Graphene-loaded activated carbon composite material and preparation method thereof

A composite material, activated carbon technology, applied in graphene, chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, etc. Increased conductivity, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

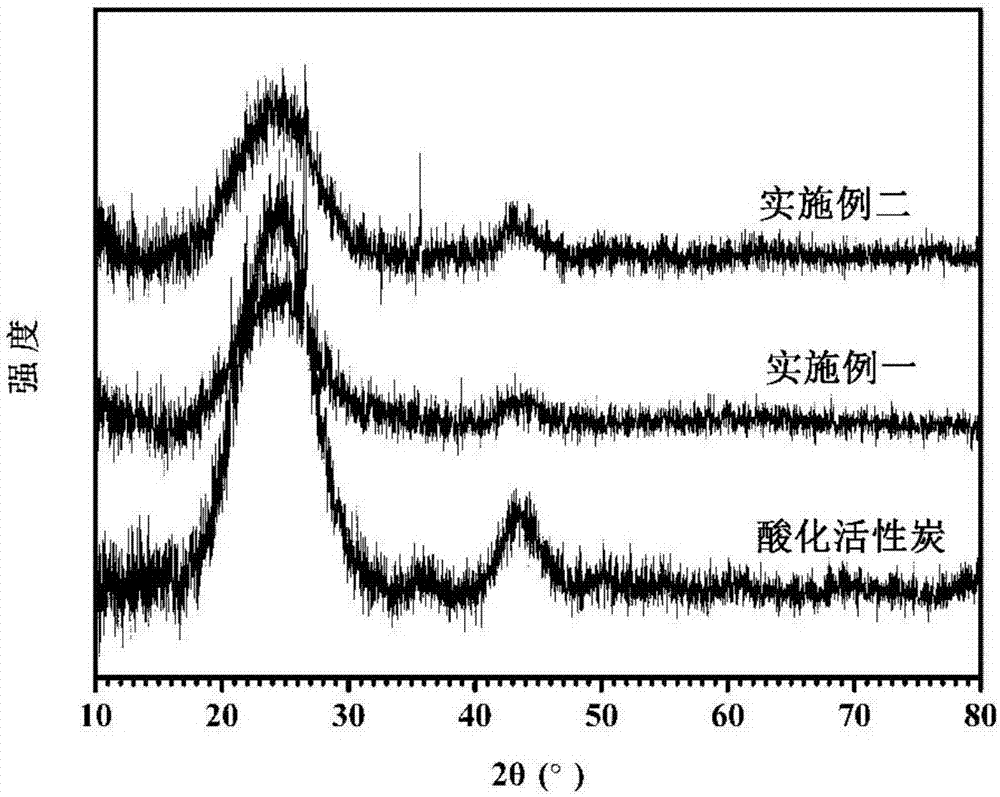

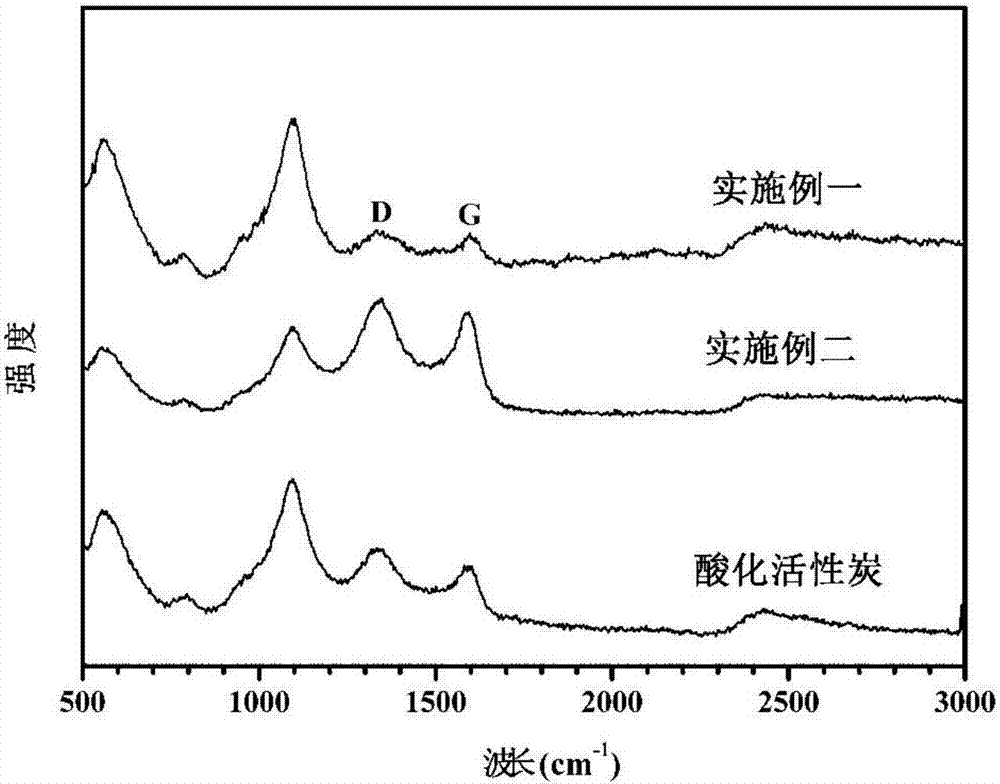

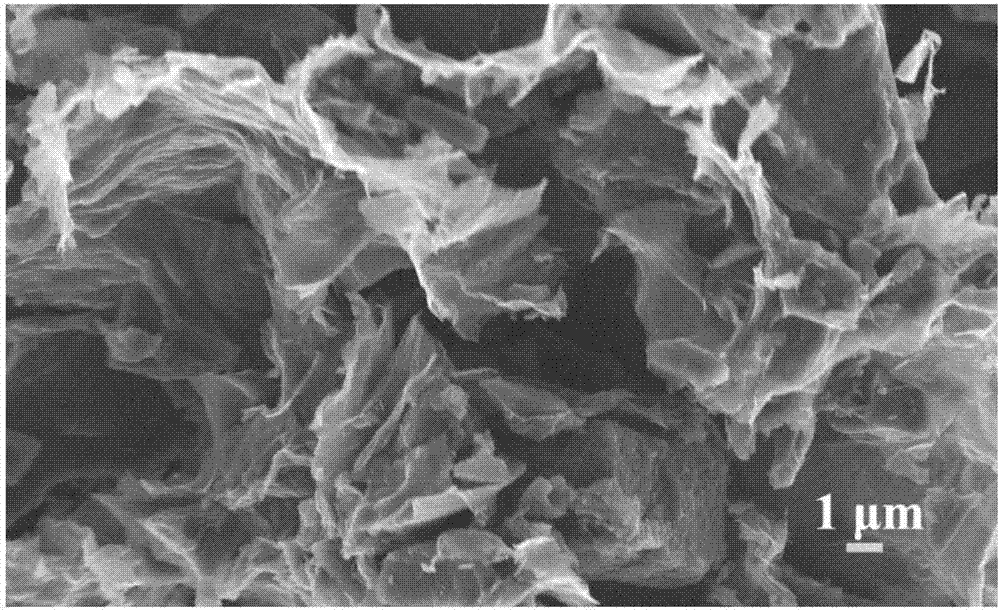

[0037] The preparation method of the activated carbon composite material loaded with graphene comprises the following steps: a) Grinding the activated carbon to 1000 mesh, washing and drying the activated carbon with deionized water, adding it to 1 M hydrochloric acid solution for soaking for 24 h, and then washing until the pH is low change, pH = 6.5, dried in an oven at 105 °C for 24 h; b) according to the mass ratio of activated carbon to graphene oxide of 10:1, ultrasonically dispersed in 100 mL ultrapure water for 4 h, the concentration was 0.3 mg / mL, then add 0.3 g of activated carbon to the solution, and stir for 12 h; c) Slowly add 100 mL of ethylenediamine solution with a concentration of 9 mg / mL, so that the mass of ethylenediamine is 30 times that of graphene oxide, React in a water bath at 80°C for 8 h, and pass N 2 ; d): The product of step c) was dialyzed for 24 hours until the conductivity of the dialysate dropped to the required value and dropped to 18 us / cm, ...

Embodiment 2

[0043] The preparation method of the activated carbon composite material loaded with graphene comprises the following steps: a) Grinding the activated carbon to 1000 mesh, washing and drying the activated carbon with deionized water, adding it to 1 M hydrochloric acid solution for soaking for 24 h, and then washing until the pH is low Change, pH = 6.5, dry in an oven at 105°C for 24 h; b) According to the mass ratio of activated carbon and graphene oxide at 5:1, ultrasonically disperse in 100 mL ultrapure water for 4 h, and the prepared concentration is 0.6 mg / mL, then add 0.3 g of activated carbon to the solution, and stir for 12 h; c) Slowly add 100 mL of ethylenediamine solution with a concentration of 18 mg / mL, so that the mass of ethylenediamine is 30 times that of graphene oxide , reacted in a water bath at 80°C for 8 h, and passed N 2 ; d): The product of step c) was dialyzed for 24 h until the conductivity of the dialysate dropped to the required value, then filtered ...

Embodiment 3

[0049] The application of the activated carbon composite material of loaded graphene comprises the following steps: the composite material prepared in embodiment one and two, add the sodium carboxymethyl cellulose of composite material quality 0.5%, then add a small amount of deionized water and mix , pressed into tablets with a tablet press, and dried at a constant temperature in a desiccator; the conductivity of the compressed tablets was tested using the four-probe method.

[0050] The results show that the resistivity of the sample prepared in Example 1 is 48.09 Ω cm, and the conductivity is 2.08 S m -1 ; The resistivity of the sample prepared in embodiment two is 20.55 Ω cm, and the conductivity is 4.87 S m -1 . Compared with the conductivity of coconut shell activated carbon itself (0.05 S·m -1 ), the resistivity of the sample in Example 1 increased by about 42 times, and the conductivity of the sample in Example 2 increased by nearly 100 times. It shows that the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com