Method for preparing pinpoint of nano-tungsten probe

A probe tip and nano-tungsten technology, which is applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of complicated manufacturing process, low success rate, and small output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Configure a NaOH solution with a concentration of 5mol / L as the corrosion solution, take an appropriate amount and pour it into the corrosion pool and a beaker; select a tungsten wire with a diameter of 0.2mm, cut off a length of 3-4cm as needed, and place it with tweezers In the aforementioned beaker, add an AC voltage of 15V to corrode and remove the oxide layer on the surface of the tungsten wire (WO 3 );

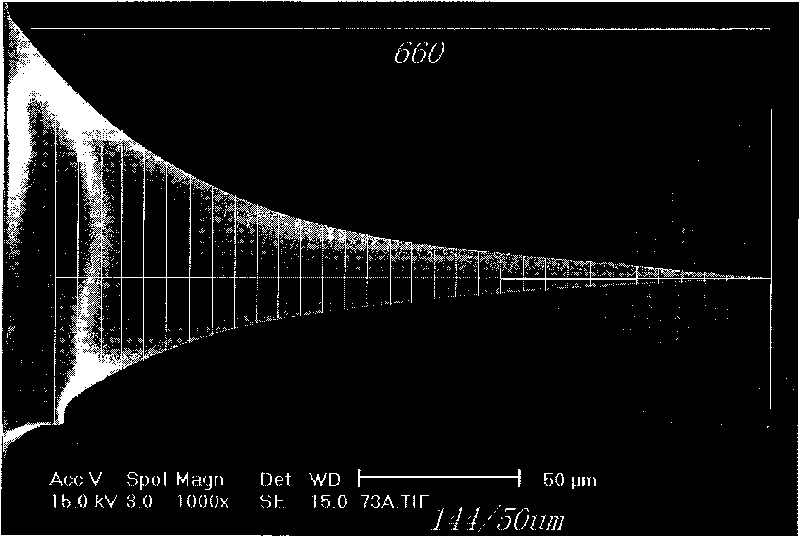

[0019] Insert the tungsten wire into the corrosion pool with a depth of 1mm, and control the corrosion voltage through the corrosion circuit, which is 5V DC. After 12 minutes of etching, the nano-tungsten tip is formed under the dominance of the "neck-in" phenomenon, and the instantaneous corrosion circuit formed at the tip is automatically cut off. The response time is within 600-700ns, and the curvature radius of the tungsten tip is Between 20nm-50nm;

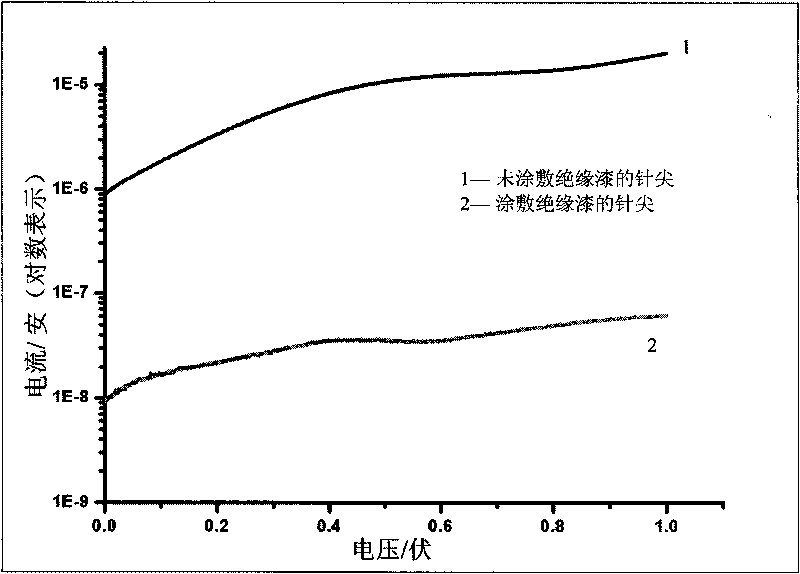

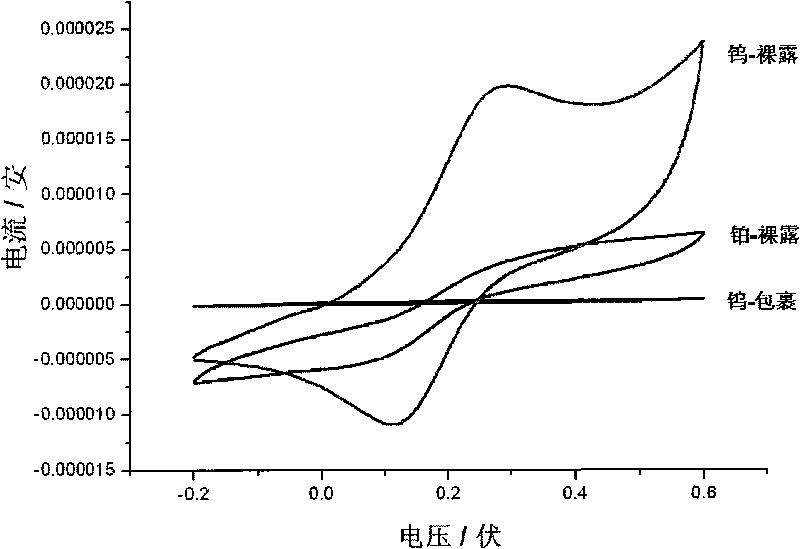

[0020] 2) After carefully removing the tungsten needle tip, rinse it with a large amount of deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com