Method for preparing SCR (Selective Catalytic Reduction) denitration catalyst by slag and catalyst thereof

A denitrification catalyst and slag technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of not being able to improve the denitrification rate and the denitrification rate is not high enough, so as to save raw material costs, improve low-temperature activity, The effect of decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

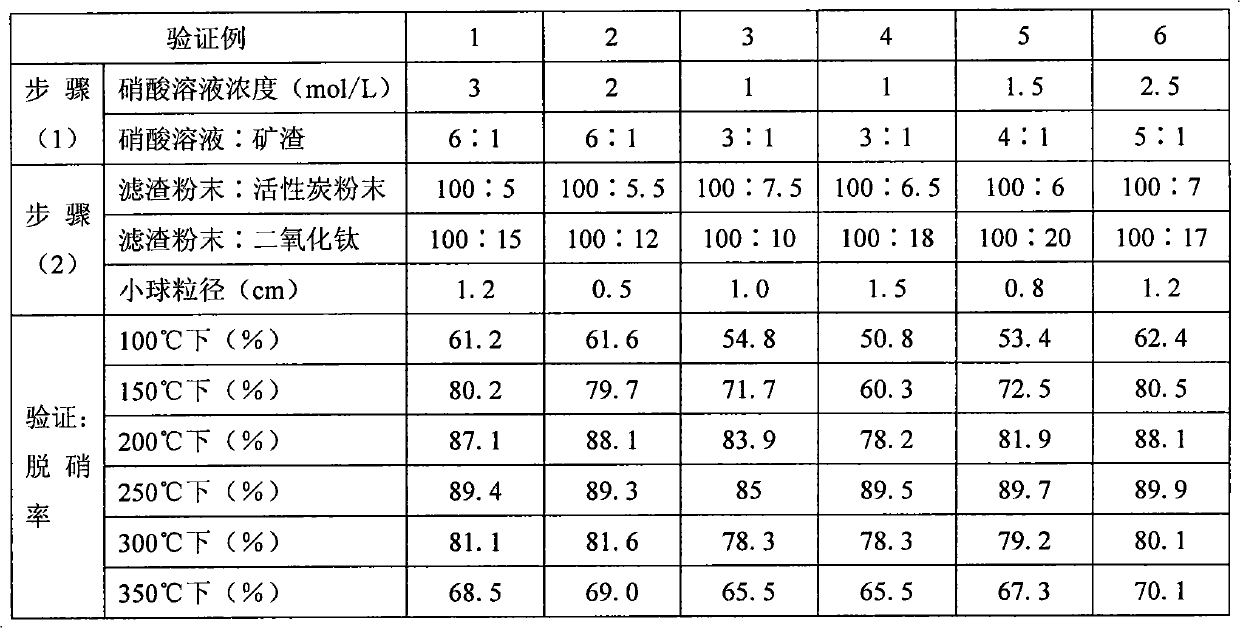

[0009] One, a kind of method that prepares SCR denitrification catalyst with slag, used slag is the slag after extracting potassium manganate in the method, and its preparation step is, (1) slag pretreatment: fully with nitric acid solution and described slag at normal temperature Mixing and stirring for pickling, the number of times of washing is such that no potassium ions can be detected, then the filter residue is dried and pulverized into powder; then filtered, the filter residue is dried and pulverized into powder. (2) Forming: fully mix the filter residue powder and pore-forming agent powder, adjust it into a slurry, rub it into pellets, and make pellets; (3) Activation: place the pellets obtained in step (2) successively at 70-90°C and Bake at 90-100°C for 2 hours each, then place these pellets at 250-270°C for 1 hour, 440-460°C for 2 hours, 590-610°C for 2 hours, and then cool to room temperature naturally. The obtained solid pellets are the SCR denitration catalyst. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com