Preparation of modified active carbon

A technology of activated carbon and modification, applied in the field of preparation of modified activated carbon, can solve the problems of large operator injury, low recovery rate, performance difference, etc., and achieve the effects of low cost, easy operation and strong pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

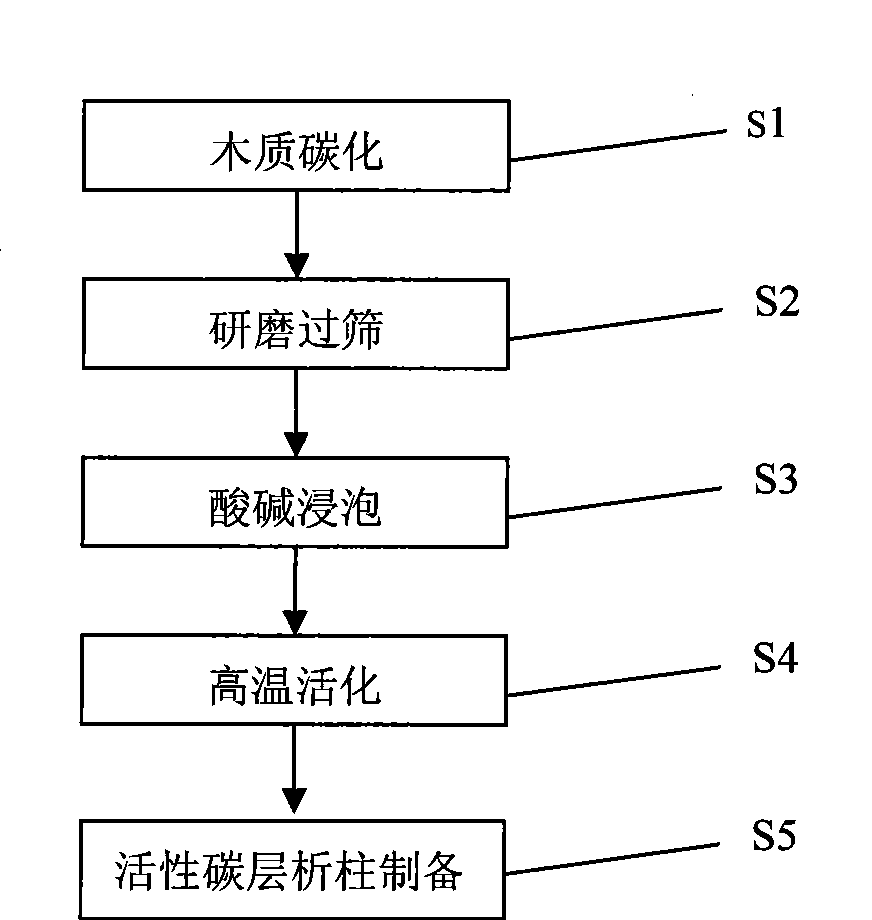

[0035] Example 1. Preparation of activated carbon glass chromatography column

[0036] Wood carbonization: Put the wood block in the muffle furnace and keep it at 150℃ for 12h; then heat it to 275℃ and keep it for 12h; then continue to raise the temperature to 400℃ and keep it for 24h; finally, heat it up to 500℃ and keep it 8h. Turn off the muffle furnace, and when the temperature drops to the greenhouse, take out the charcoal block.

[0037] Grinding and sieving: the carbonized charcoal block is crushed into pieces, crushed by a pulverizer, ground in a mortar, and passed through a sieve of 40 mesh to 100 mesh to obtain charcoal powder.

[0038] Acid-base soaking: Take 10g of the above wood charcoal powder and place it in a beaker. After soaking and stirring with 100mL of 2mol / L hydrochloric acid solution, ultrasonically shake for 30min, let it stand for 30min to make it penetrate completely, and then rinse with tap water and distilled water to Neutral; After pouring out the wate...

Embodiment 2

[0041] Example 2: Using activated carbon glass chromatography column to separate organochlorine pesticides and PCBs in marine biological samples

[0042] Weigh 20.0g of marine biological sample (wet sample) and 20g of anhydrous sodium sulfate (mixed), place them in a 100mL glass conical flask with stopper, and add 30mL of a 1:1 mixture of n-hexane and acetone. Place the extraction in an ultrasonic extraction instrument for 20 minutes, then transfer the entire amount of the extract to a rotary evaporator; then add 20 mL of a 1:1 hexane-acetone mixture into a stoppered glass conical flask, and ultrasonically extract for 10 minutes ; Combine the above two extracts in the same rotary evaporator, evaporate in a 45 ℃ water bath, concentrate until nearly dry, add 1 mL of n-hexane and mix well to obtain a marine biological sample containing PCBs and organochlorine pesticides. N-hexane extraction liquid.

[0043] Transfer the entire amount of the above-mentioned marine biological sample n-...

Embodiment 3

[0044] Example 3. Separation of organochlorine pesticides and PCBs in marine sediment samples using activated carbon glass chromatography columns

[0045] Weigh 10.0g of marine sediment sample (dry sample) and 10g of anhydrous sodium sulfate, mix them, place them in a 100mL glass conical flask with stopper, and add 30mL of a 1:1 mixture of n-hexane and acetone. Carry out ultrasonic extraction, and use activated carbon glass chromatography column to separate organochlorine pesticides and PCBs in the sample. The operation steps are the same as those in Example 2 (but in a constant volume of 2mL n-hexane solution, 1g of high-purity copper powder should be added , Ultrasonic oscillation for 5min, standing for 12h, after desulfurization, can be measured by capillary GC-ECD).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com