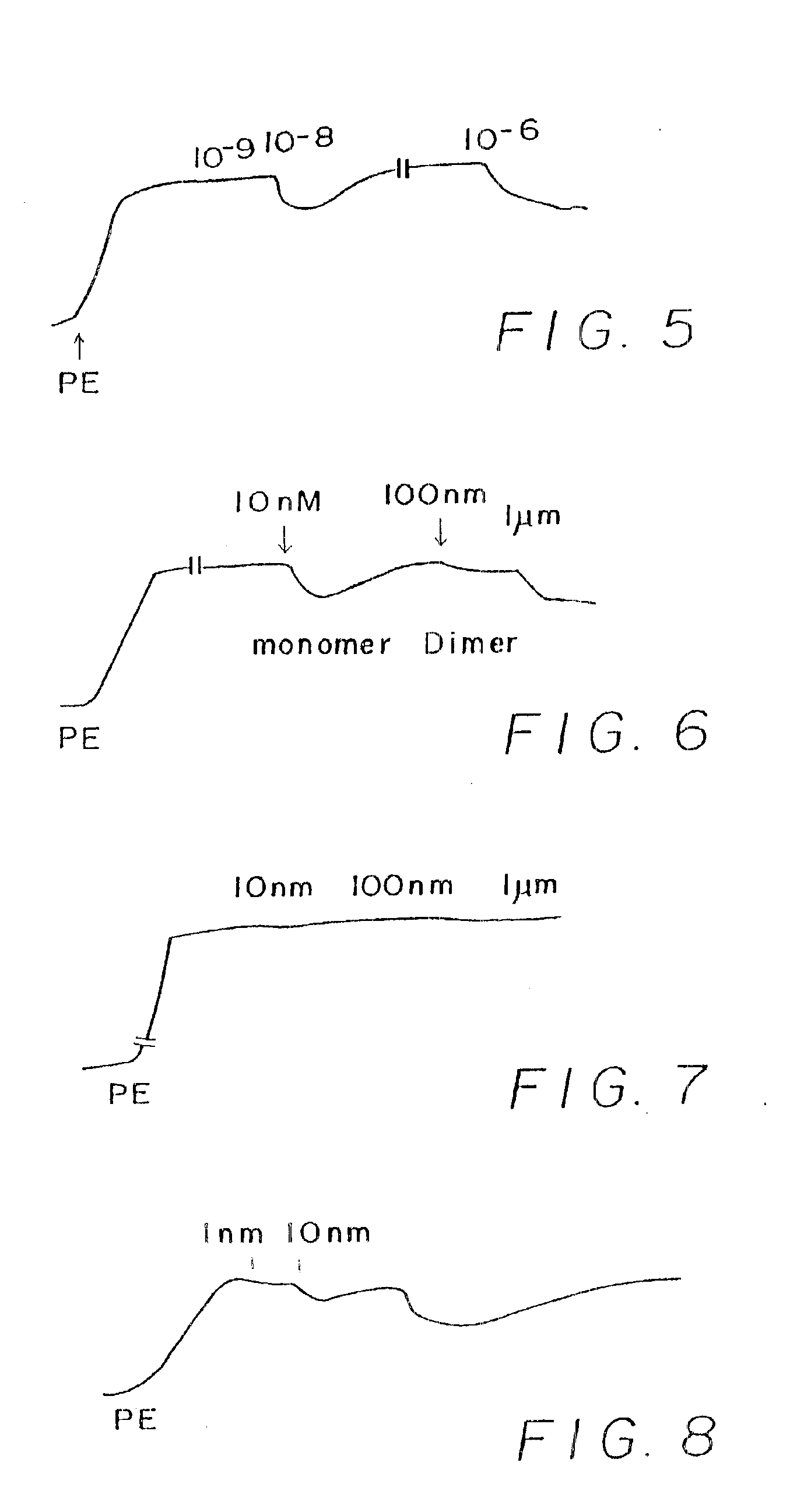

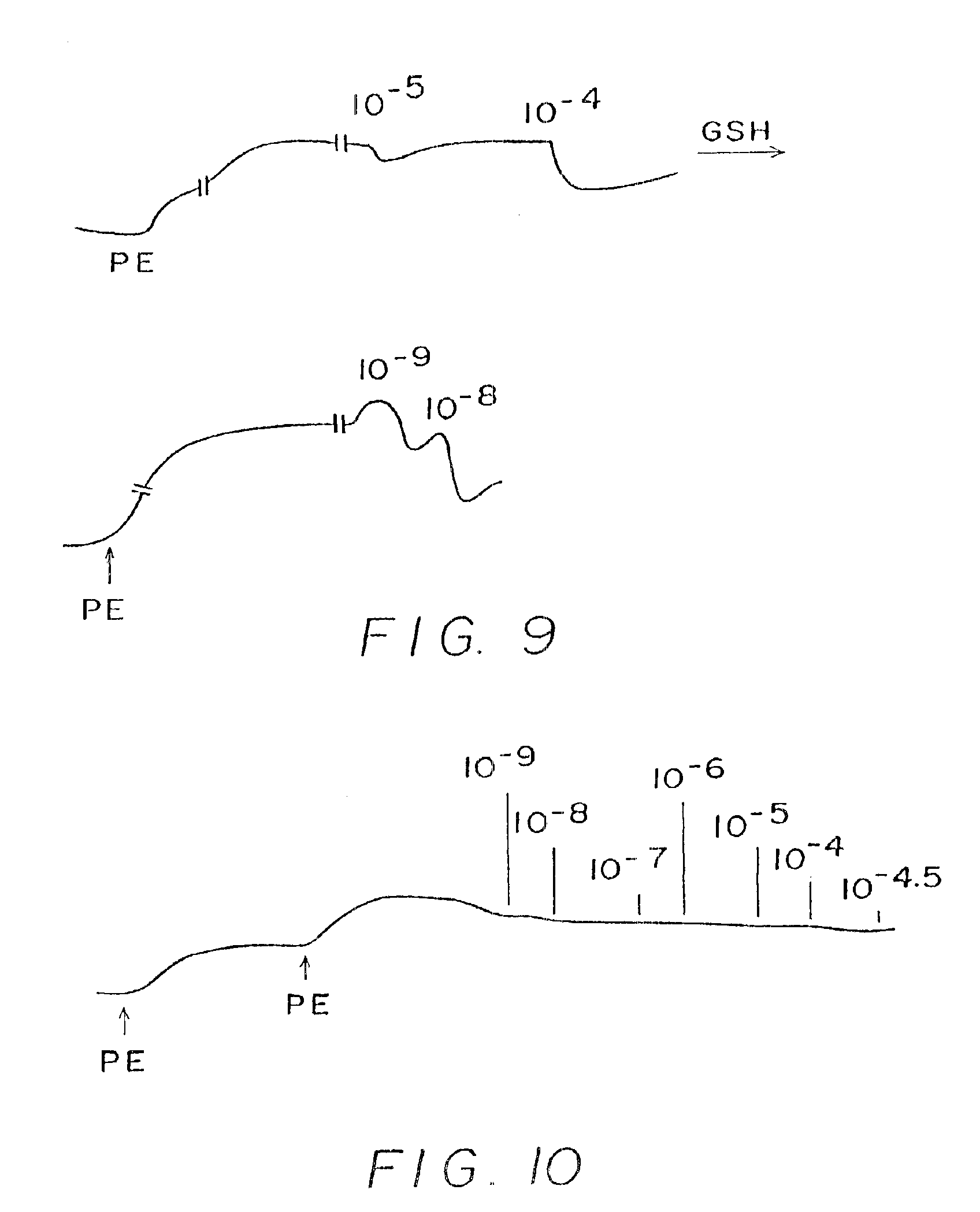

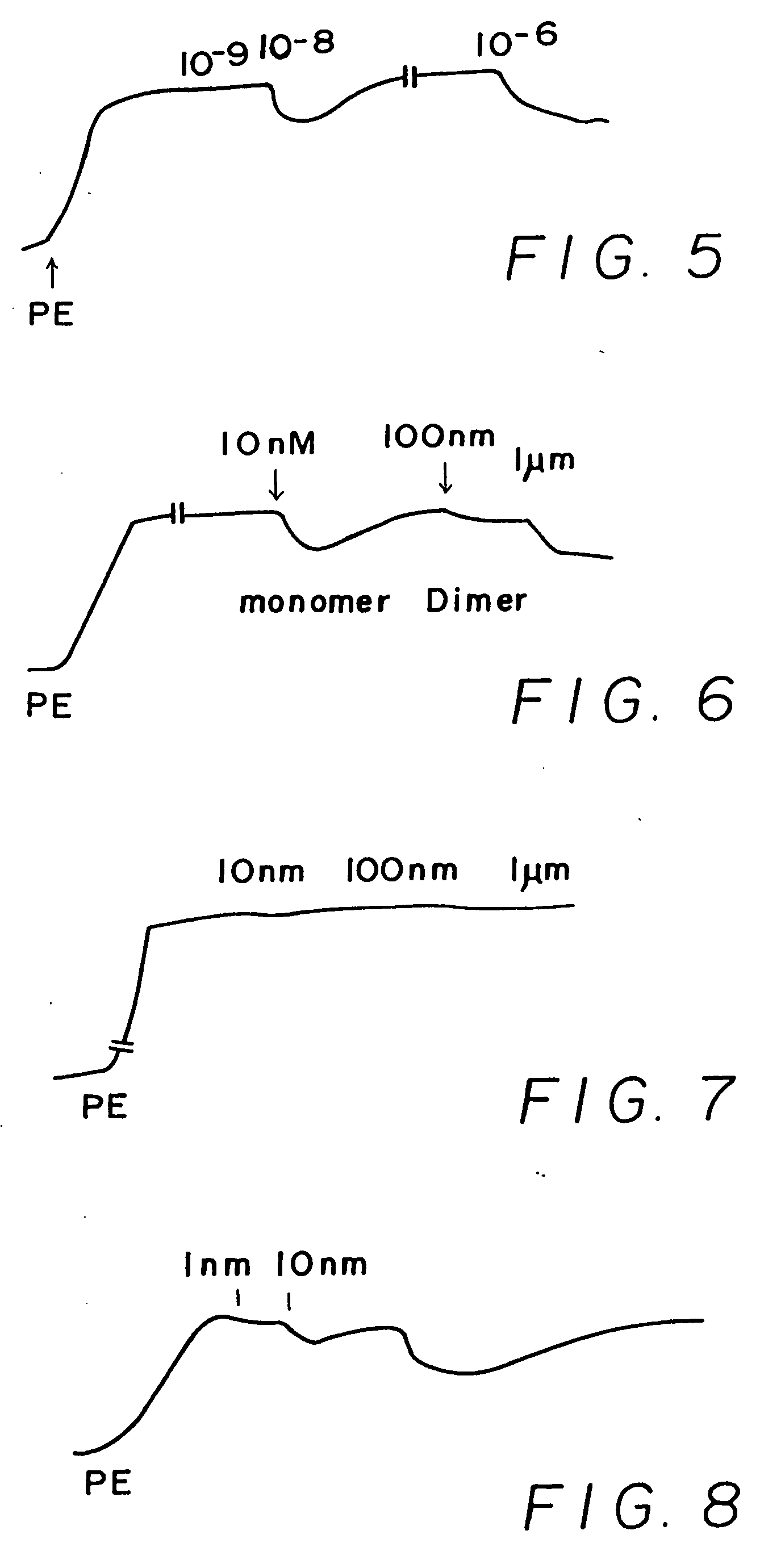

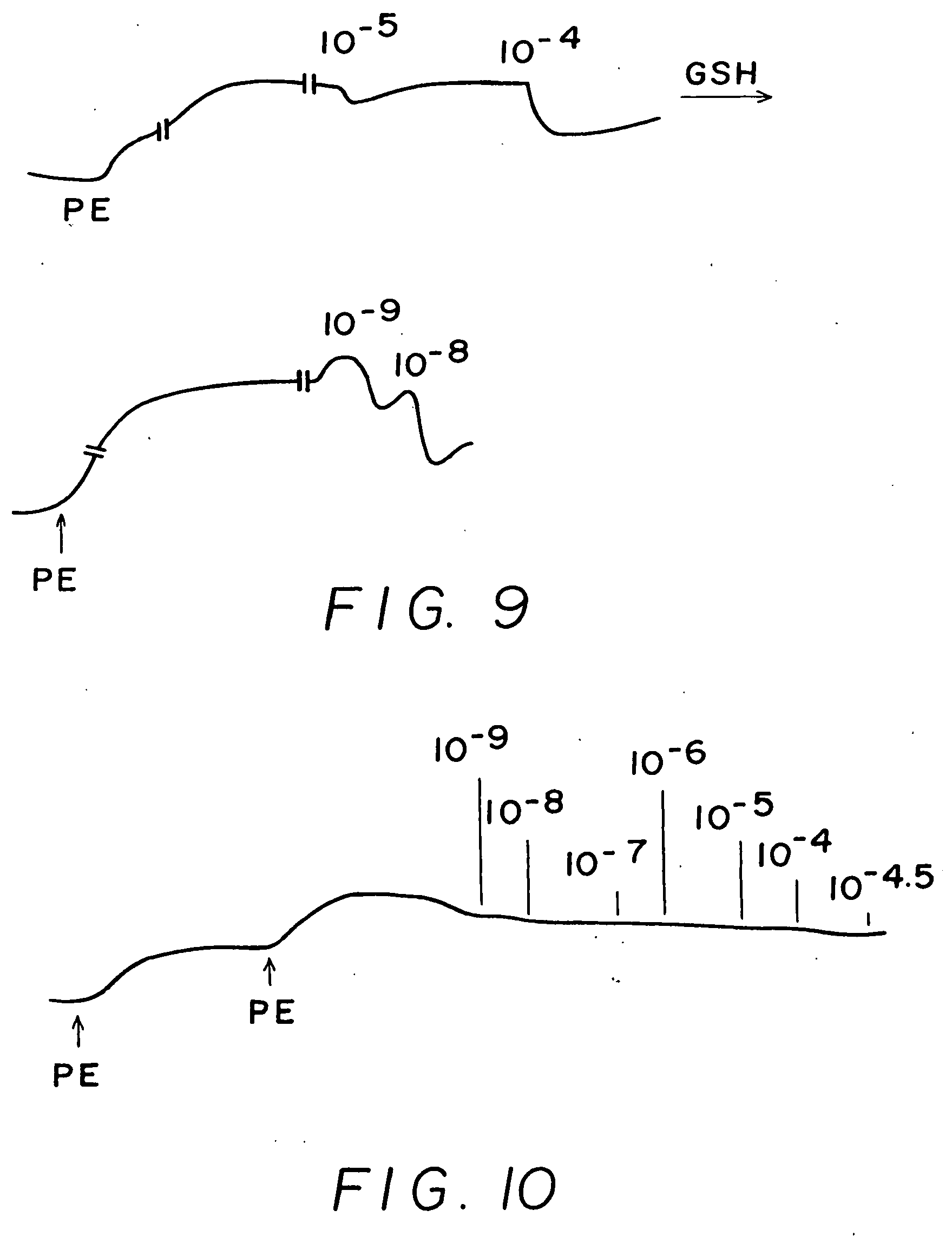

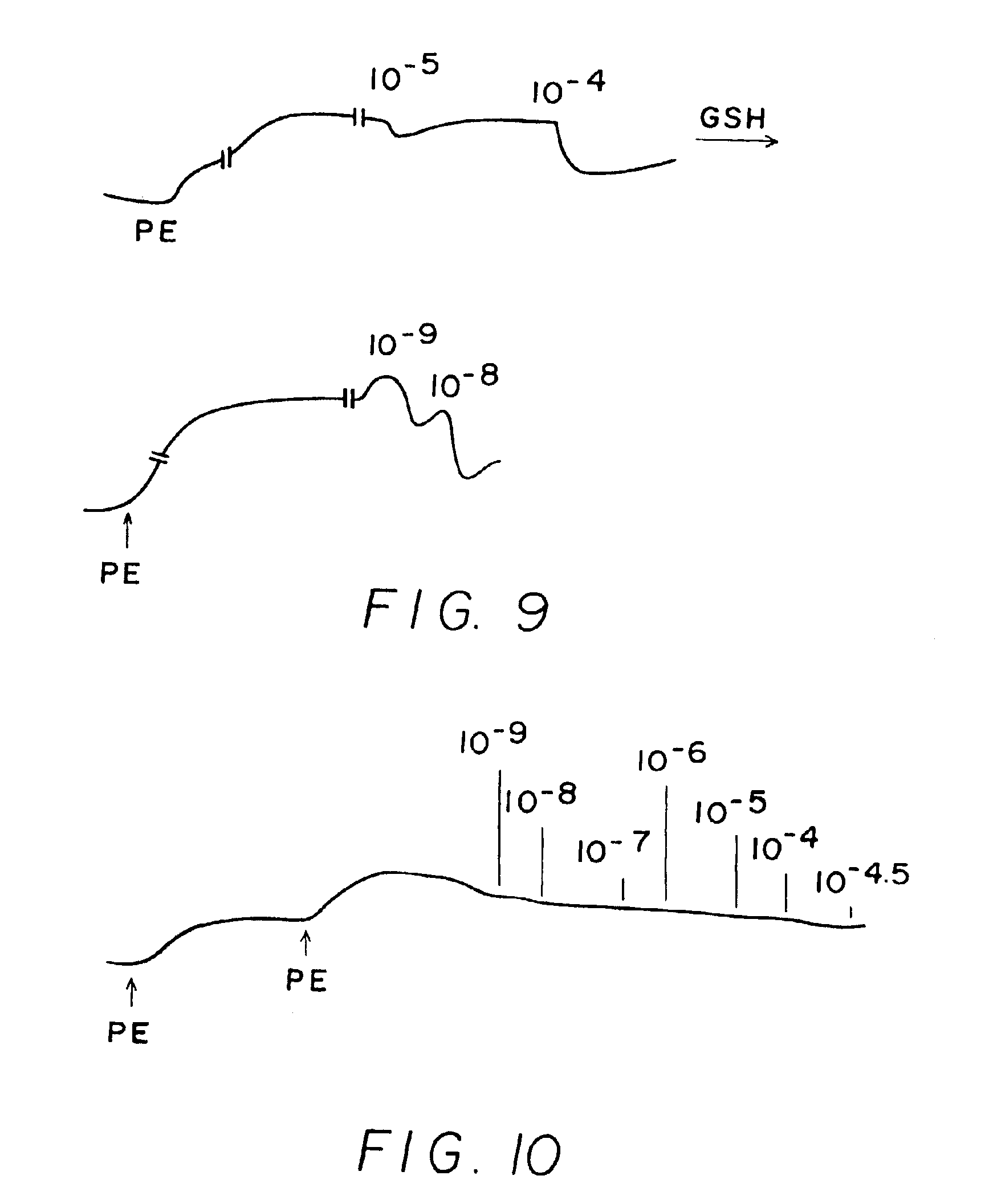

C-nitroso compounds and use thereof

InactiveUS6887994B2Inhibition productionReduce impactAntibacterial agentsOrganic chemistryNitrosoNo donors

A C-nitroso compound having a molecular weight ranging from about 225 to about 1,000 (from about 225 to about 600 for oral administration) on a monomeric basis wherein a nitroso group is attached to a tertiary carbon, which is obtained by nitrosylation of a carbon acid having a pKa less than about 25, is useful as an NO donor. In another case, the C-nitroso compound contains the moiety—C—N(O)X—where X is S, O or NR. One embodiment is directed to COX-2 inhibitors where a tertiary carbon atom and / or an oxygen atom and / or a sulfur atom is nitrosylated.

Owner:DUKE UNIV

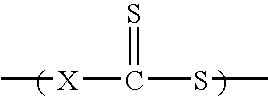

Vinyl-Thiocarbonate and Polyol Containing Block Copolymers

Block copolymers comprising polyols and / or siloxanes and vinyl-thiocarbonate blocks can be made by reacting a thiocarbonate compound such as a dithio- or trithiocarbonate with generally any hydroxyl-terminated polysiloxane via an esterification reaction. The polysiloxane can have a very wide number average molecular weight range and can be chain extended and / or crosslinked as by using a polyisocyanate or a polycarboxylic acid. Desirably, vinyl compounds are then reacted in situ into the thiocarbonate to increase molecular weight thereof. The block copolymers can be used in personal care applications.

Owner:LUBRIZOL ADVANCED MATERIALS INC

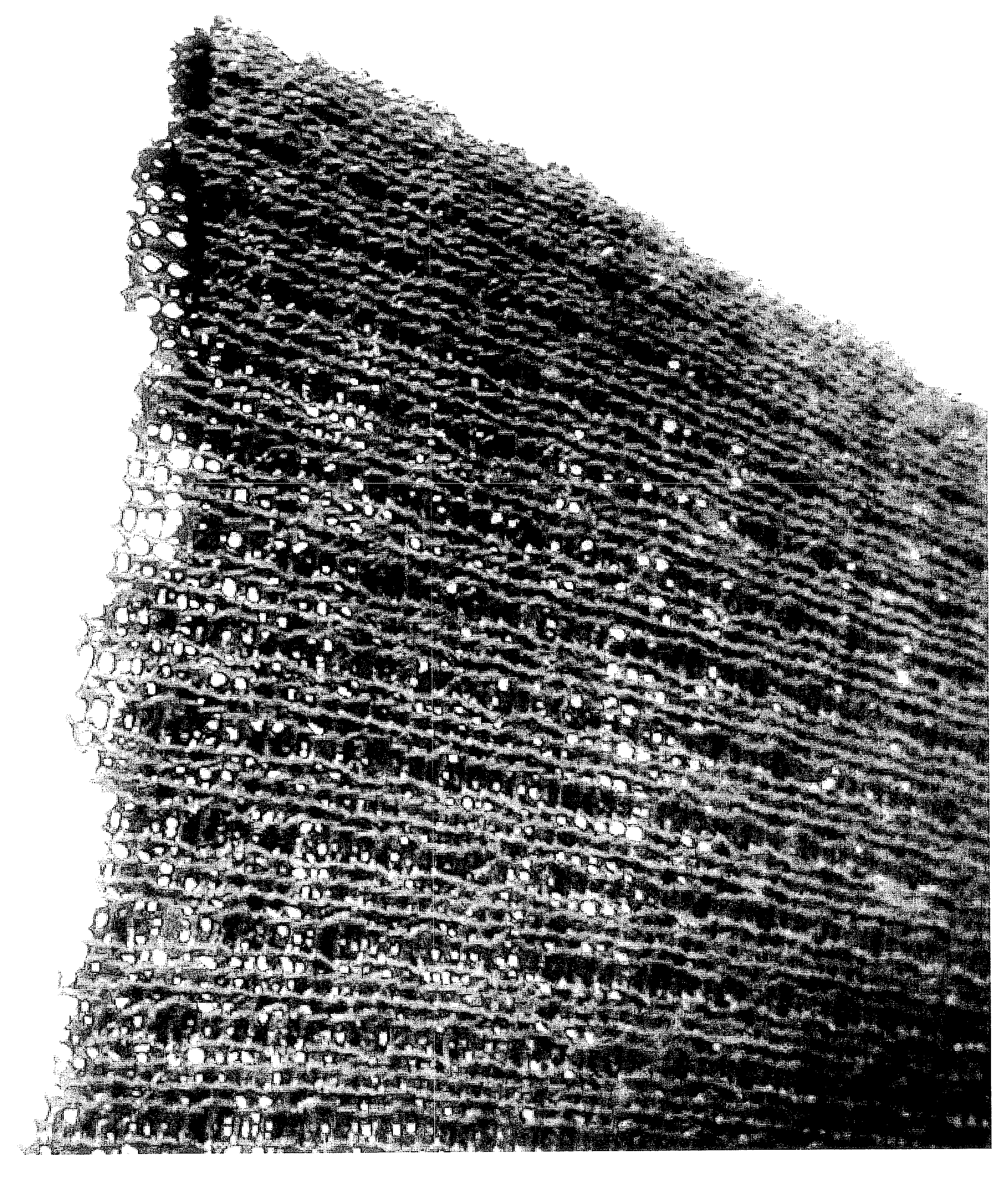

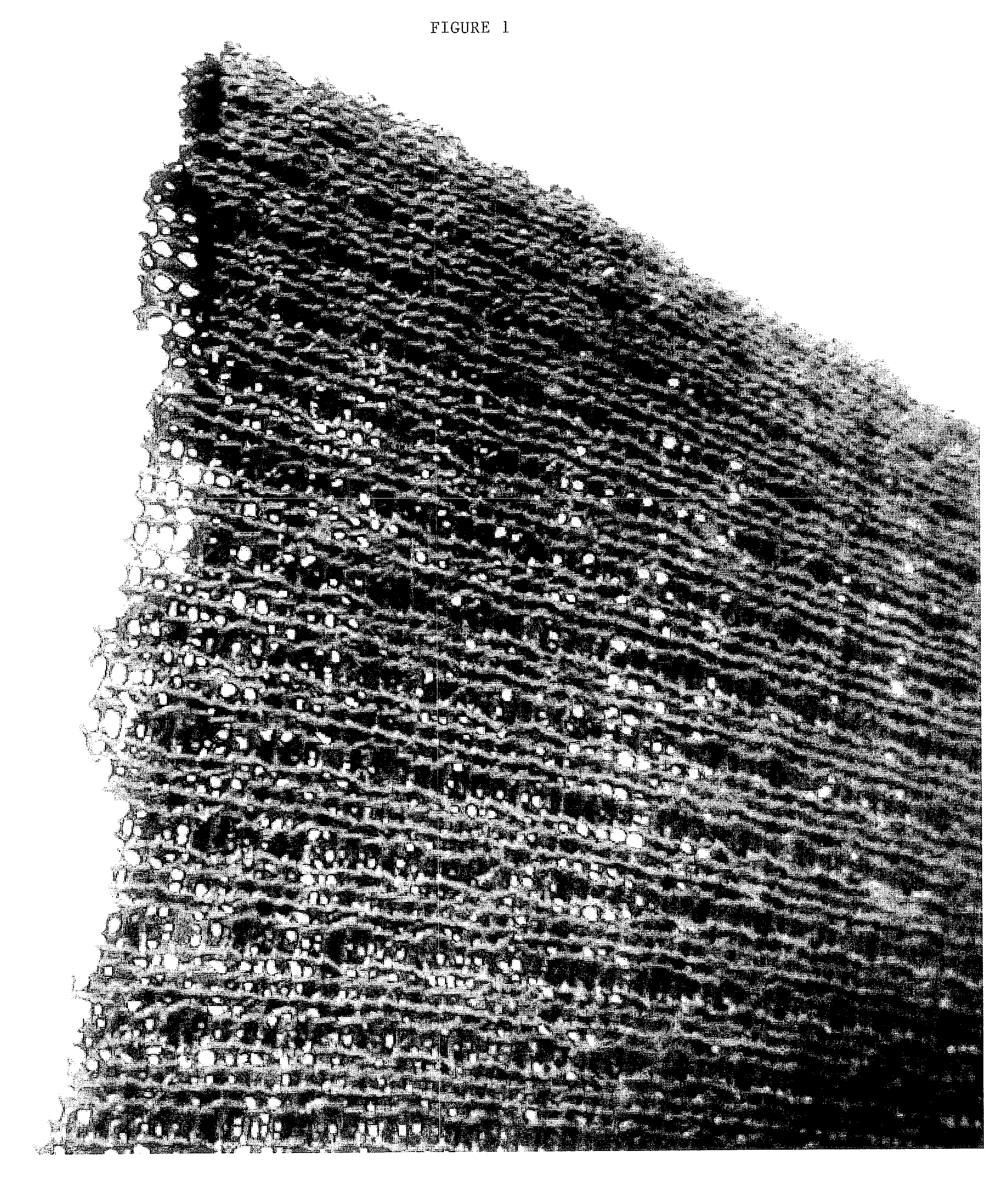

Knit fabrics and base layer garments made therefrom with improved thermal protective properties

ActiveUS20090019624A1Effective thermal protective characteristicHigh tensile strengthChemical protectionHeat protectionFiberYarn

Knit fabrics and military apparel such as T-shirts made therefrom are disclosed. The fabrics are constructed from blended yarns made from an intimate combination of nylon and cotton staple fibers. Such fabrics comprise a weight ratio of cotton to nylon which ranges from about 55:45 to about 85:15, and these fabrics also have a weight ranging from about 3 to about 8 oz / yd2. Knit fabrics of this type possess a desirable combination of good thermal protective properties, provided the specified high level of staple fiber blend uniformity is achieved, along with very useful abrasion resistance, bursting strength and drying time characteristics.

Owner:INV PERFORMANCE MATERIALS LLC

Chemically prepared toner and process therefor

InactiveUS6991884B2Simplifying toner production processShorten reaction timeDuplicating/marking methodsInksCharge controlVolume average

A chemically prepared toner for electrophotographic printers and method therefor using a unique polymeric dispersant. The chemically prepared toner includes agglomerated polymeric dispersant stabilized pigment particles, a fuser release agent, a charge control agent dispersion, and a self-stabilized essentially surfactant free latex binder. The polymeric dispersant includes at least three segments, a hydrophilic polymeric segment, a hydrophobic polymeric segment, and a protective colloid or reactive surfactant segment. The weight average molecular weight range of the dispersant ranges from about 5,000 to about 30,000, and a hydrophobicity ranging from about 10 to about 90 percent by weight. The chemically prepared toner includes agglomerated toner particles have a unimodal particles size distribution with a number average particle size (N) ranging from about 5.0 to about 8.5 microns and a volume average particle size (V) ranging from about 5.0 to about 8.5 microns.

Owner:LEXMARK INT INC +1

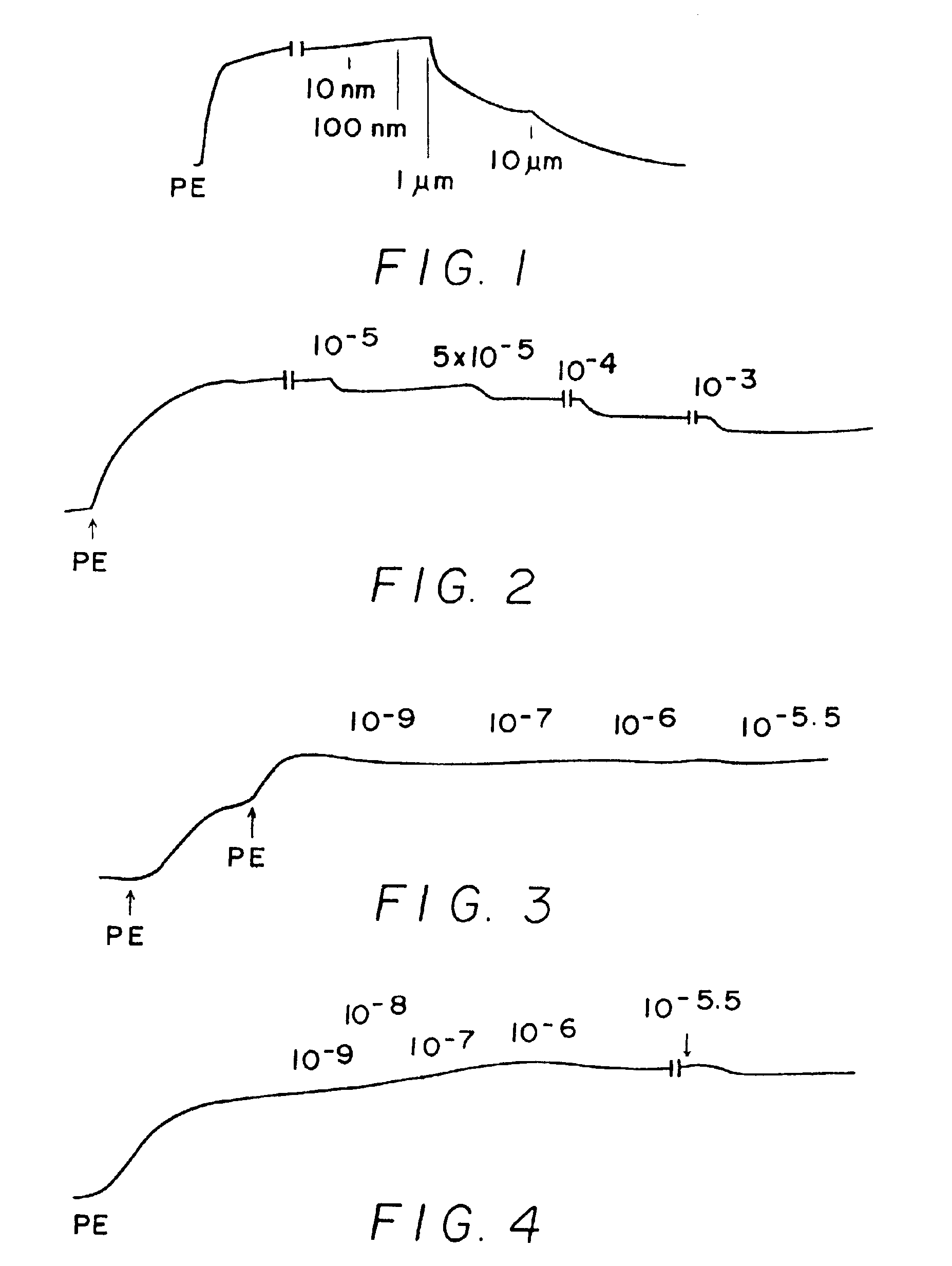

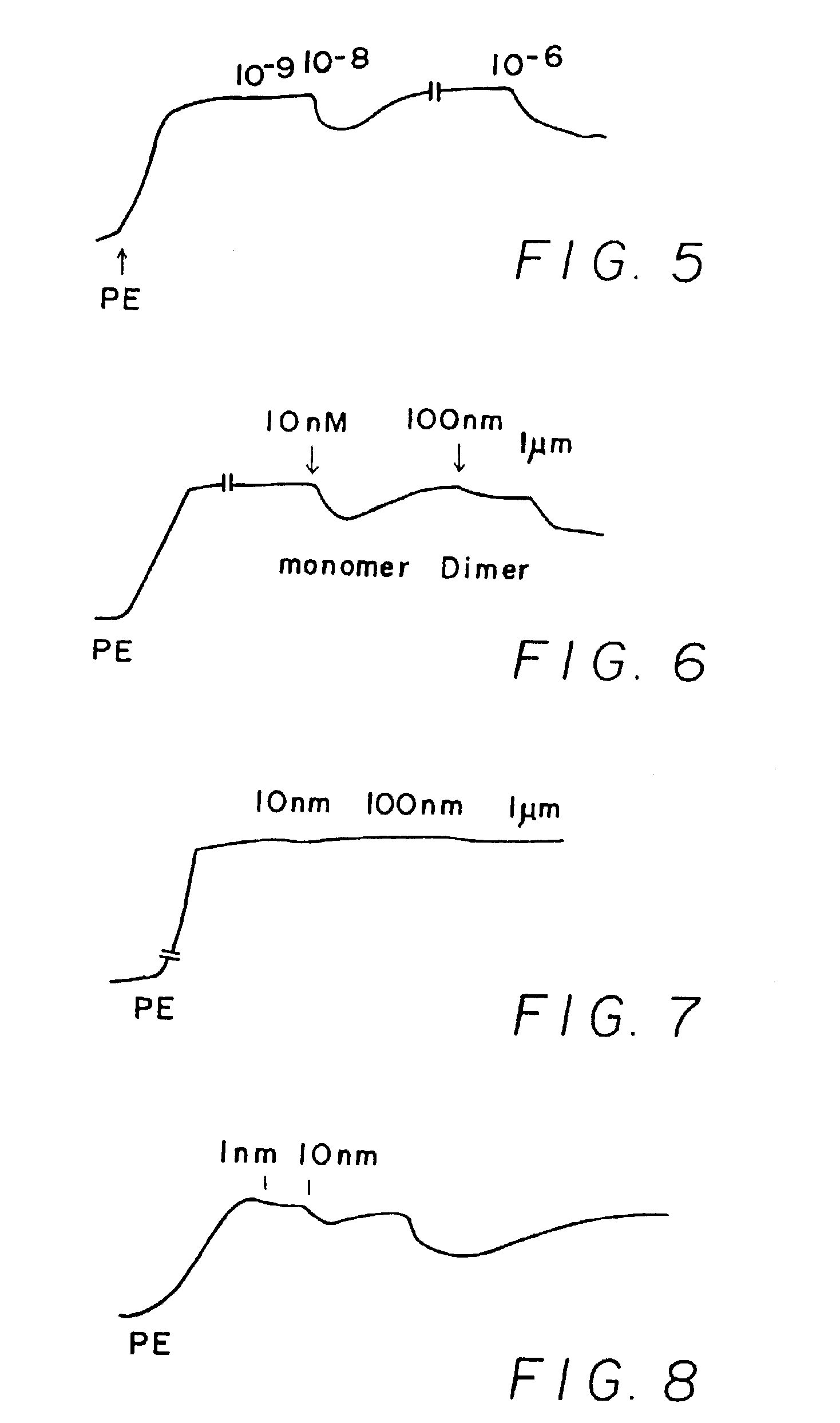

C-nitroso compounds and use thereof

InactiveUS20050187166A1Improve mitigation effectInhibition productionBiocideOrganic chemistryNitrosoOral medication

A C-nitroso compound having a molecular weight ranging from 225 to 1,000 (from 225 to 600 for oral administration) on a monomeric basis wherein a nitroso group is attached to a tertiary carbon, which is obtained by nitrosylation of a carbon acid having a pKa less than about 25, is useful as an NO donor. When the compound is obtained from a carbon acid with a pKa less than about 10, it provides vascular relaxing effect when used at micromolar concentrations and this activity is potentiated by glutathione to be obtained at nanomolar concentrations. When the compound is obtained from a carbon acid with a pKa ranging from about 15 to about 20, vascular relaxing effect is obtained at nanomolar concentrations without glutathione. In another embodiment, a biocompatible polymer incorporates a C-nitroso moiety.

Owner:DUKE UNIV

Method for reducing sag in drilling, completion and workover fluids

InactiveUS6861393B2Reduce saggingHigh viscosityDrilling compositionBorehole/well accessoriesWell drillingFluid viscosity

A method is disclosed for reducing sag in drilling and completion fluids and in workover fluids. The method employs a drilling fluid comprising a low molecular weight polyalkyl methacrylate with an average molecular weight ranging from about 40,000 to about 90,000. This additive does not result in increased viscosity of the fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

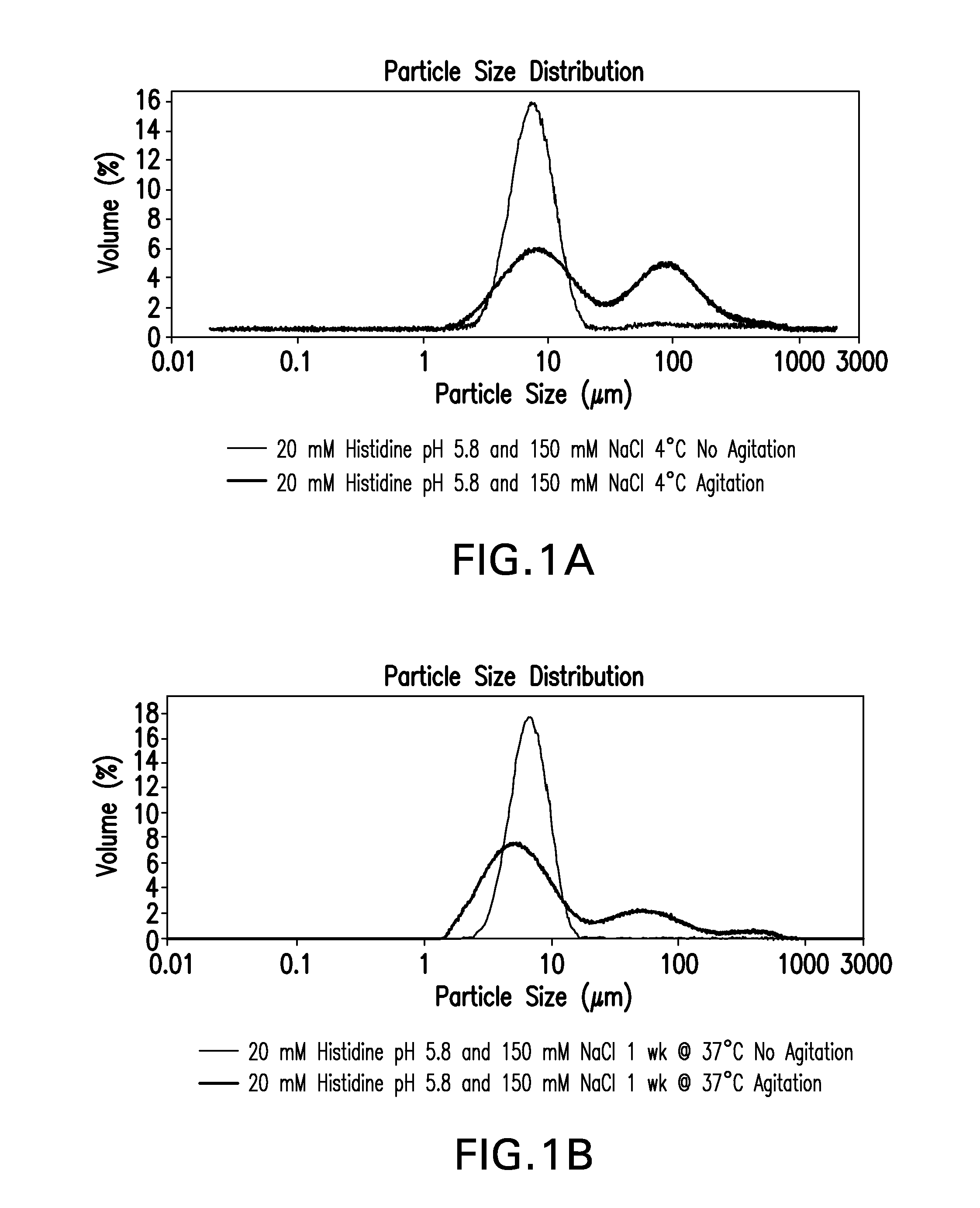

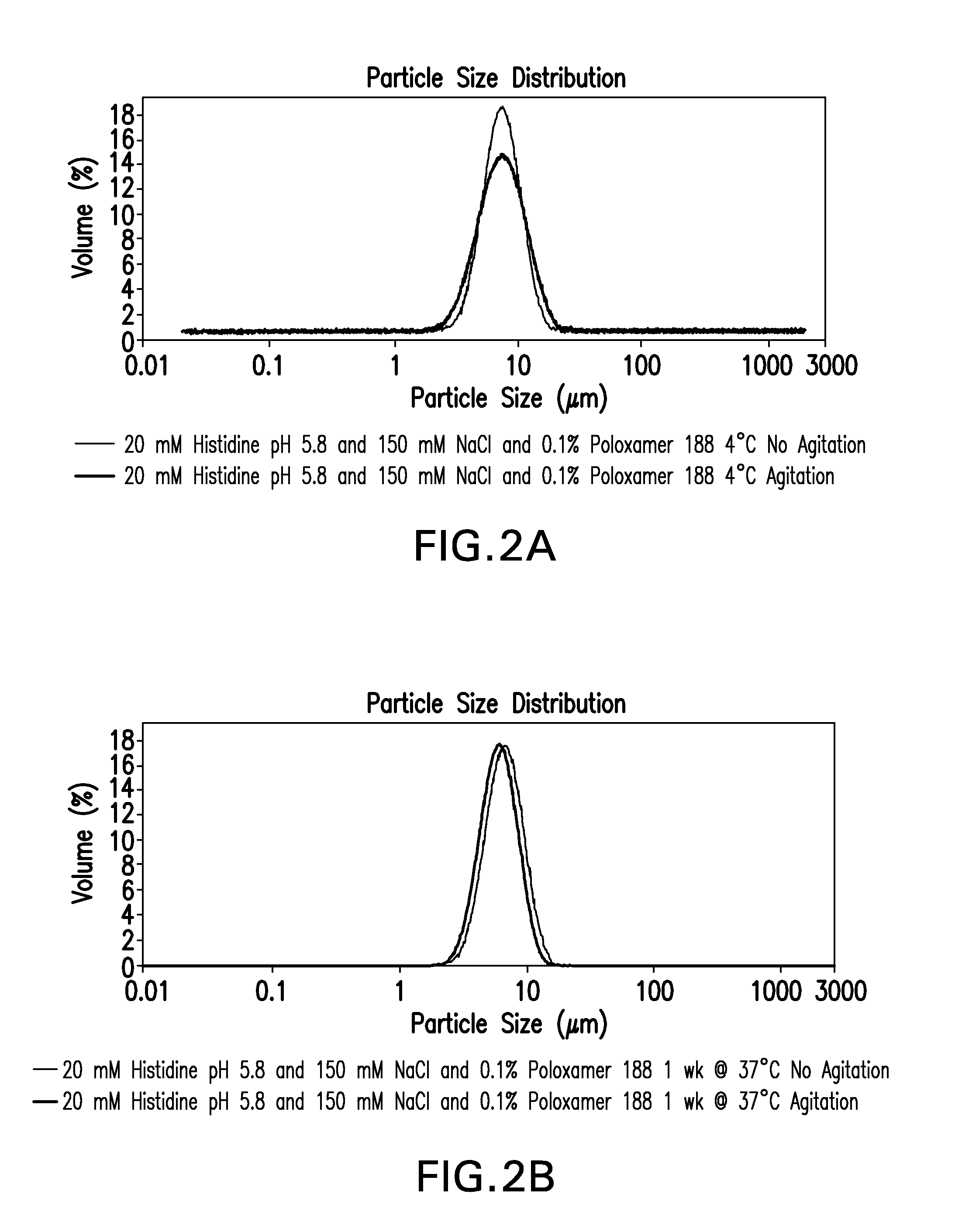

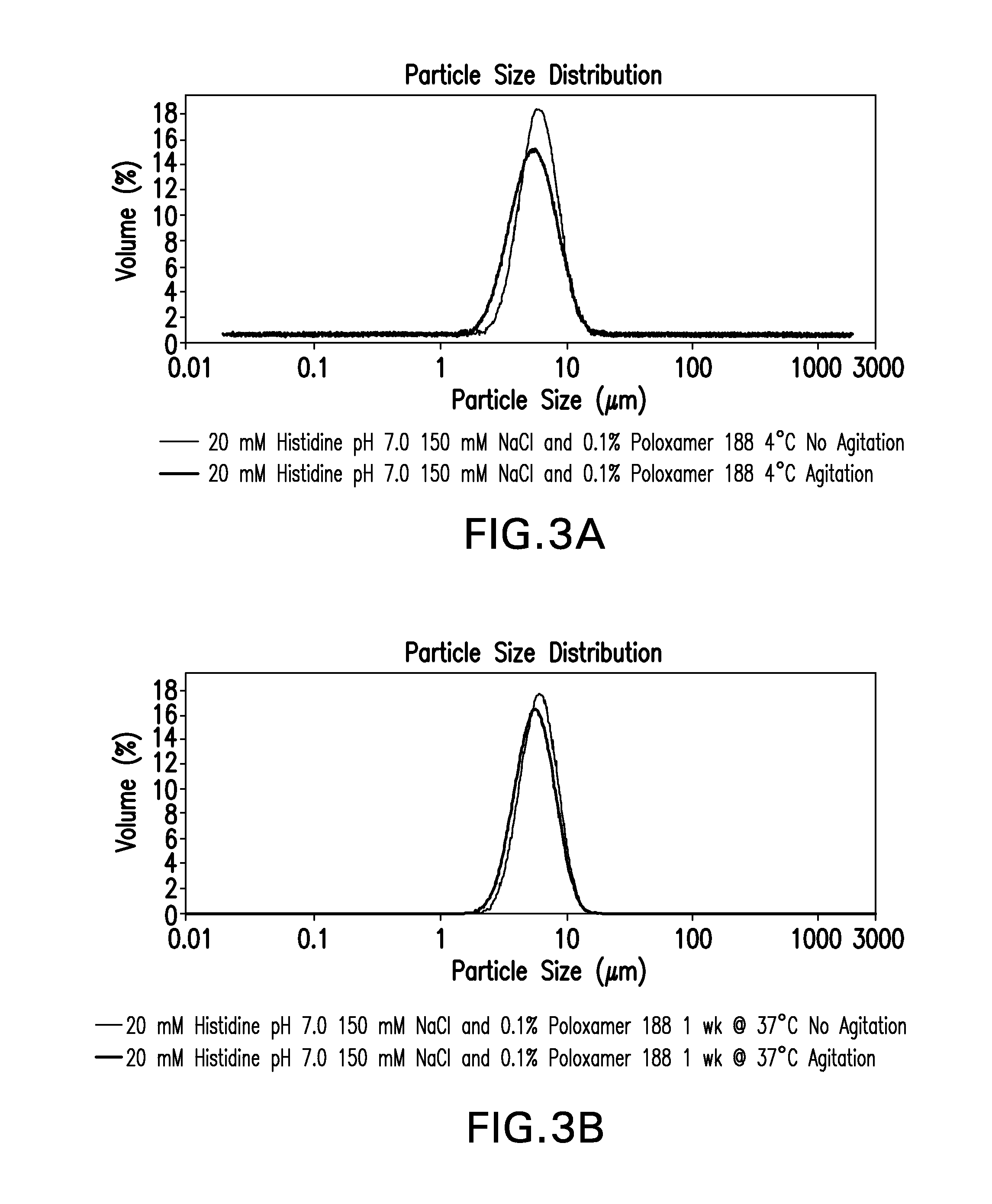

Novel formulations which mitigate agitation-induced aggregation of immunogenic compositions

InactiveUS20130273098A1Stabilize immunogenic compositionInhibit aggregationAntibacterial agentsBiocideStreptococcus pneumoniaeCarrier protein

The present invention provides novel formulations which mitigate agitation-induced aggregation of immunogenic compositions particularly those having polysaccharide-protein conjugates. Specifically, the novel formulations comprise a poloxamer within a molecular weight range of 1100 to 17,400 which provides significant advantages over previously used surfactants including polysorbate 80. In one embodiment, the present invention provides a multivalent immunogenic composition having 15 distinct polysaccharide-protein conjugates and a poloxamer. Each conjugate consists of a capsular polysaccharide prepared from a different serotype of Streptococcus pneumoniae (1, 3, 4, 5, 6A, 6B, 7F, 9V, 14, 18C, 19A, 19F, 22F, 23F or 33F) conjugated to a carrier protein, preferably CRM197.

Owner:MERCK SHARP & DOHME CORP

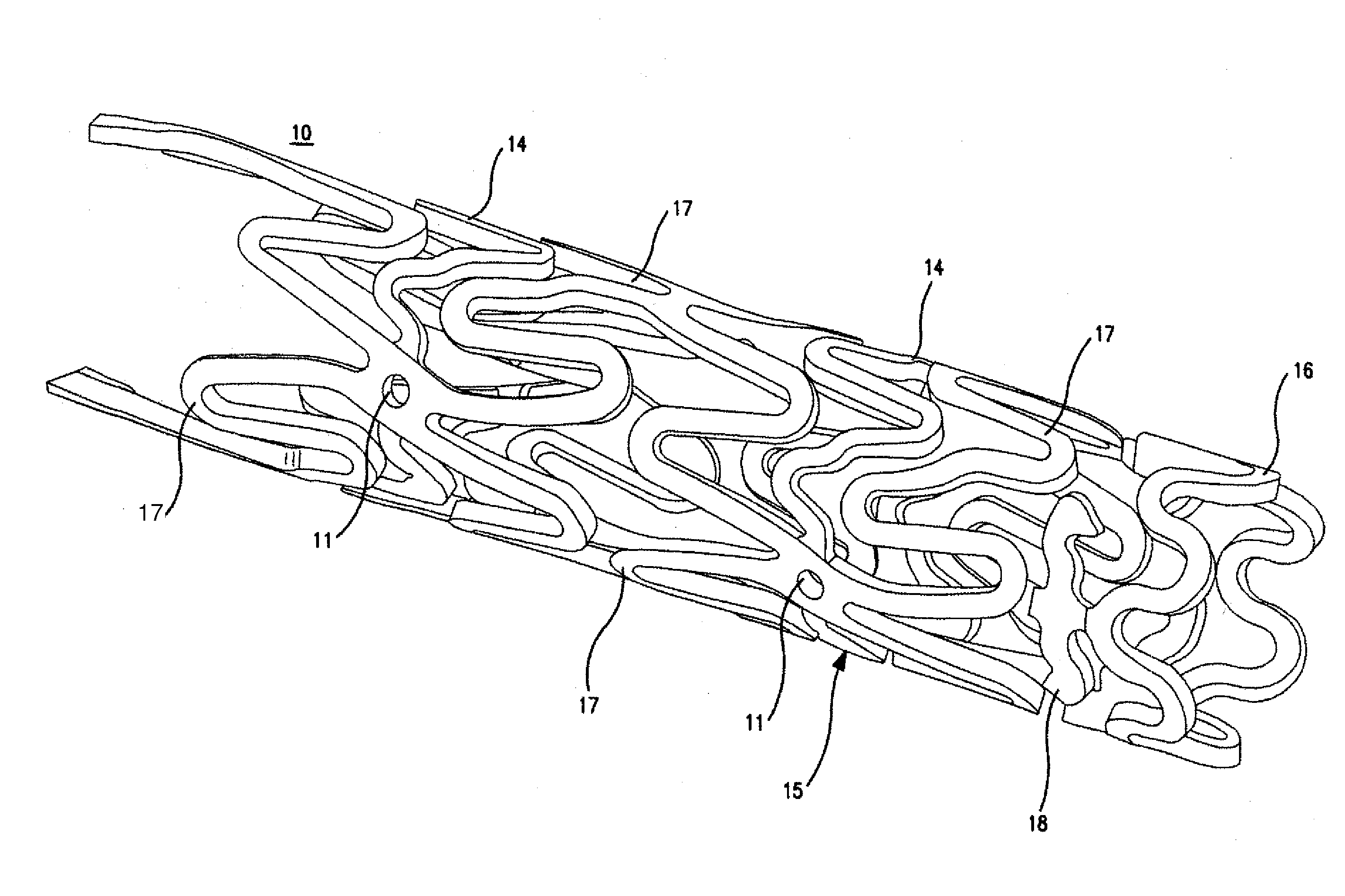

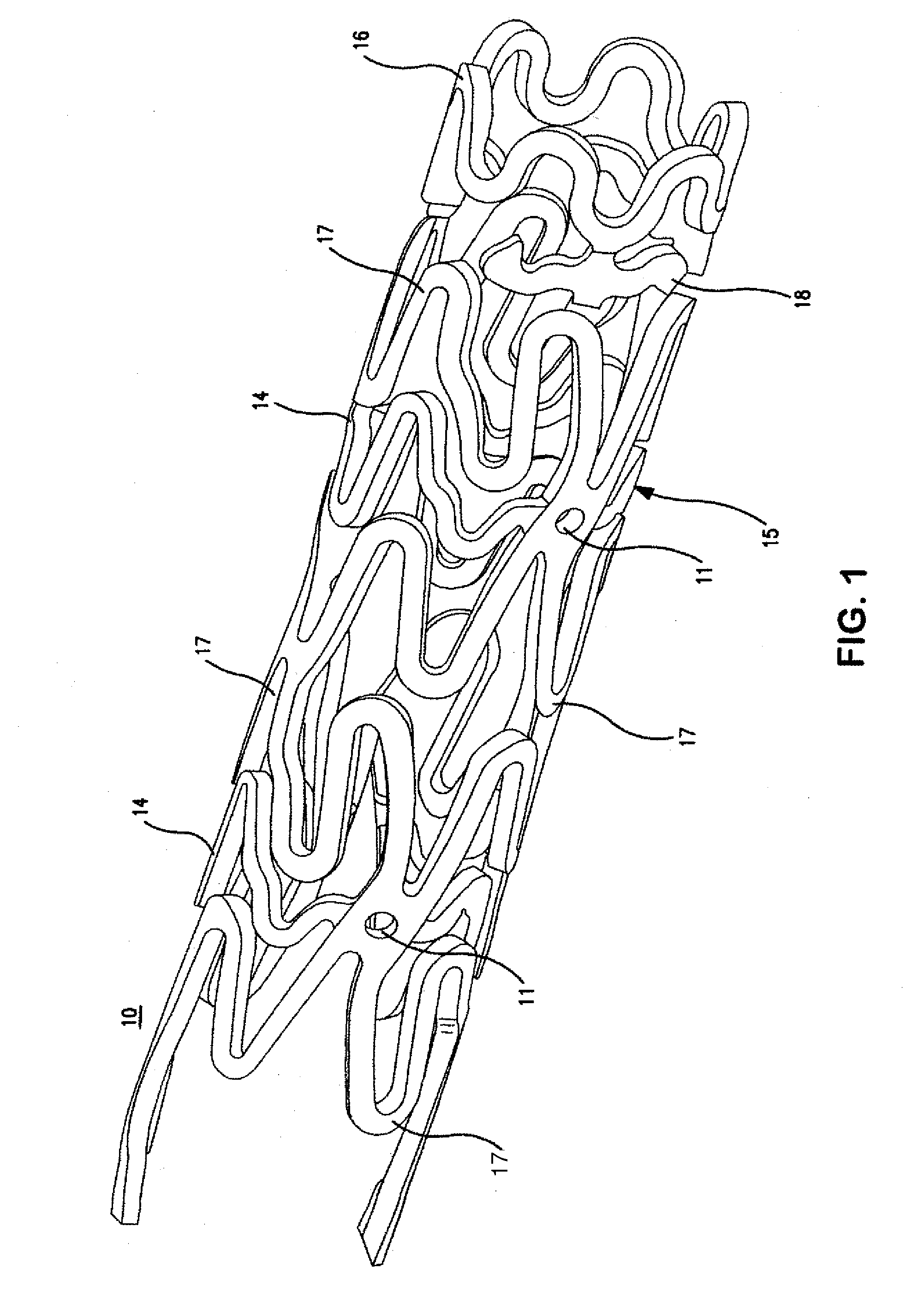

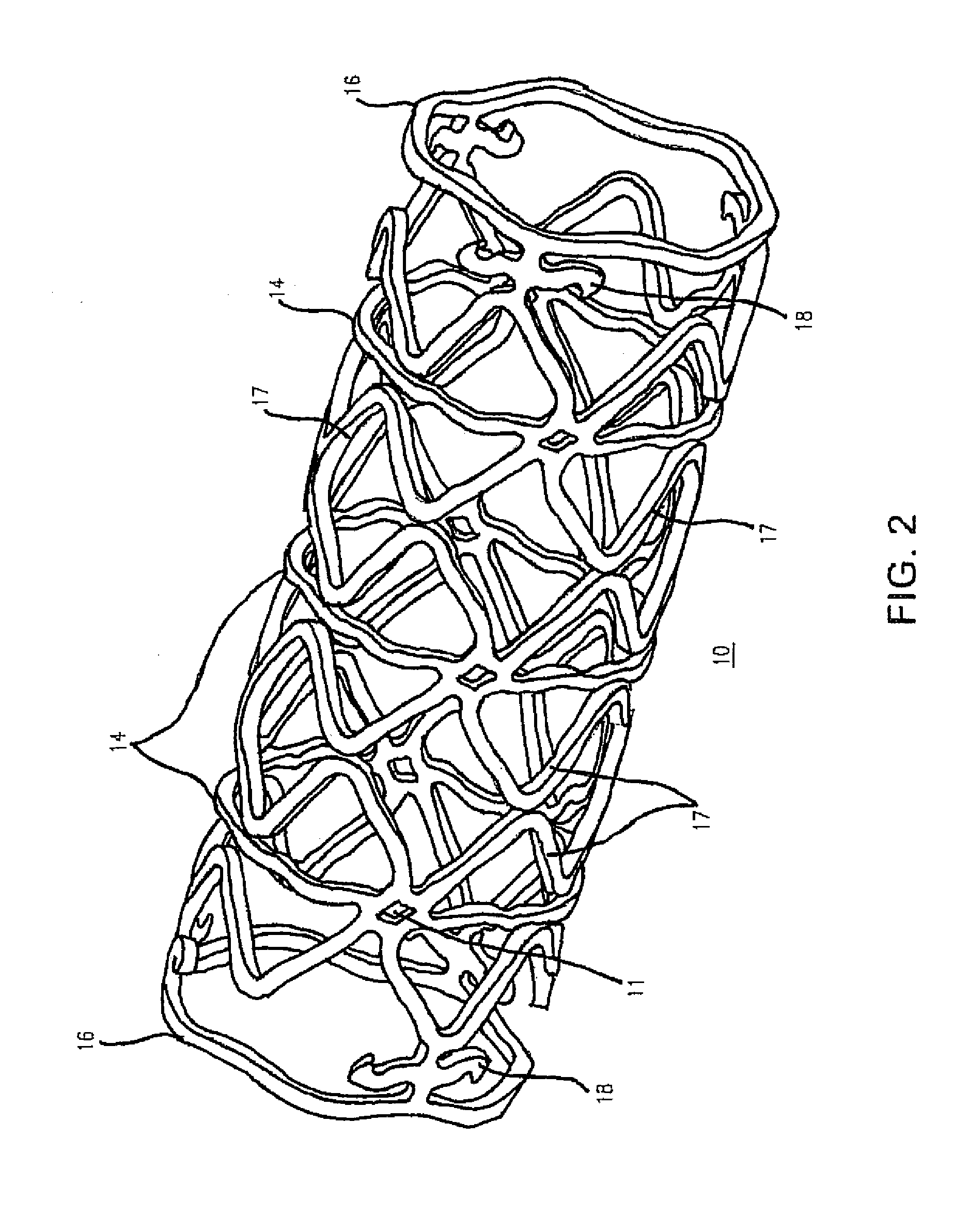

Bioabsorbable Polymeric Compositions and Medical Devices

The present invention comprises a stent forming a plurality of meandering elements comprising a blend formed from a polymer. The polymer comprises poly-L-lactide, poly-D-lactide or mixtures thereof and a copolymer moiety comprising poly-L-lactide or poly-D-lactide linked with ε-caprolactone or trimethylcarbonate. The poly-L-lactide or poly-D-lactide sequence in the copolymer moiety is random with respect to the distribution of ε-caprolactone or trimethylcarbonate and the copolymer moiety molecular weight ranges from about 1.2 IV to about 4.8 IV. The meandering elements may be stretched to a modulus ranging from about 250000 PSI to about 550,000 PSI, one segment of the meandering element has a decreased cross-sectional area and may have a wide-angle X-ray scattering (WAXS) 2θ values of ranging from about 1 to about 35. In various embodiment, two, three or n segments of the meandering element have a decreased cross-sectional area and may also have a wide-angle X-ray scattering (WAXS) 2θ values of ranging from about 1 to about 35 after stretching. In another embodiment, all segments of the meandering element have a decreased cross-sectional area and may also have a wide-angle X-ray scattering (WAXS) 2θ values of ranging from about 1 to about 35 after stretching. The meandering element may comprise a helical winding, a circumferential winding or stent ringlet. The properties of the bioabsorbable polymers allow for both crimping and expansion of the stent. The crystal properties of the bioabsorbable polymers may change during crimping and / or expansion allowing for improved mechanical properties such as tensile strength and slower degradation kinetics.

Owner:ORBUSNEICH MEDICAL PTE LTD

Phase-change heat-insulation interior wall coating and preparation method for same

ActiveCN102604500AGuaranteed practicalityImprove reflectivityAntifouling/underwater paintsPaints with biocidesMicrospherePolyethylene glycol

The invention discloses phase-change heat-insulation interior wall coating, which is characterized by comprising elastic emulsion, water, dispersing agent, wetting agent, thickener, antiseptic, hollow polyurethane microspheres, nano titanium dioxide and non-transparent polymers, wherein the hollow polyurethane microspheres wrap polyethylene glycol with the molecular weight ranging from 1000-2000. The temperature can be regulated by making full use that the polyethylene glycol generates phase change at the different temperatures to result in physical changes of heat release and heat absorption, light reflection of the nano titanium dioxide plays a role in radiation and heat insulation, and a conductivity coefficient is decreased in the presence of the hollow swelling microspheres and the non-transparent polymers. The phase-change heat-insulation interior wall coating is particularly suitable for indoor external layers by combining the three heat-insulation mechanisms of phase change, radiation and conductivity.

Owner:SKSHU PAINT

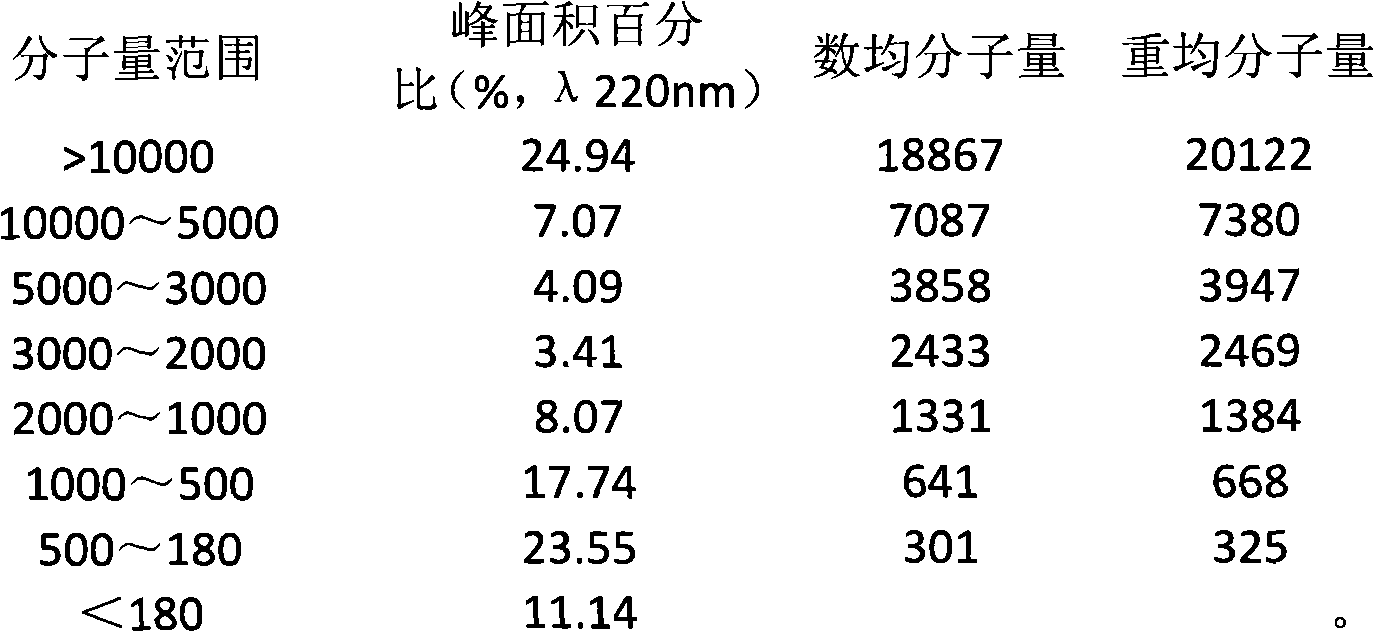

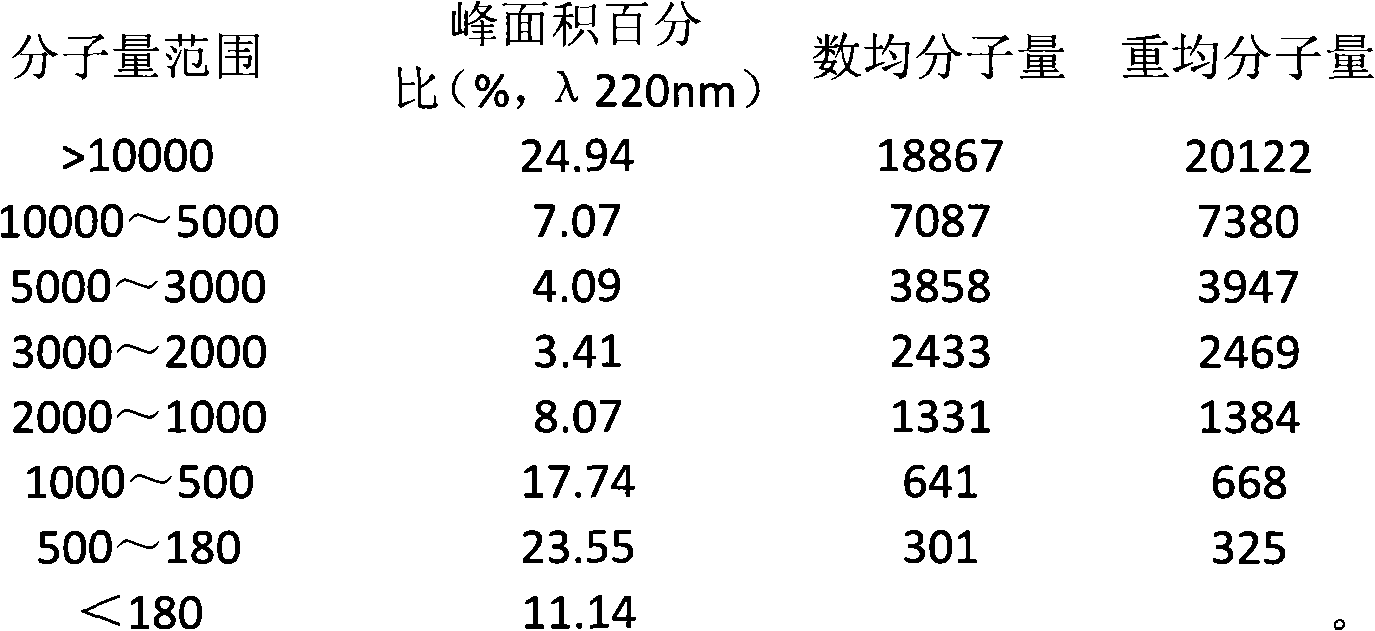

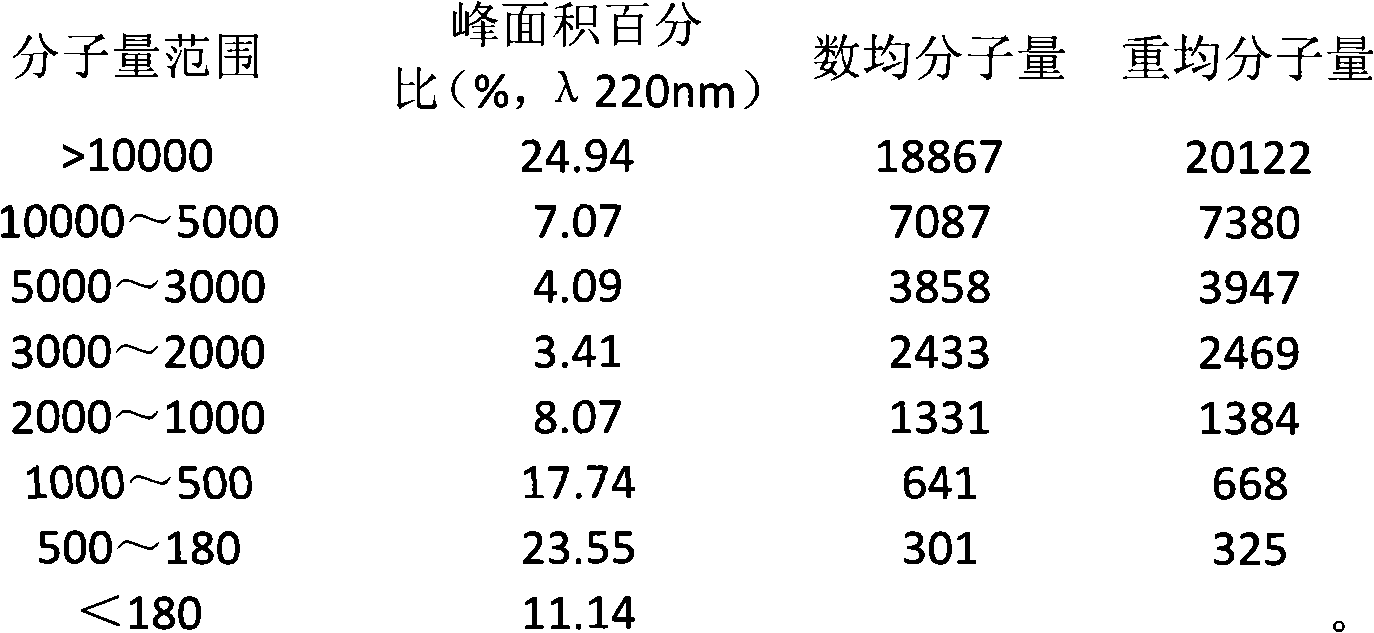

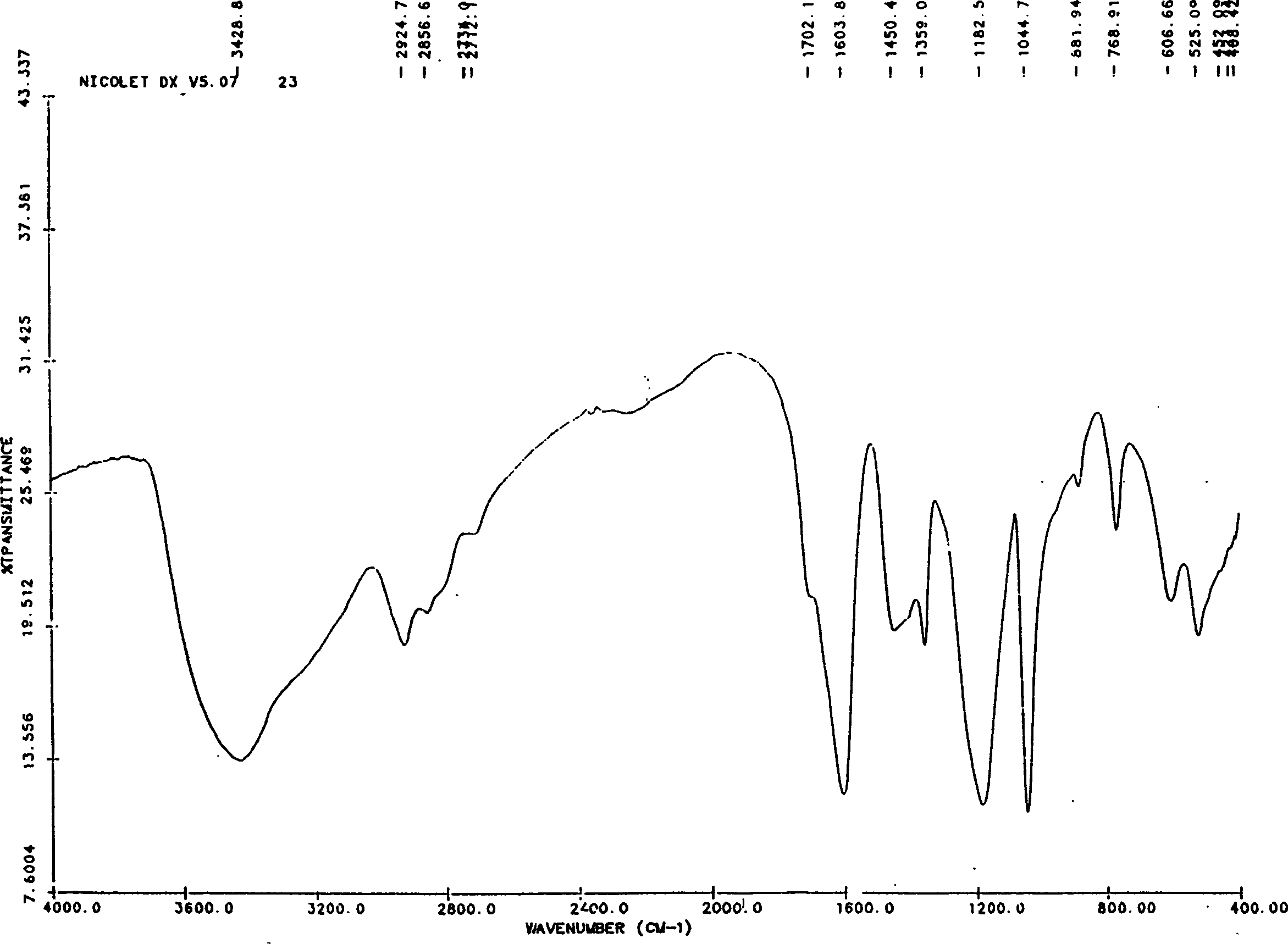

Bird's nest oligopeptide composition and preparation method and use thereof

ActiveCN102102119AImprove immunityUnique biological functionCosmetic preparationsPeptide/protein ingredientsBULK ACTIVE INGREDIENTOligopeptide

The invention provides a method for extracting small molecule oligopeptides from bird's nests by hydrolysis, which is to obtain a small molecular nano oligopeptide containing composition by hydrolyzing the bird's nests through the combination of enzymolysis and acid hydrolysis. The bird's nest oligopeptide composition is characterized in that: the molecular weight of the nano oligopeptides mainlyranges from 180 to 1,000D; preferably, the percentage of Gaussian distribution peak area of the nano oligopeptides with a molecular weight ranging from 180 to 1,000D in the composition is over 40 percent. The Cordyceps militarisoligopeptide extract provided by the invention retain other active ingredients such as polysaccharide, bird's nest sialic acid, micro elements and the like. The invention also relates to the use of the nano oligopeptide containing composition extracted from bird's nests in the preparation of medicines, health-care products and cosmetics.

Owner:BEIJING INST OF OLIGO PEPTIDE BIOLOGY

High efficiency aliphatic sulfonate water reducing agent and method for preparing same

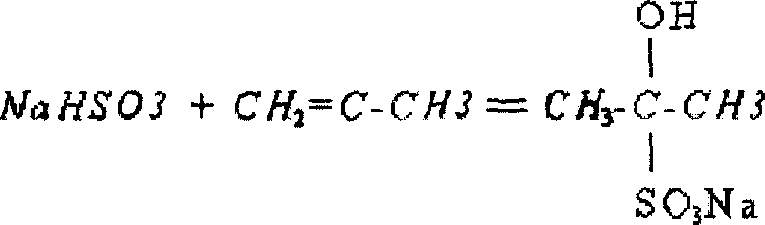

InactiveCN1634794AExcellent water reducing rateImprove performanceHigh strength concreteSuperplasticizer

The present invention relates to a high efficiency water reducing agent for manufacturing high performance cement based material such as high-strength concrete, fluid state and / or pumping concrete, etc. and method for preparing same. The invention takes ketones compound and aldehydes as condensation monomer, and sulphite as sulphonating agent, and take condensation reaction in alkaline aqueous solution. Then a water-soluble high-polymer condensate containing hydrophilic group such as sulfonic group, carboxy, hydroxyl, etc. in molecule with molecular weight ranging from 3000 to 10000 is obtained. By changing the matching, charging sequence of raw material, the technological process is simplified, the reaction time is shortened, and burst boiling and geling phenomena are also avoided at the same time. By controlling charging rate and condensation temperature, the condensation product is made with required molecular weight and can meet application performance. The fatty group sulphonate condensation compound made by the invention can be served as high efficiency water reducing agent of cement concrete, the water reducing, dispersion and reinforcing effects are better than the traditional albocarbon group high efficiency water reducing agent. The water reducing agent provided by the invention has the advantages of wide raw material source, simple synthesizing process, clean and suitable for industrial production.

Owner:吴霖秀 +2

C-nitroso compounds and use thereof

A C-nitroso compound having a molecular weight ranging from 225 to 1,000 (from 225 to 600 for oral administration) on a monomeric basis wherein a nitroso group is attached to a tertiary carbon, which is obtained by nitrosylation of a carbon acid having a pKa less than about 25, is useful as an NO donor. When the compound is obtained from a carbon acid with a pKa less than about 10, it provides vascular relaxing effect when used at micromolar concentrations and this activity is potentiated by glutathione to be obtained at nanomolar concentrations. When the compound is obtained from a carbon acid with a pKa ranging from about 15 to 20, vascular relaxing effect is obtained at nanomolar concentrations without glutathione. In another embodiment, a biocompatible polymer incorporates a C-nitroso moiety.

Owner:DUKE UNIV

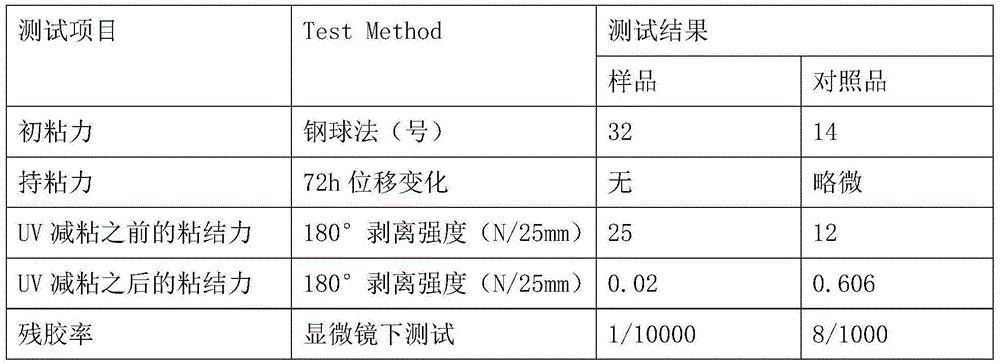

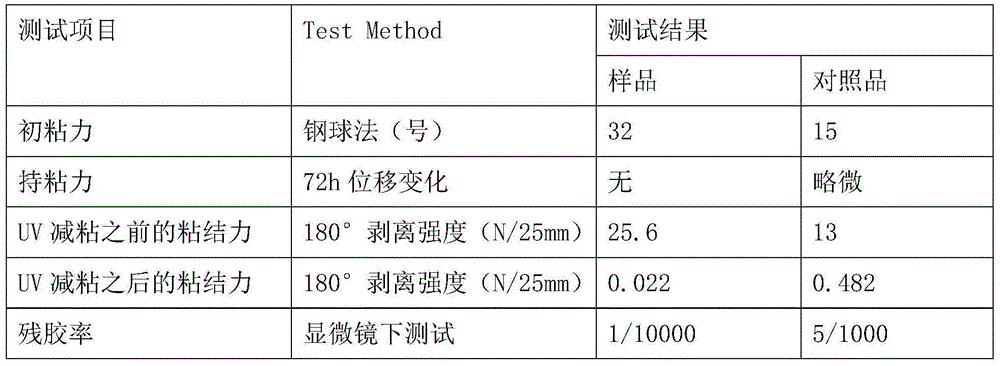

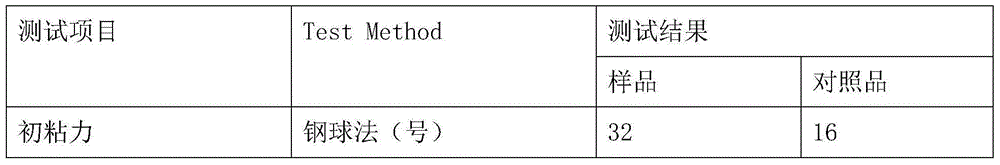

Bi-component cured UV viscosity-decreasing adhesive

ActiveCN105086730AImprove initial tack performanceImprove yield ratePolyurea/polyurethane coatingsAdhesiveDiluent

The invention relates to a bi-component cured UV viscosity-decreasing adhesive. The bi-component cured UV viscosity-decreasing adhesive comprises two components of the component A and the component B. The component A is composed of, by weight, 35-60 parts of cured resin, 22-45 parts of photosensitive monomers, 2-10 parts of photopolymerization initiators, 2-15 parts of diluents and 2-10 parts of auxiliaries, wherein the cured resin is resin containing hydroxyl or resin containing carboxyl; the component B is one of a curing agent containing NCO and a curing agent containing sulfydryl or a mixture of the curing agent containing NCO and the curing agent containing the sulfydryl, the curing agent containing NCO is isocyanate, the content of NCO of the isocyanate ranges from 12.5% to 23.5%, and the molecular weight ranges from 200 to 600; the curing agent containing the sulfydryl is polymercaptans, wherein the content of the sulfydryl ranges from 5% to 15%; the weight of the component B is 5%-20% of that of the component A. The bi-component cured UV viscosity-decreasing adhesive has the advantages that the initial viscous force is strong after curing forming is conducted at room temperature, after UV-irradiation is conducted for decreasing viscosity, the stripping effect is good, and adhesive residues do not exist.

Owner:GUANGZHOU SHENWEI NEW MATERIAL TECH

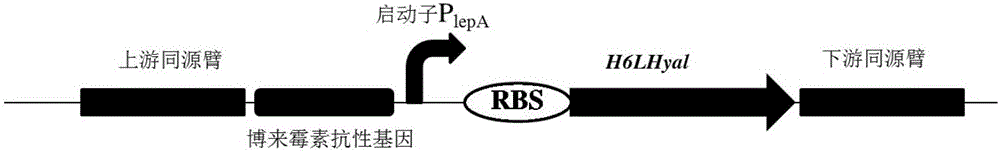

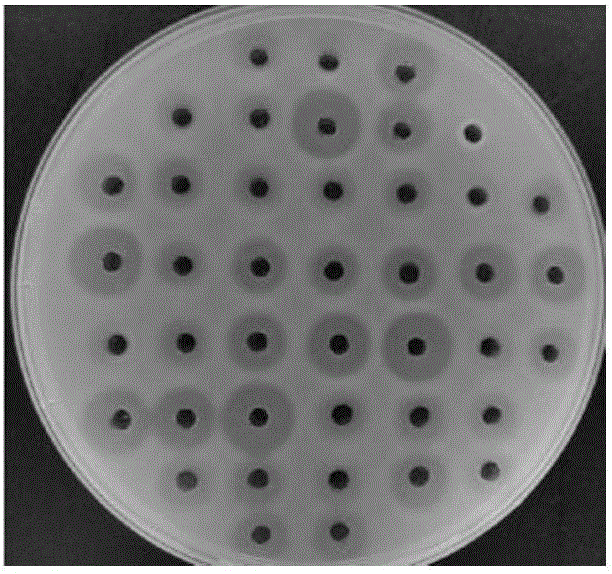

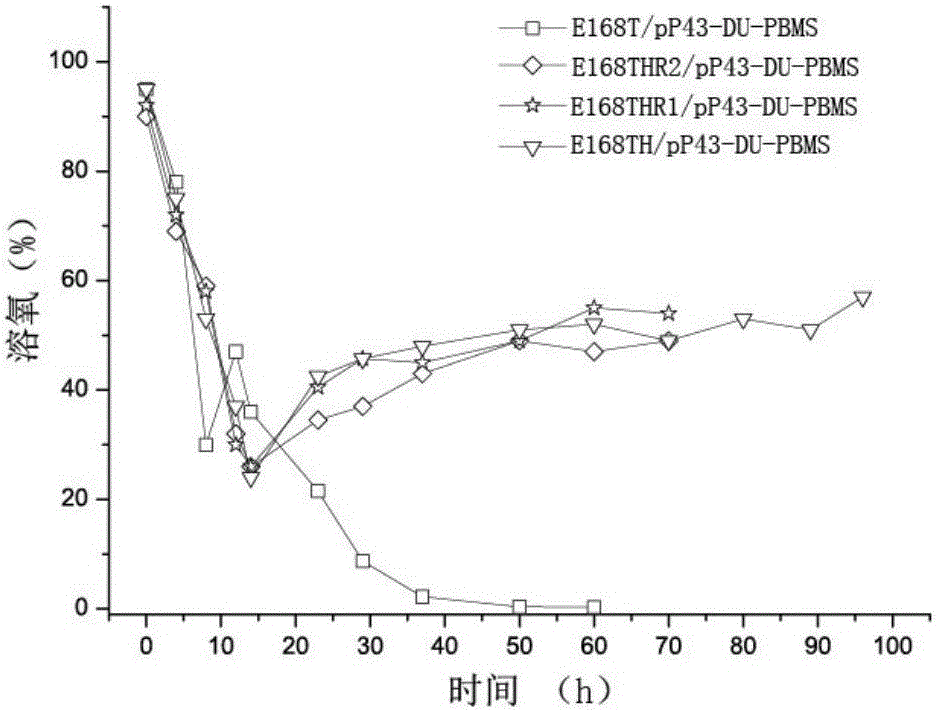

Construction method of recombinant bacillus subtilis capable of generating hyaluronic acid with specific molecular weight

ActiveCN105087456AIncrease productionReduce viscosityBacteriaTransferasesStreptococcus zooepidemicusHigh-Throughput Screening Methods

The invention discloses a construction method of recombinant bacillus subtilis capable of generating hyaluronic acid with specific molecular weight, belonging to the field of the bioengineering technology. According to the method, the production of hyaluronic acid is realized through integration of hyaluronic synthase (hasA) with streptococcus zooepidemicus source to bacillus subtilis; meanwhile, overexpression is realized on key genes of the synthetic route of HA, so that the high yield of bacillus subtilis is realized; on the basis, the hyaluronidase with the leech source is integrated to the genome of the bacillus subtilis, then mutant library construction is realized on ribosome bind sites (RBS) from the genetic expression translational level, and thus a series of mutants with different expression levels of hyaluronidases are obtained through high throughput screening; the yield of the hyaluronic acid achieves 19.38g / L, the molecular weight ranges from 103-106 Dalton, certain basis is laid for efficiently preparing micromolecule hyaluronic acids, and the construction method is suitable for industrial production and application.

Owner:JIANGNAN UNIV

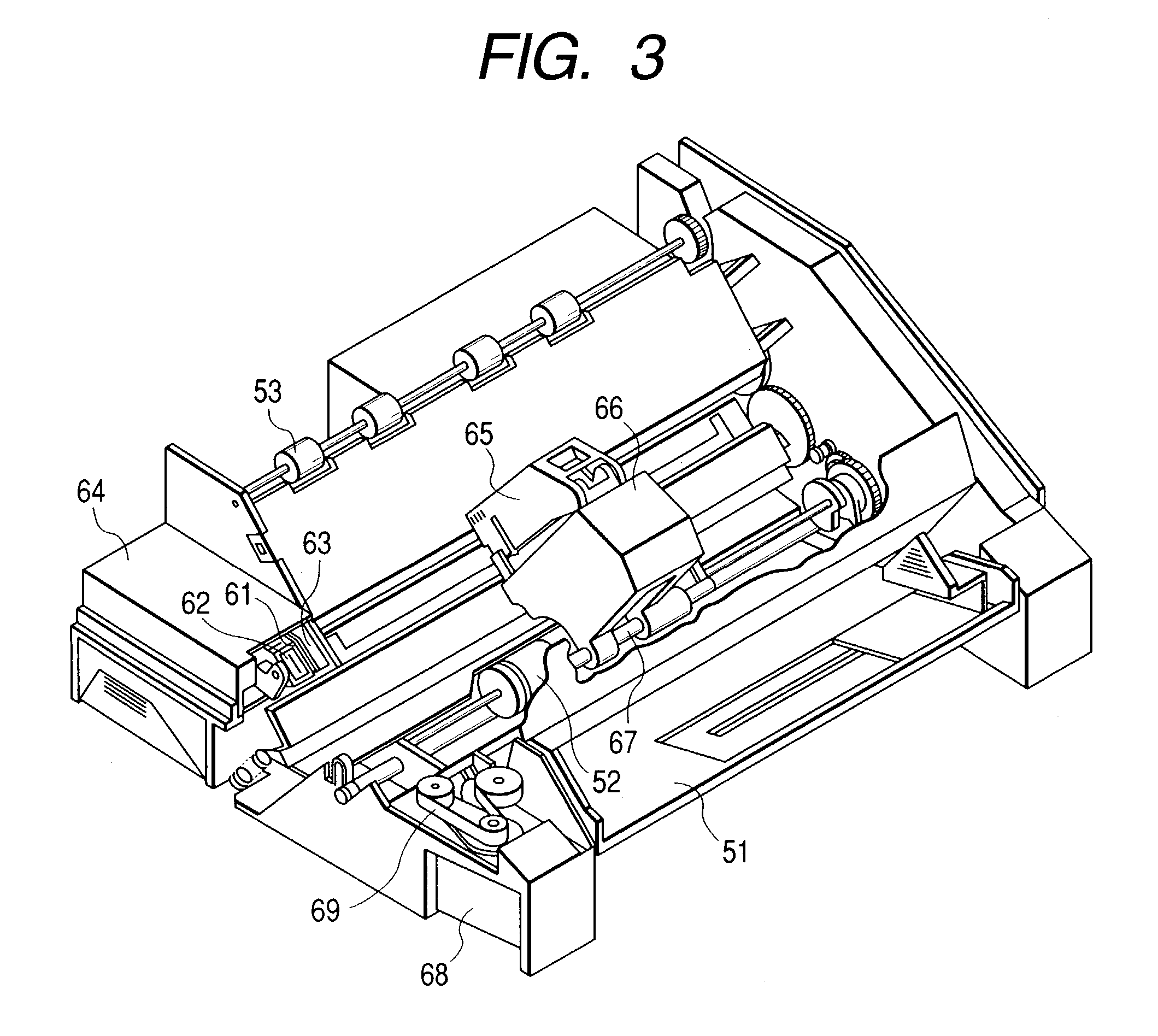

Epoxy resin composition, surface treatment method, liquid ejection recording head, and liquid ejection recording apparatus

InactiveUS7074273B2Improve impact performanceImprove printing qualityRecording apparatusLiquid surface applicatorsEpoxyCationic polymerization

An embodiment of the invention relates to a novel epoxy resin composition. The epoxy resin composition comprises (i) a first epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, and having a number average molecular weight ranging from 8,000 to 22,000 and a polydispersity ranging from 3.5 to 5.0, (ii) a second epoxy resin having in the molecule thereof at least one water-repellency-imparting group and two or more cyclic aliphatic epoxy groups, having a number average molecular weight ranging from 2,500 to 8,000 and a polydispersity ranging from 1.5 to 3.0, and (iii) a cationic polymerization catalyst.

Owner:CANON KK

Steam-resistant solvent-free laminating adhesive and preparation method thereof

ActiveCN102604583ALow viscosityImprove heat resistancePolyureas/polyurethane adhesivesPolyesterPolymer science

The invention provides steam-resistant solvent-free laminating adhesive applicable to compound soft package, which comprises a component A and a component B. The component A is isocyanate terminated polyurethane polymer formed by reacting polyhydroxy compound and polyisocyanate terminated compound. The component B is formed by mixing more than one type of plant oil polyalcohol, curing accelerator and synthetic modifier. The polyhydroxy compound in component A is formed of polyester polyol and / or polyether polyol with more than two degrees of functionality and a molecular weight range of from 600-2000, and more than one type of plant oil polyalcohol. The curing accelerator in the component B is formed of small molecular polyalcohol with more than two degrees of functionality. The synthetic modifier is formed by reacting more than one type of silane coupling agent and polyalcohol. The steam-resistant solvent-free laminating adhesive is low in viscosity and fast in curing speed, has high peel strength after boiled in water at 100 DEG C, and is especially suitable for soft packages requiring long-term high temperature sterilization (such as soft packages for foods, drugs and baby products). The invention further provides a preparation method of the steam-resistant solvent-free laminating adhesive.

Owner:SOUTH CHINA UNIV OF TECH +1

Globefish skin active collagen and method for preparing peptide thereof

ActiveCN101182357ABroaden the field of useIncrease profitConnective tissue peptidesFermentationUltrafiltrationPepsin

The preparation methods of globefish skin active collagen and the peptide of the active collagen are that the globefish skin is cut into small pieces to be frozen, dried, crushed and put into sodium chloride solution to be stirred for 12 hours and then for centrifugation to discard supernatant and remove non-collagen proteins, deposition is put in to acetum, pepsin is added under 0 DEG C to 10 DEG C for enzymolysis and centrifugation, the supernatant is put through an ultrafiltration membrane, and the above part is frozen and dried to obtain the collagen. After the active collagen is prepared, the rest deposition is centrifugated until the pH value is between 2.0 to 7.0, papain is added into the deposition for the enzymolysis, the supernatant is centrifugated and respectively put through the ultrafiltration membrane after enzyme-denaturing to obtain the globefish skin collagen peptide of different molecular weight ranges, and the globefish skin collagen peptide are frozen and dried to obtain the light yellow or white powdery globefish skin collagen active peptide which has good antioxidation character and takes effects of eliminating free radical and reducing the senescence degree.

Owner:DALIAN POLYTECHNIC UNIVERSITY +1

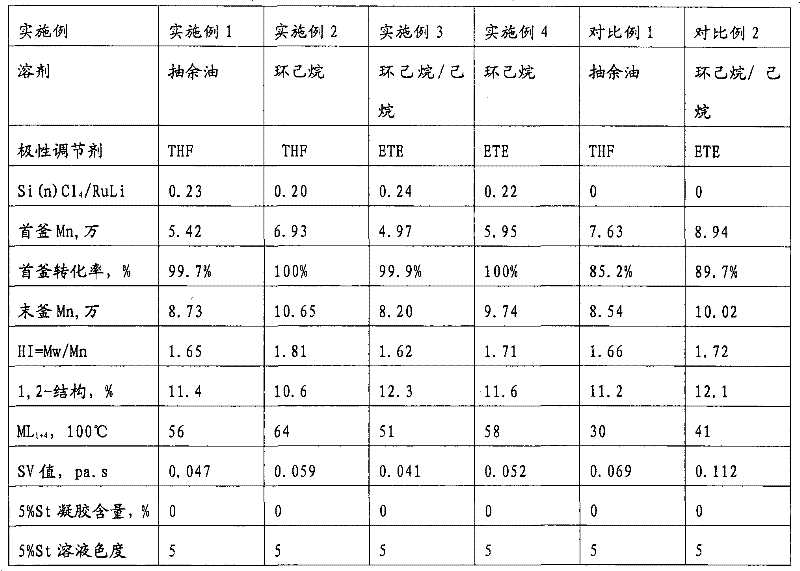

Low cis-polybutadiene rubber as well as preparation method and application thereof

The invention relates to a low cis-polybutadiene rubber as well as a preparation method and application thereof. The preparation method is characterized in that in a polymerization system formed by connecting at least two polymerization reaction kettles in series, in a non-polar solvent containing a structure regulating agent, an stable single-functionality initiator is adopted to initiate the polymerization of polybutadiene and then a conventional chain-end coupling technology is combined, so as to prepare the low cis-polybutadiene rubber having high Mooney viscosity and low SV (styrene viscosity) value (5% rubber-styrene solution viscosity at 25 DEG C). The properties of the prepared low cis-polybutadiene rubber are as follows: (1) the content of the vinyl group in a monomer unit is 8-14%wt; (2) a number-average molecular weight range is 80,000-110,000; (3) the Mooney viscosity ML[1+4] at the temperature of 100 DEG C is 45-65; (4) molecular weight distribution is 1.5-1.8; and (5) the SV value is 0.04-0.059Pa.s. The low cis-polybutadiene rubber synthesized by using the method can be applied to the field of plastic modification, and is especially suitable for preparation of a high-impact high-gloss grade polystyrene (PS) resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com