Active sensor element and method of determining the temperature of an active sensor element

A technology of sensor elements and source sensors, applied to devices using electric/magnetic methods, engine components, instruments, etc., can solve problems such as high impeller speed, damaged turbocharger, wrong speed signal, etc., to achieve low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

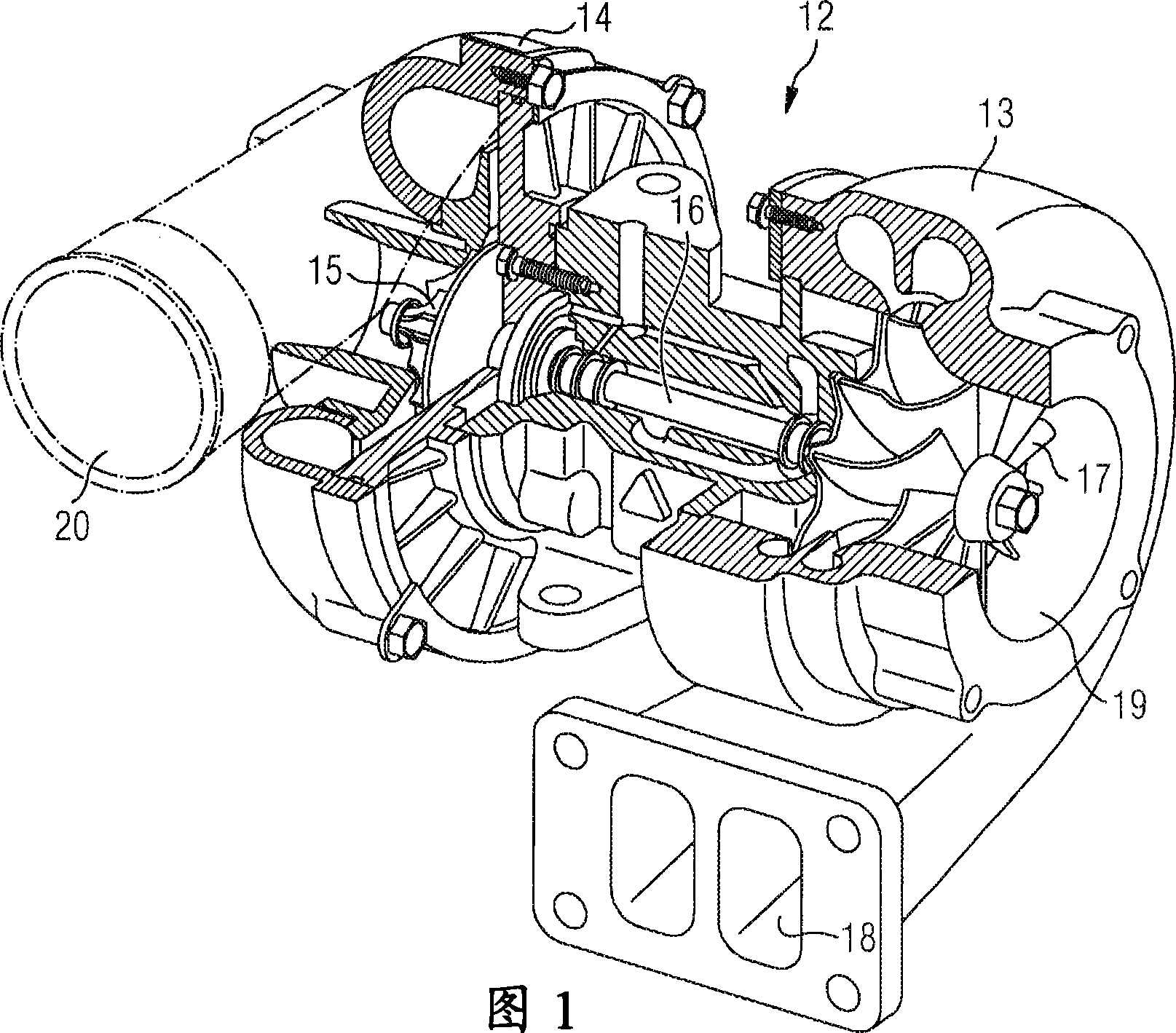

[0026] FIG. 1 shows an exhaust gas turbocharger 12 with a turbine 13 and a compressor 14 . A compressor wheel 15 is rotatably mounted in the compressor 14 and connected to a turbine shaft 16 . A turbine shaft 16 is also rotatably mounted and its other end is connected to a turbine 17 . The hot exhaust gas enters the turbine 13 from the internal combustion engine (not shown here) via the turbine inlet 18 , whereby the turbine 17 is rotated. The exhaust gas flow exits the turbine 13 through a turbine outlet 19 . The turbine 17 is connected to the compression wheel 15 via a turbine shaft. The turbine 13 thus drives the compressor 14 . Air is sucked into the compressor 14 via an air intake 21 , is compressed in the compressor 14 and delivered to the internal combustion engine via an exhaust air port 20 .

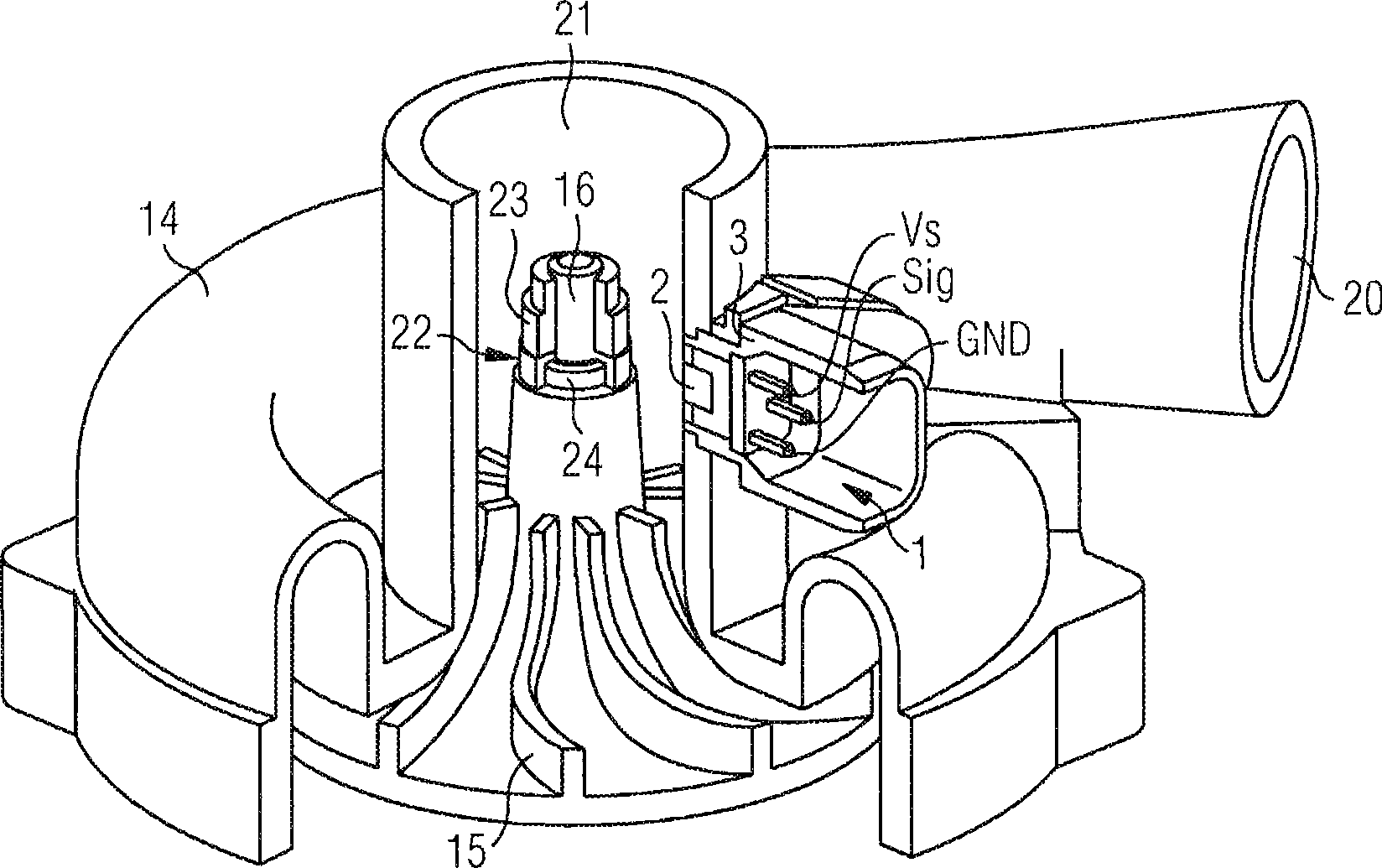

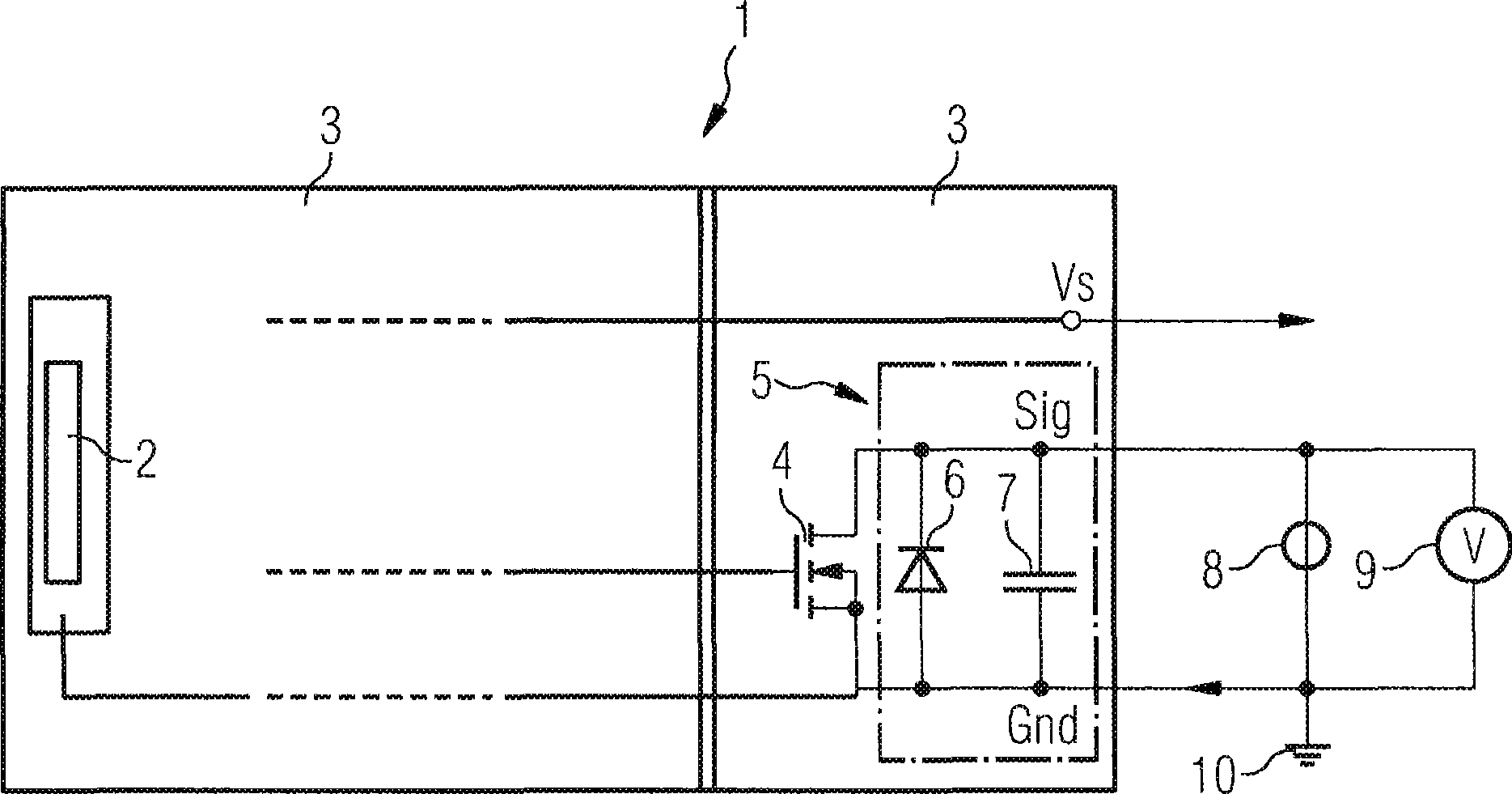

[0027] figure 2 A compressor 14 of the exhaust gas turbocharger 12 is shown with a turbine shaft 16 and a compressor wheel 15 . The compressor wheel 15 can be produced, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com