Patents

Literature

212results about How to "Does not affect other performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special plastic/acrylonitrile butadiene styrene (PC/ABS) alloy for notebook computer shell

ActiveCN101974218AExcellent surface hardnessImprove scratch resistanceGlass fiberPolymethyl methacrylate

The invention discloses a special plastic / acrylonitrile butadiene styrene (PC / ABS) alloy for a notebook computer shell. The formula comprises the following materials in parts by weight: 30-80 parts of polycarbonate, 5-65 parts of acrylonitrile-butadiene-styrene copolymer, 5-15 parts of compatilizer, 1-15 parts of flame retardant agent, 3-20 parts of filler, 1-10 parts of hardness modifier, 0.5-5 parts of anti-falling agent and 0-1 part of auxiliary agent. By adopting specific high-molecular polymers of polymethyl methacrylate (PMMA), ultrahigh-molecular polysiloxane and the like, the special PC / ABS alloy selects mineral fillers of specific-size mica, glass fiber and the like to carry out rematching therewith and generates synergistic effect, thus obviously improving the surface hardness and scraping resistance of the material and simultaneously having no influence on the other performances of the material. The PC / ABS alloy material has excellent impact resistance, surface scraping resistance and flame retardance, can meet the requirements of plastic for the notebook computer shell and has considerable promotion and application values.

Owner:大河宝利材料科技(苏州)有限公司

Novel high-silicon aluminum alloy electronic packaging material and preparation method thereof

InactiveCN102978485AImprove thermal stabilityHigh strengthSemiconductor/solid-state device detailsSolid-state devicesIngotElectronic packaging

A novel high-silicon aluminum alloy electronic packaging material and a preparation method thereof. The alloy of the present invention consists of the following ingredients, in percentage by mass: 12-40% of Si, 0.3-0.6% of Fe, 0.3-0.45% of Mn, 0.3 to 0.5% of Mg, and the balance being industrial pure aluminum. Spray deposition is used to prepare ingots; and then a plurality times of small deformation thermal densification are carried out for the ingots after annealing for elimination of thermal stress, to prevent cracking of the alloy during processing, thereby enhancing the density of the material. The alloy of the present invention has the characteristics of high strength, low coefficient of expansion, high thermal conductivity and good air tightness.

Owner:CHANGSHA HUAXI METAL MATERIAL

Negative electrode slurry of lithium ion battery, positive electrode of lithium ion battery prepared by slurry and battery

ActiveCN103515607AThe compacted density does not decreaseHigh porosityActive material electrodesSecondary cellsPore distributionHigh energy

The invention provides negative electrode slurry of a lithium ion battery, a positive electrode of the lithium ion battery prepared by using the slurry, and the battery. The negative electrode slurry comprises a negative-electrode active material, a bonding agent, a solvent and a pore-forming agent, wherein the pore-forming agent is selected from one or more in azo-compound and / or sulfonylhydrazine compound. The slurry, the positive electrode and the battery have the advantages that under the condition of guaranteeing no reduction of the compaction density of a negative electrode piece, the porosity of the electrode piece can be increased, the uniformity of pore distribution is increased, the effective area of a liquid phase for conducting lithium ions is improved, the high energy density of the battery is guaranteed, simultaneously the rate capability and the low-temperature performance of the battery are improved and simultaneously the capacity is also improved.

Owner:BYD CO LTD

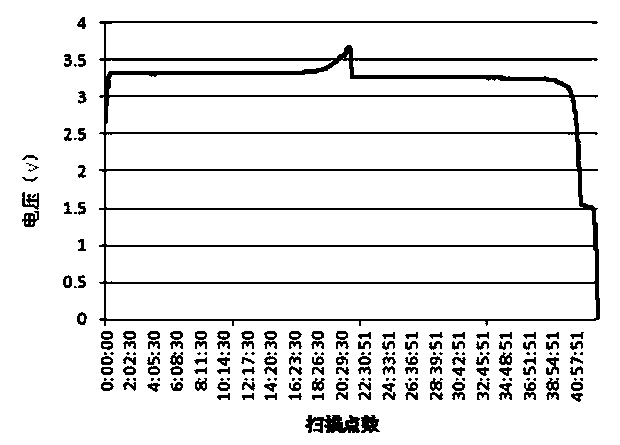

Lithium ion battery

ActiveCN103700860AExcellent anti-over-discharge abilityImprove performanceCell electrodesSecondary cellsLithium iron phosphateGraphite

The invention provides a lithium ion battery. The lithium ion battery comprises a shell, and an electrode group and an electrolyte which are sealed in the shell, and the electrode group comprises a positive electrode, a negative electrode and a diaphragm positioned between the positive electrode and the negative electrode, wherein the positive electrode comprises a positive conductive matrix and a positive material adhered to the positive conductive matrix, and the positive material comprises a lithium iron phosphate positive active material, a lithium-containing additive, iron phosphate, a conductive agent and a positive binder; the lithium-containing additive is selected from one or more of Lix1Niy1Mnz1O2, Lix2M1y2Oz2, a silicate series positive active material and Lix3M2(WOz3), and the primary particle diameter of iron phosphate is not lower than 20mum; and the negative electrode comprises a negative conductive matrix and a negative material adhered to the negative conductive matrix, the negative material comprises a negative active material and a negative binder, and the negative active material comprises graphite and lithium titanate. The over-discharge resistance capability of the lithium ion battery made in the invention is excellent.

Owner:BYD CO LTD

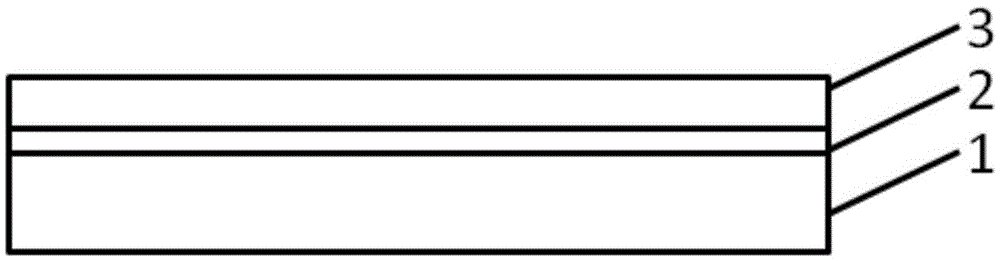

Graphene-doping conductive polymer modified metal bipolar plate of proton exchange membrane fuel cell and preparation method of metal bipolar plate

ActiveCN105552399ADoes not affect other performanceLow corrosion current densityFinal product manufactureCollectors/separatorsConductive polymerPre treatment

The invention relates to a graphene-doping conductive polymer modified metal bipolar plate of a proton exchange membrane fuel cell and a preparation method of the metal bipolar plate, belonging to the technical field of a fuel cell. The bipolar plate comprises a metal plate, a polarity oxide film layer and a graphene-doping conductive polymer film layer, wherein the polarity oxide film layer covers the surface of the metal plate, the graphene-doping conductive polymer film layer covers the surface of the polarity oxide film layer, and the thickness of the graphene-doping conductive polymer film layer is 0.005-0.3 millimeter, the thickness of the polarity oxide film layer is 5-30 nanometers, and the thickness of the metal plate is 0.1-2 millimeters. A graphene-doping conductive polymer film is deposited on the surface of a stainless steel plate after preprocessing by an electrochemical synthesis method, the metal bipolar plate prepared according to the invention has the advantages of relatively low contact resistance, low corrosion current density and high bonding firmness of the metal substrate and the conductive polymer film, moreover, the method is simple, the processing cost is low, and mass production can be achieved.

Owner:HUBEI UNIV +1

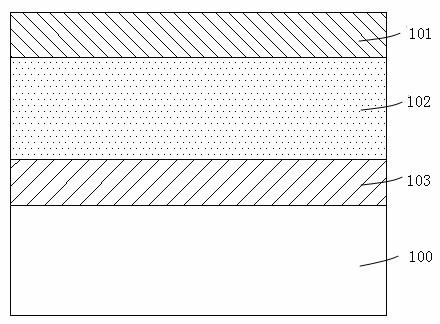

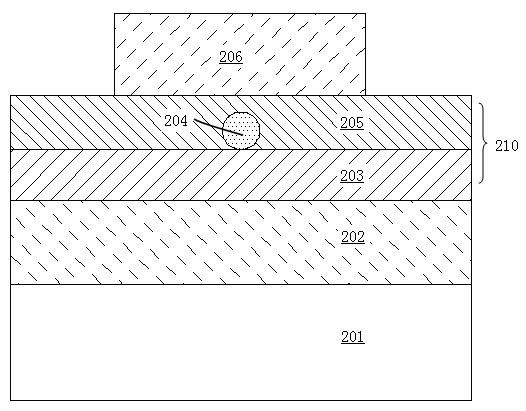

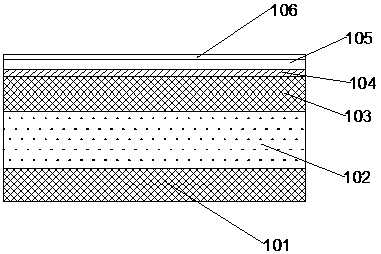

Flexible nanodot resistive random access memory (RRAM) based on all low-temperature process and manufacturing method thereof

The invention belongs to the technical of low-temperature Atomic Layer Deposition (ALD), and particularly relates to a flexible nanodot resistive random access memory (RRAM) based on all low-temperature process and a manufacturing method thereof. The method comprises the steps: at first, growing a bottom electrode on a flexible substrate by using a low temperature PVD (Physical Vapor Deposition) method, then growing an oxide layer through a low temperature ALD method; growing nanodots and then growing another oxide layer through the low temperature ALD method;and finally growing a top electrode. The nanodots accessed to the oxide layer can effectively improve the stability of high / low resistant state transformation of the RRAM and reduce the occurrence possibility of errors, thereby solving the problems regarding reliability and practicability. The method can be applied to the manufacturing of flexible low-temperature memory in the future, and change the packaging and existing manner of the memory at present, enables the folding and bending of portable memories to be possible.

Owner:FUDAN UNIV

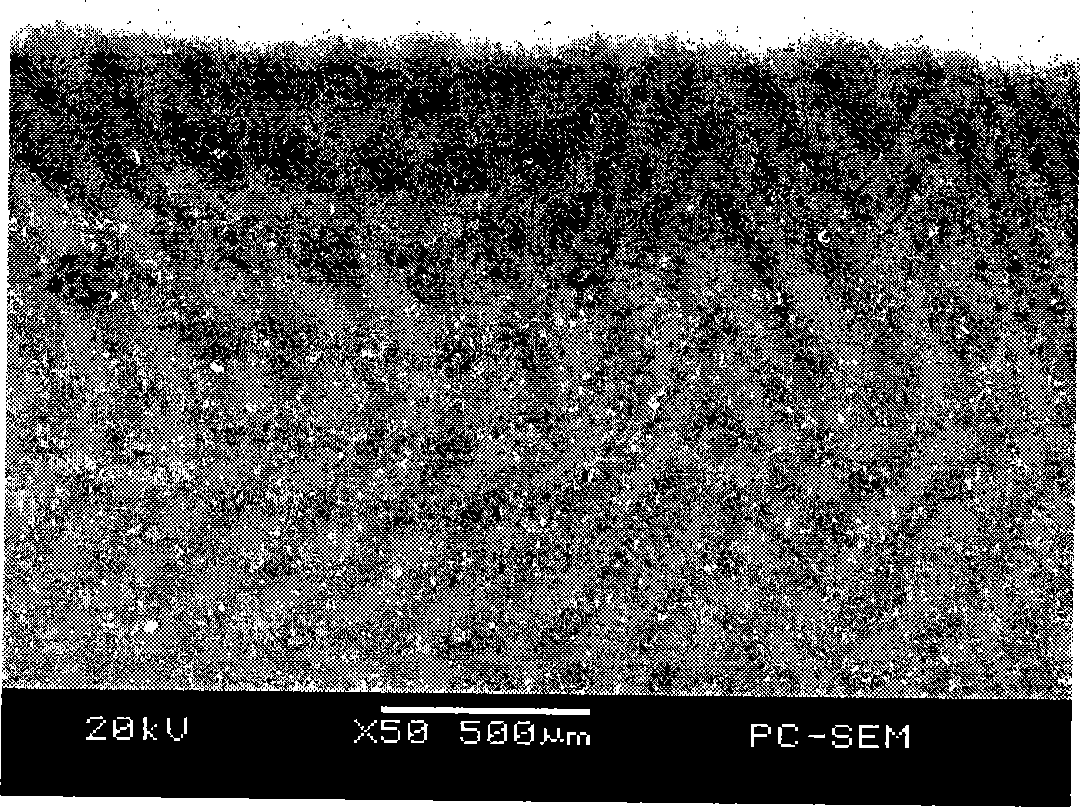

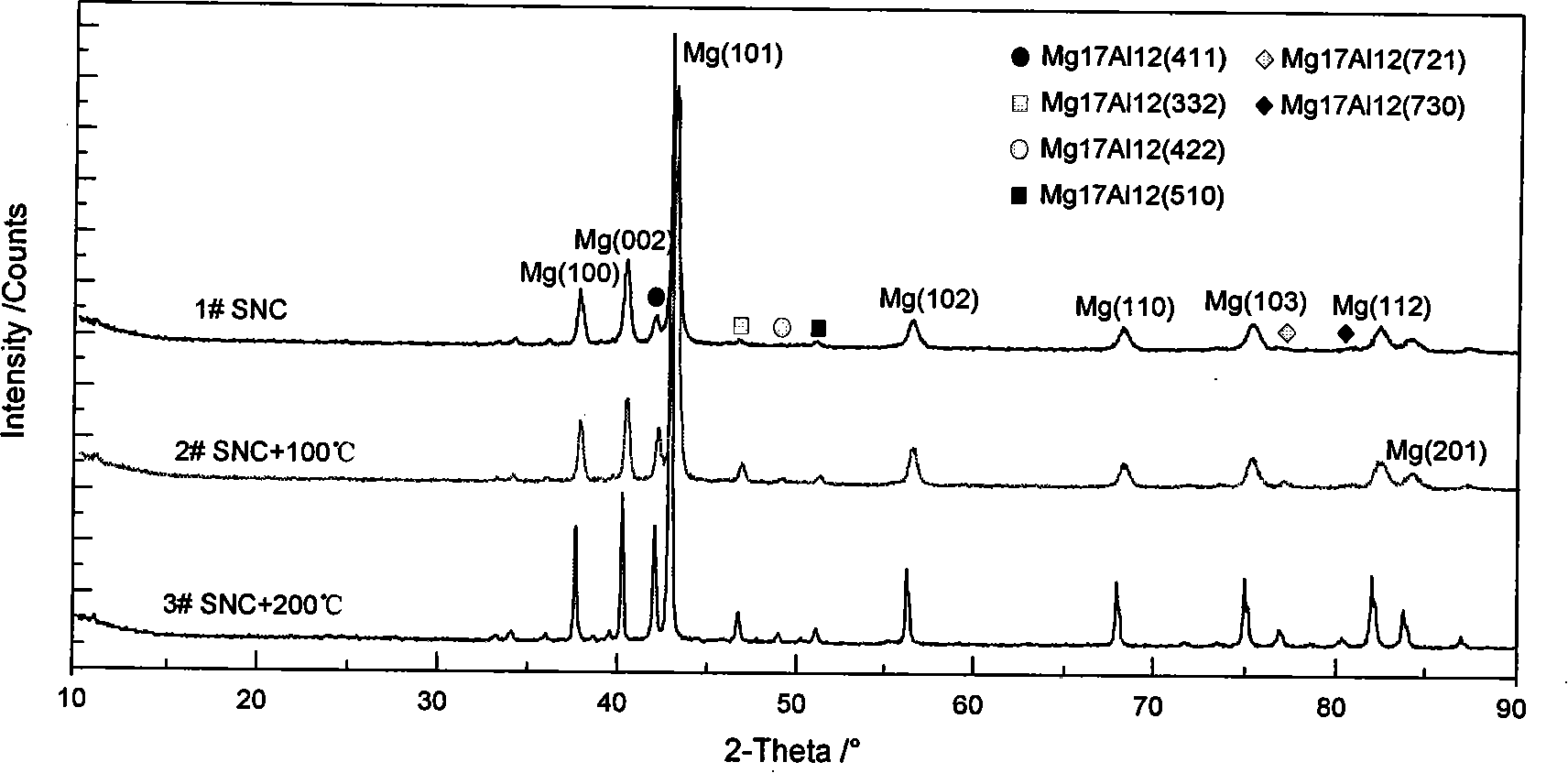

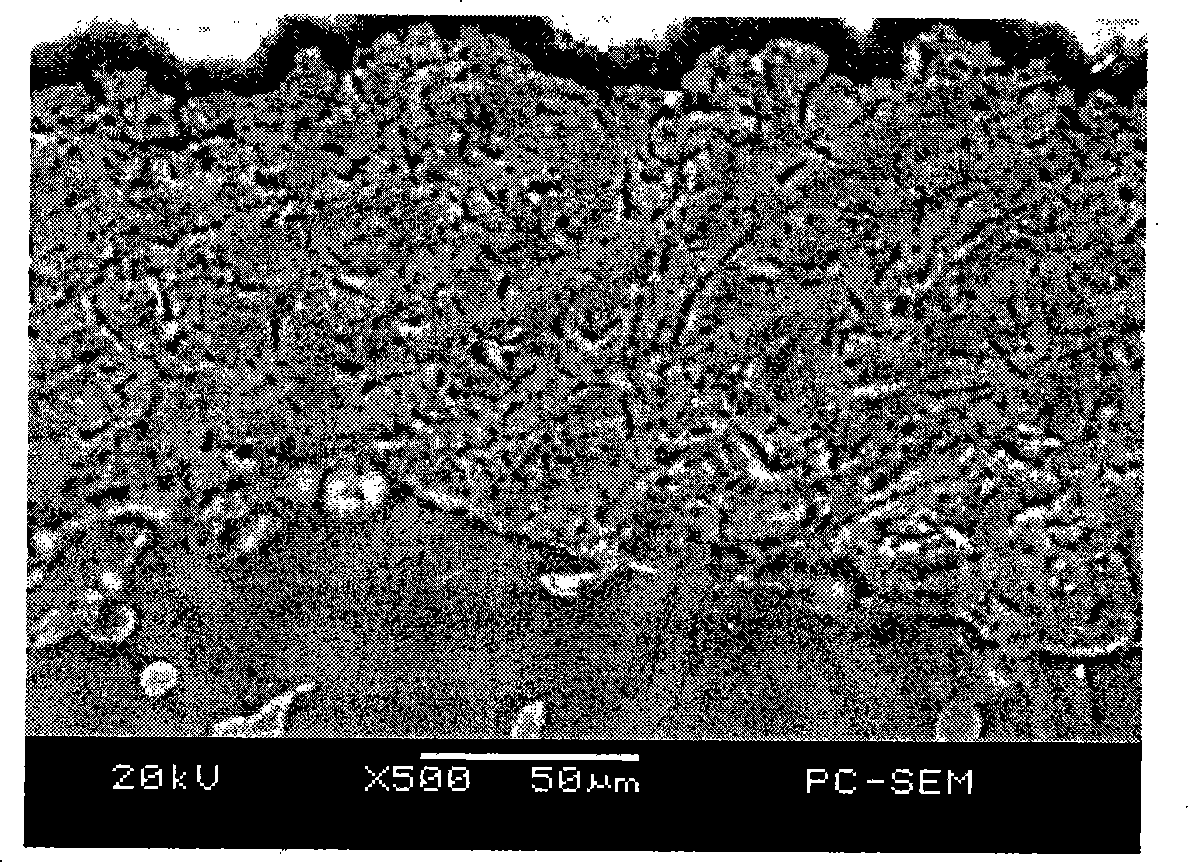

Method for reducing diffusion temperature of magnesium alloy surface spraying coating

InactiveCN101161853AIncreased diffusion rateImprove diffusion abilityMolten spray coatingNano sizeThermal spraying

The invention provides a method for reducing the diffusion temperature of spraying coating of magnesium alloy surface. First, nanocrystallization treatment is done on the magnesium alloy surface before the hot spray coating is done on the magnesium alloy matrix surface, which ensures the thinning of the crystal grain on the magnesium surface to the size of nanometer and eliminates the roll scale of the magnesium surface and coarsening to increase the mechanical riveted bonding force of matrix and coating; and then the magnesium alloy surface is hot sprayed by aluminum or zinc or a zinc / aluminium complex coating; finally, the magnesium alloy is treated to preserve heat in an ordinary heat treatment furnace at a temperature of 200 to 400 degrees, which facilitates the coating and the matrix to form metallurgical bonding. The invention adopts the surface nanocrystallization technique, which can not only reduce the diffusion temperature of spraying coating of magnesium alloy surface, but also avoid the necessary sand blasting pretreatment technology before spray finishing. In addition, special processing step is not needed, which eliminates the roll scale of the matrix surface and coarsening surface and ensures that a layer of nanocrystal is formed on the magnesium alloy matrix surface, thereby saving the processing time before spray finishing and raising the productivity effect.

Owner:重庆工学院

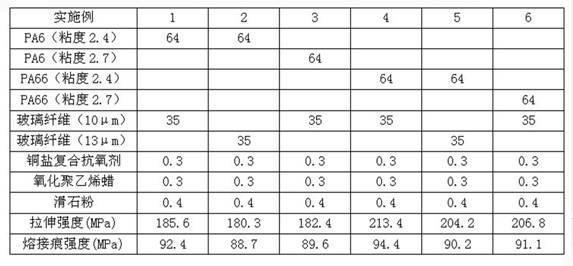

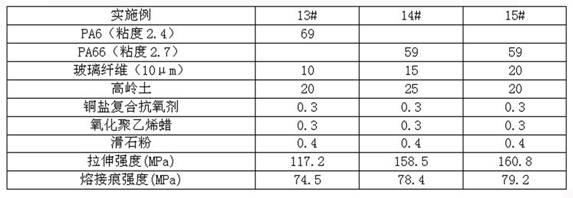

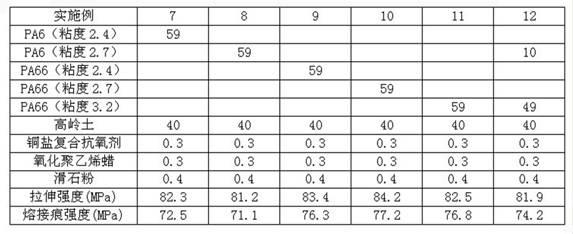

Modified nylon material with high weld line strength and preparation method thereof

InactiveCN102153860AImprove weld line strengthDoes not affect other performanceAntioxidantInorganic filler

The invention relates to a modified nylon material with high weld line strength and a preparation method thereof. The modified nylon material with high weld line strength comprises the following components in percentage by weight: 38.2-94.7% of nylon resin, 5-60% of inorganic filler, 0.1-0.6% of antioxidant, 0.1-0.6% of lubricant and 0.1-0.6% of talcum powder with the particle diameter being smaller than 1 micron, wherein the inorganic filler is chopped alkali-free glass fiber or kaolin processed by using a silane coupling agent. In the invention, the specially appointed inorganic filler processed by using the specially appointed coupling agent is added to the processing formula of the nylon material, thus the dispersity of the inorganic filler in the nylon resin and the interfacial binding force of the inorganic filler with the nylon resin can be effectively modified, and the weld line strength of the nylon material is enhanced. Furthermore, the inorganic filler is fed into an extruder for extrusion processing from a side feed inlet in the form of lateral feeding during the preparation of the nylon material, thus the structure of the inorganic filler can be prevented from being damaged due to long-time mixing, and the further guarantee is provided for the excellent service performance of the nylon material.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

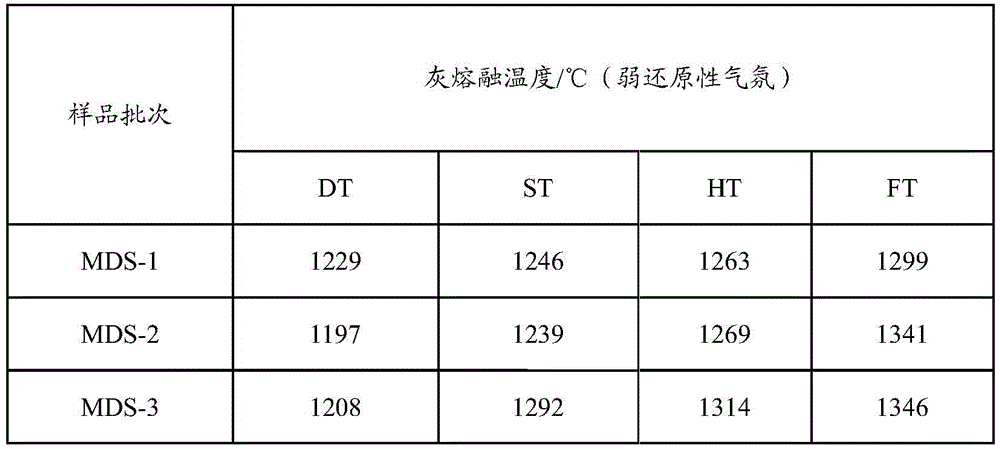

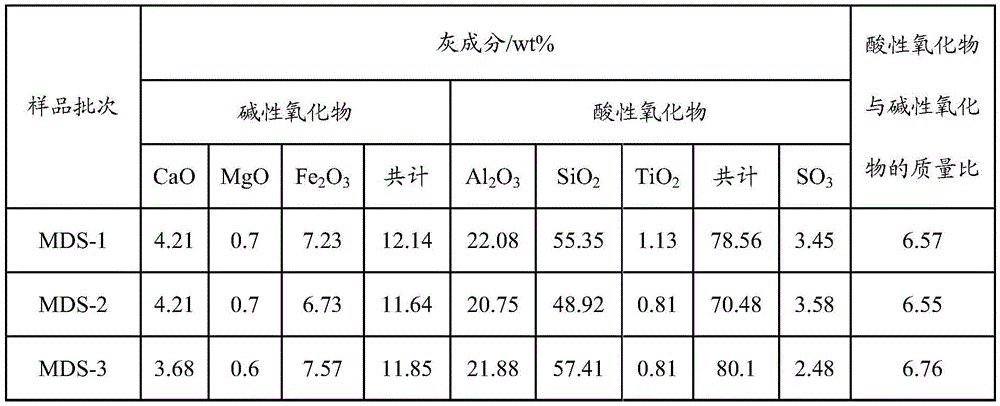

Method for lowering fusing temperature of coal ash

ActiveCN105542901ALower melting temperatureImprove applicabilitySolid fuelsFuel additivesCoal waterMass ratio

The invention provides a method for lowering a fusing temperature of coal ash. The method comprises the step of adding a fusing assistant into feed coal, wherein the mass ratio of acidic oxides to alkaline oxides in the coal ash resulting from the ashing of the feed coal is greater than 6.5; and the addition level of the fusing assistant is such that the mass ratio of the acidic oxides to the alkaline oxides in the coal ash resulting from the ashing of a mixture of the feed coal and the fusing assistant is 1.5 to 4.5. The method provided by the invention has outstanding applicability, has practical guiding significance in specific industrial coal and is particularly applicable to coal types, of which the mass ratio of the acidic oxides to the alkaline oxides is large; proceeding with adjustment on the ash ingredient ratio of the coal ash, the addition level of the fusing assistant can be adjusted according to different ash ingredients of different feed coals, so that the flexibility is high, and the applicability is high; the fusing assistant is wide in source and low in cost, so that the production cost cannot be increased markedly; and the method is easy and feasible, and the fusing assistant and the feed coal can be subjected to industrial grinding simultaneously and be mixed uniformly, so that the method is applicable to a gas-flow bed technology for coal-water slurry and dry powder coal gasification.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

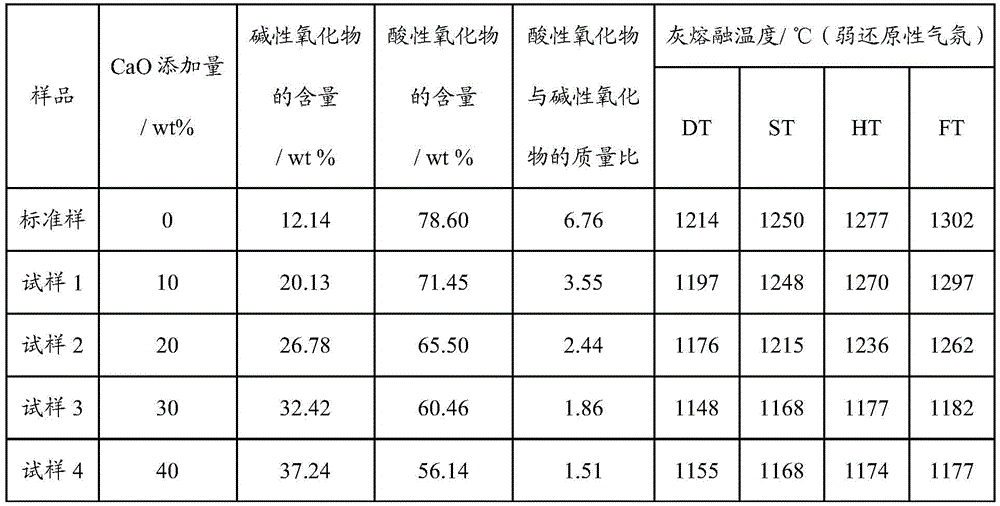

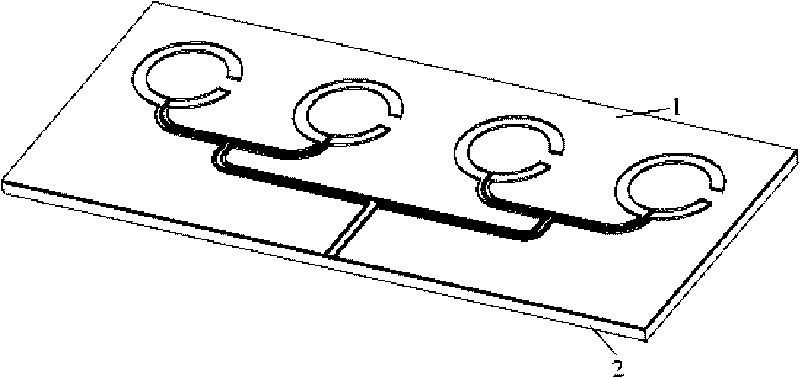

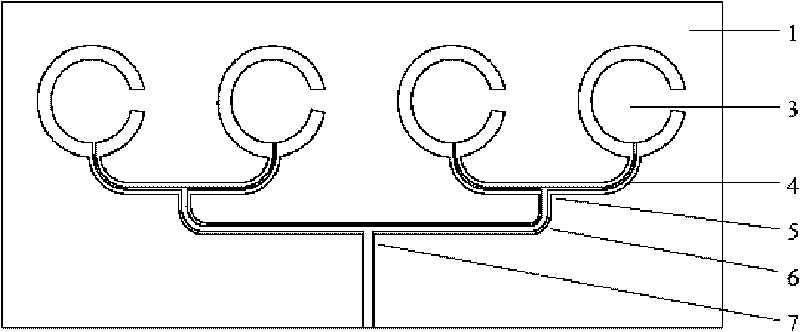

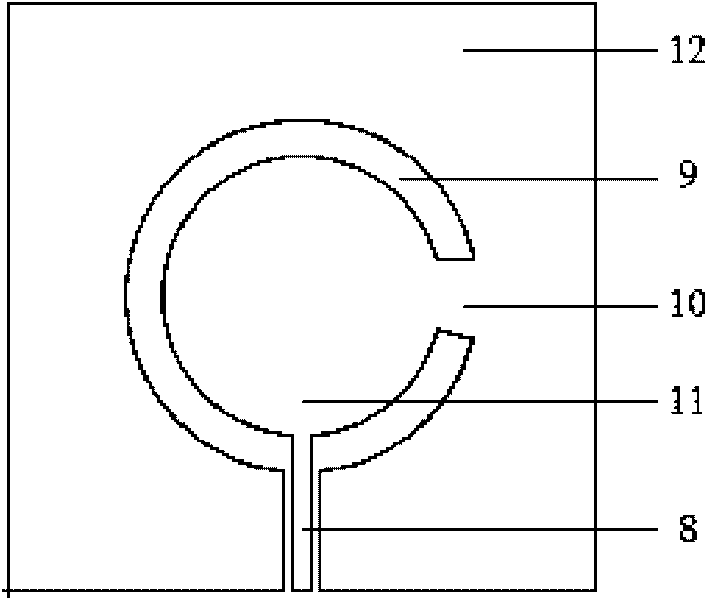

Multi-layer three-dimension suspending unidirectional broadband circle polarized millimeter wave plane gap antenna

InactiveCN101102012AFunction as cut-off reflectionRealize one-way radiationSlot antennasCoplanar waveguideOptoelectronics

The invention is concerned with a kind of multi-layer three-dimensional impending unilateralism and broad-band entelechy millimeter wave plane gap antenna, belonging to communication technology field, relating to circular metal gap inducting layer, microwave medium layer, entelechy gap radiation unit for coplanar wave-guide feeding, supporting layer and circular metal gap layer to cut off reflection of wave-guide. The circular metal gap inducting layer sets on a side of microwave medium layer, while entelechy gap radiation unit, circular metal gap layer and supporting layer are on the other side. The entelechy gap radiation unit for coplanar wave-guide feeding connects with microwave medium layer, and circular metal gap layer to cut off reflection of wave-guide connects with entelechy gap radiation unit for coplanar wave-guide feeding through the supporting layer. This invention is easy to adjust the size of coplanar wave-guide feeding to match with impedance and to prepare. It reaches the demand of entelechy and broad-band, unilateralism radiation and enhances plus of antenna remarkably.

Owner:SHANGHAI JIAO TONG UNIV

Method for decreasing acrylic ester rubber glass-transition temperature

Owner:BEIJING UNIV OF CHEM TECH

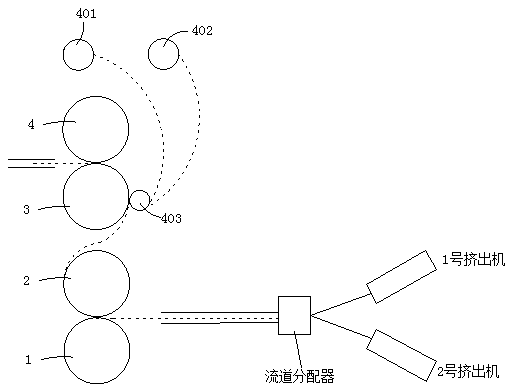

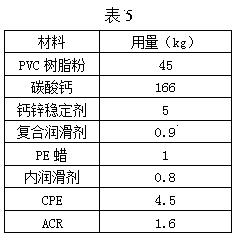

Co-extruded SPC stone-plastic floor

ActiveCN110593520ADoes not affect other performanceNo thermal expansion and cold contraction deformationFlooringWear resistantThermal expansion

The invention belongs to the field of synthetic floors, and particularly relates to a co-extruded SPC stone-plastic floor. The co-extruded SPC stone-plastic floor comprises a stone-plastic base material layer forming a floor main body, a decoration layer arranged on the stone-plastic base material layer, a wear-resistant layer arranged on the decoration layer and a UV coating arranged on the wear-resistant layer. The stone-plastic base material layer is composed of an elastic layer, an intensity layer and a stable layer. The stone-plastic base material layer is formed through a co-extrusion mode. According to the co-extruded SPC stone-plastic floor, thermal expansion and contraction deformation can be ensured, other performances of the floor are not affected, and the cost is low.

Owner:ZHEJIANG YONGYU FURNITURE CO LTD

Low-dielectric high-toughness reinforced PBT/PPO (polybutylene terephthalate/polyphenylene oxide) composition and preparation method thereof

InactiveCN109575528AExcellent dielectric propertiesImprove mechanical propertiesPolytetramethylene terephthalateGlass fiber

The invention relates to a low-dielectric high-toughness reinforced PBT / PPO (polybutylene terephthalate / polyphenylene oxide) composition and a preparation method thereof. The low-dielectric high-toughness reinforced PBT / PPO composition is made from, by weight, 45-85 parts of PBT and 15-55 parts of PPO, adding up to 100 parts, as well as 20-40 parts of glass fiber, 6-14 parts of a compatibilizer, 0.6-1 part of an antioxidant, 5-20 parts of polytetrafluoroethylene, 0.2-1 part of a plasticizer, 0.2-1 part of a silane coupling agent, wherein the weight ratio of the plasticizer to the silane coupling agent is 1:1 to 5:1. The PBT / PPO composition can meet the high requirements of the fields, such as electronic and electrical engineering, integrated circuit packaging and electromagnetic wave shielding, for dielectric properties, strength and toughness.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

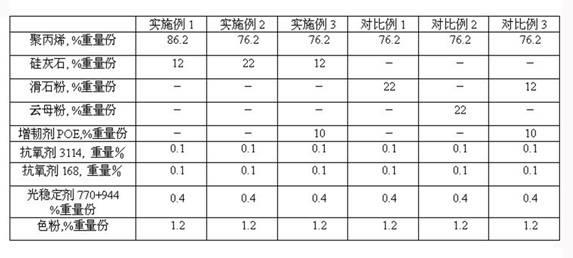

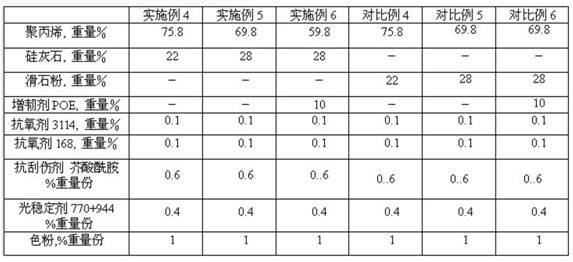

Anti-scratching polypropylene composite material and preparation method thereof

InactiveCN102181093AImprove scratch resistanceScratch Resistance GuaranteePolypropylene compositesMetallurgy

The invention relates to an anti-scratching polypropylene composite material and a preparation method thereof. The formula of the composite material comprises the following components in percentage by weight: 55 to 95 percent of polypropylene, 1 to 30 percent of aedelforsite, 0 to 30 percent of inorganic filler, 0 to 30 percent of toughening agent, 0.1 to 1 percent of main antioxidant, 0.1 to 1 percent of auxiliary antioxidant, 0 to 1 percent of anti-scratching agent, 0.1 to 2 percent of light stabilizer and 0 to 5 percent of other auxiliary agent. By adding the needle-like or needle-like crystal aedelforsite powder into the processing formula of the polypropylene material, the anti-scratching performance of the material can be effectively improved, the mechanical property of the material is improved, and meanwhile, other using properties of the material are not affected. In the preparation process of the polypropylene material, the aedelforsite powder is fed into an extruder from a second feeding hole in a lateral feeding form and extruded, so the structure of the aedelforsite can be prevented from being damaged by long-time mixing; and the processing method is skilful in design and simple in operation, can further ensure the anti-scratching performance of the material, and can also improve the mechanical property of the material.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

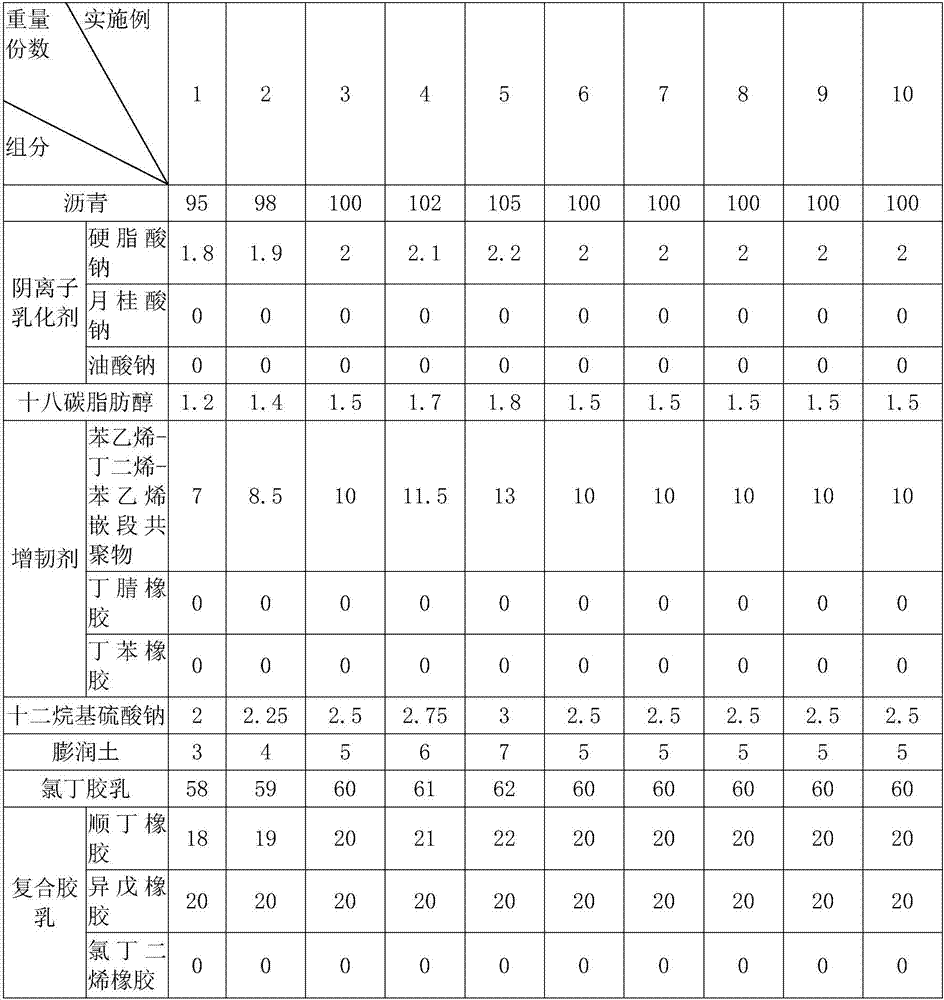

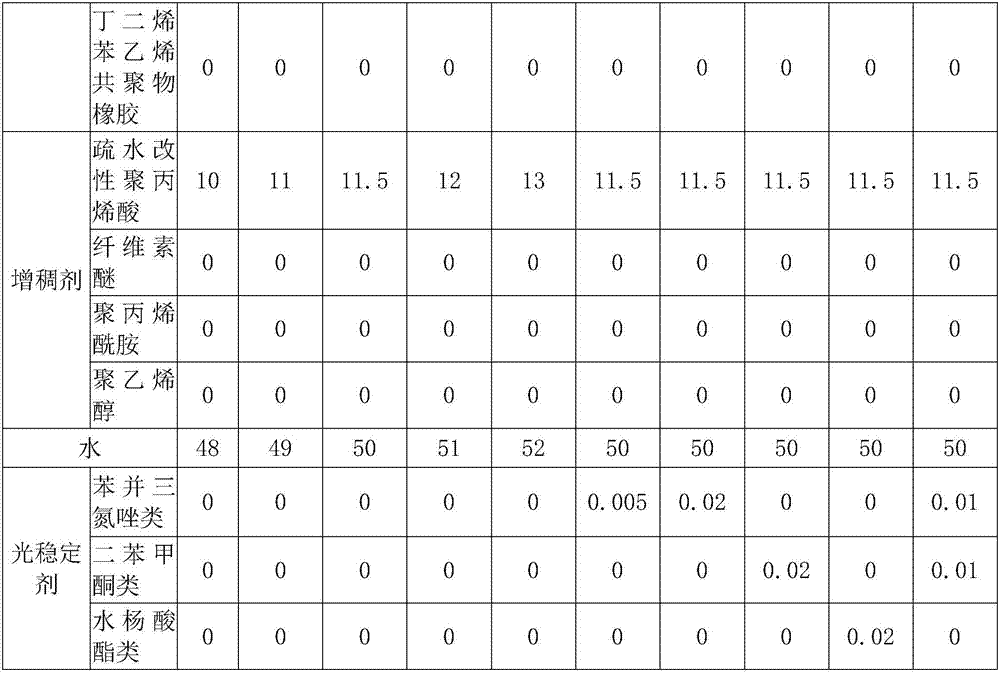

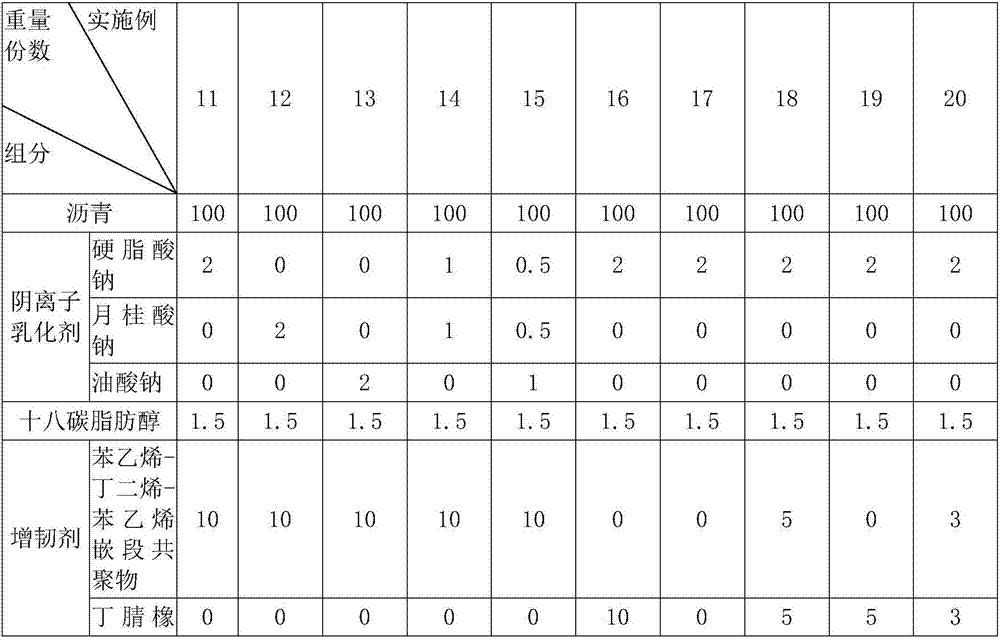

Non-cured rubber asphalt waterproof coating and preparation method thereof

ActiveCN107325729AGood adhesivenessImprove stabilityFireproof paintsChloropene polymer coatingsBituminous waterproofingSodium Bentonite

The invention discloses a non-cured rubber asphalt waterproof coating and a preparation method thereof. The waterproof coating comprises the following raw materials in parts by weight: 95-105 parts of pitch, 1.8-2.2 parts of an anionic emulsifier, 1.2-1.8 parts of Eighteen carbon fatty alcohol, 7-13 parts of a flexibilizer, 2-3 parts of lauryl sodium sulfate, 3-7 parts of bentonite, 58-62 parts of neoprene latex, 38-42 parts of compounded latex, 10-13 parts of a thickener, and 48-52 parts of water; and the solid content of the compounded latex is 40%-50%. The waterproof coating is cold-applied, can be blade-coated or rolling-coated, is widely suitable for places of roofs, garages and basements, factory buildings and the like, especially suitable for places such as substations, pharmaceutical factories, oil refinery and the like requiring fire proofing and explosion proofing, is safe and free from fire disaster risks, capable of saving a great amount of fuel gas energy, and incapable of releasing carcinogenic gases such as phenol, naphthalene, anthracene, benzene, pyrene, chlorine and the like, thus being environment-friendly and pollution-free. Under the action of piezoresistivity and creep resistance performances, the damaged part can be self-repaired so as to always keep the completeness of a waterproof layer, so that the waterproof performance is excellent.

Owner:上海京球新材料科技有限公司

Ultraviolet resistant cold-feeling finishing fabric and processing method, and application of silica coated dodecanol microcapsule to fabric

InactiveCN102720054AUV resistantHas a cooling effectVegetal fibresPolyurethane adhesivePolymer science

The invention discloses an ultraviolet resistant cold-feeling finishing fabric and a processing method thereof, and application of a silica coated dodecanol microcapsule to ultraviolet resistant cold-feeling finishing fabric. The fabric is characterized in that the inner surface and outer surface of the fabric and the interior of the fabric are distributed with silica coated dodecanol microcapsules. The processing method of the fabric comprises the step that the silica coated dodecanol microcapsules are finished to the fabric by using a padding method. The microcapsule particles have size distribution of 0.2-6 mum; in the padding process, rolling waste rate is 80-90%; a capsule dosage is 40-60g / L; drying conditions include a temperature at 80-100 DEG C and a time of 3-5 min; and baking conditions include a temperature at 140-160 DEG C and a time of 1-2 min. A polyurethane adhesive can be used together with the microcapsules. The fabric has ultraviolet resistant and cold-feeling effects.

Owner:SHANGHAI JIALE

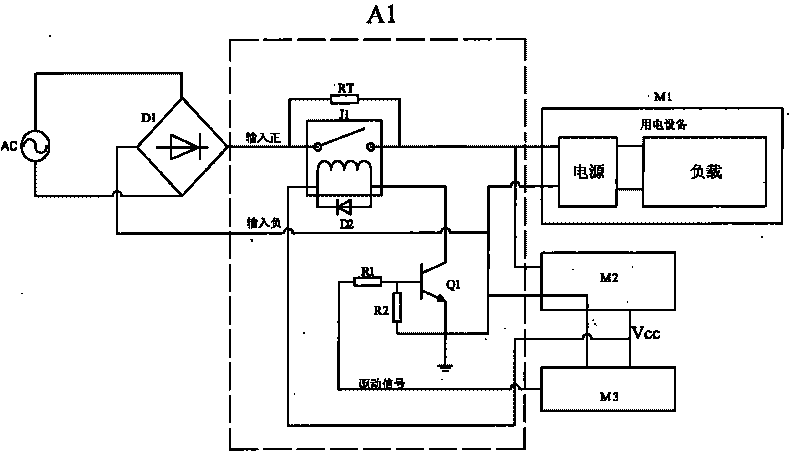

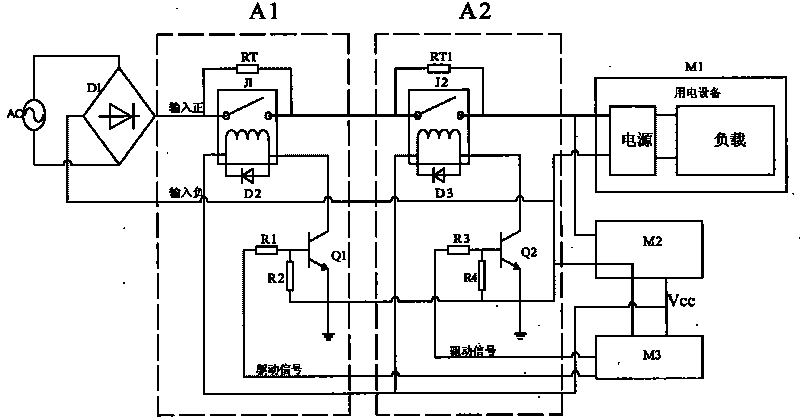

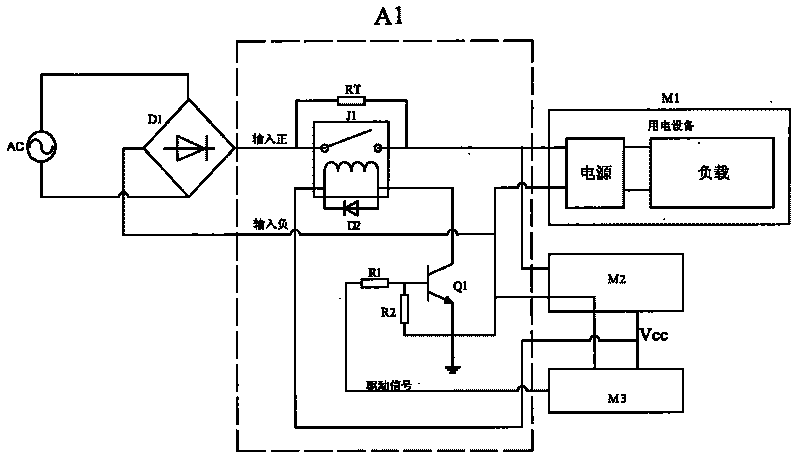

Surging current suppression method

InactiveCN101694938AInhibit high current shockSuppress surge currentEmergency protective arrangements for limiting excess voltage/currentPower gridElectromagnetic interference

The invention discloses a surging current suppression method, which belongs to the application technology of device power ports. The method is formed as follows: at least one surging current suppression circuit is in series connection between an electric equipment power port and a commercial power, and large current impacts produced when electric equipment is started routinely can be effectively suppressed by adjusting impedance of an electric equipment power terminal through the surging current suppression circuit. The surging current suppression method can simultaneously guarantee power supply quality of a power network, avoid producing severe electromagnetic interference and not affect other properties of equipment while effectively suppress surging current.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

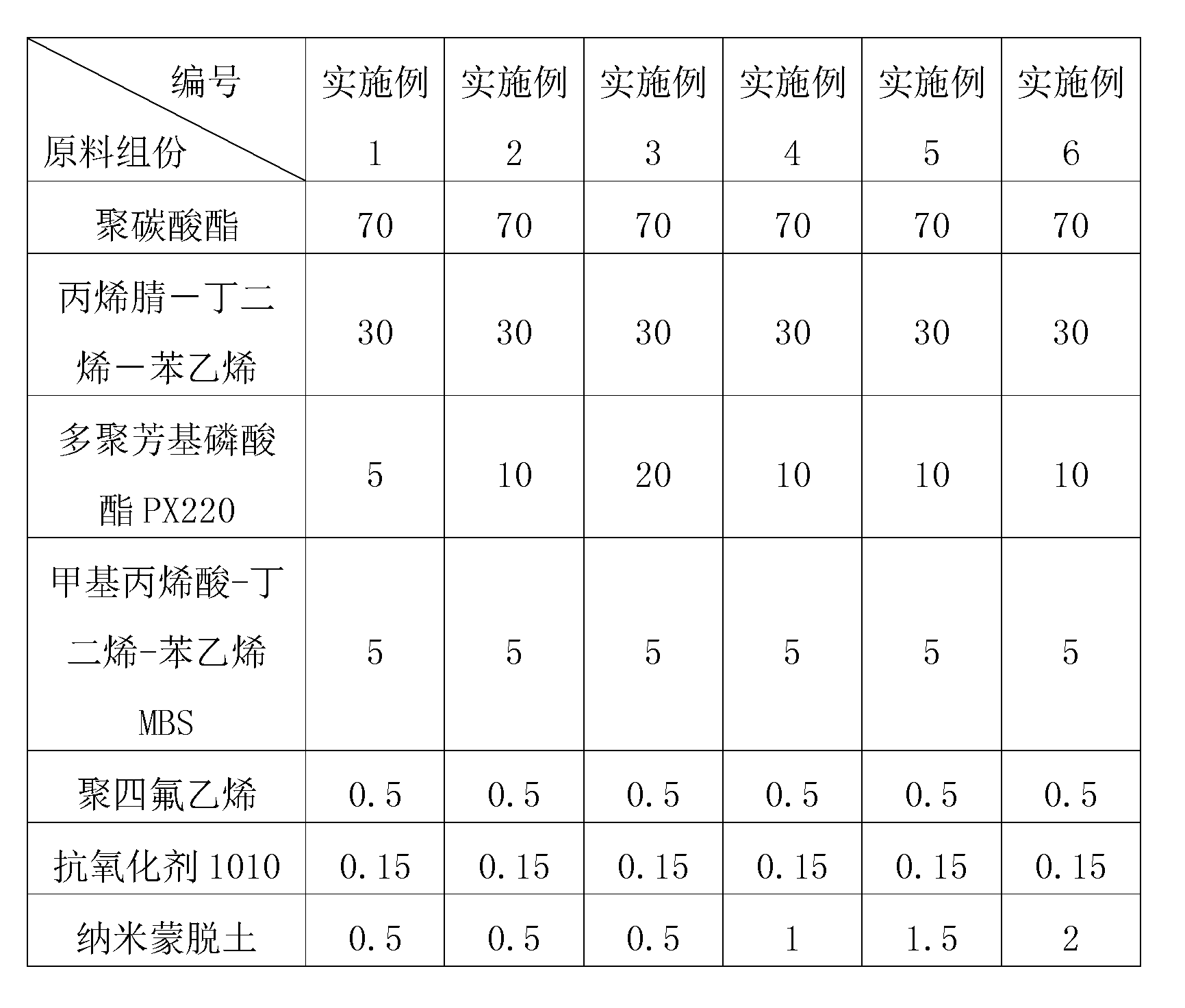

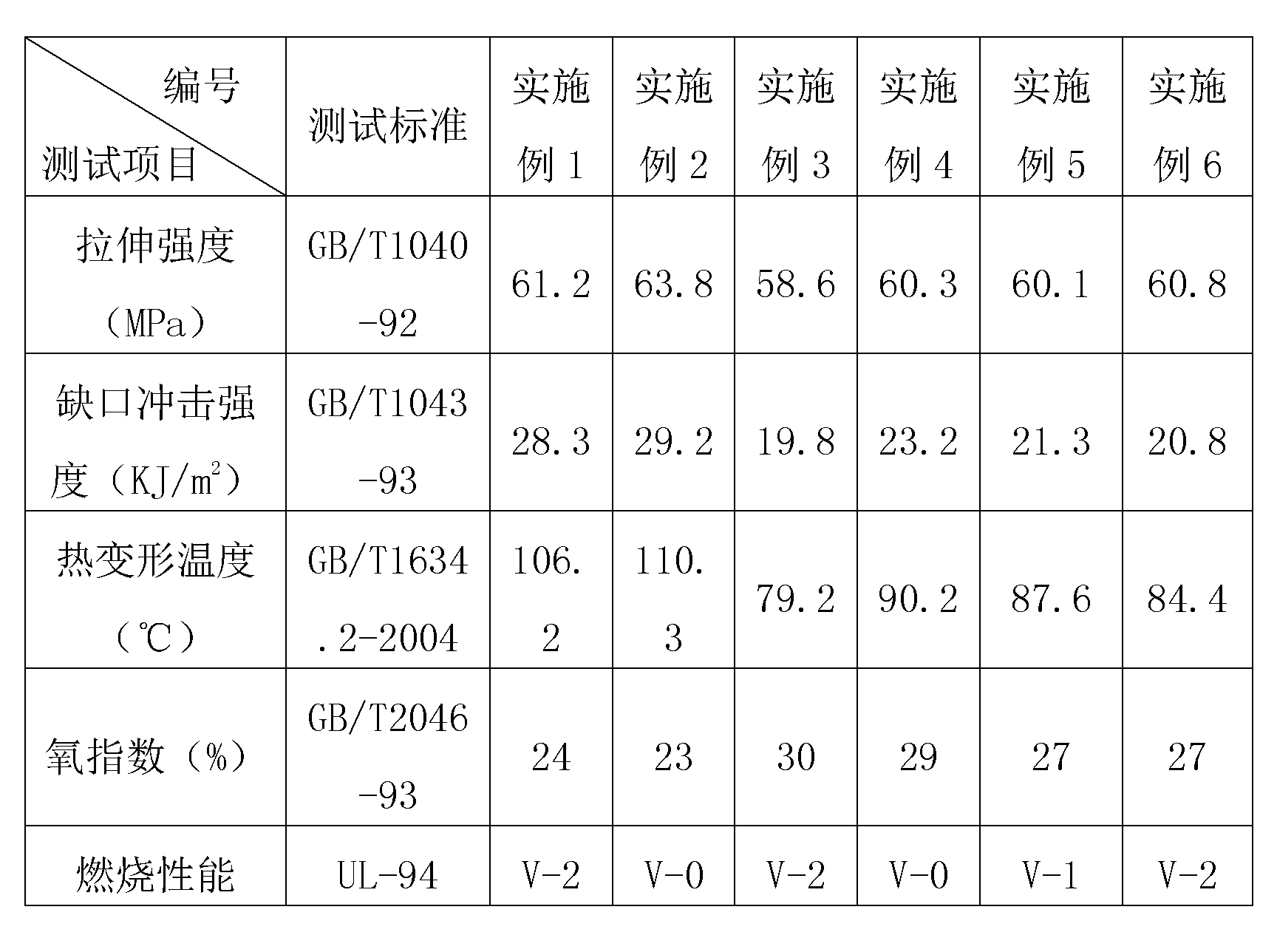

High-performance halogen-free flame-retardant PC/ABS alloy material and preparation process thereof

The invention discloses a high-performance halogen-free flame-retardant PC / ABS alloy material and a preparation process thereof. Raw materials for the material comprise main materials and accessory materials, wherein the main materials comprise, by weight, 70 parts of polycarbonate and 30 parts of acrylonitrile-butadiene-styrene, and the accessory materials comprise, on the basis of 100 parts of the main materials, 5 to 20 parts of a fire retardant, 0 to 5 parts of a compatilizer, 0 to 0.5 part of polytetrafluoroethylene and 0 to 0.15 part of an anti-oxidant. The alloy material prepared in the invention has a unique self-extinguishing character, good processability, compatibility and thermal stability; the addition amount of the fire retardant in the whole alloy material is obviously decreased compared with the addition amount of a fire retardant in the prior art, good flame resistance is obtained while other performances of the alloy material are not influenced, and obviously decreased addition amount of the fire retardant is beneficial for environmental protection.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

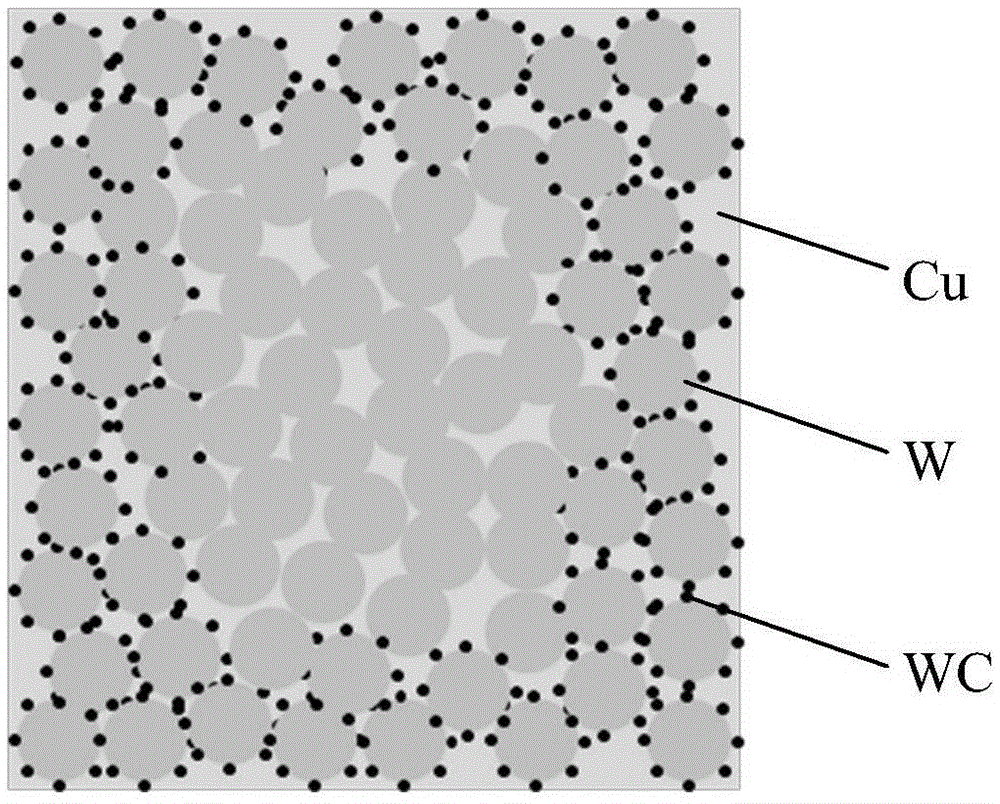

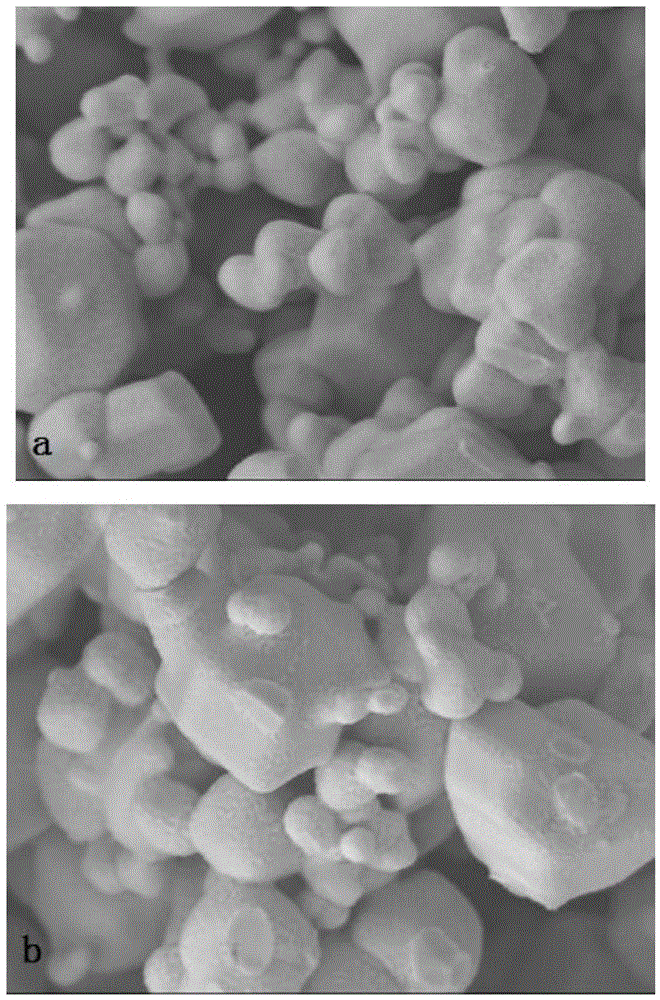

In-situ formation preparation method for gradient WC-strengthened CuW composite material

ActiveCN105568209ADoes not affect other performanceGuaranteed sintering effectSolid state diffusion coatingMicrocomputerCarbon potential

The invention discloses an in-situ formation preparation method for a gradient WC-strengthened CuW composite material. The in-situ formation preparation method for the gradient WC-strengthened CuW composite material comprises the steps that a tungsten framework is heated in a vacuum carburization furnace under the protection of argon, then a furnace body is vacuumized, acetylene is introduced into the furnace body, the furnace body is kept in the state for 2-10 min, the furnace body is vacuumized again till the pressure in the furnace body reaches 1 Pa, then heat preservation is conducted, heat preservation is conducted again after the operation is circulated, then nitrogen is introduced into the furnace body, and a sample is cooled along with the furnace, so that a gradient WC-strengthened W framework is obtained; and copper infiltration is conducted on the gradient WC-strengthened W framework in a microcomputer program-control sintering furnace in a high-temperature hydrogen atmosphere, and then the gradient WC-strengthened CuW composite material is obtained. By the adoption of the preparation method, the high-temperature strength and abrasion resistance of the W framework are improved; meanwhile, in the carburization process, the WC component gradient exists between the interior and the exterior of the framework under the influence of the carbon potential in the framework and the carbon potential outside the framework.

Owner:XIAN UNIV OF TECH

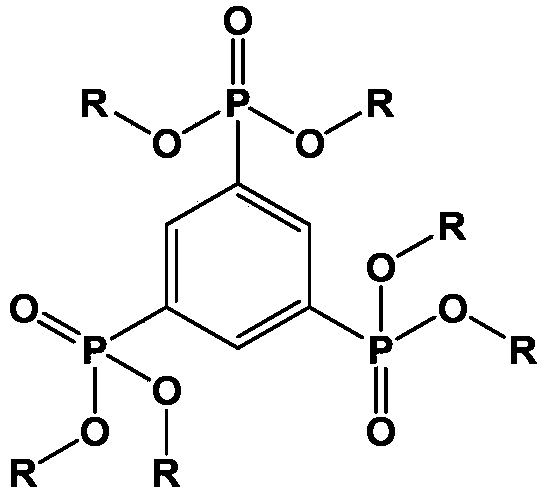

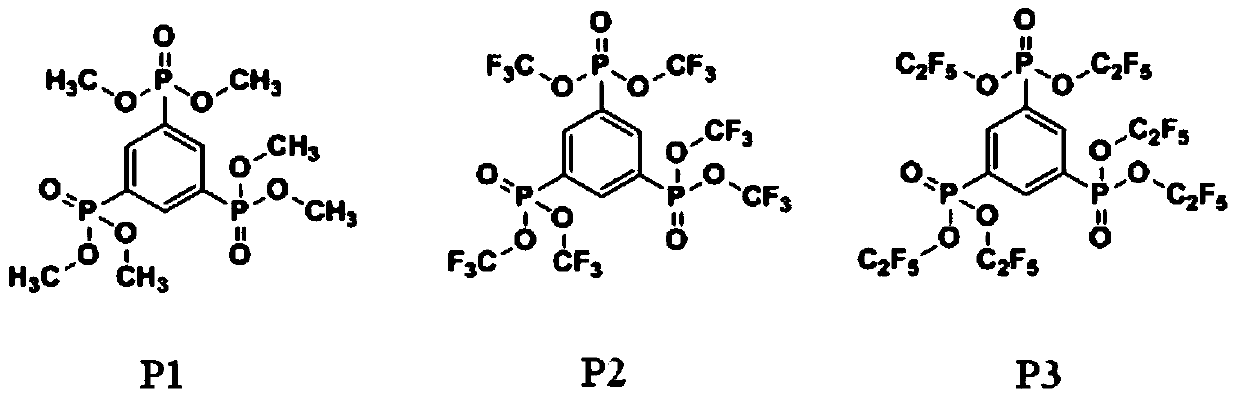

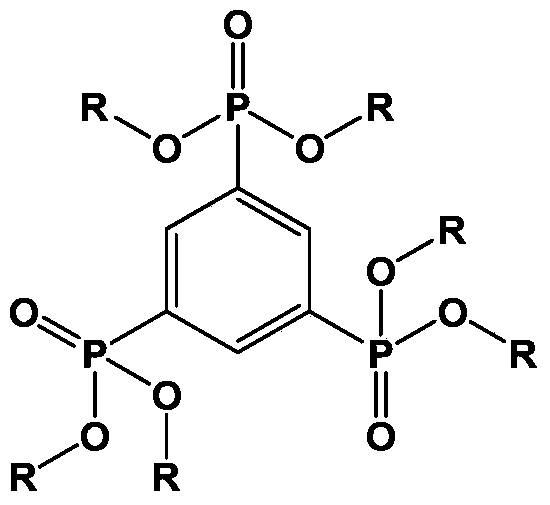

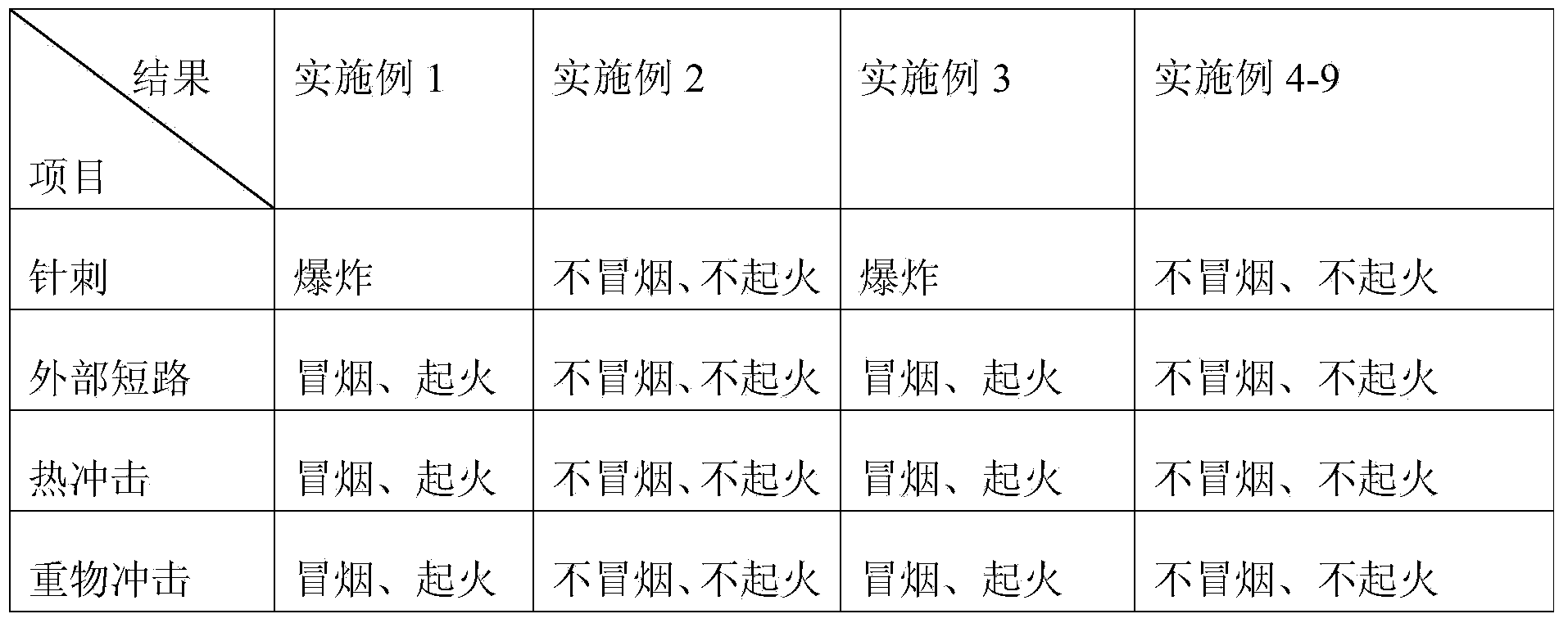

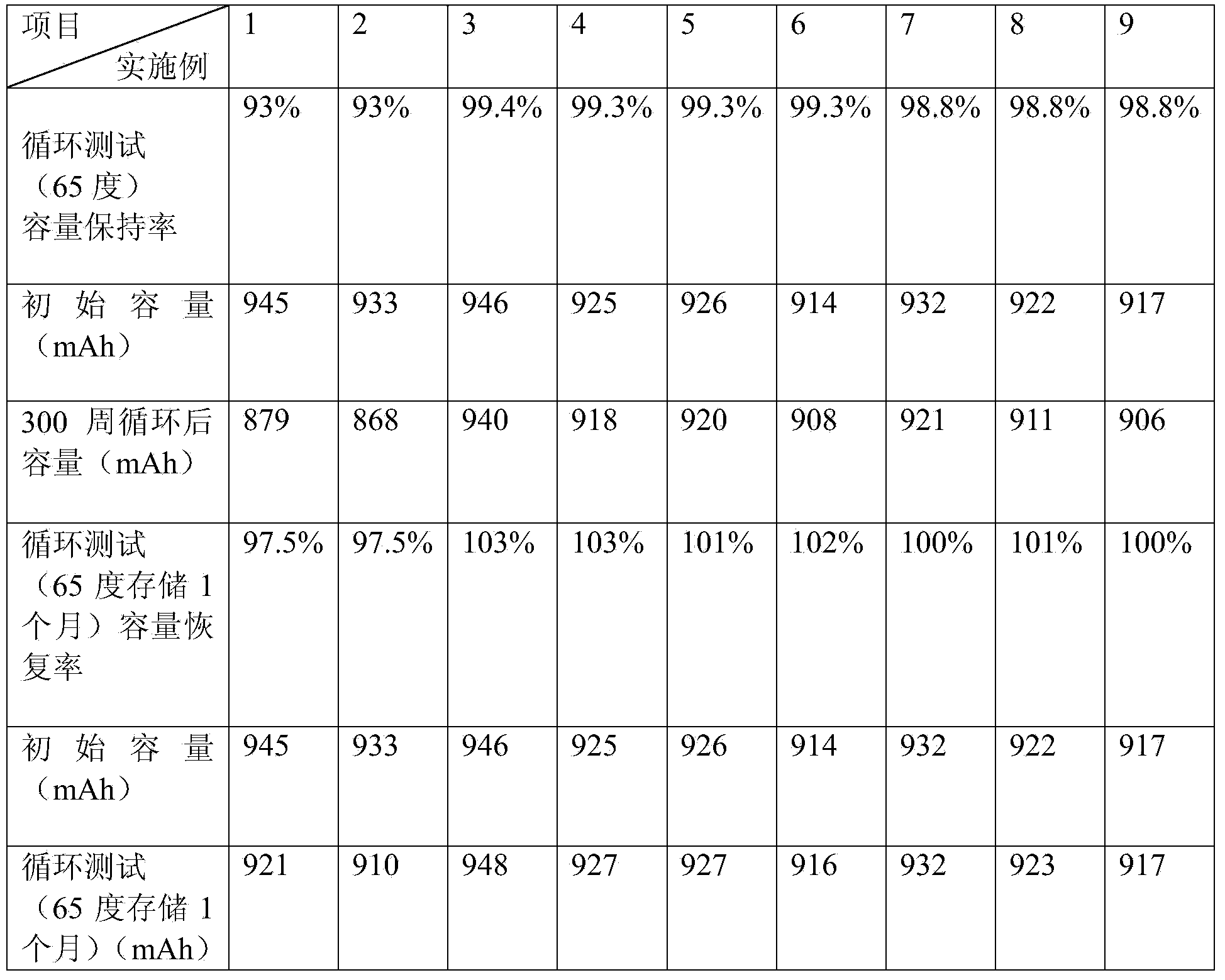

Lithium ion battery and electrolyte thereof

InactiveCN105514483ADoes not affect other performanceDoes not affect other properties such as first-time efficiencyGroup 5/15 element organic compoundsSecondary cellsAluminium-ion batteryOrganic solvent

The present invention discloses a lithium ion battery and an electrolyte thereof, wherein the lithium ion battery electrolyte contains a non-aqueous organic solvent, a lithium salt, film forming additives such as vinylene carbonate and ethylene sulfate, and a phosphonate derivative flame retardant additive, and the weight content of the phosphonate derivative flame retardant additive in the electrolyte is 0.1-20%. According to the present invention, the lithium ion battery electrolyte contains the phosphonate derivative flame retardant additive, such that the flame retardant property of the electrolyte can be significantly improved, and the first time efficiency, the rate and the cycle performance of the lithium ion battery cannot be affected.

Owner:CONTEMPORARY AMPEREX TECH CO

Method for preparing welding wire made of nickel base alloy

ActiveCN103949805AEasy to processImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaHydrogenSlag

The invention relates to a method for preparing a welding wire made of nickel base alloy. The welding wire comprises the following components by mass percent: 0.4-0.45% of C, 1.0-1.5% of Mn, 0.15-1.2% of Si, less than or equal to 0.025% of P, less than or equal to 0.02% of S, 28-30% of Cr, 49-51% of Ni, less than or equal to 0.1% of Co, less than or equal to 0.1% of Mo, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Al, 4.0-5.0% of W and the balance of Fe. The method for preparing the welding wire comprises the steps of smelting the alloy, remelting electro-slag, carrying out hot forging and cogging down, carrying out hot rolling and annealing, carrying out acid pickling, polishing, carrying out cold drawing and removing hydrogen, wherein a CaF2, Al2O3 or CaO slag system is adopted in the step of remelting the electro-slag. The thinner welding wire can be prepared by the method for preparing the welding wire made of the nickel base alloy, the performances of the welding wire meet the requirements, and the welding wire is high in yield.

Owner:JIANGSU TOLAND ALLOY

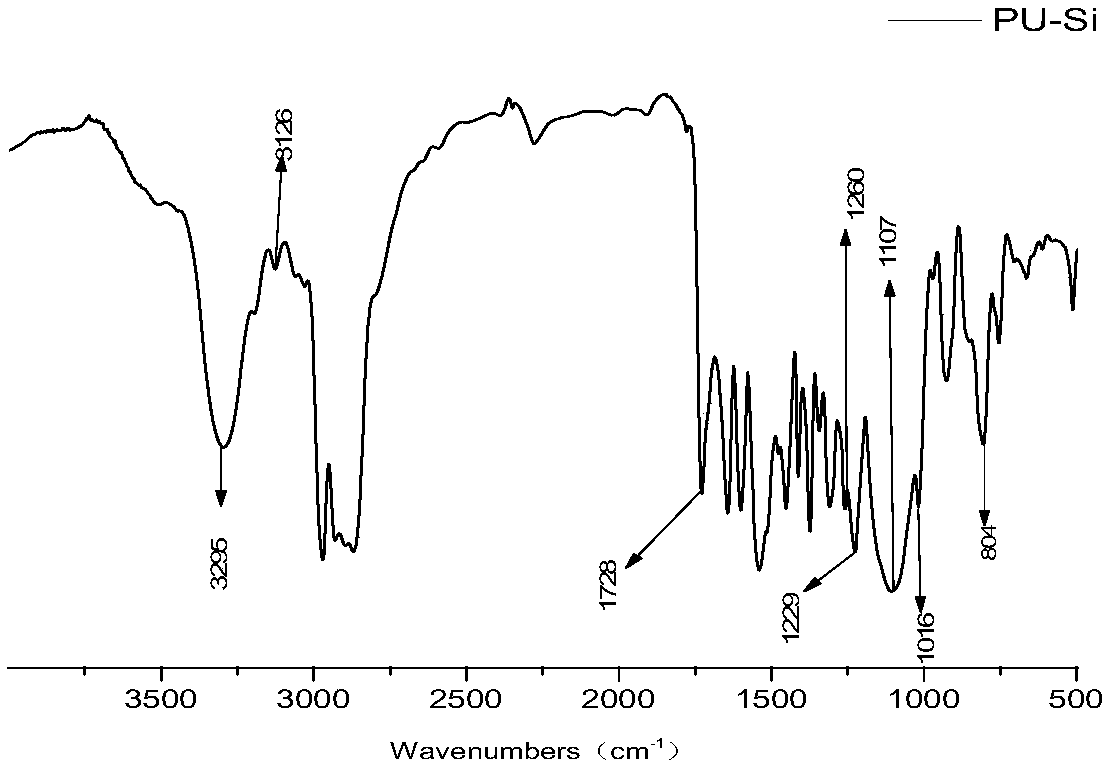

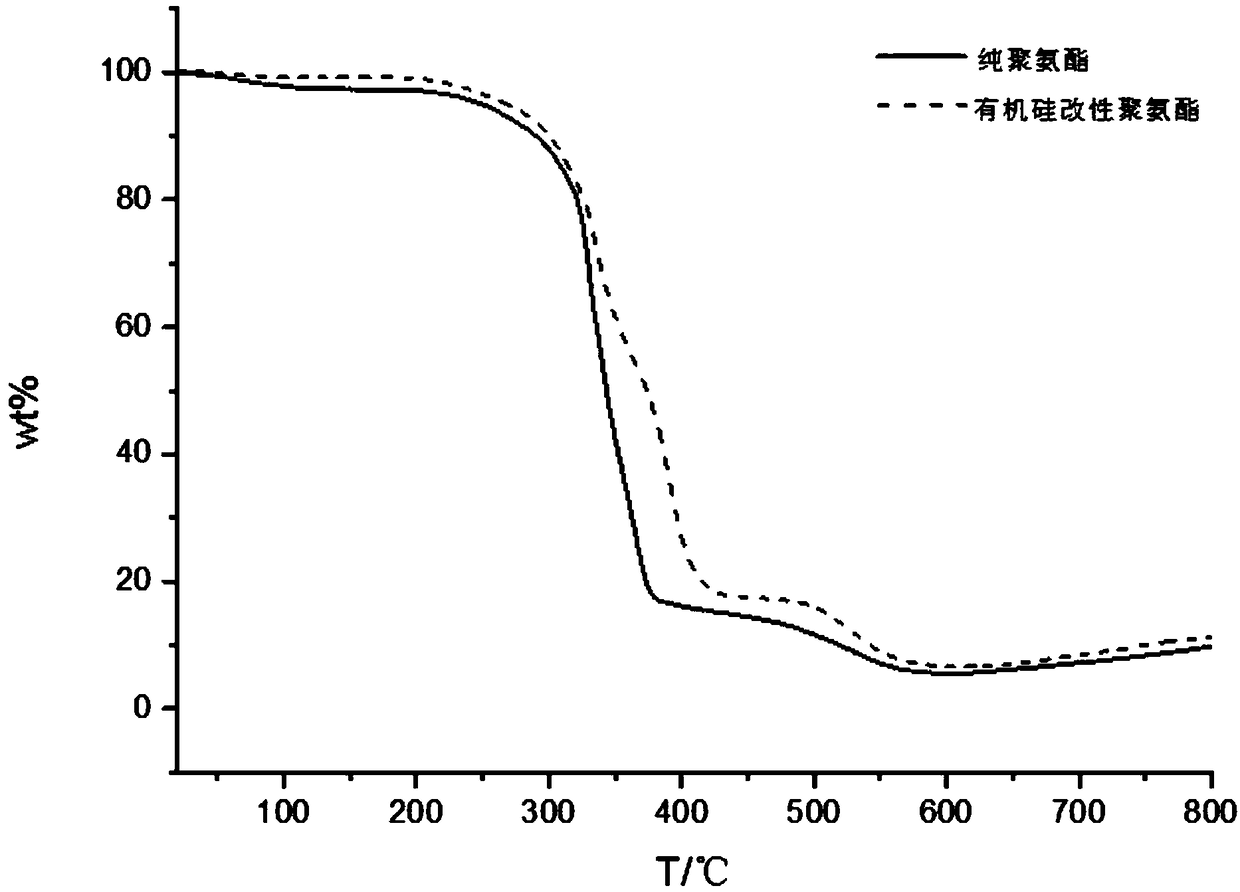

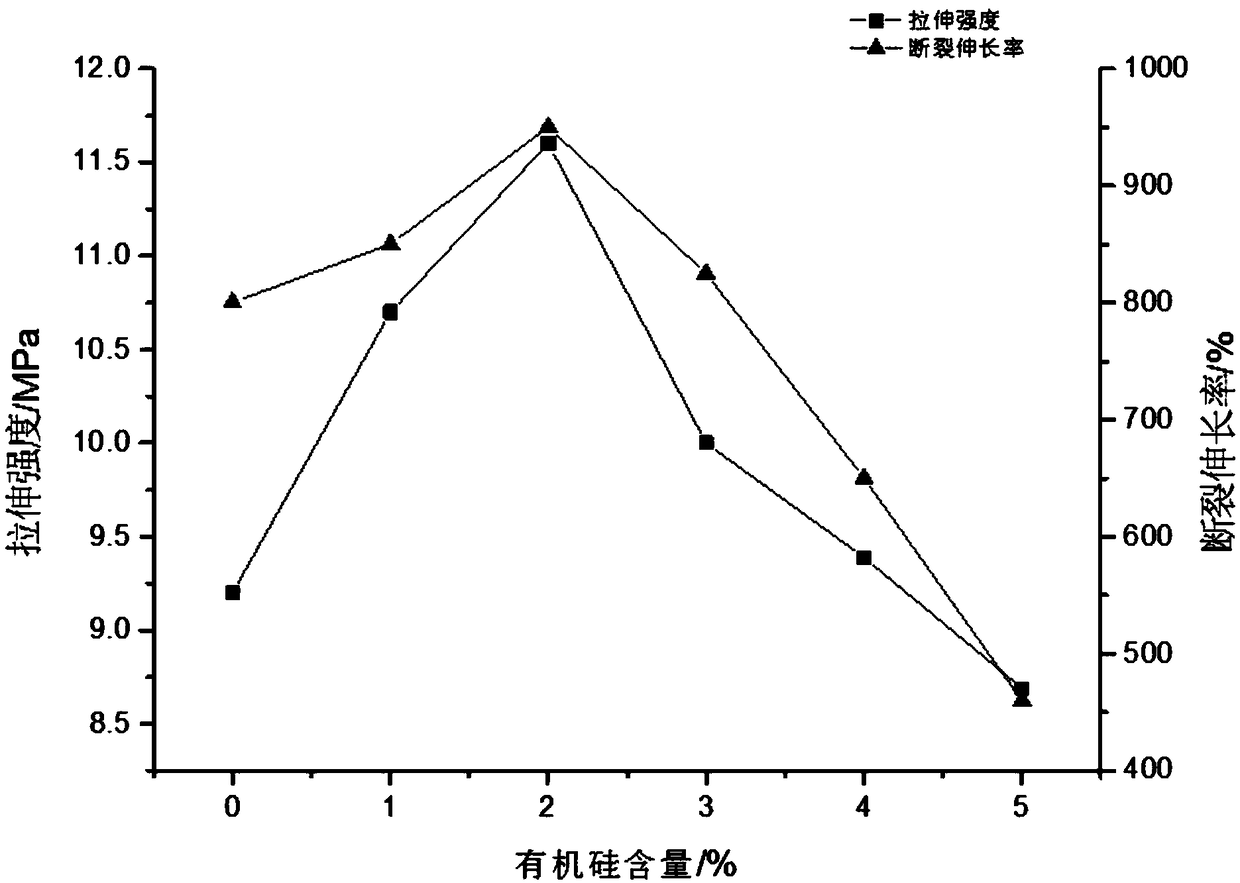

Organic silicon modified flame-retardant polyurethane and preparation

ActiveCN108864399AImprove water resistanceWeather resistantPolyureas/polyurethane adhesivesPolyesterSolvent

The invention relates to organic silicon modified flame-retardant polyurethane and a preparation. The environment-friendly weather-resisting flame-retardant polyurethane is prepared by co-polymerizinghydroxyalkyl silicone oil, MDI-50, polyether polyalcohol, polyester polyalcohol, an amine chain extender, and a reaction-type organic phosphorus flame-retardant agent, an organic silicon chain segment and an organic phosphorus structural unit are introduced into a polyurethane main chain by virtue of chemical bonding way, so that the material can reserve the original advantages of polyurethane, can also improve the performance of polyurethane such as water resistance, weather resistance, heat resistance, flame retardance, mechanical performance, has good durance, and can prolong the outdoor service life. By regulating and controlling the silicone oil content, the chain extender content and the soft hard segment content in the organic silicon modified polyurethane, the product can better meet the application requirements. The problems of the existing polyurethane which is not resistant to heat, water and contamination can be solved, the flame retardance of polyurethane can be improved,and the organic silicon modified polyurethane conforms to an environment-friendly material. The synthetic process is simple, no solvent is used, and by adopting the double-component synthetic method,the product performance can be improved by adjusting the proportion of the two components.

Owner:SHANTOU UNIV

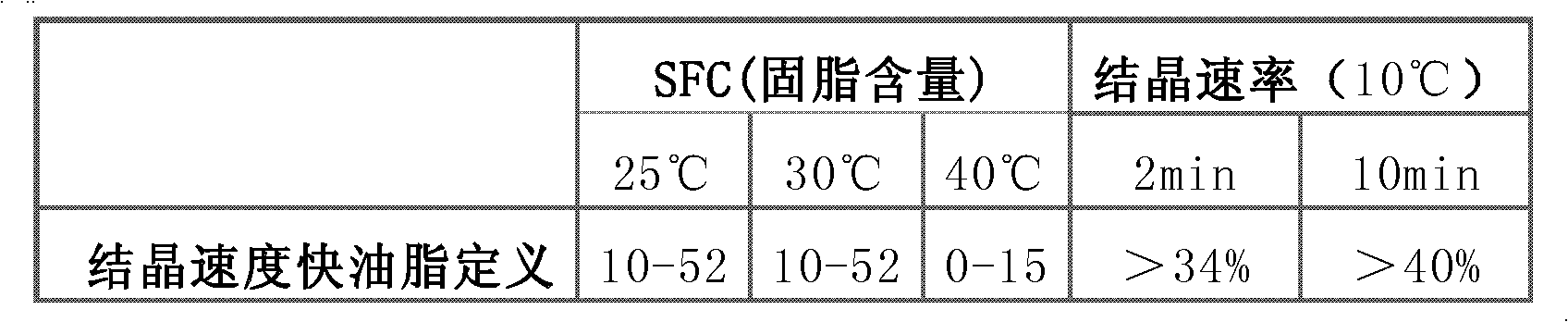

Grease composition, composite grease composition, product and preparation method thereof

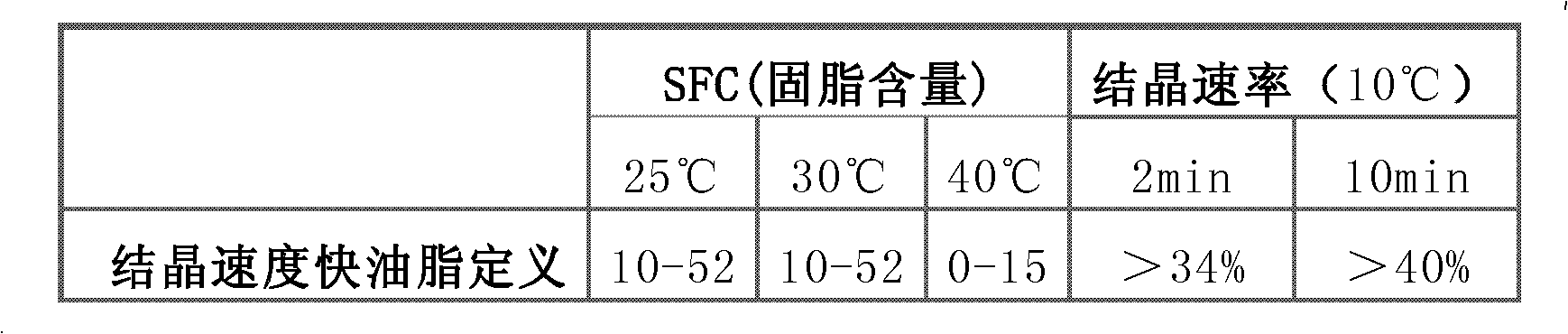

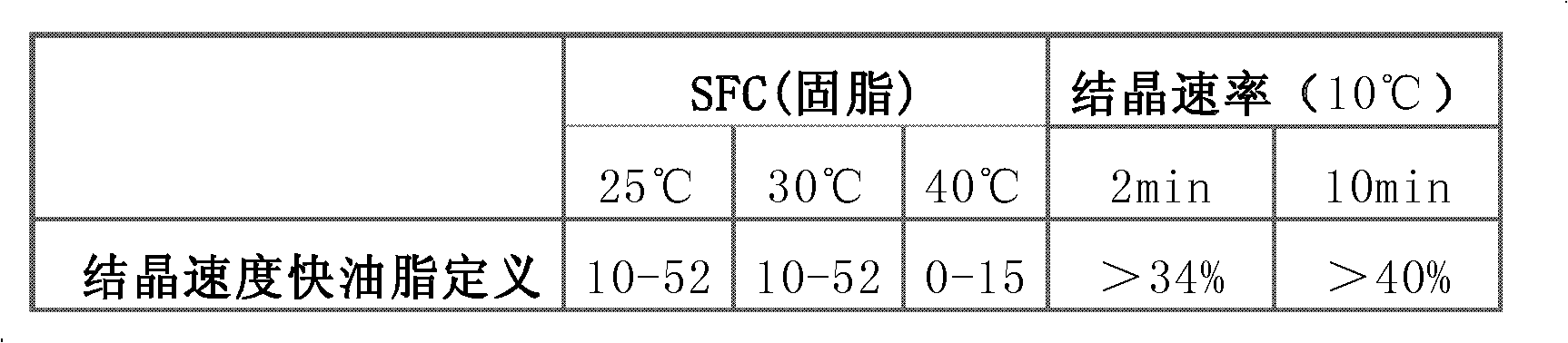

InactiveCN103181417AShorten the ripening timeDoes not affect other performanceEdible oils/fats production/working-upNutritive valuesTrans esterification

The invention provides a grease composition, which comprises a triglyceride composition obtained by an ester exchange treatment. In terms of the weight of the total fatty acids constituting the grease composition, the content of saturated fatty acid is 30%-100%; in terms of the weight of the total fatty acids constituting the grease composition, the content of fatty acid with a carbon atom number of less than 11 is 0-60%; and in terms of the weight of the total fatty acids constituting the grease composition, the content of fatty acid with a carbon atom number of greater than 19 is 0-60%. The invention also provides grease prepared from the grease composition and a preparation method thereof. The grease composition provided in the invention has a low content of trans-fatty acids, a solid fat content in line with the requirement, a fast crystallization speed, and higher nutritive value, and can be used for making a grease composition of plastic grease.

Owner:WILMAR SHANGHAI BIOTECH RES & DEV CENT

Flame-proof polyamide composition with improved electricity insulating property

InactiveCN1990548AHigh electrical insulationDoes not affect other performancePlastic/resin/waxes insulatorsElectricityLow voltage

The invention relates to a flame retardant combiantaion polyamide with modified electrical insulating property. It comprises a mixture, and the detail components and the proportion by weight of them are as follows: nylon66 40- 75%, red phosphorus agglomerate 10- 20%, compatibilizer 1- 10%, glass fiber 10- 35%, anti-oxidation agent 0- 1% and metallic oxidant 0- 1%. The grade of flame retardance of said polyamide can reach to VO grade of UL94 standard, and the electrical insulating property can reach to 400 V evaluated with relative leakage current index.The product is also characterized by good rigidity, high thermal resistance and stable size. It is suitable to be used to inject and shape various low voltage electrical equipment and domestic appliance with requirement for flame retardance and insulating property.

Owner:SHANGHAI SUNNY

Functional electrolyte for preventing overcharge of lithium battery and production method of functional electrolyte

ActiveCN104037453AImprove securityAvoid fireElectrolyte accumulators manufactureMethyl carbonateSolvent

The invention provides functional electrolyte for preventing the overcharge of a lithium battery and a production method of the functional electrolyte. The functional electrolyte comprises basic electrolyte and a functional additive, wherein the basic electrolyte comprises a carbonic ester type mixed solvent, lithium hexafluorophosphate and vinylene carbonate; the carbonic ester type mixed solvent comprises ethylene carbonate, ethyl methyl carbonate and propylene carbonate; the functional additive comprises 2, 3, 4-trifluorobiphenyl and 1, 3-propene sulfonic acid lactone. The production method comprises the following steps: adding the ethylene carbonate, the ethyl methyl carbonate and the propylene carbonate into a clean container in sequence; reducing the temperature to room temperature, and then adding the lithium hexafluorophosphate; standing for clarification, and then adding the vinylene carbonate, the 1, 3-propene sulfonic acid lactone and the 2, 3, 4-trifluorobiphenyl; and standing for clarification for spare use. The functional electrolyte provided by the invention has the advantages that the occurrence of the safety problems such as ignition and explosion caused by the overcharge of the lithium battery can be effectively prevented, so that the safety of the battery is improved, the high-temperature circulating performance of the lithium battery is improved, and the functional electrolyte is strong in applicability and can be used in multiple electro-chemical systems.

Owner:SHIJIAZHUANG SAN TAI CHEM CO LTD

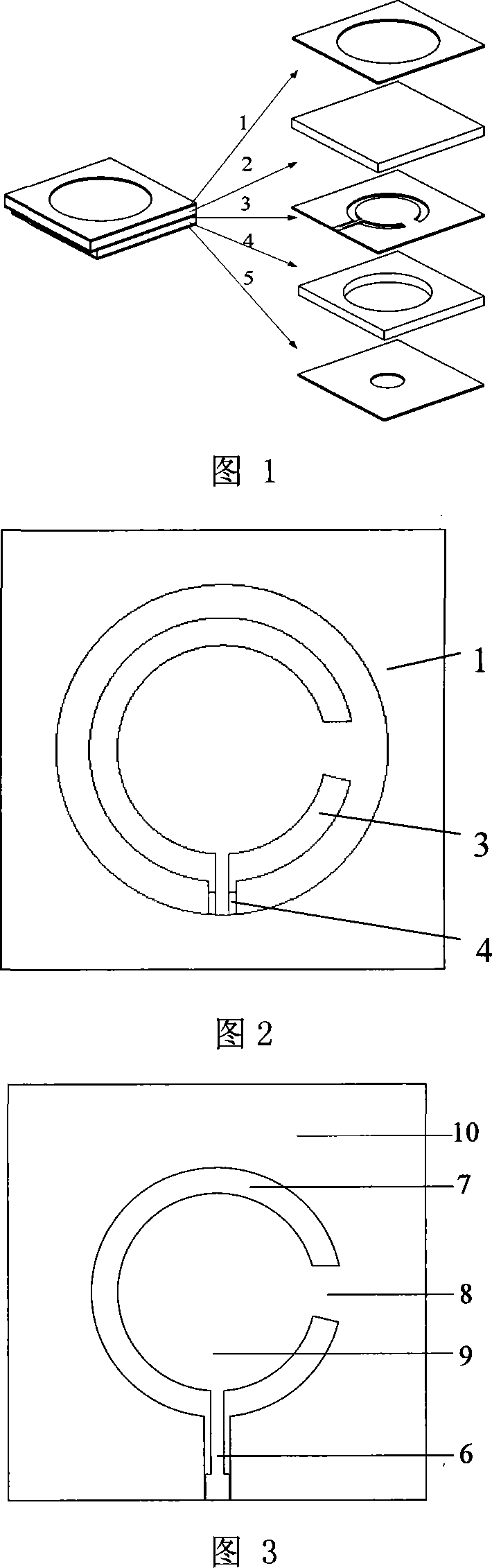

Broad band circular polarization plane gap quaternary antenna array

InactiveCN101702468AEasy to processAchieve circular polarizationSlot antennasOptoelectronicsMicrowave

The invention relates to the technical field of wireless communication, in particular to a broad band circular polarization plane gap quaternary antenna array which comprises a circular polarization gap radiation array and a microwave medium layer, wherein the circular polarization gap radiation array is arranged on the microwave medium layer. The circular polarization gap radiation array comprises four circular polarization gap radiation units and a plurality of feeders, wherein, every two circular polarization gap radiation units are connected in parallel by the feeders into a radiation branch, and two radiation branches are connected in parallel by the feeders into a radiation trunk path, and the circle centers of the four circular polarization gap radiation units are on the same axis. The invention has the characteristics of miniaturization, complanation and broad frequency band, and solves the problem that a plane gap antenna cannot be realized easily; in addition, the structure of antenna units are arranged in a 1*4 linear array, thereby improving gain and frequency band.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing wear-resistant sole

InactiveCN102504416ADoes not affect elasticityWithout compromising comfortSolesPolyvinyl alcoholPolystyrene

The invention discloses a method for preparing a wear-resistant sole, which comprises the following steps of weighing the following materials in weight parts: 70-78 parts of ethylene propylene diene rubber, 11-13 parts of carbon black, 5-7 parts of aluminum triethyl, 10-12 parts of p-nitrophenol, 10-12 parts of polystyrene, 30-35 parts of natural 3L rubber, 5-8 parts of polyvinyl alcohol and 11 parts of talcum powder; mixing the weighed raw materials together and then putting the materials into an internal mixer for banburying; pouring out the mixture after all the raw materials are evenly mixed when the temperature reaches 110-113 DEG C; then pelletizing the banburied mixture via a pelletizer to obtain granules, and then putting the granules into a water tank for cooling and then drying the granules under room temperature; finally injection molding the dried granules so as to obtain the sole. The sole prepared by the invention is greatly improved in wear resistance on the premise of not influencing the elasticity, comfort and other properties, and the sole has no toxic or polluting effects and also guarantees safety and environmental friendliness.

Owner:WUJIANG TIANYUAN PLASTIC

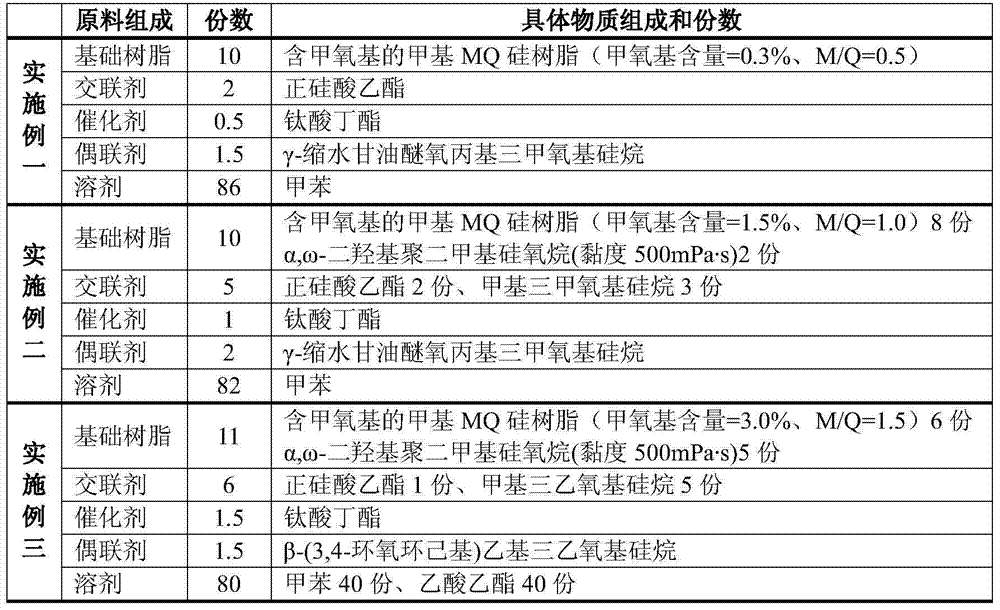

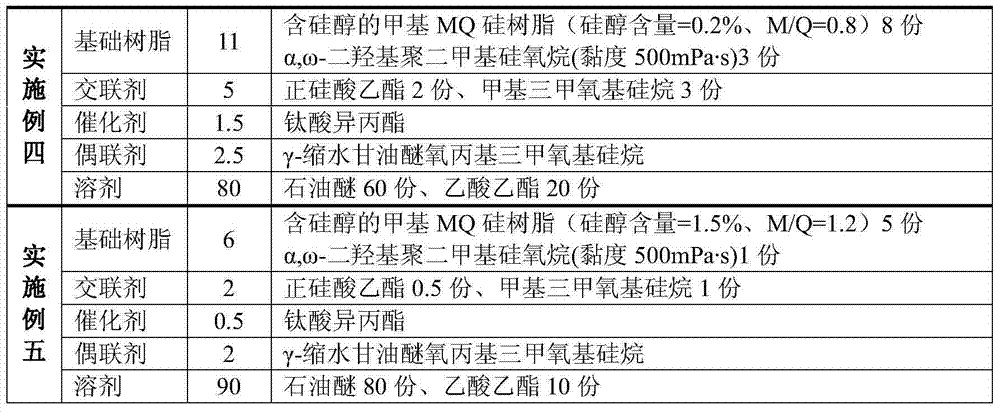

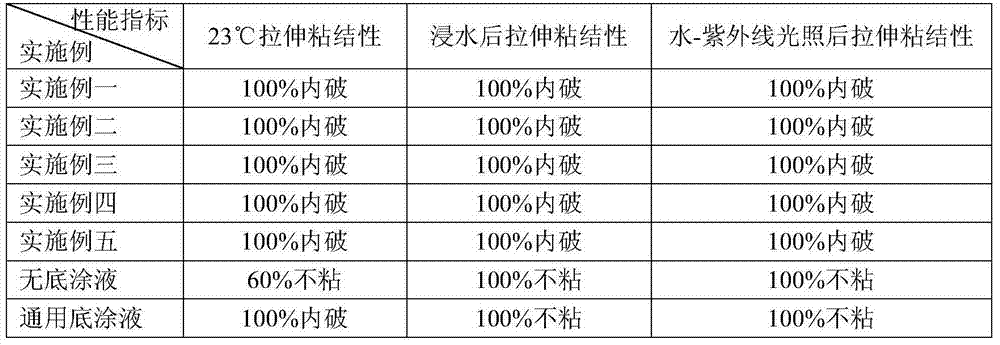

Silicone sealant base coat liquid suitable for fiber cement board

The invention discloses a silicone sealant base coat liquid suitable for a fiber cement board. The silicone sealant base coat liquid comprises the following raw materials in parts by weight: 5-15 parts of base resin, 2-8 parts of a crosslinking agent, 0.1-2 parts of a catalyst, 0.5-4 parts of a coupling agent and 70-95 parts of a solvent. The silicone sealant base coat liquid is available in raw material, low in cost, simple in preparation method, and convenient to construct; the water-resistant cohesiveness and the non-staining property of a silicone sealant are improved; other properties of the silicone sealant are not affected; and the problems of the water-resistant cohesiveness and the contaminativity of the silicone sealant on the fiber cement board are effectively solved.

Owner:GUANGZHOU BAIYUN CHEM IND

Formula of modified polypropylene composite material with low shrinking percentage and production method thereof

Owner:SUZHOU SUNWAY POLYMER

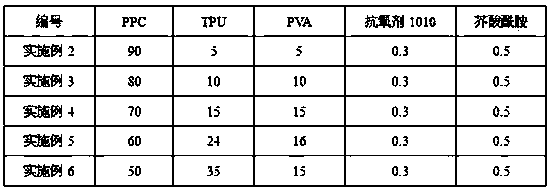

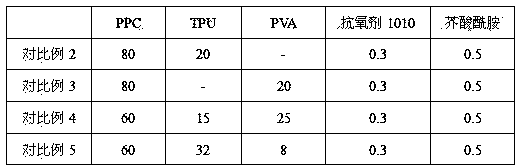

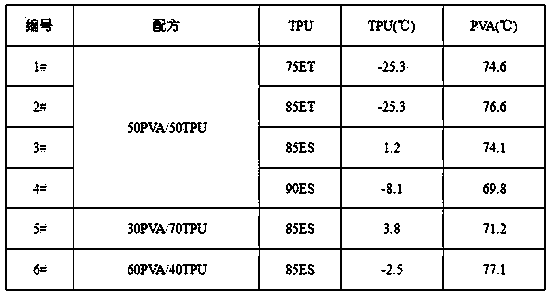

Poly-methyl ethylene carbonate composition and preparation method thereof

ActiveCN104371296AImprove film formationGood dimensional stabilityAdjuvantThermoplastic polyurethane

The invention relates to the technical field of modified materials, and discloses a poly-methyl ethylene carbonate composition and a preparation method thereof. The composition comprises the following raw materials: a poly-methyl ethylene carbonate matrix, a modified material and an adjuvant, wherein the modified material is composed of thermoplastic polyurethane and polyvinyl alcohol in melting and blending manners; the mass ratio of the modified material to the poly-methyl ethylene carbonate is (10-100) to 100; polyvinyl alcohol accounts for 30%-50% by mass of the modified material; the adjuvant accounts for 0.5%-2%. The preparation method comprises the following steps: melting and blending TPU with PVA; and then blending and pelletizing with PPC. The composition disclosed by the invention has the advantages of good film-forming property and dimensional stability, good tensile strength, breaking elongation, biodegradability and the like. The composition disclosed by the invention does not agglomerate or deform, and does not affect the processability after being placed for a long period of time when the matrix cost is lowered; the film is not bonded; the breaking elongation of the film disclosed by the invention after water absorption is increased; and meanwhile, good tensile strength is kept.

Owner:SUN YAT SEN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com