Filter medium for removing benzene and homologous compounds thereof from drinking water and preparation method thereof

A technology for filter media and homologues, applied in the field of filter media and its preparation for removing benzene and its homologues in drinking water, can solve the problems of low removal rate, benzene and its homologues with little effect, and achieve removal rate High, damage-free, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

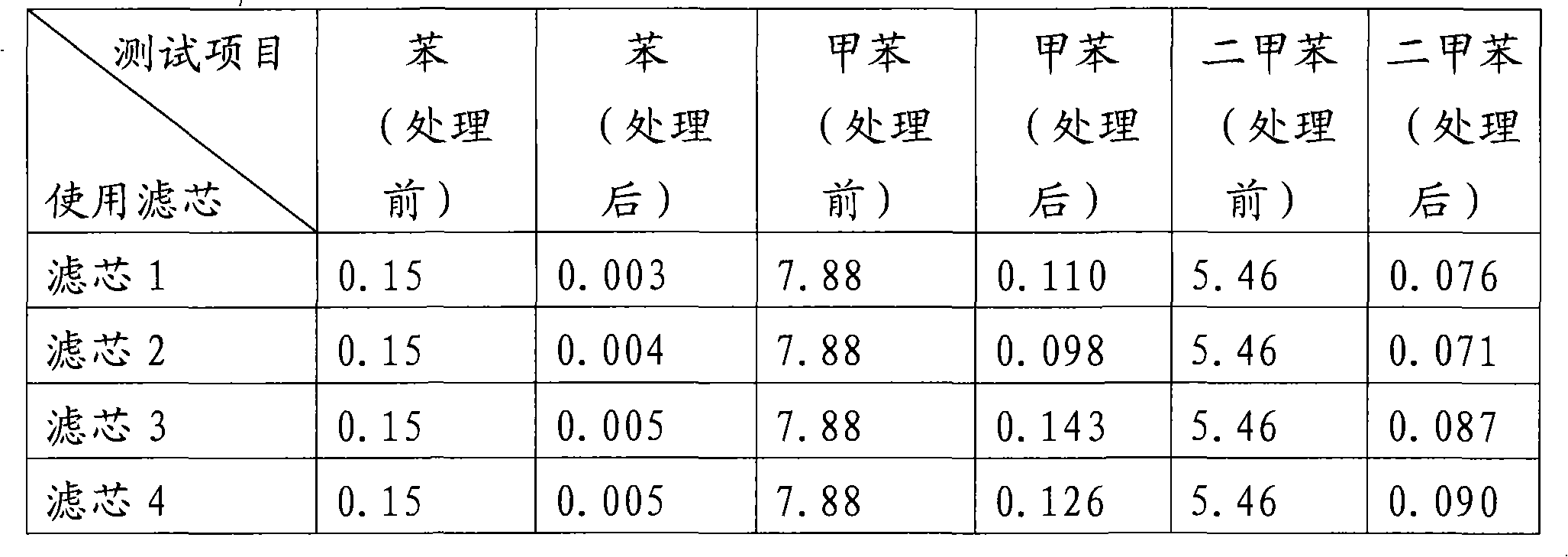

Examples

Embodiment 1

[0043] (1) Take medical activated carbon powder 65g, the particle diameter of described medical activated carbon is 74~89 microns;

[0044] (2) Grinding the natural zeolite to 5-80 meshes, impregnating it with hydrochloric acid with a concentration of 8wt% for 15 hours, washing after neutralization with sodium carbonate, and boiling in water for 40 minutes; drying the boiled zeolite at 400°C Lower roasting, then pulverized to 104 ~ 150 microns, weighing 75g of the prepared modified zeolite powder;

[0045] (3) Take ultra-high molecular weight polyethylene powder 290g, said ultra-high molecular weight polyethylene is the M-II type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 2.5 million;

[0046] (4) The diatomite powder is impregnated with sulfuric acid with a concentration of 6wt% for 18 hours, washed after being neutralized by caustic alkali, and then boiled for 60 minutes; the boiled diatomite powder is dried and h...

Embodiment 2

[0053] (1) Take medical active carbon powder 70g, the particle diameter of described medical active carbon is 74~89 microns;

[0054] (2) Treat the zeolite with excess sodium chloride, dry it at 100°C after forming, and finally heat and activate it at 500°C to obtain Na-type zeolite powder, then crush it to 104-150 microns, and weigh the prepared Na-type zeolite Zeolite powder 80g;

[0055] (3) Take ultra-high molecular weight polyethylene powder 300g, said ultra-high molecular weight polyethylene is the M-III type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 3.5 million;

[0056] (4) The diatomite powder is impregnated with sulfuric acid with a concentration of 6wt% for 18 hours, washed after being neutralized by caustic alkali, and then boiled for 60 minutes; the boiled diatomite powder is dried and heated at 500°C roasting, then pulverized to 89-104 microns, and weighed 90 g of the prepared modified diatomite powd...

Embodiment 3

[0063] (1) Take medical activated carbon powder 120g, the particle diameter of described medical activated carbon is 74~89 microns;

[0064] (2) Put 10-20 mesh zeolite ore into NaOH solution, and then heat at 95°C for 70 hours to obtain P-type zeolite powder, and after cooling, crush it to 104-150 microns, and weigh the prepared P-type zeolite powder 120g;

[0065] (3) Take ultra-high molecular weight polyethylene powder 260g, described ultra-high molecular weight polyethylene is the M-II type product of Beijing Dongfang Petrochemical Co., Ltd. Auxiliary No. 2 Factory, and its molecular weight is 2.5 million;

[0066] (4) When the natural zeolite is roasted to 600°C, it is quenched with water, then dried and pulverized to 89-104 microns to obtain modified diatomite powder, and 120 g of the prepared modified diatomite powder is weighed;

[0067] (5) Weigh 130 grams of azodicarbonamide with a purity of 99.99%;

[0068] (6) Put the above four powders into a mechanical stirrer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com