A kind of high welding line strength polyethylene/polycarbonate alloy and its preparation method

A technology of polycarbonate and polyethylene, applied in the field of high weld line strength polyethylene/polycarbonate alloy and its preparation, can solve the problems of component fracture failure, poor compatibility, low weld line strength, etc., and achieve weld line strength Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

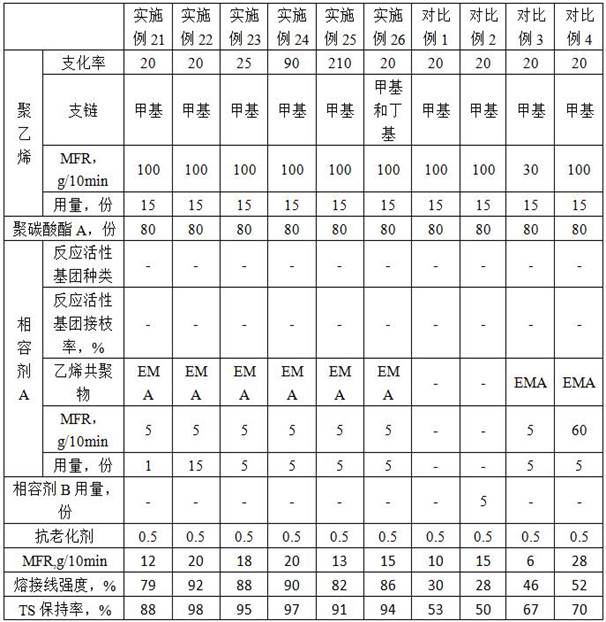

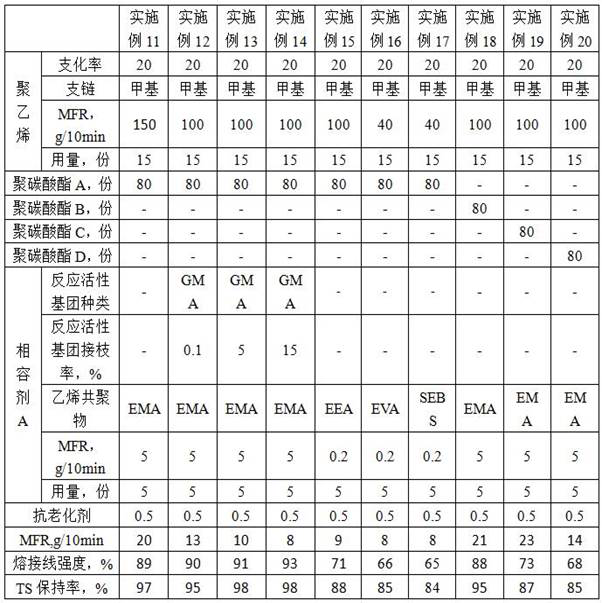

[0032] The present invention will be further described below through specific embodiments. The following examples are preferred implementation forms of the present invention, but the implementation manners of the present invention are not limited by the following examples.

[0033] Embodiment, comparative example raw material is derived from commercially available, specifically:

[0034] Polyethylene: the number of branches contained in the branching rate of 1000 carbon atoms, the branching rate in the table is the base number of 1000 carbon atoms.

[0035] EMA: ethylene-methacrylic acid copolymer;

[0036] EEA: ethylene-ethyl acrylate copolymer;

[0037] EMA – g-GMA: ethylene-methacrylic acid grafted epoxy group, (GMA is epoxy group);

[0038] EVA: ethylene-vinyl acetate copolymer;

[0039]SEBS: styrene-ethylene-butadiene-styrene copolymer;

[0040] Compatibilizer B: PP-G-MAH (polypropylene grafted maleic anhydride);

[0041] Polycarbonate A: aromatic polycarbonate with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com