Impact type waterturbine wheel

A water turbine and impact technology, which is applied in the direction of impact engines, hydroelectric power generation, mechanical equipment, etc., can solve the problems of bucket fatigue and other problems, and achieve the effect of short processing cycle, low investment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

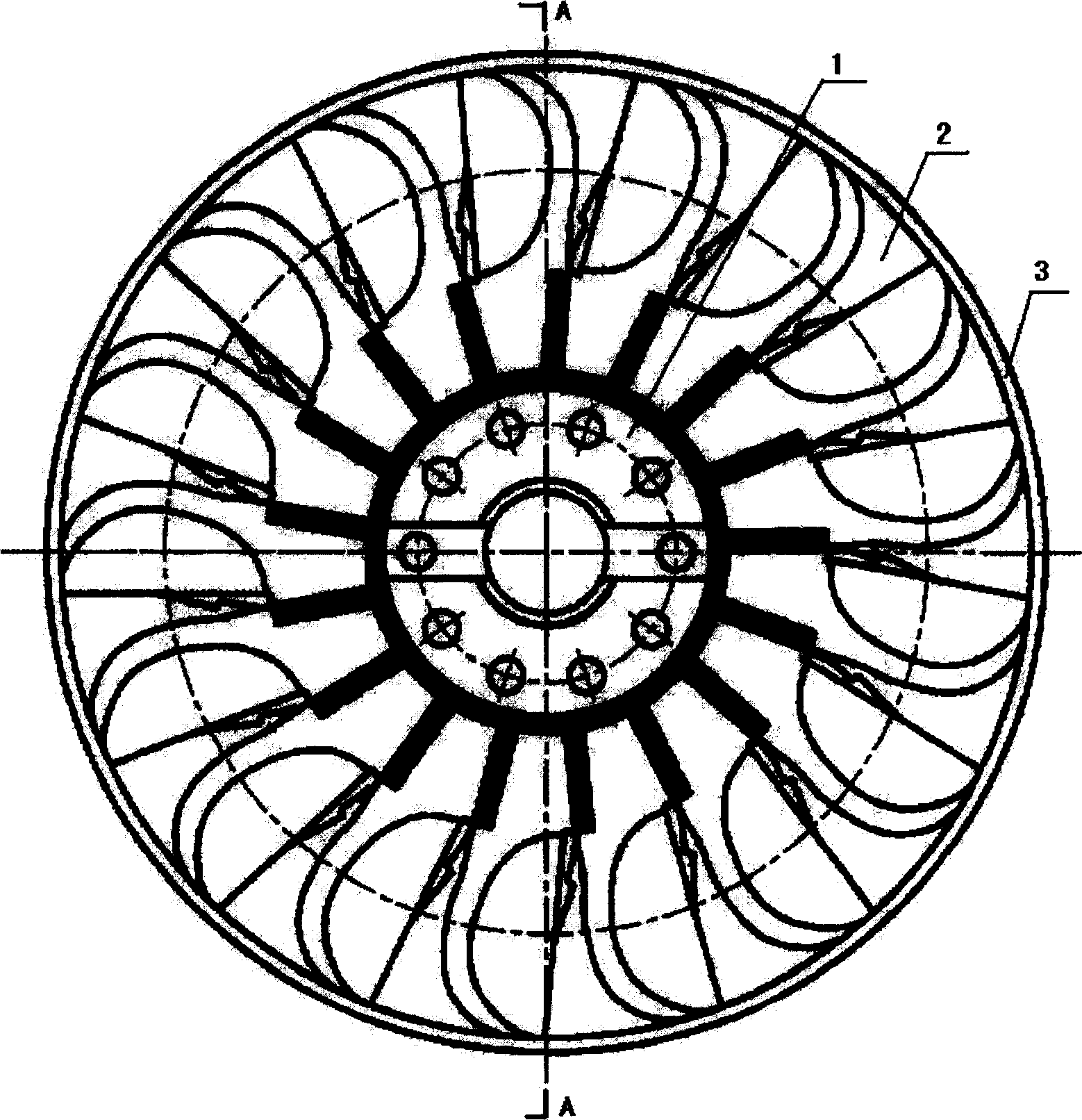

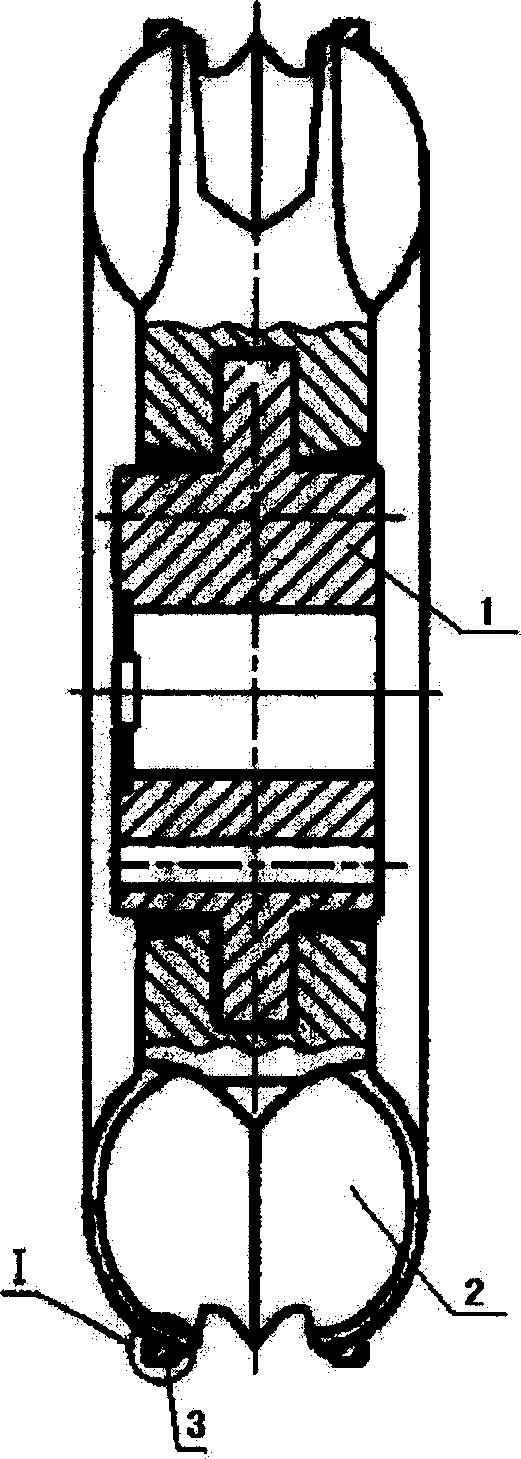

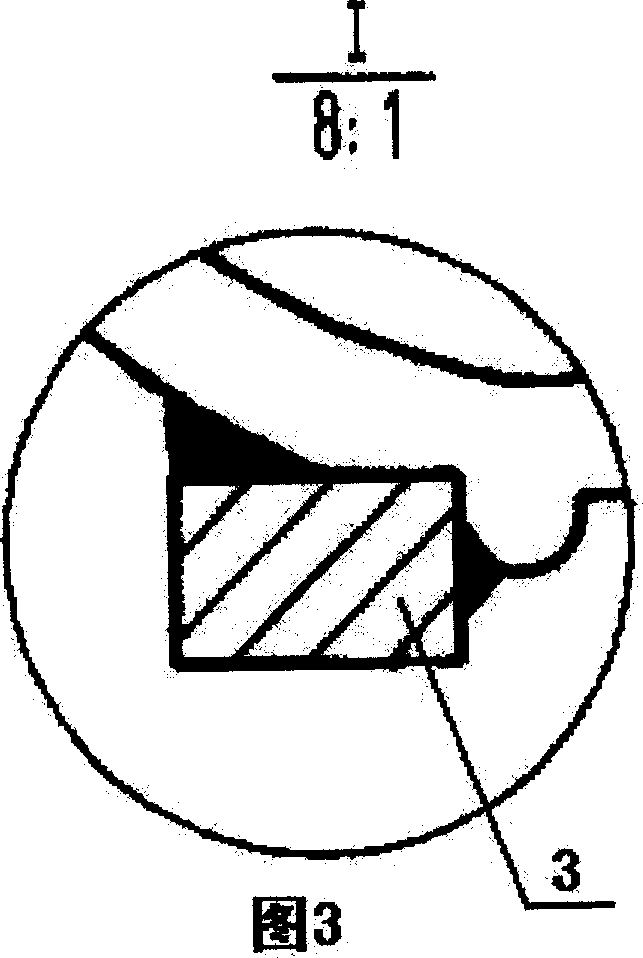

[0011] The present embodiment includes runner 1, hoop 2, bucket 3.

[0012] At least one hoop 2 is provided on the outer circle of the runner 1, and the hoop 2 connects adjacent buckets 3 to each other.

[0013] exist figure 1 In the shown embodiment of the present invention, an impact runner with a cast-welded structure is taken as an example, and a hoop 2 is welded on both sides of the outer circle. The hoop 2 is connected to the outer edge of the water bucket 3 and is located on the At the largest radius of the runner 1, the hoop 2 is an integral circular hoop. During the manufacturing process, the section of the hoop 2 can be of any shape and material, as long as the strength meets the requirements and the weldability is good. The hoop 2 can be integrally welded, or can be welded in sections. The runners with welded hoops are balanced according to the conventional production process. After the hoop 2 is added, under the impact of the water flow, the stress on the runne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com