Patents

Literature

40results about How to "Improve weld line strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

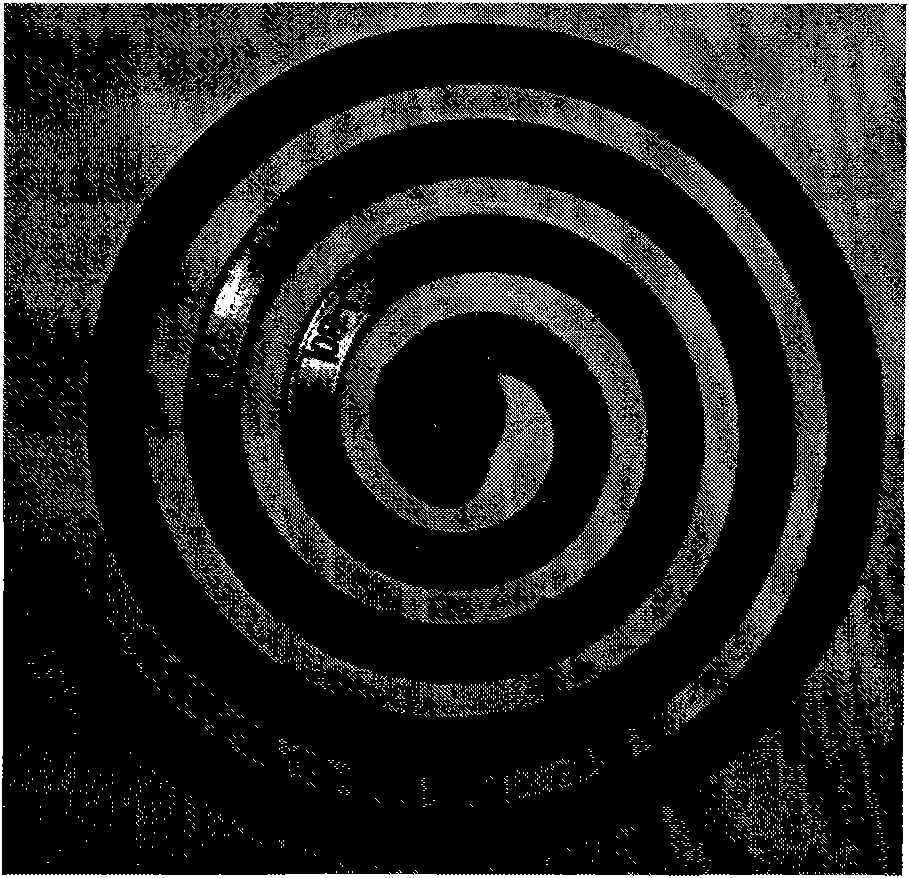

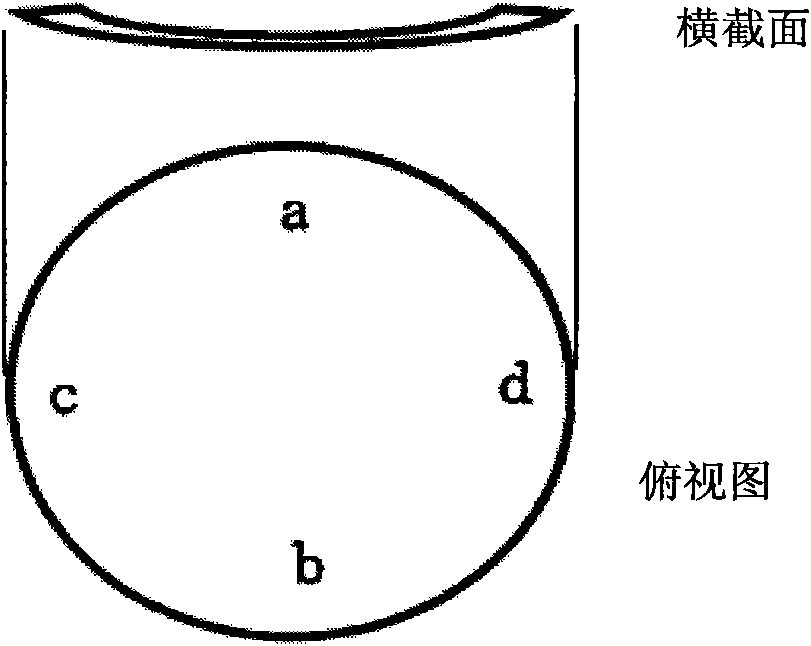

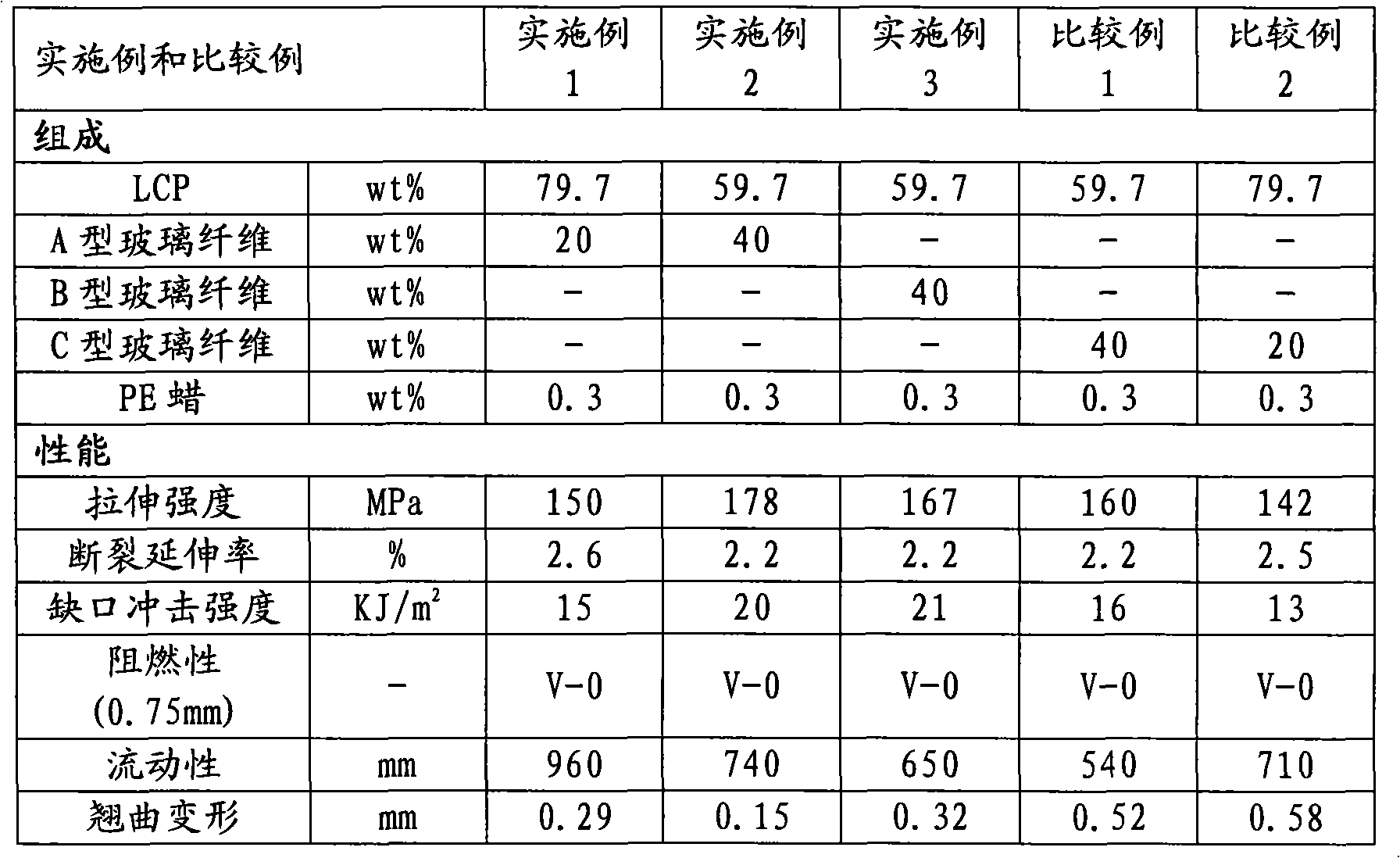

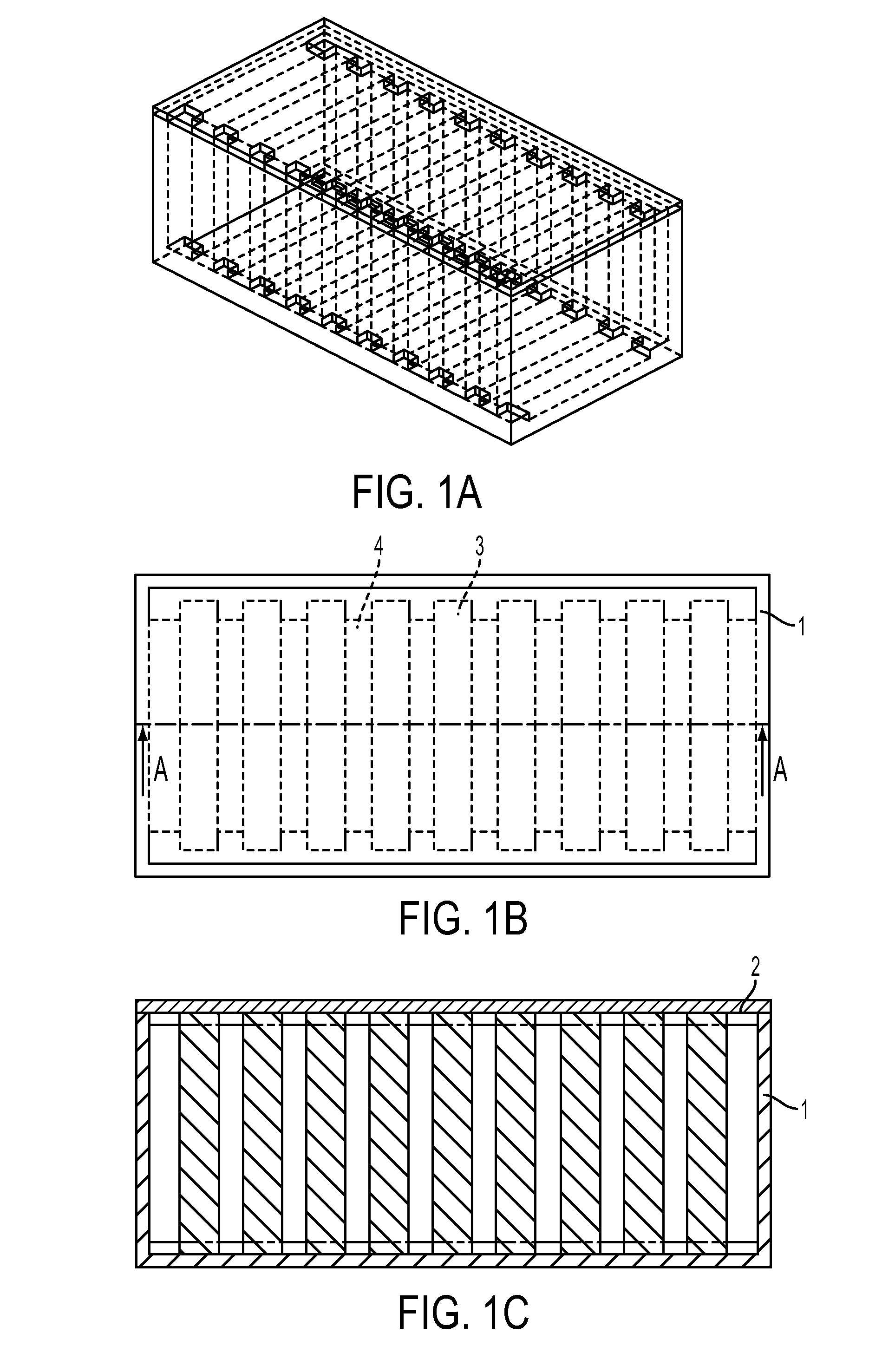

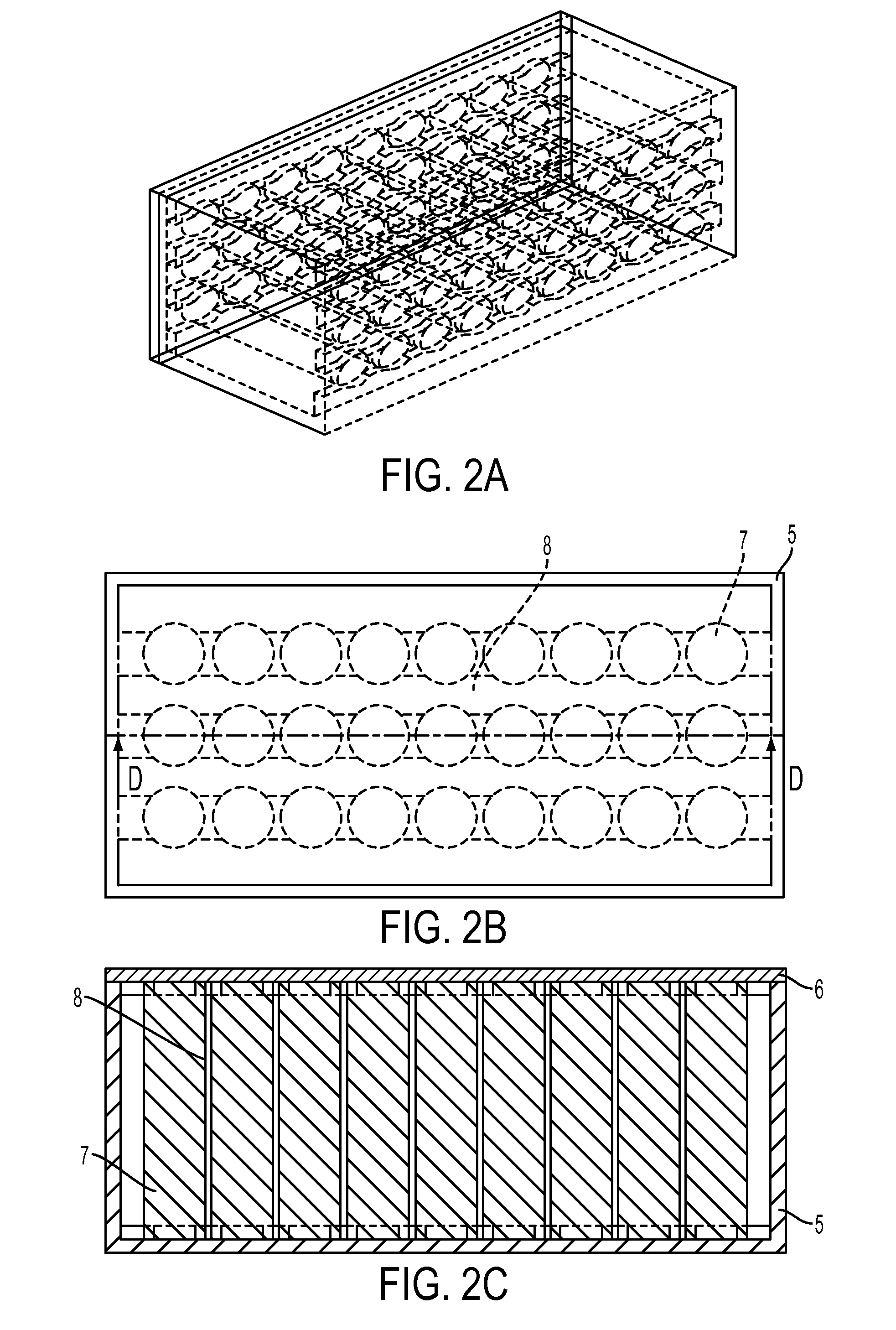

Liquid crystal polymer material reinforced by glass fibers with non-circular cross sections and preparation method thereof

InactiveCN101891938ALarge specific surface areaLarge interface contact areaLiquid crystal compositionsGlass fiberPolymer science

The invention provides a liquid crystal polymer material reinforced by glass fibers with non-circular cross sections. A liquid crystal polymer material with high flowability, low buckling deformation and high weld line strength is obtained by replacing a conventional liquid crystal polymer reinforced with glass fibers with circular cross sections with glass fibers with the non-circular cross sections, and particularly, the improvement effect achieved by adopting glass fibers with rectangular cross sections is more obvious.

Owner:KINGFA SCI & TECH CO LTD +1

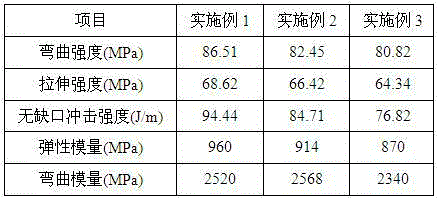

High-toughness high-modulus polypropylene composite material and preparation method thereof

The invention discloses a high-toughness high-modulus polypropylene composite material and a preparation method thereof. The high-toughness high-modulus polypropylene composite material consists of 50-62.5 parts of a polypropylene base body, 10-12 parts of high-density polyethylene, 12-15 parts of a polyolefin elastomer, 6-9 parts of modified wollastonite, 0.5-2 parts of nano modified particles, 1-2 parts of modified boron nitride, 5-6 parts of a compatibilizer, 1-1.5 parts of an antioxidant and 2-2.5 parts of a lubricating agent, wherein the nano modified particles are obtained by mixing a silane coupling agent and nano titanium dioxide in a weight ratio of 1 to 100. The preparation process is simple and convenient, the adopted materials are cheap, the comprehensive cost is lower than that of conventional toughness-modified polypropylene, and the produced high-toughness high-strength high-modulus polypropylene is excellent in performance. A composite system disclosed by the invention forms a polymer / flexible interface layer / inorganic particle three-phase composite system.

Owner:HENAN UNIV OF SCI & TECH

High weld mark strength enhanced polyamide material, preparation method thereof and application

The invention discloses a high weld mark strength enhanced polyamide material, a preparation method thereof and an application. The high weld mark strength enhanced polyamide material comprises components: polyamide resins 40-82%, glass fibers 10-50%, polyamide copolymers 2-8%, nucleating agents 0.3-0.5% and an antioxidant 0.1-0.2%, wherein the components are melted and mixed uniformly to prepare the high weld mark strength enhanced polyamide material. The high weld mark strength enhanced polyamide material selects the polyamide copolymers and the efficient nucleating agents to improve weld mark strength of glass fiber reinforced polyamide materials, improves welding strength of the glass fiber reinforced polyamide materials under the situation that the own strength of the glass fiber reinforced polyamide materials is not affected, enlarges application field, and can be widely applied in the fields with high combination property demands for the glass fiber reinforced polyamide materials such as vehicles, architectural furniture and electric tools and the like.

Owner:合诚技术股份有限公司

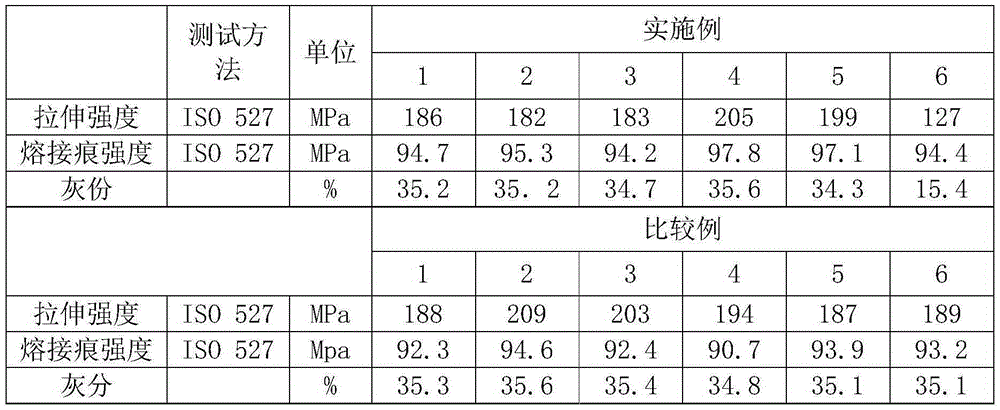

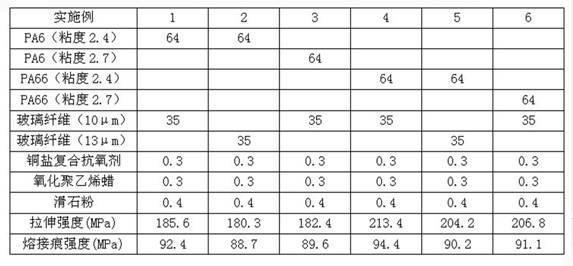

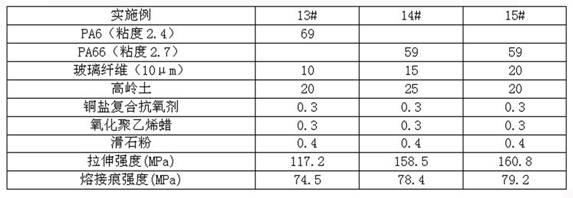

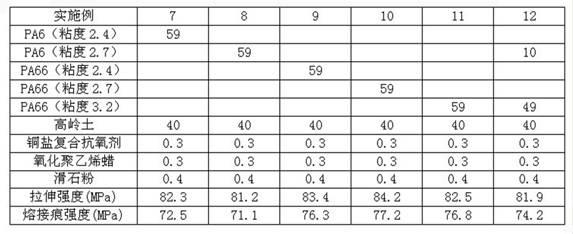

Modified nylon material with high weld line strength and preparation method thereof

InactiveCN102153860AImprove weld line strengthDoes not affect other performanceAntioxidantInorganic filler

The invention relates to a modified nylon material with high weld line strength and a preparation method thereof. The modified nylon material with high weld line strength comprises the following components in percentage by weight: 38.2-94.7% of nylon resin, 5-60% of inorganic filler, 0.1-0.6% of antioxidant, 0.1-0.6% of lubricant and 0.1-0.6% of talcum powder with the particle diameter being smaller than 1 micron, wherein the inorganic filler is chopped alkali-free glass fiber or kaolin processed by using a silane coupling agent. In the invention, the specially appointed inorganic filler processed by using the specially appointed coupling agent is added to the processing formula of the nylon material, thus the dispersity of the inorganic filler in the nylon resin and the interfacial binding force of the inorganic filler with the nylon resin can be effectively modified, and the weld line strength of the nylon material is enhanced. Furthermore, the inorganic filler is fed into an extruder for extrusion processing from a side feed inlet in the form of lateral feeding during the preparation of the nylon material, thus the structure of the inorganic filler can be prevented from being damaged due to long-time mixing, and the further guarantee is provided for the excellent service performance of the nylon material.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

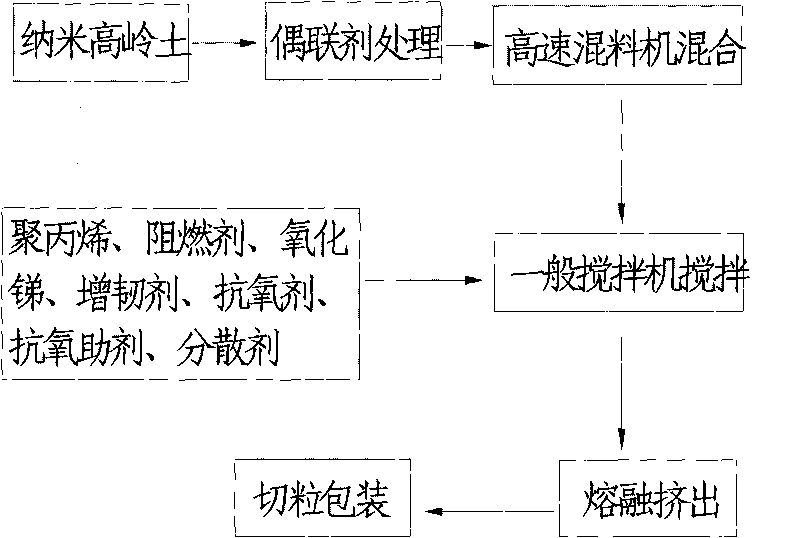

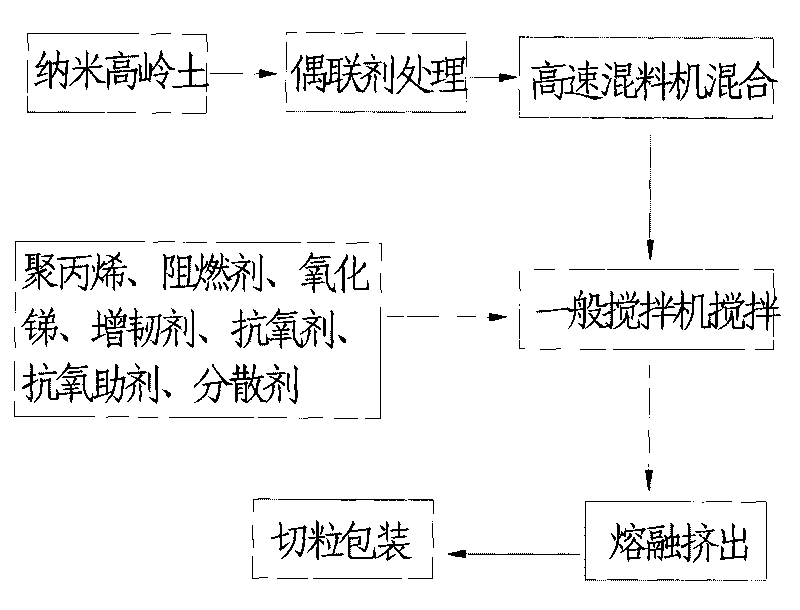

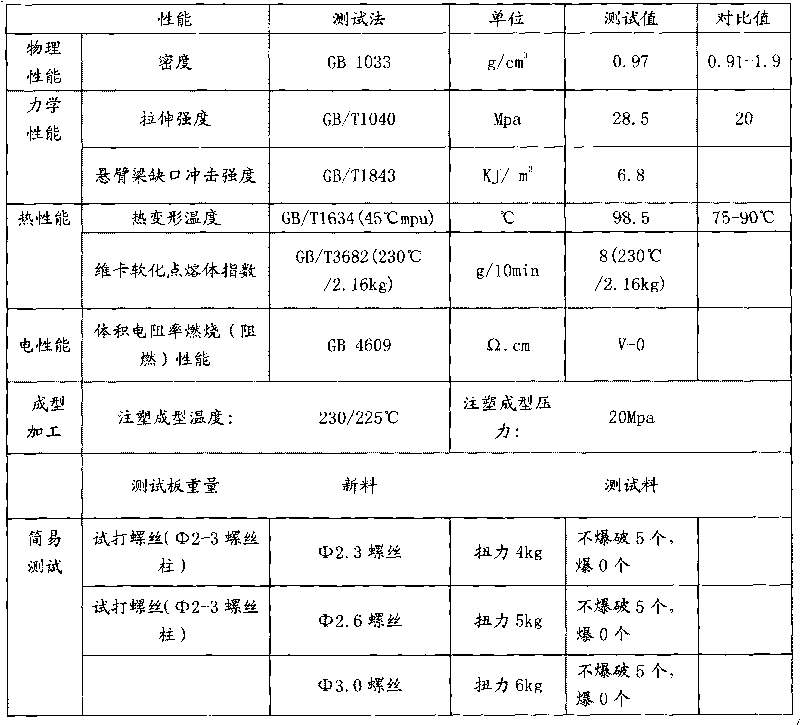

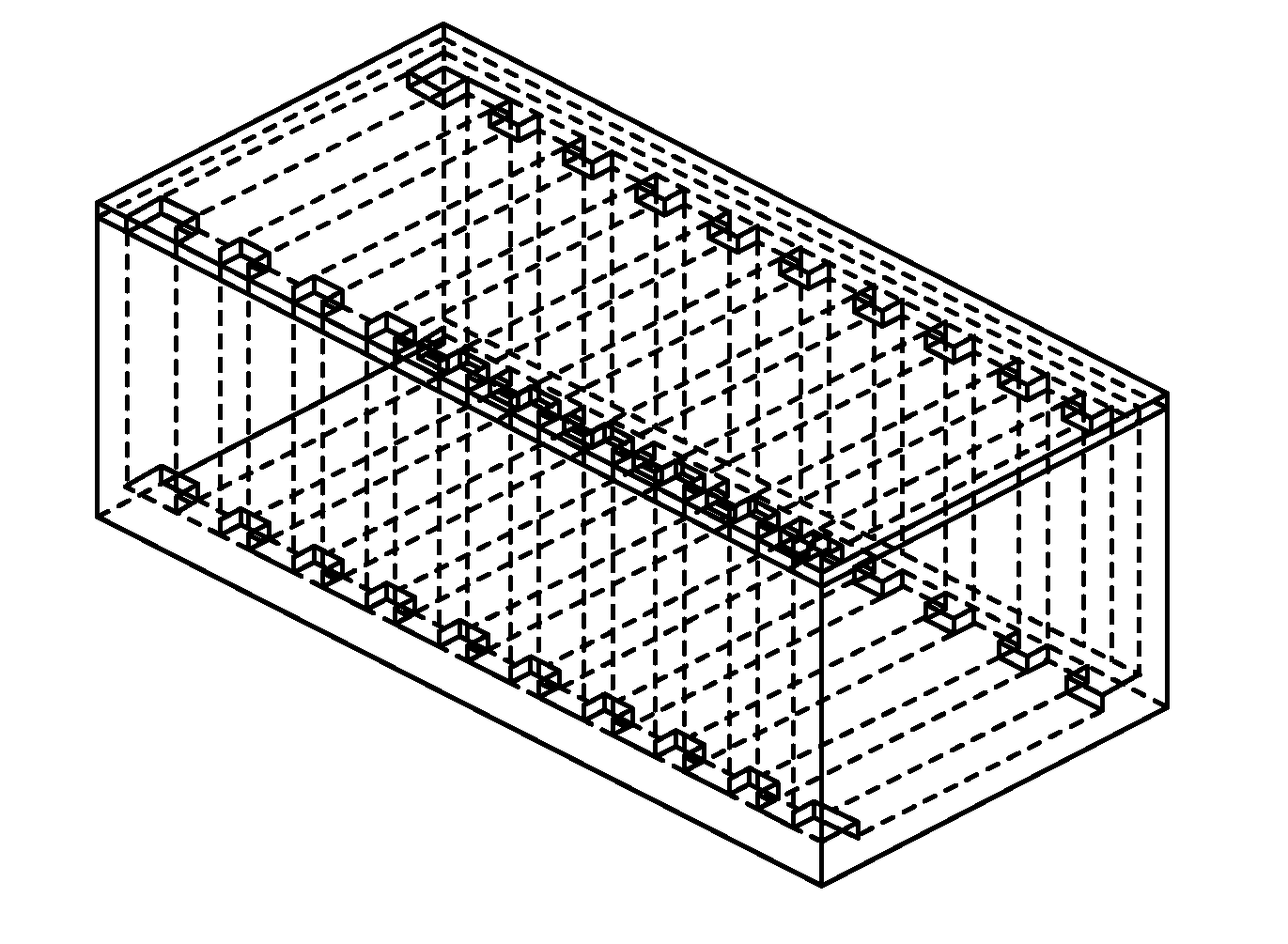

Flame-retardant polypropylene with light specific gravity and impact resistance and preparation method thereof

The invention relates to the technical field of polypropylene, in particular to a flame-retardant polypropylene with light specific gravity and impact resistance and a preparation method thereof. The flame-retardant polypropylene comprises 70-80 percent of polypropylene, 6-10 percent of flame retardant, 3-8 percent of antimony oxide, 5-8 percent of flexibilizer, 5-10 percent of antioxidant, 5-10 percent of antioxidant adjuvant and 5-10 percent of hexylene radical bis stearamide according to weight percentage. The flame-retardant polypropylene not only is light in specific gravity and resistant to impact, but also retards flame, greatly reduces the production cost of manufacturers while clearing away the potential fire hazard of plastic furniture, especially solves the technical difficulty of PP reactive flame retardant and flexibilizer with cooperativity and is at leading level at home and abroad. Proved by tests, the physical property can simultaneously meet the requirements of impact-resistant and fireproof UL94-V0 of plastic chairs.

Owner:东莞市中洲石化有限公司

Flame-retardant impact-modified battery boxes based on polycarbonate ii

InactiveUS20120074036A1Improve flame retardant performanceImprove weld line strengthBattery isolationOther accessoriesPolyesterThermoplastic

The present invention relates to battery boxes comprising flame-retardant compositions comprising A) linear and / or branched aromatic polycarbonate and / or aromatic polyester carbonate, B) at least one graft polymer, C) one or more phosphorus compounds, D) optionally one or more antidripping agents, optionally E) thermoplastic vinyl (co)polymer (E.1) and / or polyalkylene terephthalate (E.2), and F) optionally one or more further additives, wherein the composition is preferably free from rubber-free polyalkyl(alkyl)acrylate.

Owner:BAYER MATERIALSCIENCE AG

Liquid crystal polymer composition, preparation method and application thereof

ActiveCN102352259AGood toughening effectImprove weld line strengthLiquid crystal compositionsUltimate tensile strengthToughening

The invention discloses a liquid crystal polymer composition, a preparation method and application thereof. The liquid crystal polymer composition is prepared from the following components in percent by mass: 30-60 percent of liquid crystal polymer, 15-35 percent of inorganic reinforcing agent, 5-35 percent of filler and 2-5 percent of toughening component, wherein the toughening component comprises silicone powder and fluorochemicals. The liquid crystal polymer composition has better flexibility and weld mark strength, and overcomes the defects of low weld mark strength and easiness in crispness of the traditional TLCP (talline polymer).

Owner:KINGFA SCI & TECH CO LTD +1

Plastic raw material

InactiveCN105037924AGood transparency and clarityIncreased clarity of transparencyElastomerPolyolefin

The invention discloses a plastic raw material. The technical scheme is as follows: the plastic raw material comprises the following components in parts by weight: 70-80 parts of PP (polypropylene), 15-21 parts of PE (polyethylene), 2-8 parts of POE (polyolefin elastomer), 0.5-2 parts of composite photodiffusion agent and 1-3 parts of assistant. The plastic raw material disclosed by the invention solves the problems of low transparency, difficulty in demolding and poor toughness in the container prepared from the existing plastic raw material.

Owner:苏州华瑞塑胶电子有限公司

Reinforced polyamide composite material with high flowability and good surface and preparation method thereof

InactiveCN103694680AImprove weld line strengthHigh Molecular Weight DistributionFiberPolymer science

The invention relates to a reinforced polyamide composite material with high flowability and a good surface. The reinforced polyamide composite material is prepared from the following raw materials by weight percent: 20% to 70% of nylon, 5% to 20% of PA6 (Polyamide 6), 25% to 60% of reinforced fibers, 0.5% to 1% of chain reducing agent, 0.2% to 0.6% of nucleating agent, 0.2% to 0.4% of antioxidant and 0.2% to 1% of lubricant. The invention further provides a preparation method of the polyamide composite material. The method has the technical characteristics that the PA6 with high flowability, the chain reducing agent, the nucleating agent and other aiding agents are added, so that the molecular weight distribution and the crystallization performance of nylon are improved, and the flowability of the polyamide composite material is improved. The polyamide composite material prepared by the method is excellent in mechanical strength, very good in flowability and apparent quality and high in welding mark strength, thereby being especially suitable for large-sized functional components with complicated appearance requirements.

Owner:SHANGHAI SUNNY

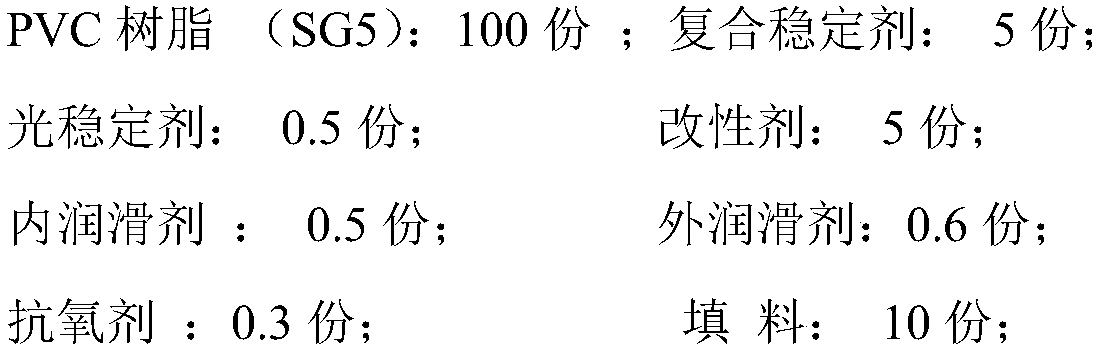

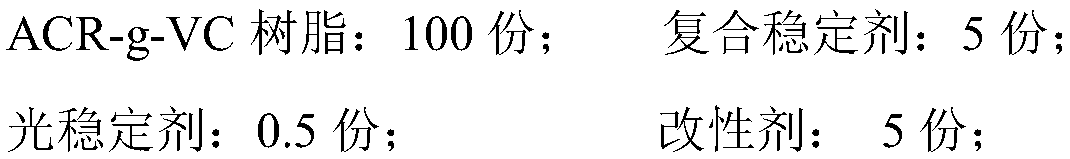

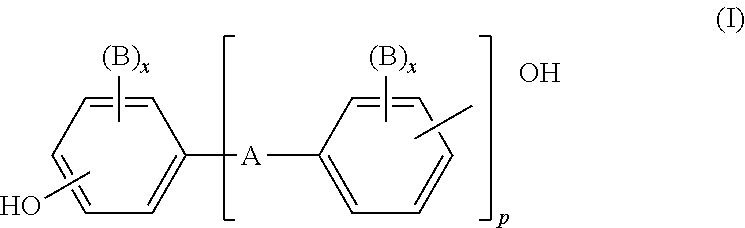

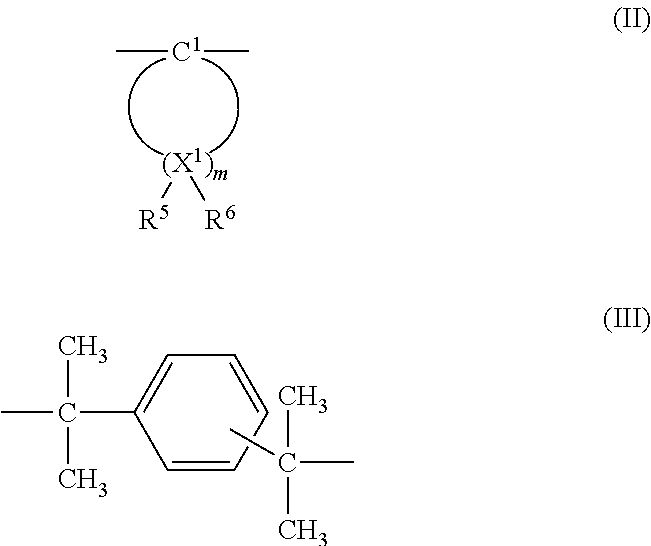

High-strength high-toughness polyvinyl chloride manhole cover and preparation method thereof

InactiveCN109517294AImprove the lubrication effectImprove thermal stabilityWeather resistanceAntioxidant

The invention discloses a high-strength high-toughness polyvinyl chloride manhole cover and a preparation method thereof. The manhole cover is prepared from the following components in parts by weight:5-40 parts of PVC resin, 60-95 parts of ACR-g-VC resin, 2-8 parts of modifier, 2-5 parts of compound stabilizer, 0.5-2 parts of an internal lubricating agent, 0.5-1.2 parts of an external lubricatingagent, 0.1-1 part of optical stabilizer, 0.1-1 part of antioxidant and 1-80 parts of filler. The preparation method comprises the following steps: mixing the materials to obtain a polyvinyl chloridemixture; granulating in a twin-screw extruder, extruding and dicing with an extruder; and adding particles into an injection molding machine, performing injection molding to form the manhole cover. The manhole cover has the advantages of strong impact resistance, high tensile strength, good weather resistance, low temperature resistance and the like.

Owner:YIBIN TIANYUAN GRP CO LTD

Easy-flowing polycarbonate/abs moulding compositions with good mechanical properties and a good surface

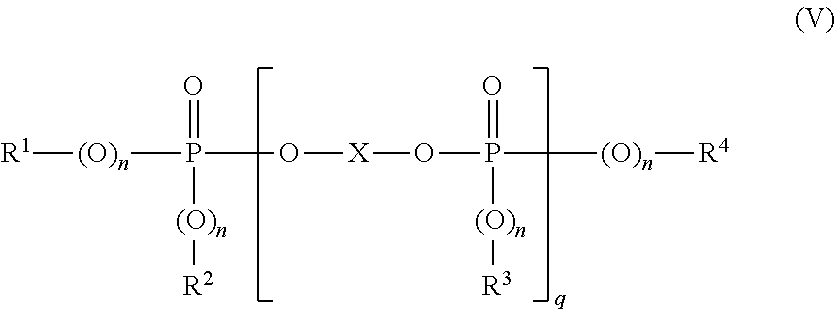

ActiveUS20110263766A1Improve mechanical propertiesGood and trouble-free surfacePhosphorus organic compoundsFree formInjection moulding

The present invention relates to flame-resistant moulding compositions of polycarbonates and graft polymers which, in addition to good flow properties, have very good mechanical properties and a particularly good, trouble-free surface. These moulding compositions are suitable in particular for injection moulding uses for mouldings with thin wall thicknesses and high-gloss surfaces. The thermoplastic moulding compositions according to the invention comprise A) 65.0 to 82.0 parts by wt. of at least one aromatic polycarbonate, B) 4.0 to 11.0 parts by wt. of at least one graft polymer, C) 14.0 to 24.0 parts by wt. of at least one phosphorus-containing flameproofing agent, wherein the sum of the parts by weight of components A to C adds up to 100 parts by weight and the total content of the polymer which is formed from the grafting monomers or is added in the free form and is not bonded chemically to the graft base is less than 2.0 wt. %, based on the total moulding composition.

Owner:COVESTRO DEUTSCHLAND AG

Transfusion bag with self-contraction function and transfusion bag special material thereof

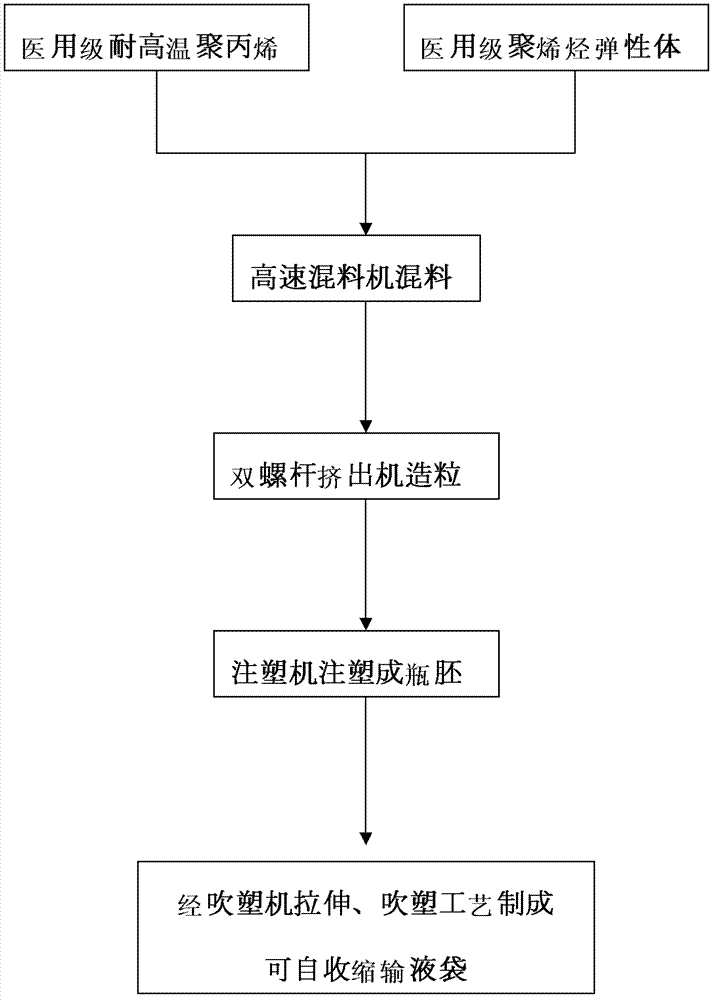

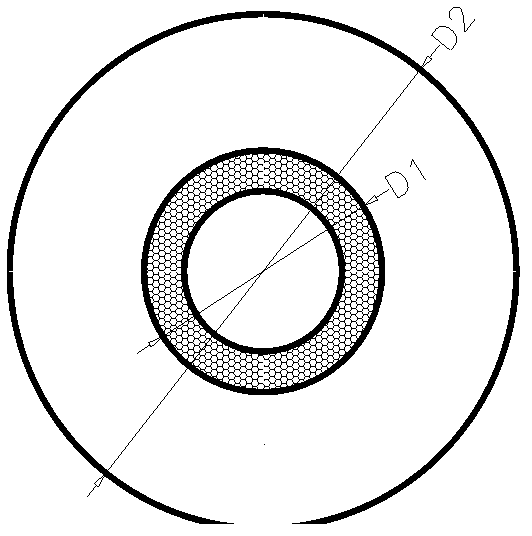

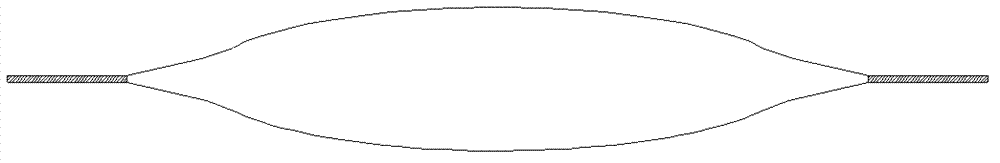

The invention relates to a transfusion bag with a self-contraction function and a transfusion bag special material thereof. The transfusion bag special material comprises the following materials: medical-grade high temperature resistant polypropylene, a medical-grade polyolefin elastomer, an anti-oxidant, and an acid scavenger. The manufacturing process of the transfusion bag of the invention comprises the following steps: weighing according to the formula; well mixing the raw materials; performing extrusion granulation by a double screw extruder, cooling with circulating water, drying in the air, and cutting granules mechanically. According to the transfusion bag special material of the invention, a POE elastomer is added into the raw materials, which increases the flexibility of the transfusion bag, and provides the self-contraction function for the transfusion bag which is produced by injection molding, stretching, blow molding technology and has an elliptic cross section; the bag prepared by the transfusion bag special material of the invention has no soldering joint, which greatly reduces the risk of liquid leakage.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

Low-odor high-weld-line-strength flame-retardant PC/ABS (polycarbonate/acrylonitrile butadiene styrene) composite

InactiveCN105778463AAvoid problems such as precipitationImprove flame retardant performancePolymethyl methacrylateUltimate tensile strength

The invention relates to a low-odor high-weld-line-strength flame-retardant PC / ABS (polycarbonate / acrylonitrile butadiene styrene) composite which comprises PC, a phosphorus-containing flame retardant, ABS, PMMA (polymethyl methacrylate) and an impact resistant modifier. The low-odor high-weld-line-strength flame-retardant PC / ABS composite is prepared by means of preparing the ABS, PMMA and impact resistant modifier into a one-step material YBL-ABS through physical extrusion prior to mixing the one-step material YBL-ABS with waste materials. The composite has the advantages that the one-step material used is simple and easy to obtain, the preparation process is simple, cost is low, small molecules in material molecules can be removed effectively, meanwhile, weld line strength of the material is improved, and mechanical properties of the material can be improved significantly; the material can be applied to industries such as automobiles, refrigerators and televisions.

Owner:TIANJIN KINGFA NEW MATERIAL

Special polypropylene reinforcing material for water pump and preparation method thereof

PendingCN111171443ASolving Recycling ProblemsRaw materials are easy to getGlass fiberPolymer science

The invention provides a special high-strength high-fluidity polypropylene reinforcing material for a water pump and a preparation method thereof. According to the invention, a long glass fiber composite material and chopped glass fibers are compounded to be used as a filling main body; high-melting high-crystallized copolymerized PP is used as a main raw material; 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane is used as a chain breaking agent; and the material is prepared through twin-screw extrusion. The problems that when a plastic strip steel material is exploded on an industrial water pump, the service life of the water pump is short, damage is likely to happen, and water leakage is prone to occurring due to insufficient weld line strength are solved in the invention. The prepared material has the characteristics of high strength, high fluidity, high weld line strength and the like, the original bursting pressure of the water pump can be improved by 20% under standard experimentalconditions, and the time of the pressure at a bursting point is prolonged by 50%.

Owner:合肥圆融新材料有限公司

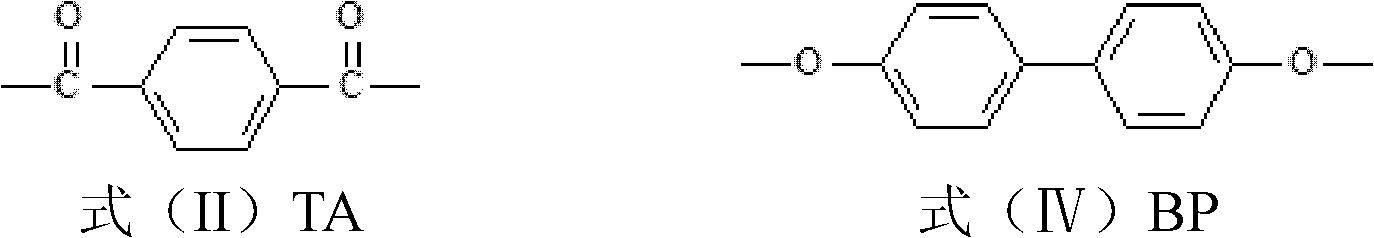

Liquid crystal polymer composition, preparation method and application thereof

ActiveCN102352259BGood toughening effectImprove weld line strengthLiquid crystal compositionsUltimate tensile strengthToughening

The invention discloses a liquid crystal polymer composition, a preparation method and application thereof. The liquid crystal polymer composition is prepared from the following components in percent by mass: 30-60 percent of liquid crystal polymer, 15-35 percent of inorganic reinforcing agent, 5-35 percent of filler and 2-5 percent of toughening component, wherein the toughening component comprises silicone powder and fluorochemicals. The liquid crystal polymer composition has better flexibility and weld mark strength, and overcomes the defects of low weld mark strength and easiness in crispness of the traditional TLCP (talline polymer).

Owner:KINGFA SCI & TECH CO LTD +1

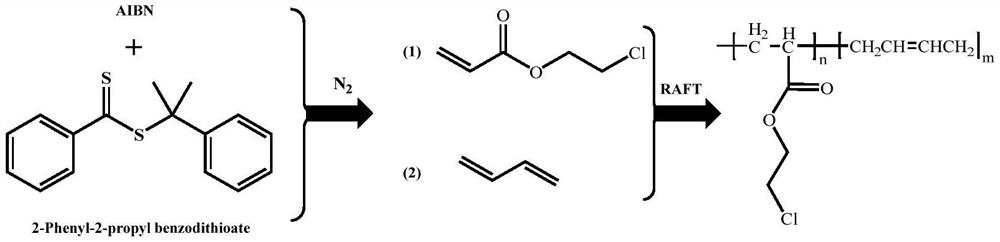

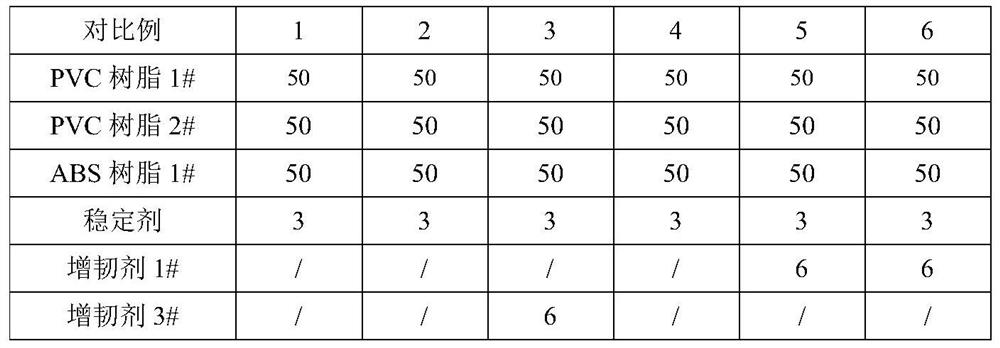

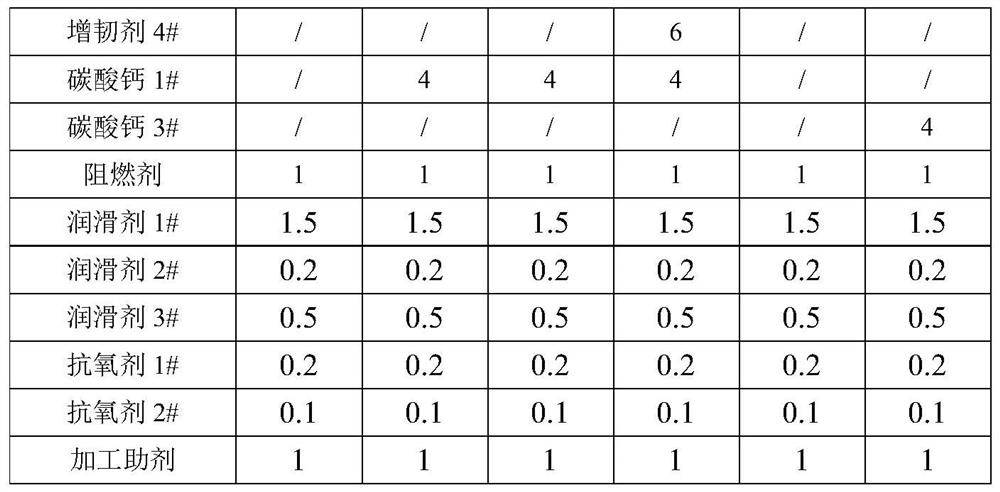

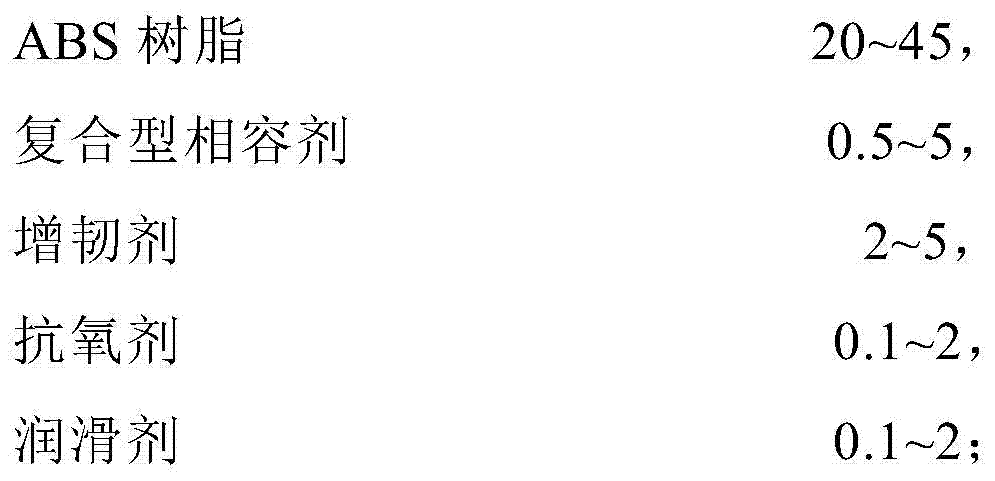

PVC alloy material as well as preparation method and application thereof

ActiveCN112795113AImprove weld line strengthNo reduction in impact strengthButadiene DioxideEthyl ester

The invention relates to a PVC alloy material and a preparation method and application thereof. The PVC alloy material comprises PVC resin, ABS resin, a stabilizer, a flexibilizer, calcium carbonate, a lubricant and other auxiliaries. According to the PVC alloy material provided by the invention, the calcium carbonate with a specific particle size is taken as a filling agent, and the chloroethyl acrylate-butadiene copolymer with a specific ratio is taken as a toughening agent. Through synergistic cooperation of the calcium carbonate and the copolymer, the weld mark strength of the material can be greatly improved while the impact strength of the PVC / ABS alloy material is basically not reduced, and the alloy material can be widely applied to thin-wall multi-screw-hole security and protection, electrician and electric appliance products.

Owner:KINGFA SCI & TECH CO LTD

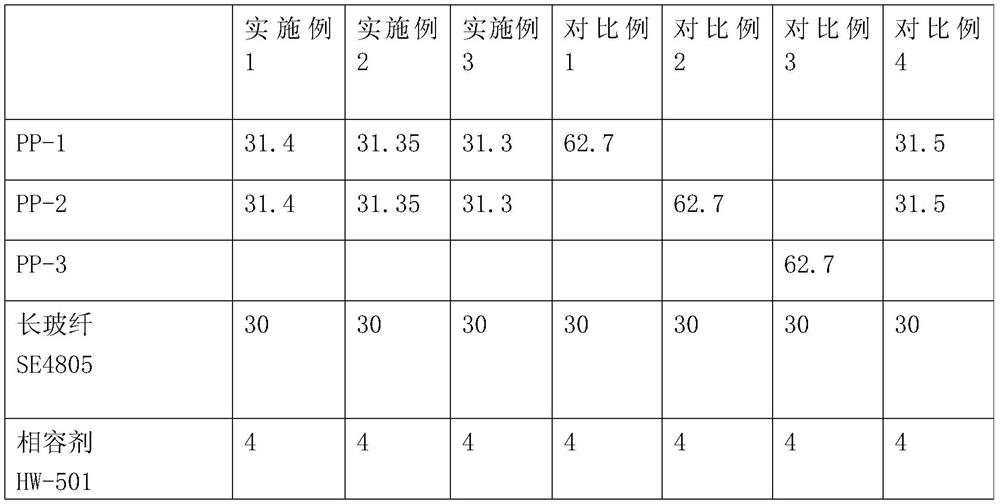

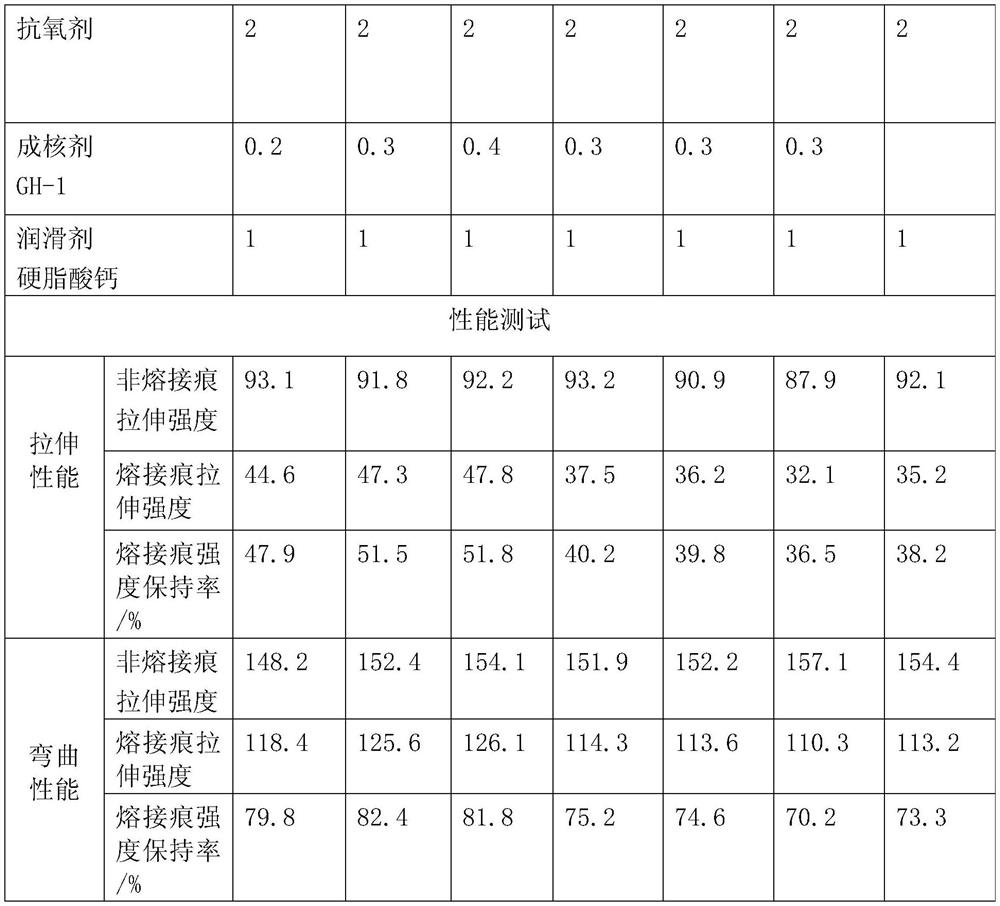

High-weld-mark-strength long glass fiber reinforced polypropylene composite material and preparation method thereof

The invention discloses a preparation method of a high-weld-mark-strength long glass fiber reinforced polypropylene composite material. The high-weld-mark-strength long glass fiber reinforced polypropylene composite material is prepared from the following raw materials in percentage by weight: 42.6-72.8% of polypropylene resin, 20-50% of continuous long glass fibers, 4% of a compatilizer, 2% of an antioxidant, 0.2-0.4% of a nucleating agent and 1% of a lubricant. Wherein the polypropylene resin adopts a random copolymerization type and a high crystallization type and adopts a 1: 1 blending scheme, and the nucleating agent is selected from organic phosphates and has the characteristics of low molecular weight, small viscosity and low interaction force with polymers. According to the formula design, on one hand, the interpenetration and entanglement degree of molecular chains when multiple strands of melts intersect is improved, on the other hand, ordered arrangement of the polymer molecular chains is facilitated, and finally the purpose of optimizing the strength of a weld mark area is achieved. Aiming at the welding mark injection molding defect inevitably existing due to the multi-pouring-gate design of a large injection molding part, the characteristic of high welding mark strength can effectively avoid the risk of product performance failure, and the design freedom degree of the part is further improved.

Owner:SHANGHAI PRET COMPOSITES +3

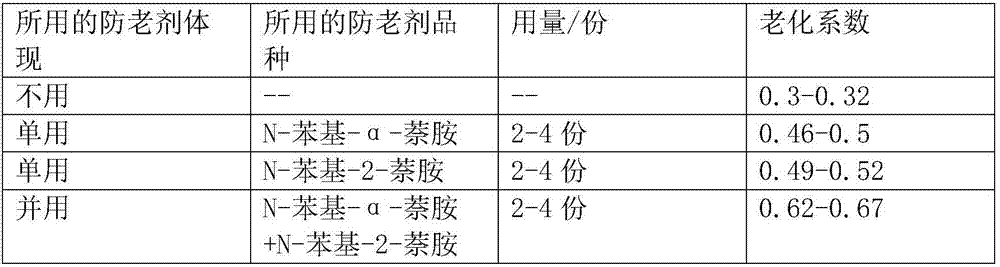

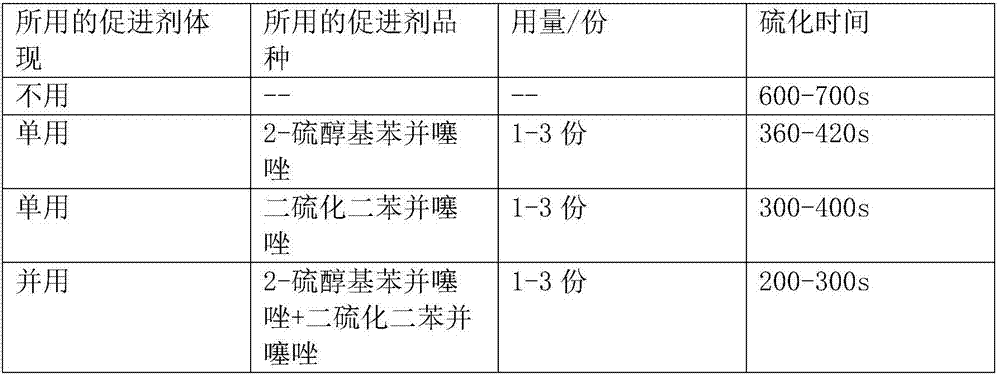

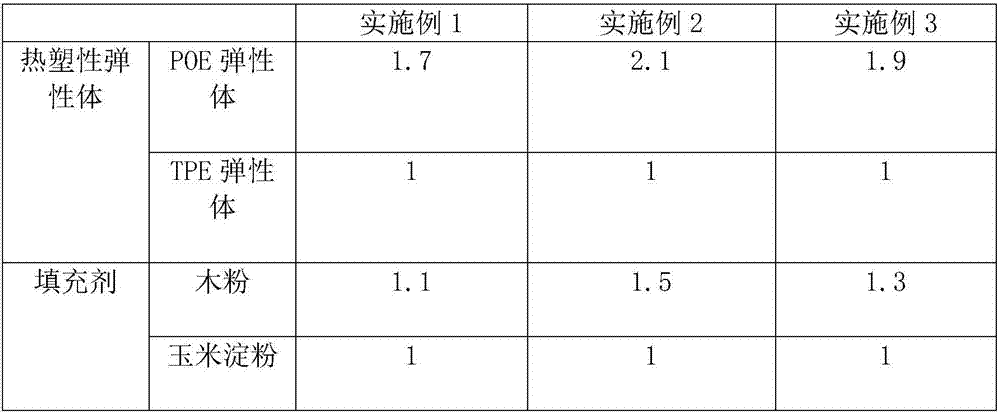

Elastic non-slip mat

The invention relates to an elastic non-slip mat. The elastic non-slip mat is prepared from components in parts by weight as follows: 28-32 parts of a thermoplastic elastomer component, 28-32 parts of EVA (ethylene vinyl acetate copolymer), 20-30 parts of polyethylene, 16-24 parts of a filling agent, 2-4 parts of an anti-aging agent and 1-3 parts of an accelerant, wherein the thermoplastic elastomer component is prepared from a POE (polyolefin elastomer) and a TPE (thermo plastic elastomer) through mixing, and a mass ratio of POE to TPE is (1.7-2.1):1; the filling agent is prepared from wood flour and corn starch through mixing, and a mass ratio of the wood flour and the corn starch is (1.1-1.5):1. The elastic non-slip mat has the advantages as follows: content of the components is strictly controlled, and under the compatible action of the components, the mat is light in mass, good in elastic resilience and excellent in heat resistance and aging resistance and further has excellent slip resistance.

Owner:MEITOKU PLASTIC

Glass fiber reinforced polyamide composite material with high weld mark strength and preparation method thereof

The invention discloses a glass fiber reinforced polyamide composite material with high weld mark strength, which comprises the following components in parts by weight: 100 parts of polyamide, 0.2-0.8part of a carboxyl compound, and 1-50 parts of glass fibers. The carboxyl compound is one or a combination of more of an aliphatic monocarboxylic acid compound with the 12-18 carbon atoms and / or an aliphatic dicarboxylic acid compound with the 12-18 carbon atoms. By adding a certain amount of the carboxyl compound into the glass fiber reinforced polyamide material, the intermolecular interactionforce at a weld mark can be improved, and the weld mark strength of the composite material is further improved.

Owner:GUANGDONG IND TECHN COLLEGE

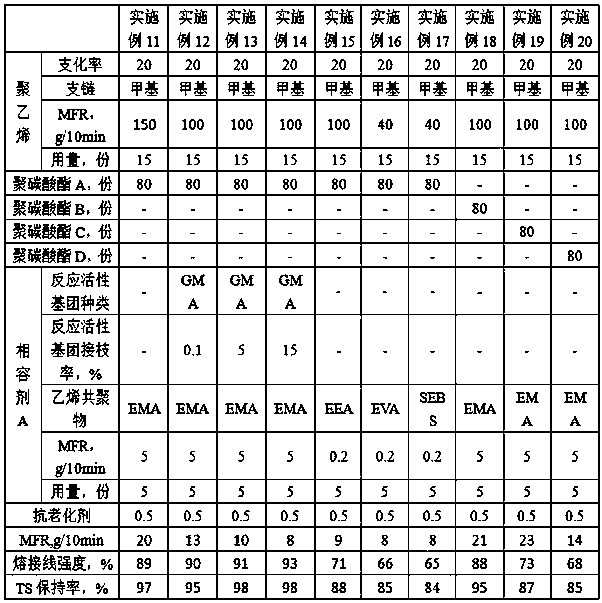

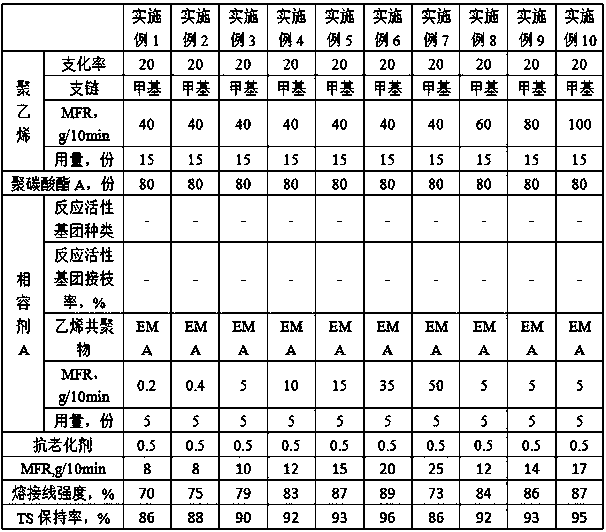

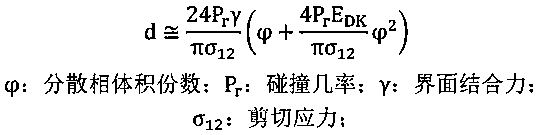

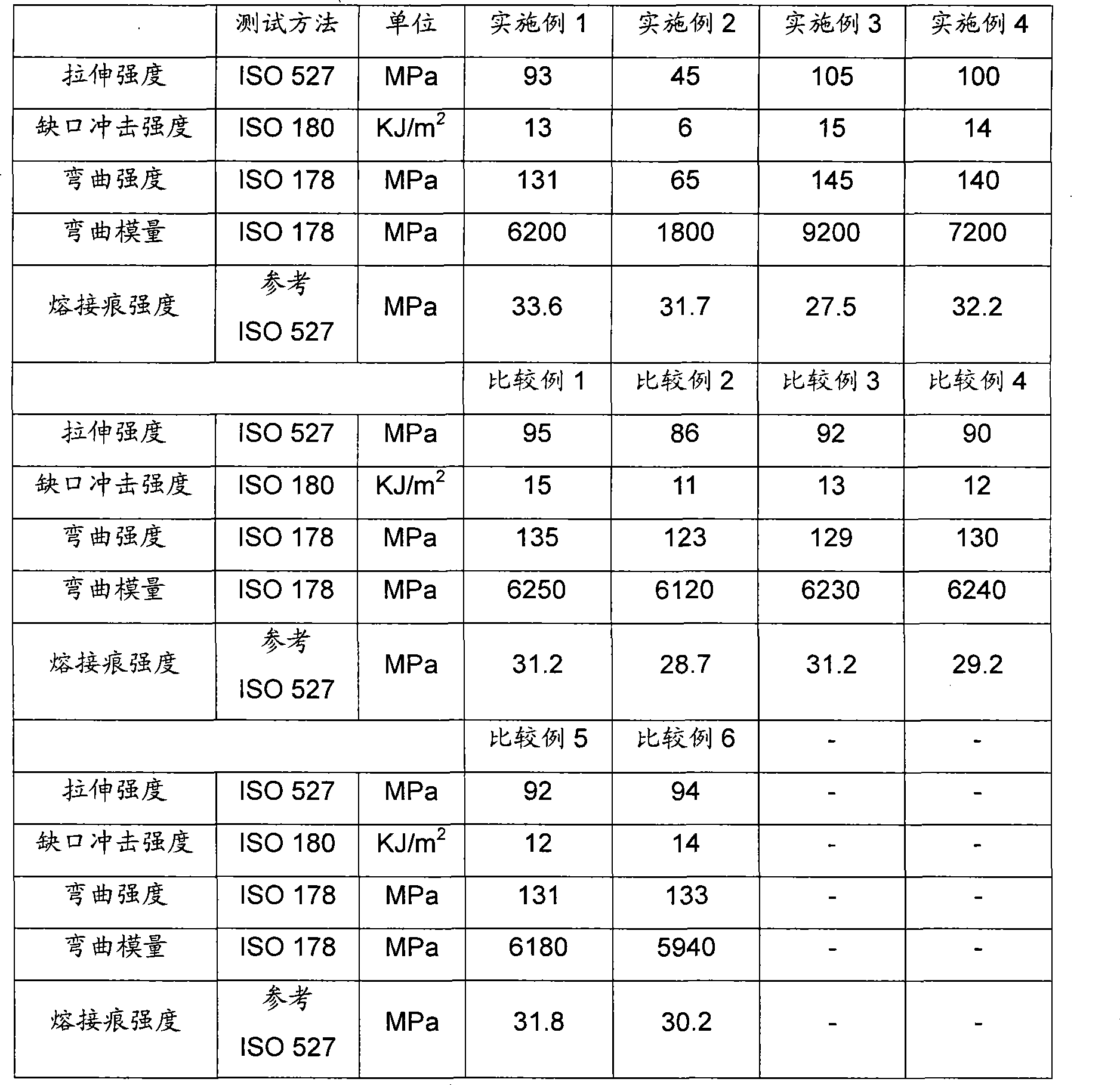

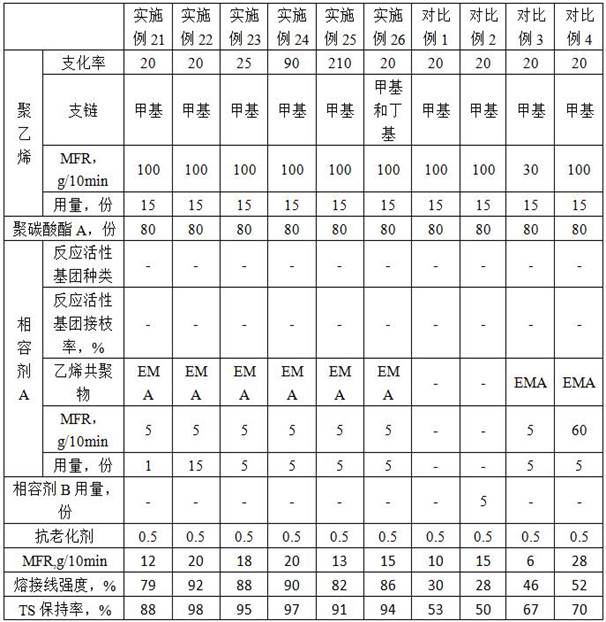

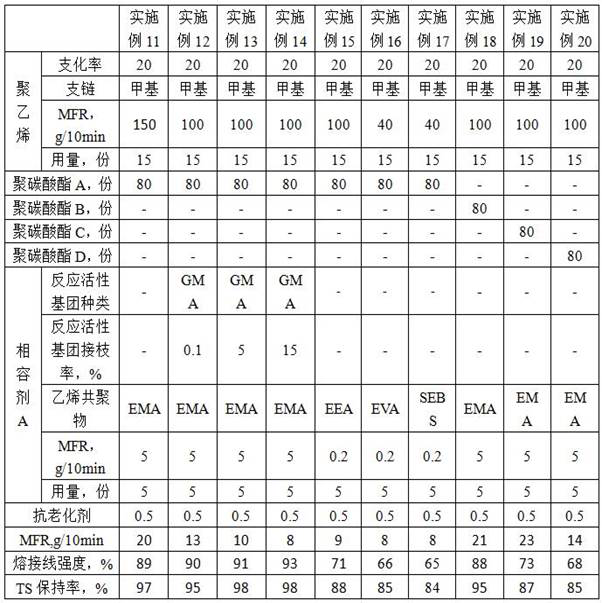

High-weld bond strength polyethylene/polycarbonate (PE/PC) alloy and preparation method thereof

The invention discloses a high-weld bond strength PE / PC alloy including, by weight, 5-40 parts of PE, 40-85 parts of PC, and 1-15 parts of an ethylene copolymer compatibilizer. The PE / PC alloy has high weld bond strength, excellent melt index and good thermal aging resistance, etc.

Owner:KINGFA SCI & TECH CO LTD

High fusion bonding strength glass fiber reinforced polypropylene composite material and preparation method thereof

The invention relates to a high fusion mark strength glass fiber reinforced polypropylene composite material which comprises the following components in parts by weight: 100 parts of polypropylene, 0.1-2 parts of sulfonated polyolefin wax, 1-10 parts of maleic anhydride grafted polypropylene and 1-50 parts of glass fiber. Due to addition of the sulfonated polyolefin wax and the maleic anhydride grafted polypropylene in compounding of glass fiber reinforced polypropylene, the sulfonated polyolefin wax is enriched at a front flowing end in injection molding, therefore, strong polar groups of a high density are formed at a weld mark, the intermolecular interactions at the weld mark can be greatly improved, and thus the strength of the weld mark of the glass fiber reinforced polypropylene canbe improved.

Owner:GUANGDONG IND TECHN COLLEGE

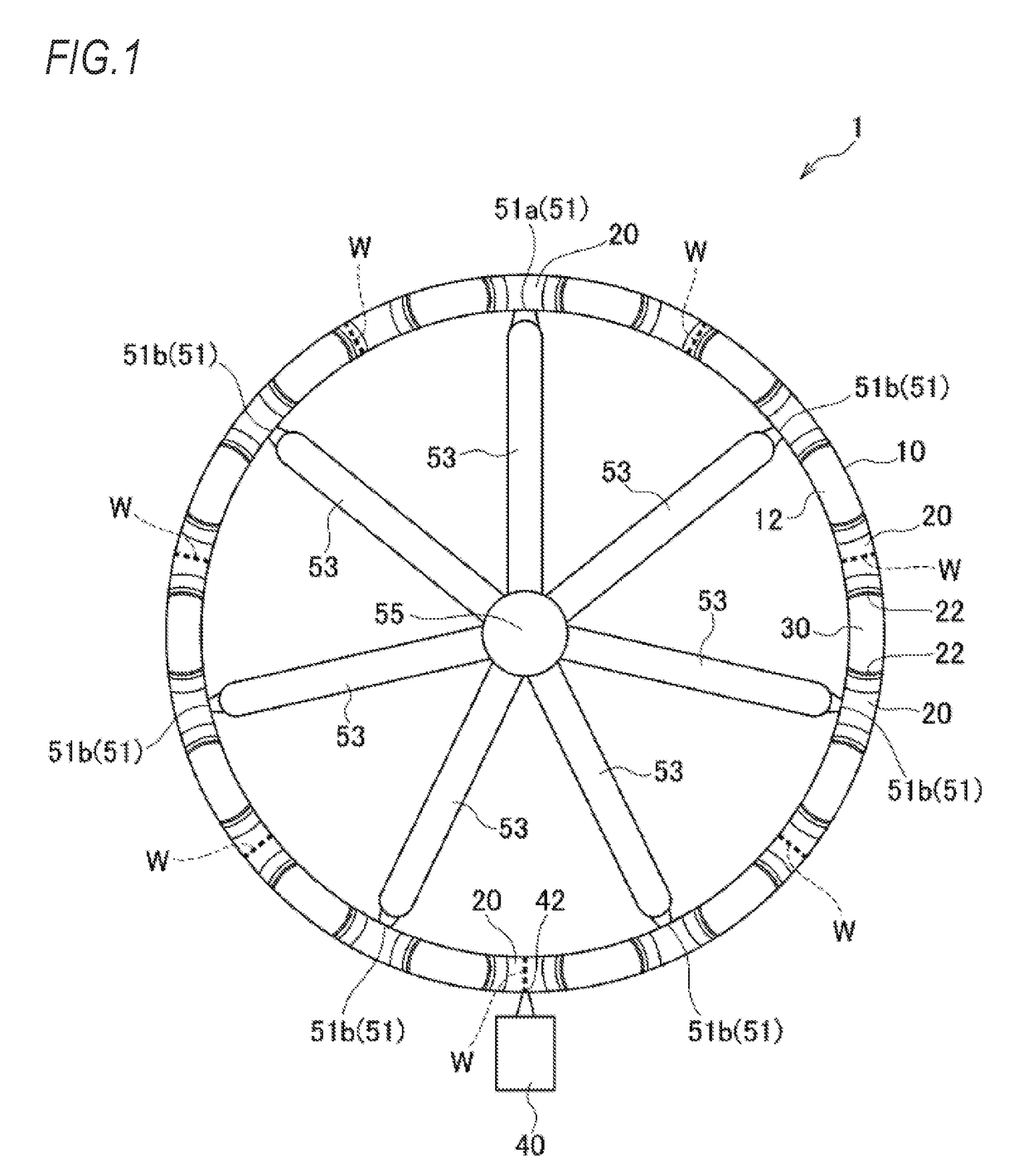

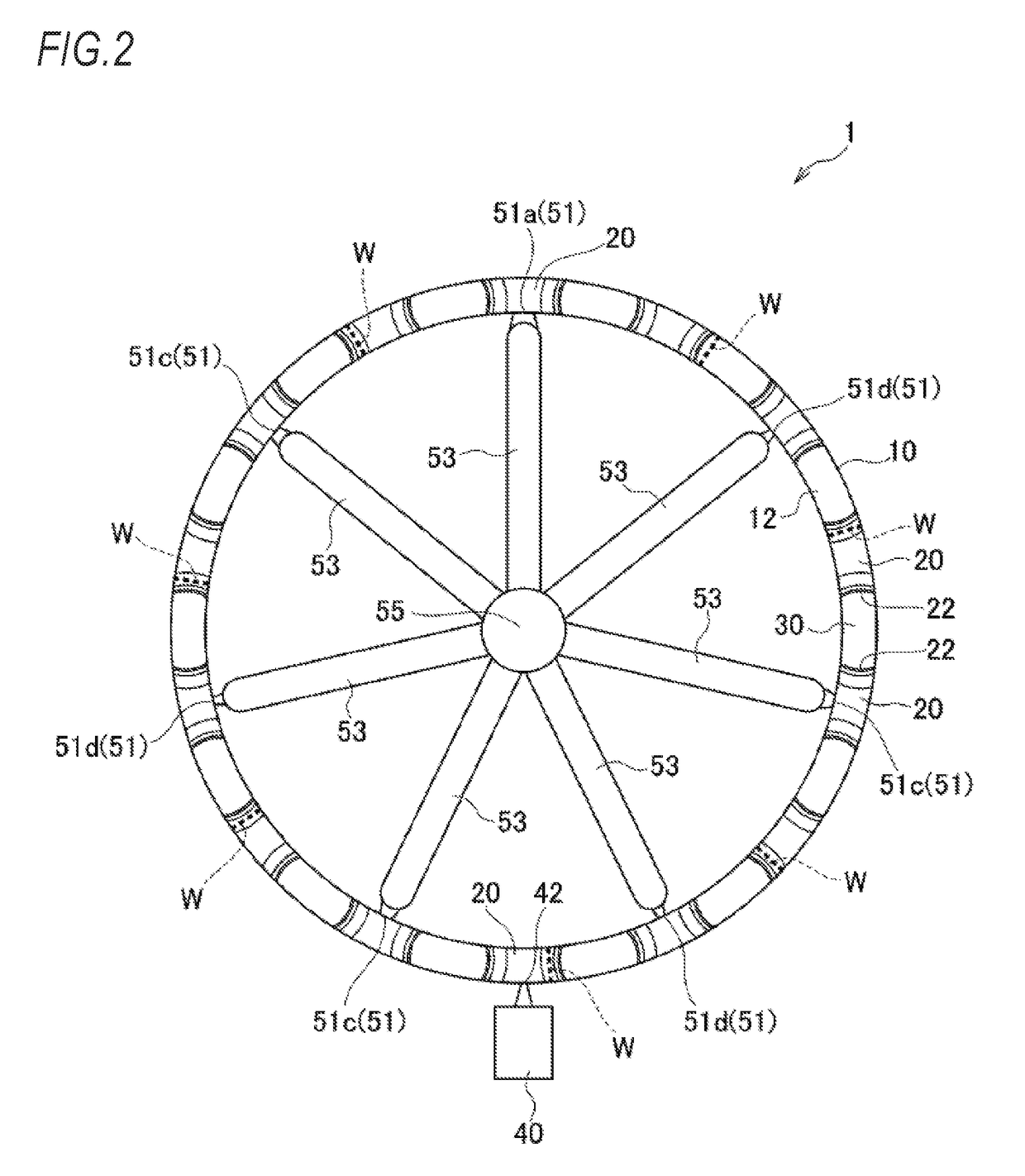

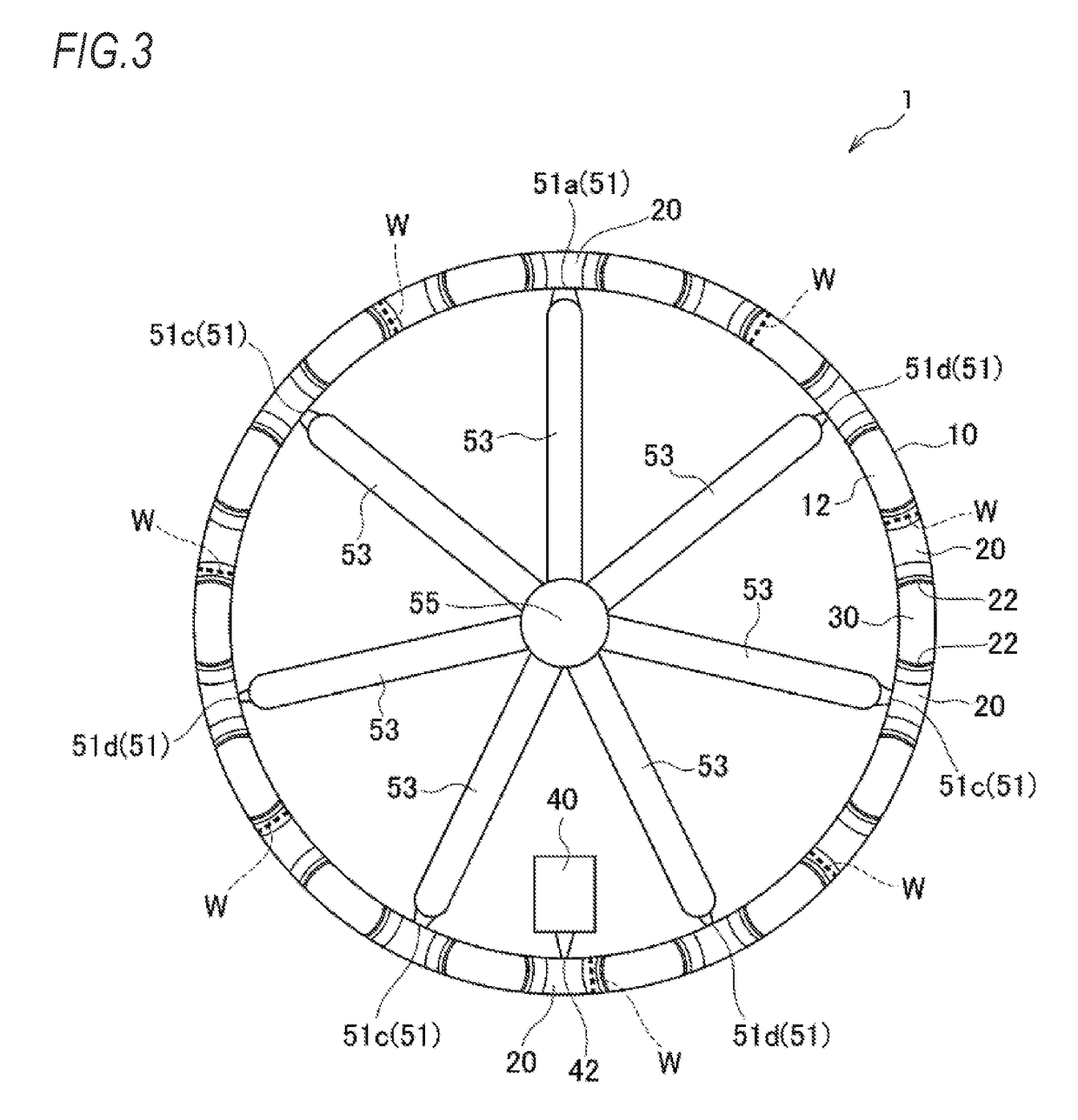

Method for manufacturing bearing cage

ActiveUS20190054673A1Suppress strength degradationImprove weld line strengthShaftsBall bearingsEngineering

Owner:NSK LTD

Glass fiber reinforced polypropylene composite material with high weld mark strength and preparation method therefor

The invention provides a glass fiber reinforced polypropylene composite material with high weld mark strength. The glass fiber reinforced polypropylene composite material comprises the following ingredients in parts by weight: 100 parts of homopolymerized polypropylene, 1-10 parts of maleic anhydride grafted polypropylene, 1-10 parts of PA6 and 1-50 parts of glass fibers, wherein the PA6 is in a molecular weight range of 5,000 to 10,000. According to the glass fiber reinforced polypropylene composite material with high weld mark strength and the preparation method therefor, through adding a certain amount of the PA6 with a specific molecular weight range into the homopolymerized polypropylene, the weld line strength of glass fiber reinforced polypropylene can be improved.

Owner:GUANGDONG IND TECHN COLLEGE

A kind of pc/abs alloy with excellent welding line appearance and high strength and preparation method thereof

ActiveCN105419291BIncrease the thickness of the phase interfaceImprove weld line strengthGlycidyl methacrylateAcrylonitrile

Owner:SHANGHAI KUMHO SUNNY PLASTICS

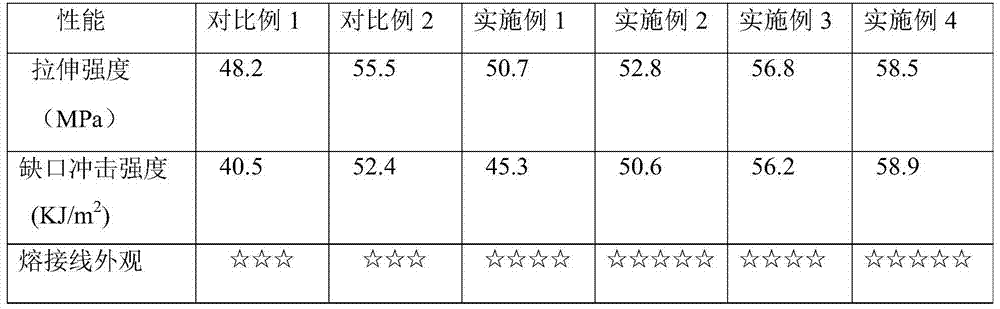

A kind of polypropylene composite material that improves the mechanical property of weld line and its preparation method

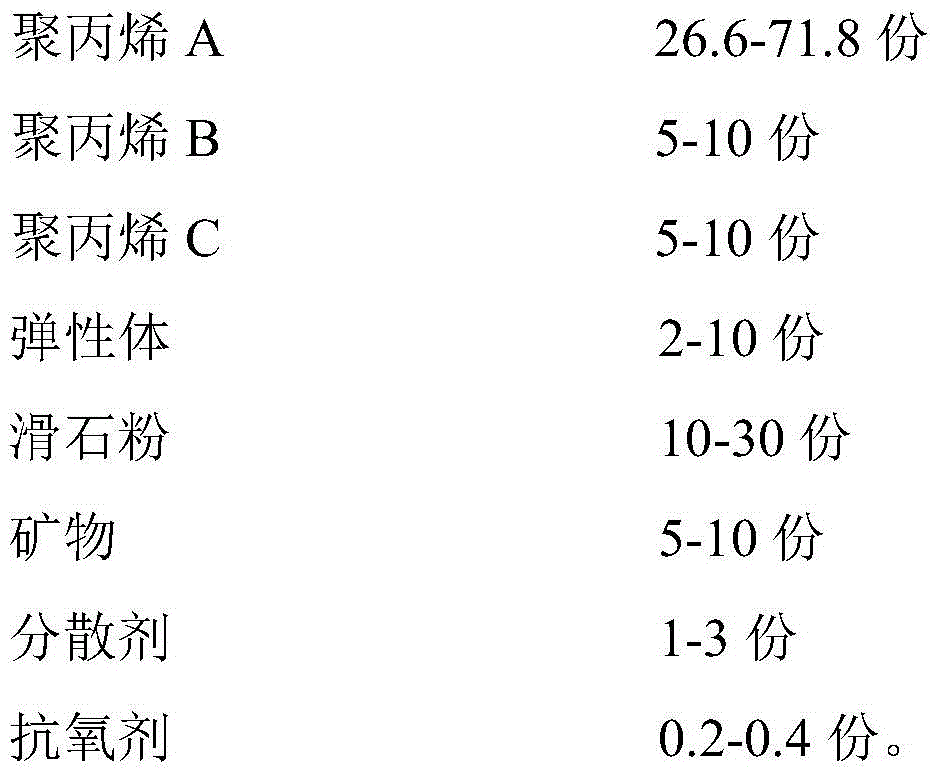

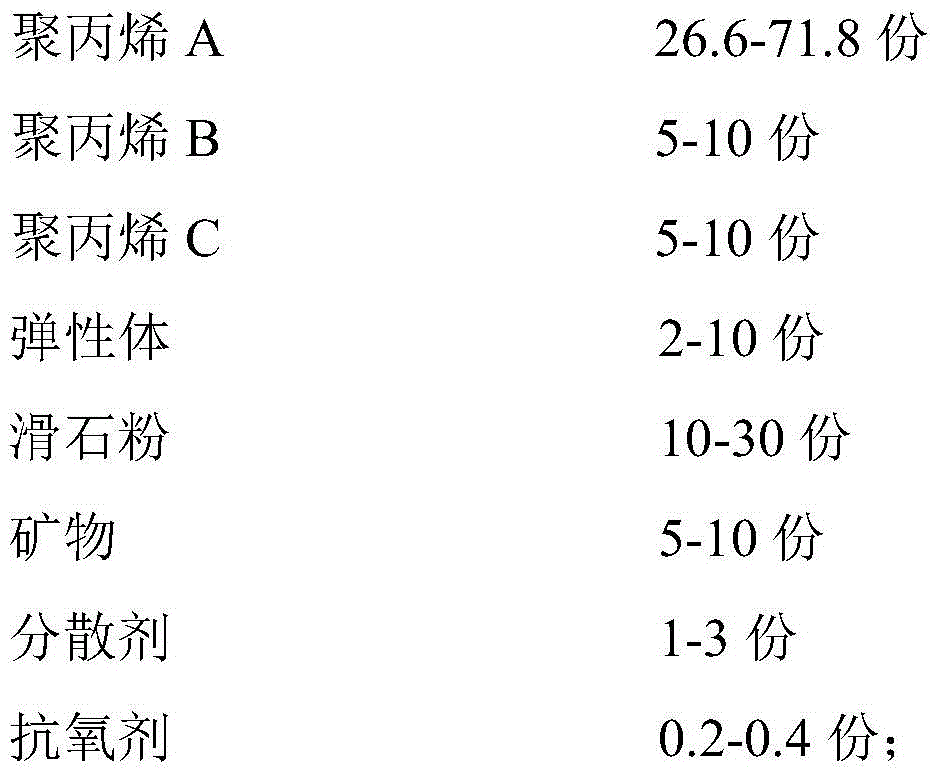

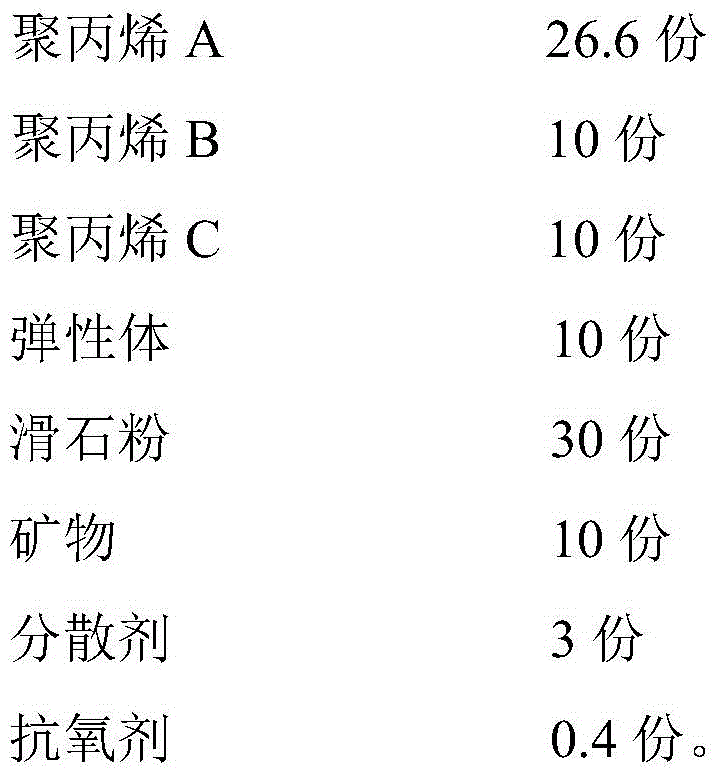

The invention relates to a polypropylene composite material capable of improving mechanical properties of weld lines. The composite material comprises the following components in parts by weight: 26.6-71.8 parts of polypropylene A, 5-10 parts of polypropylene B, 5-10 parts of polypropylene C, 2-10 parts of an elastomer, 10-30 parts of talc powder, 5-10 parts of a mineral, 1-3 parts of a dispersant and 0.2-0.4 part of an antioxidant. A preparation method of the composite material comprises the following steps: preparing polypropylene A, polypropylene B, polypropylene C, the elastomer, talc powder, the mineral, the dispersant and the antioxidant according to the parts by weight, placing in a high-speed mixer and fully mixing to obtain a mixture, placing the mixture in a twin-screw extruder, extruding and granulating and carrying out online vacuum to obtain the polypropylene composite material. Compared with the prior art, the preparation method is simple, wide in sources of raw materials and low in cost and is suitable for mass production; and the prepared polypropylene composite material has the advantages of excellent weld line strength and low volatile characteristics, can replace the existing talc powder reinforcing material and has good application prospects.

Owner:FINE BLEND COMPATILIZER JIANGSU CO LTD

Melt processible fluororesin composition and injection molded article formed from same

ActiveUS20190375929A1High strengthImprove injection effectCoatingsPolymer scienceUltimate tensile strength

Provided is a melt processible fluororesin composition for injection molding of articles that has melt flow that facilitates injection molding, that can enhance strength of a fluororesin weld line area in an injection molded article, and that achieves excellent release from a mold. The fluororesin composition includes two or more types of melt processible fluororesins having different melt flow rates; one of the melt processible fluororesins being a high melt flow rate melt processible fluororesin having a melt flow rate of 35 g / 10 min or greater, and another being a low melt flow rate melt processible fluororesin having a melt flow rate of 10 g / 10 min or greater but less than 35 g / 10 min; and wherein the ratio of the melt flow rate (MFRa) of the high MFR melt processible fluororesin to the melt flow rate (MFRb) of the low MFR melt processible fluororesin (MFRa / MFRb) is from 1 to 10.

Owner:CHEMOURS MITSUI FLUOROPROD CO LTD

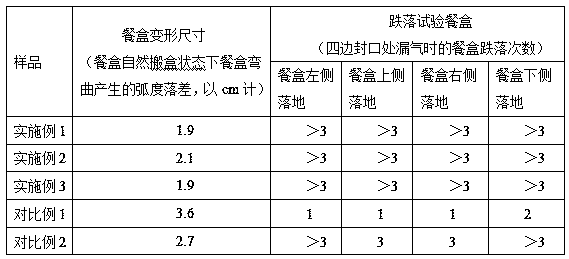

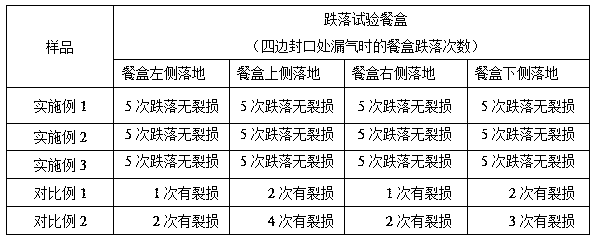

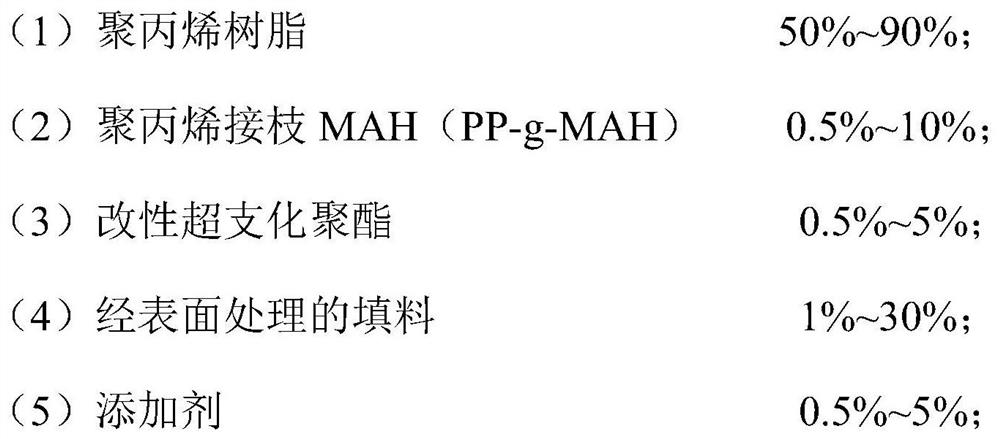

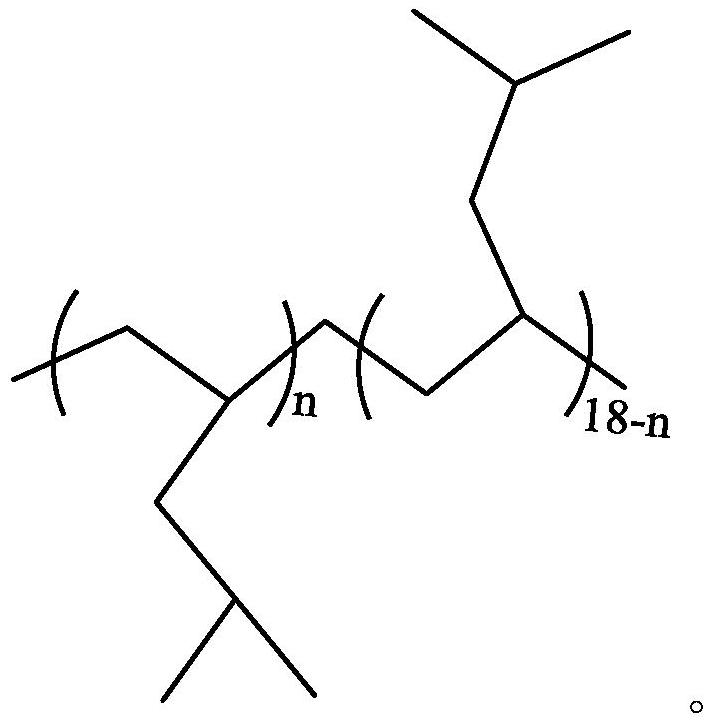

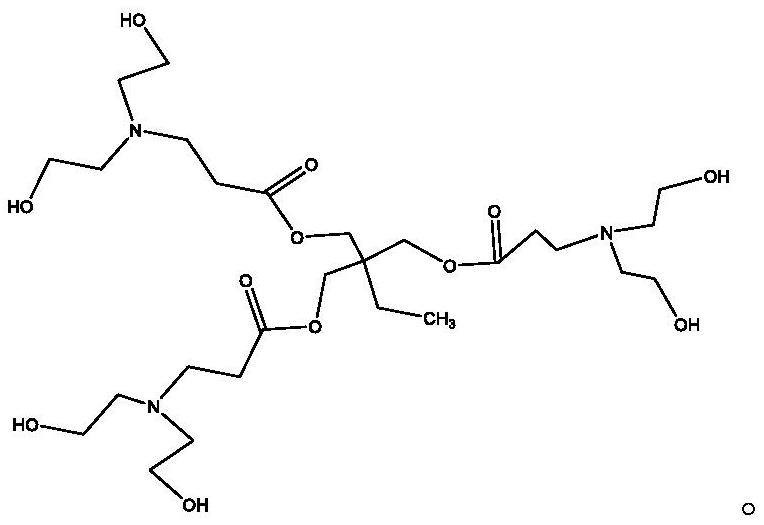

Anti-freezing microwave-resistant starch-based tableware and preparation method thereof

The invention relates to anti-freezing microwave-resistant starch-based tableware and a preparation method thereof. The anti-freezing microwave-resistant starch-based tableware is composed of polypropylene, starch, an anti-freezing agent and a compatilizer, wherein the anti-freezing agent is prepared by mixing and granulating an ethylene vinyl acetate copolymer, an ethylene acrylic acid copolymer,polypropylene maleic anhydride and a polyolefin elastomer. The anti-freezing microwave-resistant starch-based tableware is good in anti-freezing performance, good in toughness, not prone to damage, resistant to microwave heating, good in strength and applicable to fast food industries needing low-temperature freezing and fresh-keeping transportation, e.g., fast food supplied on trains and high-speed trains.

Owner:江苏中科成长环保科技有限公司

A kind of polypropylene material with high weld line strength and preparation method thereof

Owner:WANHUA CHEM (SICHUAN) CO LTD +2

High weld mark strength reinforced polypropylene material and preparation method thereof

The invention provides a high weld mark strength reinforced polypropylene material and a preparation method thereof. The high weld mark strength reinforced polypropylene material consists of 30 to 90 percent of polypropylene (PP) resin with a melt index range of between 0.5 and 100 g / 10min (230 DEG C, 2.16 kg), 5 to 50 percent of fiberglass treated by a surfactant, 0.5 to 5 percent of mineral filler treated by a surfactant, 0.5 to 10 percent of interface modifier and 0.5 to 5 percent of other additives. As the mineral filler, the interface modifier and the fiberglass are added into the polypropylene material and strong interface combination is formed between the interface modifier, the fiberglass and the polypropylene, the viscosity of disperse phase is improved and the orientation of a polypropylene molecular chain and fiberglass along the vertical flowing direction is blocked, so that the strength of a weld mark of the polypropylene material is improved.

Owner:KINGFA SCI & TECH CO LTD +1

A kind of high welding line strength polyethylene/polycarbonate alloy and its preparation method

Owner:KINGFA SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com