Catalyst for formaldehyde catalytic oxidation and preparation method of catalyst

A catalytic oxidation and catalyst technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as low reaction temperature, achieve good performance repeatability, Easy to scale production and maintain the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A catalyst used for the catalytic oxidation of formaldehyde is a core-shell structure, and the core is Co 3 o 4 , the shell is CeO 2 , the ratio of core to shell is calculated according to the mole percentage of Co and Ce metal atoms, as follows:

[0032] Co 97.60%

[0033] Ce 2.40%.

[0034] The preparation method of the catalyst used in the above-mentioned a kind of formaldehyde catalytic oxidation, promptly adopts co-current co-precipitation method at first to prepare Co 3 o 4 Catalyst particles, then in Co 3 o 4 Surface supported CeO on catalyst particles 2 Shell, its preparation process specifically comprises the following steps:

[0035] (1) Add 125 mL of Co(NO 3 ) 2 Solution I and 437.5mL Na with a concentration of 0.5mol / L 2 CO 3 Solution II is mixed according to the volume ratio of 1:3.5, and the volume of each drop is controlled to be 0.05–0.07mL. The resulting mixed solution is added dropwise to 30mL of Na 2 CO 3In the beaker of solution Ⅲ, cont...

Embodiment 1

[0045] Take the cobalt tetroxide powder obtained in step (1) of Example 1 as a control with a particle size of 200-250 mesh;

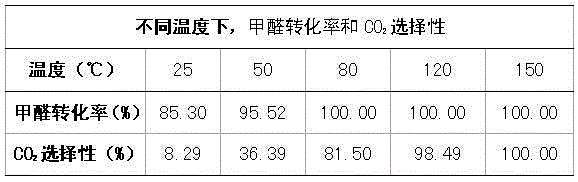

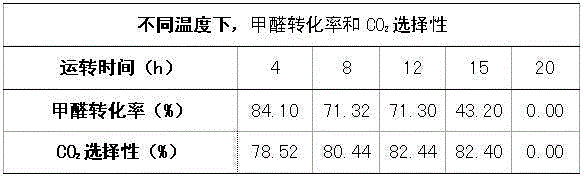

[0046] Mix 0.5 g of cobalt tetroxide powder with a particle size of 200-250 mesh obtained in Example 1 with an equal volume of quartz sand and fix it to the middle section of a reaction tube with an inner diameter of 6 mm in a micro-quartz tube fixed-bed reactor. N / min 2 After pretreatment at 200°C for 30 minutes under the atmosphere, then lower to room temperature, and then switch the reaction gas with a total flow rate of 50mL / min to carry out the catalytic reaction. In the reaction gas, the formaldehyde gas is 600ppm, the balance is air, formaldehyde gas By balance gas N 2 Bring it through a paraformaldehyde bubbler (water bath heated at 36°C). During the reaction process, the reaction temperature is controlled from 25°C, 50°C, 80°C, 100°C, 120°C, 150°C, 180°C, 200°C to 230°C. After each temperature point is reacted for 30 minutes, the reaction ta...

Embodiment 2

[0050] A catalyst used for the catalytic oxidation of formaldehyde is a core-shell structure, and the core is Co 3 o 4 , the shell is CeO 2 , the ratio of core to shell is calculated according to the mole percentage of Co and Ce metal atoms, as follows:

[0051] Co 95.55%

[0052] Ce 4.45%.

[0053] The preparation method of the catalyst used in the above-mentioned a kind of formaldehyde catalytic oxidation, promptly adopts co-current co-precipitation method at first to prepare Co 3 o 4 Catalyst particles, then in Co 3 o 4 Surface supported CeO on catalyst particles 2 Shell, its preparation process specifically comprises the following steps:

[0054] (1) Cobalt tetroxide powder with a particle size of 200-250 mesh, the specific process is the same as that in Example 1;

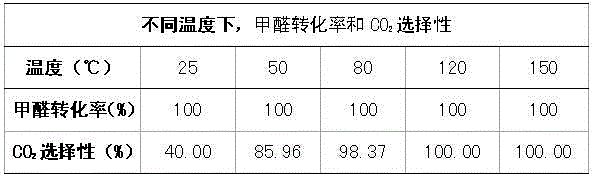

[0055] (2) Dissolve 1.439g of cerium nitrate hexahydrate salt in 50mL of water to obtain a cerium nitrate aqueous solution IV with a concentration of 0.066mol / L, add 5g of cobalt trioxide powder prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com