Photocatalytic self-cleaning fabric based on nano titanium dioxide

A nano-titanium dioxide, self-cleaning technology, applied in the field of clothing processing, can solve the problems of photocatalytic efficiency and light absorption range not ideal, and achieve the effect of large commercial value, high softness, and wide light absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A photocatalytic self-cleaning fabric based on nano-TiO2, including modified nano-TiO 2 Preparation, fabric pre-treatment, biological enzyme pre-treatment, anti-self-cleaning fabric preparation, cross-linking post-treatment, the specific operation steps are:

[0016] 1) Modified nano-TiO 2 Preparation: Slowly add 25 parts of absolute ethanol to 20 parts of tetrabutyl titanate, stir until mixed into a transparent solution, then add 4 parts of copper nitrate, stir well until uniform, then add deionized water drop by drop until a gel is formed, Modified Nano-TiO 2 , after doping metal copper ions of different valence states, due to the competition of copper ions for electrons, nano-TiO 2 The probability of recombination of photogenerated electrons and photogenerated holes on the surface is reduced, and more free radicals will be generated on the surface, which promotes the formation of nano-TiO 2 The absorption and utilization of visible light can improve the photocatal...

Embodiment 2

[0023] A photocatalytic self-cleaning fabric based on nano-TiO2, including modified nano-TiO 2 Preparation, fabric pre-treatment, biological enzyme pre-treatment, anti-self-cleaning fabric preparation, cross-linking post-treatment, the specific operation steps are:

[0024] 1) Modified nano-TiO 2 Preparation: Slowly add 20 parts of absolute ethanol to 20 parts of tetrabutyl titanate, stir until mixed into a transparent solution, then add 5 parts of copper nitrate, stir well until uniform, then add deionized water drop by drop until a gel is formed, Modified Nano-TiO 2 , after doping metal copper ions of different valence states, due to the competition of copper ions for electrons, nano-TiO 2 The probability of recombination of photogenerated electrons and photogenerated holes on the surface is reduced, and more free radicals will be generated on the surface, which promotes the formation of nano-TiO 2 The absorption and utilization of visible light can improve the photocatal...

Embodiment 3

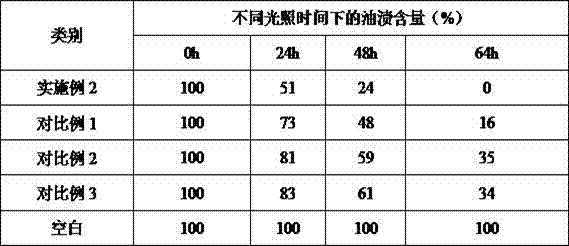

[0031] Self-cleaning and washability performance test:

[0032] Select invention embodiment 2, comparative example and blank to carry out self-cleaning test and washability test, wherein, comparative example 1: repeat the preparation process of the self-cleaning fabric in the embodiment, wherein, adopt unmodified nano-TiO 2 , all the other conditions remain unchanged; comparative example 2: repeat the preparation process of the self-cleaning fabric in the embodiment, wherein, the fabric is not subjected to biological enzyme pretreatment, and all the other conditions remain unchanged; comparative example 3: repeat the self-cleaning fabric in the embodiment Fabric preparation process, wherein the fabric is not subjected to post-crosslinking treatment, and other conditions remain unchanged. Blank is untreated raw fabric.

[0033] Self-cleaning test: red chili oil was selected as the stain, and local titration observation was carried out on the fabrics of the experimental group. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com