Organic gas withdrawal processing technique and device thereof

A technology for recovery and treatment of organic waste gas, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods. It can solve the problems of high fan power, high resistance of the adsorption bed, and high investment costs of equipment, so as to maintain adsorption capacity and improve Adsorption capacity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

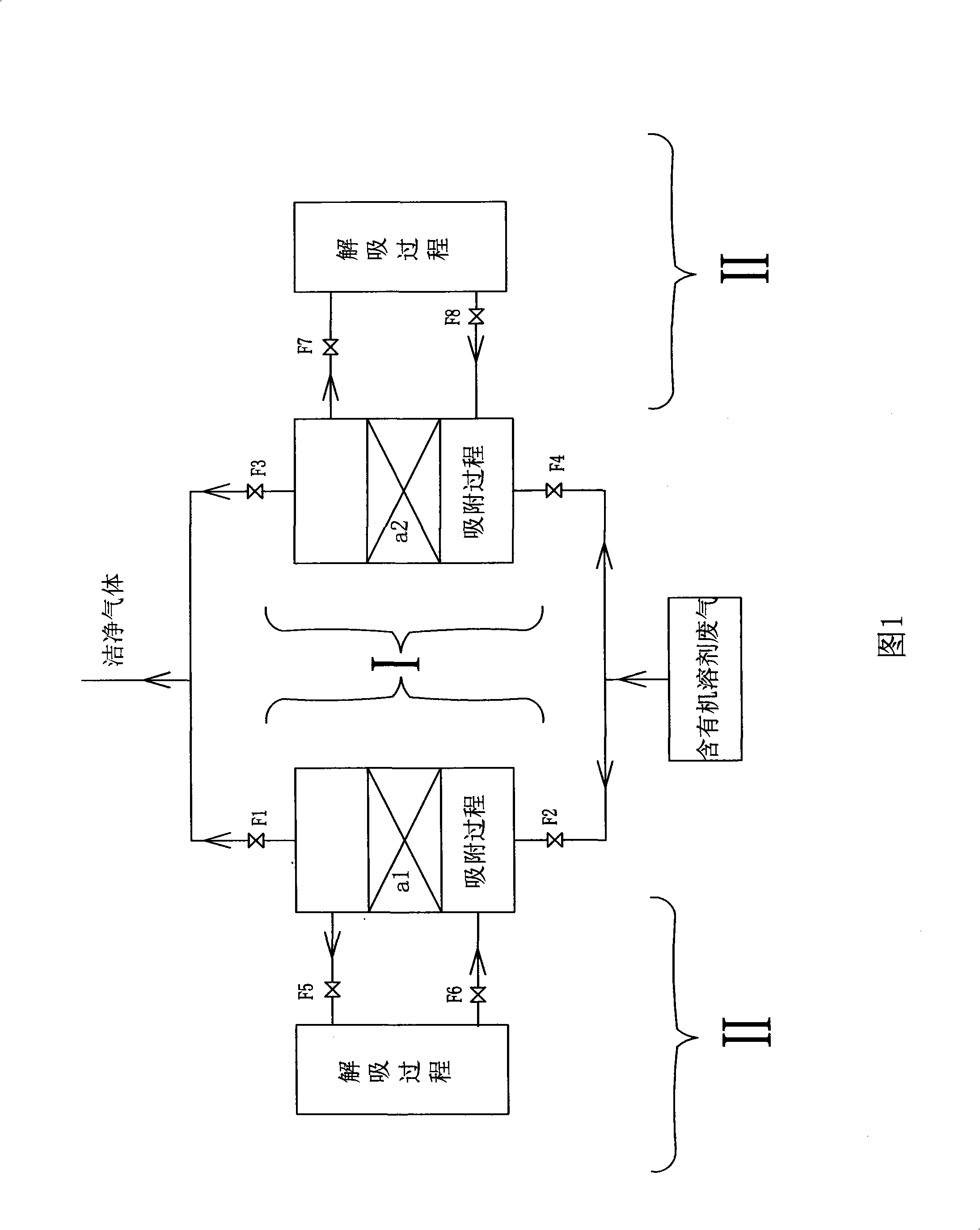

[0026] As shown in Figure 1, the organic waste gas recycling process of the present invention:

[0027] 1) The organic solvent in the waste gas is adsorbed by the adsorption material a1, in process I, after the adsorption, the waste gas becomes a clean gas and is directly discharged into the atmosphere;

[0028] 2) After the adsorption material a1 absorbs a certain amount of organic solvent, the adsorption material a1 is desorbed, process II, and at the same time, the adsorption material a2 adsorbs the organic solvent in the exhaust gas, process I;

[0029] 3) After the desorption treatment, the organic solvent adsorbed by the adsorption material a1 is desorbed, the adsorption material a1 recovers the adsorption capacity again, and the adsorption material a2 undergoes desorption treatment, process II, repeating step 1).

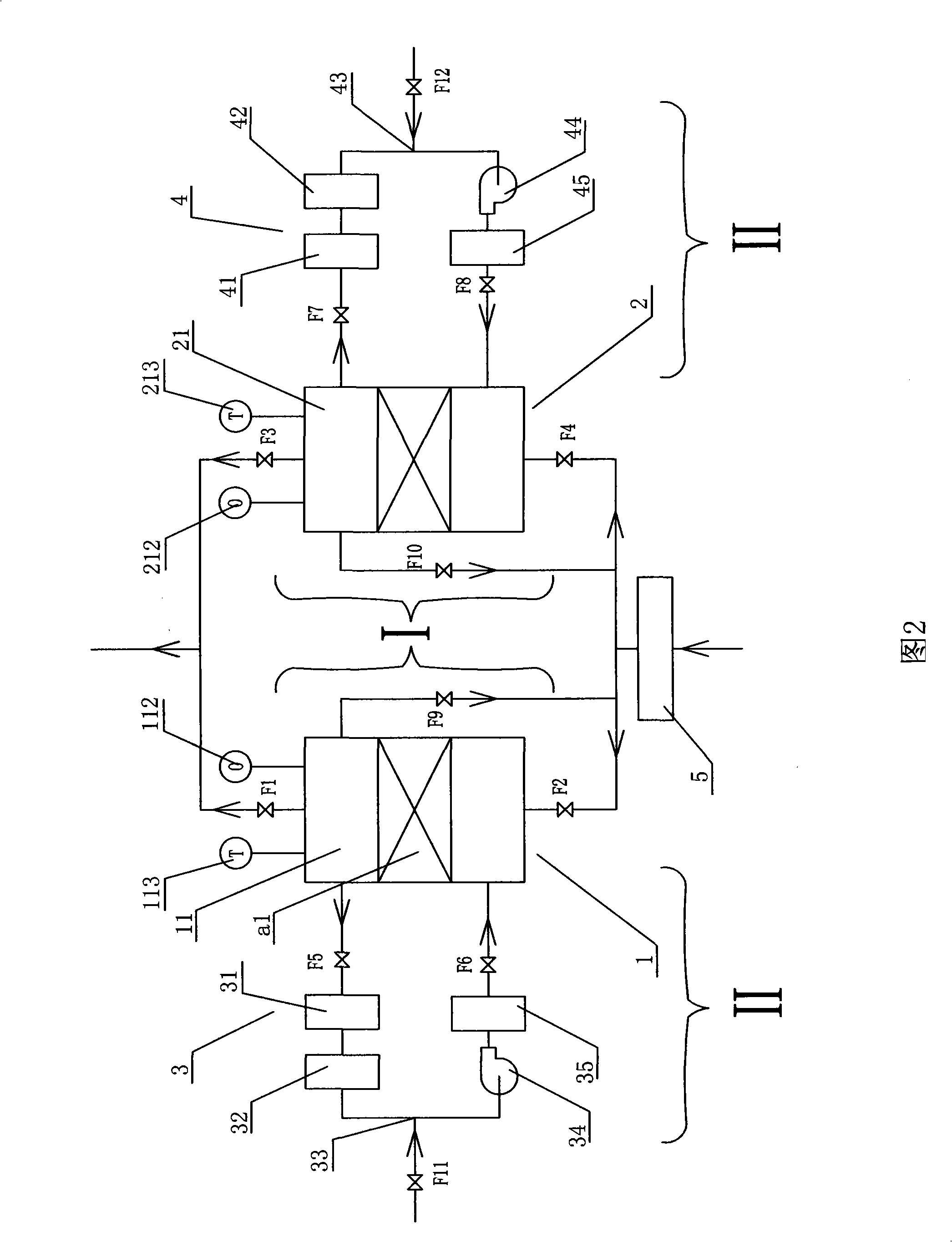

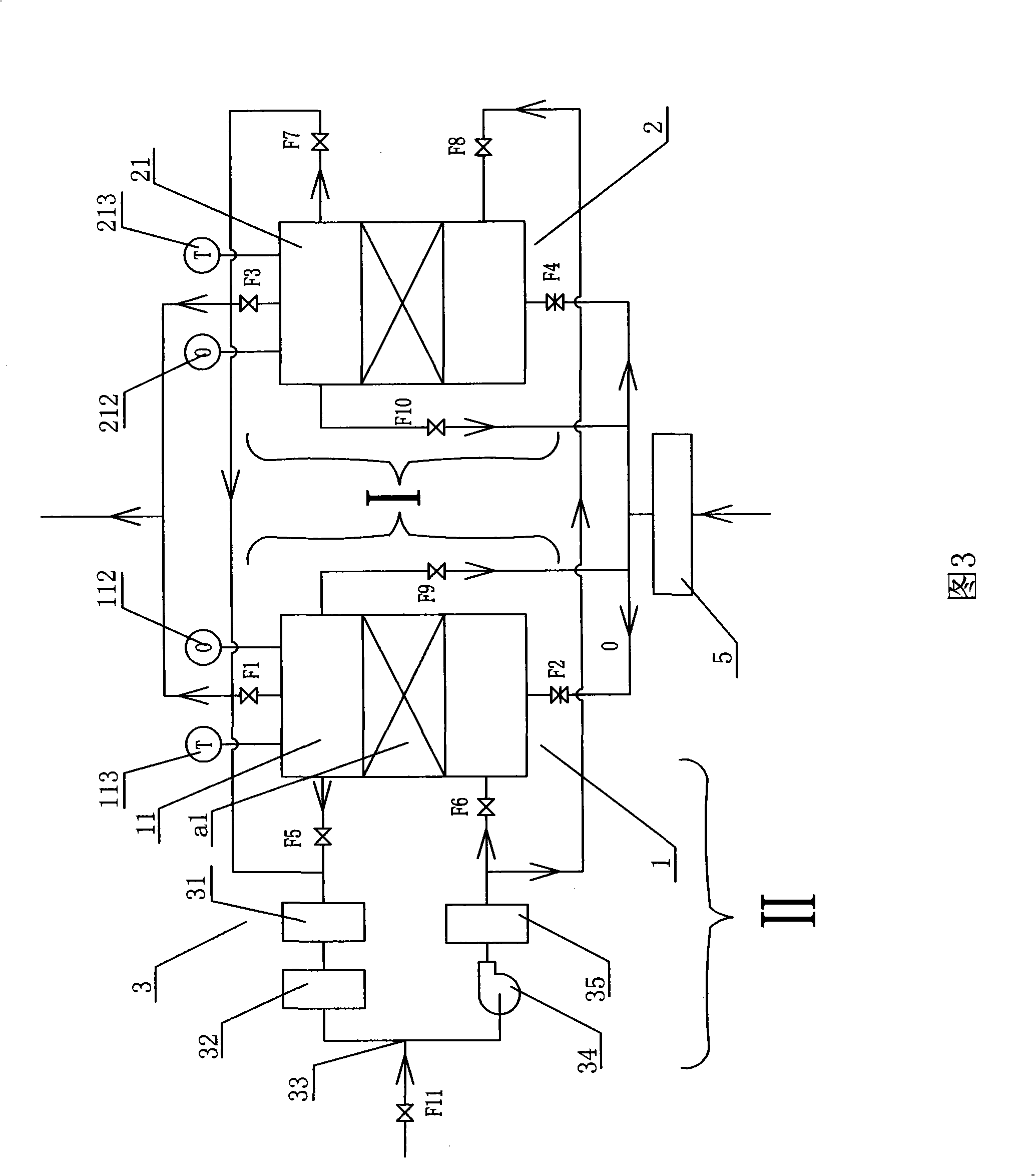

[0030] As shown in Figure 2, the device adopting the organic waste gas recovery and treatment process in the present invention includes two sets of adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com