Pd/TiO2/C composite nano-catalyst, and preparation method and application thereof

A nano-catalyst and nano-technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of scarcity and high cost of resources, and improve catalytic stability. , the effect of high catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

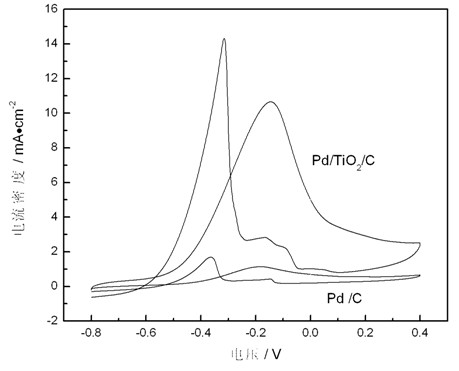

[0042] The preparation method of Pd / C catalyst catalyst:

[0043] Pd nanoparticles were loaded on the pretreated activated carbon by the liquid phase reduction method, so that the Pd metal loading was 20% of the total weight of Pd / C, and then 138.22 mg (five times the molar amount of Pd in the raw material) was added Trisodium citrate was used as a stabilizer, and excess sodium borohydride was added dropwise as a reducing agent. After reacting for 3 hours, it was filtered by suction, washed with water until there was no residual chloride ion, and dried under vacuum to obtain a Pd / C nanocatalyst.

[0044] In order to Pd / TiO of the present invention 2 / C composite nanocatalyst and the catalytic performance of Pd / C nanocatalyst to characterize, the nanocatalyst needs to be made into a catalytic electrode, and its preparation method is as follows:

[0045] The required nano-catalyst, 95% absolute ethanol and 5% Nafion (perfluororesin) solution are prepared according to the mass...

Embodiment 1

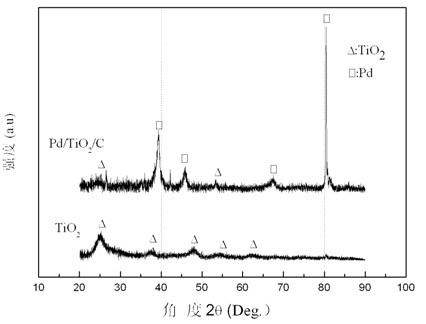

[0054] A Pd / TiO 2 / C composite nano-catalyst, composed of nano-Pd, nano-TiO 2 Composed of activated carbon powder, calculated by mass ratio, consisting of Pd: nano-TiO 2 : The ratio of activated carbon powder is 1:2:2;

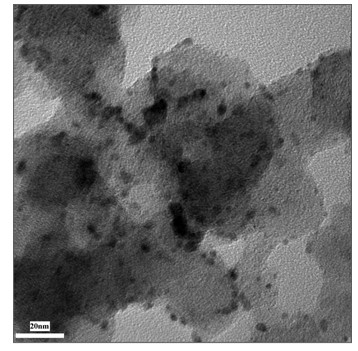

[0055] The particle size of the nanometer Pd is 3-5nm;

[0056] The nano-TiO 2 The particle size is 20-150nm;

[0057] The particle size of the activated carbon powder is 50-80 μm.

[0058] One of the above Pd / TiO 2 The preparation method of / C composite nano-catalyst comprises the steps:

[0059] (1) Nano-TiO was prepared by hydrothermal synthesis 2 powder

[0060] That is, 2.5mL of tetrabutyl titanate was used as the precursor, dissolved in 25mL of ethylene glycol with a concentration of 99%, and the magnetic stirring speed was controlled at 600-700r / min, and the concentration of (ethanol: water =10mL:1.3mL) 88%% ethanol aqueous solution to obtain a mixed solution A, then pour this mixed solution A into a high-pressure reactor with a polytetrafluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com