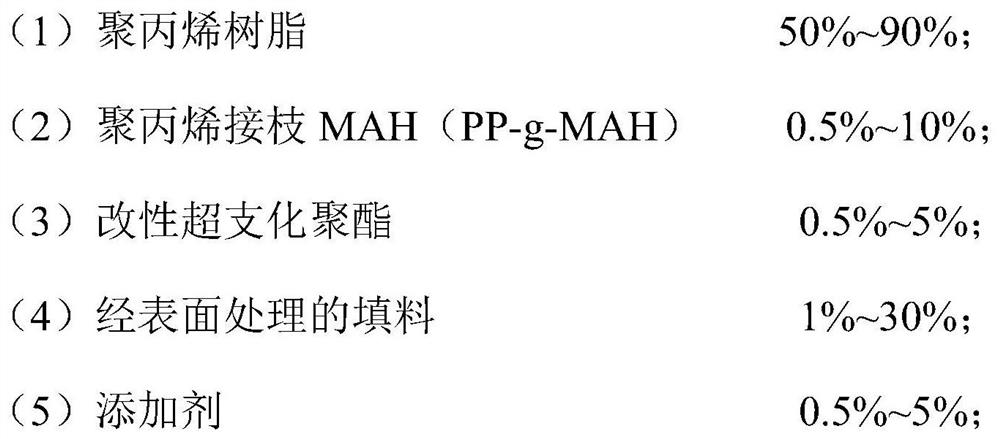

A kind of polypropylene material with high weld line strength and preparation method thereof

A polypropylene material, high-melting technology, applied in the field of polymer material processing and molding, can solve the problems of difficulty in realization, hindering the orientation of polypropylene molecular chains and glass fibers, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

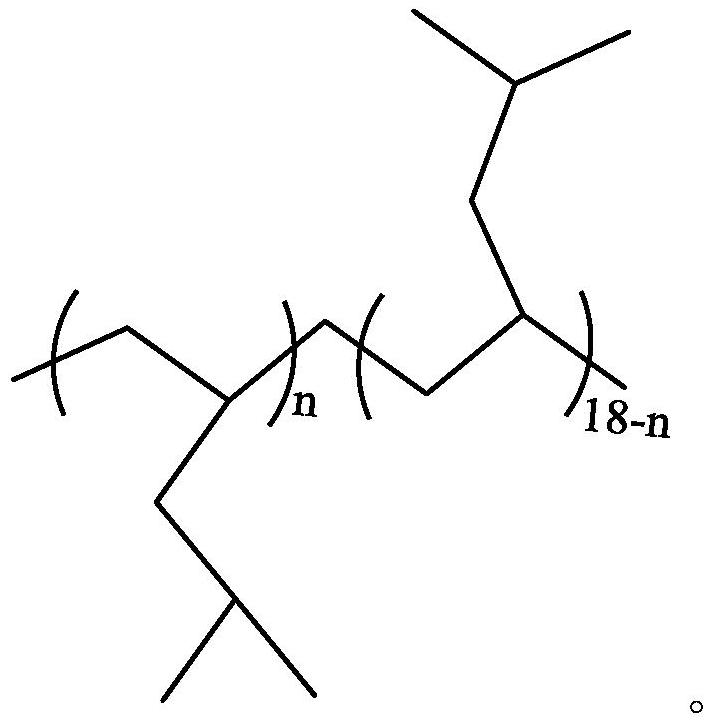

Method used

Image

Examples

Embodiment 1

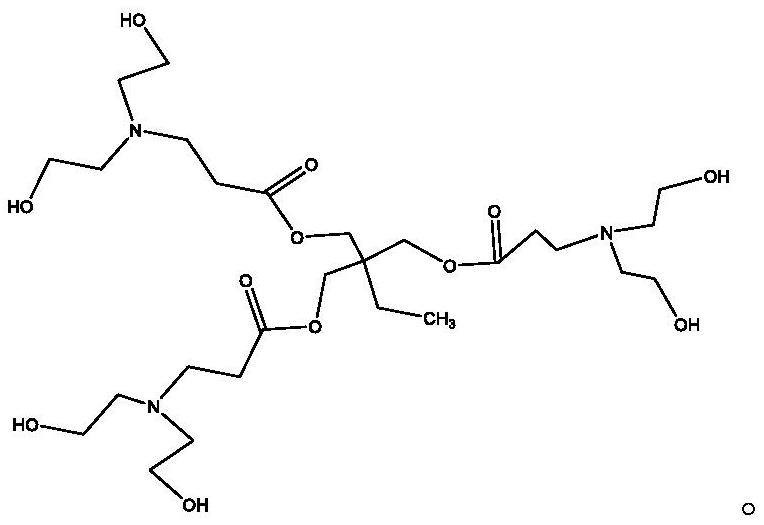

[0041] Prepare AB 2 : Add 10.51g diethanolamine and 30ml methanol into a four-necked bottle connected with nitrogen protection, condenser, and mechanical stirring, start stirring, drop 8.6g methyl acrylate at room temperature, stir the mixture for 30min under nitrogen protection, and slowly heat up to 33°C, react for 4h, vacuumize for 1h to remove methanol, cool and discharge to obtain AB 2 .

[0042] Preparation of hydroxyl-terminated hyperbranched polyesters:

[0043] Add 159.53g of AB to a four-necked flask equipped with a thermometer, a stirring device, a nitrogen device and a Dean-Stark device 2 , 31.49g of trimethylolpropane and 3.10g of p-toluenesulfonic acid, slowly heated to 120°C, after the reactants were completely melted, kept at 120°C for 4h. Methanol produced by the reaction was collected with a Dean-Stark device. After the reaction was over, the product was taken out while it was hot.

[0044] Preparation of modified hyperbranched polyester:

[0045] Slowl...

Embodiment 2

[0049] Prepare AB 2 : Add 10.51g diethanolamine and 30ml methanol into a four-necked bottle connected with nitrogen protection, condenser, and mechanical stirring, start stirring, drop 8.6g methyl acrylate at room temperature, stir the mixture for 30min under nitrogen protection, and slowly heat up to 33°C, react for 4h, vacuumize for 1h to remove methanol, cool and discharge to obtain AB 2 .

[0050] Preparation of hydroxyl-terminated hyperbranched polyesters:

[0051] Add 159.53g of AB to a four-necked flask equipped with a thermometer, a stirring device, a nitrogen device and a Dean-Stark device 2, 31.49g of trimethylolpropane and 3.10g of p-toluenesulfonic acid, slowly heated to 120°C, after the reactants were completely melted, kept at 120°C for 5h. Methanol produced by the reaction was collected with a Dean-Stark device. After the reaction was over, the product was taken out while it was hot.

[0052] Preparation of modified hyperbranched polyester:

[0053] Slowly...

Embodiment 3

[0055] Prepare AB 2 : Add 10.51g diethanolamine and 30ml methanol into a four-necked bottle connected with nitrogen protection, condenser, and mechanical stirring, start stirring, drop 8.6g methyl acrylate at room temperature, stir the mixture for 30min under nitrogen protection, and slowly heat up to 33°C, react for 4h, vacuumize for 1h to remove methanol, cool and discharge to obtain AB 2 .

[0056] Preparation of hydroxyl-terminated hyperbranched polyesters:

[0057] Add 159.53g of AB to a four-necked flask equipped with a thermometer, a stirring device, a nitrogen device and a Dean-Stark device 2 , 31.49g of trimethylolpropane and 3.10g of p-toluenesulfonic acid, slowly heated to 120°C, after the reactants were completely melted, kept at 120°C for 5h. Methanol produced by the reaction was collected with a Dean-Stark device. After the reaction was over, the product was taken out while it was hot.

[0058] Preparation of modified hyperbranched polyester:

[0059] Slowl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com