Patents

Literature

698results about How to "Improve heat aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane caulking material for expansion joints of ballastless track of high speed railway

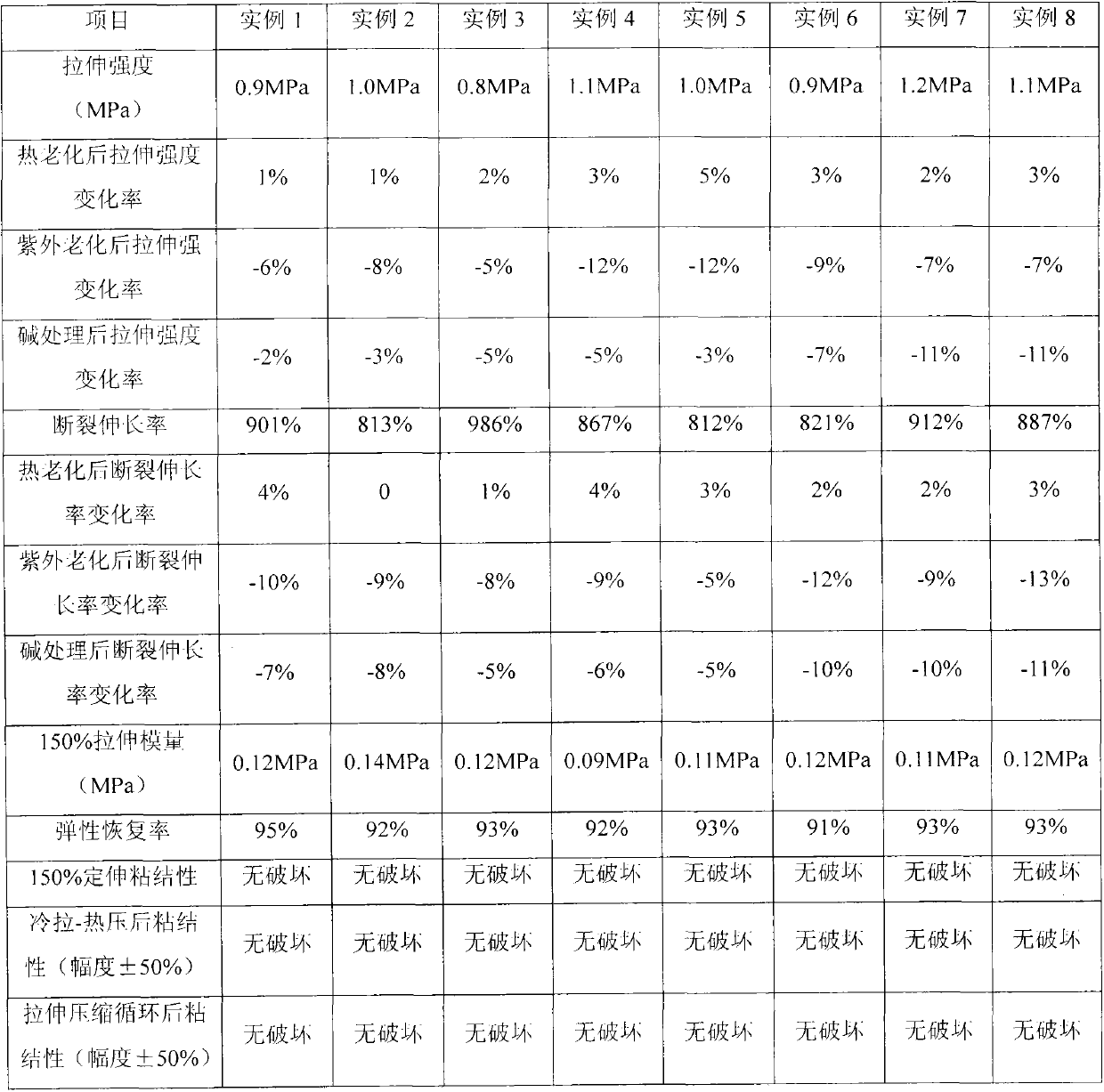

ActiveCN103992633AImprove displacement abilityModerate mechanical strengthLow temperature curingBond properties

A polyurethane caulking material for expansion joints of a ballastless track of a high speed railway is disclosed. The caulking material is prepared from two parts A and B. the part A is composed of the following raw materials, by weight, 100 parts of isocyanate and its prepolymer, 10-150 parts of a plasticizer, 5-150 parts of a solid filler, 1-20 parts of a diluents, 1-5 parts of an adhesion promoter, 0-10 parts of a thixotropic agent and 1-3 parts of a water-removal agent. The part B is composed of the following raw materials, by weight, 10-20 parts of modified polyhydric alcohol, 1-5 parts of a diluent, 2-30 parts of a plasticizer, 5-30 parts of a solid filler, 0-5 parts of a thixotropic agent, 0.5-2 parts of an antifoaming agent, 0.1-1 part of an anti-aging agent and 0-0.01 part of a catalyst. The mass ratio of the part A to the part B is 4:1-10:1. The polyurethane caulking material has advantages of good low-temperature curing performance, high displacement capability, low tensile modulus, good bond property and excellent endurance quality and fatigue resistance, and is suitable for expansion joints of a ballastless track of a high speed railway as well as expansion joints of roads and airfield runways.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

Single-core cable insulating rubber for low-smoke and zero-halogen flame-resistant rail vehicle with rated voltage of 3000V

ActiveCN101914244ASmall compression deformationImprove mechanical propertiesRubber insulatorsInsulated cablesHalogenFlame resistance

The invention discloses single-core cable insulating rubber for a low-smoke and zero-halogen flame-resistant rail vehicle with rated voltage of 3000V and temperature resistance of a 125 DEG C level. The single-core cable insulating rubber comprises the following components in parts by weight: 100 parts of crude rubber, 2-6 parts of organic peroxide curing agent, 1-5 parts of auxiliary curing agent, 1-4 parts of coupling agent, 3-8 parts of anti-aging agent, 10-25 parts of strengthening agent and 5-10 parts of plasticizing agent. The single-core cable insulating rubber has excellent insulating property and is very soft. A cable produced by the rubber is soft and is easy to bend, install and lay. The single-core cable insulating rubber has excellent insulating property, can continuously and normally work at voltage of 1000V and high temperature of 125 DEG C, can resist climates, ozone, heat, ageing, acid, alkali and fuel oil well and has low-smoke and zero-halogen flame resistance, environmental protection, safety and long service life.

Owner:JIANGSU JUYE CABLE

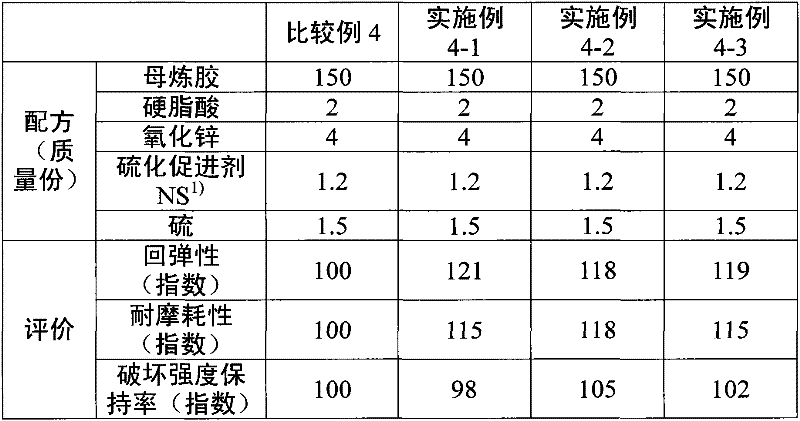

Dispersion liquid of chemical for rubbers, method for producing same, rubber wet master batch containing chemical for rubbers, rubber composition, and tire

Owner:BRIDGESTONE CORP

1E-grade K1 type halogen-free flame retardant material for nuclear power plants and application thereof

ActiveCN102731895AImprove thermal stabilityStrong absorption capacityPlastic/resin/waxes insulatorsInsulated cablesNuclear powerPhosphoric acid

The invention discloses a 1E-grade K1 type halogen-free flame retardant material for nuclear power plants. The material comprises the following substances: 100 parts of vinyl polymers, 1-20 parts by weight of polymer compatilizer, 0.5-10 parts by weight of organosilicon polymers, 1-10 parts by weight of complex antioxidant, 0.1-10 parts by weight of light stabilizer and 0.1-100 parts by weight of high molecular weight ammonium polyphosphate and / or 0.1-50 parts by weight of phosphate flame retardants and / or 0.1-50 parts by weight of melamine cyanurate and / or 0.1-50 parts by weight of melamine pyrophosphate, wherein the complex antioxidant is a complexing agent formed by blending hindered phenol main antioxidants, thioether auxiliary antioxidants, hindered amine auxiliary antioxidants and an anti-copper agent in a weight ratio of 1:(1-4):(1-2):(0.5-1). The material can serve as the insulating material of 1E-grade K1 type halogen-free flame retardant heat shrink tubes, wires and cables and cable accessories for nuclear power plants.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

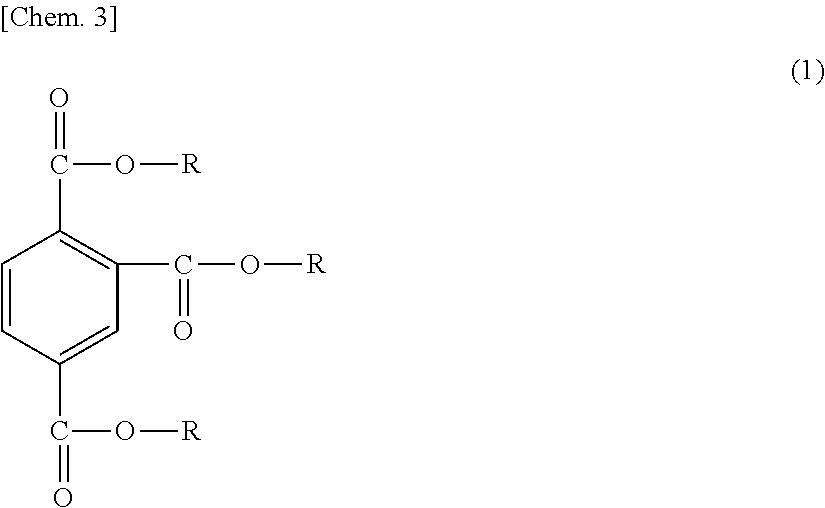

Vinyl chloride resin composition for powder molding, and molded article and laminate of vinyl chloride resin

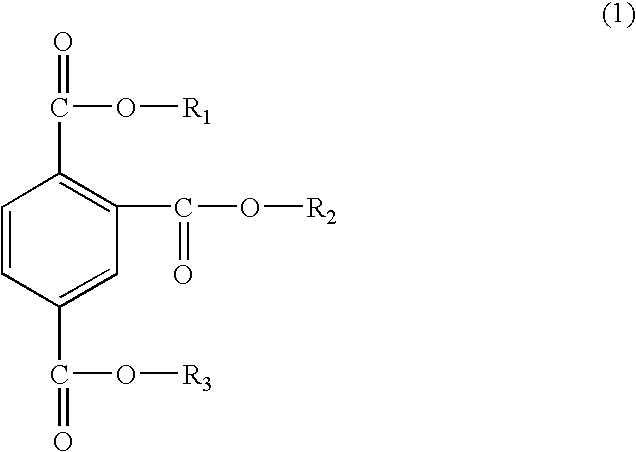

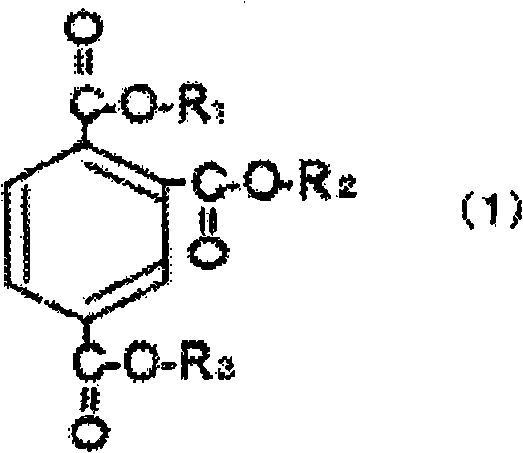

InactiveUS20130089728A1Improve heat aging resistanceImprove the immunityPlastic/resin/waxes insulatorsSynthetic resin layered productsPlasticizerPolymer chemistry

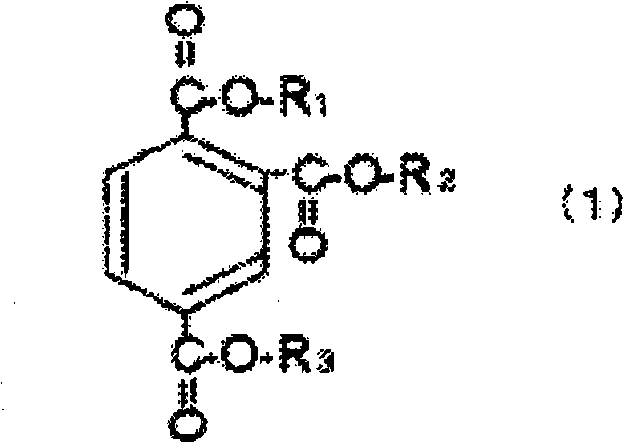

A vinyl chloride resin composition for powder molding contains 100 parts by mass of (a) a vinyl chloride resin, 65 to 105 parts by mass of (b) a specific trimellitate plasticizer, and 10 to 50 parts by mass of (c) a specific diester phthalate plasticizer. A mixture ratio of (c) the specific diester phthalate plasticizer to whole plasticizers is in a range of 5 to 50 percents by mass.

Owner:ZEON CORP

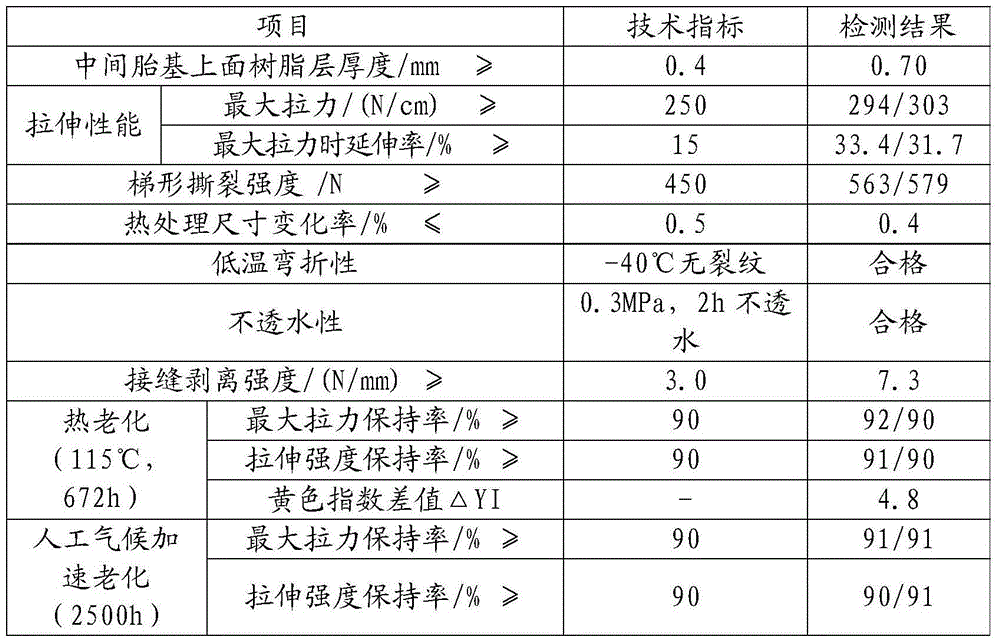

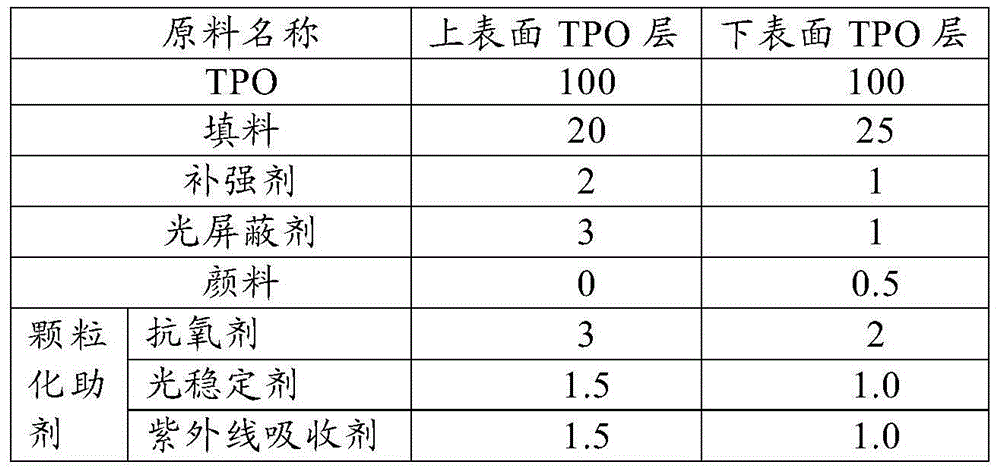

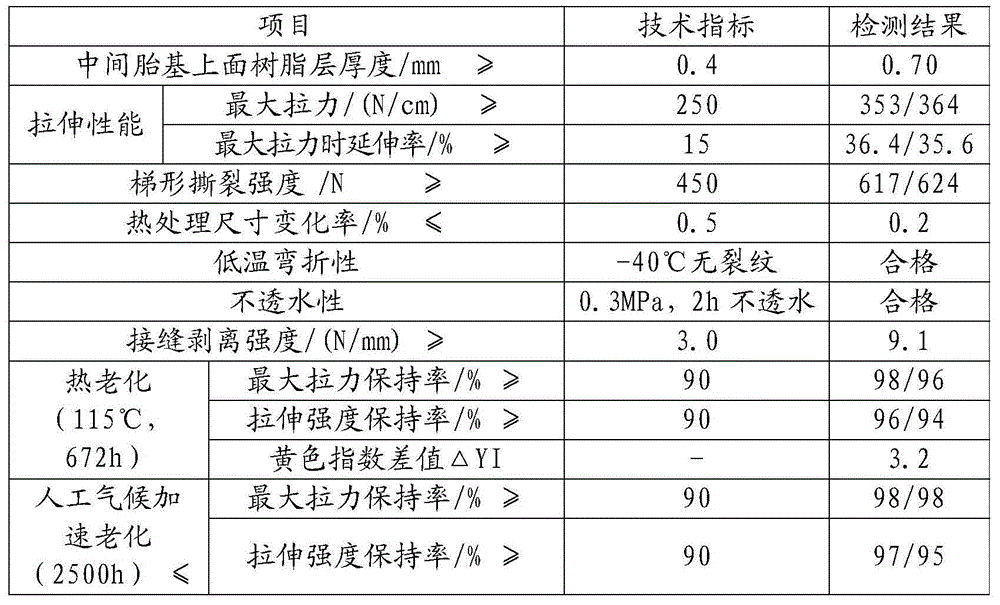

Waterproof roll and preparation method thereof

ActiveCN104669747AImprove heat aging resistanceGood weather resistanceSynthetic resin layered productsConstructions elementsThermoplasticCrazing

The invention provides a waterproof roll and a preparation method thereof, belongs to the technical field of polymer waterproof rolls, and can solve the problems of color fading, color changing, surface staining, microcracking, hairline crack and the like of a conventional TPO (thermoplastic polyolefin) roll product in the use process. The waterproof roll comprises a TPO roll layer, wherein raw materials of the TPO roll layer comprise polymeric TPO resin and a granular auxiliary; the granular auxiliary comprises an antioxidant, a light stabilizer and an ultraviolet light absorber, and the grain size of the granular auxiliary is 0.5-1.5 mm. The waterproof roll has excellent weather fastness, ageing resistance, waterproof function and fastness and reliability in construction.

Owner:苏州东方雨虹建筑材料有限公司

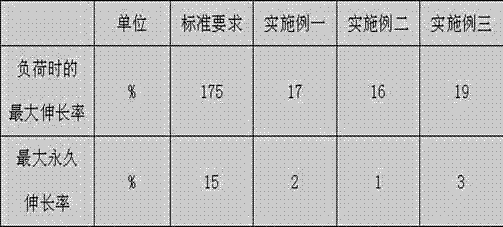

1E-level K1-type shrinkable tube used in nuclear power station and preparation method thereof

ActiveCN101661803AImprove flame retardant performanceImprove heat aging resistanceNuclear energy generationContainmentAging propertyFire retardant

The invention relates to a 1E-level K1-type shrinkable tube used in a nuclear power station, which comprises the following components by weight: 40 to 60 parts of base resin, 40 to 60 parts of hexyl-propyl rubber, 30 to 60 parts of flame retardant, 5 to 20 parts of antiradiation agent, 4 to 12 parts of antioxidizer, 2 to 5 parts of lubricant, and 3 to 8 parts of color masterbatch. The preparationmethod of the 1E-level K1-type shrinkable tube used in the nuclear power station comprises the following steps of: taking all the components by weight, carrying out mixed granulation by banburying ormixed granulation by a parallel double-screw extruder, then using a single-screw extruder for extrusion to form the tube, and carrying out radiation cross linking of cobalt 60 or electron accelerator50-180KGy to the tube, wherein the tube after the radiation cross linking expands by 2 to 6 times at the temperature of 90 to 150 DEG C. The shrinkable tube reaches and far exceeds the performance requirement of the 1E-level K1-type shrinkable tube used in the nuclear power station. The 1E-level K1-type shrinkable tube used in the nuclear power station has good flame retardant properties, can passV W-1 combustion test; has excellent heat-proof aging property, with the tensile strength and elongation at break of the product far stronger than the performance requirement; and outstanding intenseradiation-resistant function, and can pass AC withstand voltage test.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +1

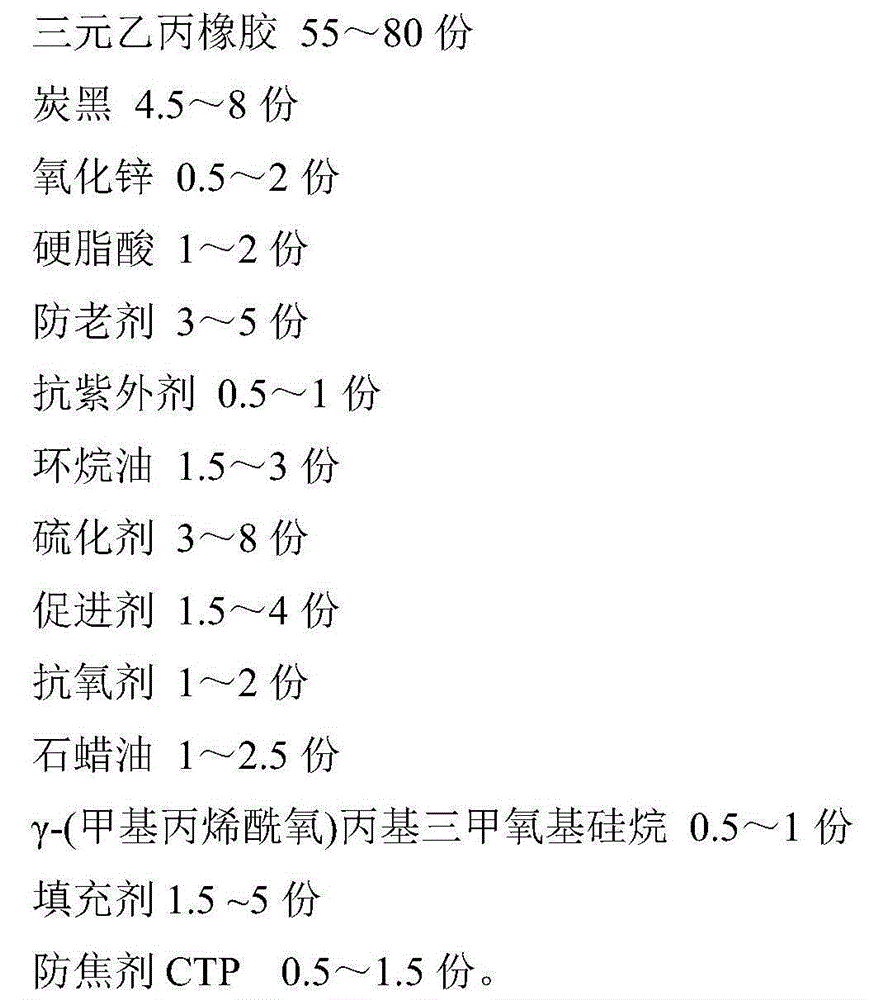

Automobile rubber sealing strip and preparation method thereof

The invention discloses an automobile rubber sealing strip and a preparation method thereof. The automobile rubber sealing strip comprises the following components in parts by weight: 55-80 parts of ethylene propylene diene monomer rubber, 4.5-8 parts of carbon black, 0.5-2 parts of zinc oxide, 1-2 parts of stearic acid, 3-5 parts of anti-aging agent, 0.5-1 part of ultraviolet-resistant agent, 1.5-3 parts of naphthenic oil, 3-8 parts of vulcanizing agent, 1.5-4 parts of accelerator, 1-2 parts of antioxidant, 1-2.5 parts of paraffin oil, 0.5-1 part of gamma-(methylacryloyloxy)propyltrimethoxy silane, 1.5-5 parts of filler and 0.5-1.5 parts of anti-scorching agent CTP. The automobile rubber sealing strip enhances the high temperature resistance, low temperature resistance, stability to light, ozone. oxygen and the like and other comprehensive properties of the product and improves the interface compatibility on the premise of keeping the original mechanical properties. The preparation method has the advantages of simple technique, short vulcanization time, lower energy consumption and lower production cost.

Owner:SUZHOU GOODTIME TECH DEV

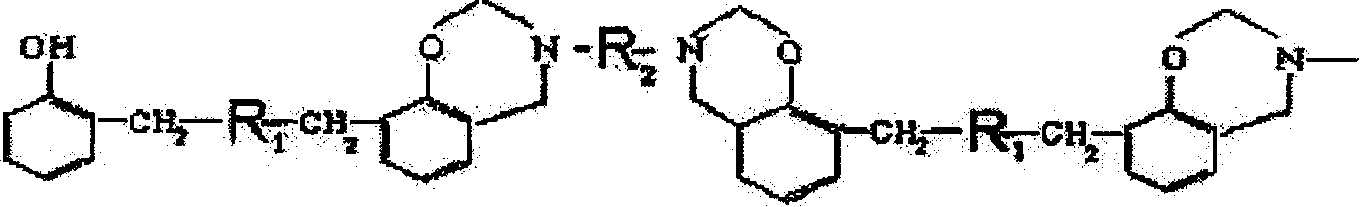

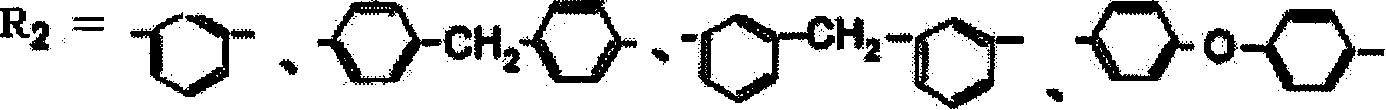

Benzoxazine resin containing aralkyl structure, its preparation method and use

The preparation method for benzoazine with aralkyl group comprises: adding phenols compound as 80-100 weight shares and 80-120 aralkyl compound into the reaction kettle; with 1-4 acidic catalyst, stirring to react for 1-3h at 80-140Deg; cooling to below 50Deg; adding 30-40% formaldehyde liquid as 160-360 weight shares and 4-8 basic catalyst to adjust pH value within 6-9; adding solvent and 40-120 diamine to reflux reaction for 2-8h at 85-95Deg; finally, vacuum dewatering at 80-40Deg. This product is used mainly to manufacture high-performance constructional material fit more than 180Deg, the electrically insulating material, or glass fabric and extruding material with vitrifying temperature more than 175Deg.

Owner:SICHUAN DONGCAI ENTERPRISE GRP CO LTD

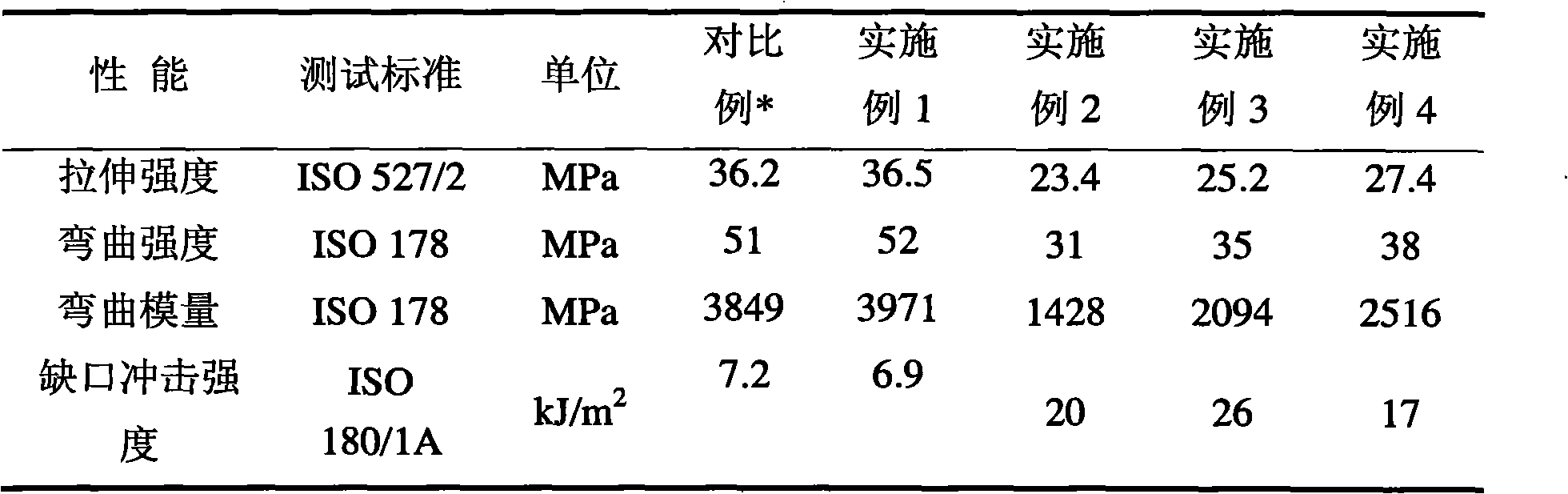

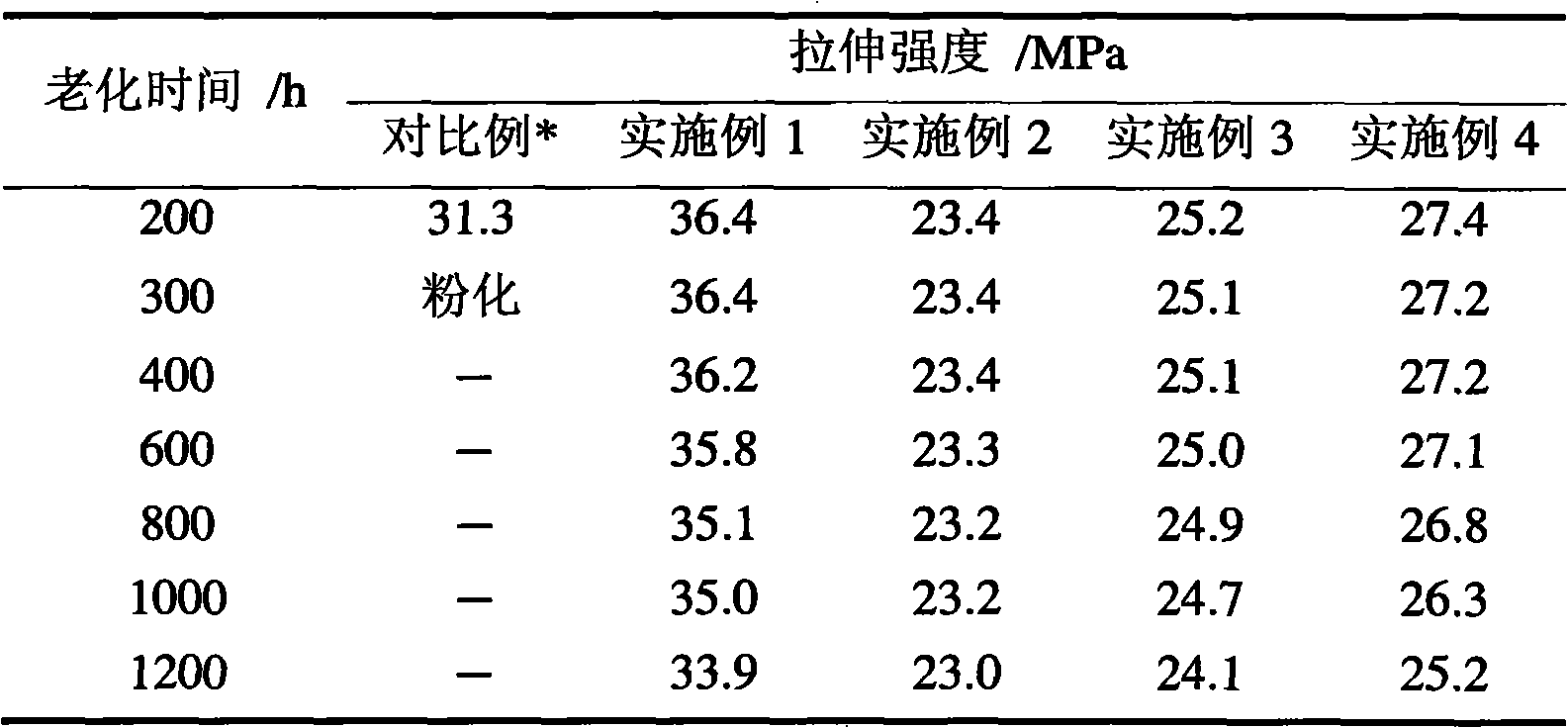

Thermo-oxidative ageing resistance black filling polypropylene composite material and preparation method thereof

The invention discloses a thermo-oxidative ageing resistance black filling polypropylene composite material and a preparation method thereof. The composite material consists of the following components in percentage by weight: 50 to 75 percent of polypropylene, 10 to 40 percent of filling, 0 to 15 percent of an elastomer, 0.5 to 2 percent of an acid acceptor, 0.7 to 1.5 percent of composite antioxidant, 0.2 to 0.6 percent of a processing aid, 0.4 to 0.8 percent of carbon black, and 0.2 to 0.8 percent of paraffin oil. In the composite material, the acid acceptor is added to adsorb acid substances on the carbon black surface, and the antioxidant containing a plurality of reactive functional groups is also added, so that the dissolubility of the antioxidant in the system is increased, the oxidation resistance of the antioxidant cannot be easily weakened by the carbon black, and the thermal-oxidative ageing resistance of a black high filling polypropylene system can be effectively improved. The acid acceptor in the polypropylene resin can eliminate halogen in the resin and the residual catalyst in the resin to prevent the halogen or the catalyst from reacting with the resin to generate gel, and can effectively prevent the halogen or the catalyst from corroding the equipment. The acid acceptor can effectively adsorb the acid substances of the PP filling system and impurities on the carbon black surface so as to improve the thermo-oxidative ageing resistance of the system.

Owner:KINGFA SCI & TECH CO LTD +3

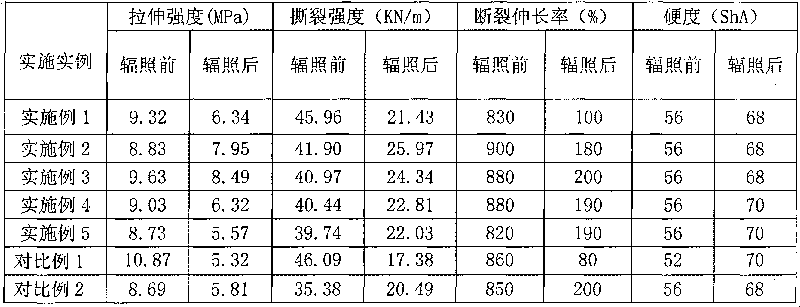

Peroxidated heat-vulcanized silicone rubber resistant to irradiation and preparation method thereof

ActiveCN101717581AImprove radiation resistanceImprove mechanical propertiesChemical industryPolymer science

The invention discloses a peroxidated heat-vulcanized silicone rubber resistant to irradiation and a preparation method thereof. The peroxidated heat-vulcanized silicone rubber comprises 100 parts of silicon rubber, 10-60 parts of anti-irradiation agent, 40-70 parts of gaseous white carbon black, 2-7 parts of concentrated crosslinker and 0.5-2.5 parts of vulcanizing agent according to parts by weight. The peroxidated heat-vulcanized silicone rubber resistant to irradiation is prepared from a main material of methyl vinyl silicon rubber by modification; the rubber has strong environmental suitability, and the stretch strength reaches more than 6MPa and the tear strength reaches more than 20KN / m after 500KGy of irradiation; the rubber can be used for producing various rubber products resistant to irradiation such as rubber cushions, sealing parts, buffer elements, distance sleeves, diaphragms, and can be widely applied to the conditions abundant in high-energy irradiation such as aerospace, nuclear industry, electronic communication, chemical industry, medicine and ship; thus, the rubber has very good economic benefit and promotional value.

Owner:SHANDONG UNIV

All-steel load radial tire tread base rubber material and preparation method thereof

InactiveCN104530499AImprove dispersion and uniformityImprove processabilitySpecial tyresChemistryCarbon black

The invention relates to an all-steel load radial tire tread base rubber material and a preparation method thereof. The base rubber material comprises the following raw materials in parts by weight: 100 parts of natural rubber, 0-0.3 part of a peptizer, 30-45 parts of carbon black, 7-18 parts of white carbon black, 1-4 parts of a silane coupling agent, 3-5 parts of zinc oxide, 1-3 parts of stearic acid, 1-3 parts of phenolic tackifying resin, 0.5-3 parts of petroleum resin, 0.5-2 parts of an anti-aging agent 6PPD, 0.5-2 parts of an anti-aging agent RD, 1-3 parts of sulfur, 0.8-3 parts of an accelerator and 0-0.3 part of a scorch retarder. Petroleum resin is added to improve the medium-term and long-term viscidity of a tire tread half member so that the tread is well bonded with belt layers during molding and the phenomenon of delamination of a tread crown is improved. The material disclosed by the invention has the advantages of good thermal resistance and aging resistance, low heat generation and tear resistance and the problem of pattern groove cracking of the finished tread is improved.

Owner:RUBBER CO LTD OF SHAANXI YANCHANG PETROLEUM GRP CO LTD

Method for preparing supercritical hydrotalcite grafted with flame retardant

ActiveCN103387757AGood dispersionImprove mechanical propertiesBulk chemical productionPigment treatment with organosilicon compoundsFiberPolyester

The invention belongs to the field of organic functional molecule modified hydrotalcite and particularly relates to hydrotalcite of which the surface is grafted with an organophosphorus heterocyclic compound, and a preparation method of hydrotalcite. According to the method disclosed by the invention, a silane coupling agent serves as a bridging linker in supercritical carbon dioxide, and the organophosphorus heterocyclic compound is chemically grafted to the surface of hydrotalcite, wherein the silane coupling agent accounts for 0.1-50 wt% of the total weight of hydrotalcite of which the surface is grafted with organic functional molecules, the organophosphorus heterocyclic compound accounts for 0.1-50 wt%, and the balance is hydrotalcite. The hydrotalcite of which the surface is grafted with the organic functional molecules, disclosed by the invention, can serve as a functional assistant, is added into macromolecular materials, such as polyolefins, polyesters, epoxy resin, binders, coating materials, rubber or fibers, and is used for improving the thermal ageing resistance, photo-aging resistance, heat resistance, transparency, flame retardance and the like of the prepared materials.

Owner:BEIJING ACAD OF BUILDING ENG

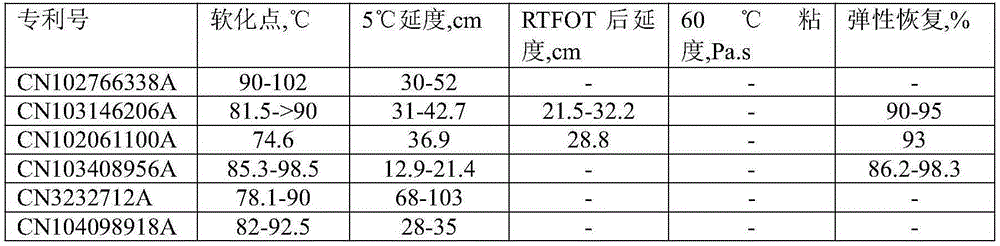

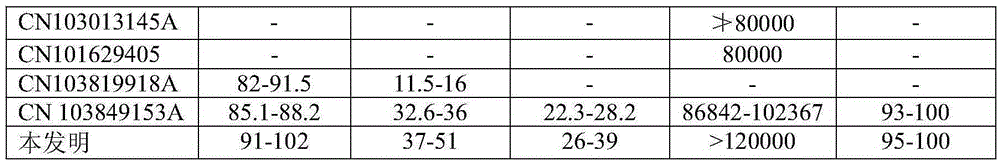

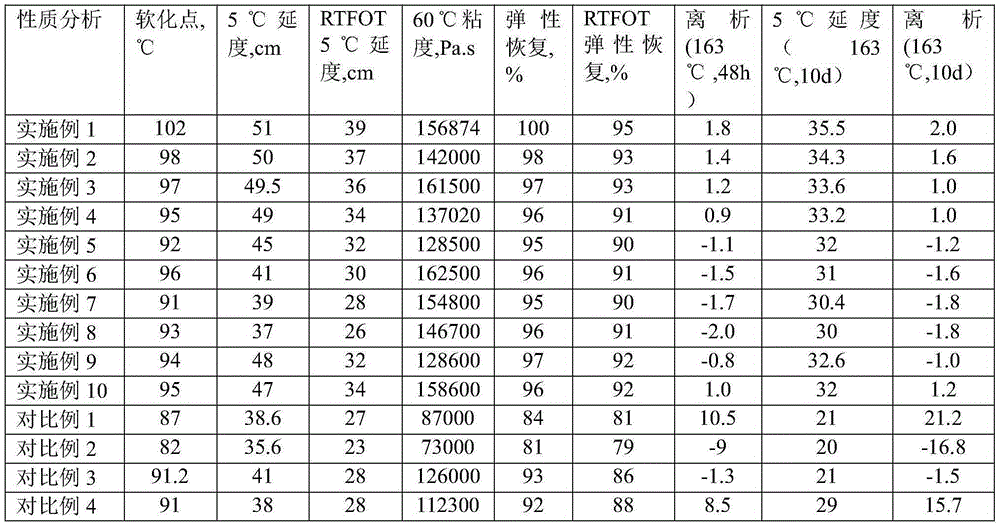

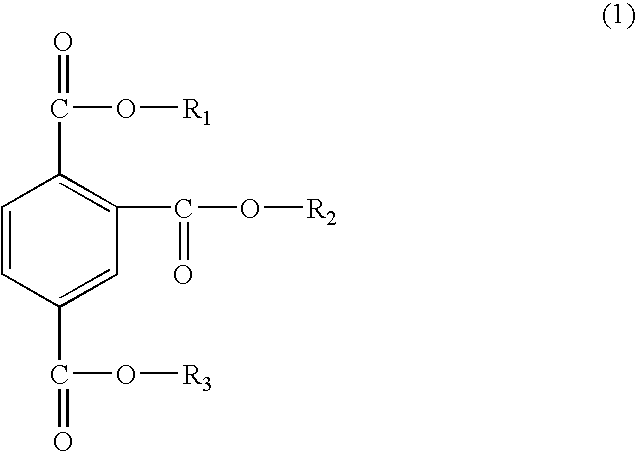

High temperature storable high viscosity and high elasticity modified asphalt and preparation method thereof

ActiveCN106800787AWide variety of sourcesEasy to promote and applyBuilding insulationsWaste rubberAging resistance

Owner:PETROCHINA CO LTD

Ultra-wearable rubber formulation for sports shoes sole

The invention discloses a superwear-resisting rubber formulation of sport sole, and is characterized in that the formulation according to parts by weight comprises 80 parts of polybutadiene rubber, 20 parts of natural gum STR-5L, 1 part of uniform tackiness resin, 45-48 parts of white carbon black, 3.5 parts of softening oil, 3-3.2 parts of coupler, 5.2-5.8 parts of activator, 1 part of zinc stearate, 1 part of antifog agent, 1.9-2.1 parts of sulphur, and 1.65-1.95 part of accelerating agent, an ideal raw material functional combination can be obtained after applying the rubber formulation for sports shoes, which makes the sport shoe rubber sole having superwear resistance which is superior to ordinary rubber sole, and has a plurality of excellent properties such as wet-skid resistance, impact resistance and the like.

Owner:ANTA CHINA

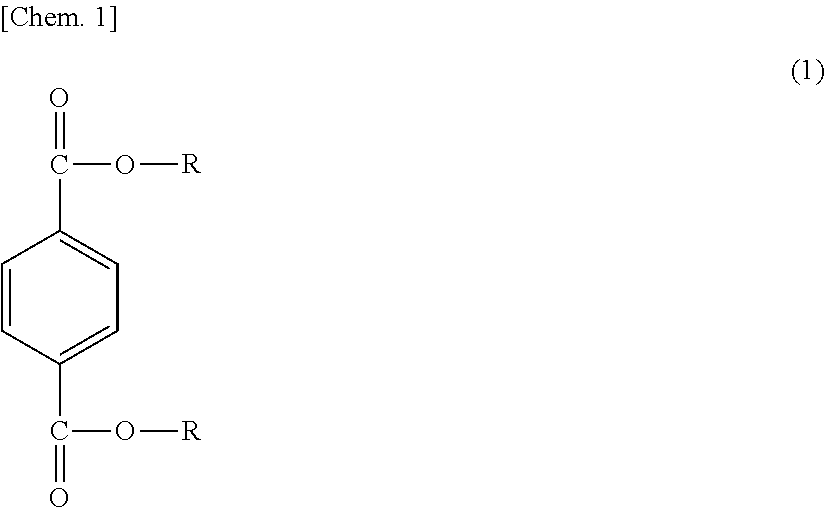

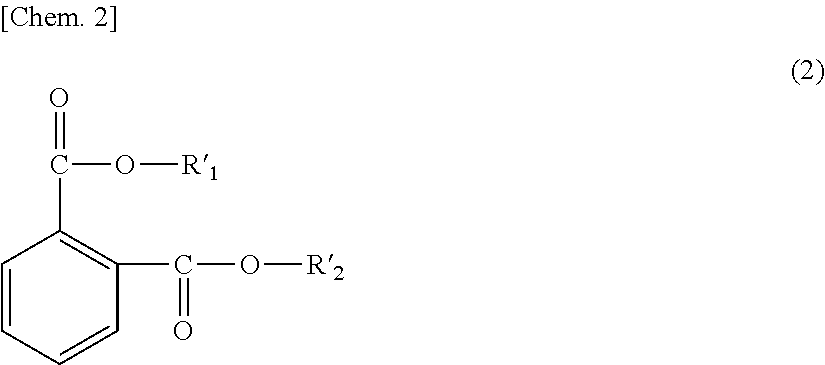

Vinyl chloride resin composition for powder molding, molded object obtained therefrom, laminate, vehicle interior material, and method for producing vinyl chloride resin composition for powder molding

InactiveUS20100272984A1Good fluidity of powderImprove heat aging resistanceSynthetic resin layered productsThin material handlingPlasticizerVinyl chloride

A vinyl chloride resin composition for powder molding of the present invention includes: 100 parts by mass of vinyl chloride resin particles made of vinyl chloride resin whose average degree of polymerization is 1500 or more, the vinyl chloride resin particles having an average particle size ranging from 50 to 500 μm; and 110 to 150 parts by mass of a particular trimellitate plasticizer. The vinyl chloride resin composition has excellent powder flowability and results in a molded object having excellent heat aging resistance and low-temperature resistance.

Owner:ZEON CORP

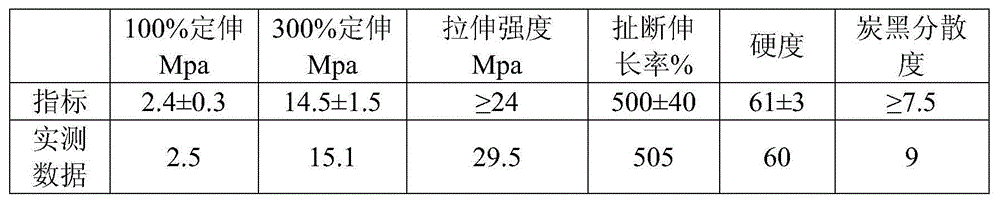

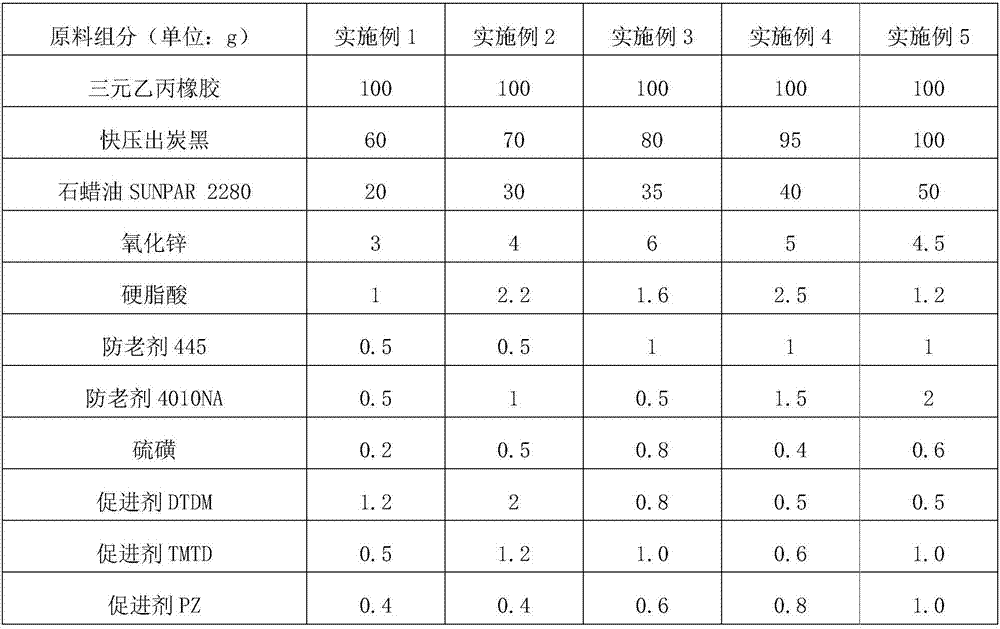

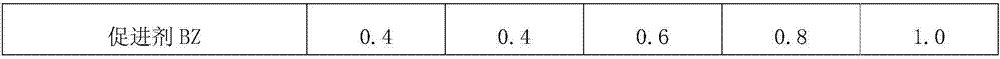

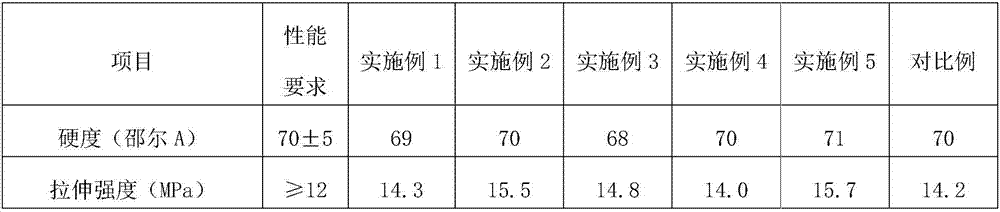

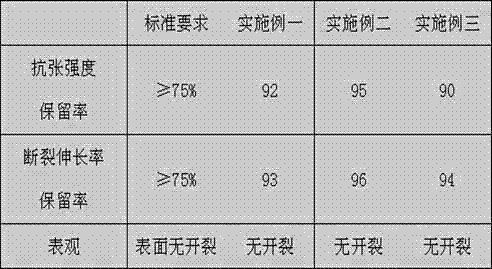

Heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, preparation method, application and application product thereof

ActiveCN107189236AImprove heat aging resistanceGood physical and mechanical propertiesVulcanizationPolymer science

The invention discloses a heat aging-resisting and low-pressure change sulfur vulcanized EPDM (Ethylene-Propylene-Diene Monomer) rubber composition, a preparation method, application and an application product thereof. The composition is prepared from 100 parts of EPDM rubber, 50 to 130 parts of carbon black, 10 to 60 parts of paroline, 2 to 8 parts of zinc oxide, 0.5 to 3 parts of stearic acid, 1 to 6 parts of an anti-aging agent, 0.2 to 1 part of sulfur and 1 to 6 parts of an accelerator. Compared with a sulfur vulcanized EPDM rubber composition prepared in the prior art, the composition has the advantages that heat aging resistance and low compression set are remarkably increased, and the composition is applied to rubber products having the requirements on heat aging resistance and low pressure change, and is particularly applied to an outer adhesive layer of a rubber hose which adopts a poly-4-methyl-1-pentene (TPX) coating and vulcanizing technology; meanwhile, the preparation method of the composition is simple, the vulcanization temperature is lower, and the purpose of saving energy is achieved.

Owner:NANJING ORIENTLEADER TECH CO LTD

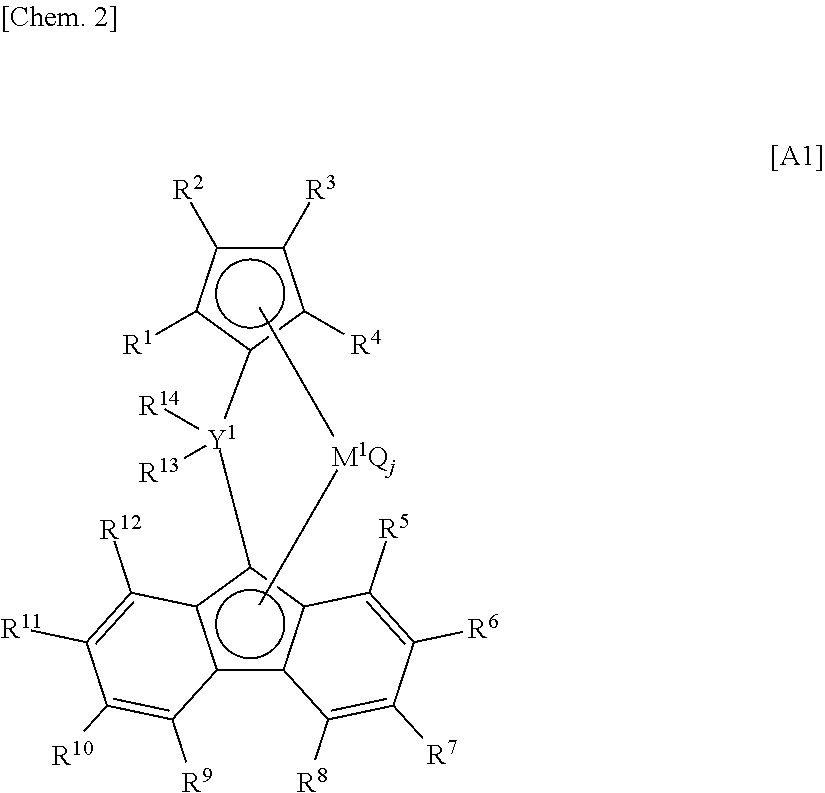

Ethylene/alpha-olefin/non-conjugated polyene copolymer, and production process and use thereof

ActiveUS20160355622A1Small long-chain branch contentExcellent curing propertyPlastic/resin/waxes insulatorsSpecial tyresChemistryStructural unit

A novel ethylene / α-olefin / non-conjugated polyene copolymer comprising structural units derived from ethylene (A), an α-olefin (B) of 3 to 20 carbon atoms, and a non-conjugated polyene (C) containing intramolecularly two or more partial structures in total selected from the group consisting of structures of Formulae (I) and (II), and having a small number of long-chain branches,The novel ethylene / α-olefin / non-conjugated polyene copolymer contains a non-conjugated polyene such as VNB as a copolymerization component and a small long-chain branch content and is excellent in curing properties in the case of crosslinking using peroxide; and a process for producing the ethylene / α-olefin / non-conjugated polyene copolymer, and a use thereof are provided.

Owner:MITSUI CHEM INC

Environmentally-friendly low-themogenesis rubber composite for high-capacity tyre body and high-capacity tyre using same

InactiveCN101928412ALow heat generationImprove heat aging resistanceSpecial tyresRolling resistance optimizationRubber materialHealth risk

The invention discloses an environmentally-friendly low-themogenesis rubber composite for a high-capacity tyre body and a high-capacity tyre using the same. The rubber composite for the high-capacity tyre body is prepared by using natural rubber, environmentally-friendly styrene rubber 1500E, white carbon black, natural gas semi-reinforcing furnace black N770, condensed aromatics removed environmentally-friendly aromatic oil and the like as raw materials and matching with reasonable proportional design, which ensures that themogenesis of rubber materials is lower so as to improve the continuous operation time of the tyre body and further ensures that the service life of the tyre is prolonged, greatly reduces health risks caused to processors and users during the production and the use and enables the competence of products to be improved.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

Halogen-free flame retardant PVC elastic material and preparation method thereof

ActiveCN102443226AGood environmental protection and flame retardancyGood thermal stabilityPlasticizerStabilizing Agents

The invention provides a halogen-free flame retardant PVC elastic material and a preparation method thereof, relating to a preparation method of a polymer composite material. The preparation method comprises the following steps of: mixing PVC resin in a kneader till the temperature is 70-80 DEG C; then adding a stabilizing agent, a plasticizer, a lubricant, pigments and a halogen-free flame retardant and continuing mixing till the temperature of the mixture is 85-95 DEG C and discharging the mixed material; cooling the mixed material in a cooling stirrer to 40-50 DEG C; and adding the cooled mixed material in a twin-screw extruder, and extruding strip-shaped halogen-free flame retardant PVC elastic material under the condition that the temperature of an extrusion die head is 130-150 DEG C. An elevator balance compensation chain sheath prepared from the special material provided by the invention has beautiful appearance, good toughness, good aging resistance, high thermal stability andgood fire retardant effect.

Owner:JIANGSU XINGHUA RUBBER BELT

Method of producing fuel hose material and fuel hose material produced by the same

InactiveUS20070202287A1Improve dispersion uniformityResistance to deteriorationSynthetic resin layered productsThin material handlingPlasticizerCarbon nanotube

A method of producing a fuel hose material which is obtained at low costs and has excellent properties such as antistatic property, resistance to thermal aging and resistance to sour gasoline, and a material produced by the method. The method includes the steps of: dispersing a carbon nanotube in a polar plasticizer comprising at least one of a sulfonamide plasticizer and an ester plasticizer; and blending the resulting compound into a polyamide resin having a relative viscosity (ηr) of 2.5 to 3.5, in which the carbon nanotube is present in a proportion of not less than 7 wt %.

Owner:SUMITOMO RIKO CO LTD

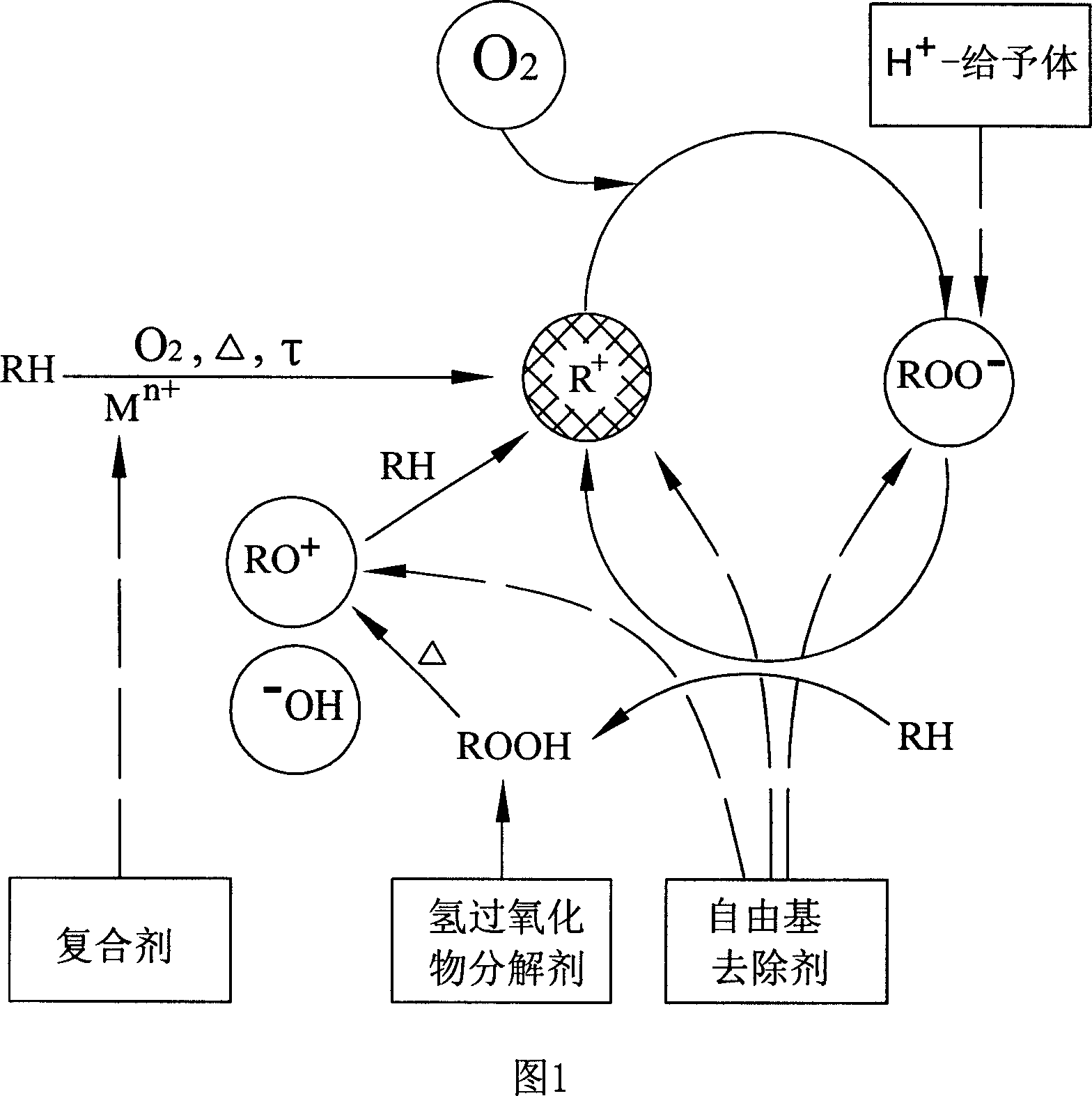

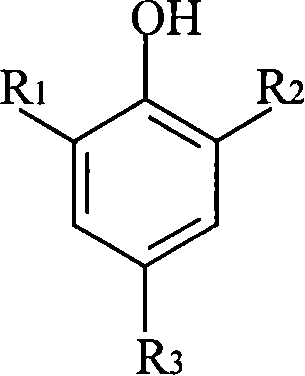

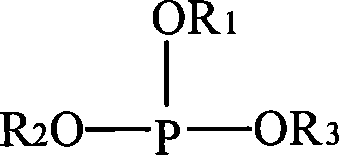

Composite heat resisting antioxidant for polyolefin and its production process and application

InactiveCN101067030AImprove heat aging resistanceEliminate catalytic cleavagePolyolefinPolymer science

The present invention relates to composite heat resisting antioxidant for polyolefin and its production process and application. The composite heat resisting antioxidant consists of hindered phenol antioxidant 20-75 wt%, phosphate antioxidant 20-75 wt%, and chelating metal component containing at least bisamide-metal ion chelating structure 5-50 wt%, and is prepared through physical mixing and airflow crushing. The composite heat resisting antioxidant is applied in polyolefin product and can raise the ageing resisting performance of polyolefin product, especially greenhouse film, greatly.

Owner:广东国望精细化学品有限公司

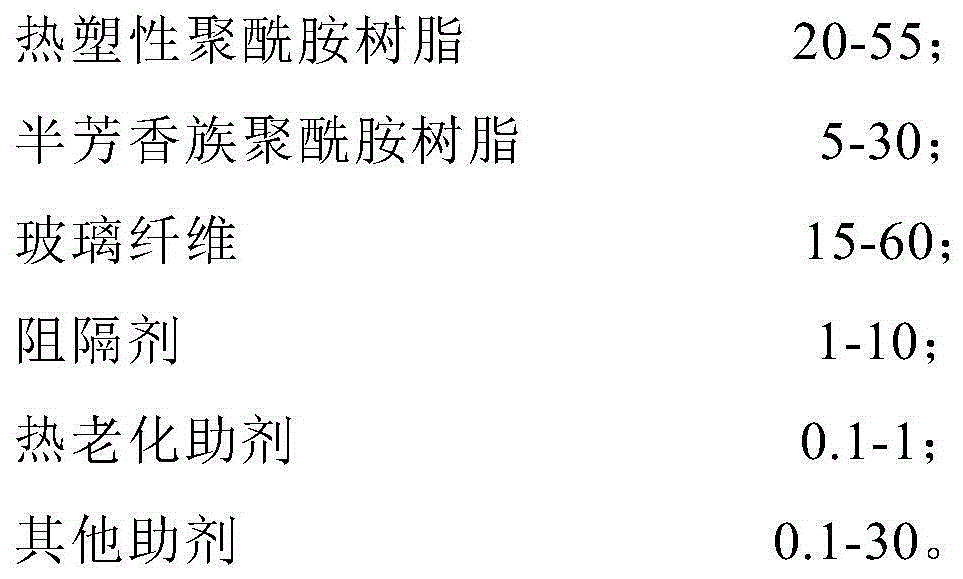

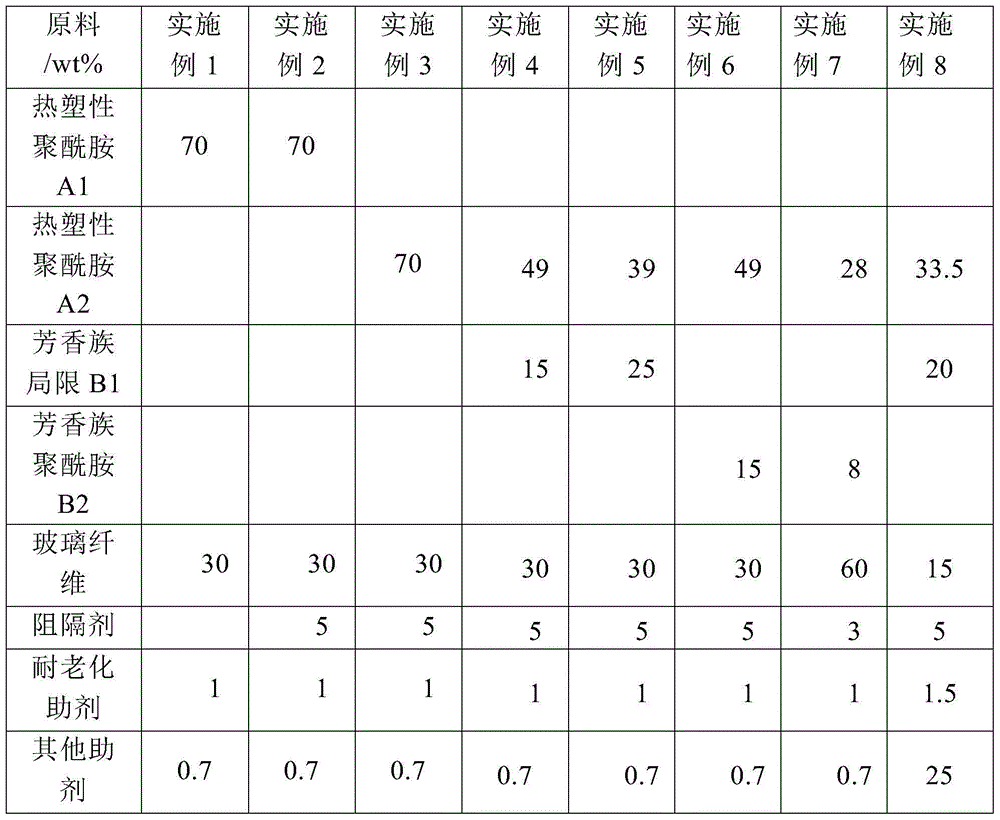

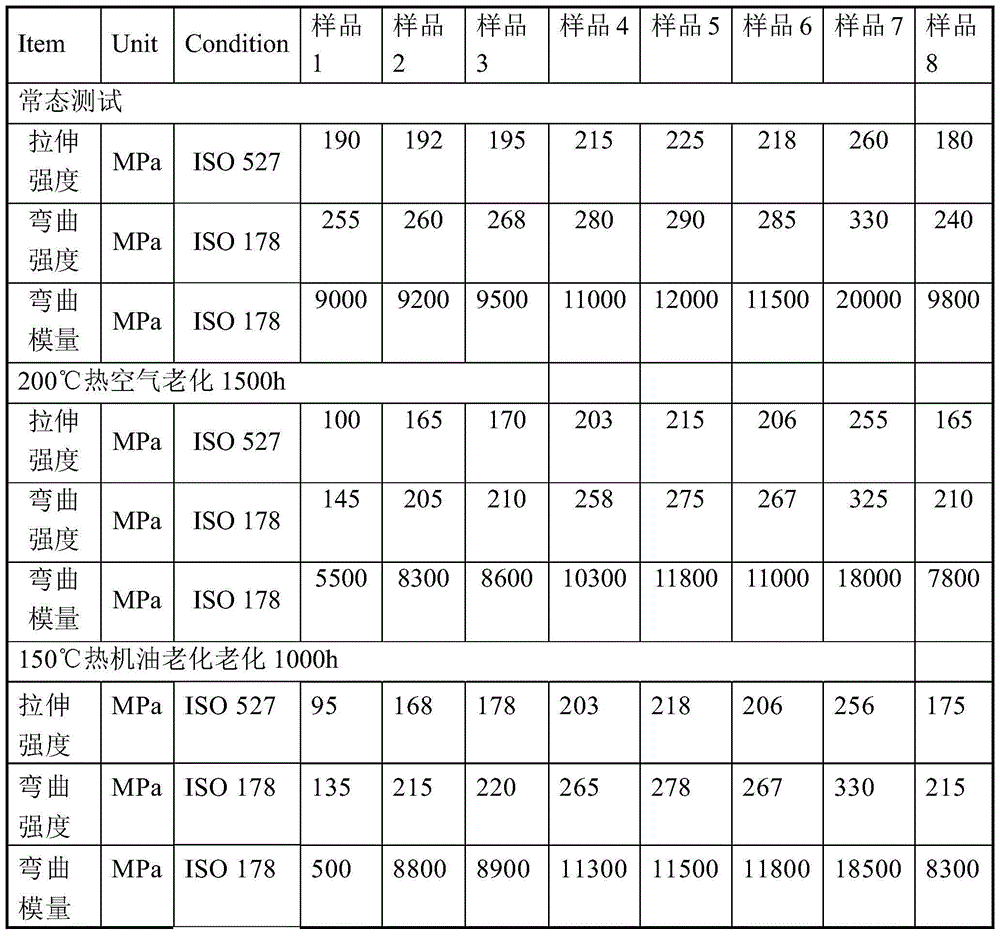

Low-moisture-absorption long-term heat-resistant aging-resistant polyamide composition and preparation method thereof

The invention relates to a low-moisture-absorption long-term heat-resistant aging-resistant polyamide composition and a preparation method thereof. The polyamide composition is prepared from the following raw materials in percentages by weight: 20-55% of thermoplastic polyamide resin, 5-30% of semi-aromatic polyamide resin, 15-60% of glass fiber, 1-10% of a blocker, 0.1-1% of a thermal aging additive and 0.1-30% of other additives. Compared with the prior art, the semi-aromatic polymer is added into the composite system, the moisture-absorption property of a matrix can be significantly decreased due to the high steric-hindrance effect of the composite system; in addition, because of the presence of benzene rings, characteristics of good barrier property and heat resistance and retention are achieved and the polyamide composition also has the advantages of low moisture absorption, very excellent mechanical strength, heat resistance, aging resistance and the like.

Owner:SHANGHAI SUNNY

Halogen-free flame-retardant POE (Polyolefin Elastomer) compound material and preparation method thereof

The invention discloses a halogen-free flame-retardant POE (Polyolefin Elastomer) compound material and a preparation method thereof. The halogen-free flame-retardant POE compound material is prepared from the following components in parts by weight: 100 parts of POE resin, 70-140 parts of halogen-free compound retardant, 5-30 parts of modifier, 3-10 parts of lubricating dispersing agent and 0.1-0.6 parts of anti-oxidant. The preparation method comprises the following steps of: putting the POE resin, the halogen-free retardant, the modifying agent, the lubricating dispersing agent and the anti-oxidant into a high-speed mixing machine for mixing till the materials are heated to 65-75 DEG C through frication heat generated by mixing, discharging and cooling; and feeding a cooled mixed material into a double-screw extruder for melting and extruding, cooling an extruded bar stock with a water groove, and drawing into a granulating machine for granulating to obtain the halogen-free frame-retardant POE compound material. The elongation rate of the halogen-free flame-retardant POE compound material is over 600 percent, the oxygen index is over 30 percent, the liquidity of a melt is high, and the heat ageing resistance is high.

Owner:JIANGSU UNIV OF TECH

Vinyl chloride resin composition for powder molding, vinyl chloride resin molded body, laminate, automobile interior material, and method for producing vinyl chloride resin composition for powder molding

InactiveCN101889054AGood fluidity of powderImprove heat aging resistanceThin material handlingPlasticizerCold resistance

Owner:ZEON CORP

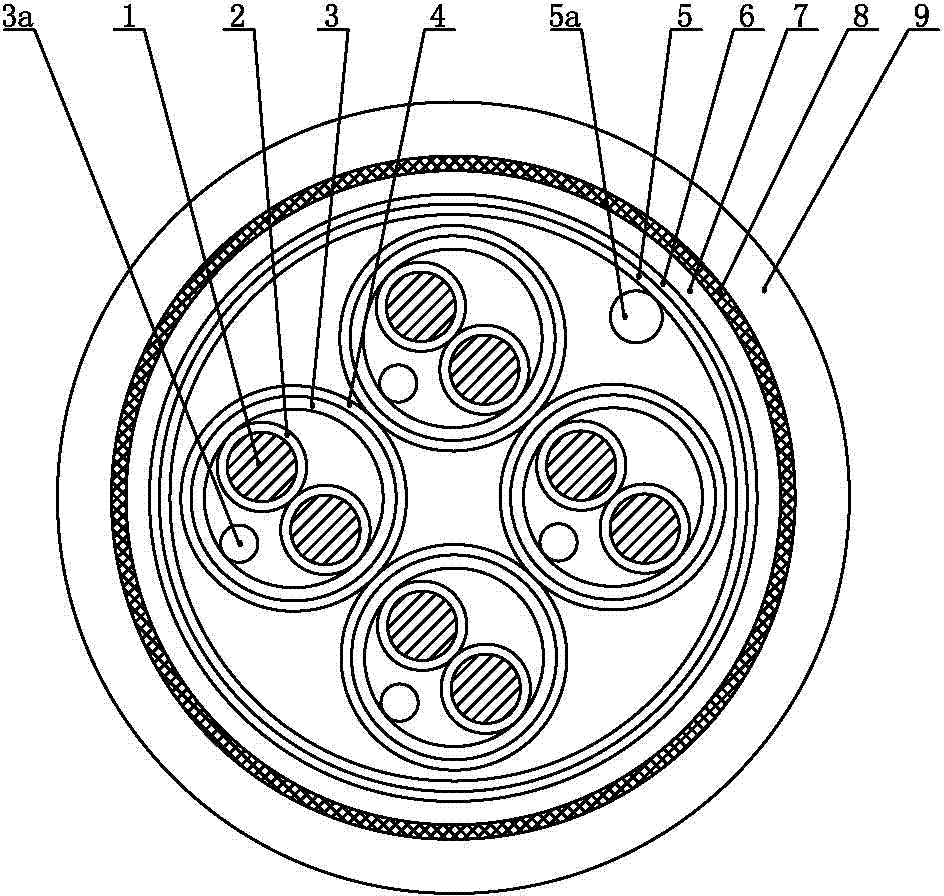

Whitening ultraviolet-proof double-shield instrument cable for ships and manufacturing method thereof

InactiveCN102969046AColor whiteGood physical and mechanical propertiesClimate change adaptationInsulated cablesCopper foilInsulation layer

The invention relates to a whitening ultraviolet-proof double-shield instrument cable for ships and a manufacturing method thereof. The cable is characterized in that a whitening ultraviolet-proof ethylene-propylene rubber insulation layer is extruded at the periphery of a tin-plated annealed stranded copper conductor to form an insulation wire core; every two insulation wire cores are twisted to form twisted wire pairs; each twisted wire pair is wrapped with a wire core copper foil polyester composite tape shielding layer at the periphery; the wire core copper foil polyester composite tape shielding layers are each wrapped with a wire core polyester tape at the periphery to form a pair-twist group; all the pair-twist groups are stranded to the right at 16-24 times of stranding lay ratio to form a cable core; the cable core is wrapped with a cable core copper foil polyester composite tape shielding layer at the periphery; the cable core copper foil polyester composite tape shielding layer is wrapped with a cable core polyester tape at the periphery; an inner sheath is extruded at the periphery of the cable core polyester tape; the inner sheath is coated with a copper alloy wire weaving armor layer at the periphery; and an outer sheath is extruded at the periphery of the copper alloy wire weaving armor layer. The insulation layer of the double-shield cable is white in color, good in mechanical property, excellent in anti-ultraviolet irradiation and anti-aging performance, and long in service life.

Owner:JIANGSU YUANYANG DONGZE CABLE

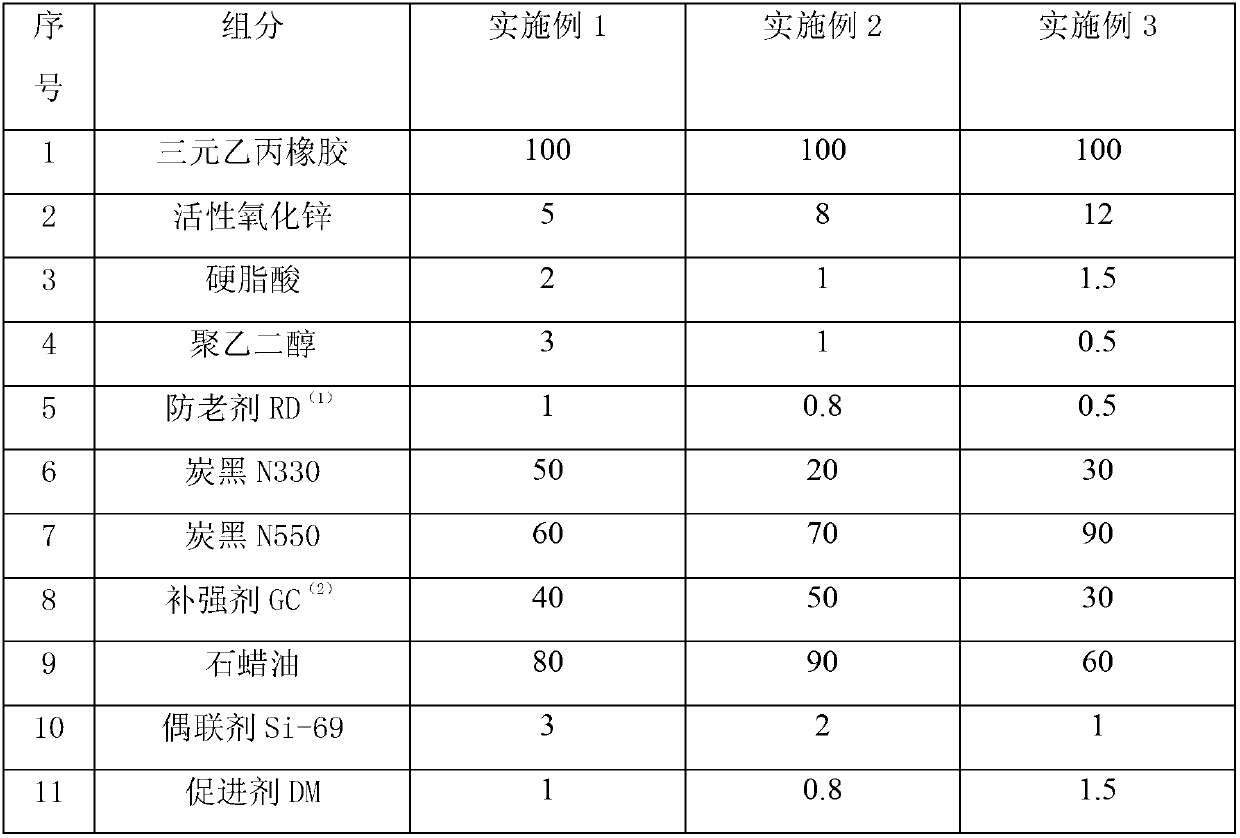

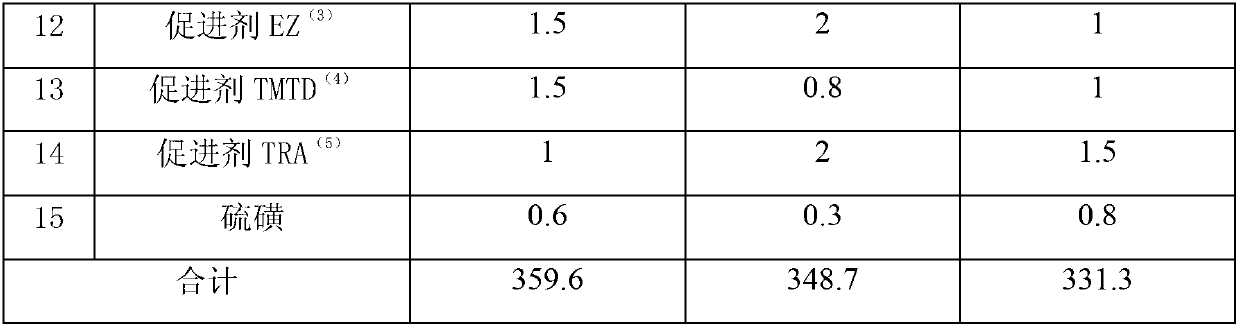

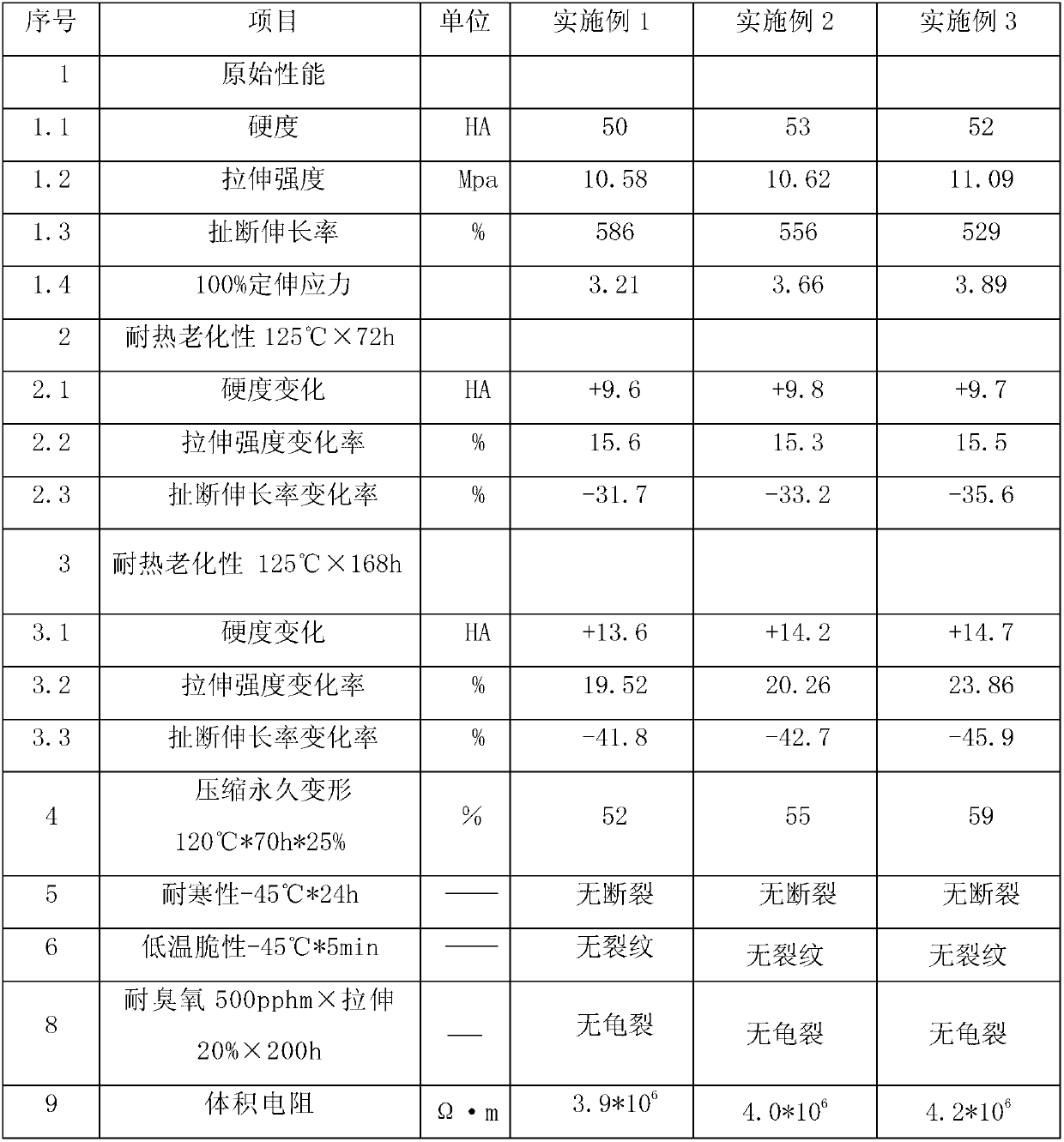

Ethylene propylene diene monomer (EPDM) composition for low-hardness glue injection

The invention relates to an ethylene propylene diene monomer (EPDM) composition for low-hardness glue injection. The composition comprises the following ingredients: EPDM rubber, activated zinc oxide, stearic acid, polyethylene glycol, 2,2,4-trimethyl-1,2-dihydroisoquinoline polymer, carbon black N330, carbon black N550, silicon dioxide hydrate, paraffin oil, coupling agent Si-69, accelerator DM, zinc diethyl dithiocarbamate, tetramethyl thiuram disulfide, bis(pentamethylene)thiuram tetrasulfide, and sulphur. According to the formula of the composition, the original hardness is low and is only about 50 degrees, the tensile strength and 100% stress at definite elongation are high, thermal air aging resistance property, the coldness resistance and low-temperature crispness are all excellent to meet the use requirement under low-temperature environment of different regions in winter, the lowest temperature can reach minus 45 degrees, glue injection technique is adopted to be capable of saving labor time and manual work. The composition formula can meet the requirements of RCF-510 grade material in MES MN300 standard.

Owner:TIANJIN PENGYI GRP CO LTD

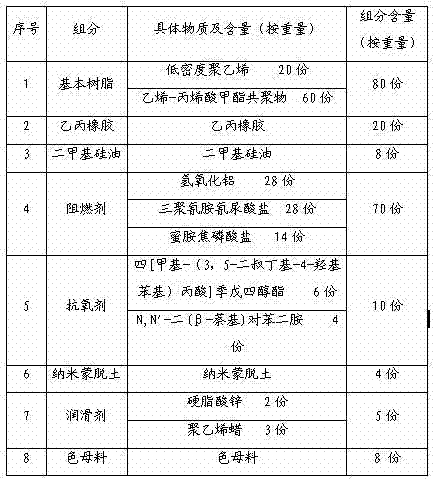

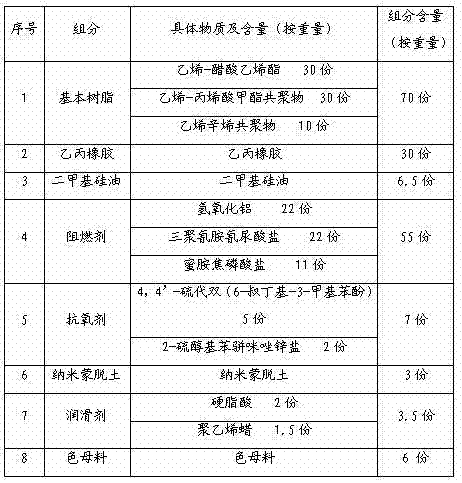

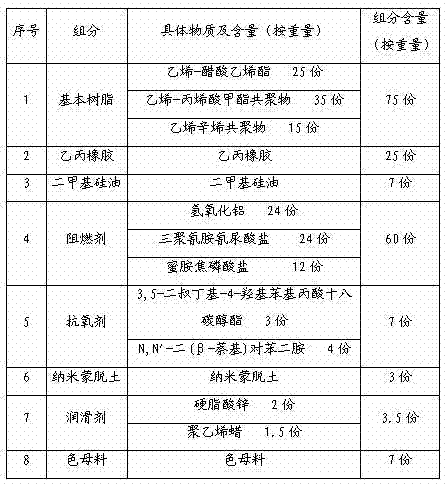

Bus bar heat-shrinkable tube and preparation method thereof

The invention relates to a bus bar heat-shrinkable tube which is prepared from the following components in parts by weight: 60-80 parts of base resin, 20-40 parts of ethylene-propylene rubber, 5-8 parts of dimethyl silicon oil, 40-70 parts of flame retardant, 4-10 parts of antioxidant, 2-4 parts of nano montmorillonite, 2-5 parts of lubricant and 4-8 parts of color batch. The preparation method of the bus bar heat-shrinkable tube comprises the following steps: 1. weighing the components according to parts by weight; 2. mixing and granulating with a Banbury mixer or parallel double screw extruder, and extruding with a single screw extruder to obtain a tube; 3. treating the external surface of the extruded tube with infrared light, of which the wavelength is 700-1600nm, in the position 5-10cm away from the extrusion die of the extruder; and 4. carrying out radiation crosslinking on the tube with cobalt 60 or electron accelerator 50-160kGy, and expanding the tube subjected to radiation crosslinking at 85-135 DEG C. The bus bar heat-shrinkable tube provided by the invention has the advantages of favorable insulating property and long service life, and is convenient for construction.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

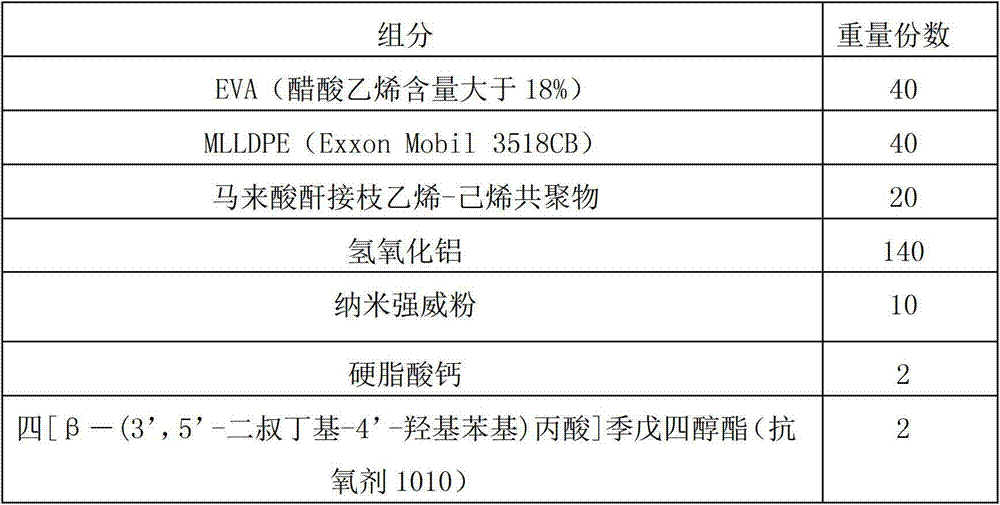

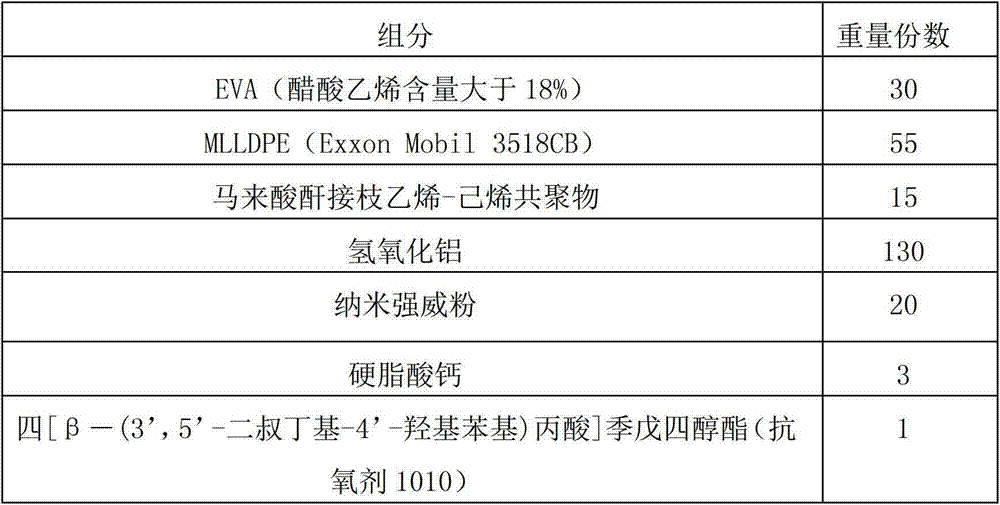

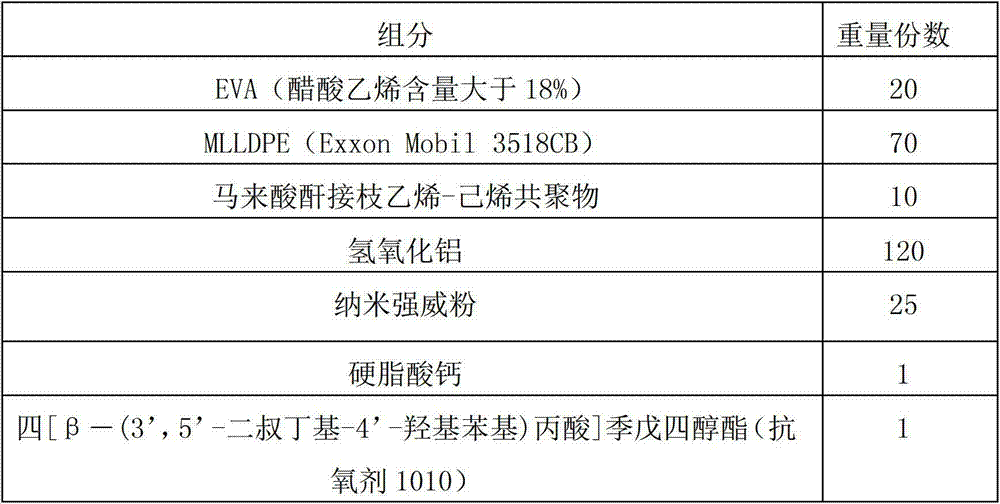

Nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material and preparation thereof

ActiveCN103205053AImprove toughnessHold powder wellPlastic/resin/waxes insulatorsInsulated cablesPolyolefinAntioxidant

The invention relates to a cable material, and in particular relates to a nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material and a preparation method thereof. The polyolefin cable material comprises the following components: EVA (Ethylene Vinyl-acetate Copolymer), MLLDPE (Linear Low-Density Polyethylene), an interfacial compatibilizer, aluminum hydroxide, nanometer strong micropowder, an antioxidant and a lubricant. The preparation method comprises the following steps of: evenly stirring the EVA and the MLLDPE as basic materials, the interfacial compatibilizer, the aluminum hydroxide, the nanometer strong micropowder, the antioxidant and the lubricant in a high-speed mixer; performing banburying in a banbury mixer at the temperature between 120 and 150 DEG C; extruding by using double screw rods; granulating by grinding and hot-cutting; conveying materials by using a cyclone separator; and screening by using a vibrating screen and packaging, thereby obtaining the finished nano-modified low-shrinkage low-smoke halogen-free and flame-retardant polyolefin cable material product. Compared with the common low-smoke halogen-free and flame-retardant polyolefin cable material, the polyolefin cable material provided by the invention has the effects that the thermal aging resistance is enhanced; the shrinkage performance of the product is improved greatly; and the problem that the low-smoke halogen-free polyolefin cable material is easy to shrink at the high temperature is solved.

Owner:JIANGSU LINRY NEW MSTAR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com