Patents

Literature

446results about How to "Play an insulating role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

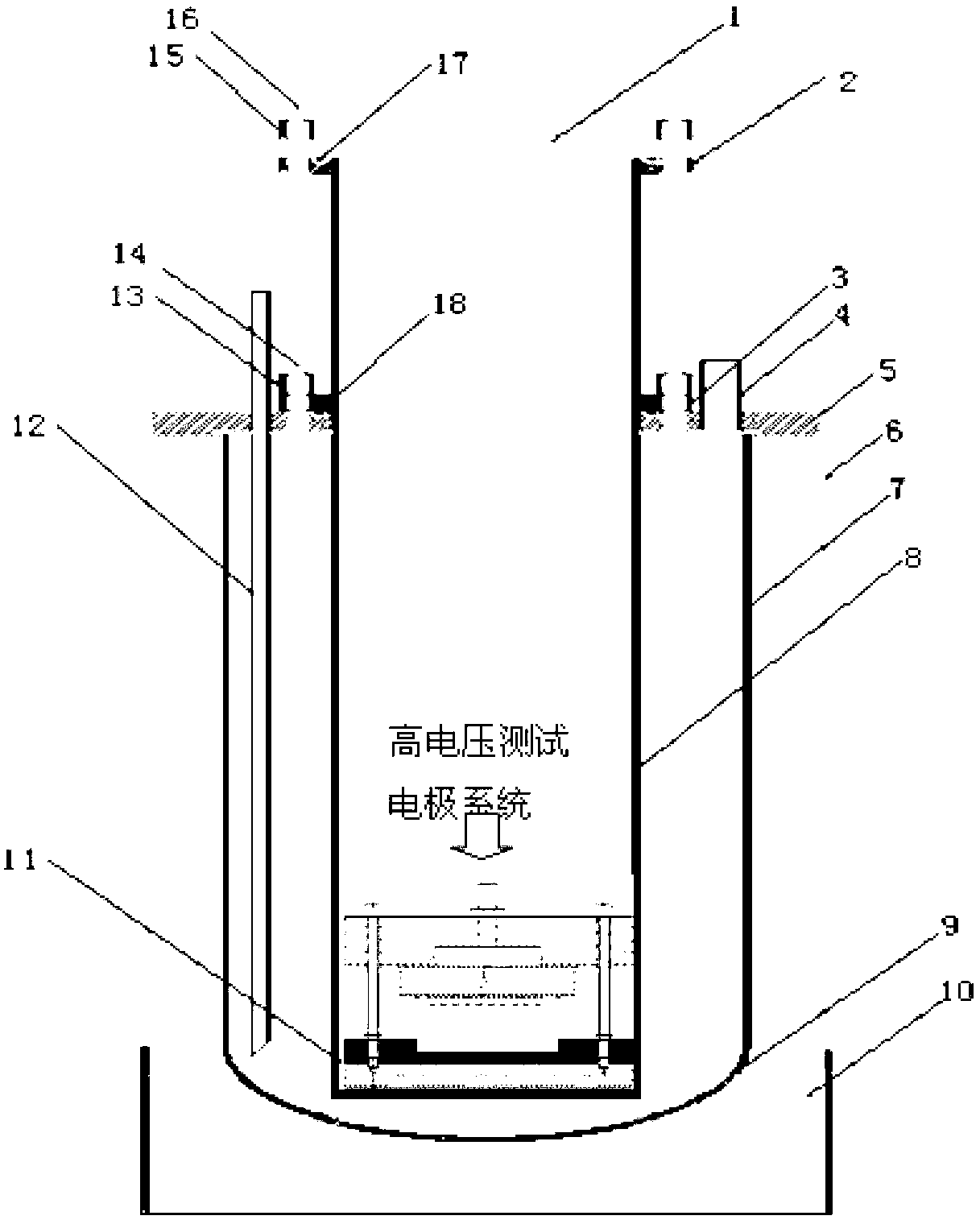

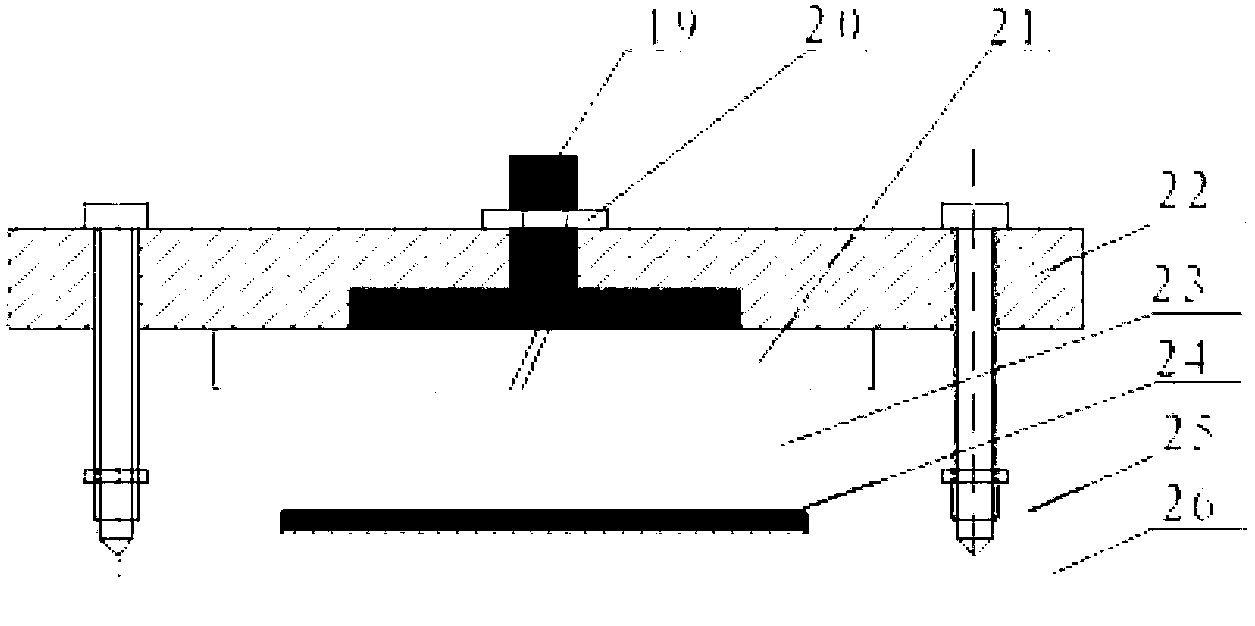

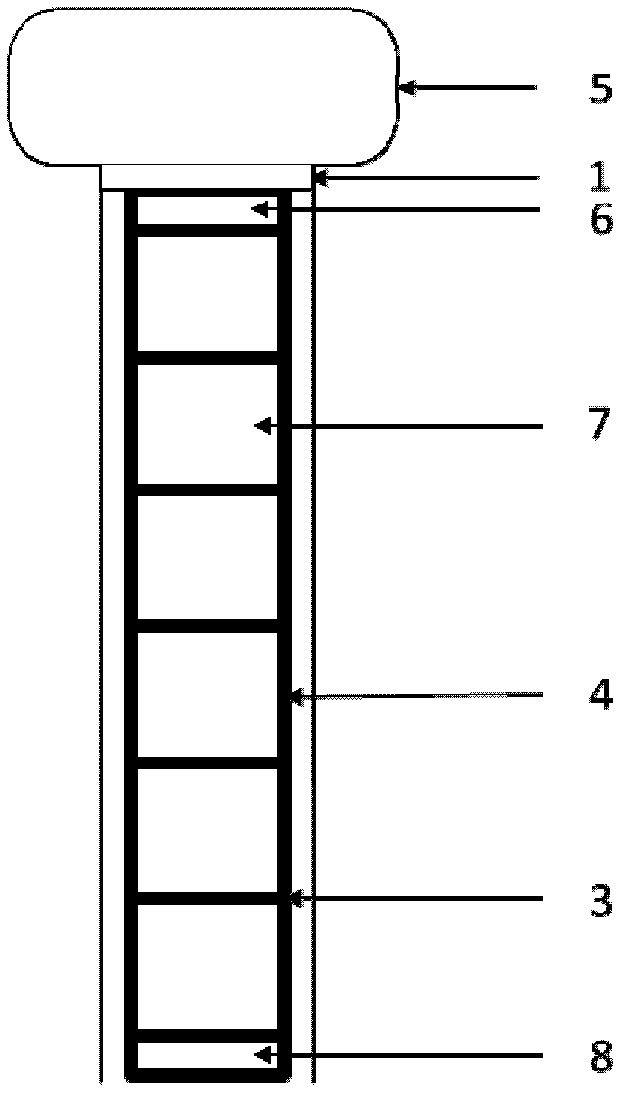

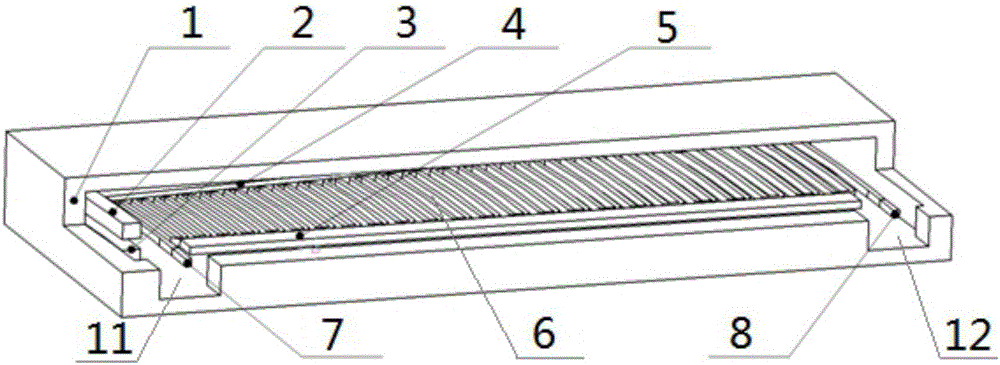

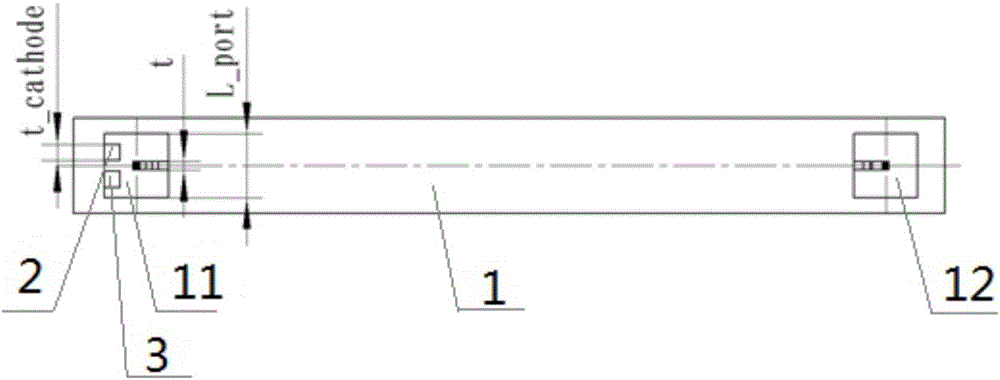

Testing experimental platform for performing disruptive discharge on insulation sample under low-temperature vacuum environment

InactiveCN102707204AGuaranteed strict isolationAffect the vacuumTesting dielectric strengthElectrical measurement instrument detailsHeat conductingEngineering

The invention discloses a testing experimental platform for performing disruptive discharge on an insulation sample under a low-temperature vacuum environment. The testing experimental platform mainly comprises a three-layered experimental Dewar type container and a high-voltage testing electrode system; the three-layered experimental Dewar type container comprises a vacuum testing container, a liquid helium (or liquid nitrogen), a cooling cylinder, and an outer vacuum insulation cylinder; the high-voltage testing electrode system is mainly composed of negative and positive electrodes, an insulating sample, upper and lower insulation supporting epoxy boards, polyimide insulating layer, a heat conducting copper supporting plate, and on the like. A cathode copper plate is used for connecting a low-potential lead and a leakage current testing lead; the leakage current testing lead is externally connected with the test system to strictly detect the disruptive discharge rule of the insulating sample. An anode copper plate is used for connecting a high-potential lead. The invention can realize the disruptive discharge performance test on various tested insulating samples under different low temperatures and vacuum degrees. According to the invention, the test temperature is ranged from 4.5 K to 300 K; and the air pressure test is ranged from 10-2 to 105 Pa.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

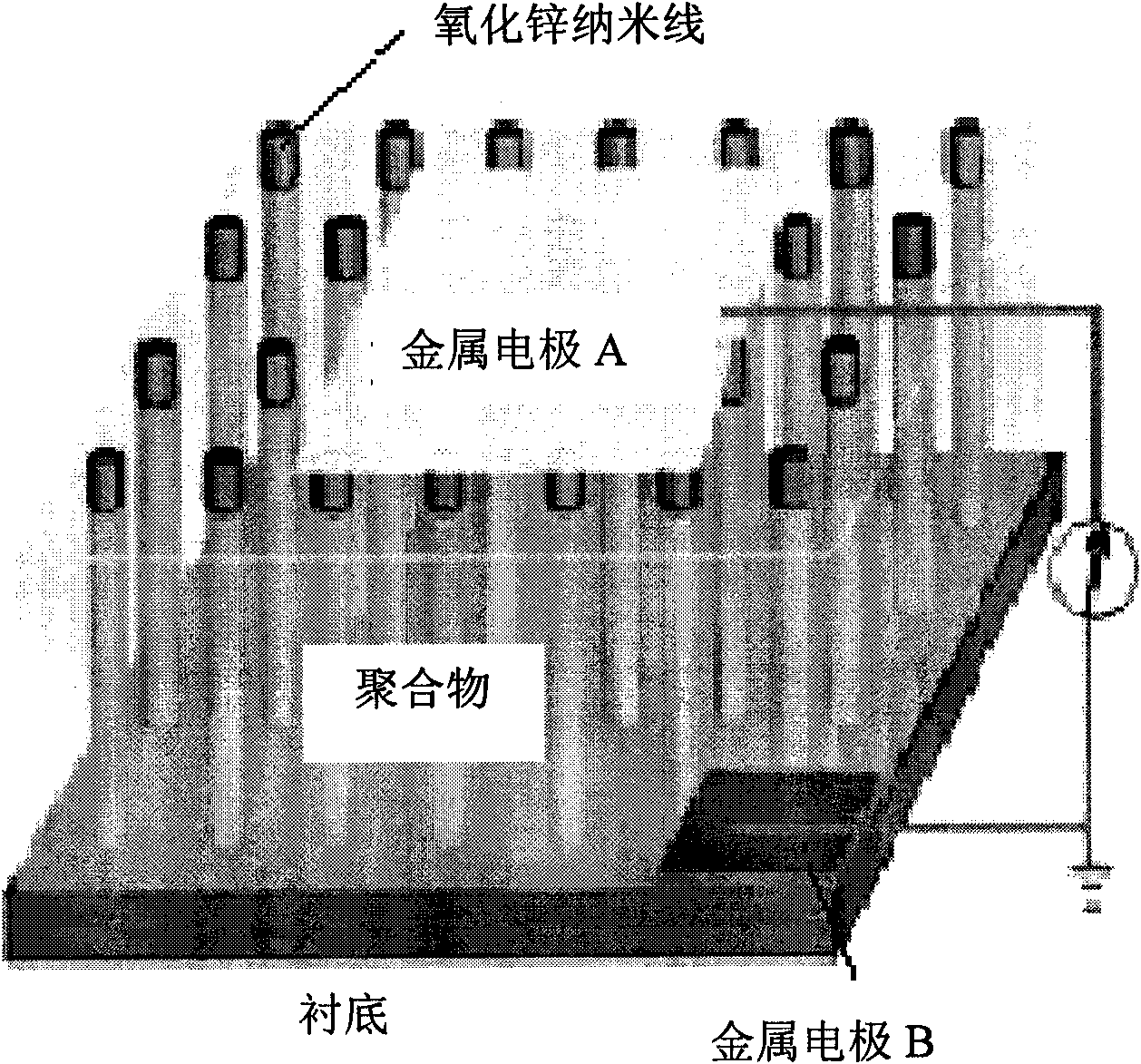

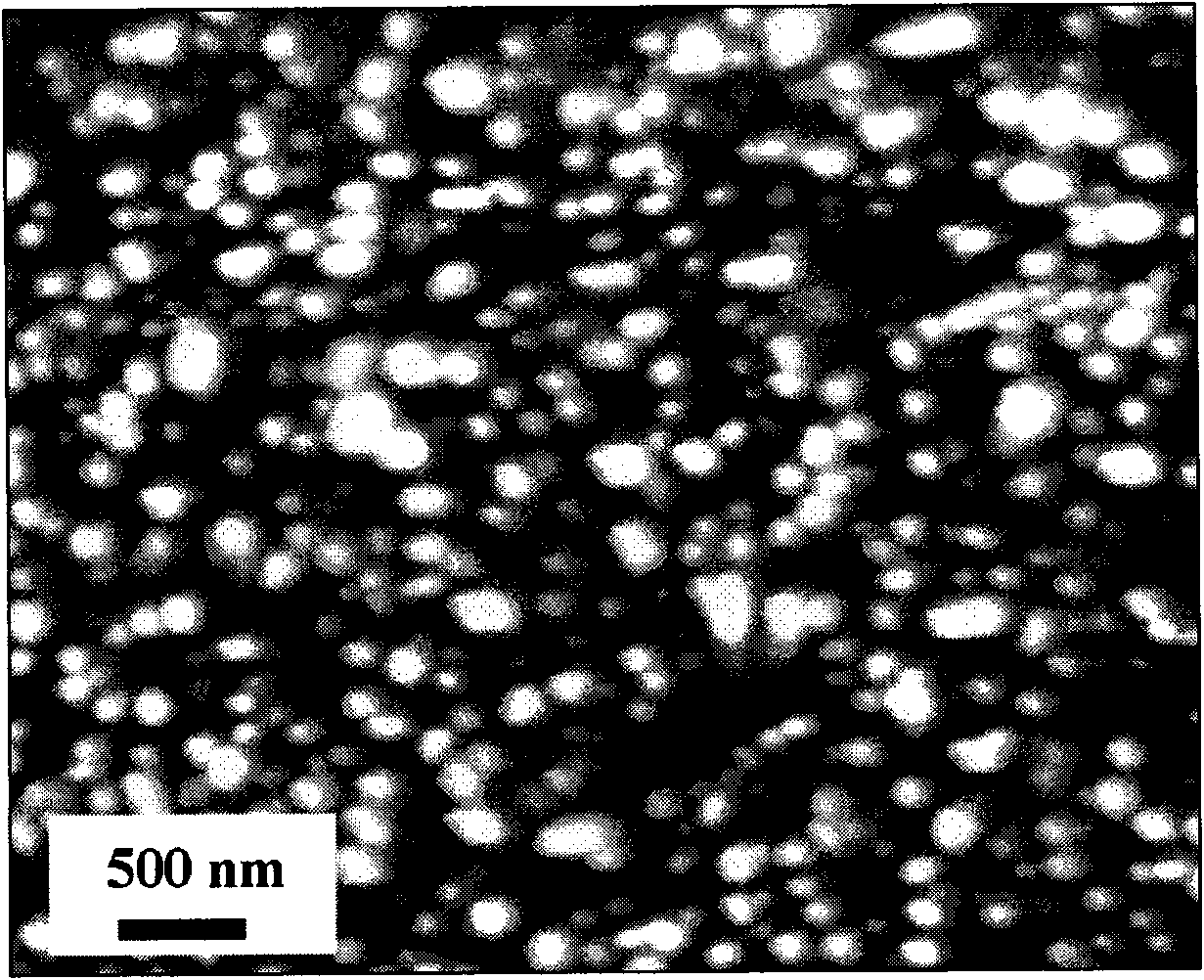

Zinc oxide nano wire/polymer nano composite energy converter and preparation method thereof

InactiveCN101656486AExpand the connotationAvoid Synthetic ProcessesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesNanogeneratorPolymer composites

The invention discloses a zinc oxide nano wire / polymer nano composite energy converter and a preparation method thereof. The oxide nano wire / polymer nano composite energy converter comprises a zinc oxide nano wire, a polymer, a substrate and two metal electrodes, wherein the polymer senses the change of an environment signal to produce shrinkage or expansion to drive the zinc oxide nano wire covered by the polymer to generate distortion, thereby producing electric signals to convert other energies in the environment into electric energy. The invention skillfully utilizes a zinc oxide nano wireand polymer composite structure to prepare a nano generator element, and enables the zinc oxide nano wire to convert heat energy, chemical energy and the like into electric energy in the environmentby means of the action of the polymer.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

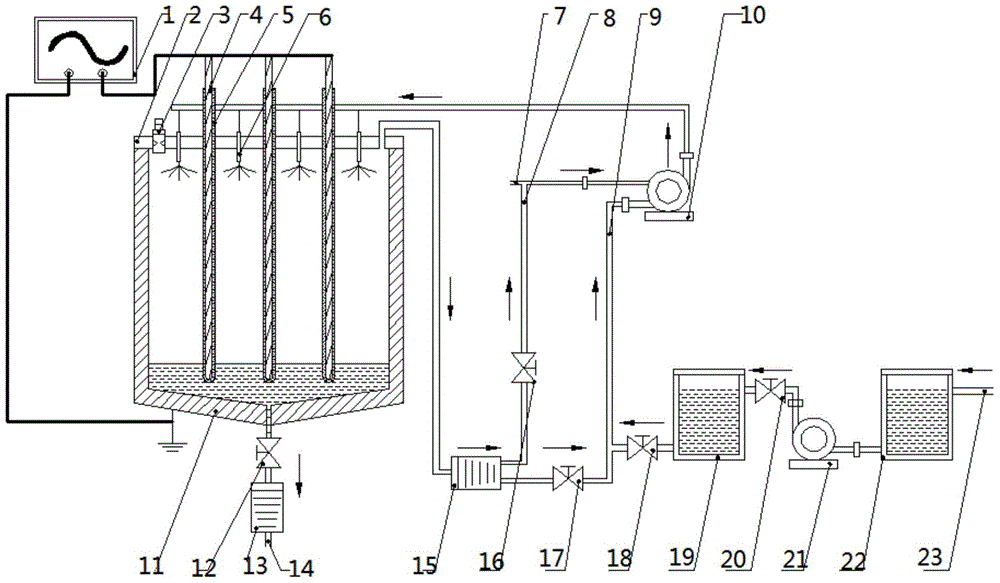

Gas-liquid mixed dielectric barrier discharge water treatment device and method

ActiveCN103819030APlasma homogeneityExtended stayMultistage water/sewage treatmentPollutantPre treatment

The invention discloses a gas-liquid mixed dielectric barrier discharge water treatment device and method. The device comprises a reactor, a plasma generator, a pretreatment device, an atomization sprinkler and a corresponding measurement control system. According to the device and the method atomized wastewater and air are taken as plasma working media to generate stable and uniform plasma at the liquid level around electrodes inserted in the wastewater and along the gas phase of the electrodes, so as to effectively solve the problem that contact between active particles in plasma and organic pollutants in the water is insufficient. The gas-liquid mixed dielectric barrier discharge water treatment device and method have the characteristics of high treatment efficiency, economy and practicability.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

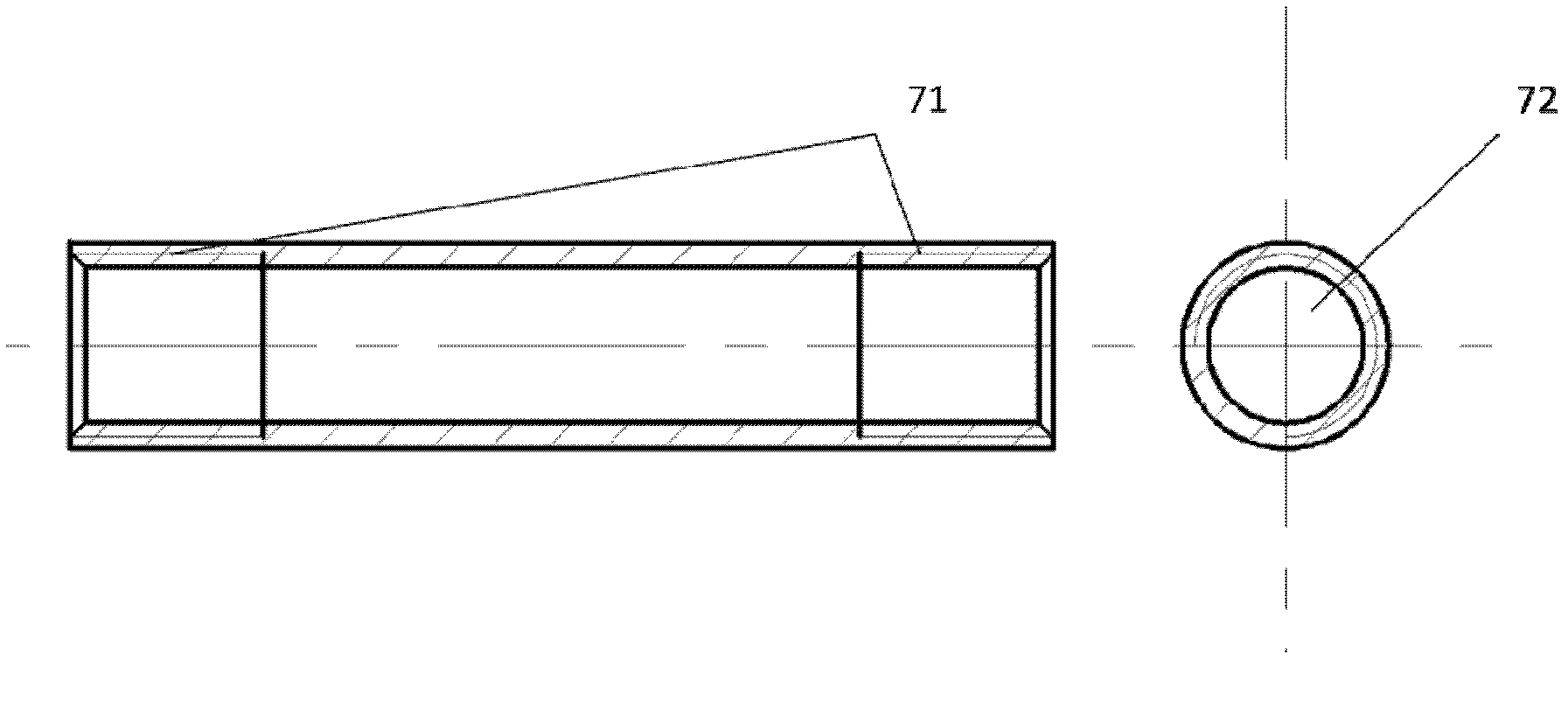

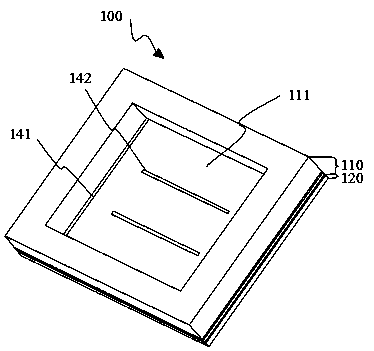

Capacitance sensor

InactiveCN102607668AHigh precisionGuaranteed linearityLevel indicators by physical variable measurementElectricityEngineering

The invention discloses a capacitance sensor, comprising a sensor gauge head, inner electrodes and an outer electrode, wherein the inner electrode is composed of a plurality of independent electrodes; the inner electrodes are the same in inner and outer diameters and are coaxially arrayed; the inner electrodes respectively comprise a top compensation electrode, a multi-section measurement electrode and a bottom compensation electrode from top to bottom; each two sections of electrodes are connected through a connecting piece which is made of an insulating material; the outer electrode is sleeved at the outer parts of the inner electrodes through screw threads, is coaxially mounted with the inner electrodes and is commonly shared by each section of the electrode in the inner electrodes; and the sensor gauge head is connected with the outer electrode. According to the capacitance sensor disclosed by the invention, the influences on liquid level measurement of temperature, pressure, mediums and the like are eliminated and the precision of the liquid level measurement is improved; and furthermore, an electricity leakage phenomenon can be effectively avoided and the linearity of the sensor is guaranteed.

Owner:BEIHANG UNIV

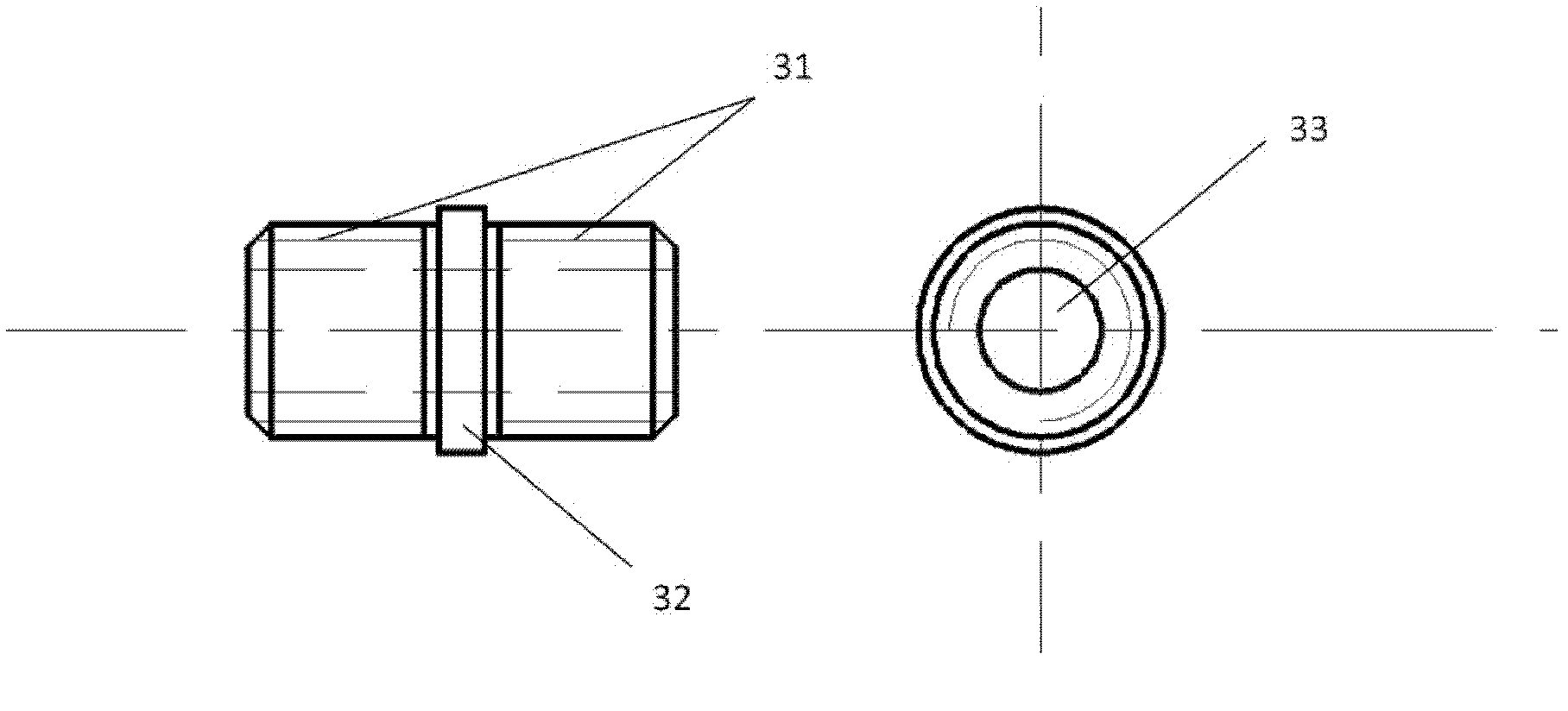

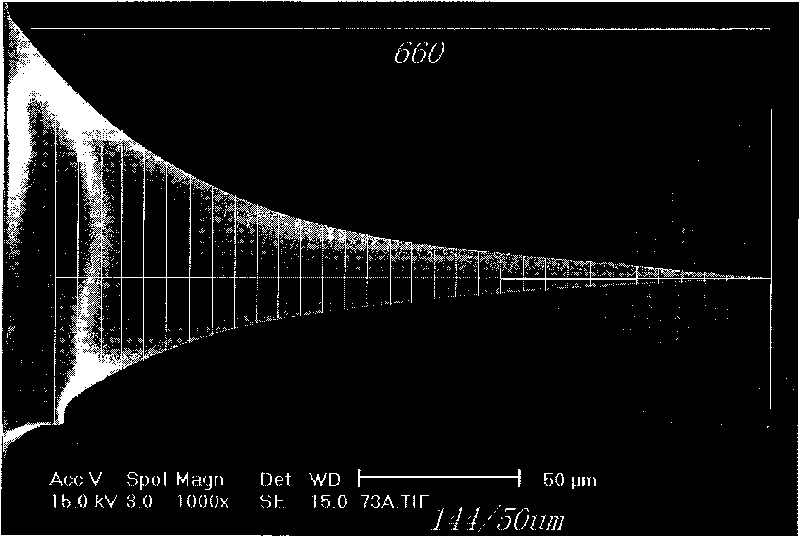

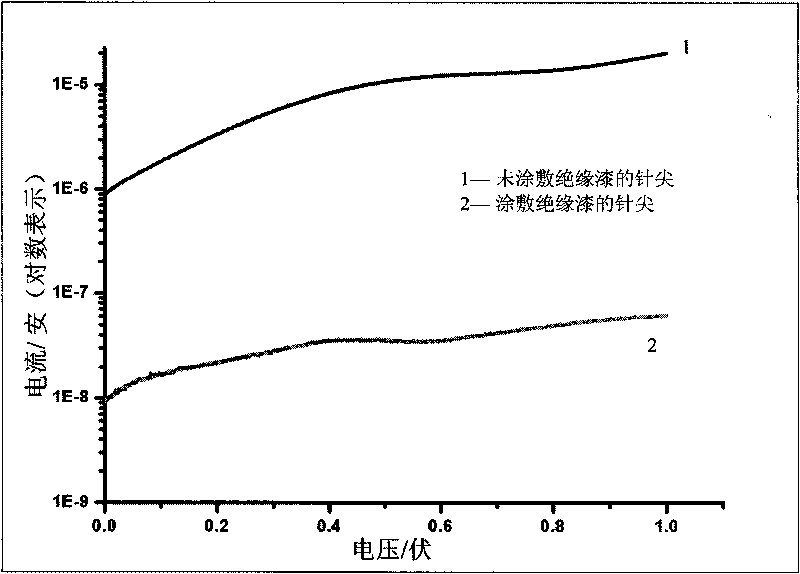

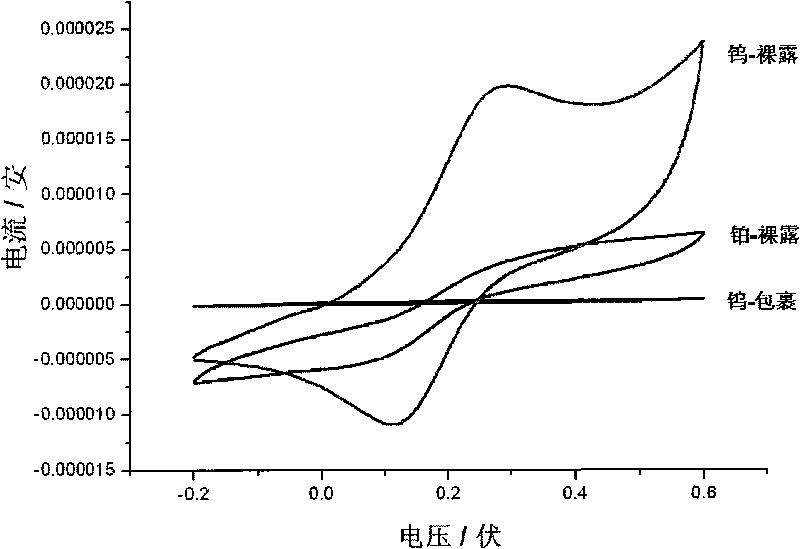

Method for preparing pinpoint of nano-tungsten probe

InactiveCN101696980ASimple and Quick Override MethodSimple and efficient overlay methodNanostructure manufactureScanning probe microscopyAlcoholLacquer

The invention discloses a method for preparing a pinpoint of a nano-tungsten probe, which comprises the following steps: 1) after removing an oxide layer on the surface of a tungsten filament by using an etching solution, inserting the tungsten filament into the etching solution, energizing the etching solution, and corroding the tungsten filament; 2) after washing the tungsten filament corroded in the step 1) by using deionized water and performing ultraphonic treatment, washing and drying the tungsten filament by using alcohol; and 3) coating an insulating varnish on the surface of the tungsten filament processed in the step 2), and drying and standing the tungsten filament to prepare the pinpoint of the nano-tungsten probe. The radius of curvature of the tip of the pinpoint of the nano-tungsten probe can reach about 20 nanometers minimally, and the pinpoint of the nano-tungsten probe can form tip conduction at a small voltage (1 mV magnitude). The method has a low preparation cost, and has a good application prospect in the study fields of nanometer channels, nano fluidonics, subcellular electrical measurement and the like.

Owner:PEKING UNIV

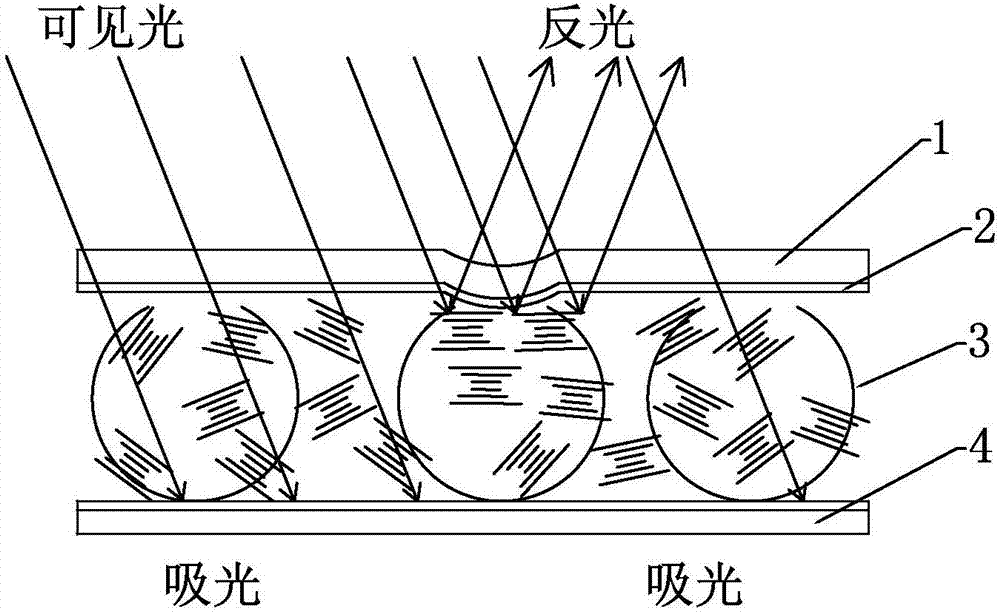

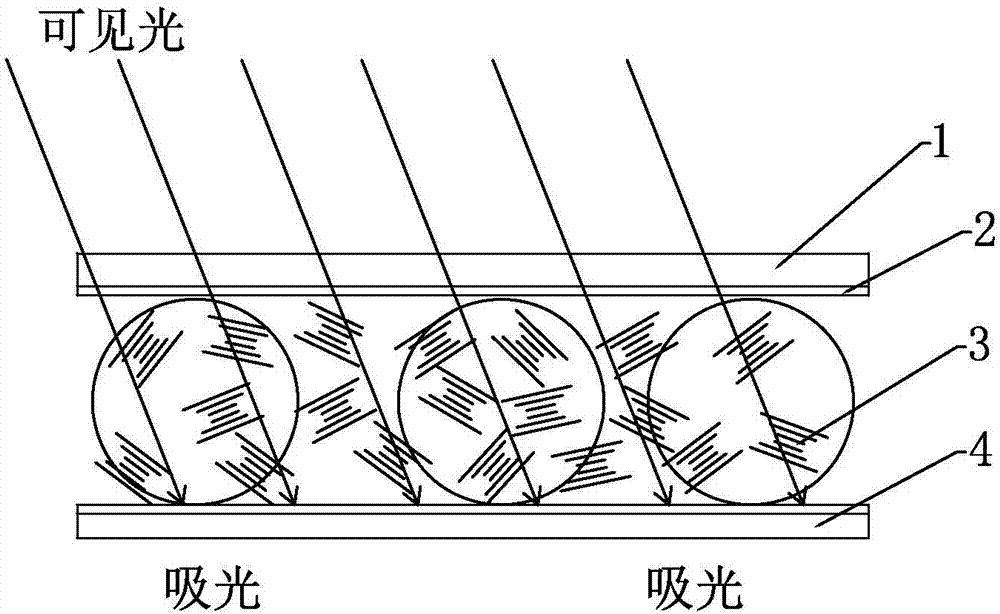

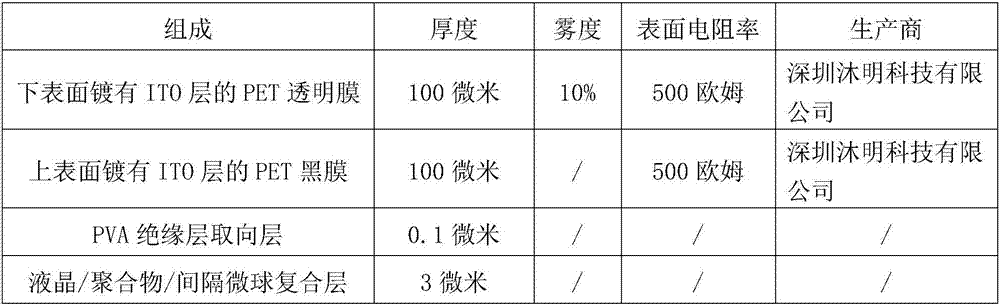

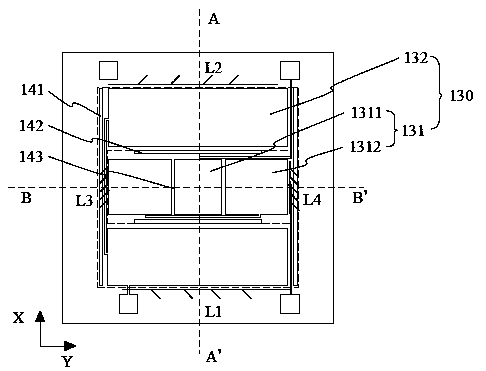

Liquid crystal composite film with writing display function and preparation method thereof

ActiveCN107300818ABig advantageIncrease frictionNon-linear opticsComposite filmLiquid-crystal display

The invention belongs to the field of liquid crystal display and particularly discloses a liquid crystal composite film with a writing display function and a preparation method thereof. The liquid crystal composite film with the writing display function comprises a PET transparent film, a PVA insulating orientation layer, a liquid crystal / polymer / interval microsphere composite layer and a PET black film sequentially from top to bottom. The lower surface of the PET transparent film is coated with an ITO layer, and the upper surface of the PET black film is coated with an ITO layer. The liquid crystal composite film with the writing display function and the preparation method thereof have advantages that due to addition of the PVA insulating orientation layer, short circuit risks of two conductive layers are avoided, and accordingly the rate of finished products is sharply increased, service lives of the products are greatly prolonged, production cost is reduced, and the driving voltage of the liquid crystal film is lowered to increase key technical indexes such as brightness and contrast ratio of the film.

Owner:SHANDONG LANBEISITE EDUCATIONAL EQUIP GRP +1

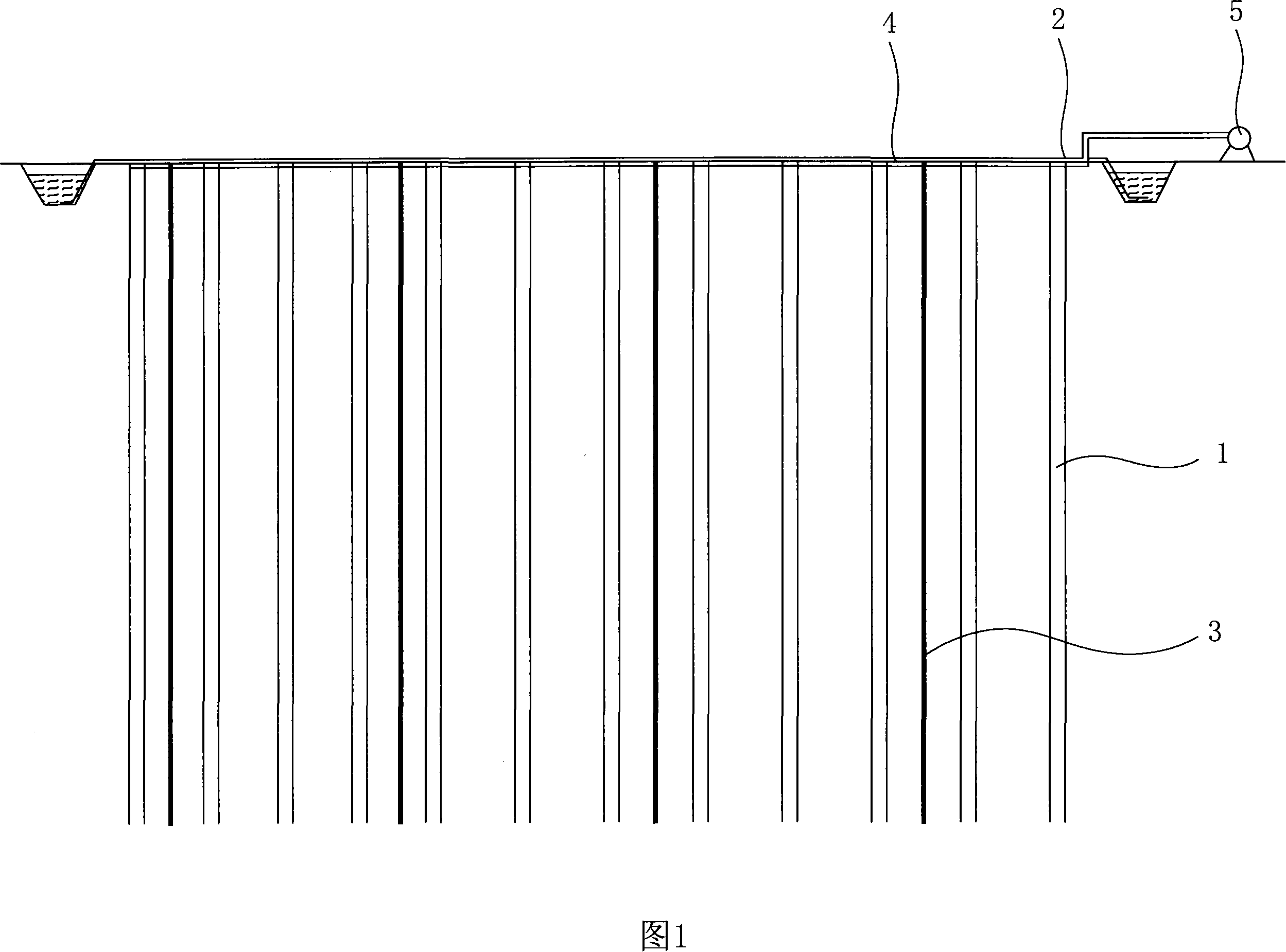

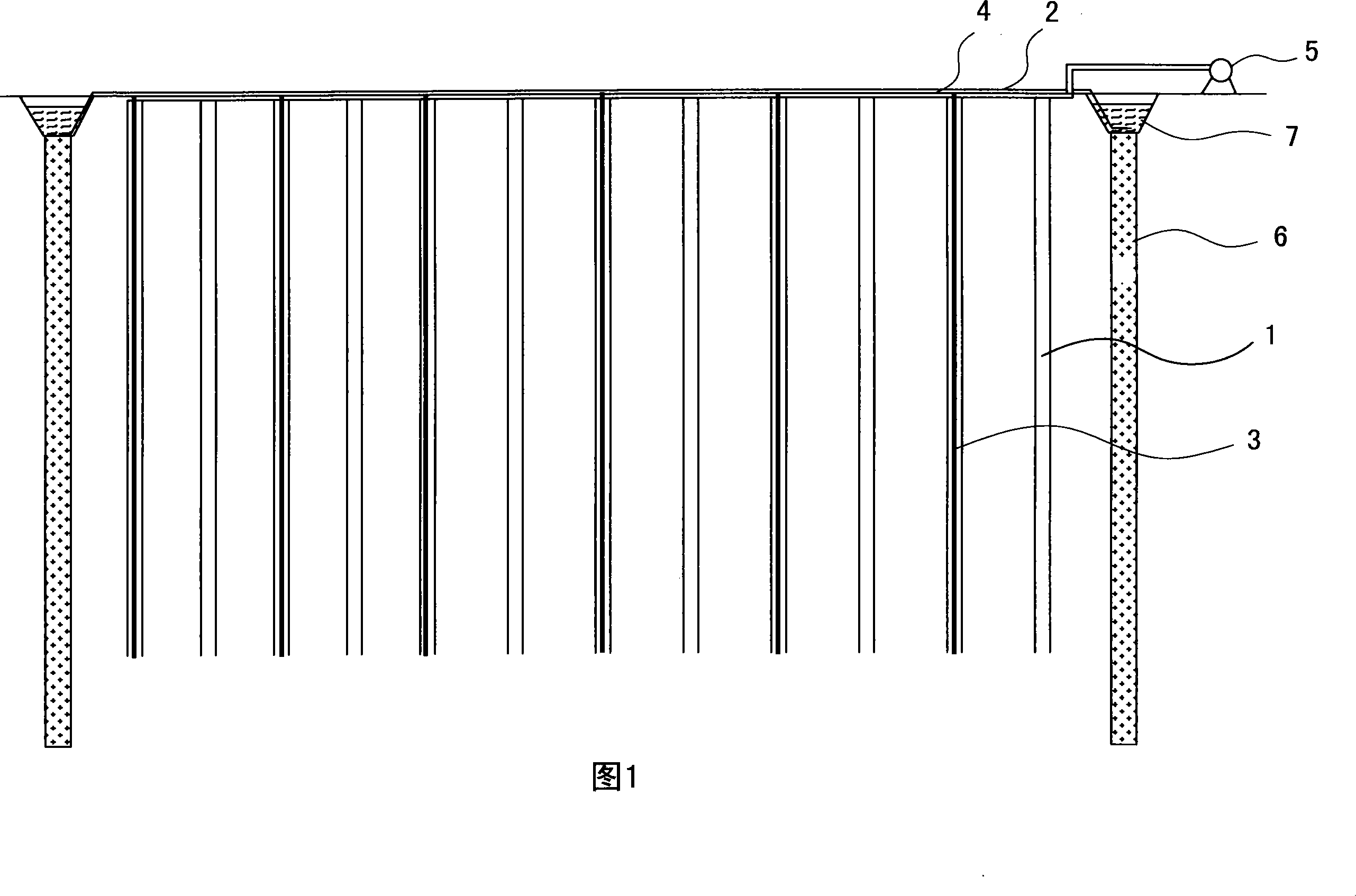

Compound vacuum precompressed soft foundation comprehensive strengthening method

InactiveCN101139833AShorten preload timeIncrease tamping energySoil preservationSoil horizonPre stressing

The invention discloses a composite vacuum pre-stressed soft foundation comprehensive reinforcement method, which is characterized in that the construction method comprises a vacuum pre-stressed precipitation and an electroosmotic precipitation. The execution steps are as follows: a) Establish a yard drainage system; b) Perform vacuum pre-stressed precipitation; c) Perform electroosmotic precipitation at the same time of step b), or when water output is lowered in step b; d) When degree of consolidation reaches a level higher than or equal to 85 percent, steps b) and c) are over to enter a low-energy forced ramming; e) Perform vibration steamroll to flatten the yard. Through composition of utilization of the two construction methods of the vacuum pre-stressed and electroosmotic precipitations, the invention retains advantages in prior vacuum pre-stressed construction methods. Meanwhile, in combination with the electroosmotic precipitation, the invention fulfills application of the vacuum pre-stressed construction method in sludge-like (low permeation factor) soft earth foundations, so that the reinforcement depth of the soft earth layer can be increased, but construction period can be shortened.

Owner:朱怡 +1

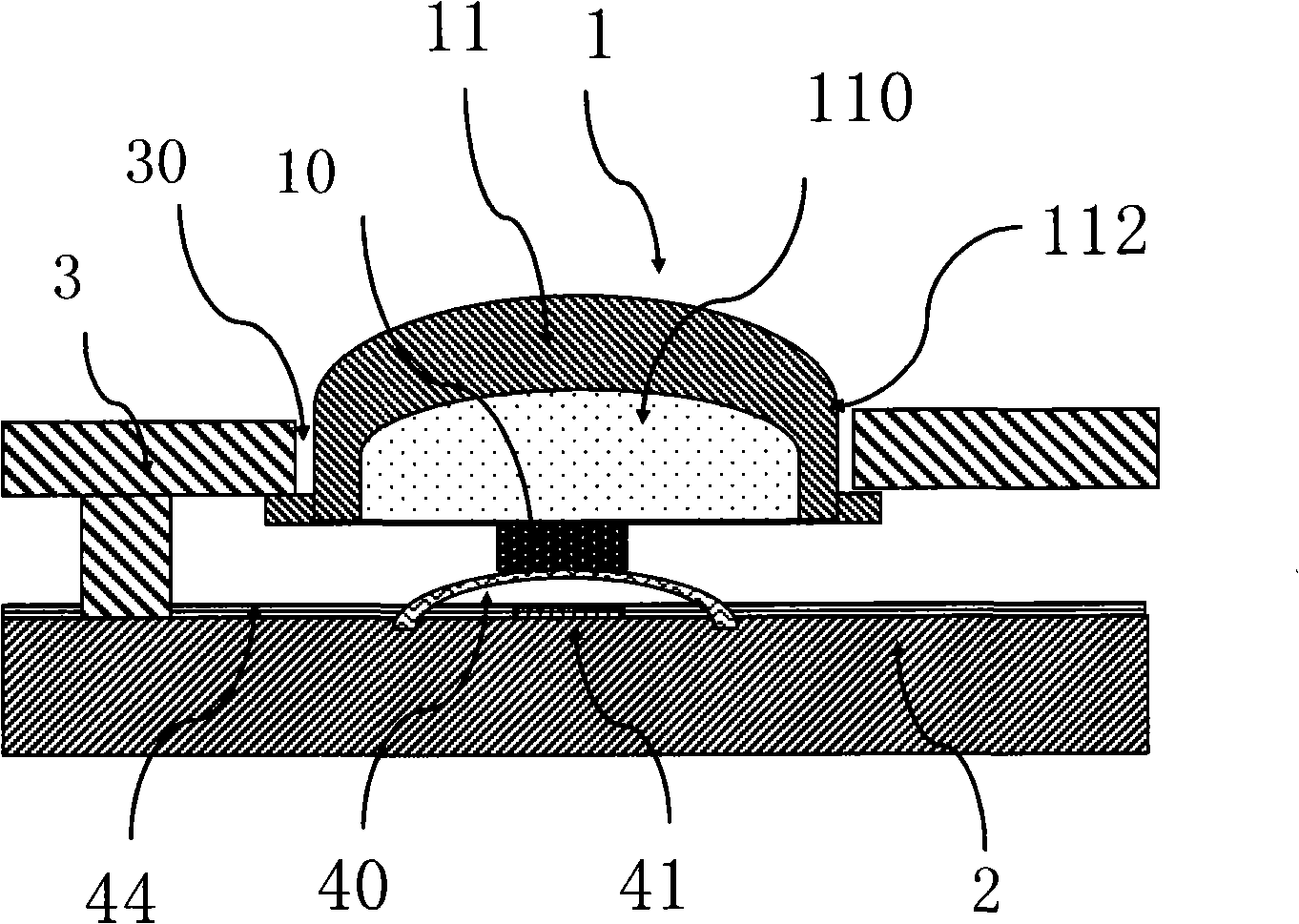

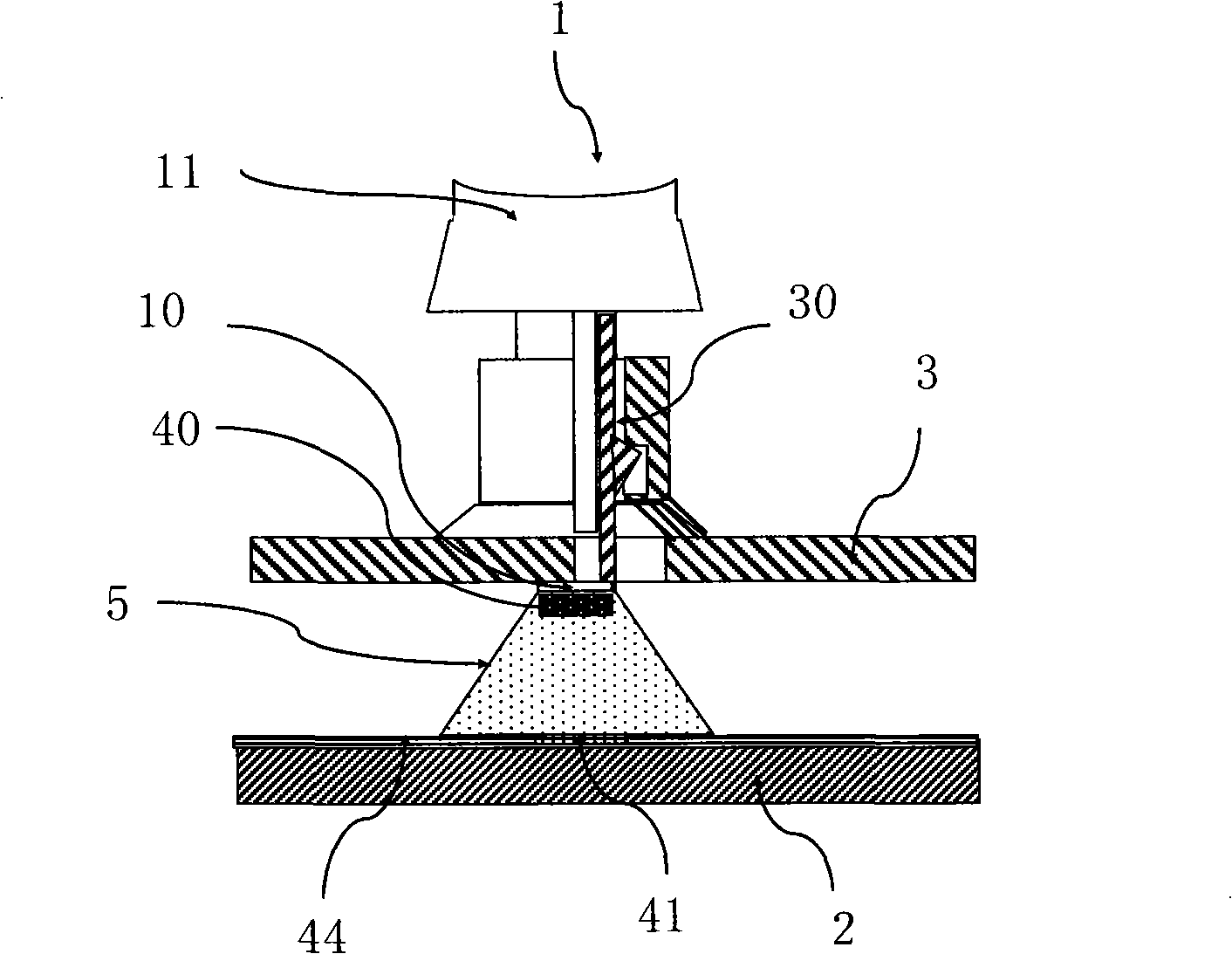

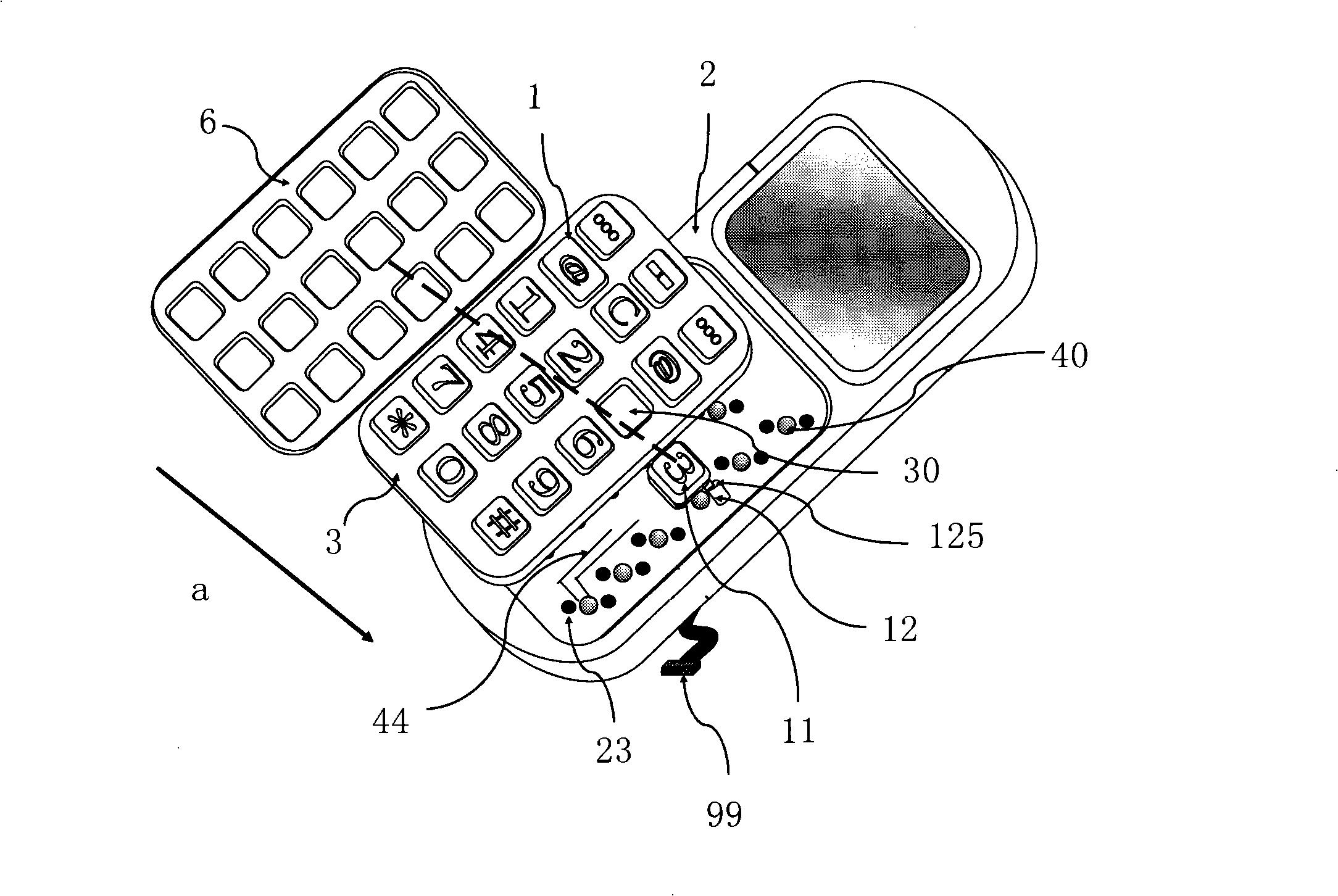

Button switch having guiding device and construction thereof

InactiveCN101335142AStructural advantageDoes not affect functionElectric switchesWhole bodyTouch switch

The invention discloses a press key provided with a guiding device, which is installed on a shell body with a curved surface (including a plane) while the shell body is provided with switch contact points and circuits. A springing device is further arranged and a front cover is integrated with the shell body as a whole body if the front cover is available. The press key with the structure of the invention has simple structure, low cost, convenient and high-efficiency installation, portable operation, and stability and durability, and provides waterproof and dustproof functions for circuits in equipment, and has ultra-thin press key with a comparatively large stroke. Furthermore, the press key of the invention does not occupy the resources of a PCB board in the equipment, can be installed on the shell boy with the curved surface (including the plane) in low cost, and is applicable to the press keys and touch switches of electronic equipment with large, middle and small strokes.

Owner:王光达

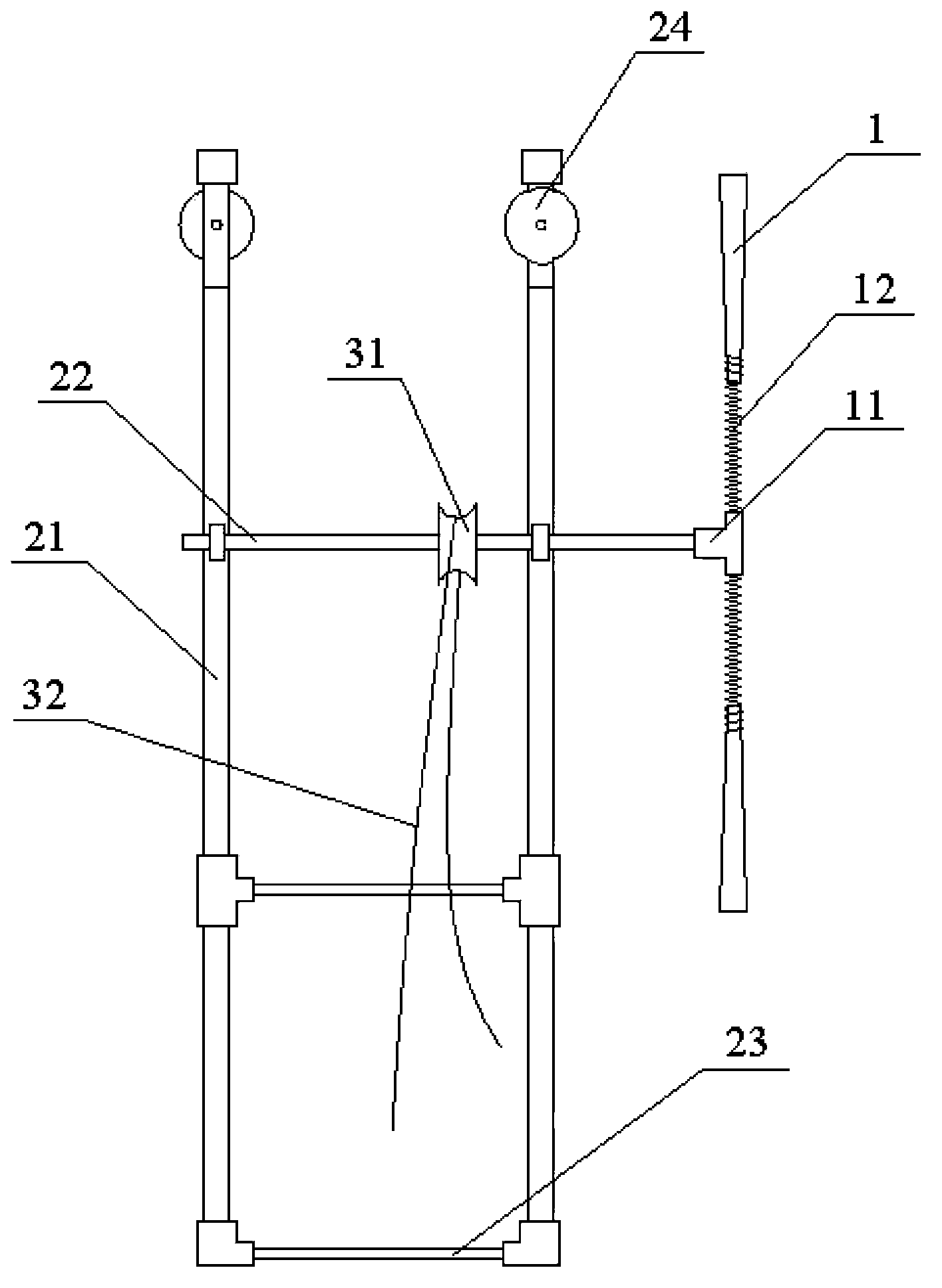

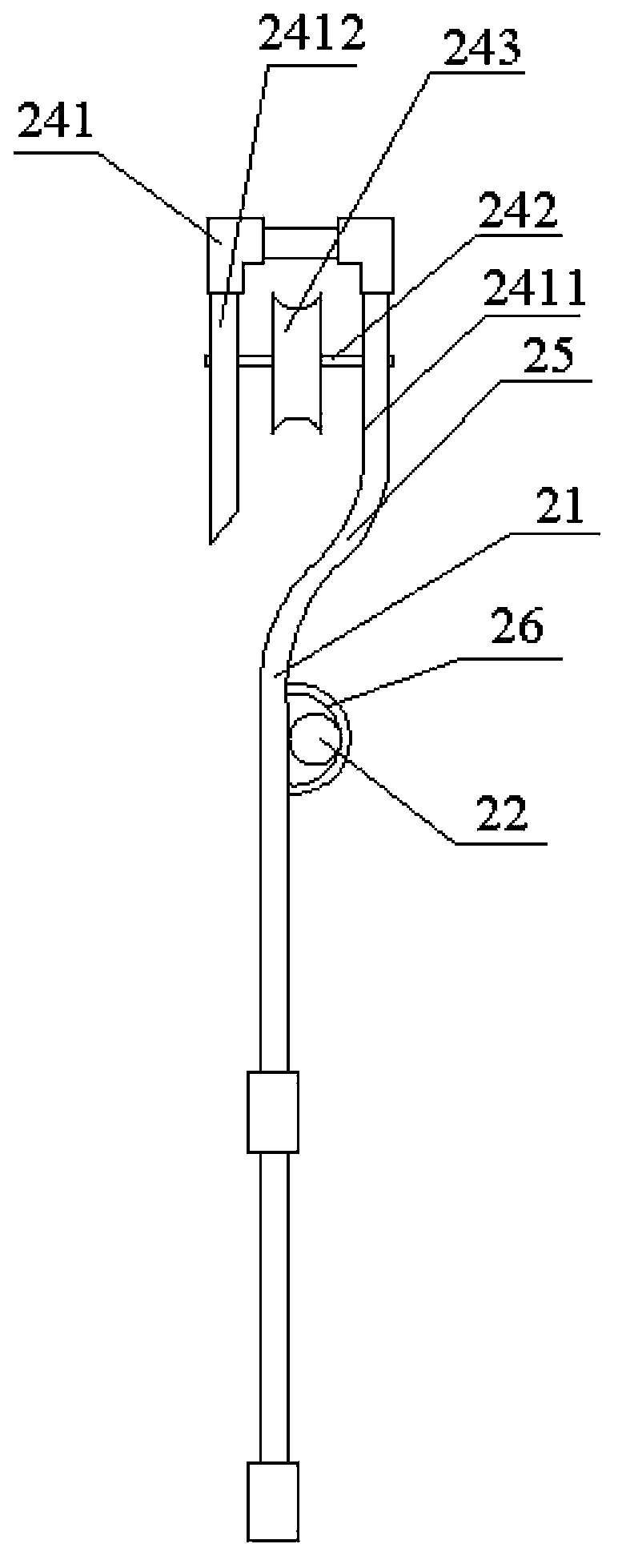

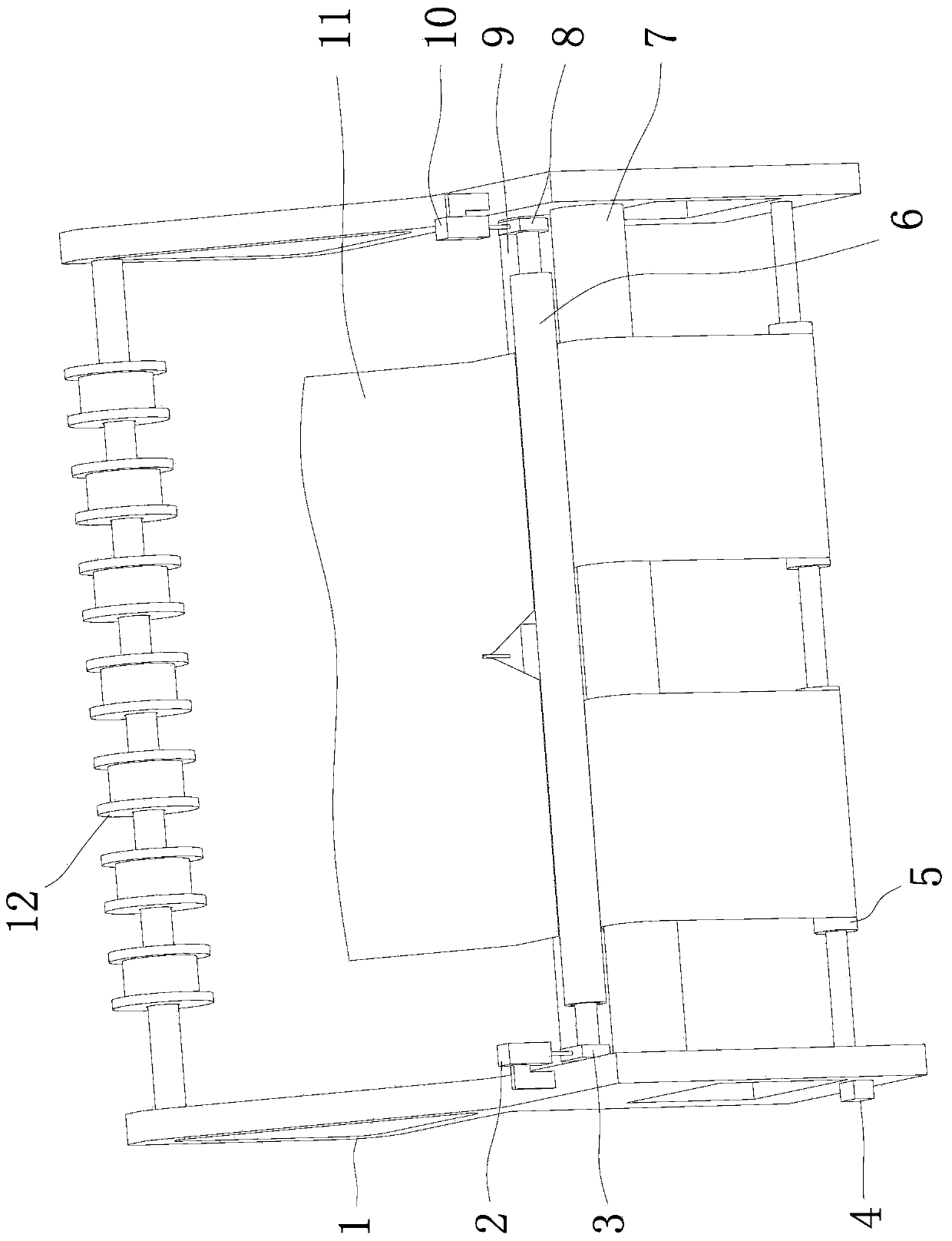

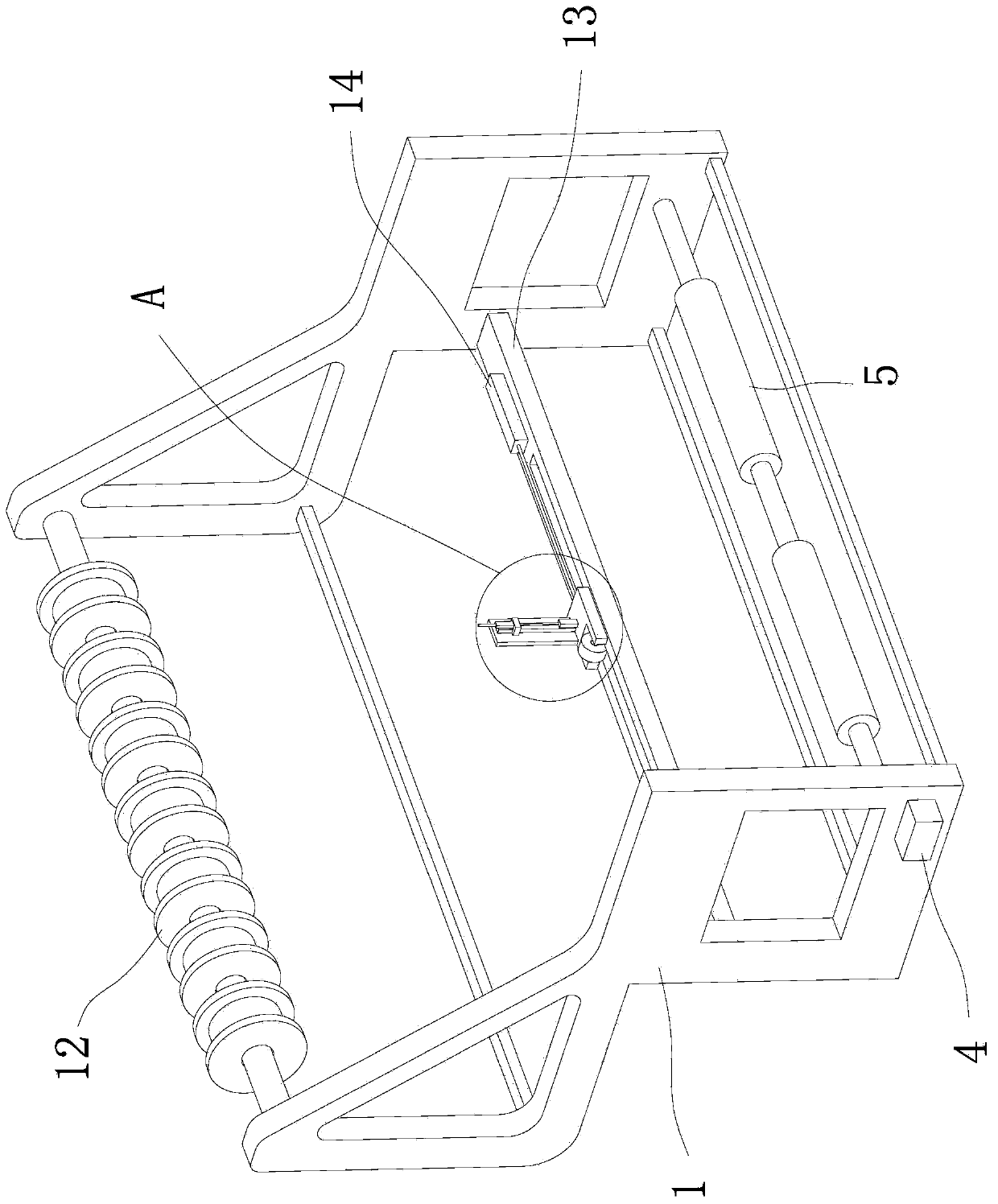

Overhead power transmission line electrification deicing device

ActiveCN103414136AReliable Power QualitySimple structureOverhead installationDrive wheelElectric power system

The invention relates to an overhead power transmission line electrification deicing device. The overhead power transmission line electrification deicing device includes an insulating deicing bar; the deicing bar is erected at one side of a power transmission line through a carrier frame; the carrier frame is provided with a driving mechanism; the carrier frame comprises two upright rods arranged in parallel; the two upright rods are positioned through at least two parallelly-arranged transverse rods between the two upright rods; the top end of each upright rod is suspended on the power transmission line through a suspending mechanism respectively; the deicing bar is vertically arranged on an end portion of a first transverse rod, wherein the end portion of the first transverse rod extends out from the upright rods; the height of the deicing bar is corresponding to the height of the top end of the upright rods; and the driving mechanism comprises a driving wheel and an insulating transmission rod wound on the driving wheel. The overhead power transmission line electrification deicing device of the invention is simple in structure. With the overhead power transmission line electrification deicing device adopted, deicing operation can be performed under a situation of electrification of a whole line, and the reliability and quality of power supply of a power system can be effectively ensured on the premise that the efficiency of the deicing operation can be improved.

Owner:STATE GRID CORP OF CHINA +1

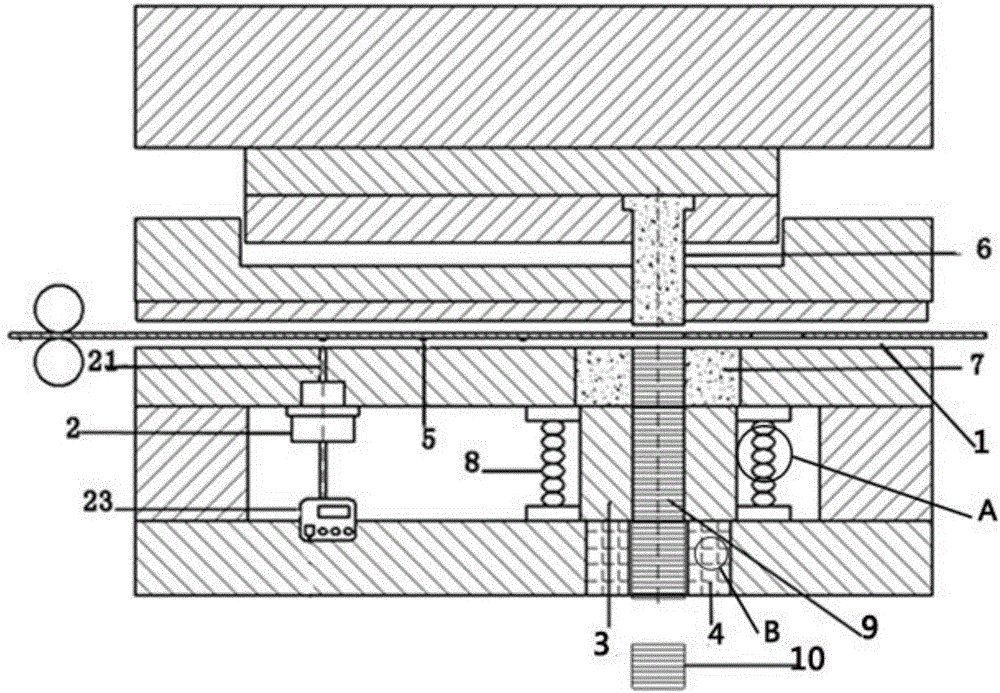

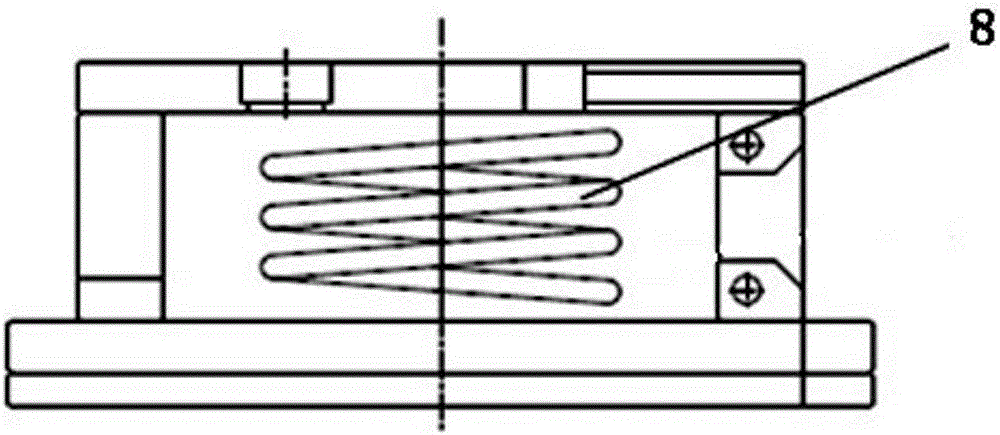

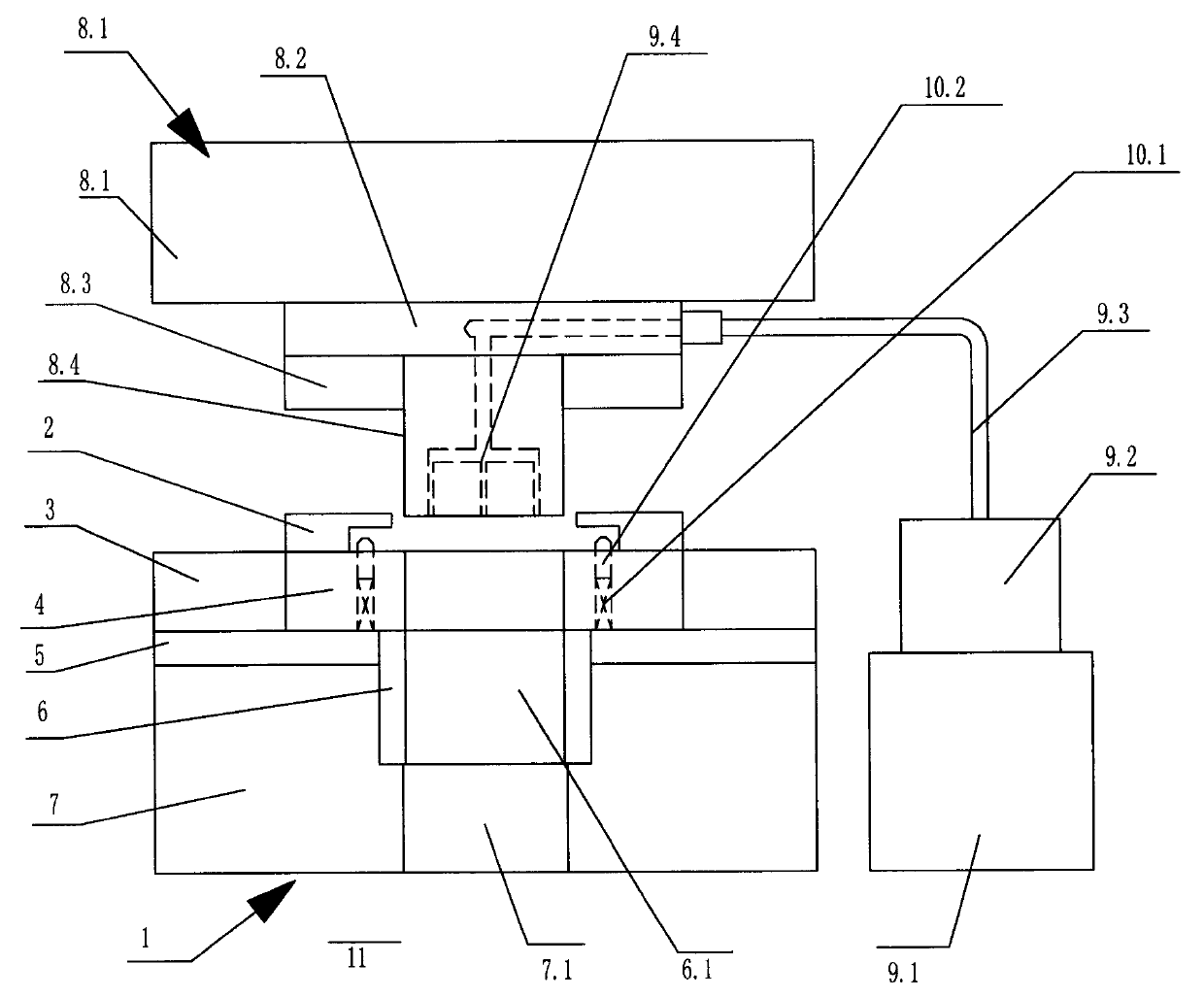

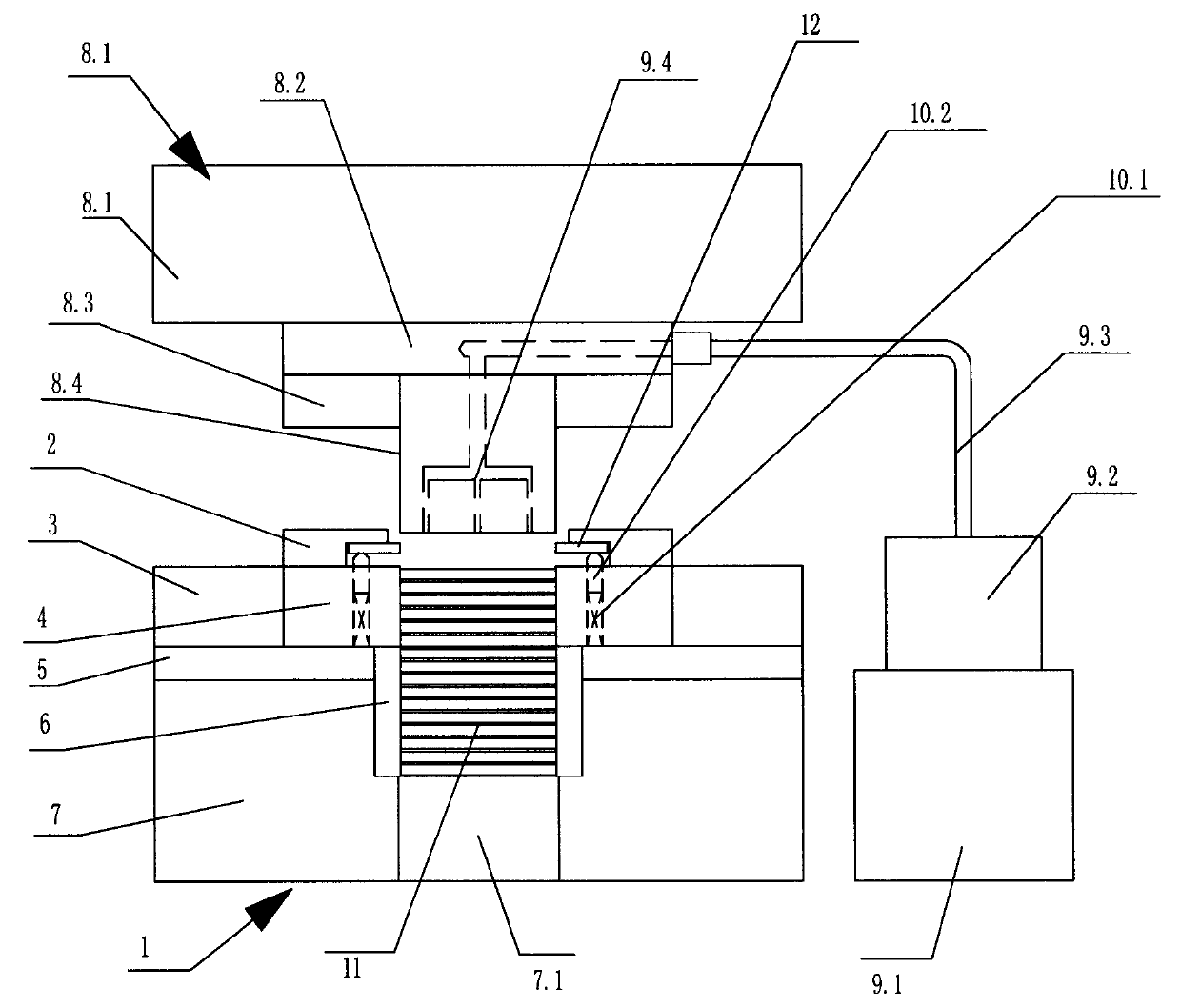

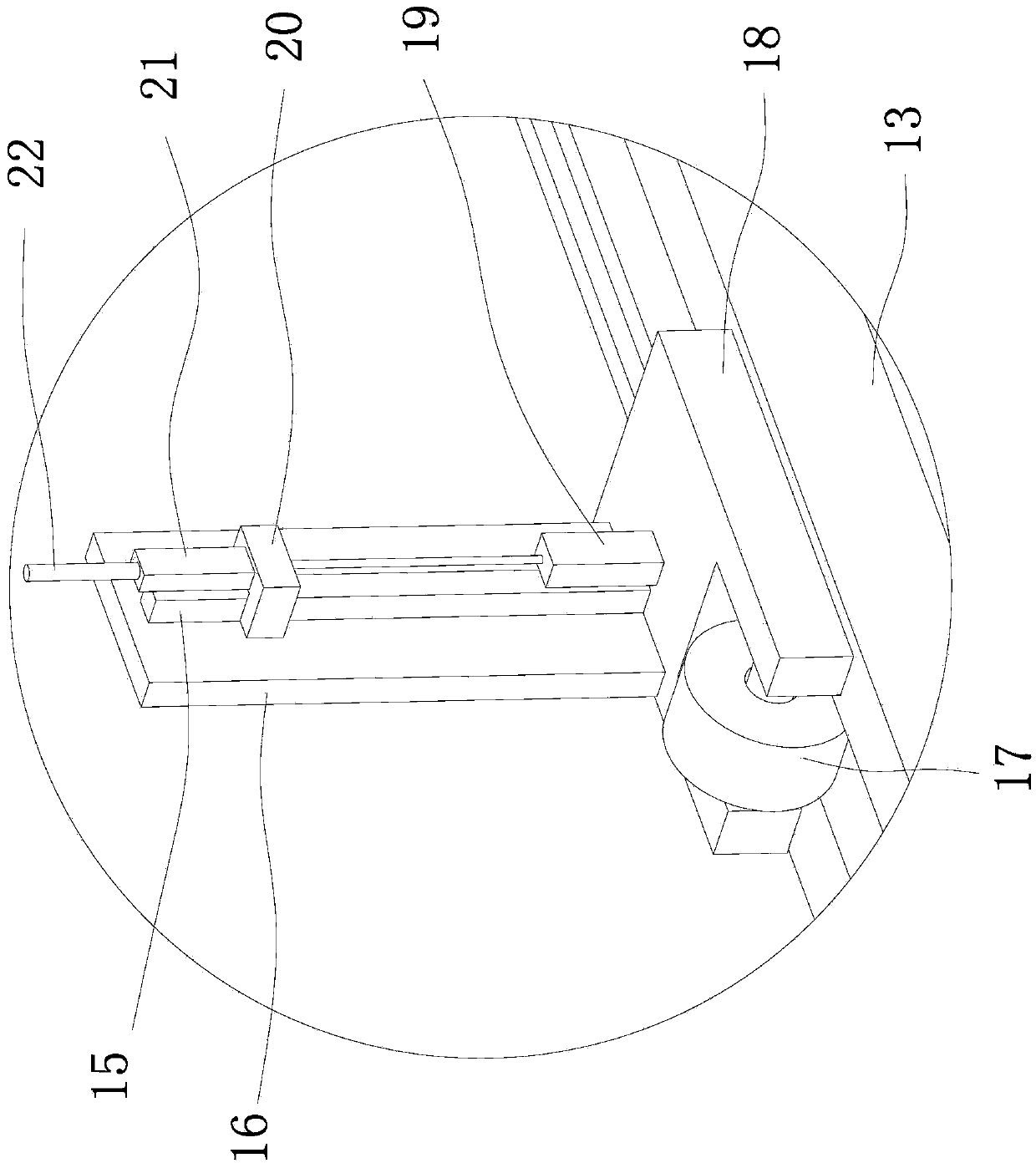

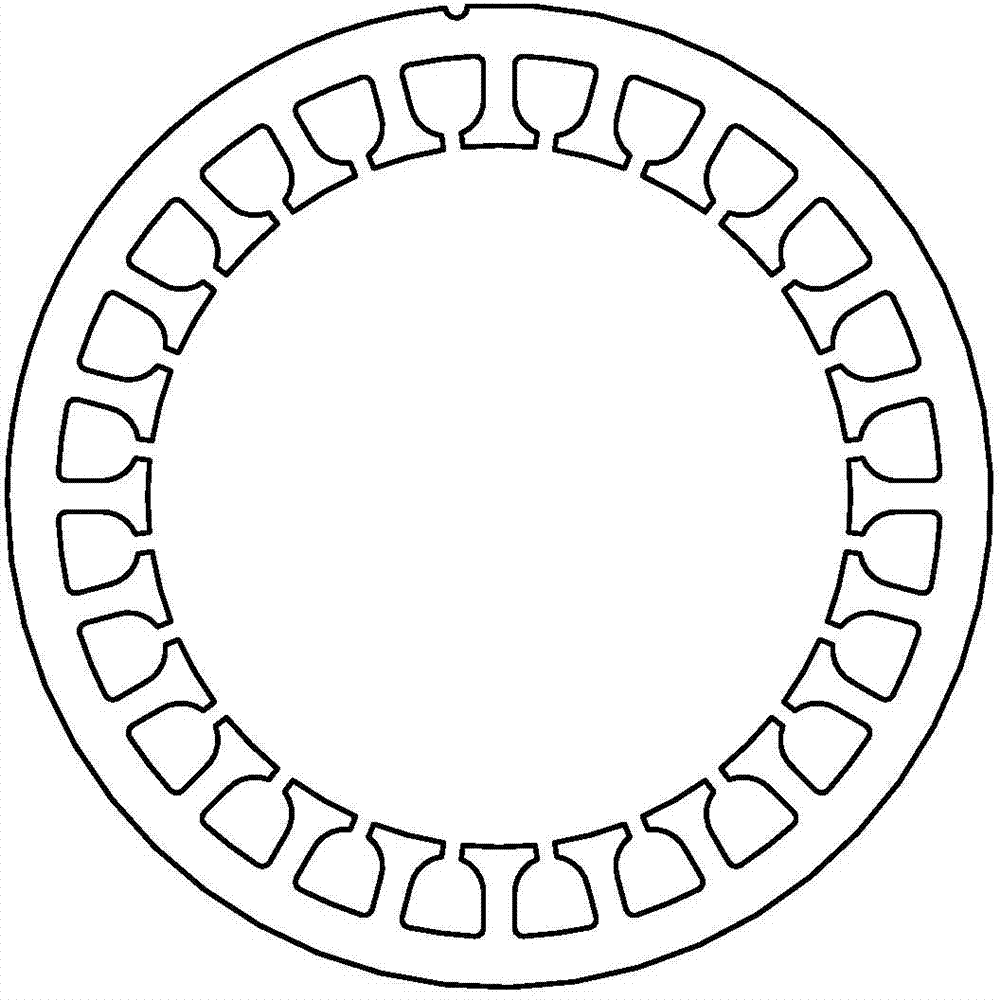

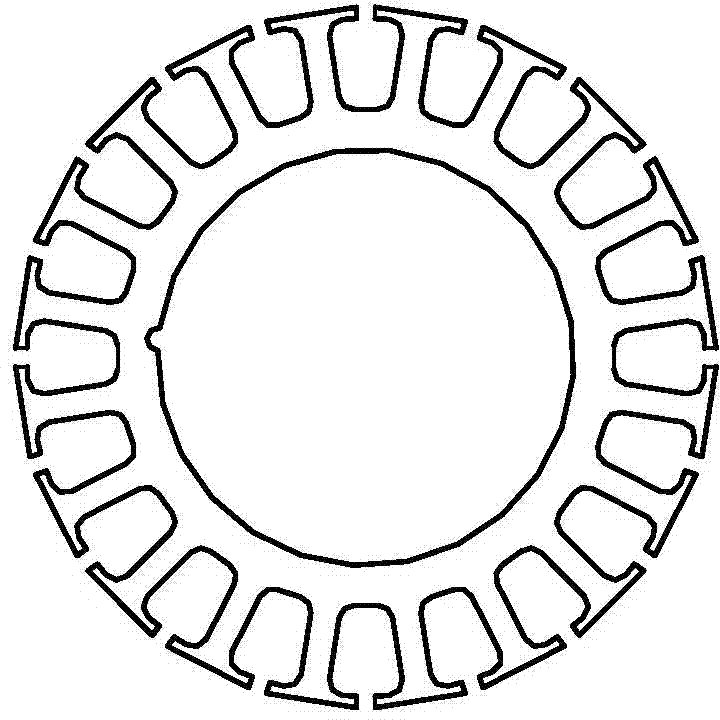

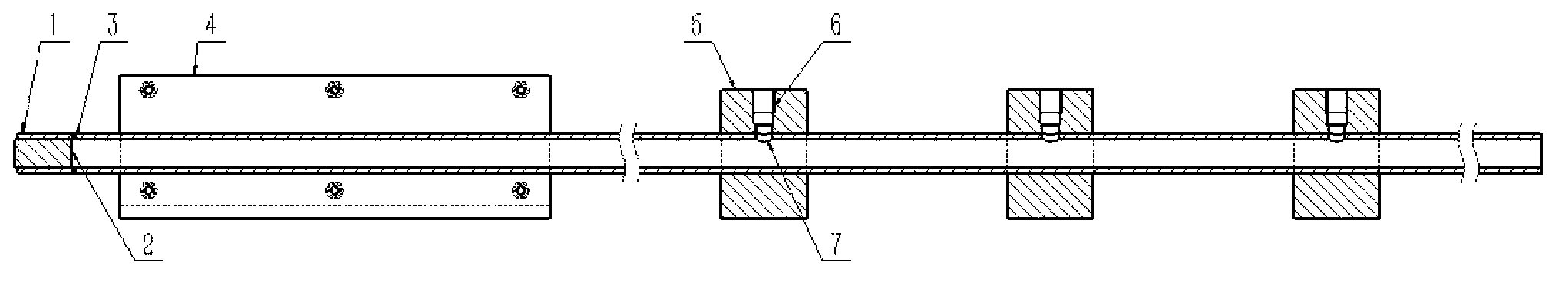

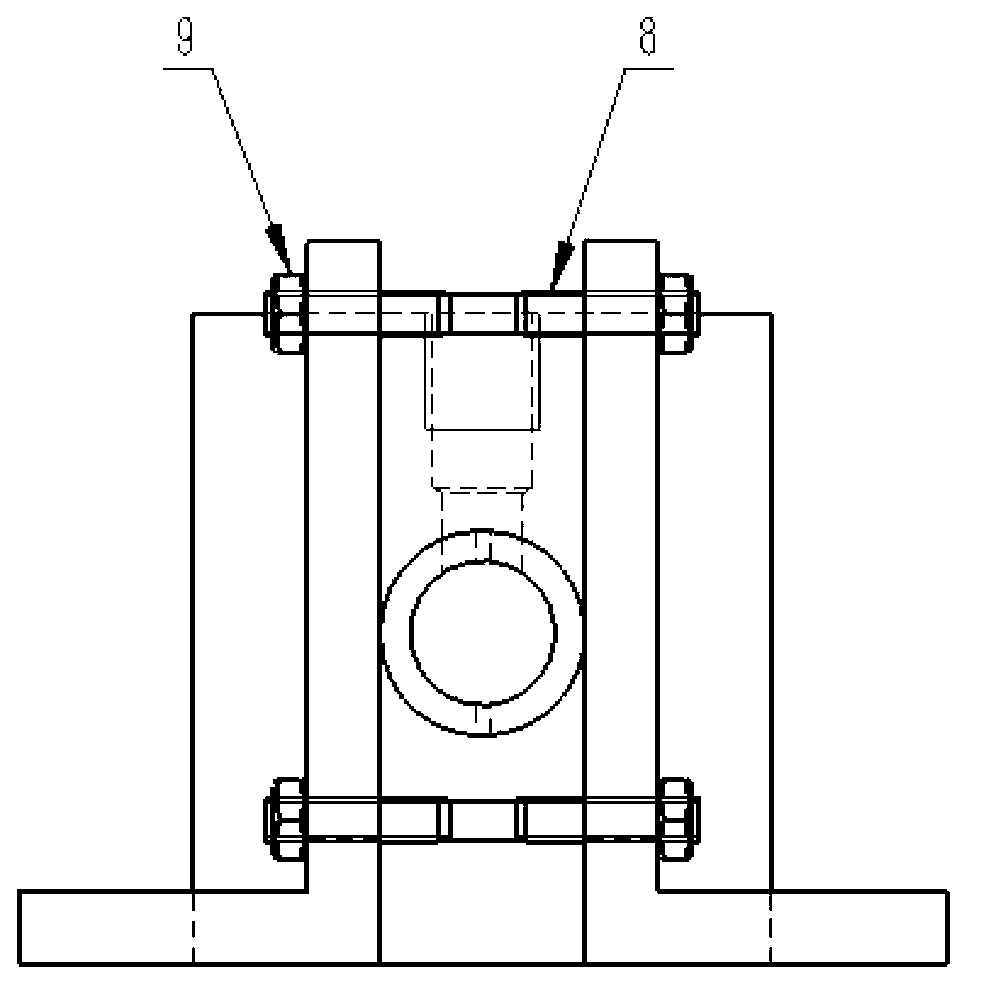

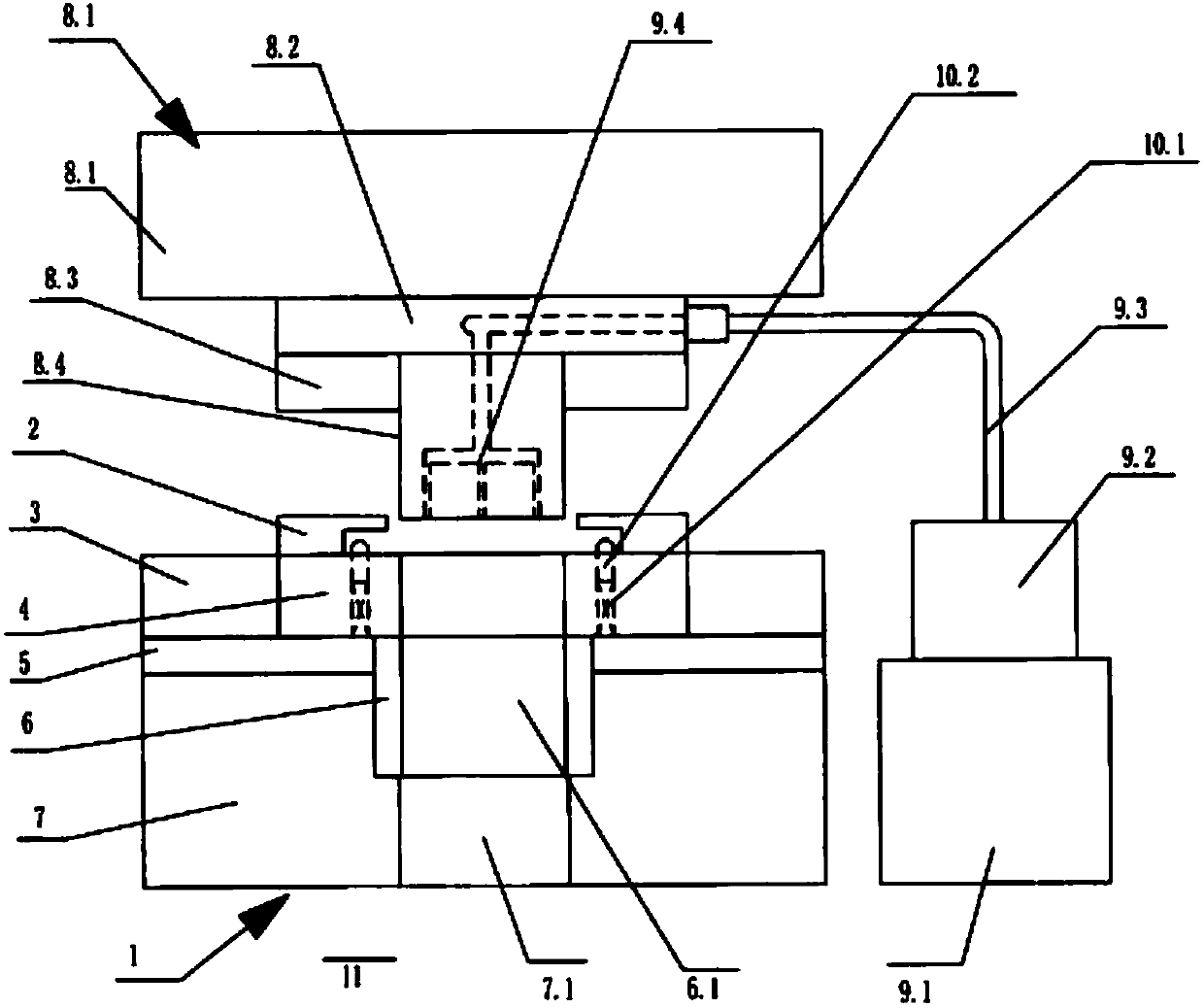

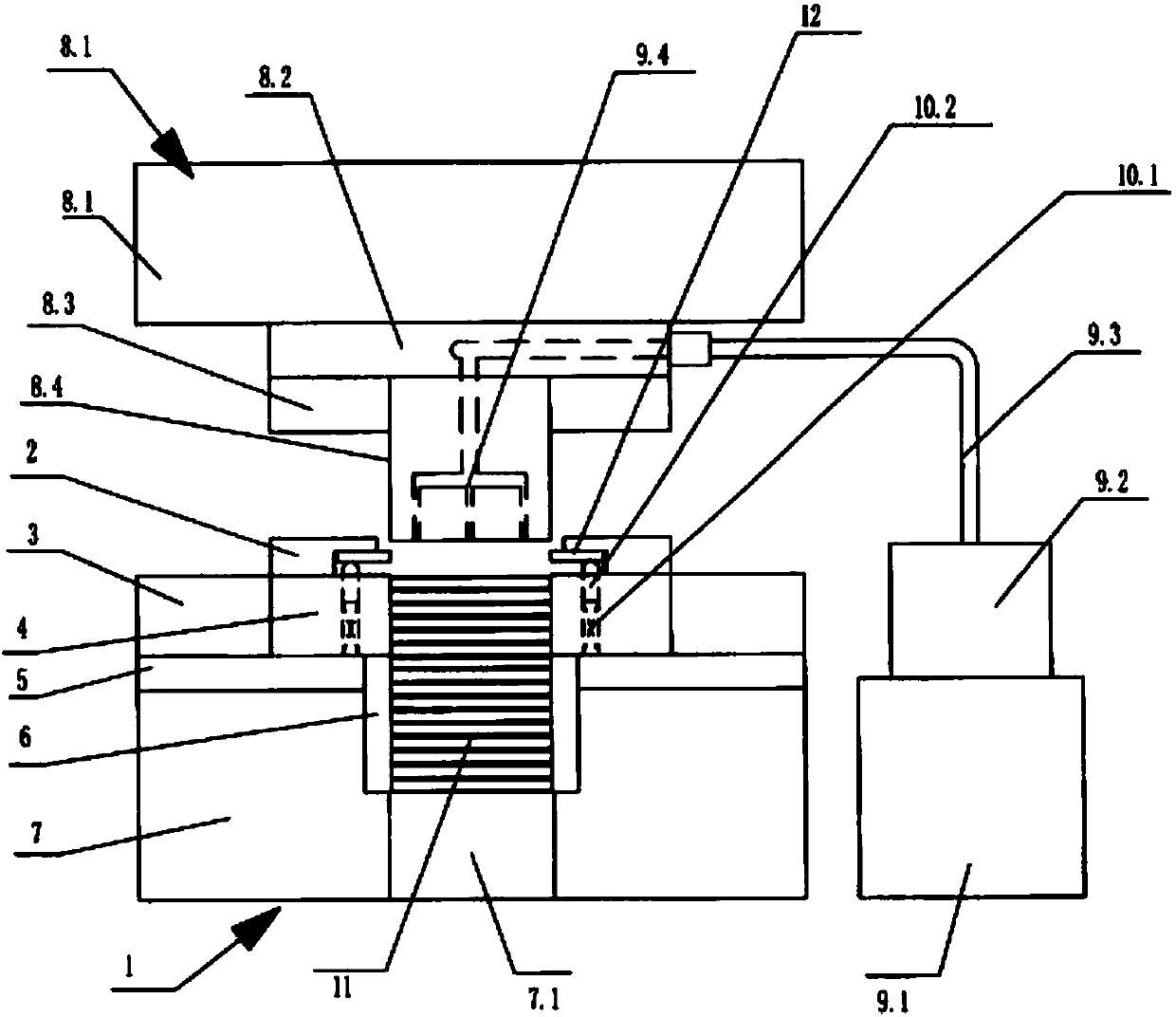

Automatic adhering and laminating device for in-mold motor core

ActiveCN106787487AGuaranteed verticalityGuaranteed flatnessManufacturing stator/rotor bodiesCore productPunching

The invention discloses an automatic adhering and laminating device for an in-mold motor core. The automatic adhering and laminating device comprises a material strip, a blanking male die and a blanking female die, wherein the blanking male die is arranged at the upper part of the material strip; the blanking female die matched with the blanking male die is arranged at the lower part of the material strip; a locking ring is arranged at the lower part of the blanking female die; a cooling pipe is arranged at the lower part of the locking ring; heating coils are arranged at two sides of the locking ring; and an adhering device is arranged at the left side of each heating coil. The automatic adhering and laminating device has the beneficial effects that synchronous stamping and bonding are achieved through the arranged adhering device, no point for laminated riveting exists on punching plates, a core product is smooth in surface and small in magnetic resistance effect and a layer of quick-drying anaerobic adhesive is arranged between two punching plates to play a certain insulating effect; by adopting the locking ring, the perpendicularity and the planeness of the core and the coincidence degree between the adjacent punching plates are ensured under the action of the gravity and the impact force of the product; and full-automatic digital control of high-temperature baking and fast cooling is achieved through a heating device and a cooling device.

Owner:NINGBO ZHENYU TECH

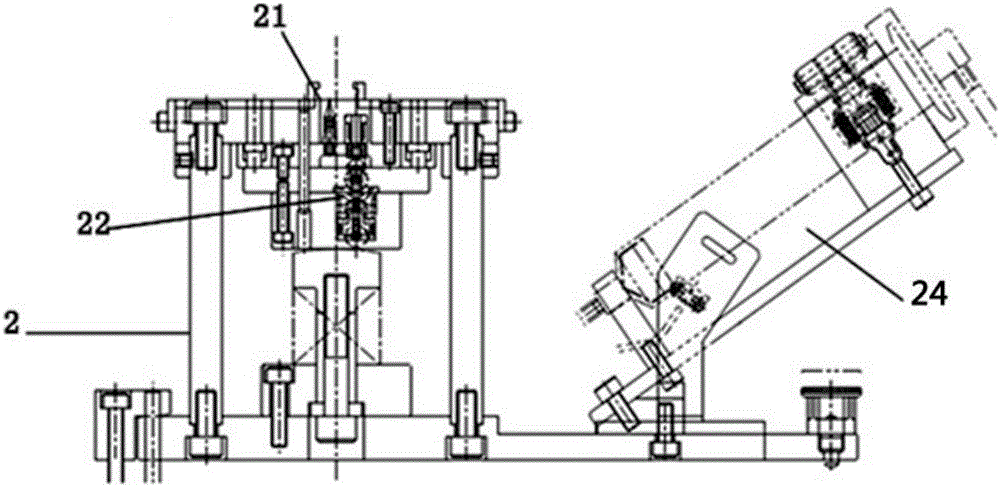

Motor iron core automatic gluing lamination high-speed stamping grading die

ActiveCN104218743AImprove performanceHigh coincidenceManufacturing stator/rotor bodiesEngineeringCushion

A motor iron core automatic gluing lamination high-speed stamping grading die comprises an upper die, a lower die, a material guiding plate, an upper die base, an upper cushion plate, a male die cushion plate, a blanking male die, a blanking female die, a concave formwork, a female die cushion plate, a locking ring and a lower die base. The blanking female die is installed in the concave formwork, the locking ring is located below the blanking female die and axially provided with a locking hole, and the blanking female die is opposite to the locking hole. The inner diameter of the locking ring is smaller than that of the blanking female die, the locking ring is placed in the lower die base, a product outlet is arranged below the lower die base, the lower end of the locking hole is communicated with the product outlet, and the motor iron core automatic gluing lamination high-speed stamping grading die further comprises an adhesion module. The locking ring is arranged below the blanking female die, perpendicularity and flatness of an iron core are guaranteed, the coinciding degree of adjacent stamping pieces is high, the locking ring is used for collecting the stamping pieces, and the later period labor cost can be greatly reduced. The upper die is provided with the adhesion module, stamping and adhesion are synchronously performed, and working efficiency is greatly improved. The invention belongs to the technical field of die devices.

Owner:宁波建欣精密模具有限公司

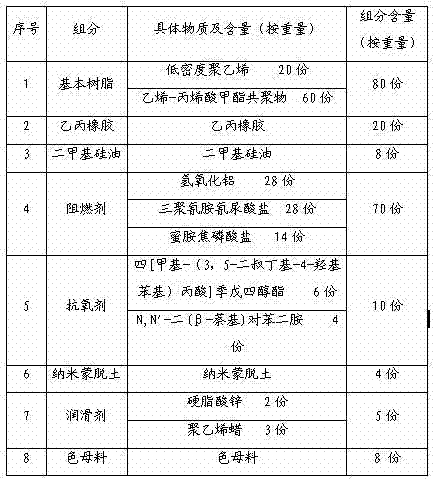

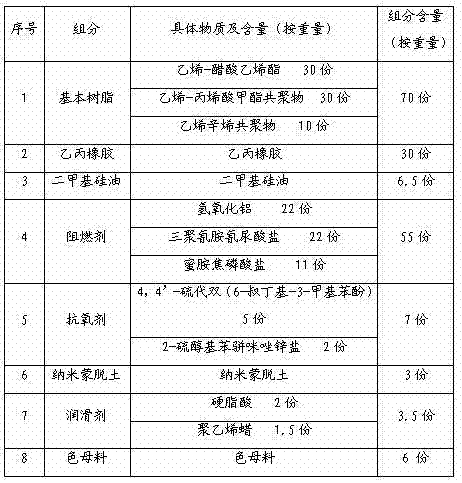

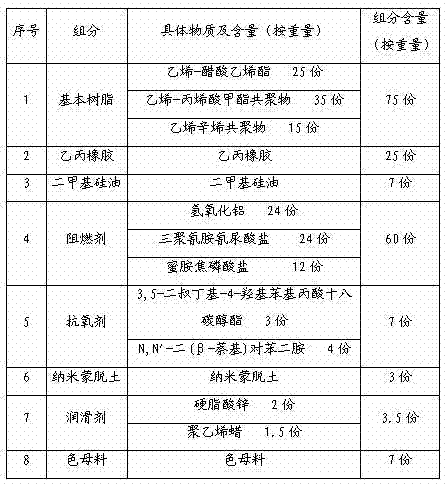

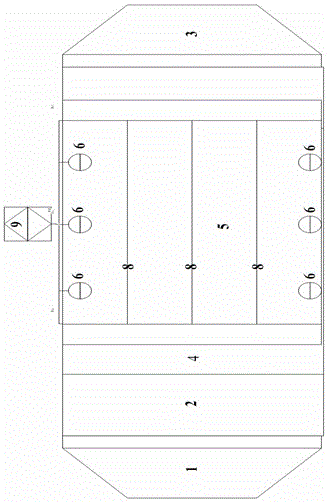

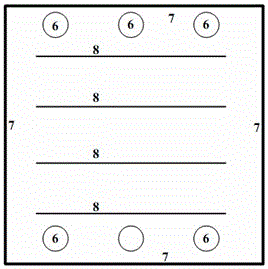

Bus bar heat-shrinkable tube and preparation method thereof

The invention relates to a bus bar heat-shrinkable tube which is prepared from the following components in parts by weight: 60-80 parts of base resin, 20-40 parts of ethylene-propylene rubber, 5-8 parts of dimethyl silicon oil, 40-70 parts of flame retardant, 4-10 parts of antioxidant, 2-4 parts of nano montmorillonite, 2-5 parts of lubricant and 4-8 parts of color batch. The preparation method of the bus bar heat-shrinkable tube comprises the following steps: 1. weighing the components according to parts by weight; 2. mixing and granulating with a Banbury mixer or parallel double screw extruder, and extruding with a single screw extruder to obtain a tube; 3. treating the external surface of the extruded tube with infrared light, of which the wavelength is 700-1600nm, in the position 5-10cm away from the extrusion die of the extruder; and 4. carrying out radiation crosslinking on the tube with cobalt 60 or electron accelerator 50-160kGy, and expanding the tube subjected to radiation crosslinking at 85-135 DEG C. The bus bar heat-shrinkable tube provided by the invention has the advantages of favorable insulating property and long service life, and is convenient for construction.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +3

Low-temperature plasma catalytic oxidation gas deodorization method

ActiveCN105126613AReduce energy consumptionLower the activation energy of the reactionDispersed particle filtrationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbon filtrationCatalytic oxidation

The invention discloses a low-temperature plasma catalytic oxidation gas deodorization method. The method comprises the steps that exhaust gas enters the interior of a stainless steel reaction box from a gas inlet, and dust particles in the gas are intercepted through an activated carbon filter layer; then the gas enters a low-temperature plasma reaction chamber, after a power supply is switched on, multiple sets of reaction polar plates in the low-temperature plasma reaction chamber conduct high-voltage discharge to generate substances with a strong oxidizing property, macromolecules, producing malodor, in the gas are broken up into small molecules under the combined action of the substance with the strong oxidizing property and ultraviolet rays, and the small molecules are further oxidized to obtain inorganic molecules when the small molecules make contact with hydroxyl free radicals and oxygen atoms which are released by a catalytic oxidation reaction coating. According to the low-temperature plasma catalytic oxidation gas deodorization method, the low-temperature plasma technology is perfectly combined with the coating catalytic oxidation and ultraviolet oxidation technologies. According to the exhaust gas treated through the method, the removing rate of malodorous gas reaches over 98 percent, the removing rate of harmful microorganisms and bacteria reaches 98.9 percent, and the removing rate of the dust particles reaches 96.2%.

Owner:浙江万泰环境工程有限公司

Method for reinforcing composite vacuum prepressing soft soil foundation

The composite vacuum pre-pressing soft foundation stabilizing process with vacuum pressing precipitation and electroosmosis precipitation includes the following steps: 1. establishing a site draining system, arranging a vacuum electroosmosis device, and setting a vacuum pressing sealing layer on the ground; 2. turning on the vacuum pump for vacuum pressing precipitation; 3. activating the circuit for vacuum electroosmosis precipitation; and 4. turning off the vacuum electroosmosis device and the vacuum pump after reaching the consolidation degree of 85 % and performing the post ground treatment and further stabilizing. The present invention combines vacuum pressing precipitation and electroosmosis precipitation to reach high consolidation degree of the soft foundation and shorten the construction period.

Owner:郁玫 +1

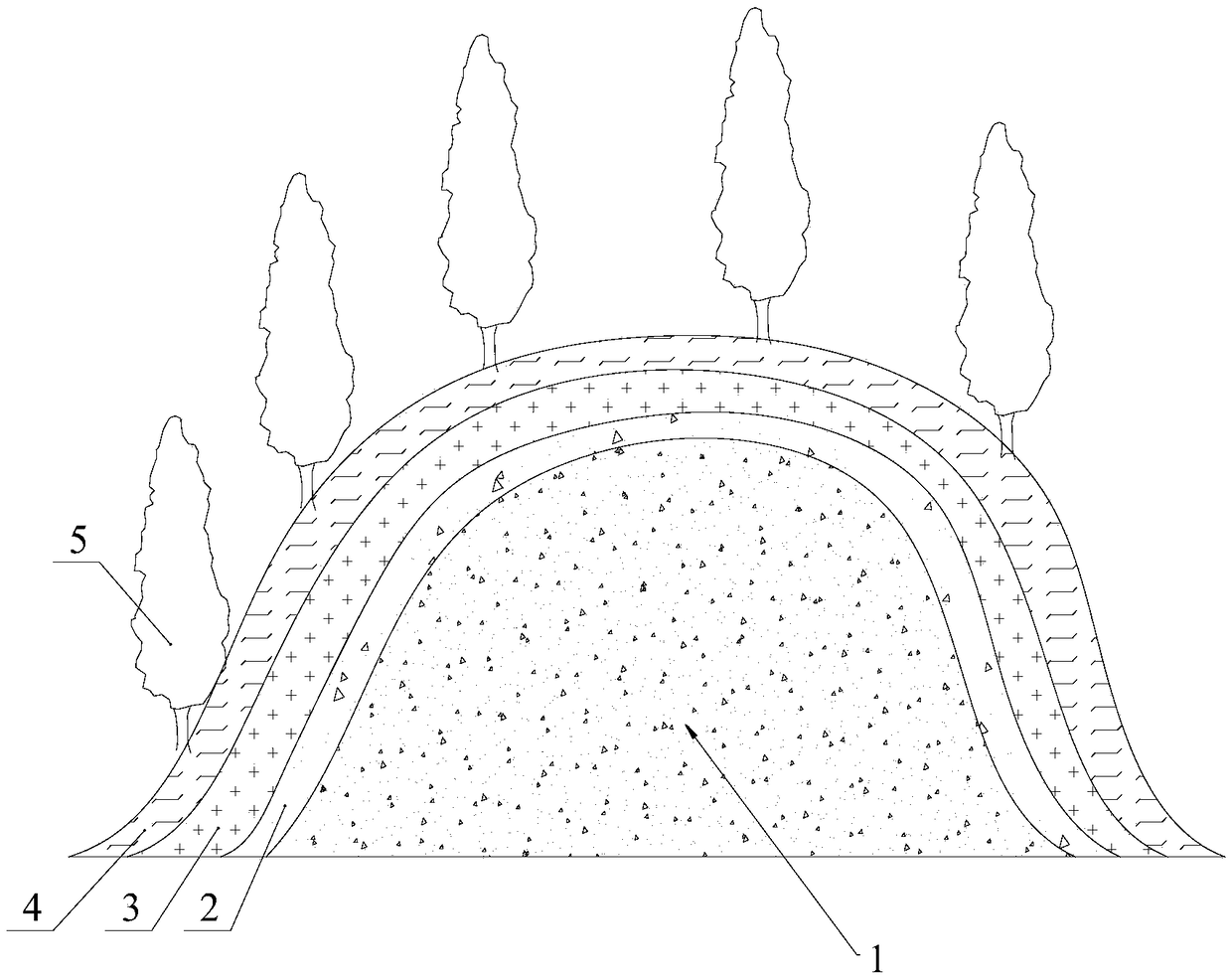

Nonferrous mine waste rock storage yard ecological environmental management method

ActiveCN108650915AImprove the environmentRealize comprehensive utilizationSoil-working methodsVegetationHigh concentration

The invention discloses a nonferrous mine waste rock storage yard ecological environmental management method. The method comprises the following steps that 1, by means of a slurry spraying machine, apasty neutralization and improvement material is sprayed to the outer surface of a waste rock storage yard, and a neutralization and improvement layer is formed; 2, by means of the slurry spraying machine, a pasty buffer isolation material is sprayed to the outer surface of the neutralization and improvement layer, and a buffer isolation layer is formed; 3, a vegetation recovery layer is formed onthe outer surface of the buffer isolation layer. Accordingly, wet spraying is adopted, a high-concentration mixed material is sprayed by adopting the slurry spaying machine to the waste rock storageyard, and specially for the neutralization and improvement layer, the pasty neutralization and improvement material is better embedded into a gap of an outer surface layer of the waste rock storage yard; compared with existing dry spraying machine spraying, the neutralization and improvement material can be sufficiently embedded, the problem that a large number of gaps are formed does not exist, and therefore due to sufficient embedding, even though the waste rock storage yard deforms slightly, a packing layer is not likely to fail.

Owner:江苏绿之源生态建设有限公司

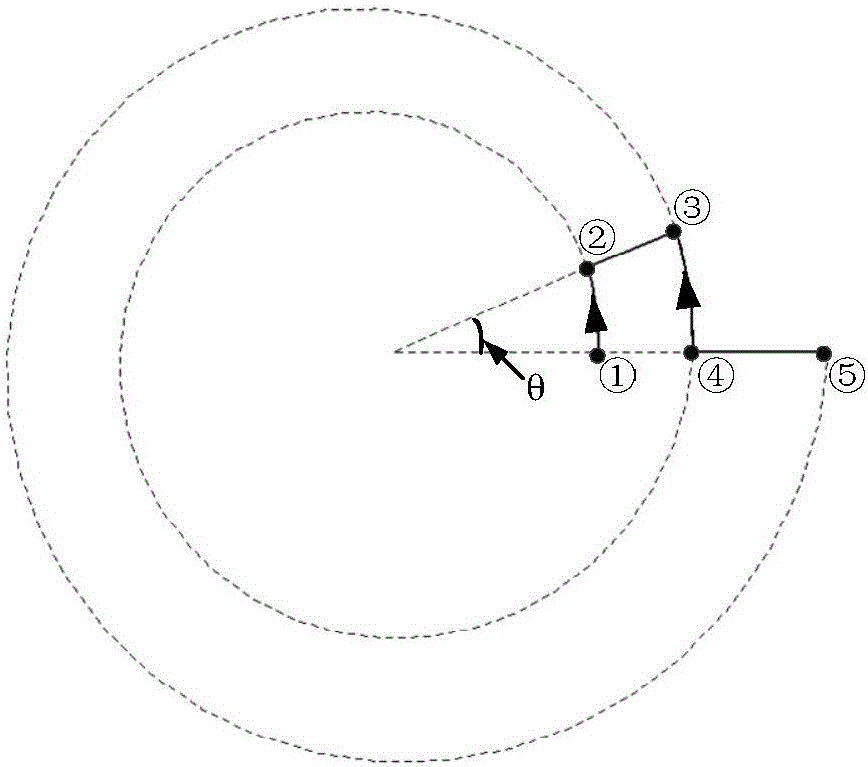

Angular-clamping biradial electron beam angle logarithmic plane zigzag slow-wave line slow-wave structure

InactiveCN107180734AAchieve improvementImprove electronic efficiencyTransit-tube circuit elementsBeam angleWave structure

The invention discloses an angular-clamping biradial electron beam angle logarithmic plane zigzag slow-wave line slow-wave structure, and relates to the field of radial beam traveling-wave tube systems. The structure comprises a metal cavity, an angle logarithmic metal plane zigzag slow-wave line, an upper ideal cathode, a lower ideal cathode, a first medium supporting rod, and a second medium supporting rod. The structure solves a problem of an ineffective angle logarithmic micro-strip slow-wave structure in a working process of a radial beam traveling-wave tube, which is caused by a condition that a defocused electron beam is liable to bombard a logarithmic micro-strip and causes the fusion of the logarithmic micro-strip.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

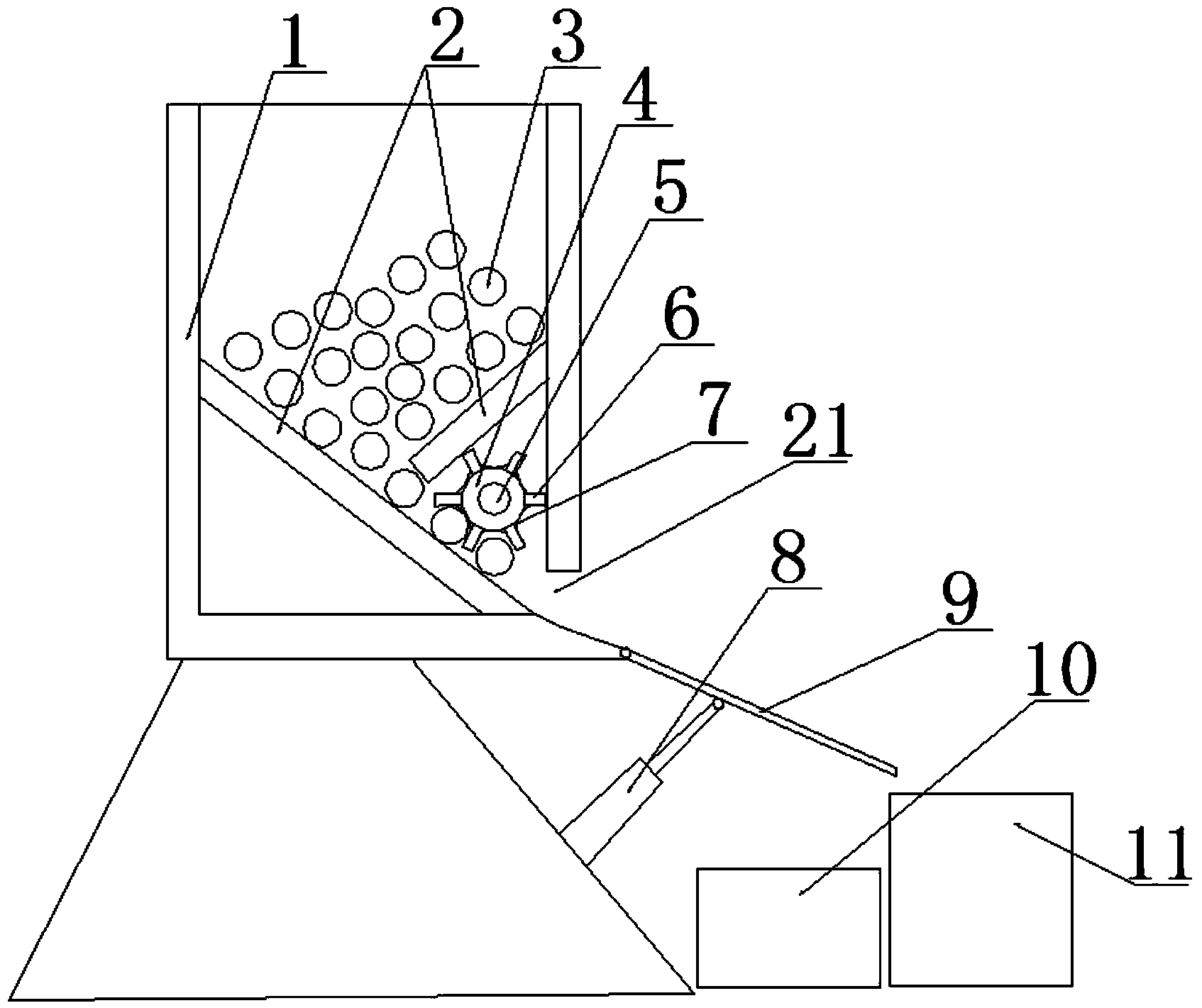

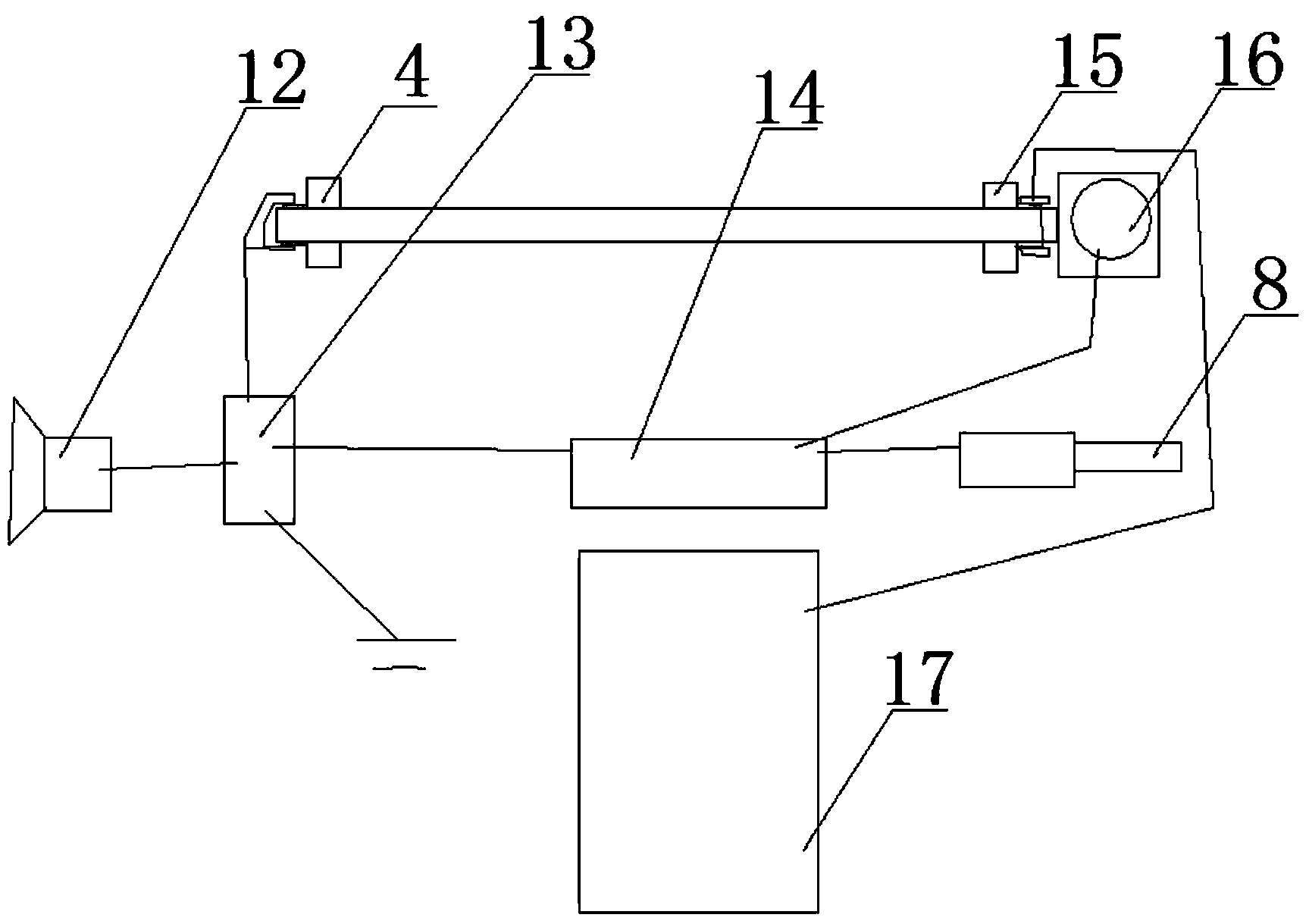

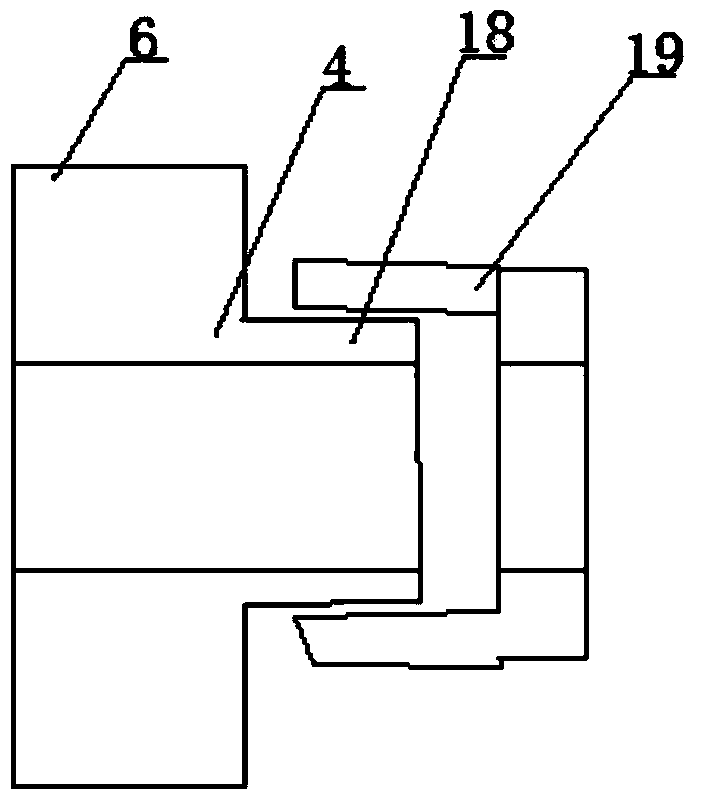

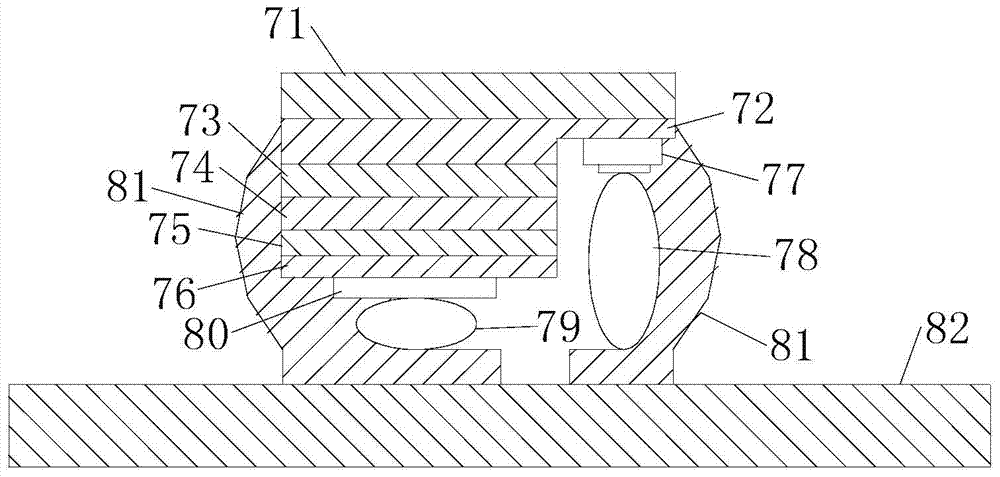

Automatic withstand voltage detecting and automatic sorting device of safety equipment

ActiveCN103901326APlay an insulating roleAvoid parallelTesting dielectric strengthSortingPower gridAlarm device

The invention discloses an automatic withstand voltage detecting and automatic sorting device of safety equipment. The automatic withstand voltage detecting and automatic sorting device of the safety equipment comprises a box, current guide parts are arranged in the box, an equipment outlet is formed in the lower portion of the box, a rotating shaft is arranged at the position of the equipment outlet, the rotating shaft is connected with a gear motor arranged on the outer side of the box, one end of the rotating shaft is provided with a grounding poking roller in a sleeved mode, the other end of the rotating shaft is provided with a high-voltage poking roller in a sleeved mode, both the grounding poking roller and the high-voltage poking roller are provided with poking plates, both the grounding poking roller and the high-voltage poking roller are provided with elastic conductive components, the box, the current guide parts, the rotating shaft and the poking plates are all made of insulation materials, the equipment outlet is provided with a carrying component, an electric telescopic rod is arranged under the carrying component, and the grounding poking roller is connected with a current detection alarm device through a wire. Compared with the prior art, the automatic withstand voltage detecting and automatic sorting device can accurately measure leaked currents on the surface of the safety equipment, solve the problem that whether the safety equipment is qualified or not is difficult to judge accurately, and guarantee the personal safety of operating personnel and safe and reliable operation of power grids.

Owner:LUOHE POWER SUPPLY OF HENAN ELECTRIC POWER CORP

Insulating and heat-conductive silicone grease composition with high heat conductivity and preparation method thereof

InactiveCN107815119AImprove thermal conductivityHigh viscosityHeat-exchange elementsFiberCarbon fibers

The invention discloses an insulating and heat-conductive silicone grease composition with high heat conductivity and a preparation method thereof. The heat-conductive silicone grease composition is prepared from polyorganosiloxane, heat-conductive filler and a super-dispersion surface modifying agent, wherein the super-dispersion surface modifying agent has anchoring groups and an organized chain; the length of the organized chain segment is not less than 20; the heat-conductive filler is prepared by selecting graphene and carbon-fiber materials in a specific range to carry out multi-dimension and multiscale compounding with common three-dimensional heat-conductive filler, and the super-dispersion surface modifying agent is combined to carry out high-efficiency modification on a surface,and therefore, the obtained silicone grease has excellent characteristics of good insulativity, low viscosity, high heat conductivity and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

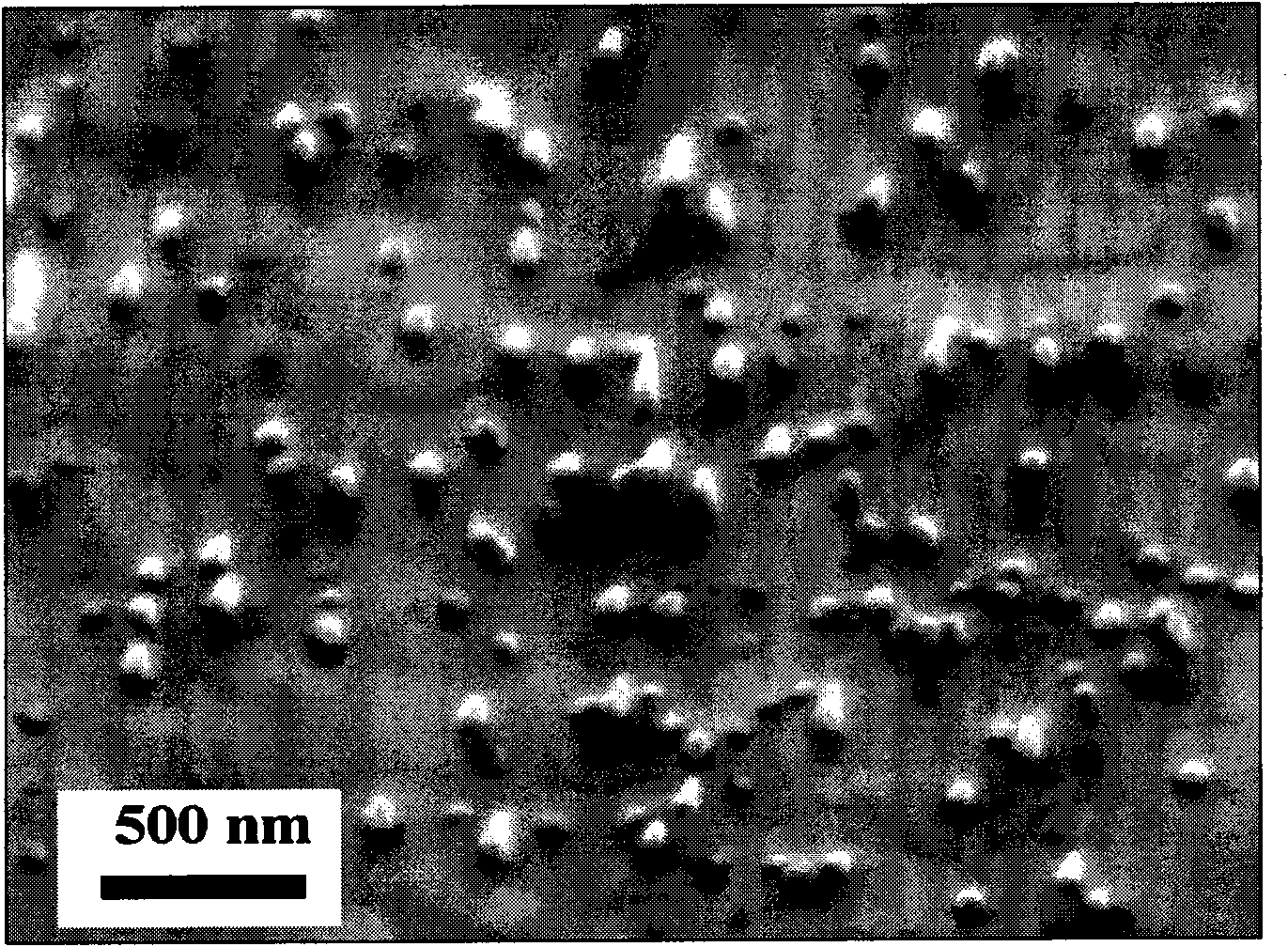

Modified transformer oil, preparation method and application

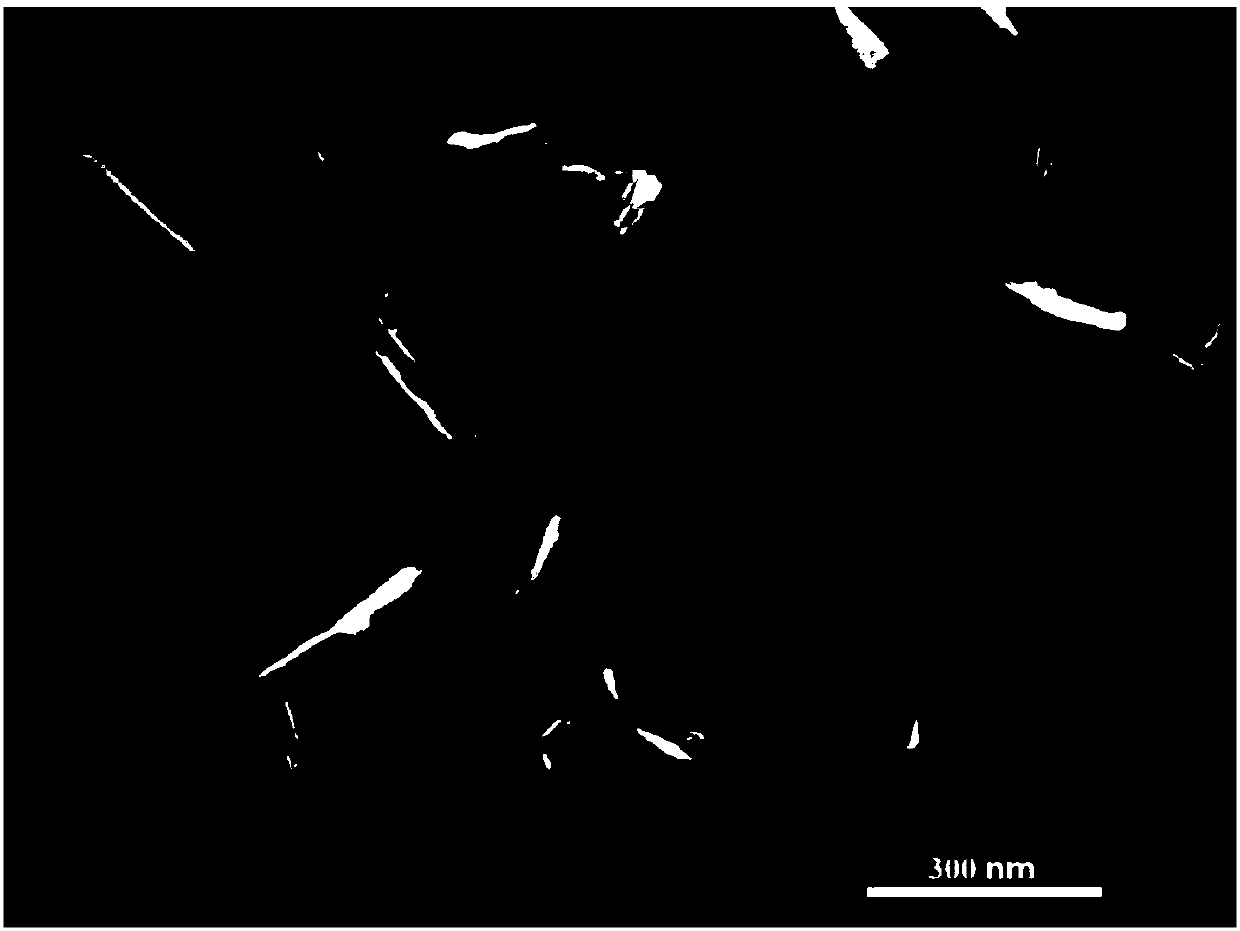

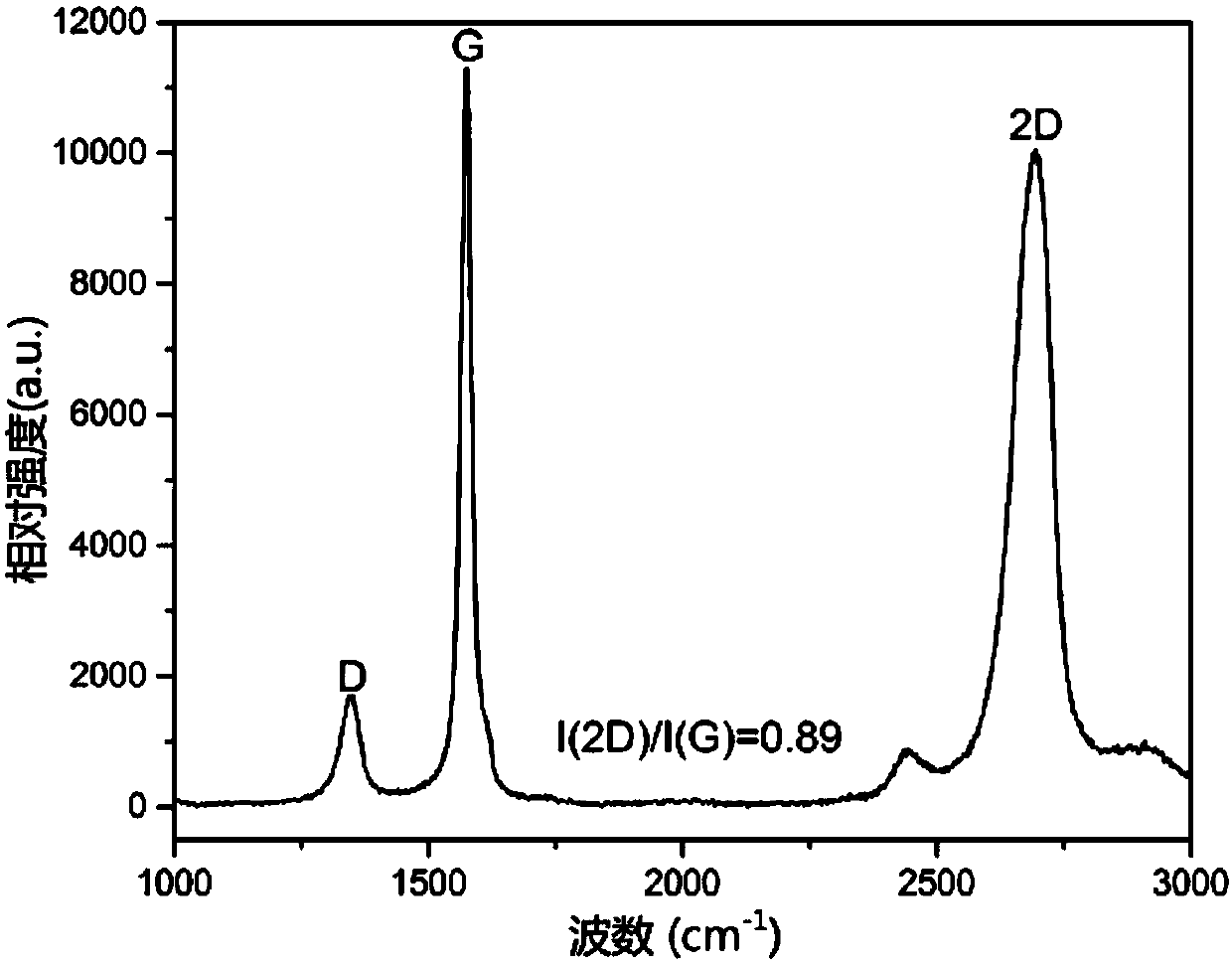

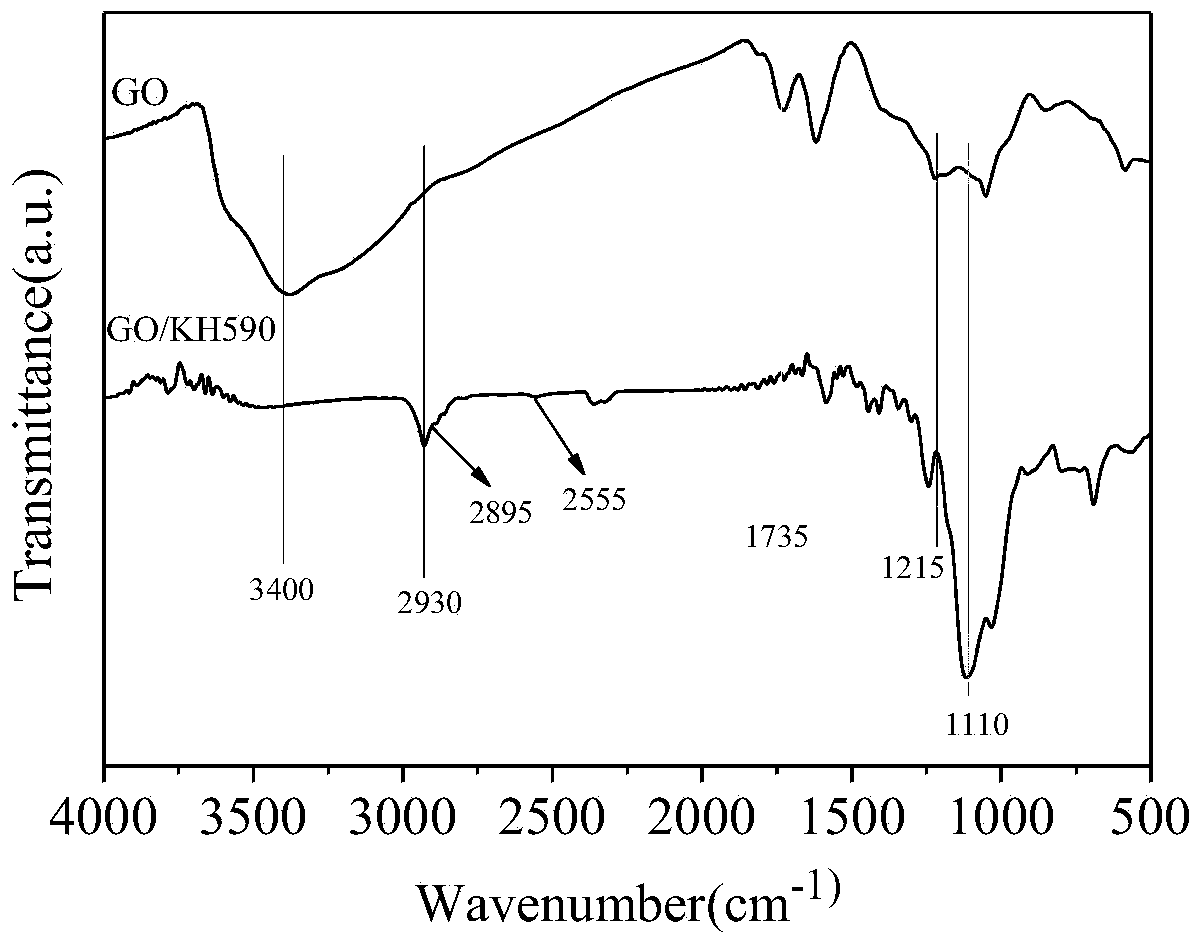

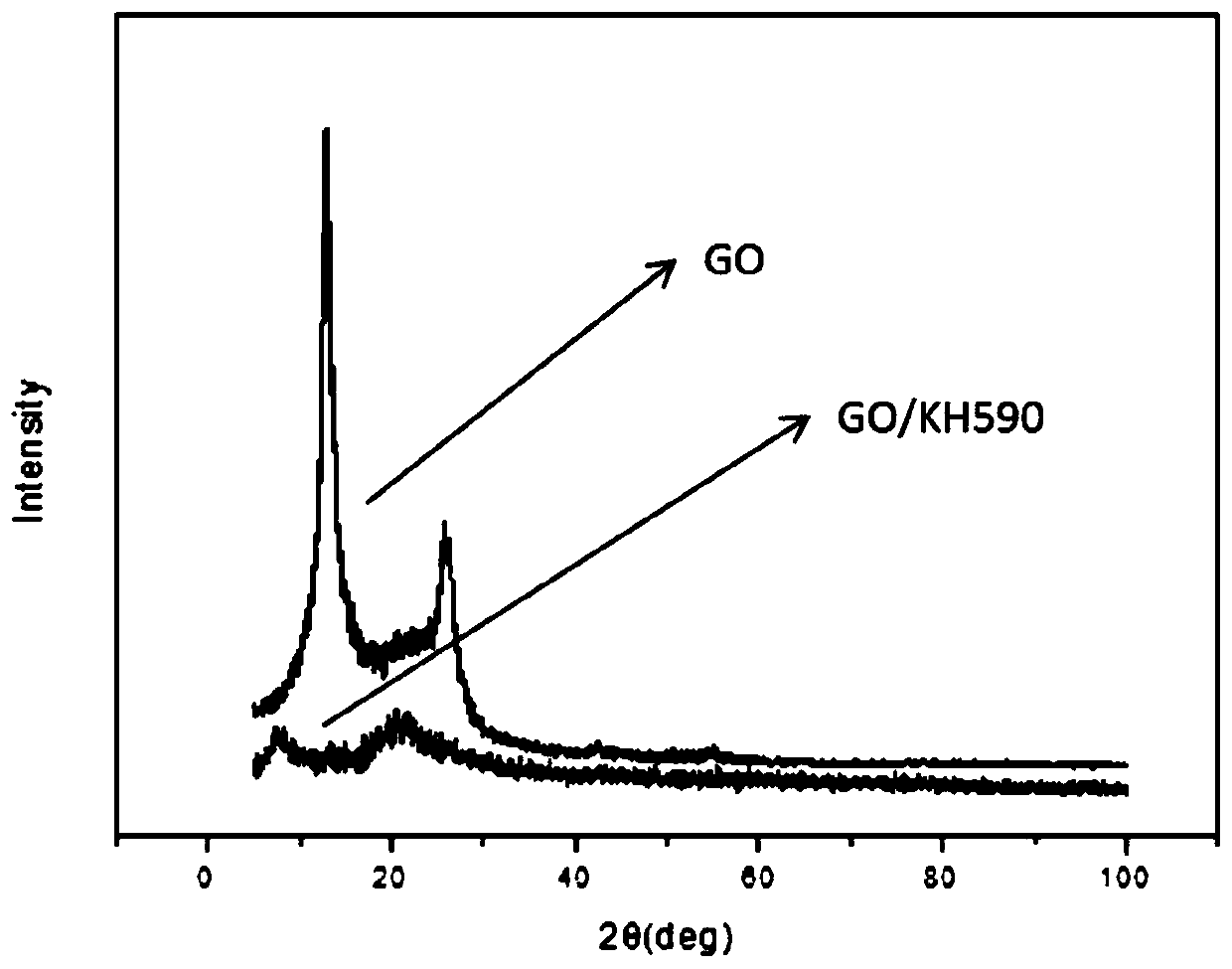

ActiveCN107739646AImprove breakdown resistancePlay an insulating roleLubricant compositionHeat conductingStructure of the Earth

The invention relates to modified transformer oil. The modified transformer oil consists of base oil and heat-conducting two-dimensional nanosheets dispersed in the base oil; the thickness of the heat-conducting two-dimensional nanosheets is less than 30nm, the sheet diameter is less than 500nm, and the ratio of thickness to radial dimension is less than 1. Since the invention adds the two-dimensional nanosheets in the base oil of the transformer oil, the two-dimensional structures are utilized to form electron traps in the transformer oil, the anisotropy of electron transfer can enhance the distortion of a local electric field in the transformer oil, thus impeding the development of streams and playing an insulating role, and thereby the anti-breakdown property of the transformer oil is effectively increased; the two-dimensional nanosheets added by the invention can form a nanofluid system along with the transformer oil, the heat conductivity coefficient is high, and the heat dispersion of the transformer oil is increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

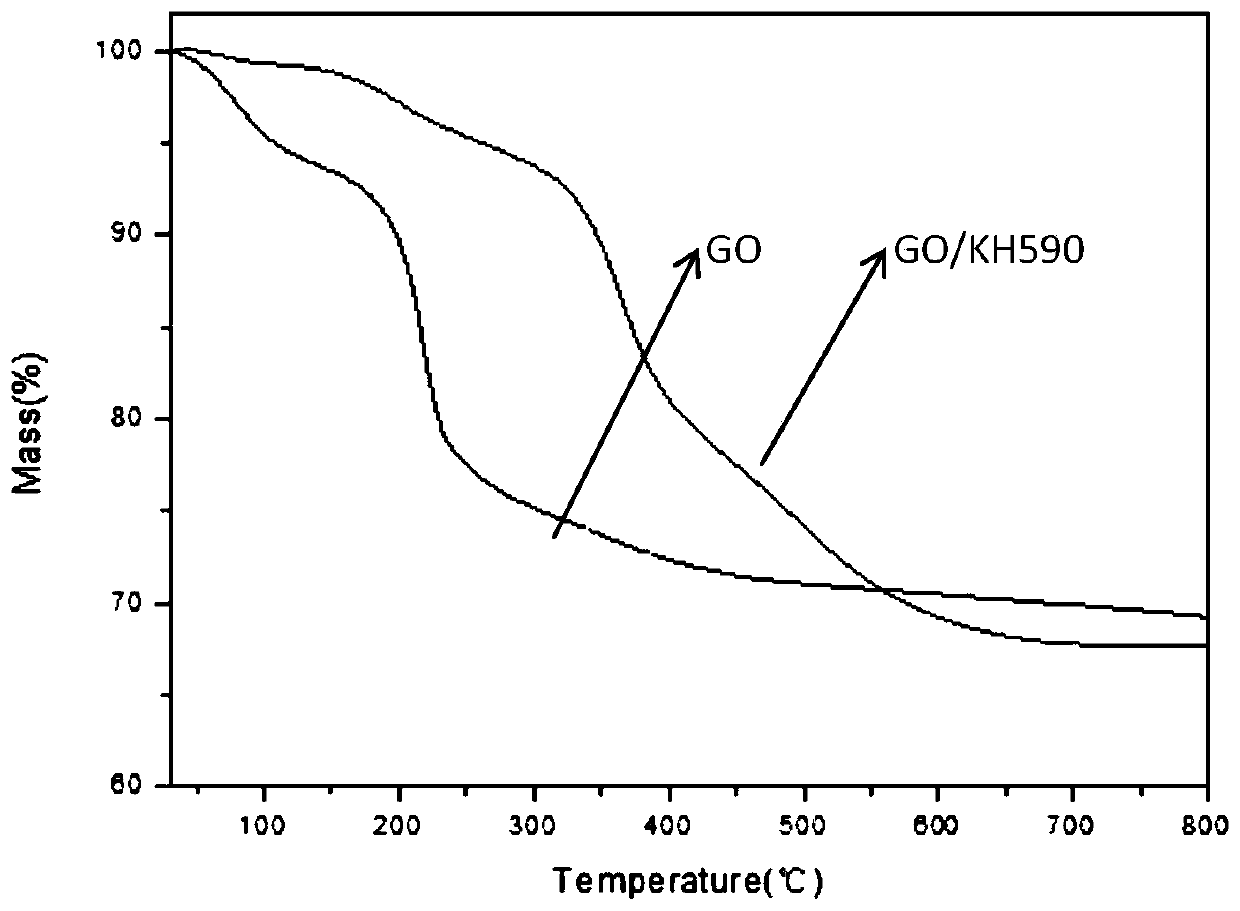

Graphene modified nitrile rubber and preparation method thereof

ActiveCN110343299ASolve the problem of poor high and low temperature resistanceImprove mechanical propertiesNitrile rubberPolymer science

The invention belongs to the technical field of graphene rubber composite materials, and provides a graphene modified nitrile rubber and a preparation method thereof. The graphene modified nitrile rubber is prepared from the following components in parts by weight: 70-90 parts of a nitrile rubber, 10-30 parts of a modified graphene oxide-carboxyl nitrile rubber master batch, 1.5-2 parts of a vulcanizing agent, 0.5-2.0 parts of a vulcanizing accelerator, 3-5 parts of a vulcanizing activator, 1-3 parts of a plasticizer, 1-2 parts of an antioxidant and 20-30 parts of fillers; and the modified graphene oxide-carboxyl nitrile rubber master batch is prepared from the modified graphene oxide and further prepared from carboxyl nitrile rubber latex, wherein mercapto-siloxane after hydrolysis reactswith the graphene oxide by being subjected to dehydration synthesis, and the modified graphene oxide is obtained. Through the technical scheme, the problem of poor high and low temperature resistanceof the nitrile rubber in the prior art is solved.

Owner:石家庄贝克密封科技股份有限公司 +1

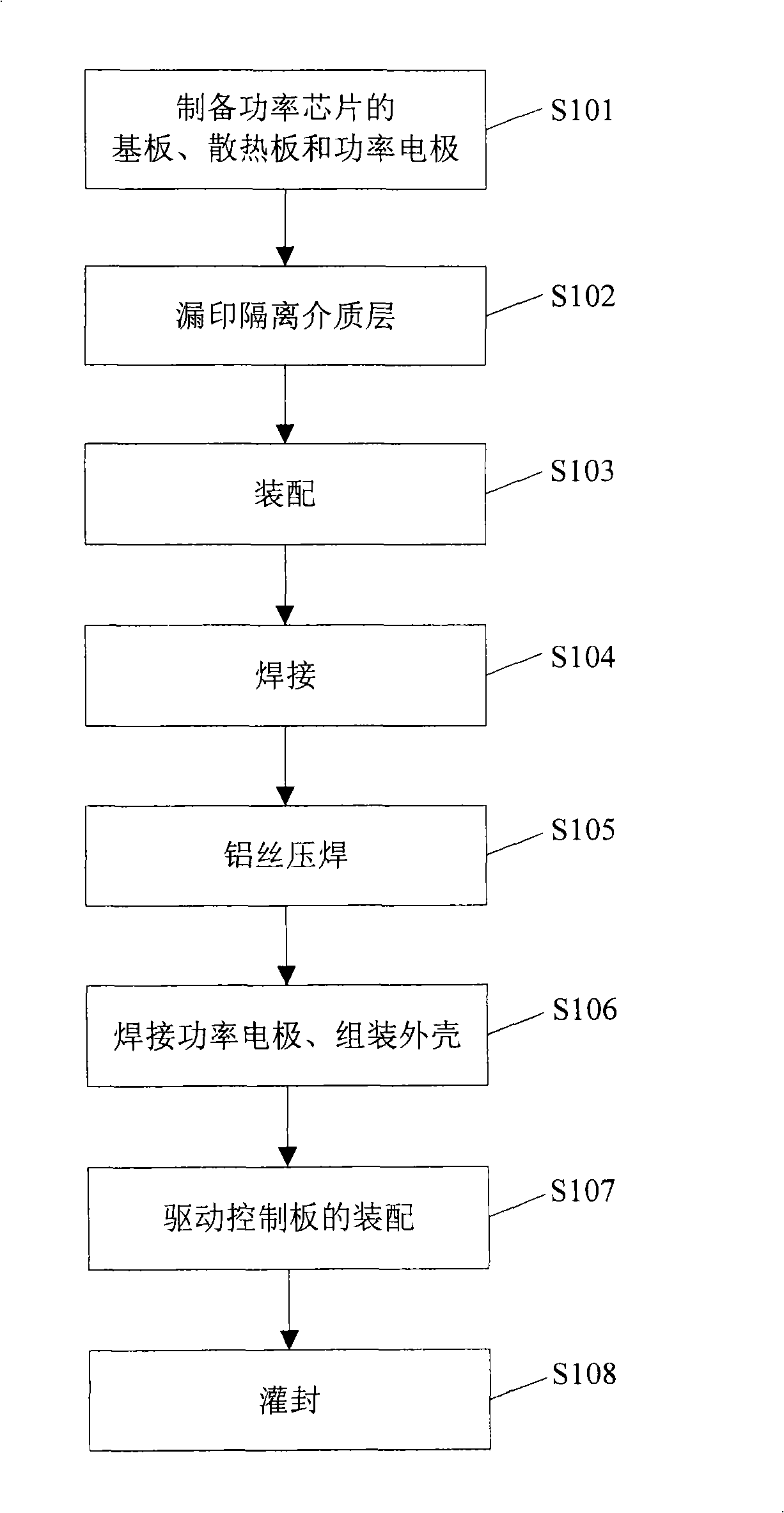

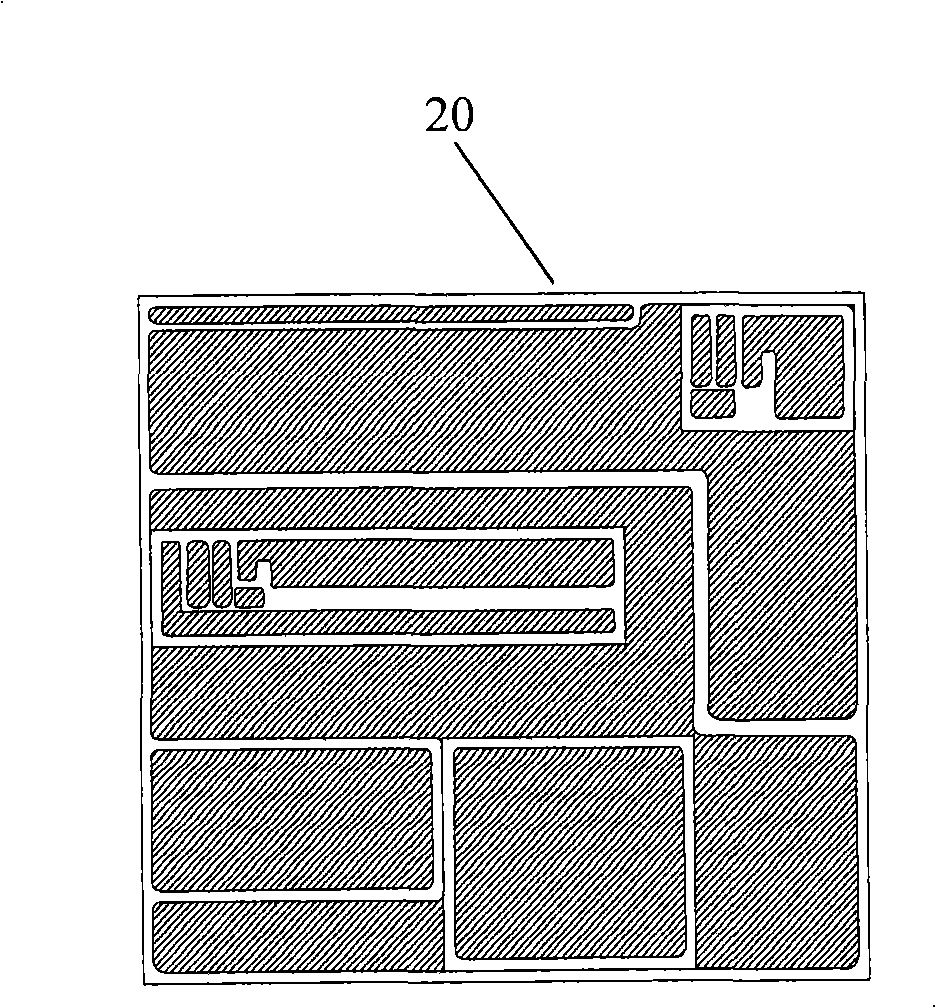

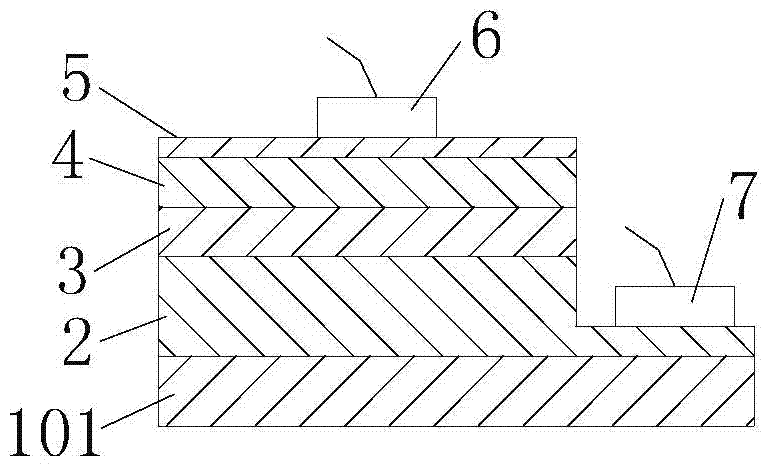

Three-layer stereo power encapsulation method and structure

InactiveCN101494175AImprove bindingEasy to weldSemiconductor/solid-state device detailsSolid-state devicesFirst FillEngineering

The invention discloses a three-layer three-dimensional power encapsulating method and a structure thereof, wherein the method comprises the following steps: step 1. a heating panel, a power electrode and a base plate are prepared and an insulating layer is respectively printed on the base plate and the heating panel to form a hollow picture and ensure the positions of a power chip and the power electrode on the base plate and the position of the base plate on the heating panel fill in the hollow picture; step 2. soldering terminals are arranged on the position of the hollow picture, and the heating panel, the soldering terminal, the base plate, the soldering terminal and the power chip are arranged in a down-top sequence and then welded; step 3. the power chip and the base plate are carried out press welding, an enclosure is arranged on the heating panel, the power electrode is welded on the base plate and a driving control panel is arranged on the power plate; and step 4. a first filled composite is filled between the base plate and the driving control panel and a second filled composite is filled between the driving control panel and the power electrode after the molding of the first filled composite. The method realizes that the power base plate, the driving control panel and the power electrode are integrated in one encapsulation.

Owner:BEIJING RES INST OF AUTOMATION FOR MACHINERY IND

Preparation method for high-wear-resistance pilling resisting 4D air layer Q elastic fabric

InactiveCN108950834APlay an insulating roleGood warmth retentionSucessive textile treatmentsWeft knittingYarnEngineering

The invention discloses a preparation method for a high-wear-resistance pilling resisting 4D air layer Q elastic fabric, and relates to a preparation method of a knitted fabric. The fabric comprises surface layer yarns, middle yarns and bottom layer yarns. The method comprises the steps that step A, the fabric is woven; step B, a fabric blank is pre-set; step C, the fabric blank is rinsed, and a rinsing solution comprises hydrogen peroxide with the concentration of 0.5 g / l-1g / l; step D, the fabric blank is dyed; step E, the fabric blank is dried; step F, re-setting is conducted on the fabric blank. Compared with the prior art, the fabric woven by means of the method has the advantages of better warm keeping effect, high wear resisting, pilling resisting, better wearability and certain stretching ductility.

Owner:NINGBO DAQIAN TEXTILE

Warp knitting machine with improved structure

The invention provides a warp knitting machine with an improved structure, belongs to the technical field of machinery, and solves the technical problems that a warp knitting machine in the prior art cannot automatically cut warp knitting fabric and the like. The warp knitting machine with the improved structure comprises a rack, wherein a bobbin used for winding yarn as well as a first conveying shaft and a second conveying shaft which are used for conveying the warp knitting fabric is fixed on the rack; and the first conveying shaft and the second conveying shaft are parallel, are close and are not contacted, a pressing shaft is arranged above a gap between the first conveying shaft and the second conveying shaft and is connected with a lifting positioning mechanism I which can drive the pressing shaft to go up and down and can position the pressing shaft, the outer diameter of the pressing shaft is larger than the gap between the first conveying shaft and the second conveying shaft, and a cutting device which can cut the warp knitting fabric into two parts is arranged between the bobbin and the first conveying shaft. The warp knitting machine has the advantages of capability of automatically cutting the warp knitting fabric, high cutting efficiency and wide application range.

Owner:海宁市成达经编股份有限公司

Motor iron core manufacturing method

ActiveCN104734431AImprove electrical accuracyImprove product qualification rateManufacturing stator/rotor bodiesElectrophoresisCoolant

The invention provides a motor iron core manufacturing method. The manufacturing method is characterized by comprising the following steps that 1, iron core punching sheets are machined and formed according to outline dimensions; 2, the iron core punching sheets are subjected to magnetic performance treatment; 3, electro-coating is conducted; 4, semi-curing treatment is conducted; 5, stack mounting is conducted; 6, complete curing treatment is conducted. According to the manufacturing method, the iron core punching sheets are subjected to electro-coating; electrophoresis paint is subjected to semi-curing treatment based on the character that the electrophoresis paint can be semi-cured; after the punching sheets are stacked, the electrophoresis paint is completely cured, and punching sheets are bonded firmly after curing is finished. By means of the manufacturing method, the problem existing when motor iron cores are stacked in coolant media is solved, the possible influence of adhesive application and machining stress on the motor performance is avoided, the electric accuracy of a rotary transformer is improved, and the qualified rate of products is increased by 50% or more.

Owner:GUIZHOU AEROSPACE LINQUAN MOTOR CO LTD

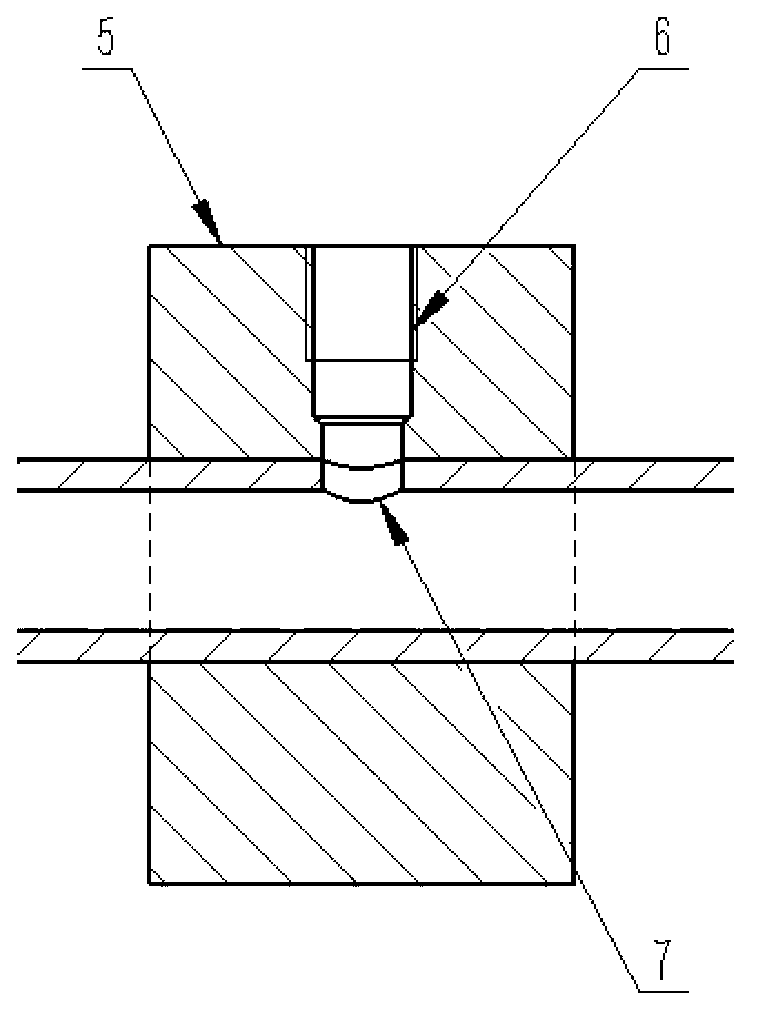

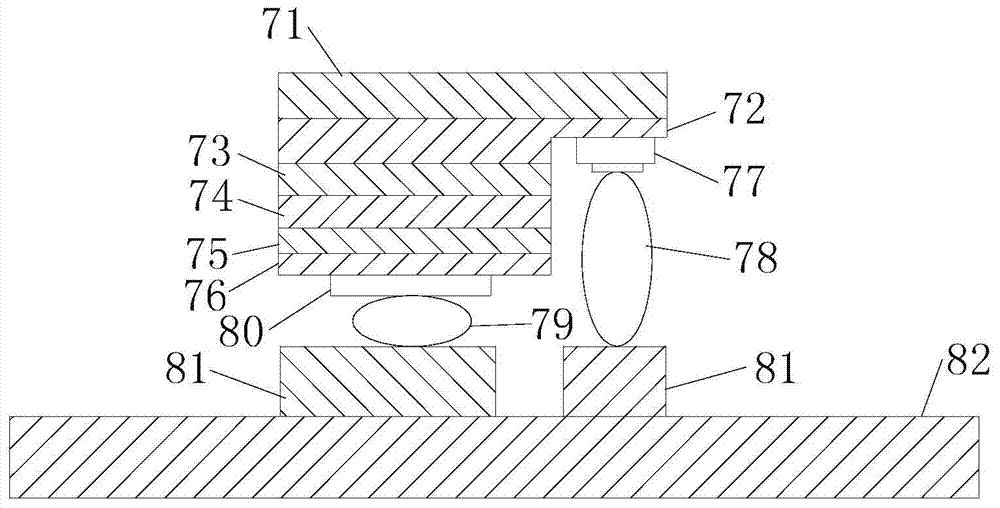

Device for measuring knocking combustion pressure in millimeter-level circular tube

InactiveCN103292954AAvoid interferencePlay an insulating roleRapid change measurementFlame propagationEngineering

The invention provides a device for measuring knocking combustion pressure in a millimeter-level circular tube. The device comprises a knocking tube, a clamping plate, a sensor mounting seat and a sensor. The clamping plate fixes and supports the front side of the knocking plate. The sensor mounting seat is arranged at the position where a flame forms knockings. A through hole is formed in a tube wall, and the through hole in the tube wall and a sensor mounting hole in the sensor mounting seat are coaxial. When the outer diameter of the knocking tube is larger than the diameter of the measuring end of the sensor, the hole diameter of the through hole in the tube wall is equal to the diameter of the measuring end of the sensor, and the measuring end face of the sensor is flush with the inner wall of the knocking tube. When the outer diameter of the knocking tube is not larger than the diameter of the measuring end of the sensor, the hole diameter of the through hole in the tube wall is smaller than the diameter of the measuring end of the sensor, and the measuring end face of the sensor is tangent to the circular face of the inner wall of the transparent knocking tube. The knocking tube, the clamping plate and the sensor mounting seat in the device are all made of organic glass, pressure can be measured, and a flame propagation mode can be observed and flame speed can be measured simultaneously. Meanwhile, the function of insulation can be achieved, and the interference of electric sparks is avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

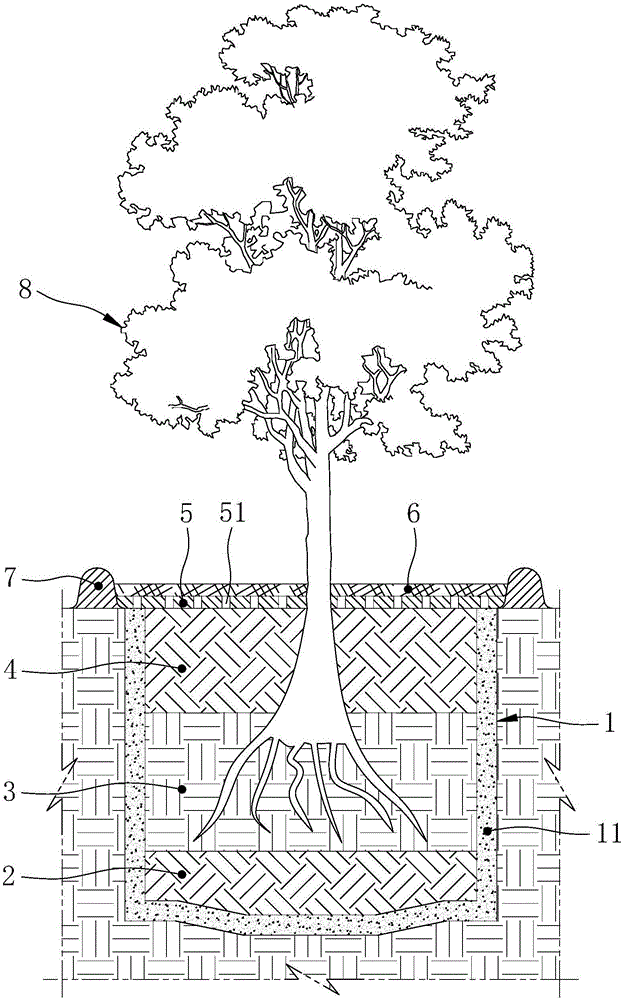

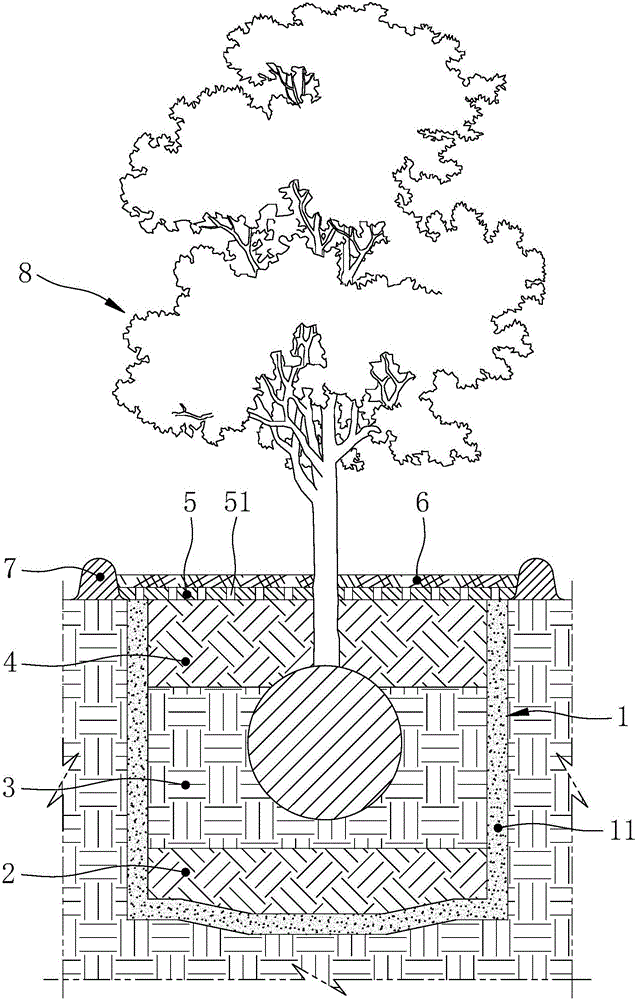

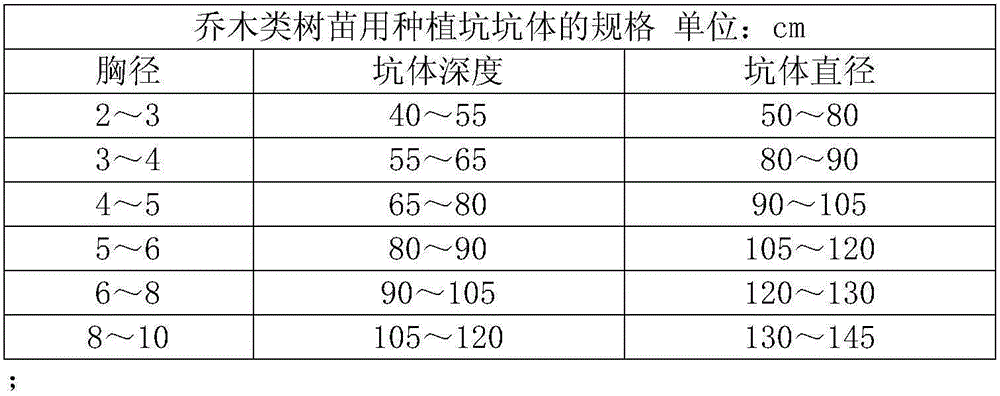

Plateau area tree planting pit and tree planting method

ActiveCN105028011APrevent floodingReduce leakageCultivating equipmentsReceptacle cultivationSlurryPlateau

The invention discloses a plateau area tree planting pit and a tree planting method. The plateau area tree planting pit comprises a pit body and planting soil positioned inside the pit body, wherein the inner surface of the pit body is provided with a layer of slurry protection wall. The tree planting method is a planting method based on the planting pit. Through the slurry protection wall arranged on the inner surface of the pit body, on one hand, an effective insulating effect can be achieved at the earlier stage of tree growth, and rain water in the pit body, leakage of irrigation water and loss of fertility in the planting soil are reduced greatly; on the other hand, the slurry protection wall also plays a certain role in water seepage when water in the pit body is excessive, and trees are prevented from being flooded; moreover, root systems can penetrate through the slurry protection wall to grow continually along with the growth of the trees, the growth of trees is well promoted, and environmental pollution is prevented.

Owner:西藏电建成勘院工程有限公司

Motor iron core automatic adhesive lamination high-speed stamping progressive die

InactiveCN109756080AImprove performanceHigh coincidenceShaping toolsOther manufacturing equipments/toolsPunching

The invention provides a motor iron core automatic adhesive lamination high-speed stamping progressive die. The high-speed stamping progressive die comprises an upper die, a lower die, a material guide plate, an upper die base, an upper base plate, a convex die base plate, a blanking convex die, a blanking concave die, a concave die plate, a concave die base plate, a locking ring and a lower die base, wherein the blanking concave die is arranged in the concave die plate; the locking ring is located below the blanking concave die; the locking ring is axially provided with a locking hole, and the blanking concave die is opposite to the locking hole; the inner diameter of the locking ring is smaller than that of the blanking concave die; the locking ring is placed in the lower die base in a shelved mode; a product outlet is formed below the lower die base, and the lower end of the locking hole is communicated with the product outlet; and the high-speed stamping progressive die further comprises a bonding assembly. The locking ring is arranged below the blanking concave die, so that high perpendicularity and flatness of the iron core and high overlapping degree of adjacent punching pieces are ensured; the locking ring is used for collecting the punching pieces, so that the later labor cost can be greatly lowered; and the bonding assembly is arranged on the upper die, so that synchronous proceeding of punching and bonding is realized, and the working efficiency is greatly improved. The invention belongs to the technical field of die equipment.

Owner:余姚市奥科五金科技有限公司

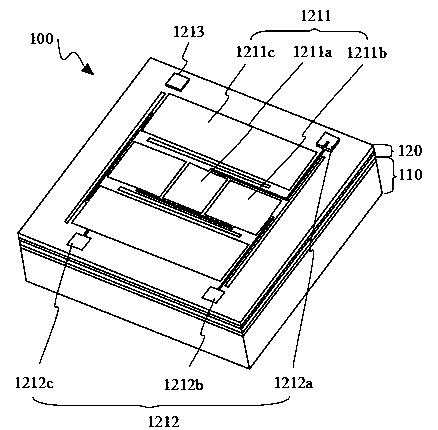

MEMS micro loudspeaker, preparation method thereof and electronic equipment

ActiveCN111147998ASmall sizeImprove high frequency performanceMicrophonesLoudspeakersEngineeringSound wave

The invention relates to an MEMS micro loudspeaker, a preparation method thereof and electronic equipment. The MEMS micro loudspeaker comprises a supporting structure and a piezoelectric vibrating diaphragm arranged on the supporting structure; a back cavity is formed in the supporting structure so as to expose part of the piezoelectric vibrating diaphragm; the piezoelectric vibrating diaphragm comprises a low-frequency region opposite to the back cavity, the low-frequency region comprises a high-frequency region and a low-frequency sub-region, and the rigidity of the low-frequency sub-regionis smaller than that of the high-frequency region. According to the MEMS micro loudspeaker, the preparation method of the MEMS micro loudspeaker and the electronic equipment, high-frequency-band soundwaves and low-frequency-band sound waves can be simultaneously emitted in the same sound production monomer, so that the bandwidth range is broadened; meanwhile, compared with a traditional mode of integrating a plurality of sound production single bodies, the effective area of the piezoelectric vibrating diaphragm can be increased, and the overall size of the MEMS micro loudspeaker is reduced.

Owner:SHANDONG GETTOP ACOUSTIC

Graphene heat dissipation anticorrosive coating and preparation method and application thereof

InactiveCN110205021AImprove processing dispersionNice appearanceTransformers/inductances coolingTransformers/inductances corrosion protectionGraphene coatingTransformer

The invention relates to the technical field of coatings, in particular to a graphene heat dissipation anticorrosive coating and a preparation method and application thereof. The graphene heat dissipation anticorrosive coating is prepared from, by mass, 40-55 parts of resin, 8-11 parts of a curing agent, 25-28 parts of a diluent, 1-20 parts of zinc powder, 2-5 parts of graphene, 2-5 parts of boronnitride and 4-10 parts of aluminum oxide. By utilizing the heat dissipation function of the graphene coating, the temperature of a transformer radiator is effectively lowered, and the heat dissipation and cooling effects are obvious. Physical shielding and conductivity of graphene are utilized to improve the corrosion resistance of the coating.

Owner:常州烯源纳米科技有限公司 +2

LED flip chip

InactiveCN103762283AIncrease the welding areaReduced precision requirementsSolid-state devicesSemiconductor devicesReflective layerLight-emitting diode

The invention provides an LED flip chip. The LED flip chip comprises a sapphire substrate. An N type layer, a light emitting layer, a P type layer, a reflecting layer and a first insulating layer are sequentially arranged on the sapphire substrate from bottom to top. An N lead electrode and a P lead electrode are arranged on the first insulating layer, the N lead electrode extends from the P type layer to holes of the N type layer along the depth to be electrically connected with the N type layer, and the P lead electrode is electrically connected with the reflecting layer; the first insulating layer is further provided with an N bonding pad layer and a P bonding pad layer, wherein the N bonding pad layer is electrically connected with the N lead electrode, and the P bonding pad layer is electrically connected with the P lead electrode; second insulating layers are arranged on the N lead electrode and the P lead electrode, through holes are formed in the second insulating layers, the N bonding pad layer and the P bonding pad layer make contact with the N lead electrode and the P lead electrode respectively through the through holes, the first insulating layer or / and the second insulating layers are materials which do not absorb visible spectrums and have certain elasticity, and Young modulus of the materials ranges from 0.1GPa to 5GPa.

Owner:ELEC TECH PHOTOELECTRIC TECH DALIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com