Patents

Literature

92results about How to "Reduce costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for in-site detecting soil carbon dioxide flux

InactiveCN1987421AEasy to operateReduce costsMaterial analysis by optical meansSoil co2 fluxEngineering

The method includes steps: fixing up foundation ring on ground to be measured in advance in order to ensure area to be measured; open ended measuring vessel (OEMS) is installed on the foundation ring hermetcally; using capnograph connected to the open ended measuring vessel measures carbon dioxide concentration level inside OEMS so as to obtain initial concentration value X1 of carbon dioxide; sealing opening of OEMS, and together with foundation ring to form a sealed measurement space in order to collect concentration of carbon dioxide released for a duration from soil; using capnograph to measure concentration of carbon dioxide released for a duration from soil so as to obtain real measured carbon dioxide concentration value X2. Features are: simple and easy operation, time saving and low cost.

Owner:BEIJING FORESTRY UNIVERSITY

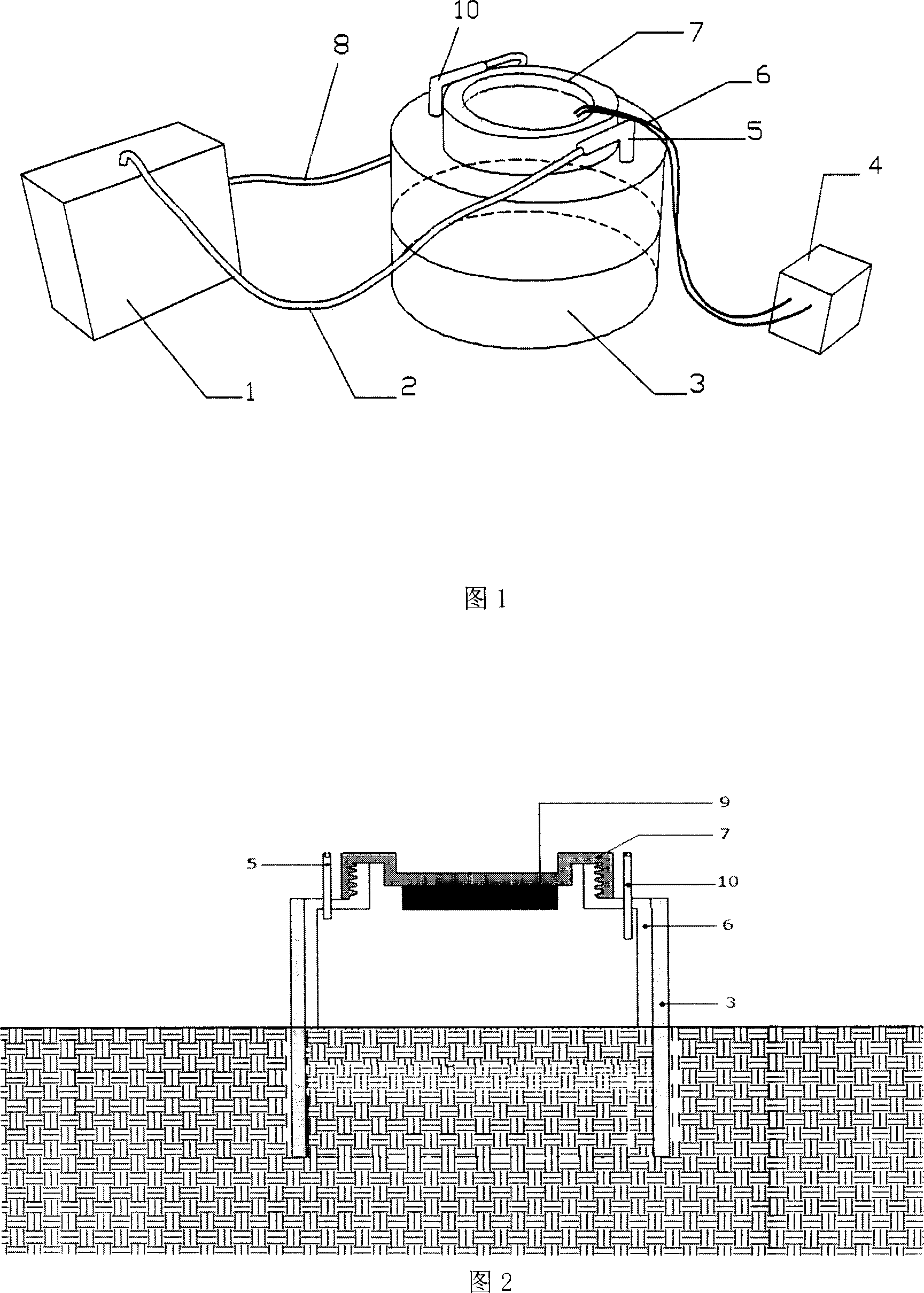

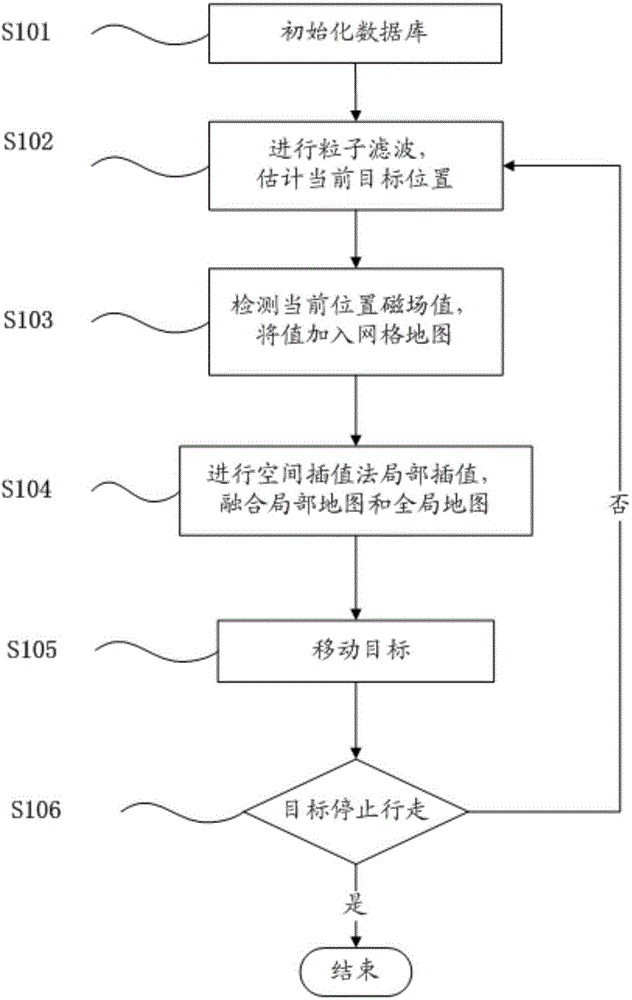

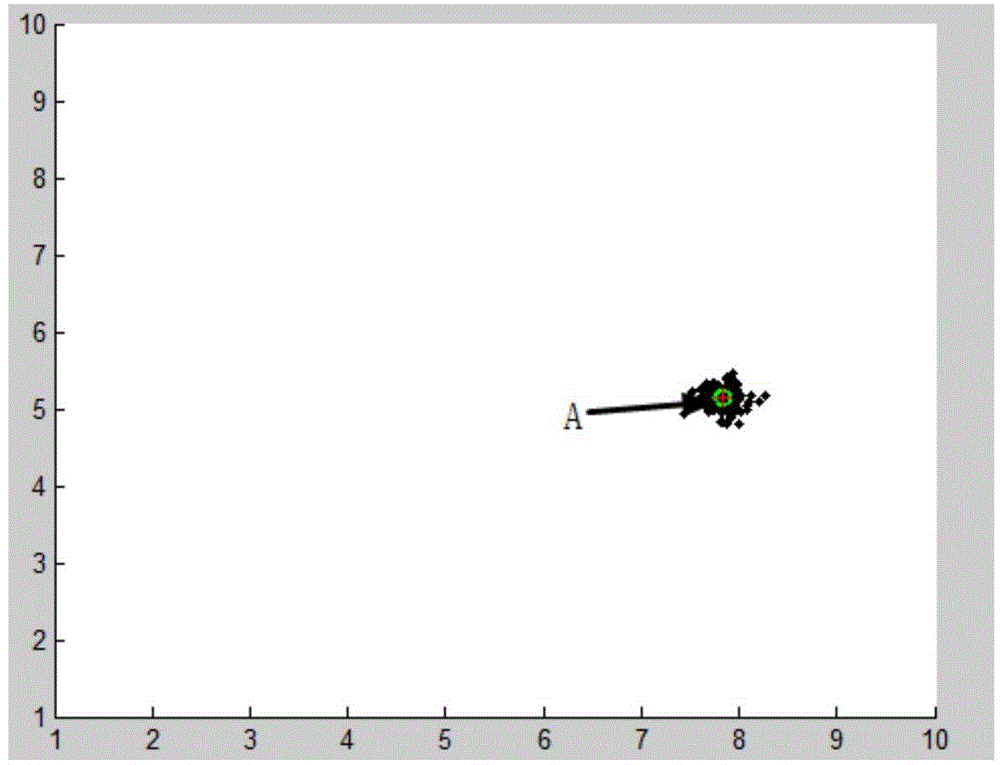

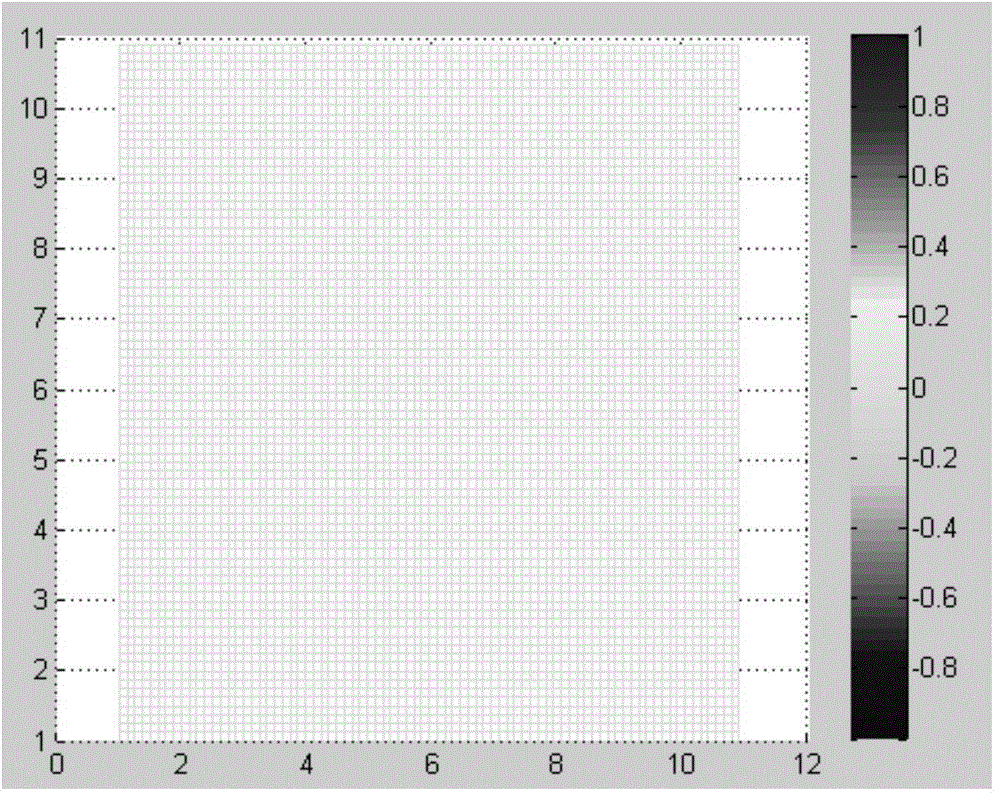

Method and system of target immediate location and map establishing

ActiveCN104019813AReduce costsThe results are highly reliableNavigation by terrestrial meansNavigation by speed/acceleration measurementsEarth's magnetic fieldComputer science

The invention discloses a method and a system of a target immediate location and map establishing. The method comprises the following steps of (1) carrying out immediate location on a moving target in a moving range; (2) immediately updating a geomagnetic field map of the movable range of the target according to the location of the moving target; (3) locating the next movable position of the target according to the updated geomagnetic field map; and repeatedly executing the step (2) and (3) to until the target stops to move. The method provided by the invention can achieve the purpose of immediate target location and accurate geomagnetic field map establishing of the indoor target under the condition that a magnetic field map cannot be detected indoors.

Owner:上海益航网络科技有限公司

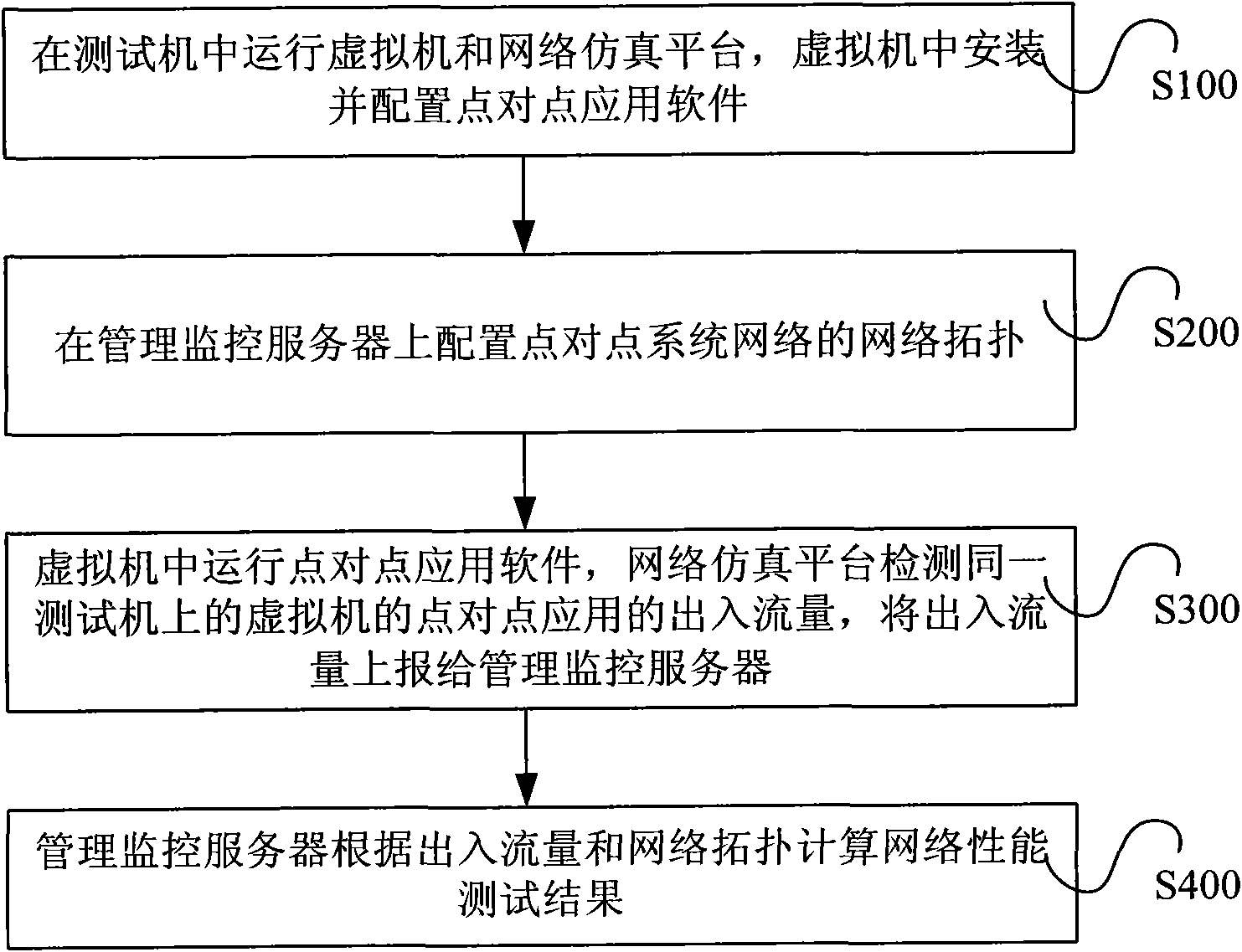

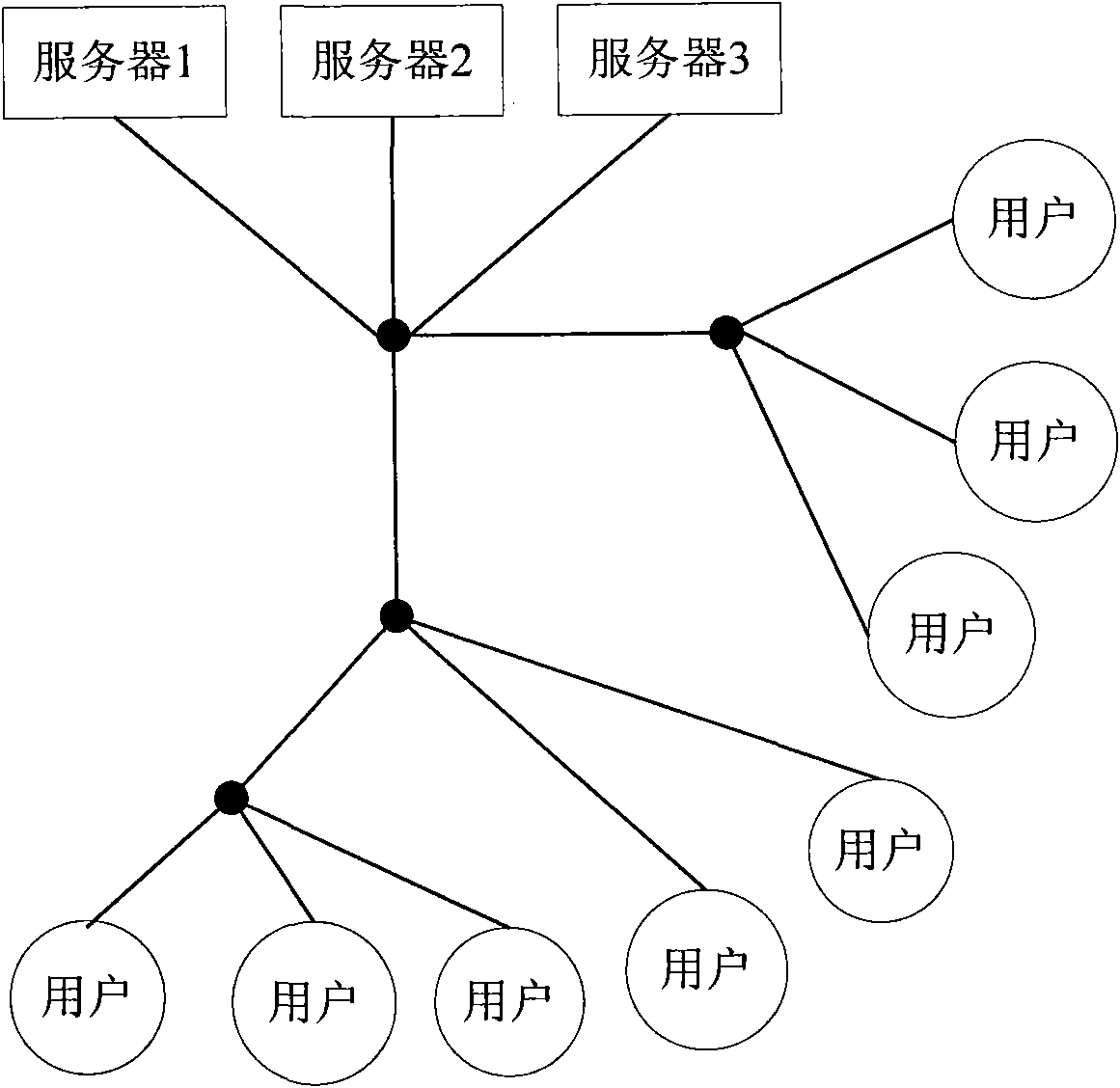

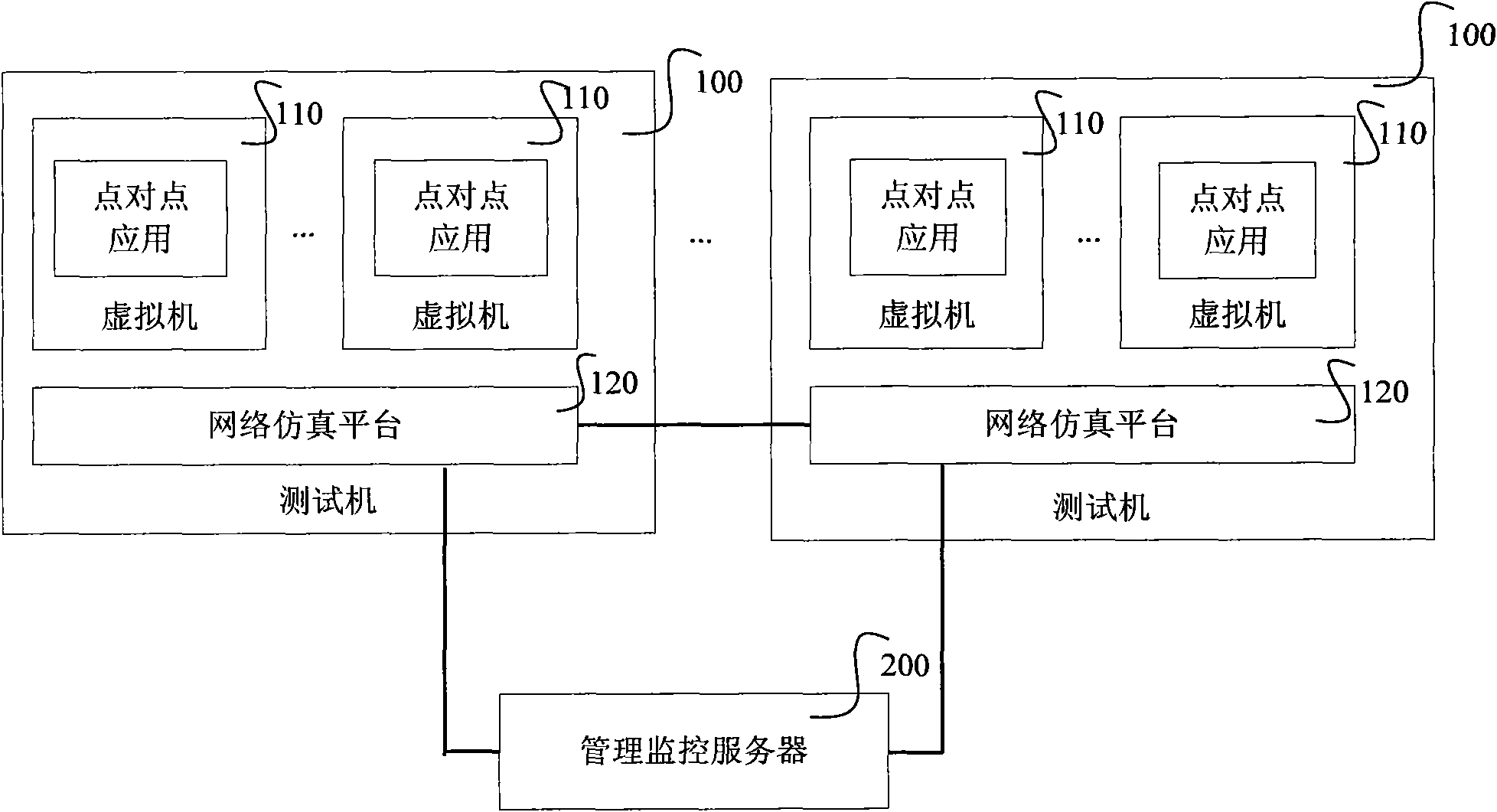

Point-to-point system network performance testing method and system thereof

InactiveCN102148716AGuaranteed authenticity and fairnessReduce costsData switching networksTraffic volumeNetwork on

The invention relates to a point-to-point system network performance testing method and a point-to-point system network performance testing system. The method comprises the following steps of: 1, running a virtual machine and a network simulation platform in a tester, and installing and configuring point-to-point application software in the virtual machine; 2, configuring the network topology of a point-to-point system network on a management monitoring server; 3, running the point-to-point application software in the virtual machine, and detecting the input / output traffic of point-to-point application of the virtual machine run on the same tester as the network simulation platform and reporting the input / output traffic to the management monitoring server by using the network simulation platform; and 4, receiving the input / output traffic reported by the network simulation platform, and calculating a network performance testing result according to the input / output traffic and the network topology by using the management monitoring server. By the method and the system, difficulties in test opening can be reduced, and the testing efficiency can be improved.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

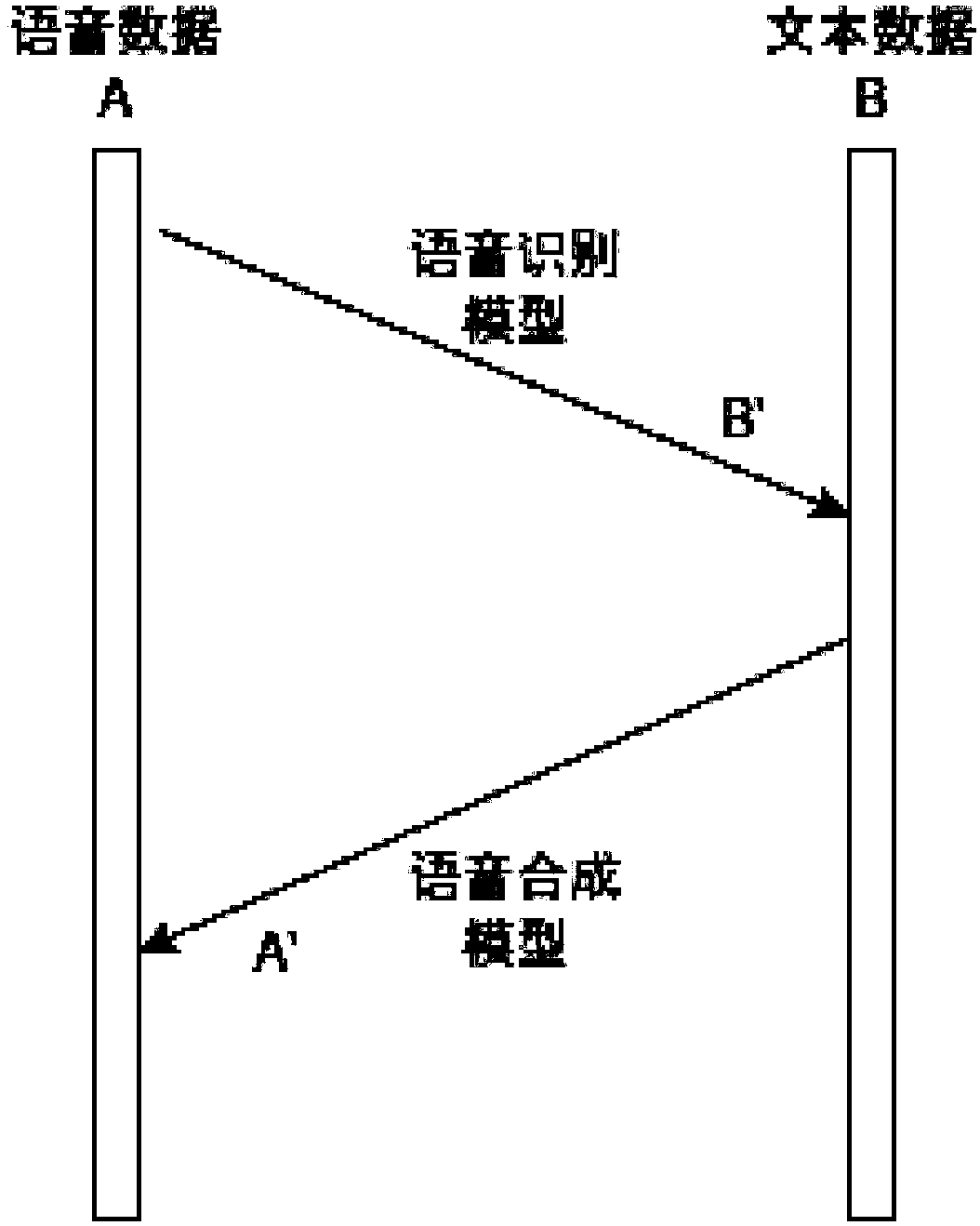

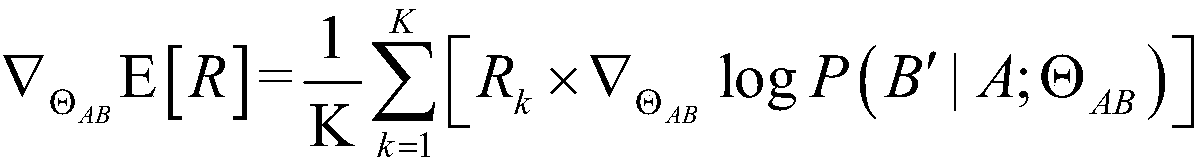

Voice recognition and voice synthesis model training method based on dual learning

InactiveCN108133705ASolve the small amount of dataReduce costsSpeech recognitionSpeech synthesisSpeech identificationVoice data

The invention provides a voice recognition and voice synthesis model training method based on dual learning. The method comprises the following steps that firstly voice recognition acts as the "main task" and voice synthesis acts as the "dual task"; the voice data A are converted into a text B' by using a voice recognition model to be trained; the confidence coefficient that the text obtained by conversion of the voice data A is written by humans rather than by machines is calculated by using a text language model obtained by pre-training; the text B' obtained by conversion of the voice data Ais converted back to the voice data A' by using a voice synthesis model to be trained; the "reconstruction similarity" between the voice data A' and the original voice data A is calculated by using avoice language model obtained by pre-training; and the final "reward" is calculated, and the parameters of the voice recognition model to be trained and the voice synthesis model to be trained are updated by using the REINFORCE algorithm of the reinforcement learning technology. A lot of cost overhead caused by data collection can be saved.

Owner:RUN TECH CO LTD

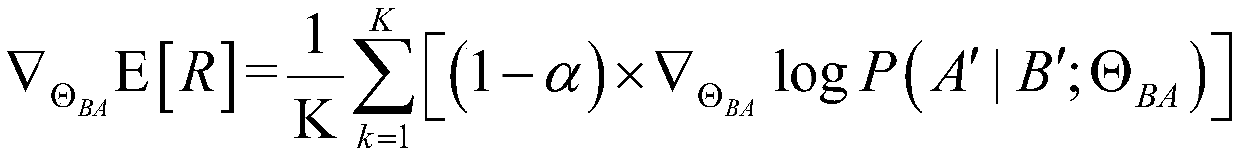

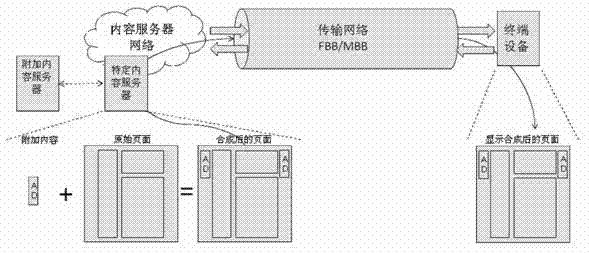

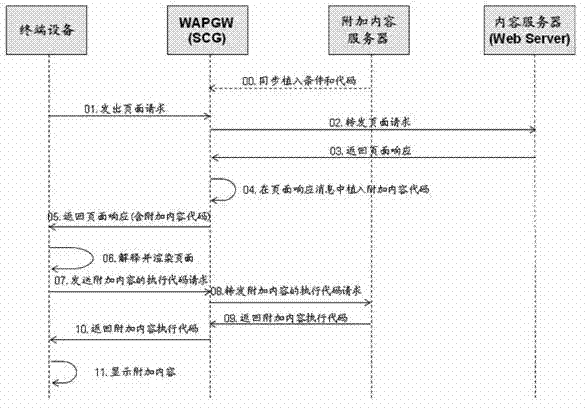

Method, device and system for embedding additional information

The invention discloses a method, a device and a system for embedding additional information. The method for embedding additional information comprises the following steps: an internet gateway device forwards user page requesting information sent by a terminal device to a page content server of the cloud; the internet gateway device embeds additional information in the original page information returned by the page content server according to the user page requesting information; the internet gateway device sends the page information embedded with the additional information to the terminal device so that the terminal device can display additional content corresponding to the embedded additional information on the page corresponding to the original page information according to the page information. According to the method, the difficulty in wide-range embedding of additional information of a page is effectively reduced, and the additional information embedding mode with low resource consumption and low time and cost is realized.

Owner:HUAWEI TECH CO LTD

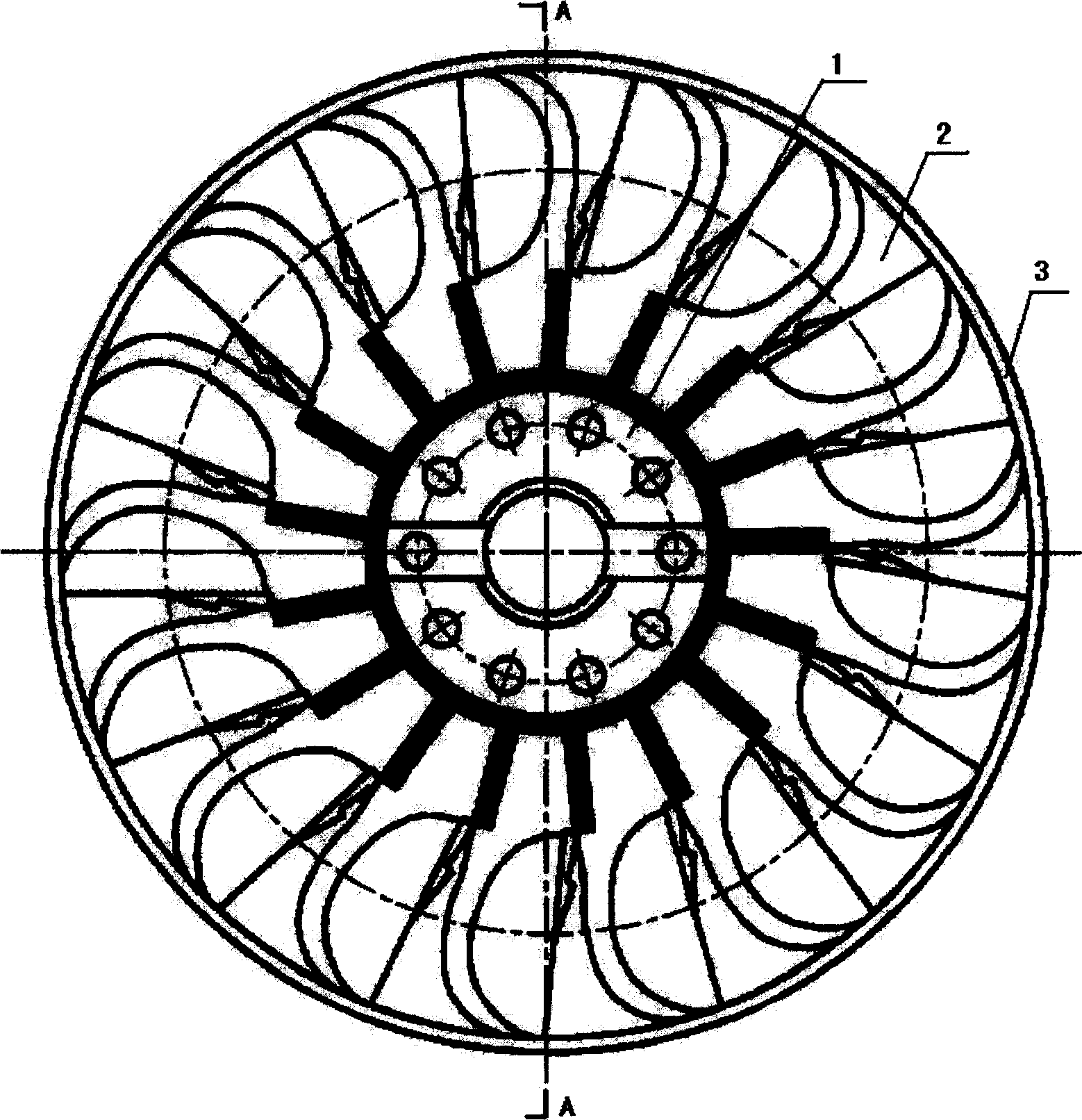

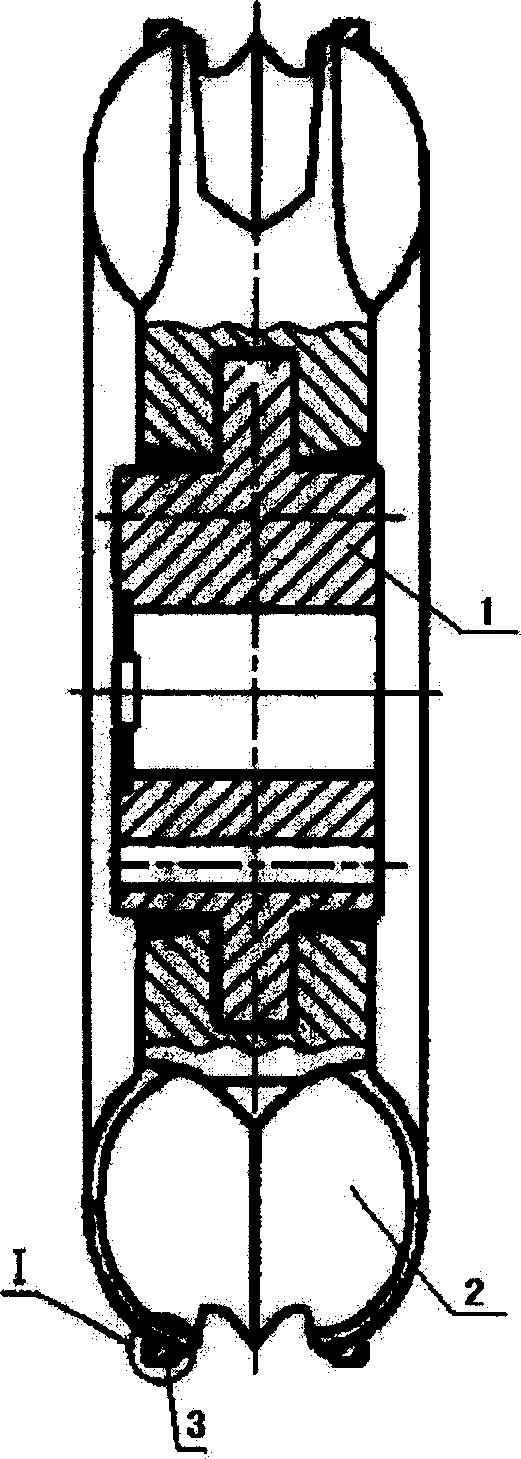

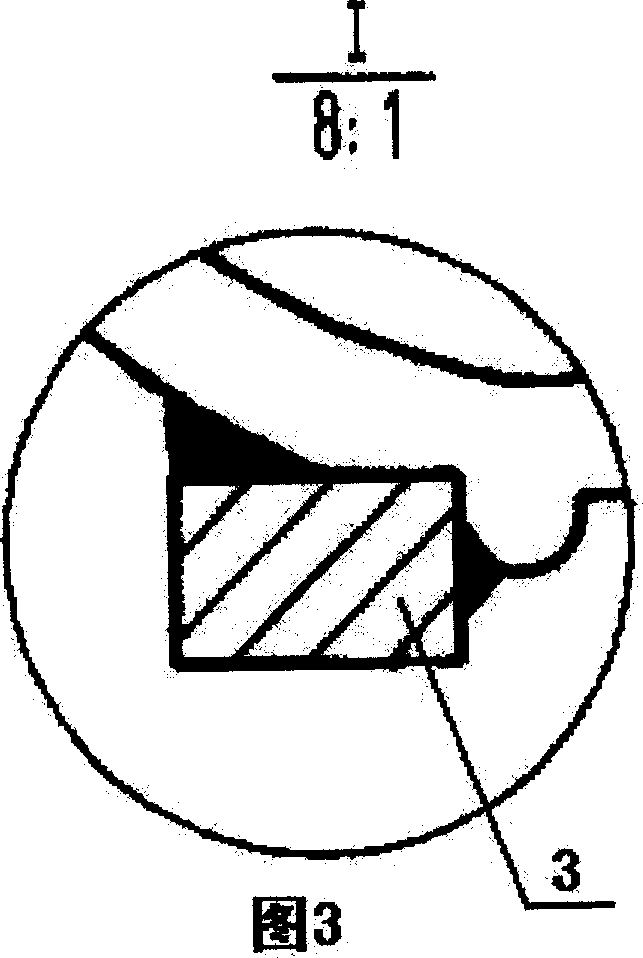

Impact type waterturbine wheel

InactiveCN1715640AReduce costsLow costFinal product manufactureHydro energy generationEngineeringStress concentration

The impact type water turbine wheel features that the wheel has at least one outer hoop to connect all the buckets successively and the circular hoop is set in the maximum position. The present invention has the advantage of changing the stress state of the buckets to avoid concentrated stress in the roots of the buckets leading to fatigue, crack and breaking while maintaining the basic structure and the production process of traditional impact turning wheel.

Owner:柳州市久源水轮机有限责任公司

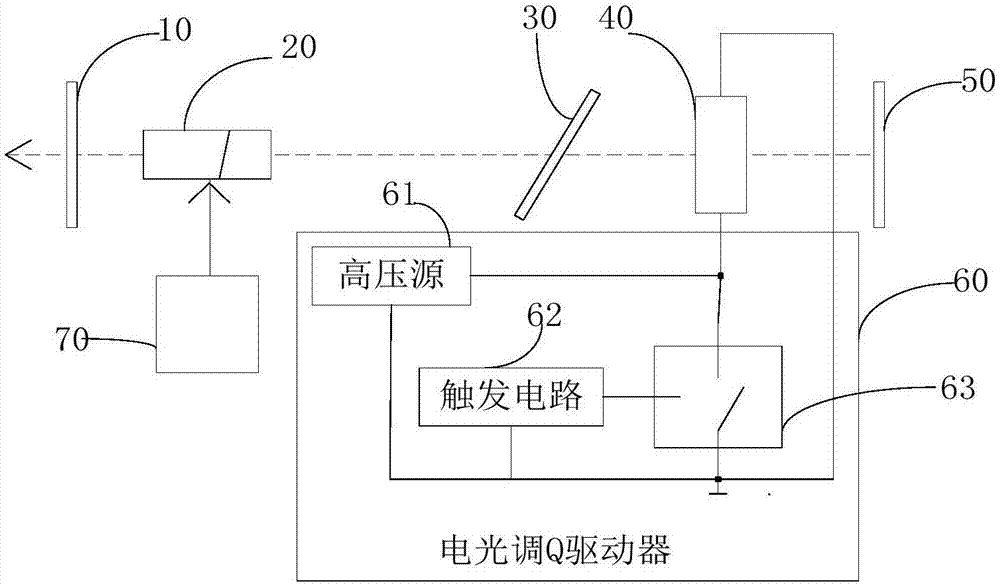

Electro-optic Q-switched solid laser

The invention relates to an electro-optic Q-switched solid laser. The electro-optic Q-switched solid laser comprises a laser resonant cavity formed by an output mirror, a laser medium and a total reflective mirror, wherein a polaroid and an electro-optic Q-switched crystal are arranged between the laser medium and the total reflective mirror sequentially, and the electro-optic Q-switched crystal is connected with an electro-optic Q-switched driver; the electro-optic Q-switched driver comprises a high-voltage source, a trigger circuit and a switch; the switch comprises a first end for being connected with one end of the electro-optic Q-switched crystal, a second end for being connected with the other end of the electro-optic Q-switched crystal and the ground and a third end for controllingon and off of the first end and the second end. According to the electro-optic Q-switched solid laser, two kinds of driving, namely, decompression or pressurization, can be realized, the output pulsewidth of laser pulses is accurate and controllable, and the output pulse width of the laser can be reduced.

Owner:成都心无界光电技术有限公司

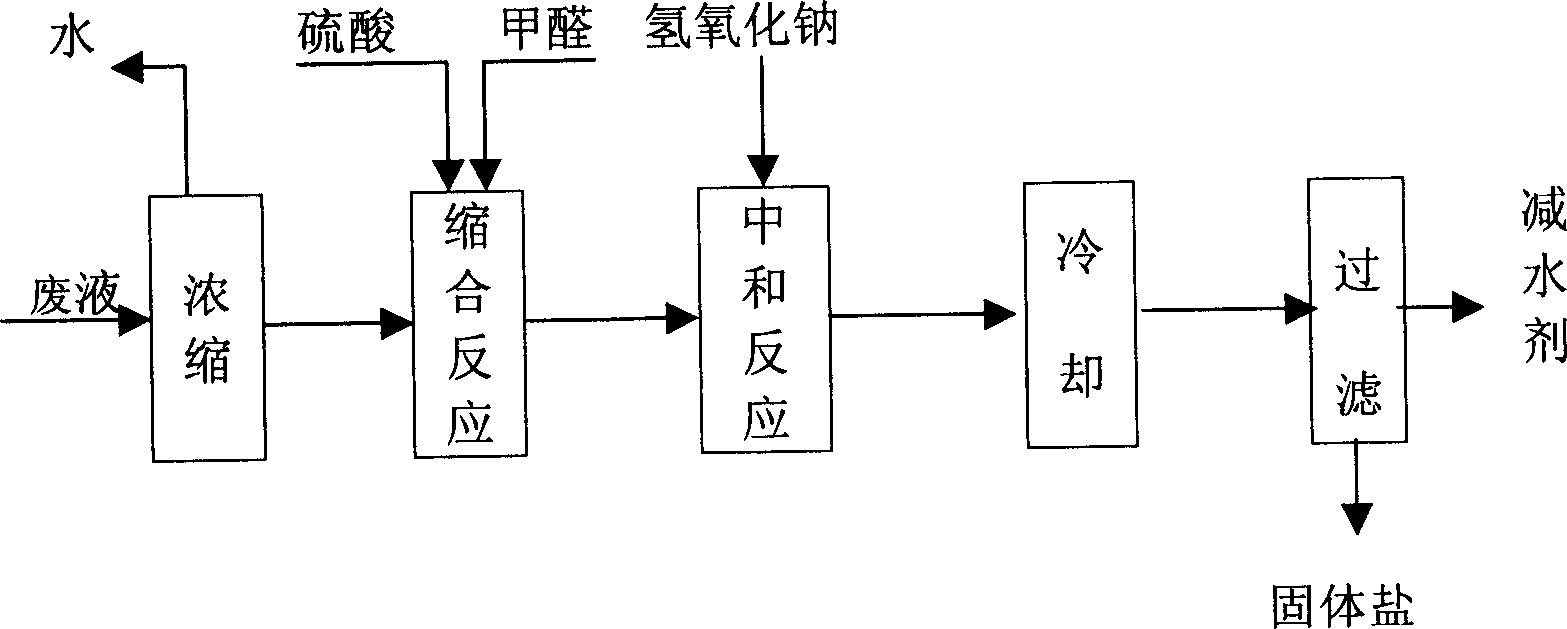

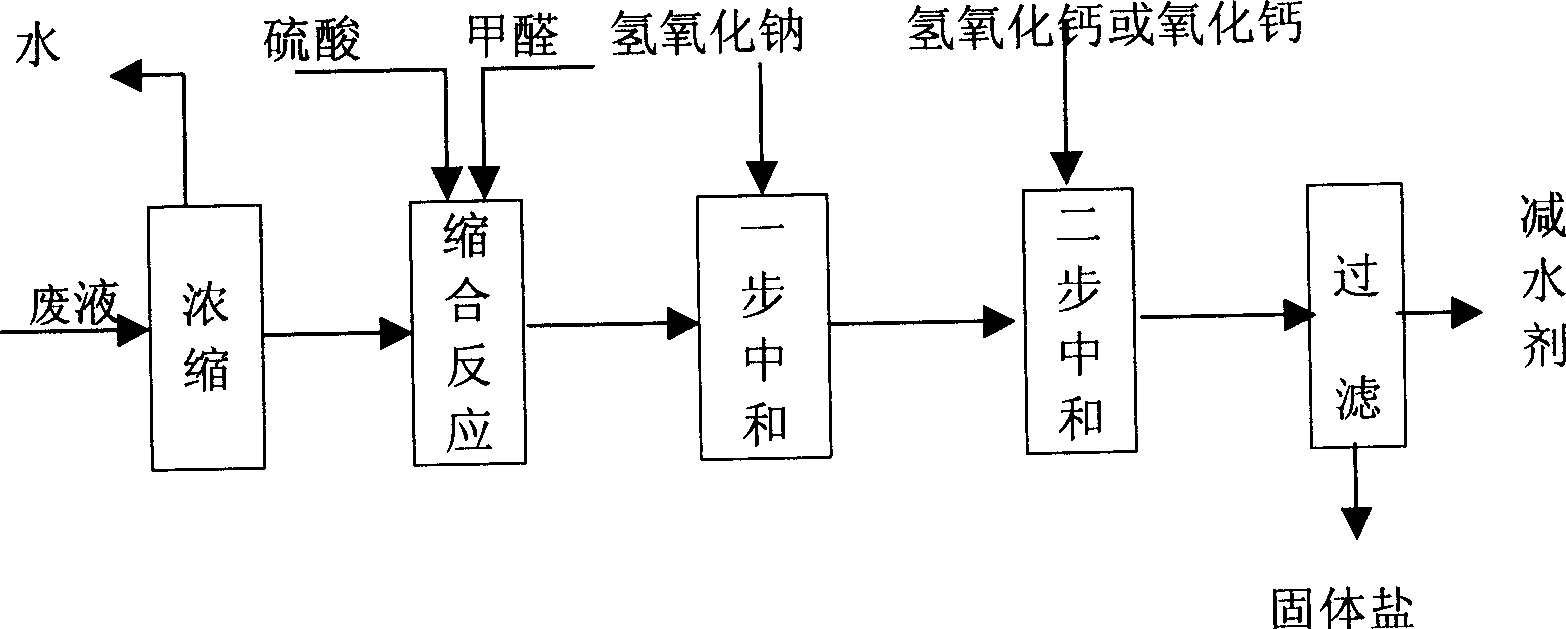

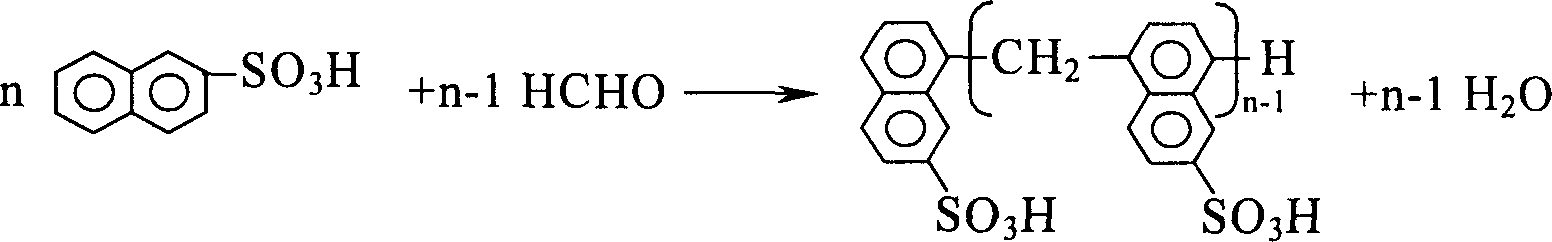

Method for reusing contaminant separated from naphthalenesulfonic acid neutralization wash waste liquor

ActiveCN1594133AEliminate secondary pollutionReduce costsWater/sewage treatment by neutralisationWater/sewage treatment by substance additionChemistryNaphthalene

Disclosed is a method for reusing contaminant separated from naphthalenesulfonic acid neutralization wash waste liquor which consists of, concentrating the isolated polluted material into waste water concentration liquid with the solid material content being 40-70%, charging sulphuric acid into the waste water concentration liquid, adjusting the total acidify to be 24%-32%, charging methylene oxide into the waste water concentration liquid for condensation reaction, charging alkali for neutralization reaction, segregating the solid sulphate, thus obtaining the filter liquor, i.e. naphthalene family water reducing agent.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

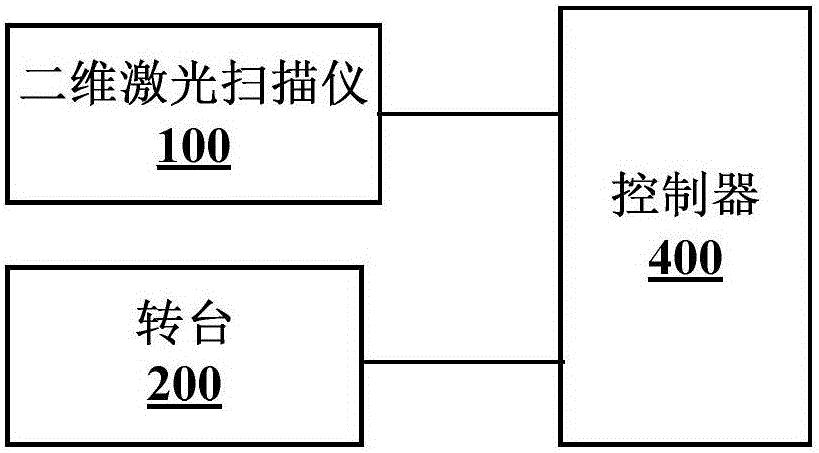

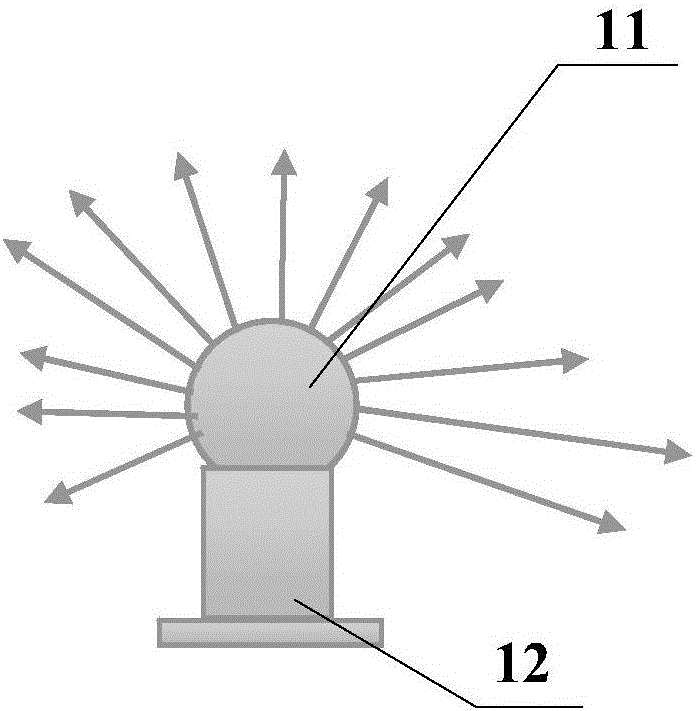

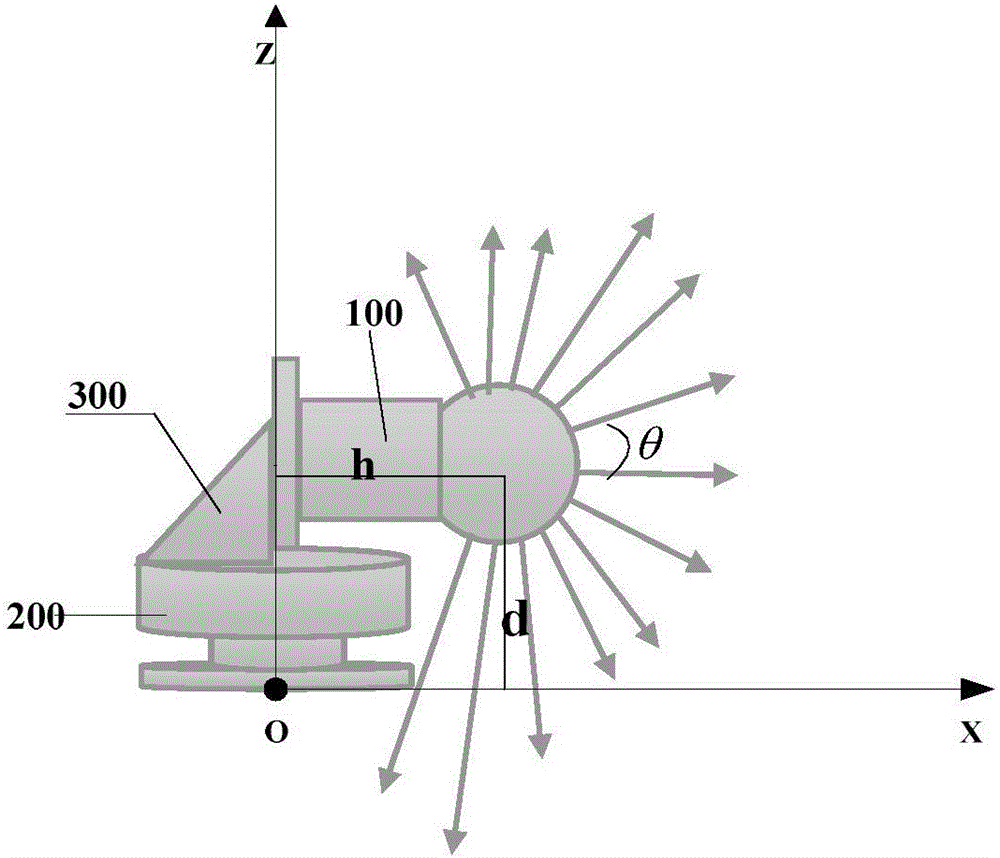

Three-dimensional laser scanning device and method

The present invention belongs to the detection technical field and discloses a three-dimensional laser scanning device and method. The device comprises a two-dimensional laser scanner used for performing two-dimensional scanning on an object to be measured and providing scanning contour point cloud data of the object to be measured, a rotary table used for performing rotation operation and providing rotation angle data, a fixing structure used for fixing the two-dimensional laser scanner to the rotary table, and a controller which is used for controlling the operation of the two-dimensional laser scanner and the rotary table and receiving the scanning contour point cloud data and the rotation angle data, and is also used for obtaining three-dimensional point cloud coordinate data of the object to be measured according to the scanning contour point cloud data and the rotation angle data. With the three-dimensional laser scanning device and method of the invention adopted, longitudinal line scanning and left-right plane scanning can be carried out, so that a three-dimensional plane scanning function can be realized. Since the two-dimensional laser scanner is used, cost can be greatly reduced, and cost performance is high.

Owner:CHINA SHENHUA ENERGY CO LTD +1

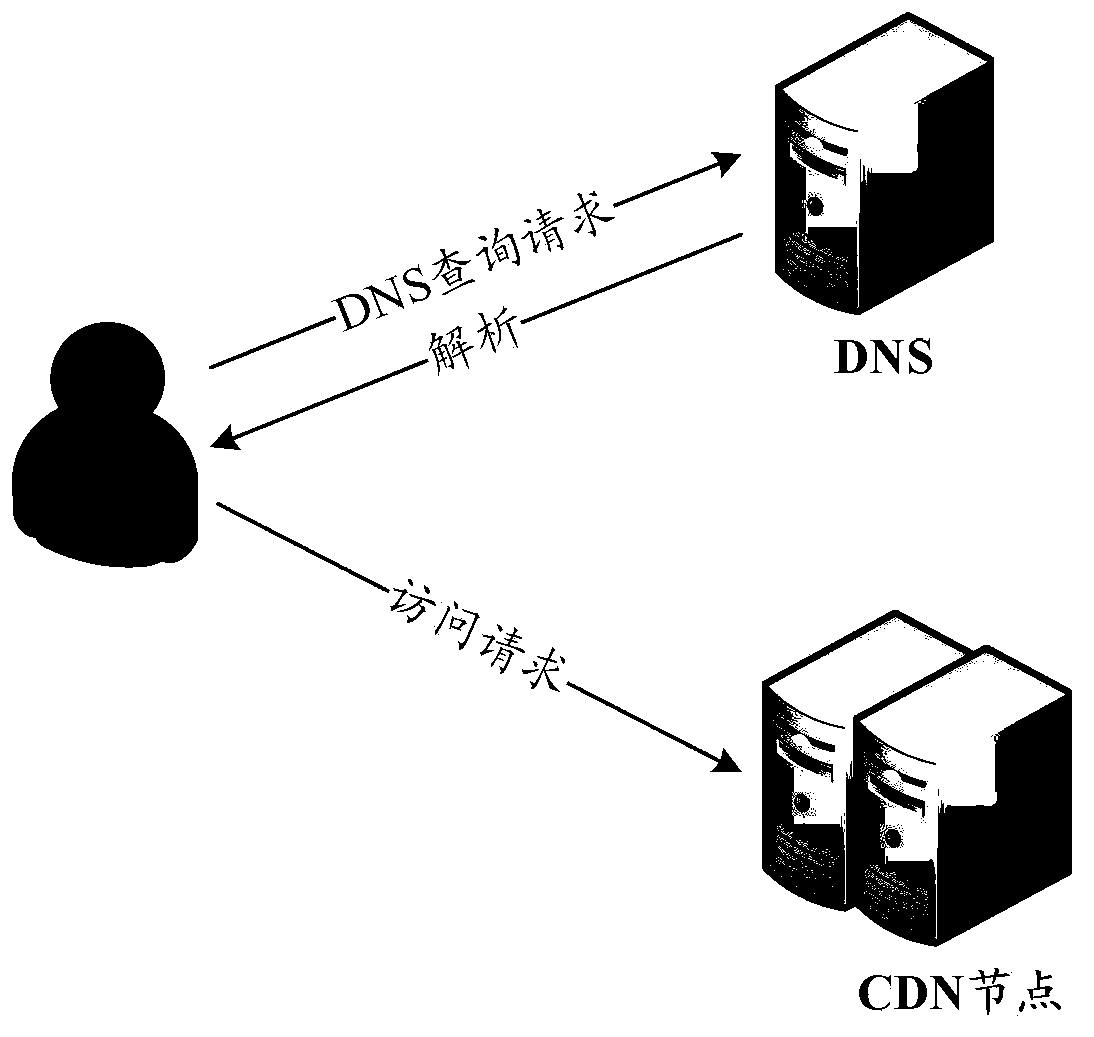

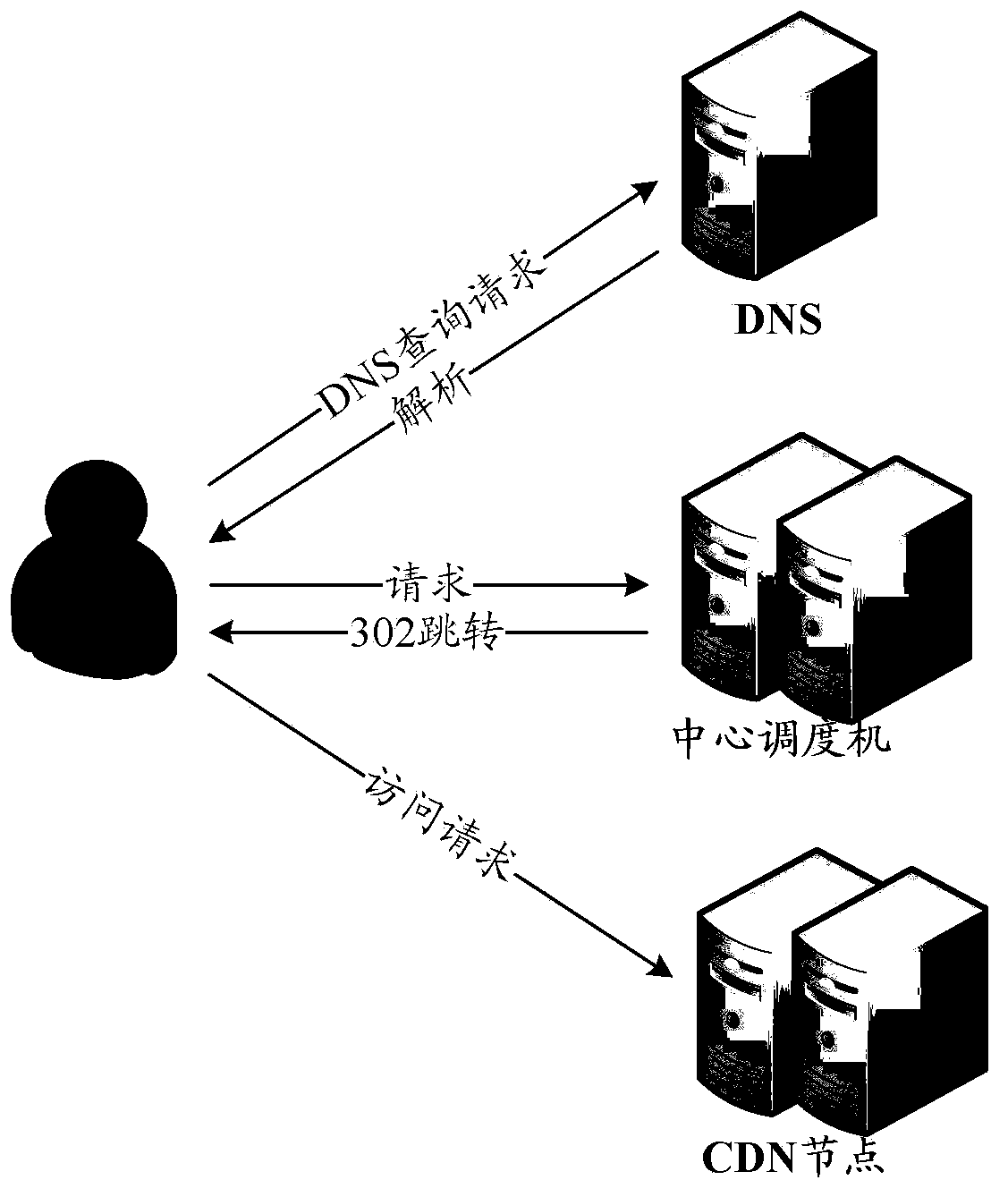

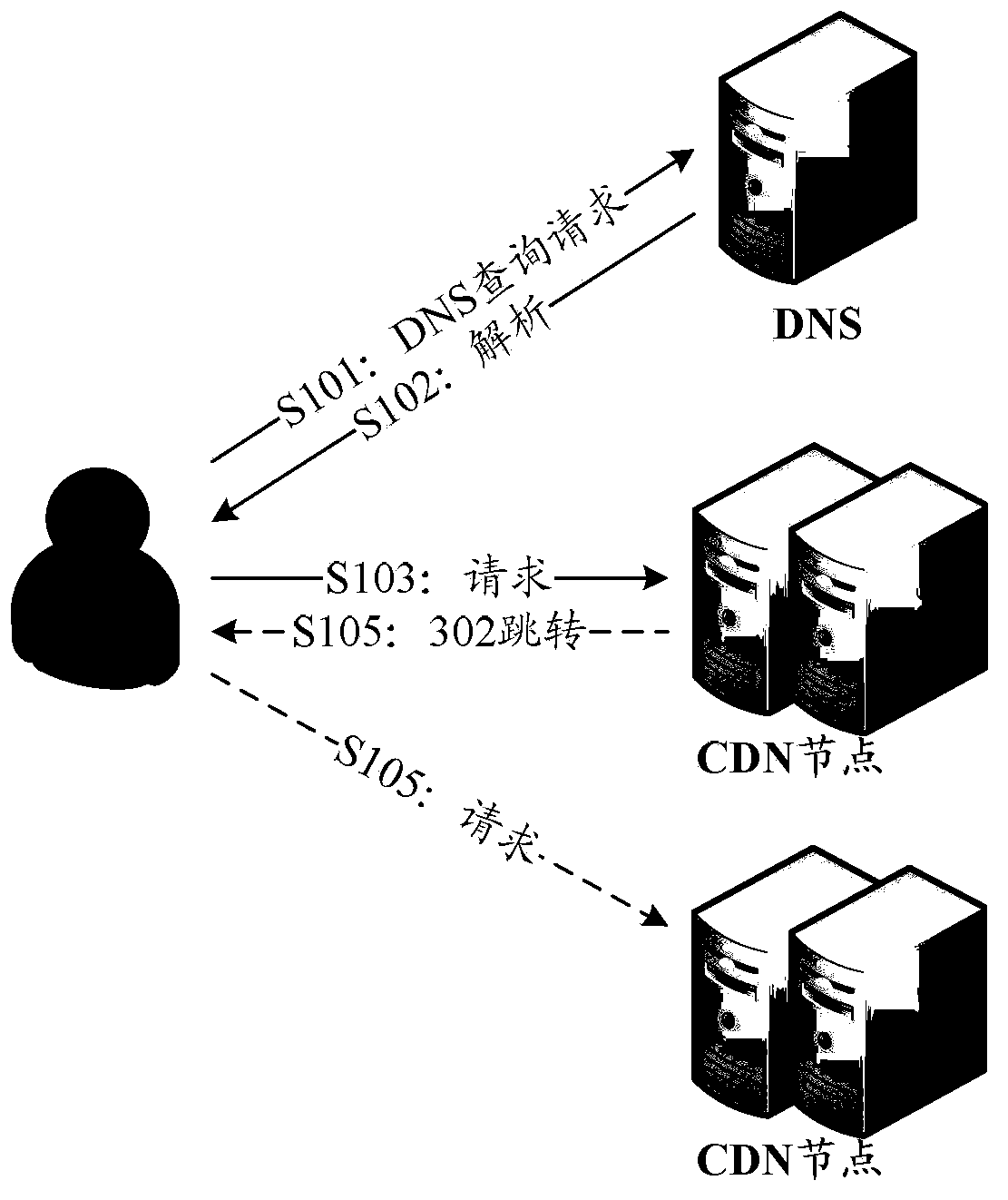

Large-scale cluster task scheduling method, large-scale cluster task scheduling system and CDN node

InactiveCN103491112AReduce costsImplement schedulingTransmissionContent delivery networkDistributed computing

The invention provides a large-scale cluster task scheduling method, a large-scale cluster task scheduling system and a CDN node. The method comprises the following steps: a client sends a (domain name system) DNS query request to a DNS; the DNS performs scheduling according to local DNS configuration of the client and returns specified content delivery network (CDN) node information to the client; the client is accessed to a specified CDN node according to the specified CDN node information; the specified CDN node judges whether the access request of the client belongs to the service of the node according to an address of the client; and the specified CDN node schedules the client to a CDN node to which the client belongs through temporary jumping according to the address of the client and a preset scheduling strategy if the access request of the client does not belong to the service of the node through judgment. According to the method provided by the embodiment of the invention, precise scheduling can be achieved, a judging step is added at the CDN node, no central scheduling machine needs to be added, and cost brought by a central scheduling machine can be saved.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

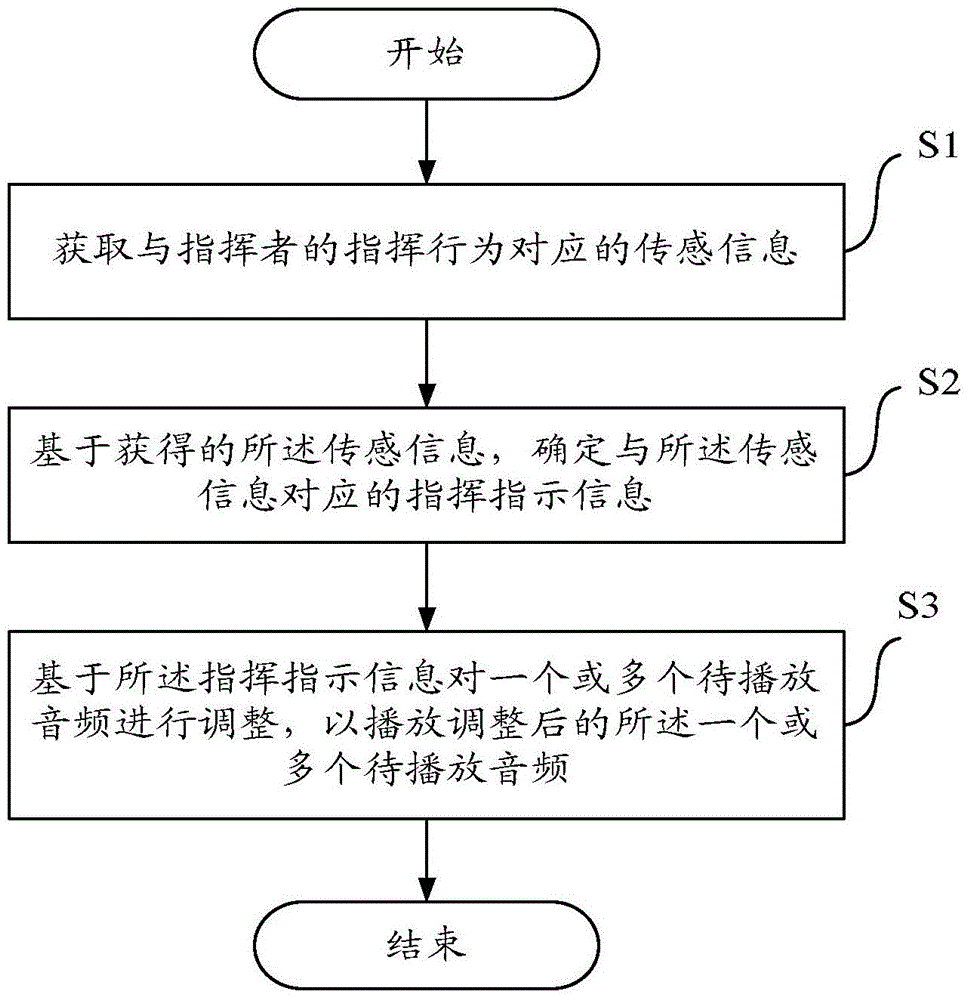

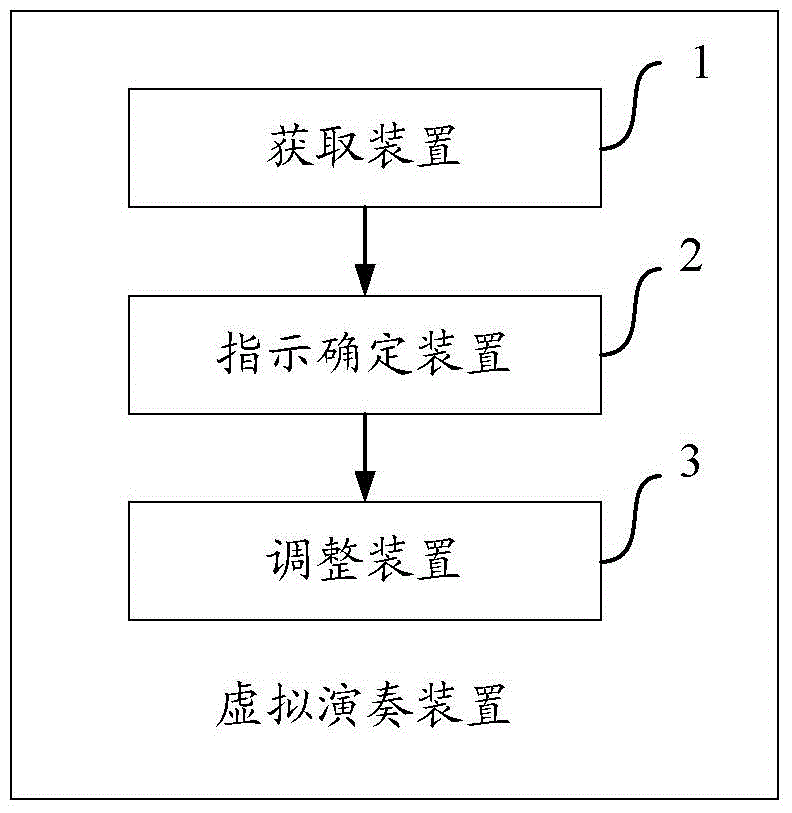

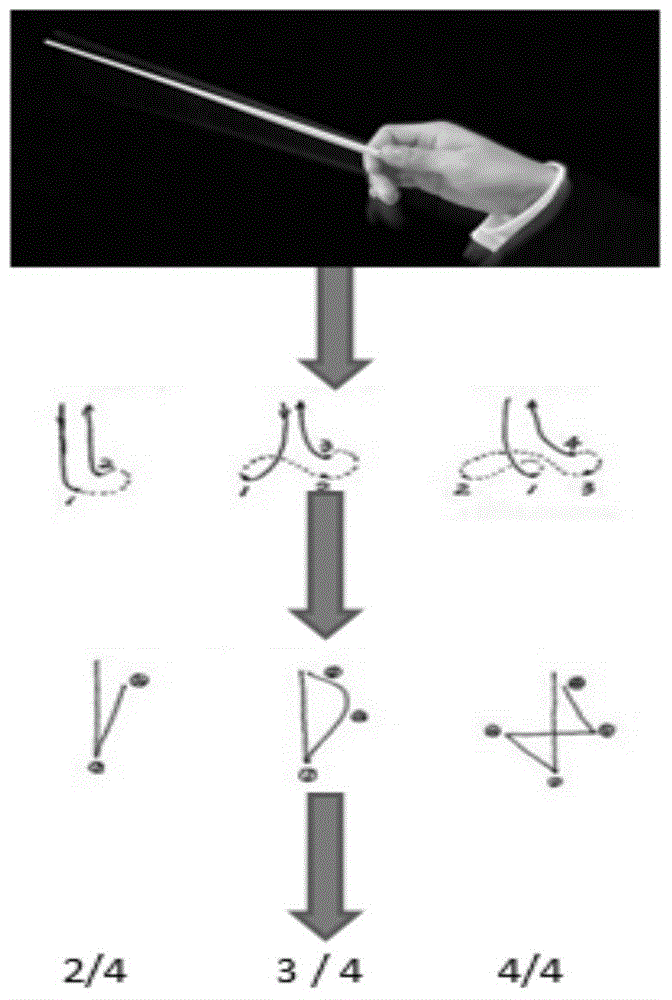

Method and device for virtual performance commanding

InactiveCN105786162AReduce costsCutting costsInput/output for user-computer interactionMusicComputer engineeringMultimedia

The invention aims to provide a method and device for virtual performance commanding. The method provided by the invention comprises the steps that sensing information corresponding to a commanding behavior of a commander is acquired; based on the acquired sensing information, commanding indication information corresponding to the sensing information is determined; and one or more than more to-be-played audios are adjusted based on the commanding indication information, and thus the one or more than one adjusted to-be-played audios can be played, wherein one to-be-played audio is played by one musical instrument.

Owner:ALCATEL LUCENT SHANGHAI BELL CO LTD

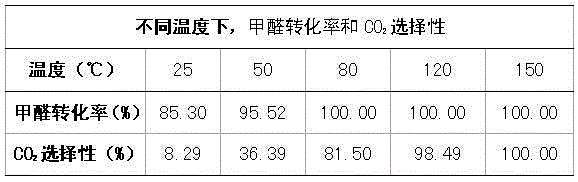

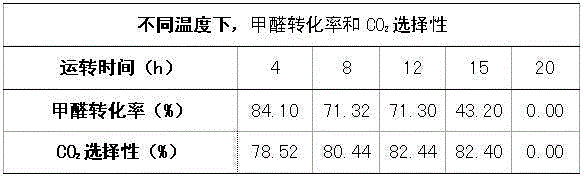

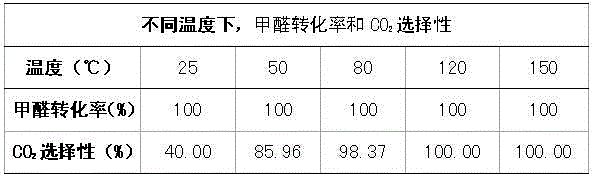

Catalyst for formaldehyde catalytic oxidation and preparation method of catalyst

InactiveCN104353465AReduce costsGood stability and CO2 selectivityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystChemical engineering

The invention discloses a catalyst for formaldehyde catalytic oxidation and preparation method of the catalyst. The catalyst for formaldehyde catalytic oxidation is of a nuclear and shell structure; a nuclear is Co3O4, and a shell is CeO2; the ratio of the nuclear to the shell is calculated according to the mole percent of Co and Ce metal atoms; Co is 95.55-97.60 percent, and Ce is 2.40-4.45 percent. According to the preparation method, Co3O4 catalyst particles are prepared by a parallel flow coprecipitation method, and the surfaces of the Co3O4 catalyst particles are loaded with a CeO2 shell layer. The catalyst for formaldehyde catalytic oxidation can be used for enabling the conversion rate of formaldehyde to be 100 percent under room temperature of 25 DEG C; meanwhile, the catalyst is extremely high in catalysis and CO2 selectivity.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

High-heat conductivity coefficient water-based nanofluid and preparation method thereof

The invention discloses high-heat conductivity coefficient water-based nanofluid and a preparation method thereof. The high-heat conductivity coefficient water-based nanofluid is prepared from the following raw materials in percentage by weight: 0.05-0.15 percent of nanoparticles, 99.73-99.90 percent of distilled water and 0.05-0.12 percent of dispersing agent. The water-based nanofluid stable in suspension prepared by adopting a two-step method is simple in process and low in cost, the nanoparticles in the nanofluid are small in particle size, low in content and narrow in distribution range, the collision frequency among the nanoparticles is low, the dispersing stability is high and can be stably maintained for 30-60 days, compared with that of a water medium, the heat conductivity coefficient of the nanofluid is increased by 10.1-15.8 percent, the nanofluid is widely applied to the fields of aerospace, electronics, medical treatment, chemical industry, buildings and foods, high-efficiency low-resistance compaction and other performance indexes of heat exchange equipment can be greatly improved, and the volume of the heat exchange equipment is reduced.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

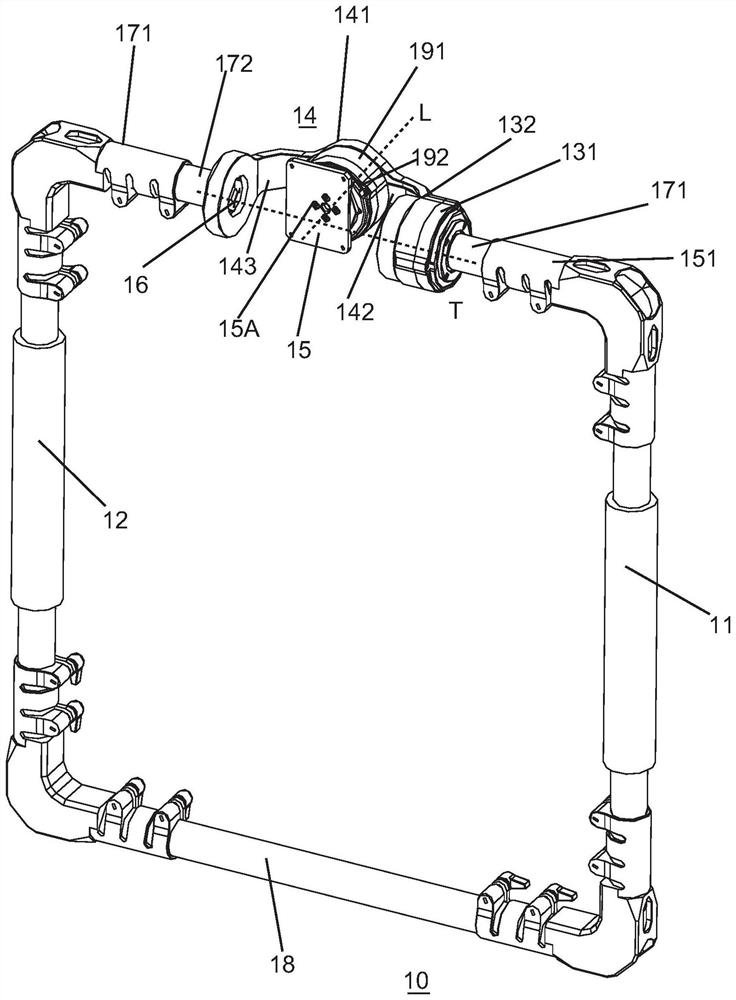

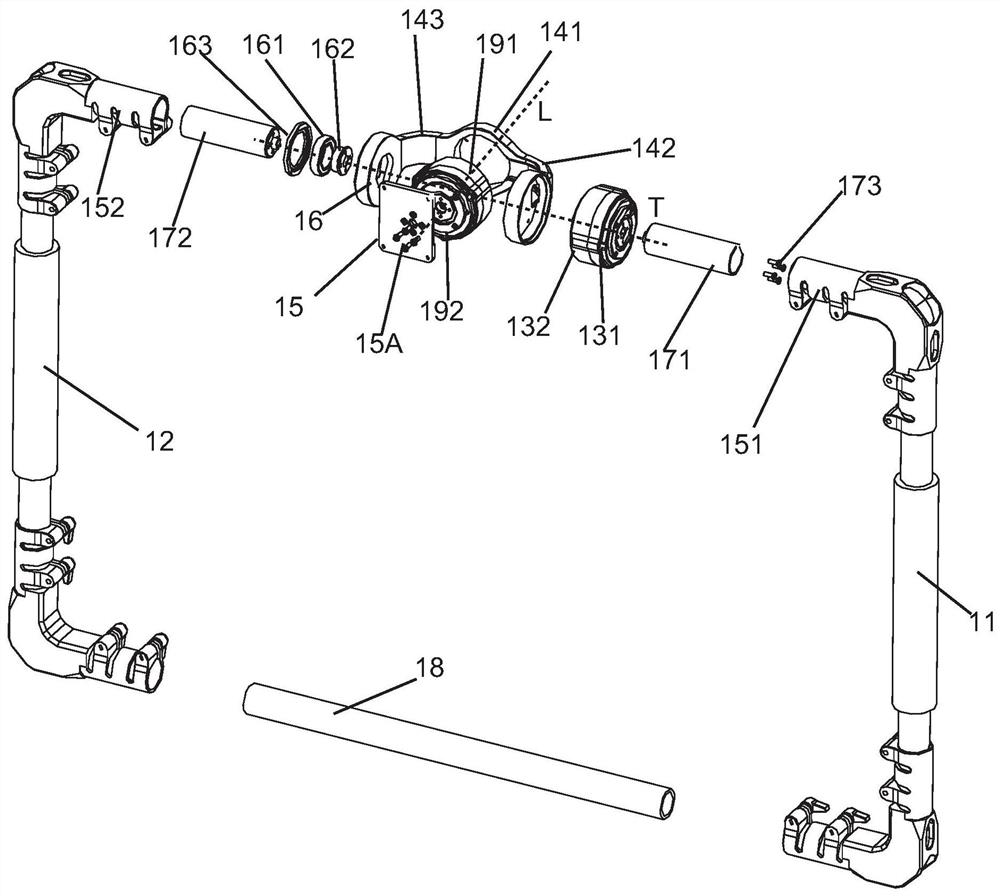

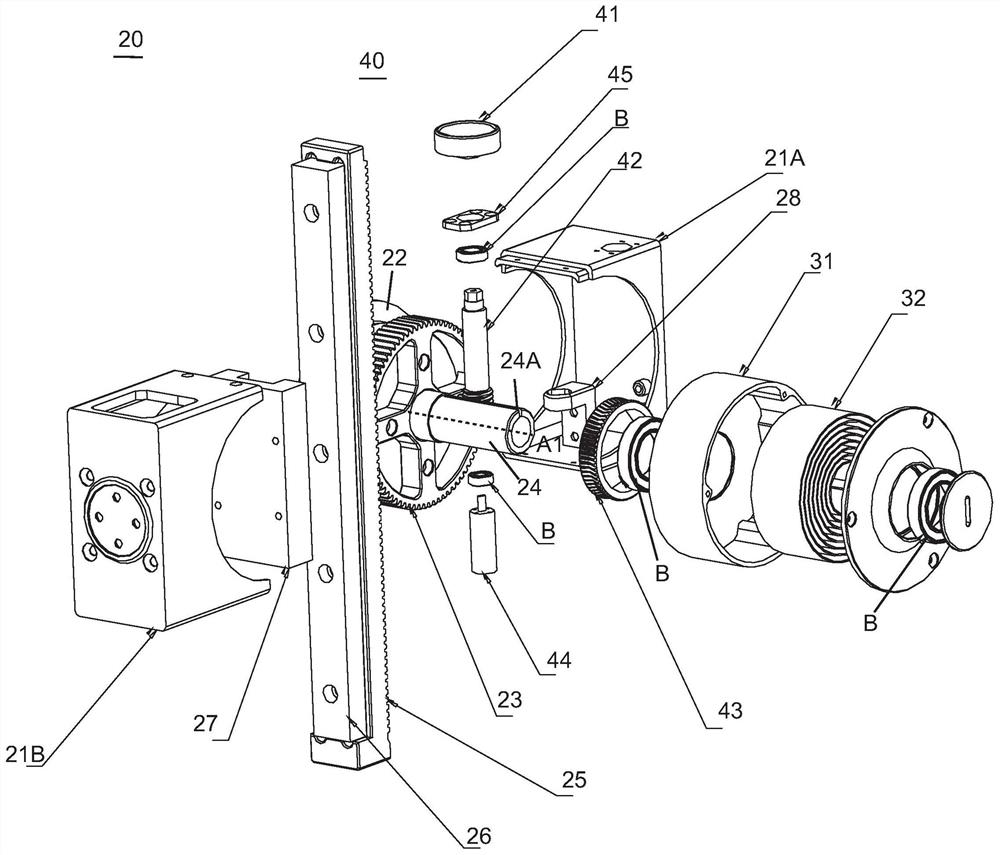

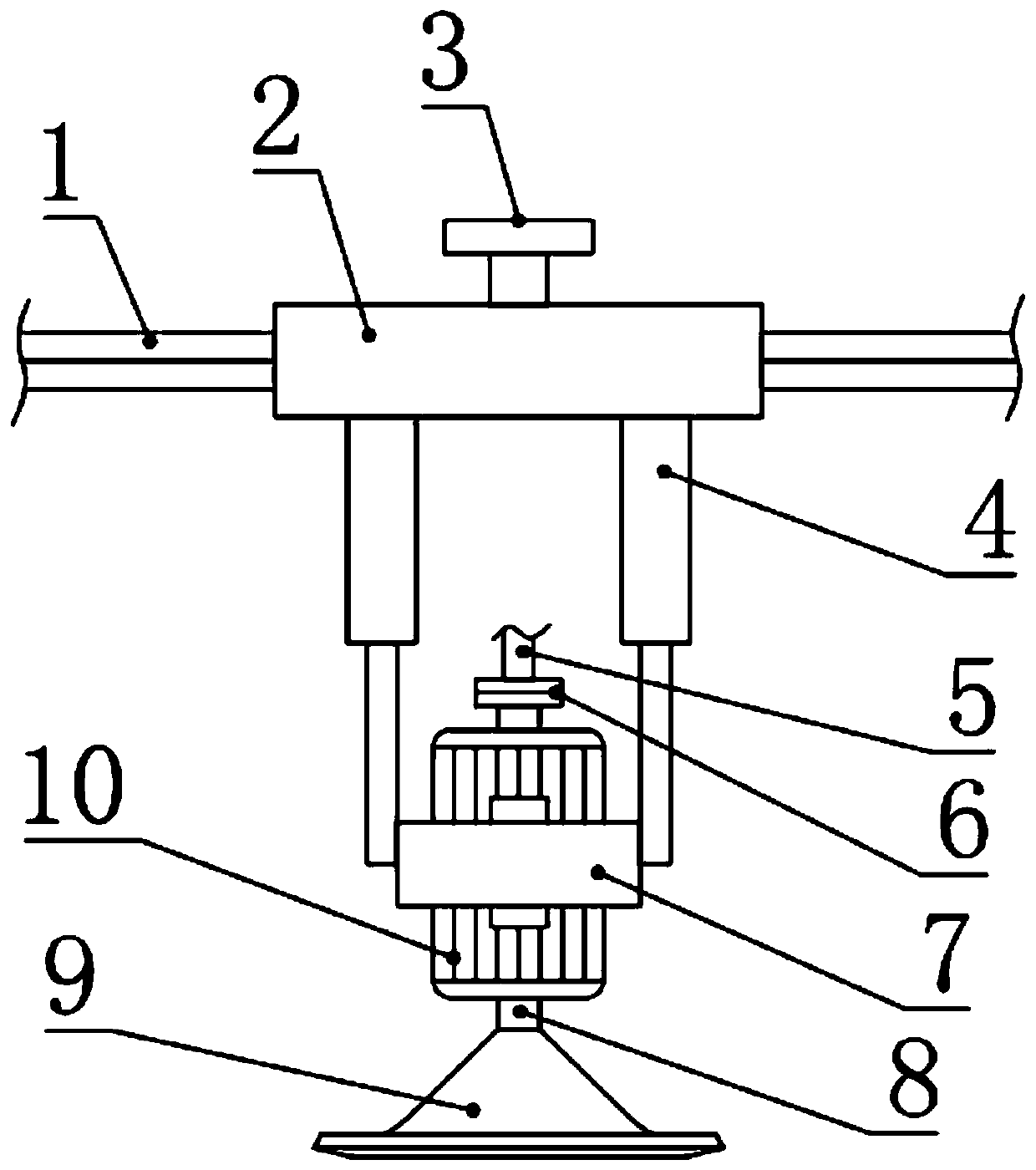

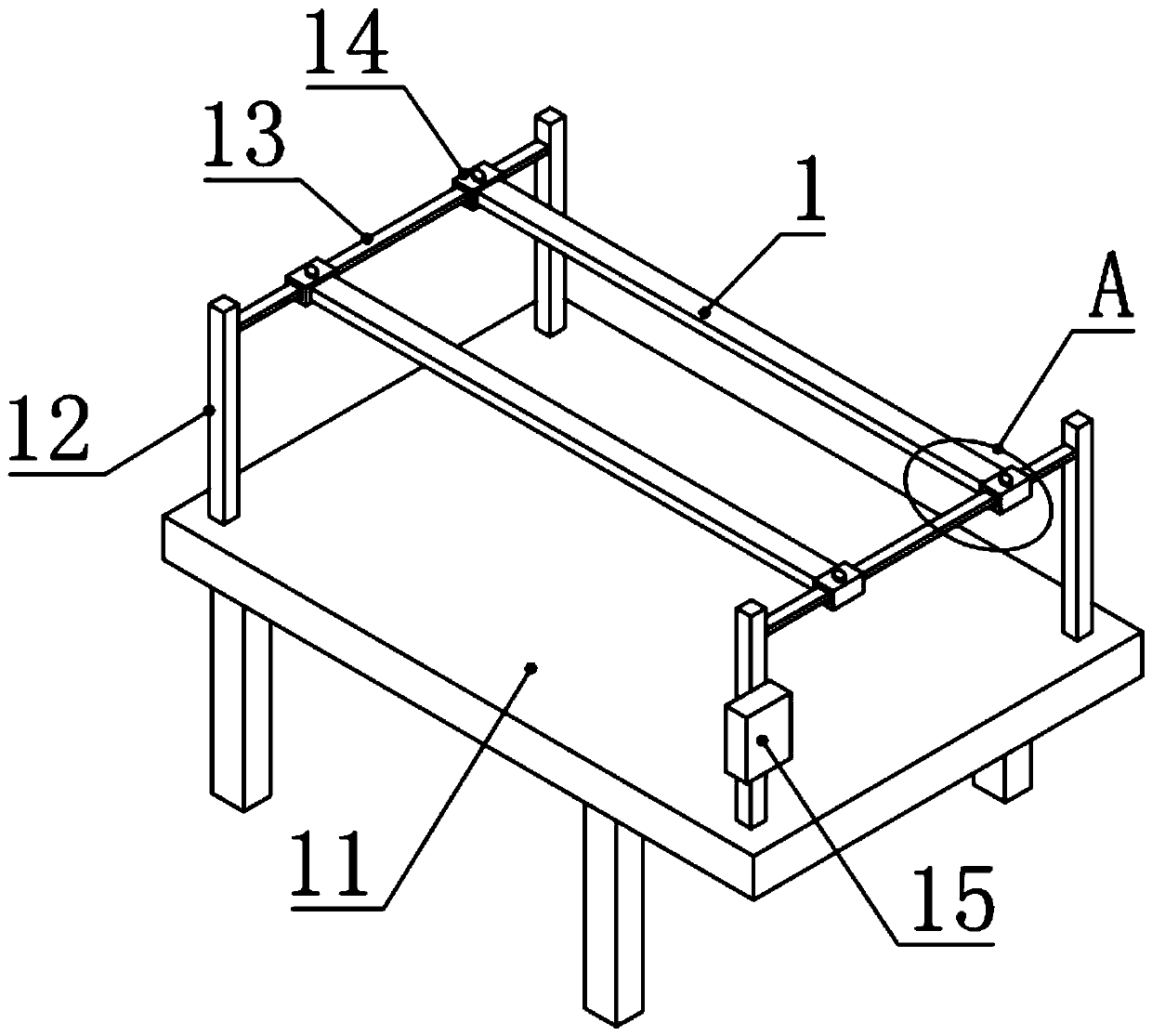

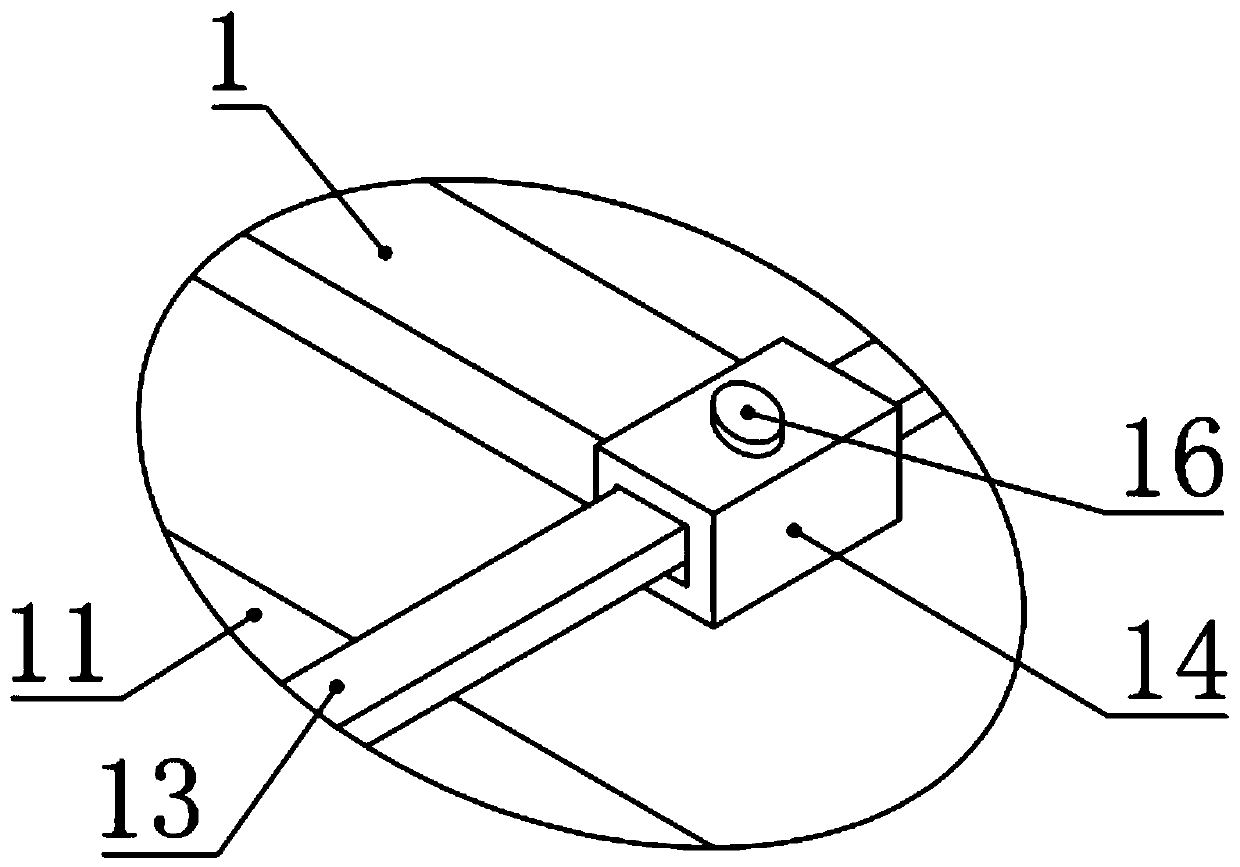

Handheld photographic equipment

ActiveCN112145881AEliminate vertical vibrationReduce costsStands/trestlesControl using feedbackElectric machineryClassical mechanics

The invention provides handheld photographic equipment. The handheld photographic equipment allows auxiliary shooting on load and comprises a handheld rack with a pitching stability augmentation motorand / or a rolling stability augmentation motor, a vertical stability augmentation device and a control device, and the controller is configured to control a longitudinal stability augmentation motor and / or a transverse stability augmentation motor to act to stabilize the vertical stability augmentation device and the load into a vertical attitude based on attitude information from an attitude sensor and control a vertical stability augmentation motor to act to always keep the load at a determined vertical height during stability augmentation so as to allow the load can be maintained at the determined vertical height regardless of user motions. By means of the handheld photographic equipment, a stability augmentation effect comparable to that of an electric sliding rail is allowed to be achieved by the portable handheld photographic equipment.

Owner:GUILIN ZHISHEN INFORMATION TECH CO LTD

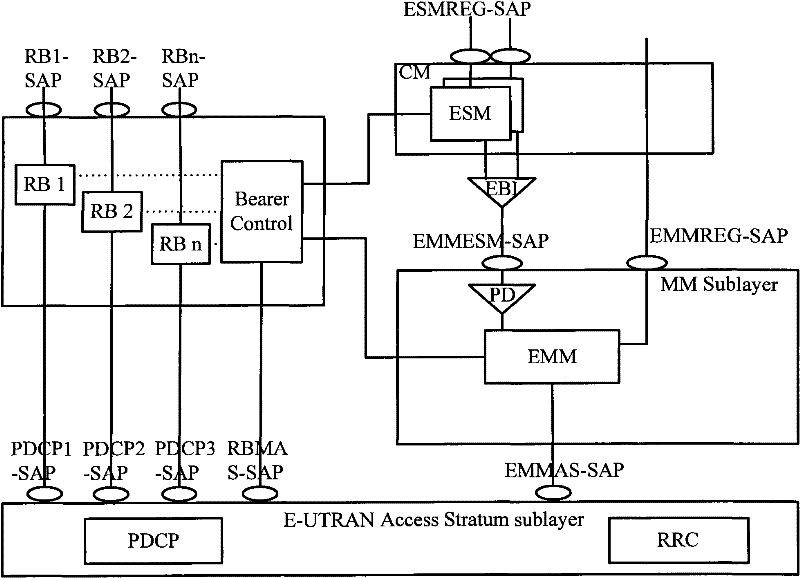

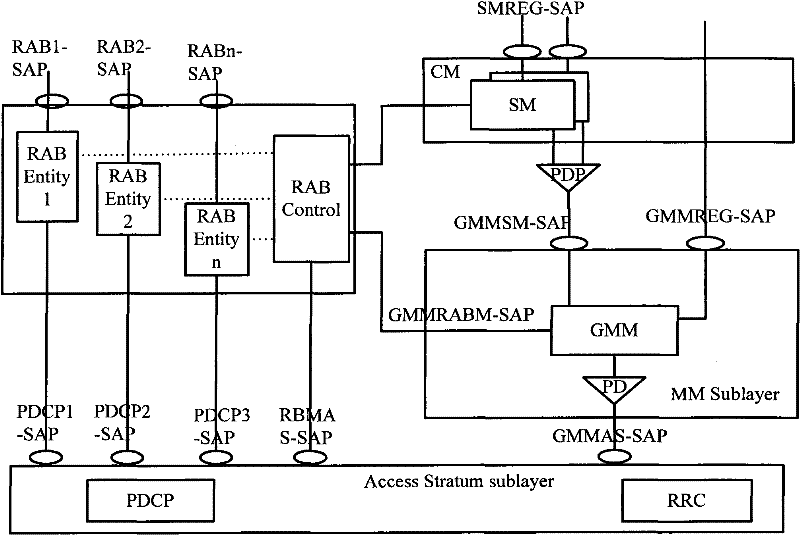

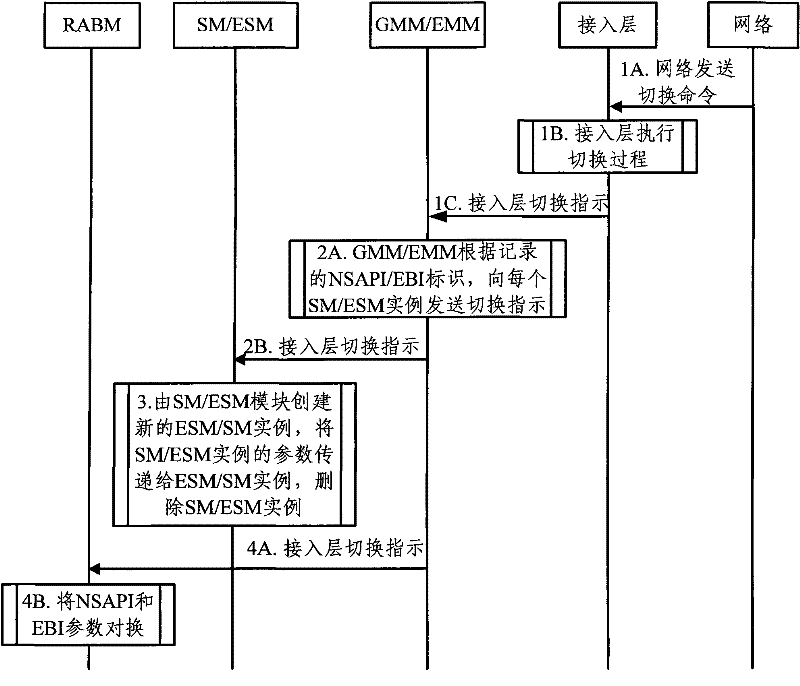

Method for switching non-access stratum of multi-mode terminal

ActiveCN102202367AReduce costsLow costWireless communicationAccess stratumProtocol for Carrying Authentication for Network Access

The invention provides a method for switching a non-access stratum of a multi-mode terminal, comprising the following steps of: in the process of switching the non-access stratum, by utilizing the characteristic of a mobile management module stored with packet data protocol context (PDP Context) / default enhanced packet service bearer context (EPS Bearer Context) identifications, after the mobile management module receives switch instruction of an access stratum, respectively informing different session management (SM) / ESM (Enhanced Session Management) examples corresponding to a PDP Context and an EPS Bearer Context according to a network service access point identification (NSA PI) / special EPS Bearer identification (EBI); and establishing ESM / SM examples by respective SM / ESM examples so that non-access switch operation of different systems is completed. Based on the traditional network architecture, the invention further provides an achievable method for switching the non-access stratum of the multi-mode terminal. The overhead cost is saved.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

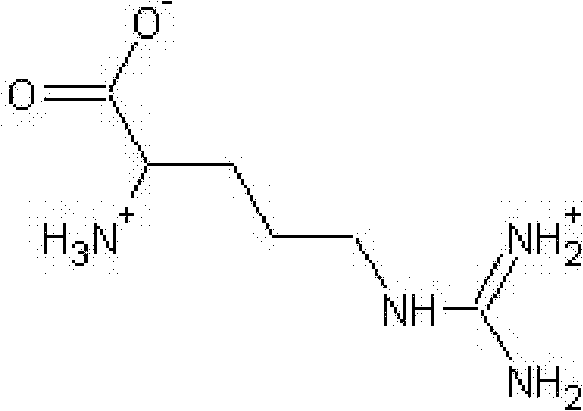

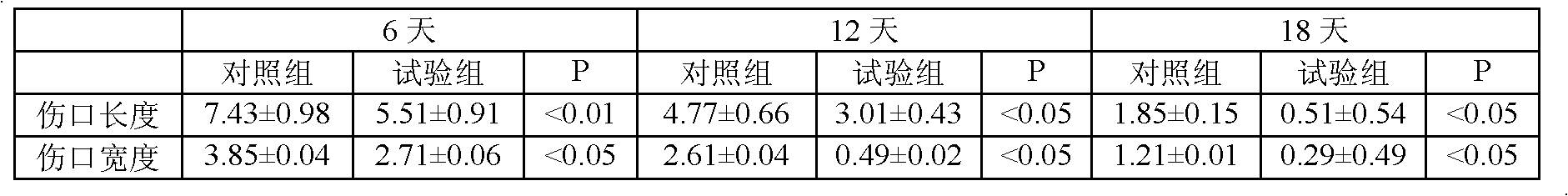

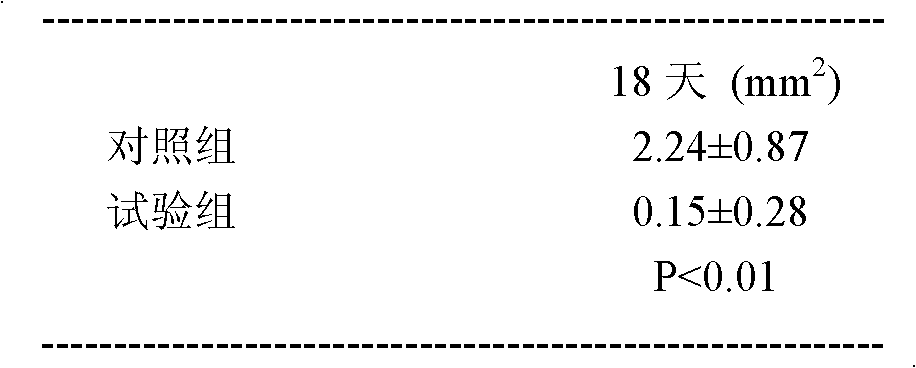

New application of arginine

InactiveCN102600123AReduce costsReduce metabolic burdenOrganic active ingredientsDermatological disorderDrugWound scar

The invention discloses new application of arginine, which is the application of arginine or a pharmaceutically acceptable salt, an ester or a mixture of the salt and the ester in preparing topical pharmaceutic preparations with at least one of the following effects: (1) treating and / or facilitating wound healing, and (2) reducing scar formation. Results in pharmacodynamics experiments show that the external use of L-arginine can remarkably facilitate trauma healing of rat skin as well as reduce the area of a wound scar. Arginine not only can be used for treatment and healing of traumas but also can be used for other skin diseases, including a pressure ulcer (bedsore), skin injuries caused by dermatitis, scald, burn and the like.

Owner:智刚

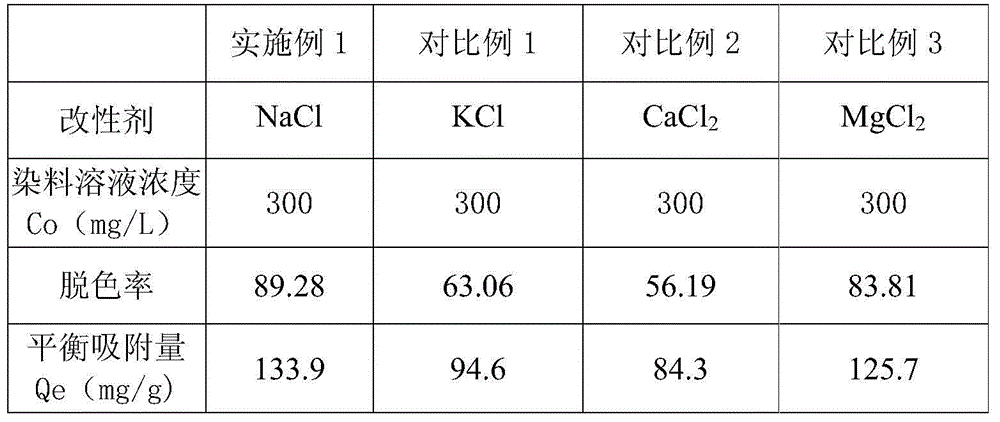

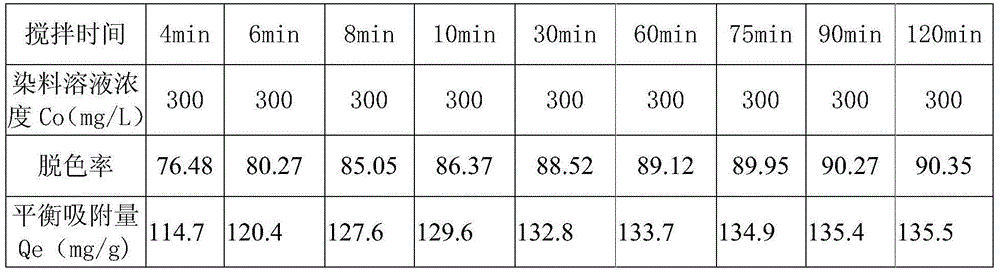

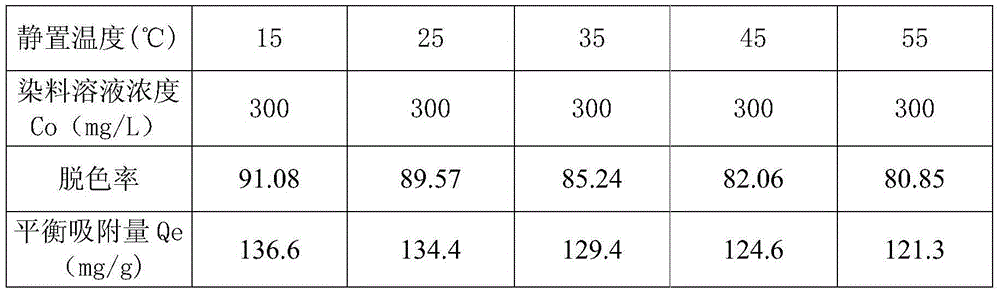

Modified slag adsorbent for anion dye wastewater treatment, and preparation method thereof

InactiveCN104826577AImprove adsorption efficiencyReduce costsOther chemical processesWater contaminantsChemistrySorbent

The present invention belongs to the technical field of environmental materials, and discloses a modified slag adsorbent for anion dye wastewater treatment, and a preparation method thereof. The preparation method comprises: washing, drying, crushing and screening slag; preparing a sodium chloride solution, and mixing the sodium chloride solution and hydrochloric acid to obtain a mixed solution; and slowly adding the mixed solution to the slag, carrying out a stirring reaction, standing, drying, and grinding to obtain the modified slag adsorbent. According to the present invention, the preparation method has characteristics of simpleness, rich raw material source, low price, and waste recycling; after the modification, the micro-pores of the slag are increased, the specific surface area is increased, and the adsorption capacity of the adsorbent is further enhanced; and the adsorbent of the present invention has the good anion dye wastewater treatment effect, has the high equilibrium adsorption capacity, and especially has the good Acid Green 27 adsorption effect.

Owner:GUANGDONG UNIV OF EDUCATION

Double-magnetic-ring micro cylindrical Hall thruster of friction welding anode

ActiveCN112431732AReduce costsReduce manufacturing costMachines/enginesUsing plasmaHigh magnetic field strengthFriction welding

The invention discloses a double-magnetic-ring micro cylindrical Hall thruster of a friction welding anode. The double-magnetic-ring micro cylindrical Hall thruster comprises a magnetic screen, an acceleration channel, a magnetic circuit and the anode, wherein the magnetic screen and the acceleration channel are coaxially mounted, and the magnetic circuit and the anode are wrapped on the outer side of the acceleration channel. According to the technical scheme, the problem that the anode of the micro Hall thruster is difficult to machine is solved; the anode machining precision and the air tightness of the micro Hall thruster are improved; the requirements for high magnetic field intensity and light weight required by the micro cylindrical Hall thruster can be met; and the magnetic circuitheat effect problem of the micro cylindrical Hall thruster is solved.

Owner:BEIHANG UNIV

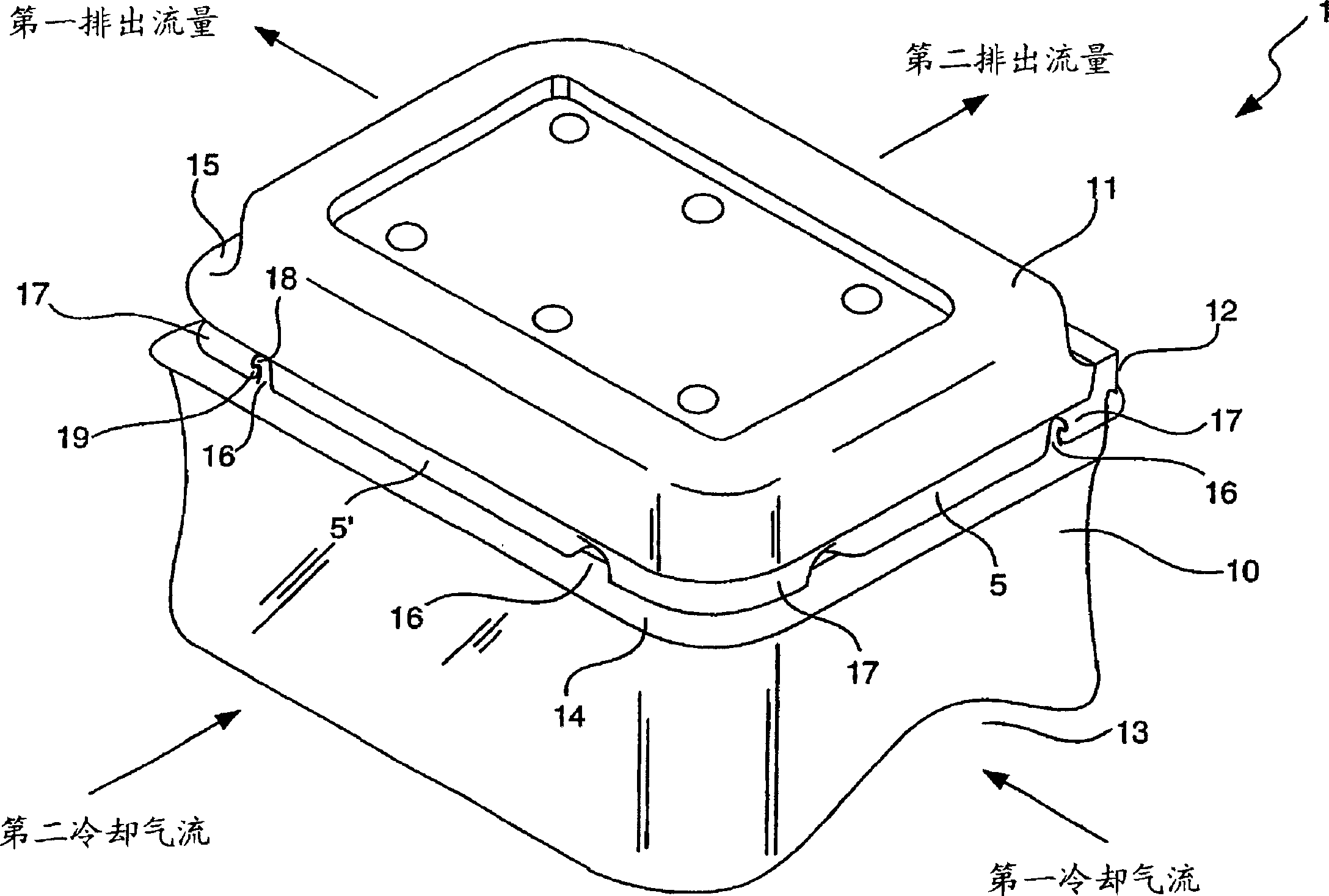

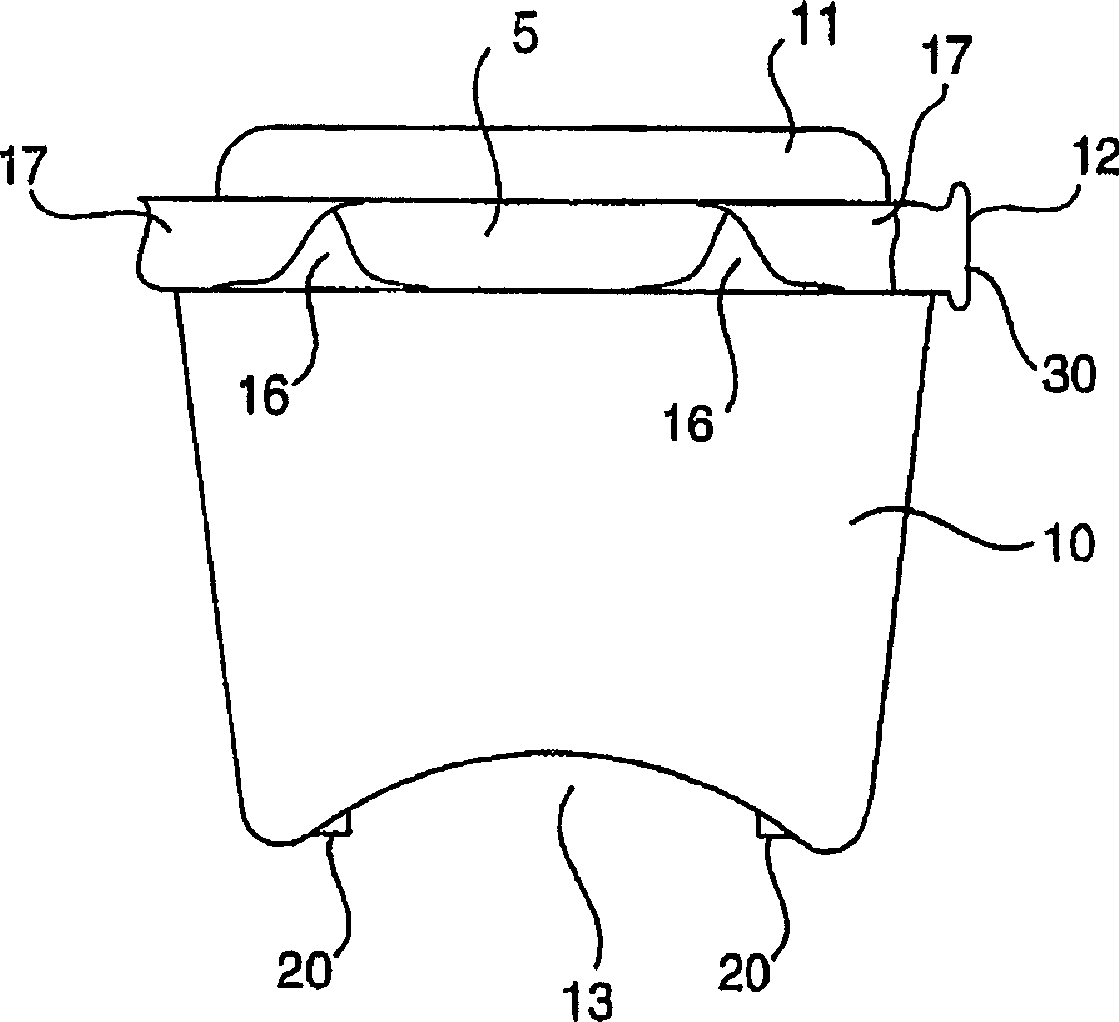

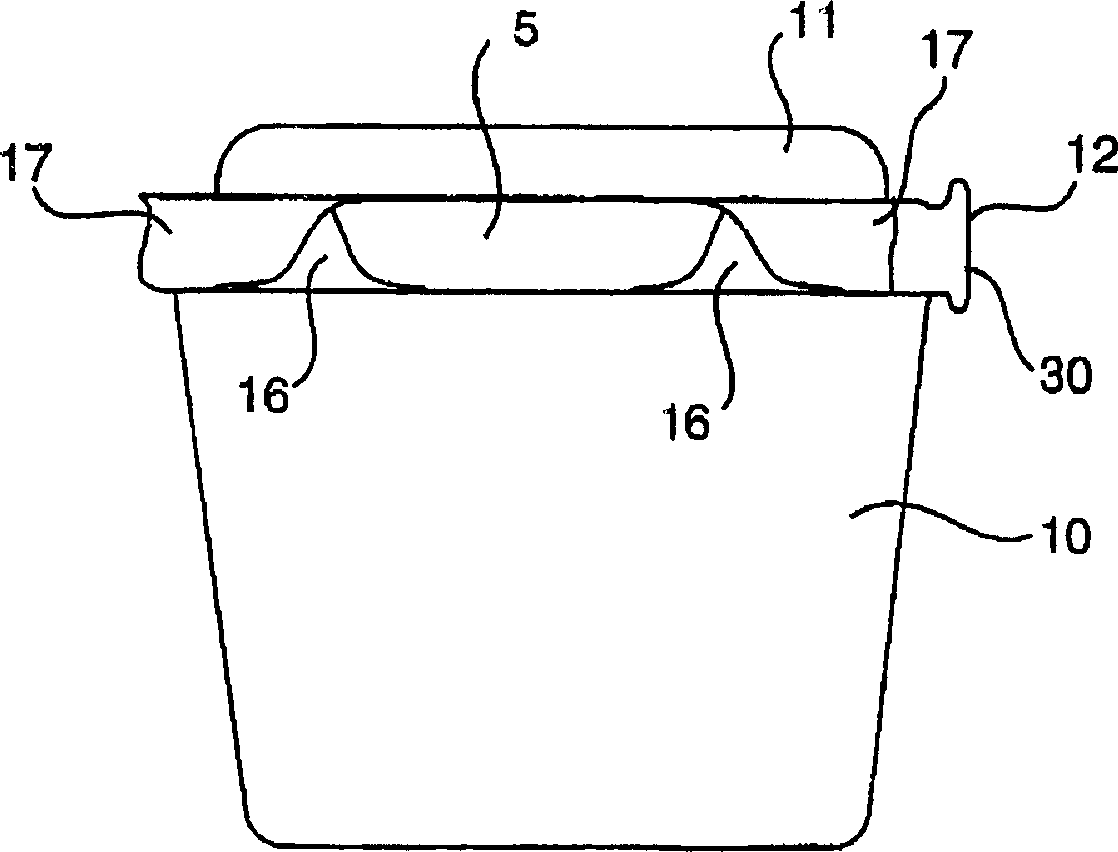

Method and apparatus for packing and bi-directional cooling of produce

Method for improved packing and cooling of produce. According to the present invention, baskets for the packing of fruit are provided with ventilation channels disposed upon a lower surface of the basket. Vent apertures communicate between the ventilation channels and the produce stored in the baskets. Upper vents are formed on four sides of an upper portion of the baskets. After packing the baskets with produce, they are loaded into trays. The trays may be provided with tray vents that align with the ventilation channels. Alternatively, the trays may be formed without tray vents to improve some cooling regimes. In this manner, entire pallets of produce-filled baskets, oriented in either the 'X' or 'Y' directions can be efficiently chilled by introducing a flow of cooling air into the baskets and thence through the produce packed inside, regardless of the orientation of the trays. The trays and baskets are sized so as to occupy all of the surface area of a standard shipping pallet, and to minimize the movement of the baskets within the trays, and of the trays with respect to one another.

Owner:SAMBRAILO PACKAGING

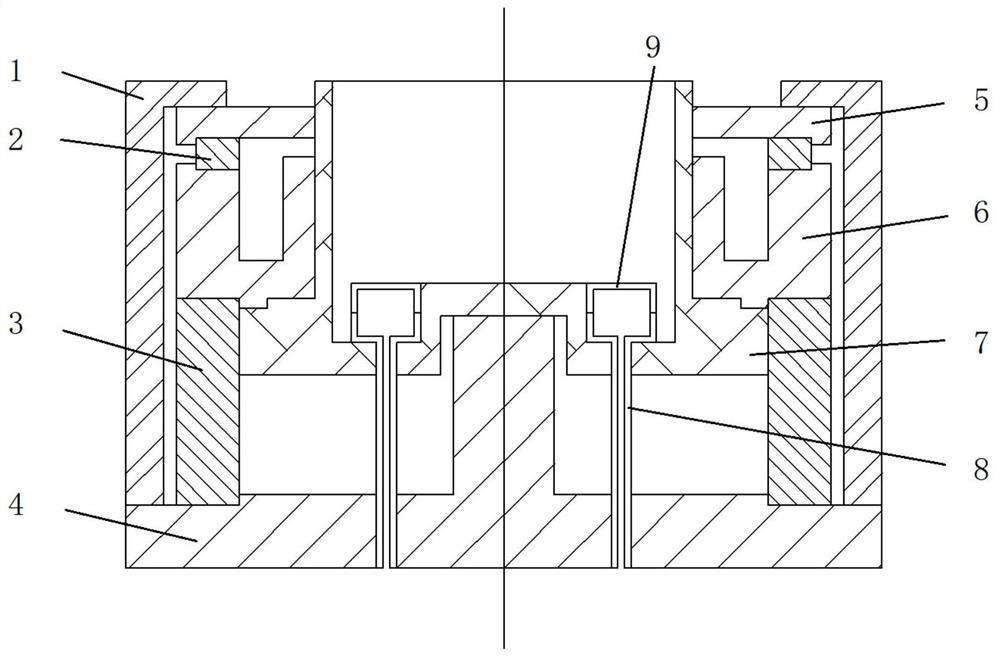

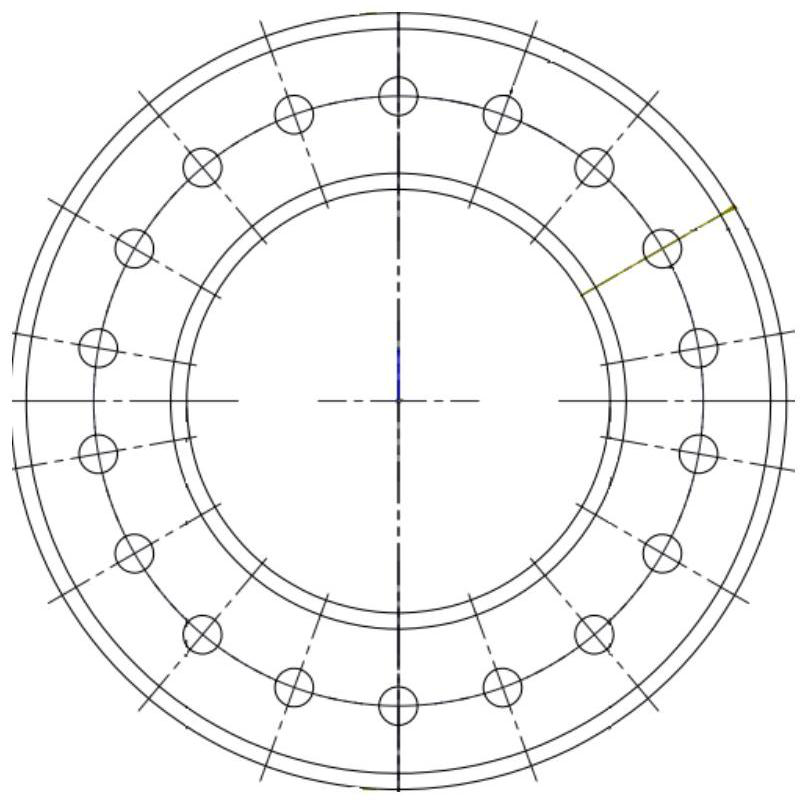

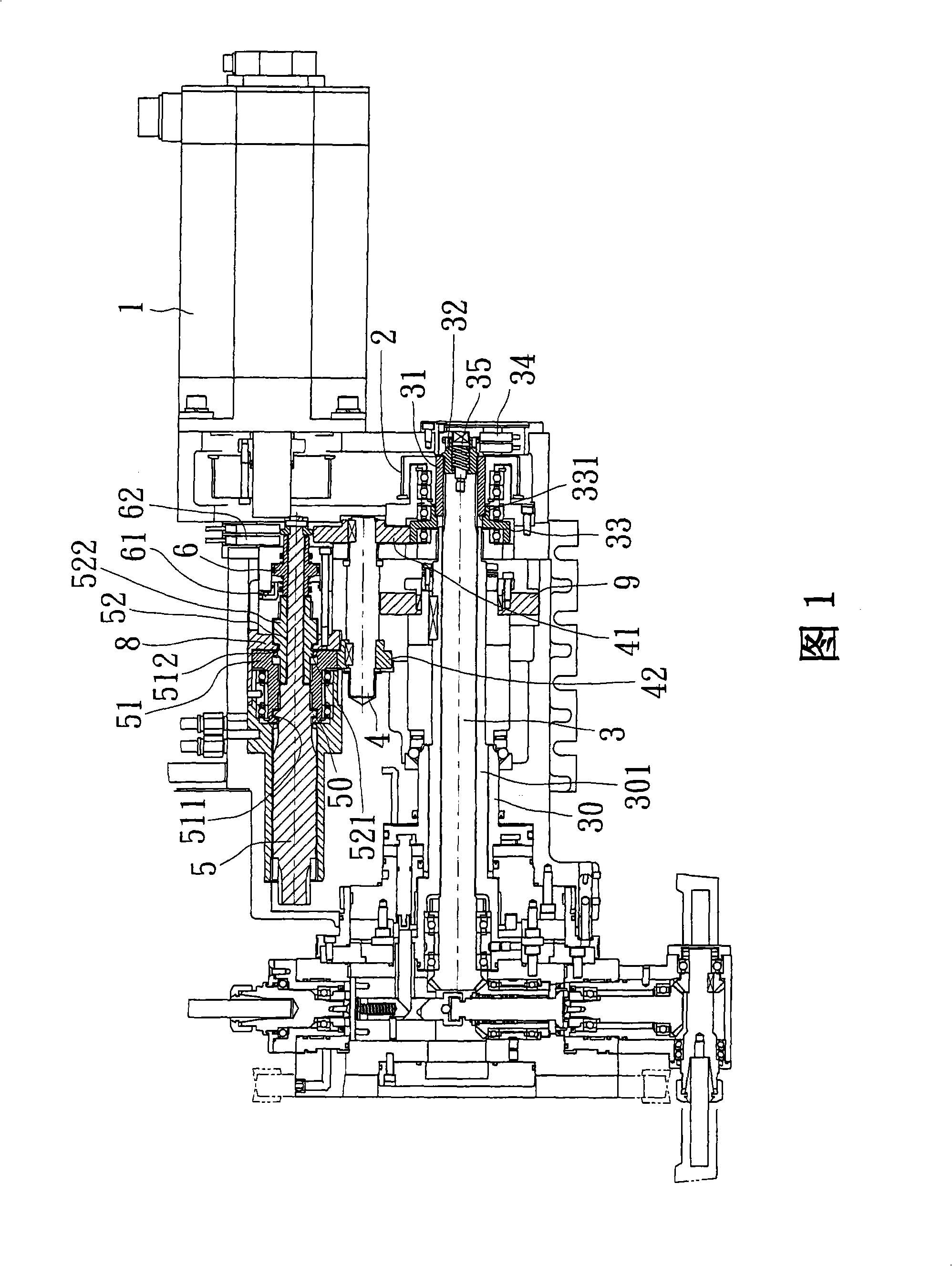

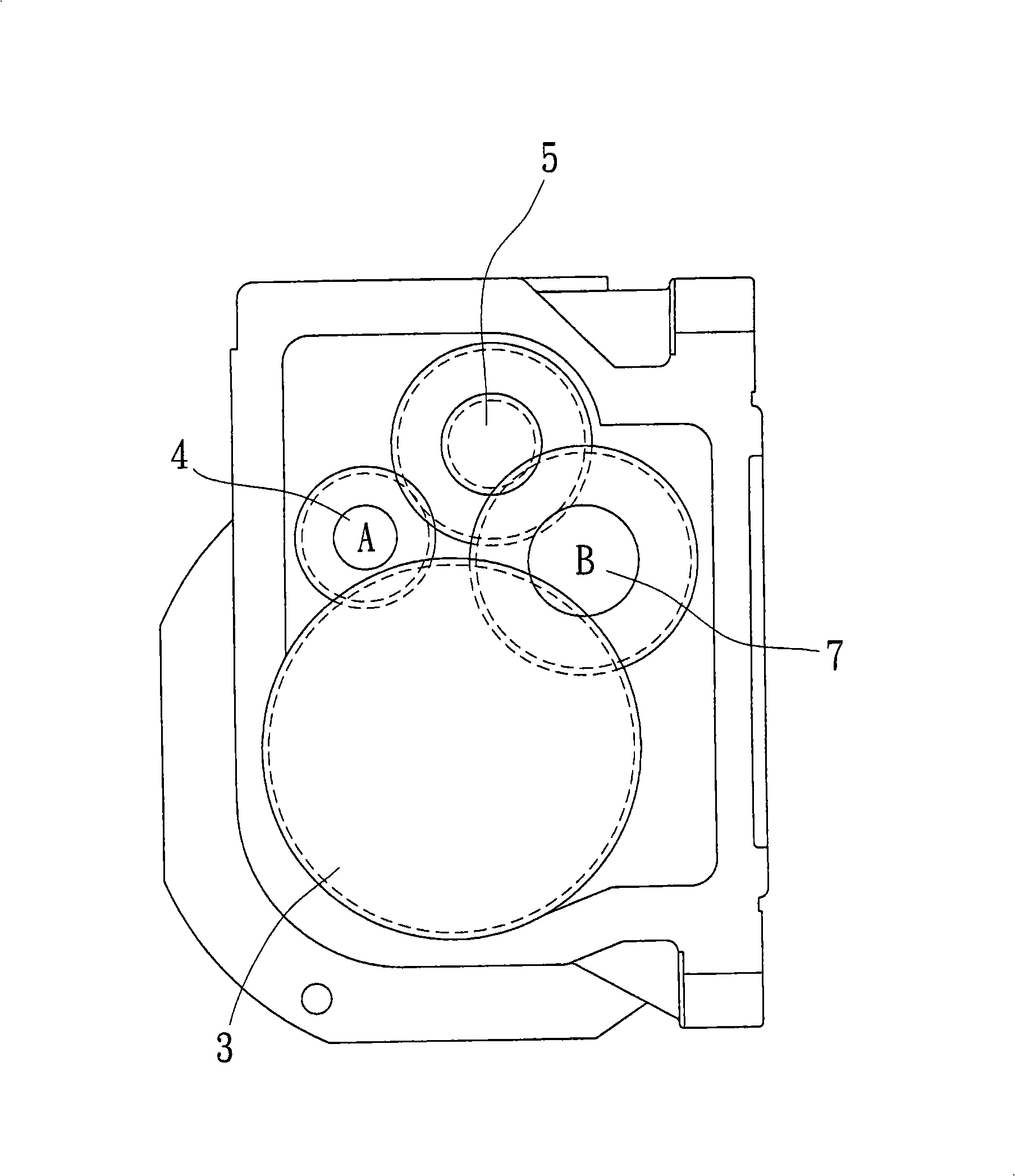

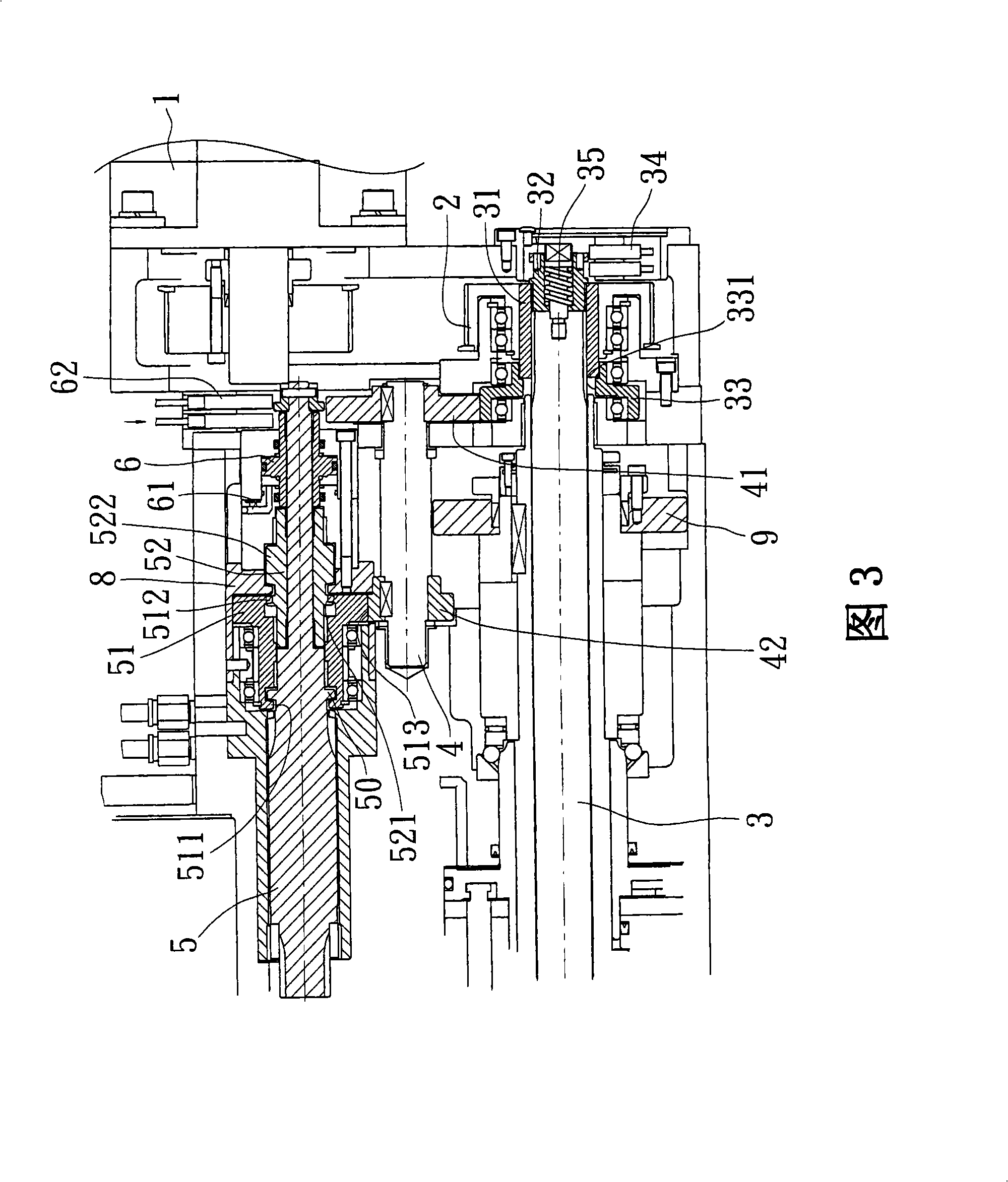

Double-cutterhead dynamic cutter tower seat structure

InactiveCN101310901AMachine equipment streamlinedReduce costsTool holdersLarge fixed membersClutchPiston

The invention discloses a dual-cutter head drive cutter tower support structure. A main power source is arranged in a machine set, when the single power source is adopted to start the processing of a main shaft or push a cutter head for selecting cutters through a power unit, a consecutive transmission component going through the main power source and a piston clutch respectively drive a rotary shaft A or B to cause the power to do selective transmission through the rotary shaft A to drive an inner cutter head for movably selecting cutters or transmit the power through the rotary shaft B to drive an outer cutter head for cutter selection, thereby, the structure of the single drive power of the invention can have the main shaft move (the original movement of the main shaft and the power transmission unchanged) or the inner cutter disc or the outer cutter disc to select cutters, thus simplifying the equipment of machine set and saving costs.

Owner:FACTORY AUTOMATION TECH CO LTD

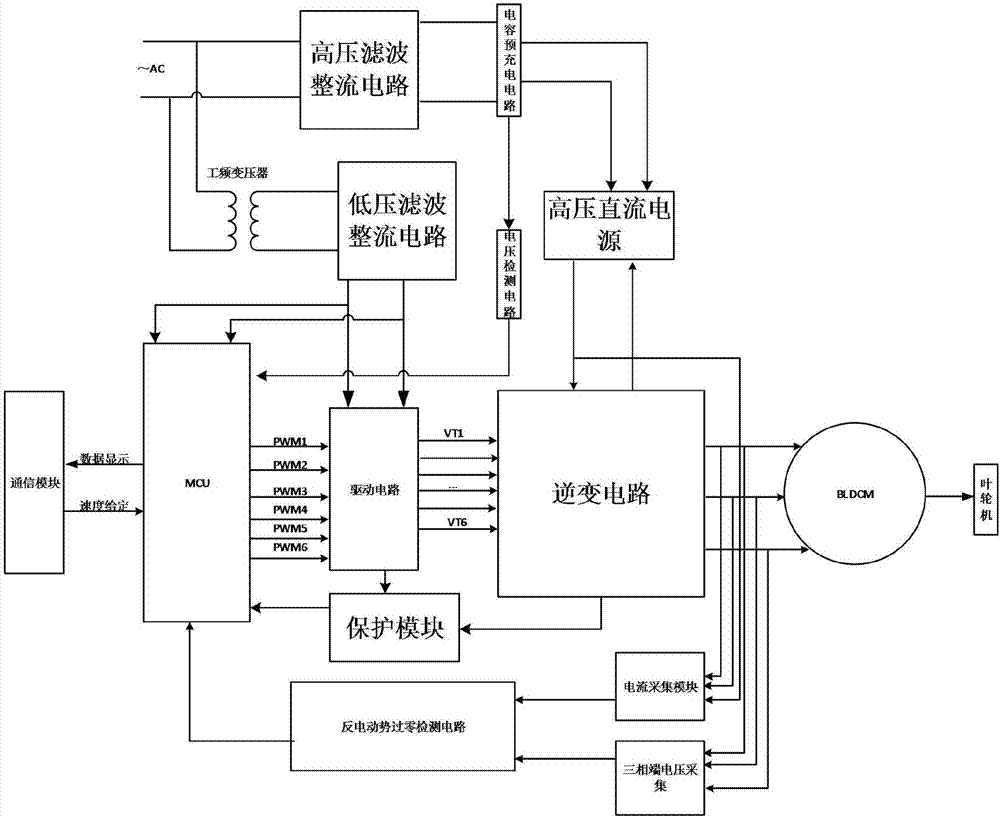

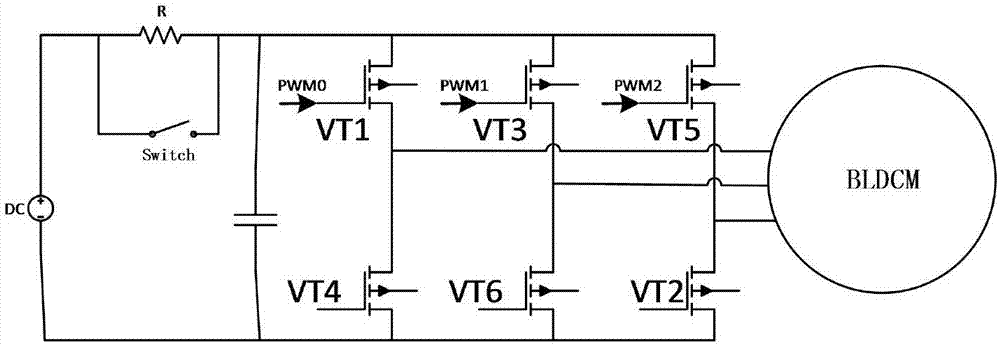

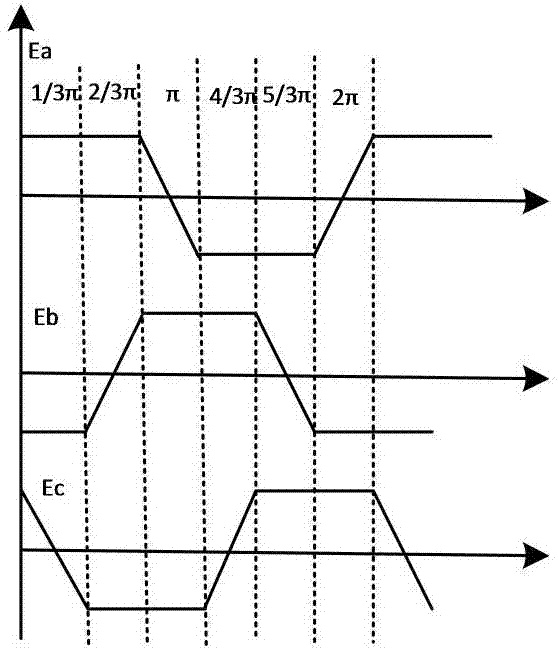

Sensorless direct-current brushless motor controller and control method thereof

InactiveCN107425765AReduce system sizeReduce costsSingle motor speed/torque controlEmergency protective circuit arrangementsPoint methodZero crossing

The invention discloses a sensorless direct-current brushless motor controller and a control method thereof. The controller is composed of a power supply circuit, an MCU inverter control drive circuit and a sensorless detection circuit. The power supply circuit provides power for the MCU inverter control drive circuit and drives the direct-current brushless motor to work by the MCU inverter control drive circuit. The sensorless detection circuit detects a working voltage and an operating current of the direct-current brushless motor and sends detection results to the MCU inverter control drive circuit; the MCU inverter control drive circuit determines a counter electromotive force zero-crossing point based on combination of a position detection mid-point method with an ADC sampling method and the 30-degree electrical angle of a rotor is delayed to determine a commutation time of the motor, so that the direct-current brushless motor is driven to accelerate slowly until a predetermined rotation speed is reached. According to the controller disclosed by the invention, the commutation time of the motor is determined and the direct-current brushless motor is controlled to work at the predetermined rotation speed. The sensor part is reduced; the cost is lowered; and the reliability is enhanced.

Owner:WUXI SHUANGNENGDA TECH

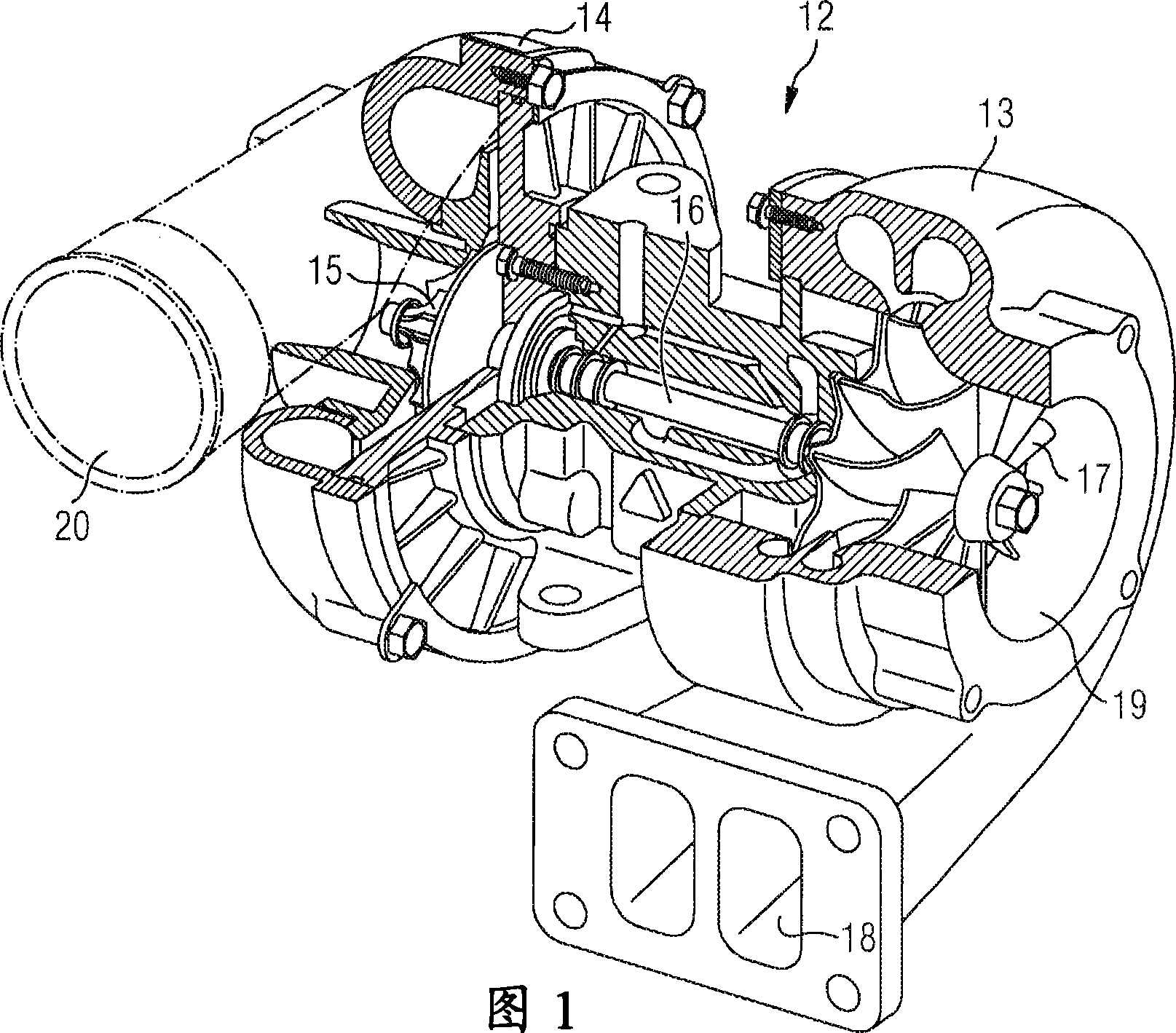

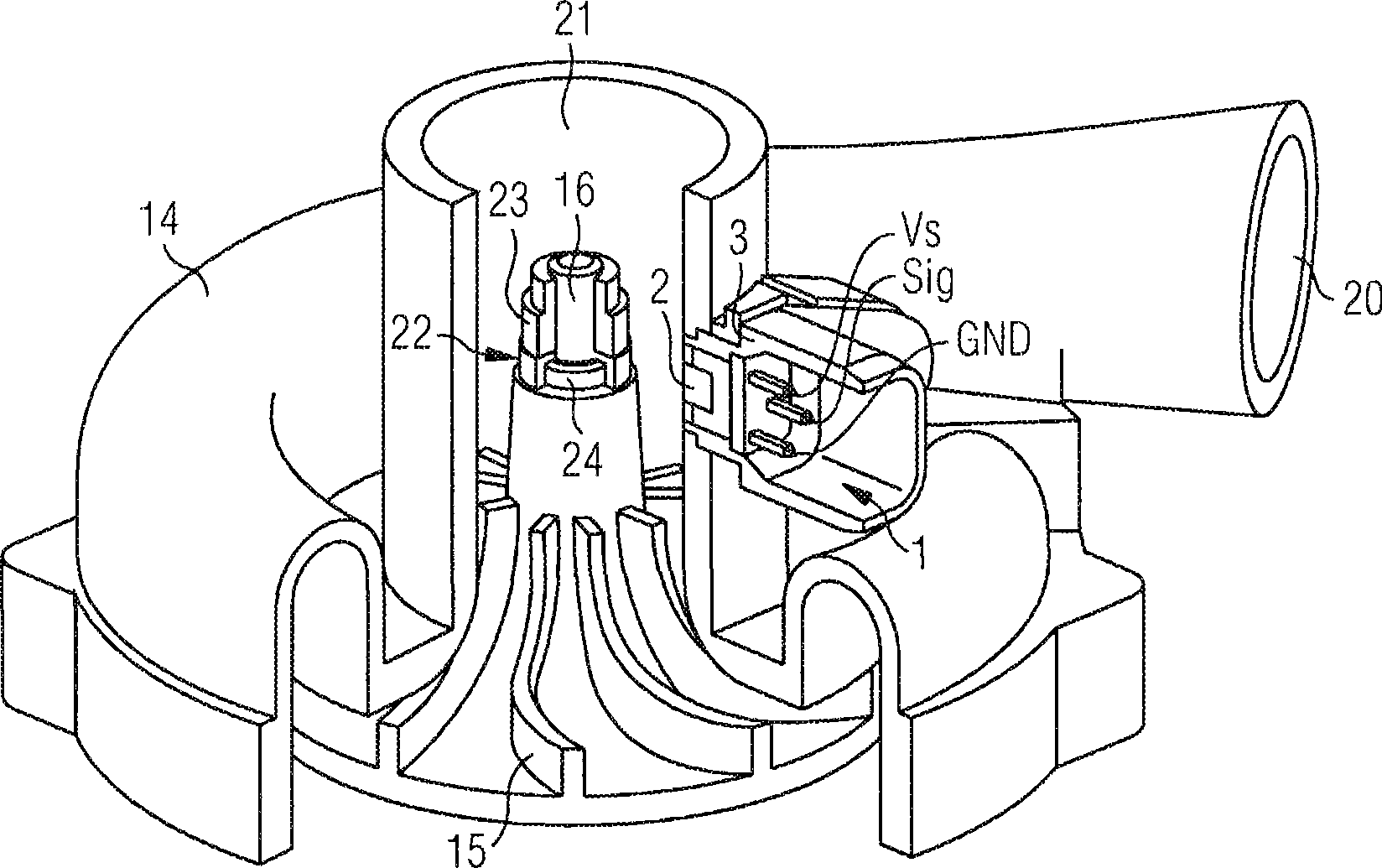

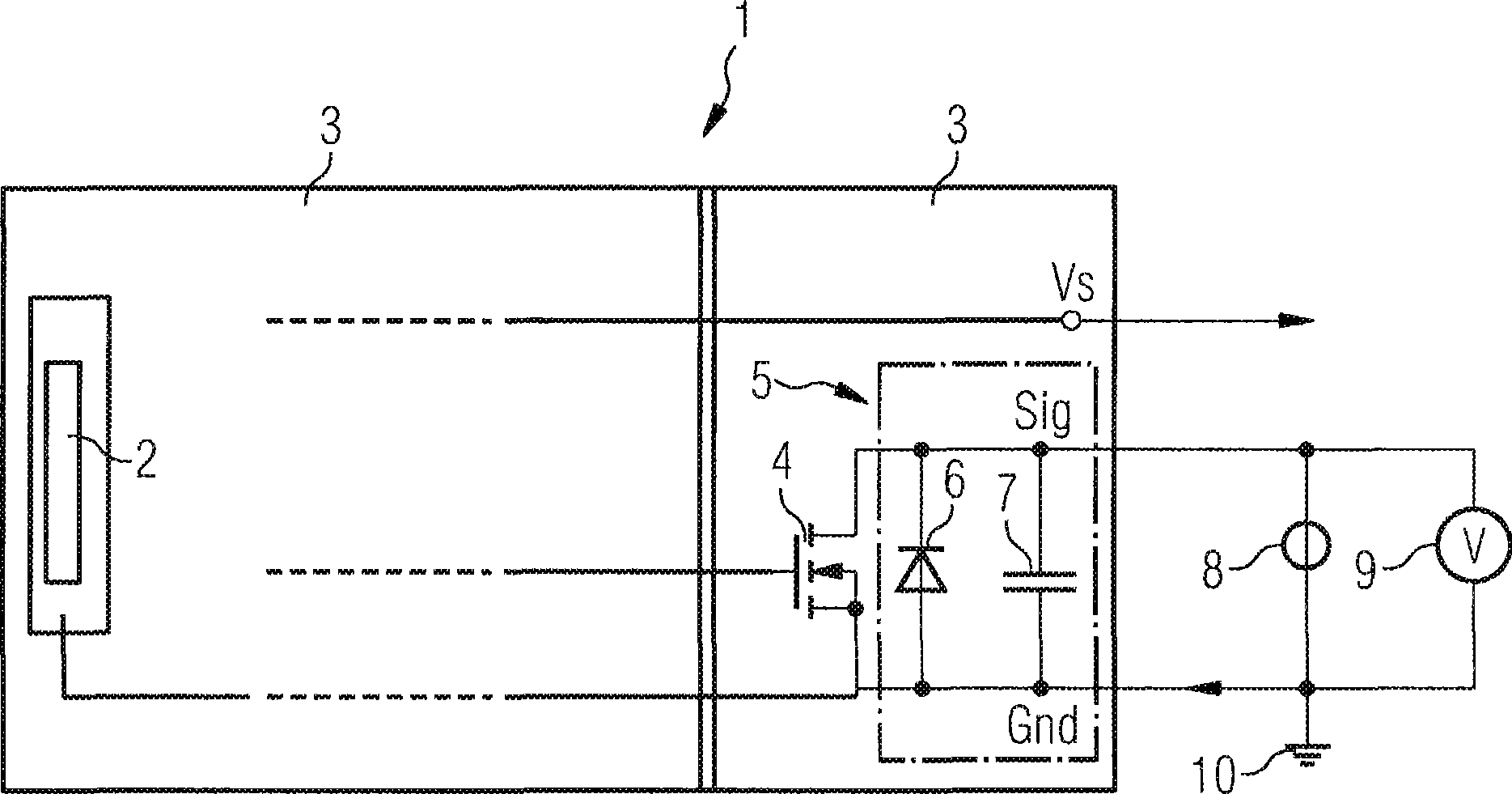

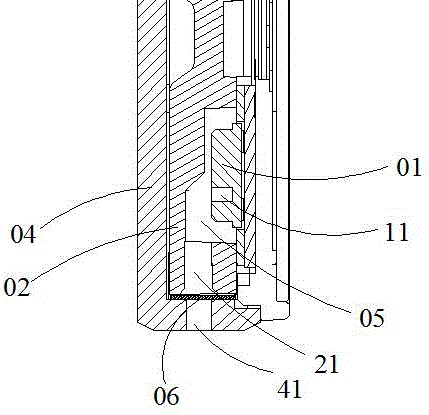

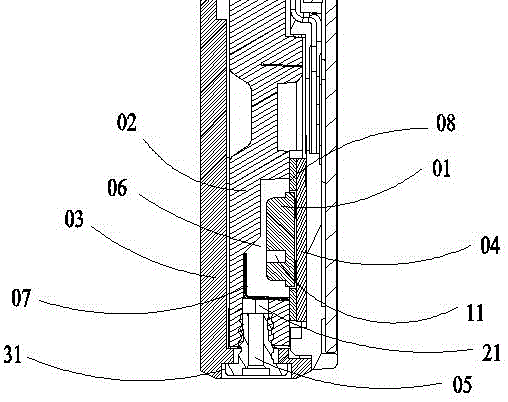

Active sensor element and method of determining the temperature of an active sensor element

ActiveCN101438030AReduce costsLow costCombustion enginesEngine componentsExhaust gasTemperature measurement

The invention relates to an active sensor element for recording the speed of an exhaust gas turbocharger, comprising a suppressor circuit which has at least one diode. In order to specify a device for temperature measurement at the turbocharger and in particular at the turbocharger in the region of the active sensor, the current-voltage characteristics of the diode are evaluated for determining the temperature in the sensor element.

Owner:CONTINENTAL AUTOMOTIVE TECH GMBH

Mobile terminal

InactiveCN105933803AHas a fixed effectReduce costsTransducer casings/cabinets/supportsEngineeringComputer terminal

The embodiment of the invention provides a mobile terminal. The mobile terminal comprises a microphone, a microphone bracket, a battery cover, a mainboard and a screw, wherein the microphone is fixed to the mainboard; the microphone bracket buckles the microphone on the mainboard to form a sound cavity; the microphone is provided with a sound output hole; the battery cover is provided with a first through hole; the microphone bracket in the sound cavity is provided with a second through hole; the screw is a hollow screw; the screw passes through the first through hole and is fixed in the second through hole; and sound produced by the microphone is output through the sound output hole and the screw. Through adoption of the mobile terminal provided by the embodiment of the invention, the problem of sound leakage due to existence of a gap between the microphone bracket and the battery cover when sound produced by the microphone needs to pass through the microphone bracket and the battery cover is solved.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Pipe jacking construction process

ActiveCN101997293AReduce costsEasy to implementPipe laying and repairCable installations in surface ductsPulleyArchitectural engineering

the invention discloses a pipe jacking construction process. The pipe jacking comprises steel pipes. The pipe jacking construction process comprises the following steps of: excavating a steel pipe groove; respectively fixing a winch on the left and right of the rear of the steel pipe groove; excavating a soil tank vertical to the steel pipe groove on the top of the steel pipe groove, arranging channel steel in the soil tank, and fixing iron piles on two sides of the channel steel; welding a steel pipe connecting sleeve at one end of the steel pipe; sleeving a conical head on the head of a first steel pipe, sleeving a cap on the tail of the first steel pipe, and hanging and connecting a movable pulley, wherein the movable pulley is connected with the winches and is connected with the steel pipe through a linkage device, and a fixed pulley is fixed to the iron pile; twisting a plurality of circles of steel wire rope on the winches; and jacking the first steel pipe, detaching the cap, sleeving the head of a second steel pipe on the tail of the first steel pipe, arranging the cap on the tail of the second steel pipe, and repeating the process until the steel pipes are jacked to pass through the road surface. The pipe jacking construction process can reduce the damage to the road surface, reduce application of large vehicles and environmental pollution, has short construction time and low cost, and has the characteristics of energy conservation, emission reduction and efficiency improvement.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

Rice breeding method incorporating high photosynthetic efficiency and presenility resistant property

InactiveCN1994063AOvercoming genetic barriersReduce costsPlant phenotype modificationVector-based foreign material introductionOryza sativaGene

The invention relates to a rice seeding method which comprises that: leading decay gene into rice seed to obtain the rice system; crossing the rice with C4 plant PEPC gene stable representation with the rice system, to obtain F1 system; checking, selecting the rice with high light effect and anti-decay character; cultivating F1, to obtain two flower systems; checking, selecting the rice pure system with high light effect and anti-decay character.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

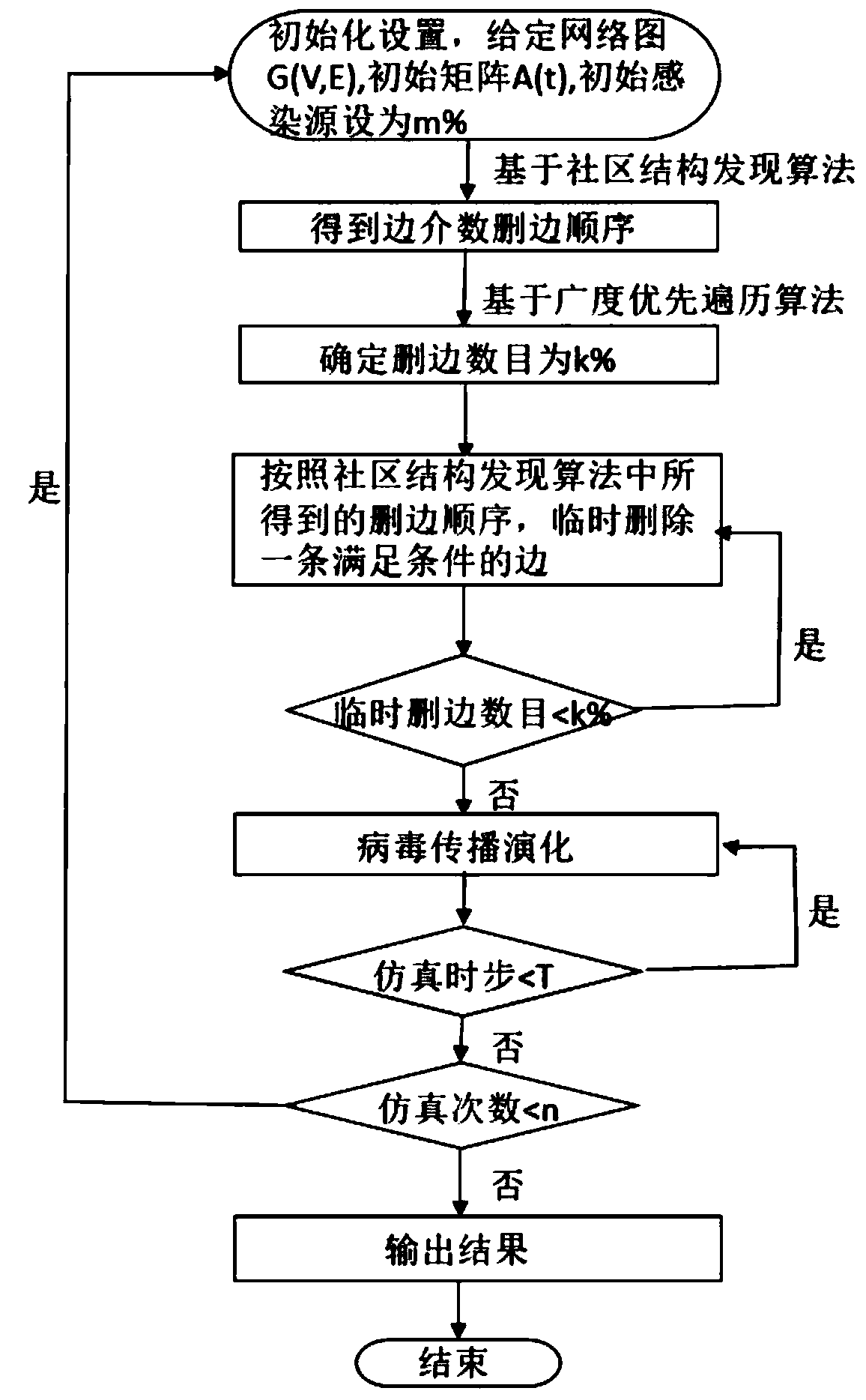

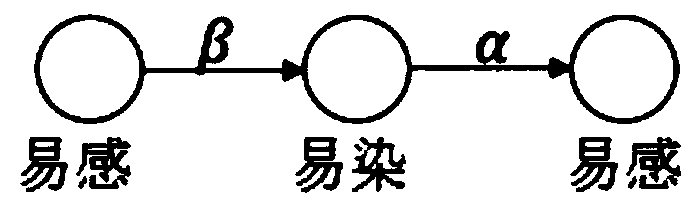

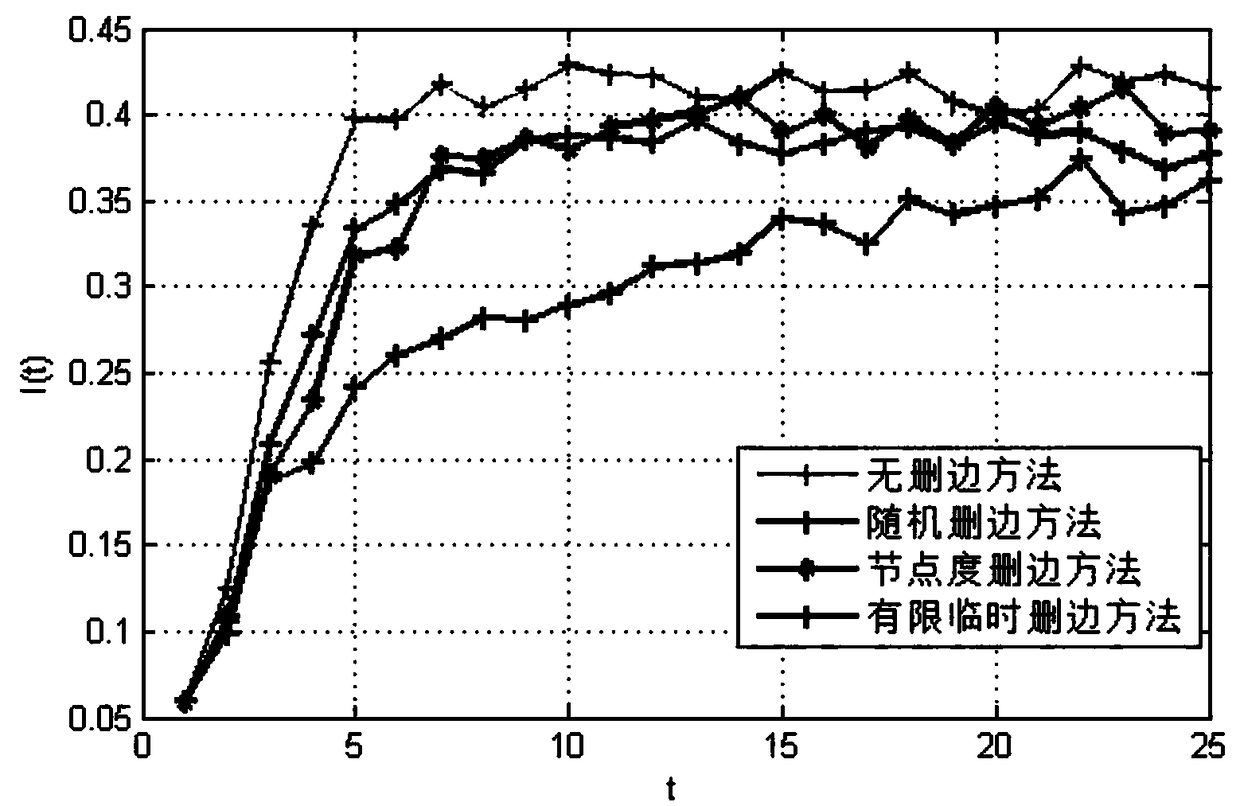

Viral transmission control method based on limited temporary frame erasure

ActiveCN108965287AReduce the speed of virus transmission and the scale of infectionReduce costsData switching networksCellular automationSearch algorithm

The present invention provides a viral transmission control method based on limited temporary frame erasure. The method comprises the steps of: constructing a viral transmission model, and establishing a susceptible-chromophilous-susceptible viral transmission model based on cellular automaton; giving a network graph G(N, E), initializing an adjacent matrix A(t) of the network at a t moment, and selecting m% nodes as primary infection sources; employing a community structure discovery algorithm to obtain a frame erasure sequence based on a whole network frame betweenness; employing the breadthfirst search algorithm to determine that the number of the frame erasure is k%, wherein k is a finite positive integer; according to the frame betweenness frame erasure sequence, temporarily erasinga frame meeting conditions; and repeating the previous step until the proportion of the temporary frame erasure reaches k%. The viral transmission control method is simple and efficient, and can obviously reduce the viral transmission speed and the infection scale.

Owner:SHAANXI NORMAL UNIV

Massage treatment bed for breast surgery

InactiveCN110169902AReduce costsImprove comfortBathing devicesRoller massageSurgery.breastSurgical department

The invention relates to the technical field of medical apparatus and instruments, and specifically relates to a massage treatment bed for breast surgery. The massage treatment bed comprises a bed body, four corners of the top of the bed body are respectively fixed with a corner post, a bed head transverse rod is fixedly mounted across a position between each two corner posts on one side of the bed body, two support rods capable of moving by adjustment are mounted across positions between the two bed head transverse rods, and at least one massage assembly which can move along the support rodsthrough adjustment and move longitudinally relative to the bed body through adjustment is mounted on the support rods. The massage treatment bed is convenient to install, use and adjust, the comfort level of the breast of a patient can be improved, or traditional Chinese medicine fumigation physical therapy can be carried out on the breast of the patient during massage, and breast diseases and inflammation can be rapidly eliminated.

Owner:董建丽

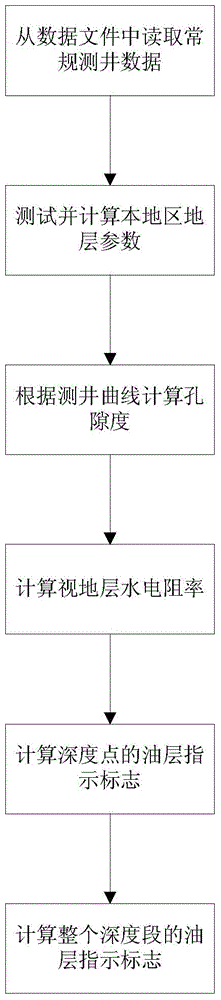

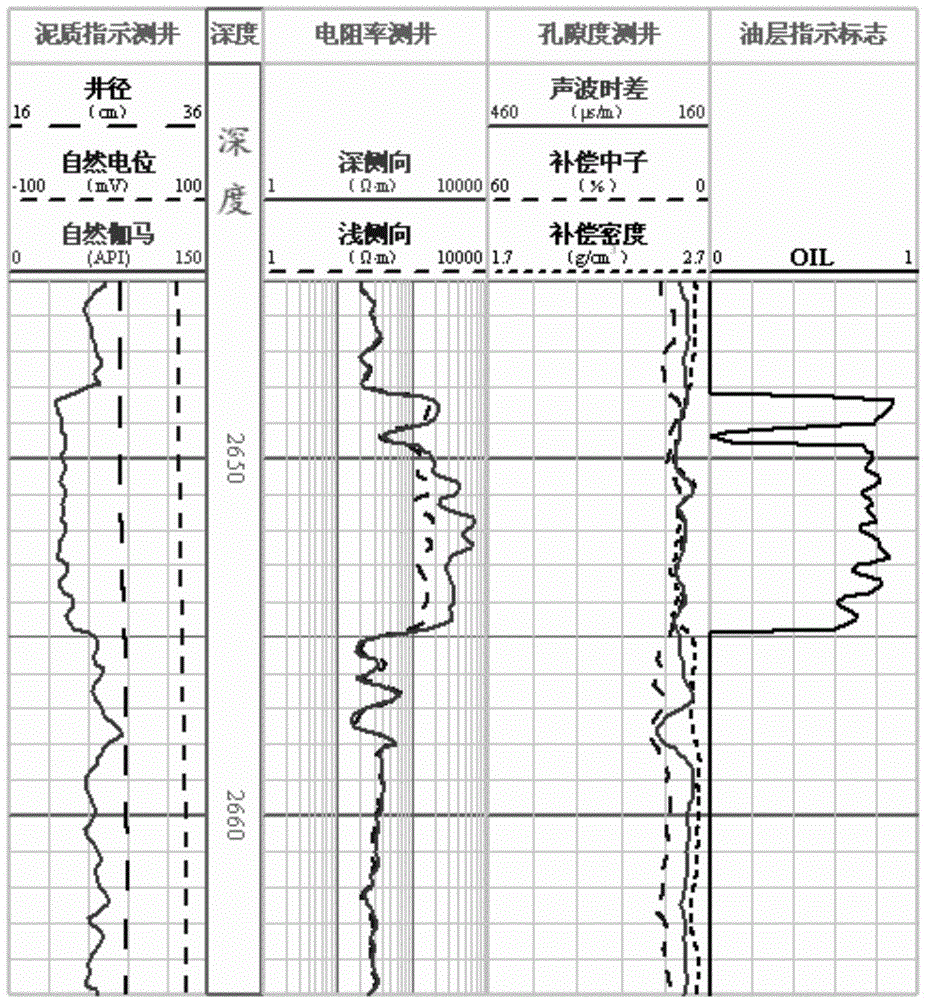

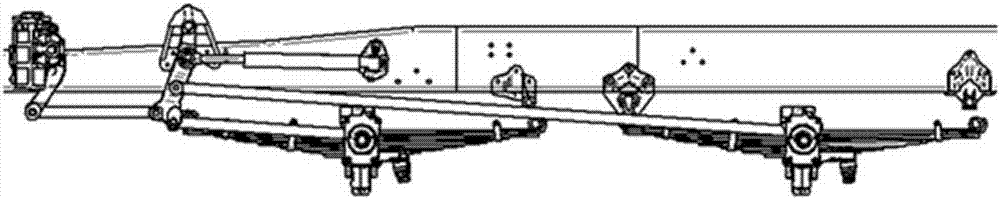

Method for obtaining indication mark of oil layer through conventional logging

InactiveCN104636592AReduce costsCutting costsSpecial data processing applicationsBorehole/well accessoriesData fileFormation water

The invention discloses a method for obtaining an indication mark of an oil layer through conventional logging. The method comprises the following steps that 1, conventional logging data are read from a data file; 2, stratum parameters of a local area are tested and computed; 3, the porosity phi is computed according to a logging curve; 4, the electrical resistivity of apparent formation water is computed; 5, the indication mark of the oil layer at a depth point is computed; 6, after computing of one depth point is finished, the first step is carried out again until computation of the whole depth section is finished. The method can effectively mark out the oil producing interval, is high in accuracy, obviously relieves the labor intensity of interpreters, and can be widely applied to the field of petroleum exploration and development.

Owner:YANGTZE UNIVERSITY

Method for determining dual-purpose line fertility by use of leaf marking trait in seedbed stage

InactiveCN1883257AReduce costsReduce economic costsVector-based foreign material introductionPlant genotype modificationHybrid seedAgricultural science

The invention relates to a method for identification of dual-purpose line fertility by leaf marker property seedbed, comprising locking gene controlling cotton male nuclear fertility and gene controlling cotton marker properties( such as purple leaves, chicken horn shape leaves, etc.), by gene cloning techniques, transferring the genome to cotton nuclear sterile dual-purpose line, culturing the transgenic dual-purpose line with leaf marker properties. The fertile plants can be identified by the marker property during seedbed period and be pulled out. The plants transplanting to field are all sterile plants, so that there is no need to identify fertility at blooming period. The method is provided with greatly simplified preparation process, improved purity and reduced production cost of cotton hybrid seeds.

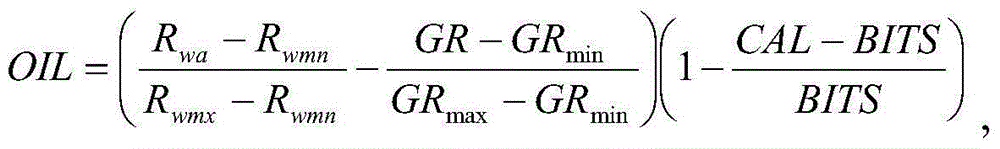

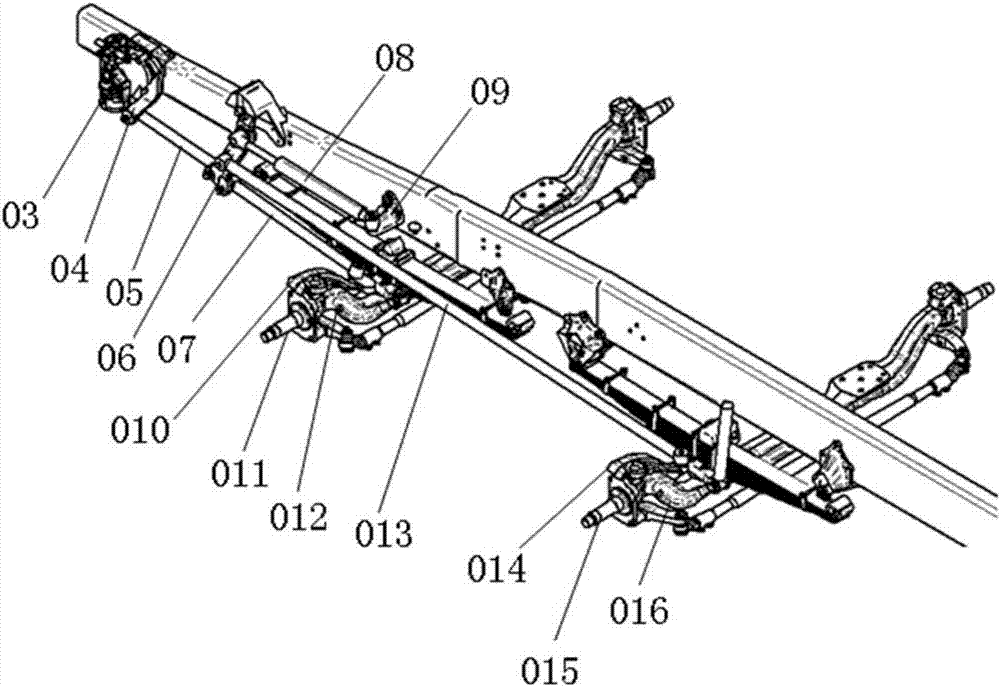

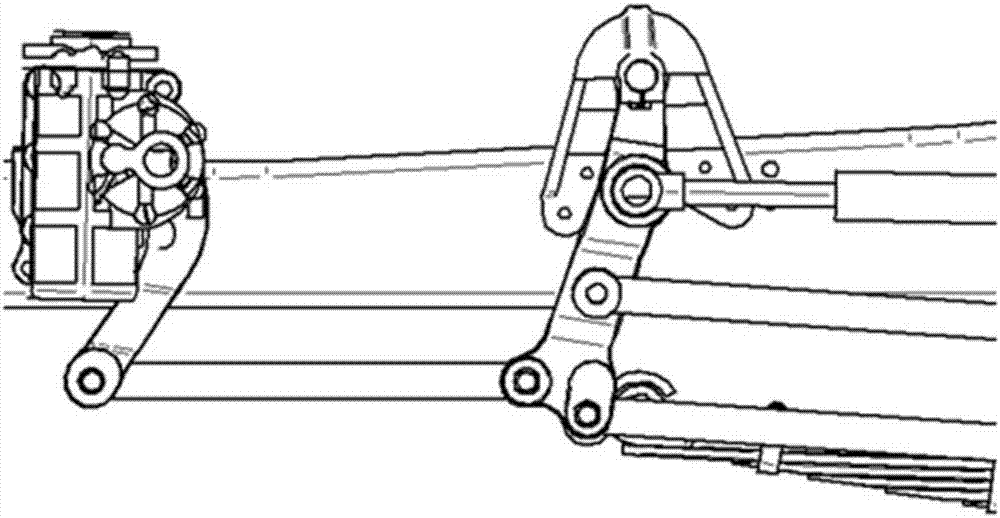

Dual-front axle vehicle steering system

ActiveCN107140013AReduce leakageImprove efficiencySteering linkagesFluid steeringVehicle framePiston

The invention relates to a dual-front axle vehicle steering system comprising a steering gear, a plumbing arm, a first front axle drag link, a transition pull bar, a power-assisted cylinder assembly, a second front axle drag link, a first front axle and a second front axle; the steering gear is arranged on a frame vertical beam through a steering gear rack; the top of the plumbing arm is connected with the steering gear, and the bottom of the plumbing arm is movably connected with the front end of the transition pull bar; the rear end of the transition pull bar is movably connected with the power-assisted cylinder assembly; the front end of the first front axle drag link is movably connected with the power-assisted cylinder assembly, and the rear end is movably connected with the first front axle; the front end of the second front axle drag link is movably connected with the power-assisted cylinder assembly, and the rear is movably connected with the second front axle. The power-assisted cylinder assembly can provide steering assist power, can serve as the transition rocking arm, needs no piston, and can bear more pressure, thus outputting bigger steering moment; the dual-front axle vehicle steering system is long in service life, and good in reliability.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com