Sensorless direct-current brushless motor controller and control method thereof

A brushless DC motor and sensor technology, applied in the direction of electronic commutation motor control, single motor speed/torque control, control system, etc., can solve the problem of short service life of the whole machine, low output power efficiency, poor use of motor materials, etc. problems, to achieve the effect of low cost, stable and reliable performance, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

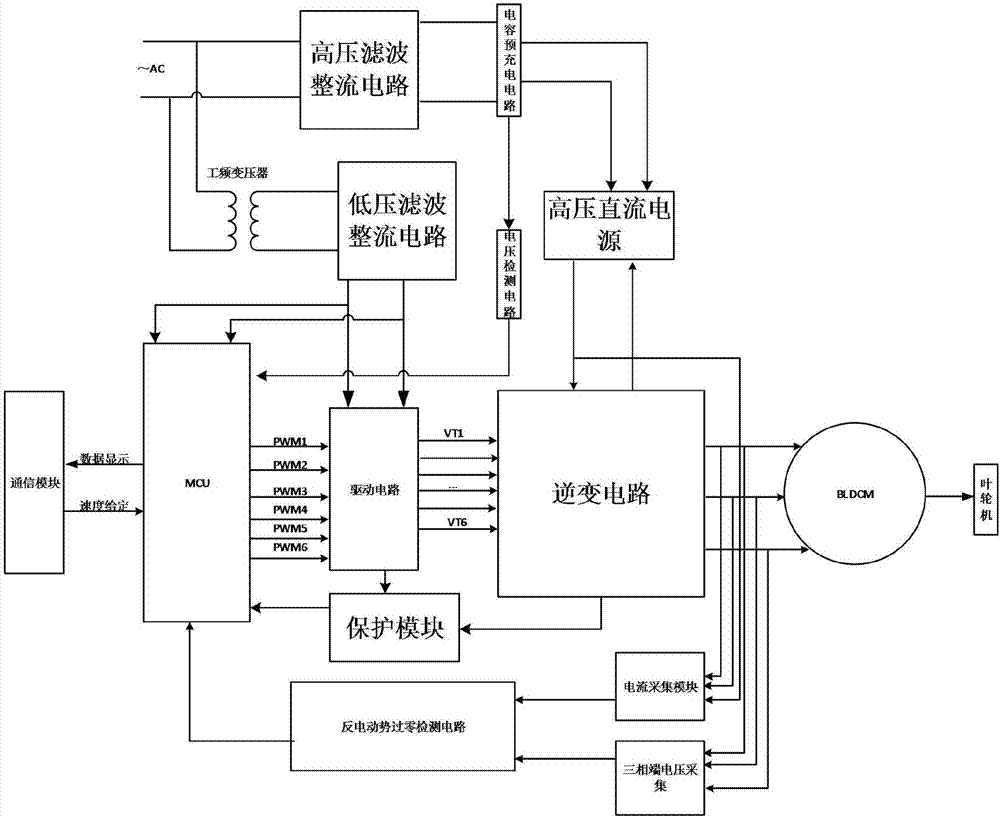

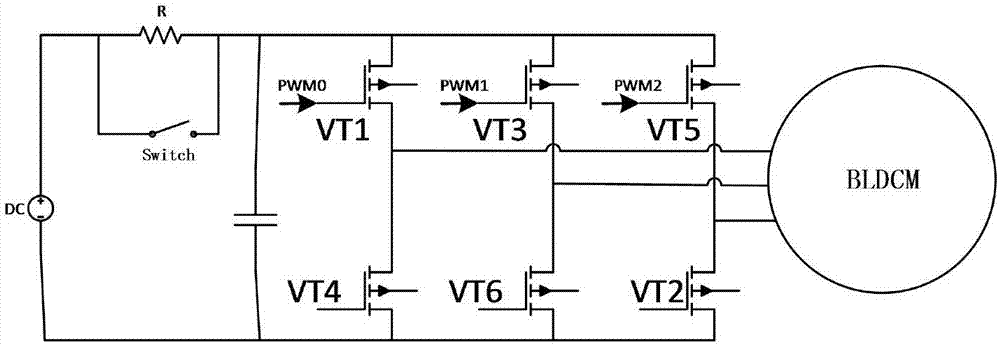

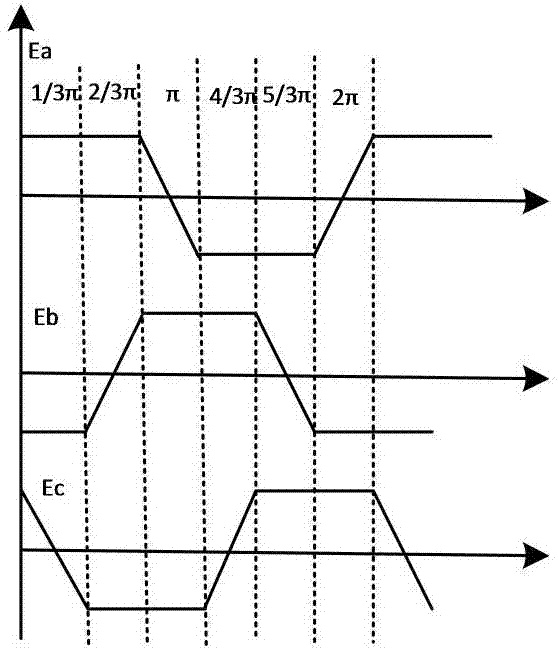

[0036] Figure 1 to Figure 5 As shown, it is a brushless DC motor controller based on a position sensor, which includes a power supply circuit, an MCU inverter control drive circuit and a sensorless detection circuit; the power supply circuit supplies power to the MCU inverter control drive circuit , and drive the DC brushless motor to work through the MCU inverter control drive circuit; the sensorless detection circuit detects the operating voltage and operating current of the DC brushless motor, and sends the detection result to the MCU inverter control drive circuit, the MCU inverter control drive circuit determines the counter electromotive force zero-crossing point according to the position detection midpoint method in combination with the ADC sampling method, and then delays the rotor 30° electrical angle to determine the commutation moment of the motor, so as to Drive the DC brushless motor to accelerate slowly until it reaches the predetermined speed.

[0037] The des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com