Patents

Literature

524 results about "Tungsten filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

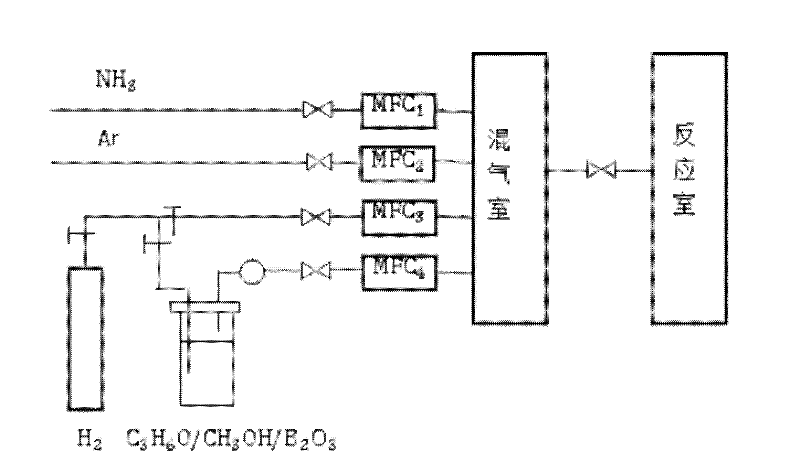

Method for preparing silicon thin film heterojunction solar cell

InactiveCN1588649AAvoid damageReduce hydrogen contentFinal product manufacturePhotovoltaic energy generationHeterojunctionSilicon thin film

A prepn. method of silicon thin film heterojunction solar cell includes following steps: cleaning substrate, semiconductor cleaning technology is used to do primary cleaing to substrate surface, then do ultrasonic cleaning in deionized water several times; nitrogen blow drying; prepare nitrinsic amorphous silicon layer by heater chemical vapour phase depositing technology, tungsten filament temp. is measured by pyrometer, temp of heater and sample are determined separately by two electric thermo-couples, temp. is controlled by electric temp. controller; to react and grow thin film on substrate surface; to redeposit a transmitting layer on intrinsic amorphous silicon thin film; front and back electrodes forming, sputtering technology is used to form front and back electrodes; finally to proceed vacuum heat annealing process. The thin film produced by the invention has illumination stability, the photoconduction gain can reach to 10 to the power 6 on Am1.5 100mW / cm2 standard illumination.

Owner:SHANGHAI JIAO TONG UNIV

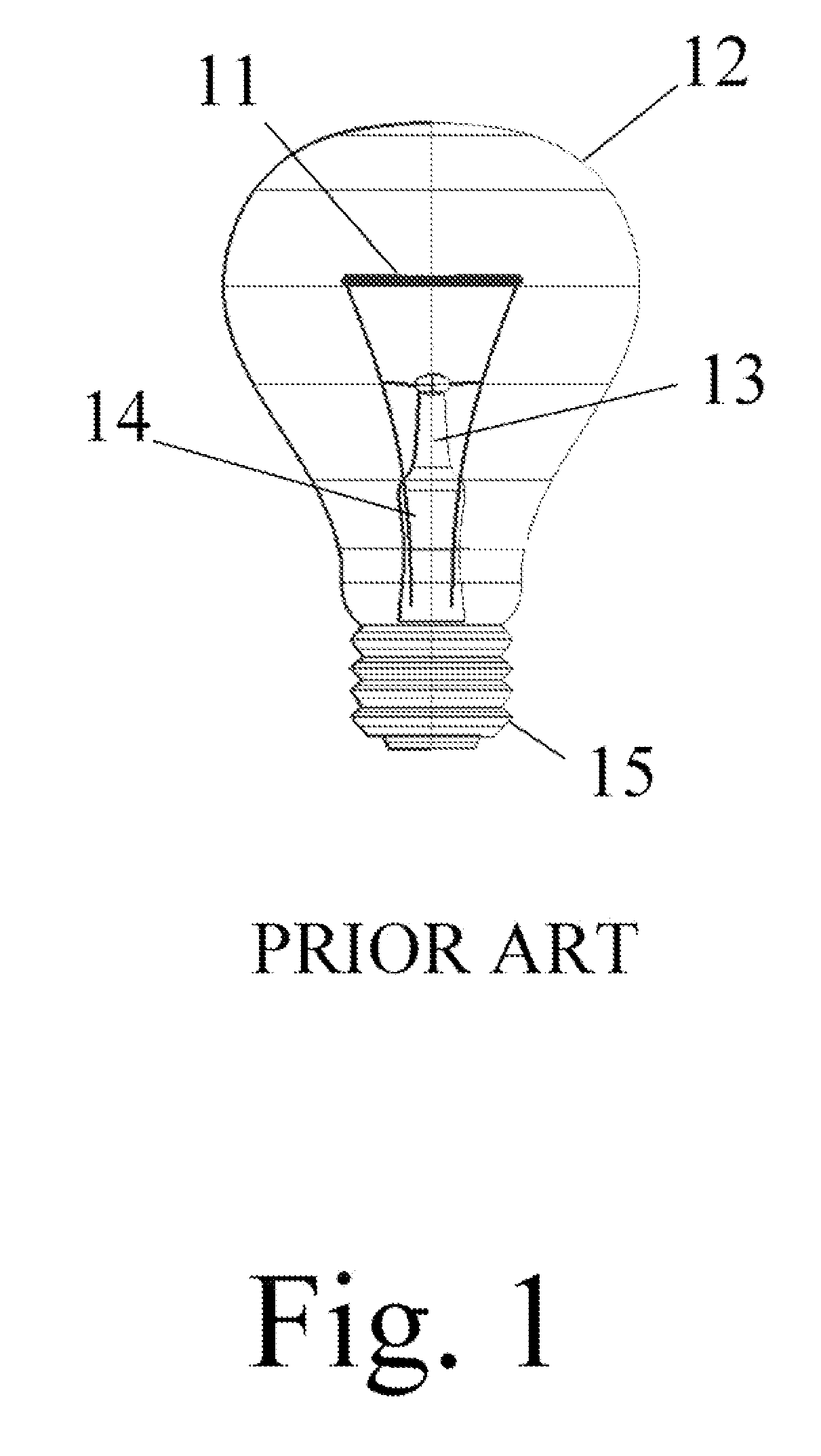

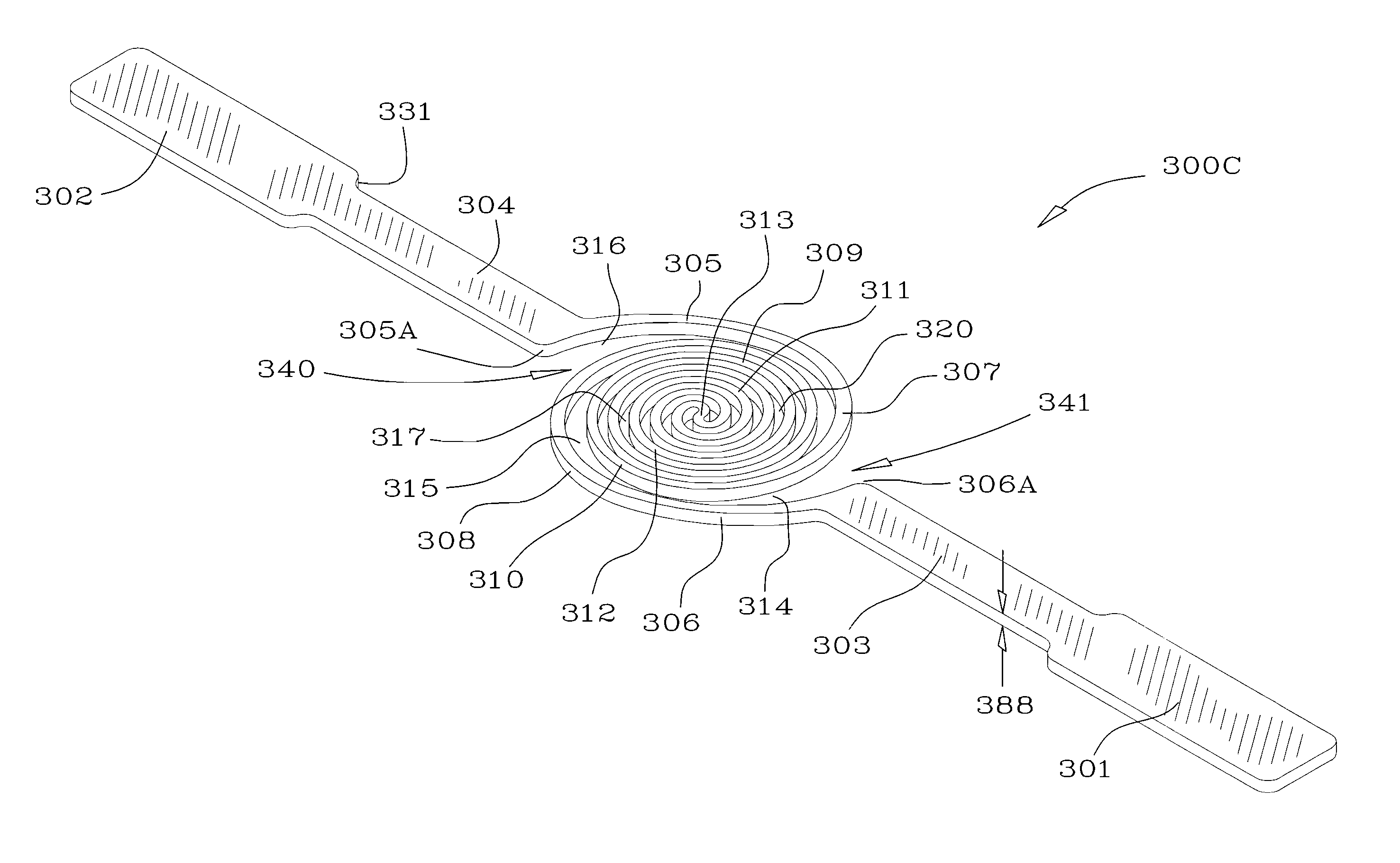

Solid-state luminescent filament lamps

InactiveUS20090212698A1Improve wavelength conversion efficiencyEliminate thermal quenching lossDischarge tube luminescnet screensPoint-like light sourcePhotonicsPhosphate glass

Traditional incandescent and halogen lamps produce a high CRI warm white light with indirect emission patterns at the cost of poor energy efficiency. This new advancement in solid-state lighting enables the production of a new solid-state filament wherein the tungsten filament is replaced with an array of high efficiency LED emitters which combine through an equiangular spiral, or t-spline / TNURCC lightpipe network to produce a single homogeneous blue light source which then pumps a luminescent filament comprised of a phosphor loaded silicone, phosphor loaded polymer, a lanthanide doped fluoro-phosphate glass, glass ceramic tape, quantum dot filled composite, or super-continuum spectrum producing photonic crystalline structure.

Owner:ILLUMINATION MACHINES

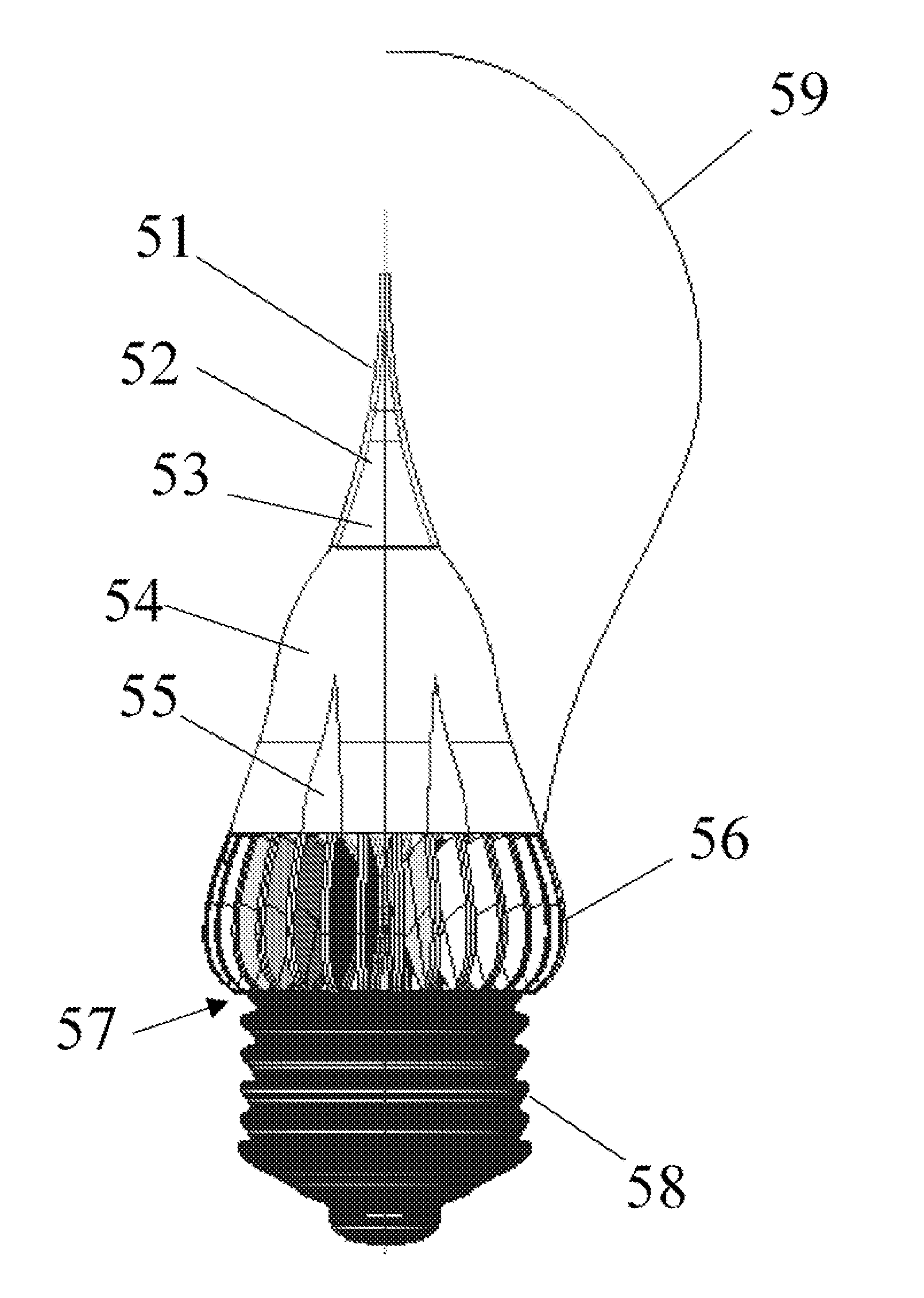

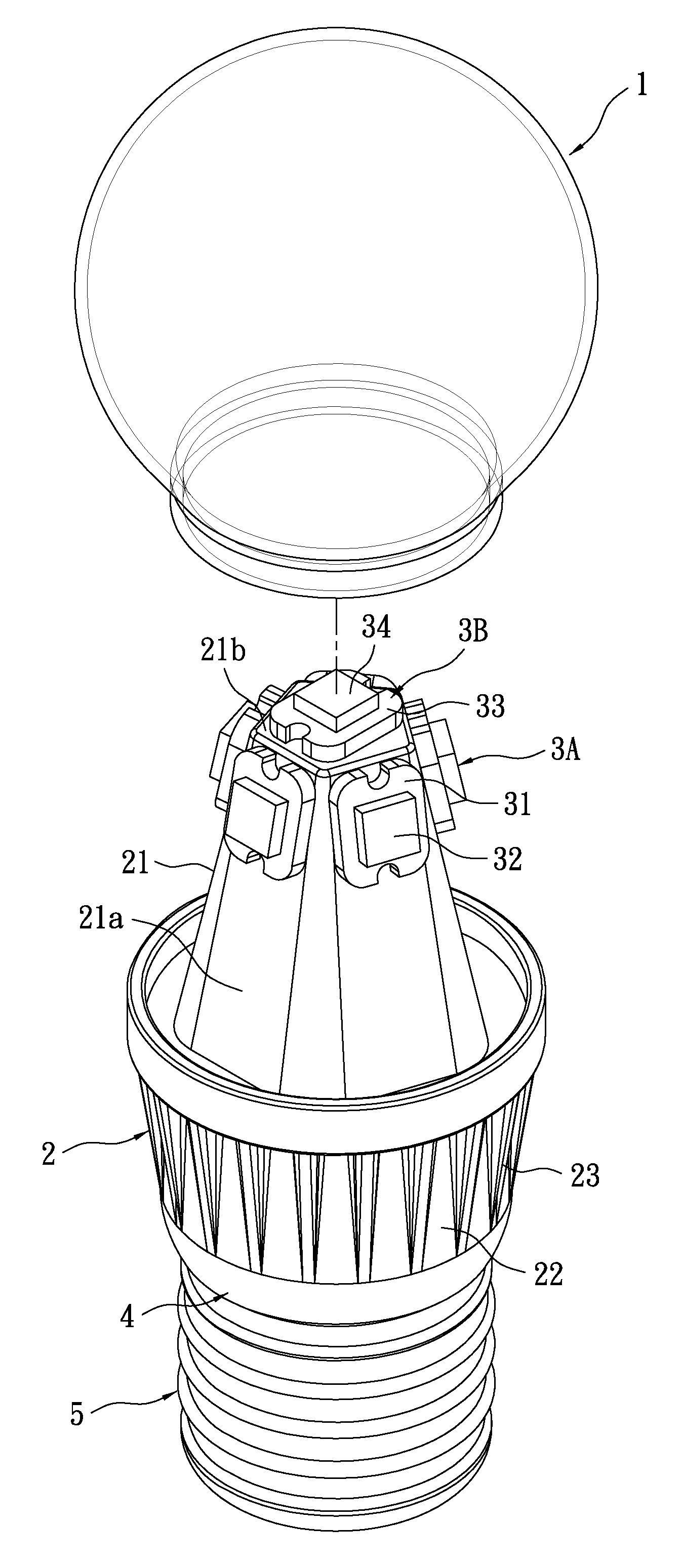

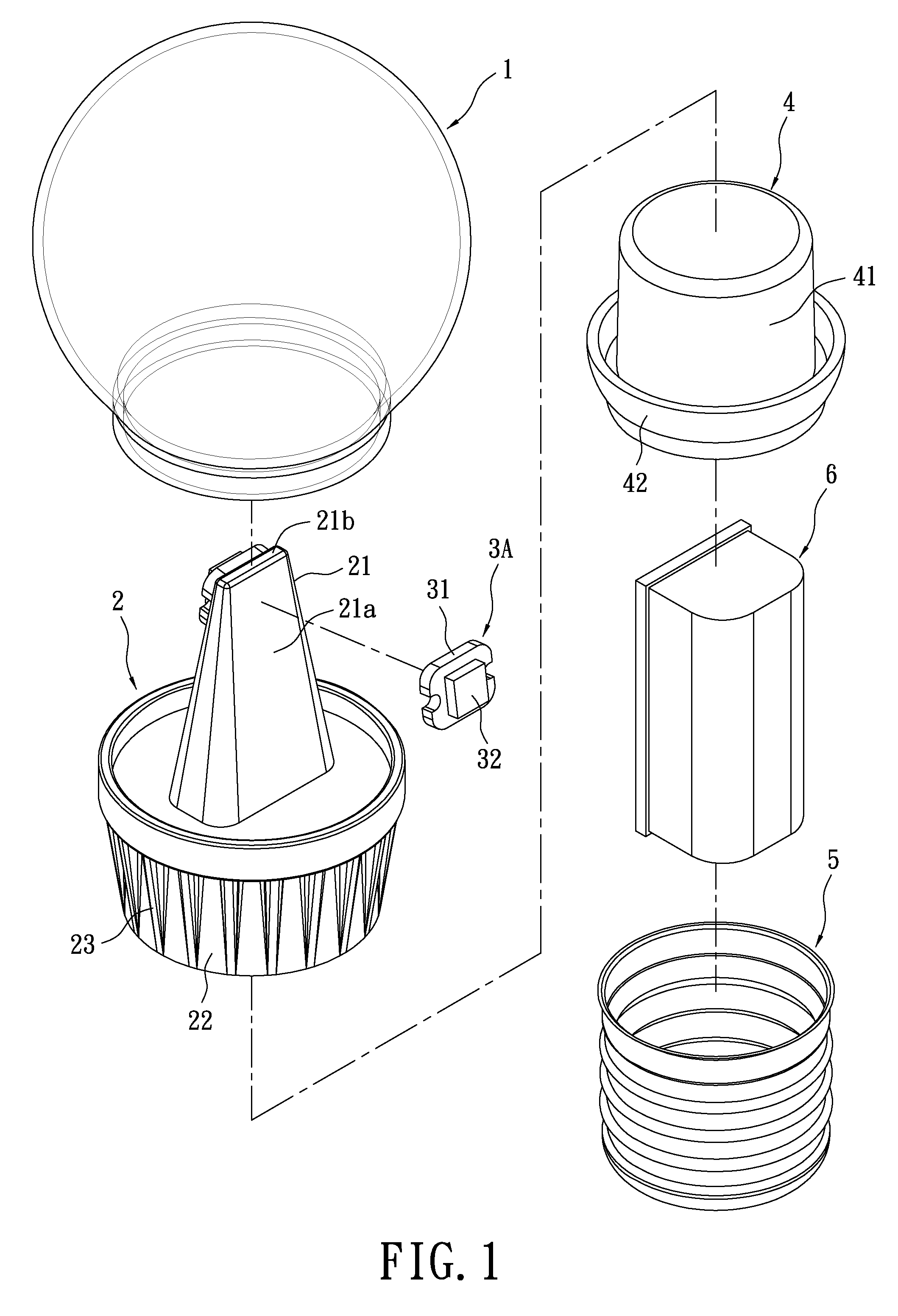

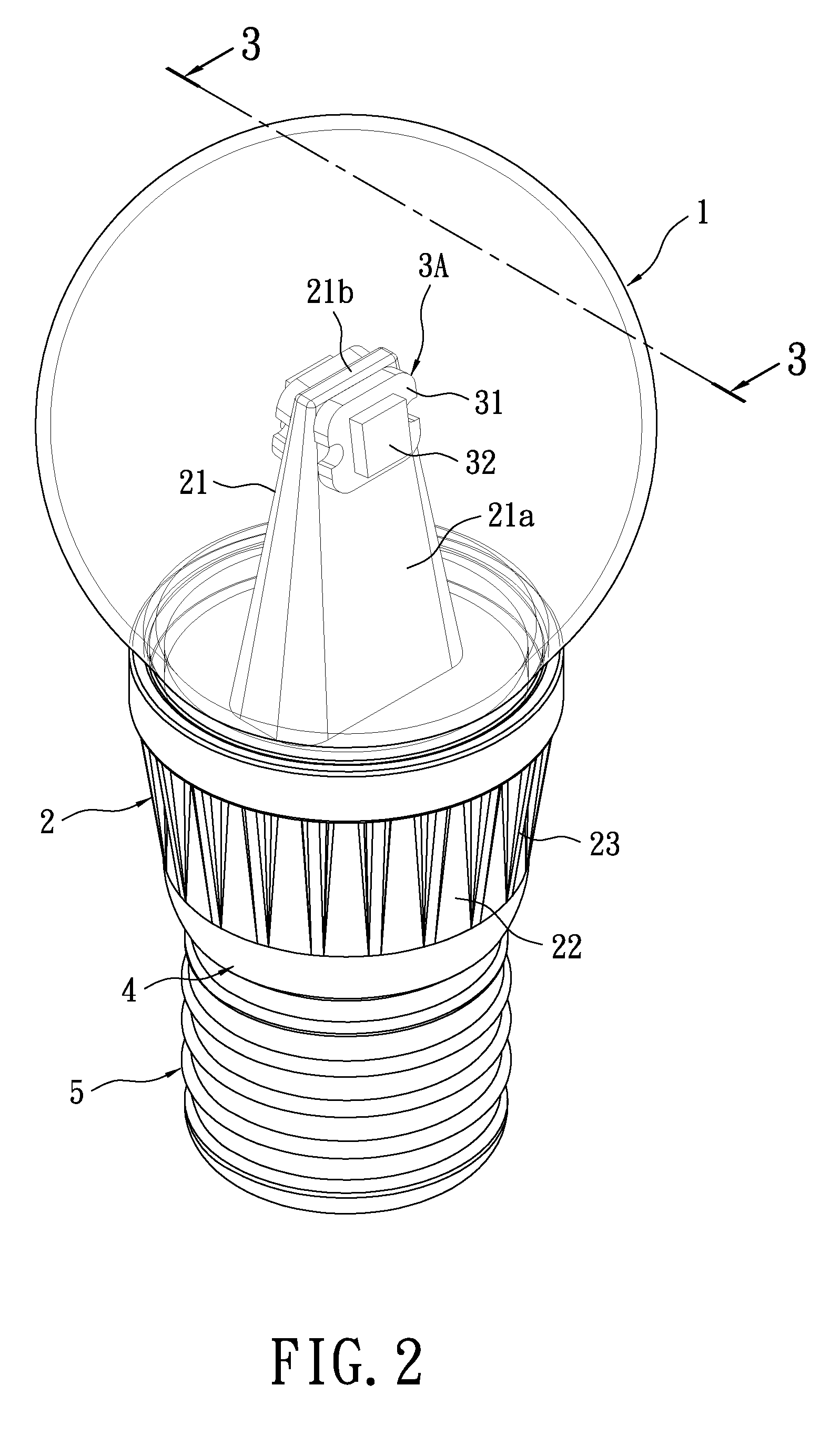

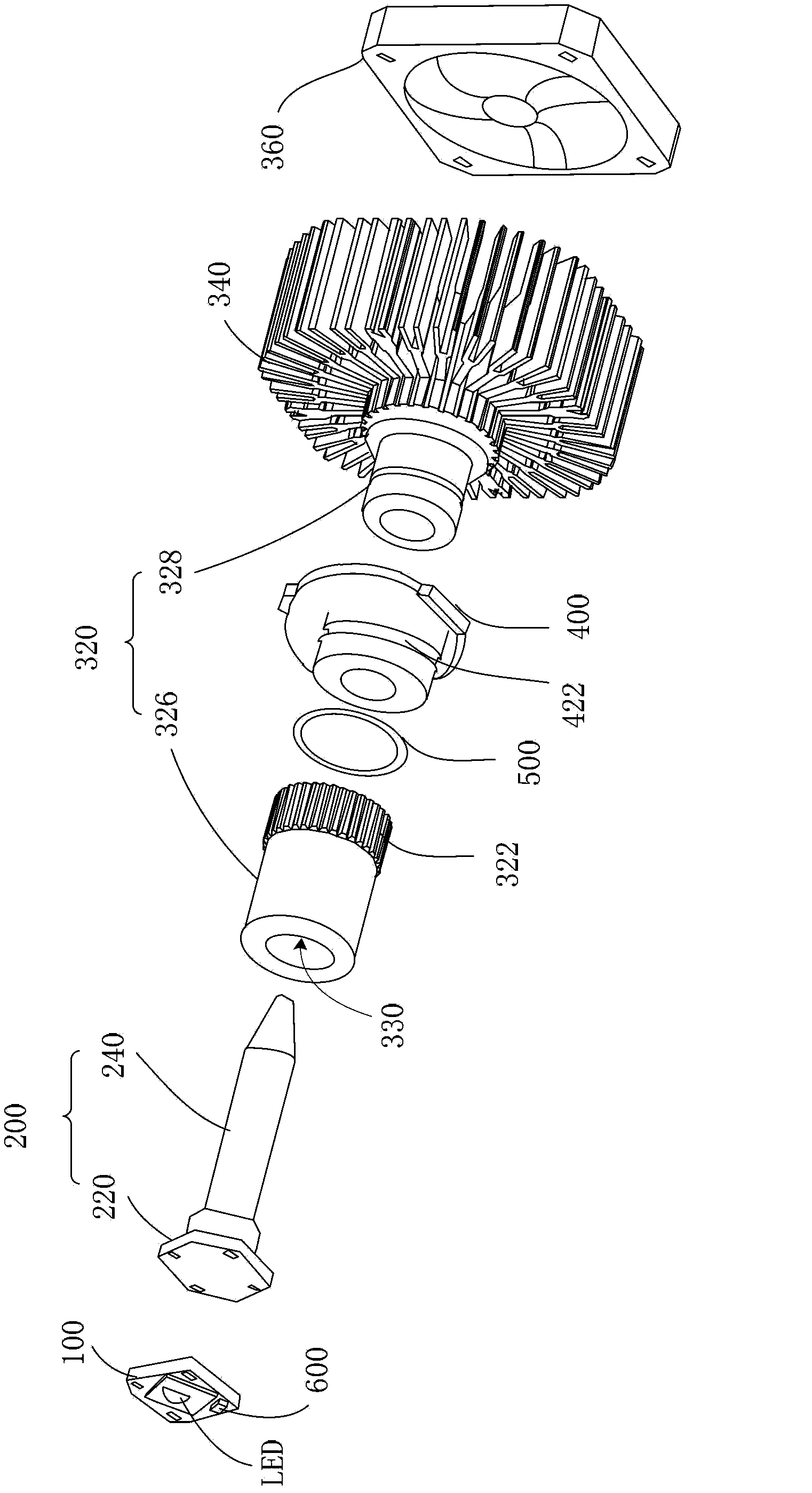

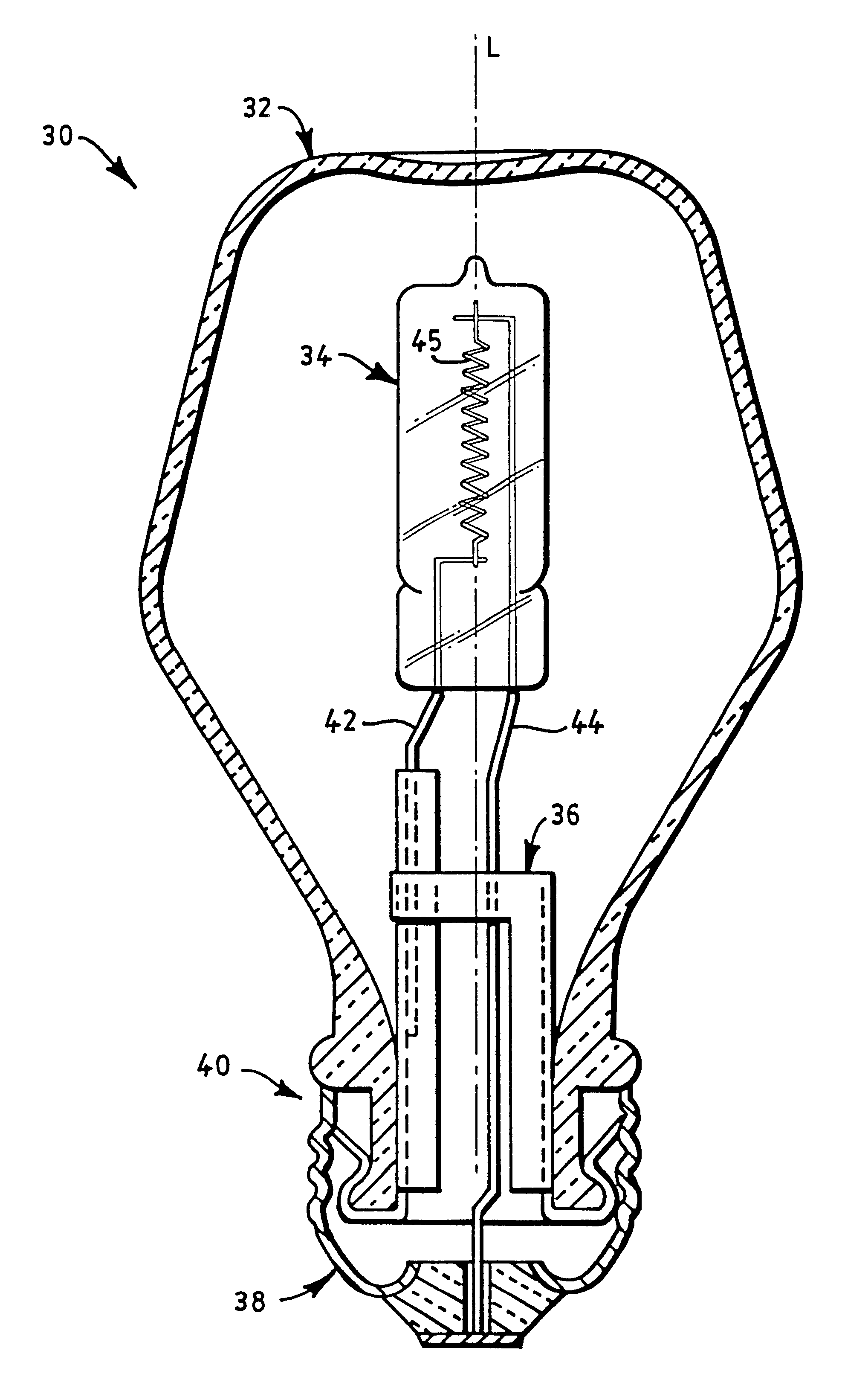

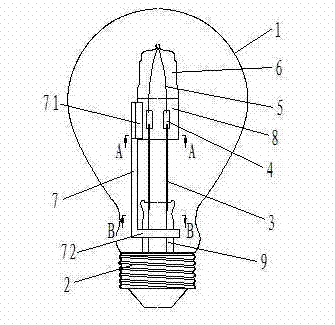

Light bulb

InactiveUS20120320591A1Improved heat dissipation conducting capabilityMore energy efficientLighting support devicesElectric circuit arrangementsEngineeringTungsten filament

The instant disclosure relates to a light bulb, which includes a base, a conducting cap arranged on one end of the base, a heat-dissipating member disposed on the opposite end of the base, and a lamp cover. The heat-dissipating member has a wedged structure, and a plurality of inclined surfaces are formed adjacently thereon. A plurality of LEDs is disposed on the inclined surfaces, and the lamp cover is arranged over the wedged structure and the LEDs. The instant disclosure uses the LEDs to replace tungsten filament as the light sources, and arranging the LEDs on the wedged structure of the heat-dissipating member. Thereby, the light bulb can have higher heat-dissipating rate.

Owner:ENLIGHT

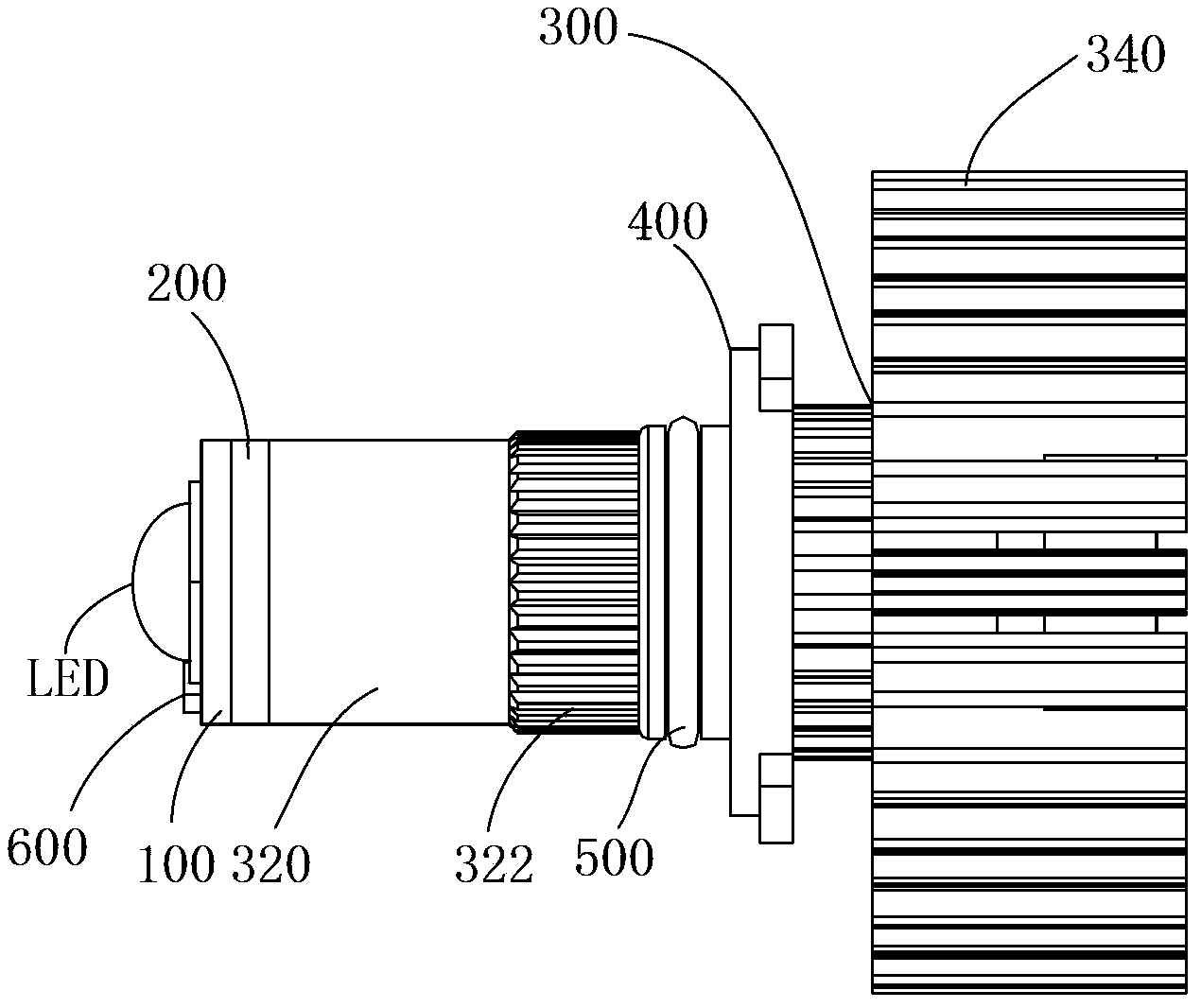

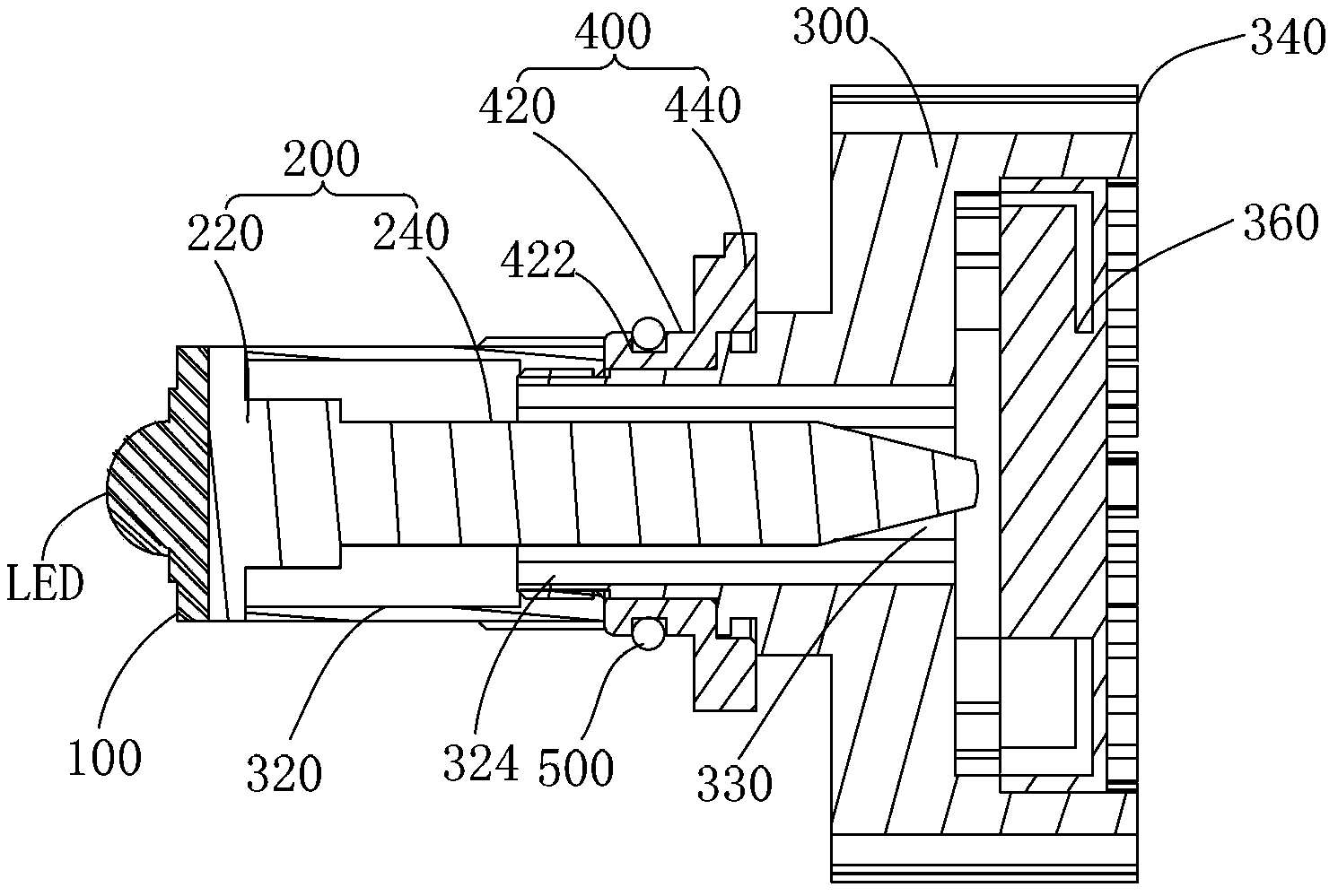

Light-emitting diode (LED) automobile headlamp

ActiveCN103574455AIncrease brightnessImprove work efficiencyPoint-like light sourceLighting heating/cooling arrangementsBoiling pointHigh intensity

A light-emitting diode (LED) automobile headlamp comprises an LED lamp, a heat conduction component and a heat dissipation component, wherein the LED lamp is arranged on a substrate; the heat conduction component is in a long strip shape, the substrate is fixed at one end of the heat conduction component, and the heat conduction component is filled with low-boiling-point liquid; the heat dissipation component comprises a heat dissipation barrel and cooling fins, the heat dissipation barrel is provided with a through hole for accommodating the heat conduction component, and the cooling fins are fixedly arranged around one end of the heat dissipation barrel away from the substrate. According to the LED automobile headlamp, traditional tungsten filaments and high intensity discharge (HID) are replaced with the LED lamp, the low-boiling-point liquid in the heat conduction component is utilized to transmit heat generated by the LED lamp to the rear end in a circulated mode, and the heat dissipation component is utilized to dissipate the heat.

Owner:SHENZHEN YIKE PHOTOELECTRIC TECH

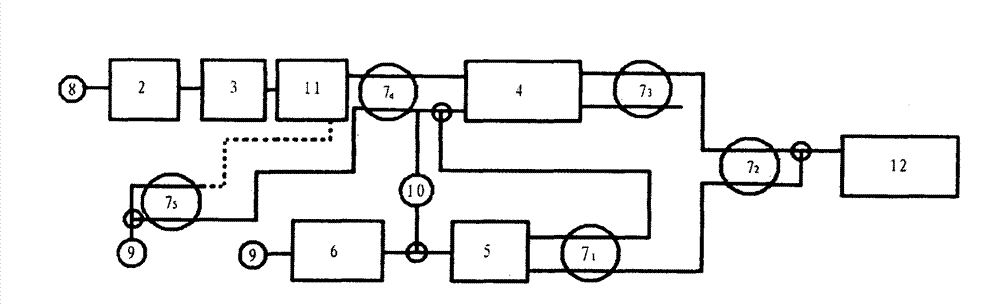

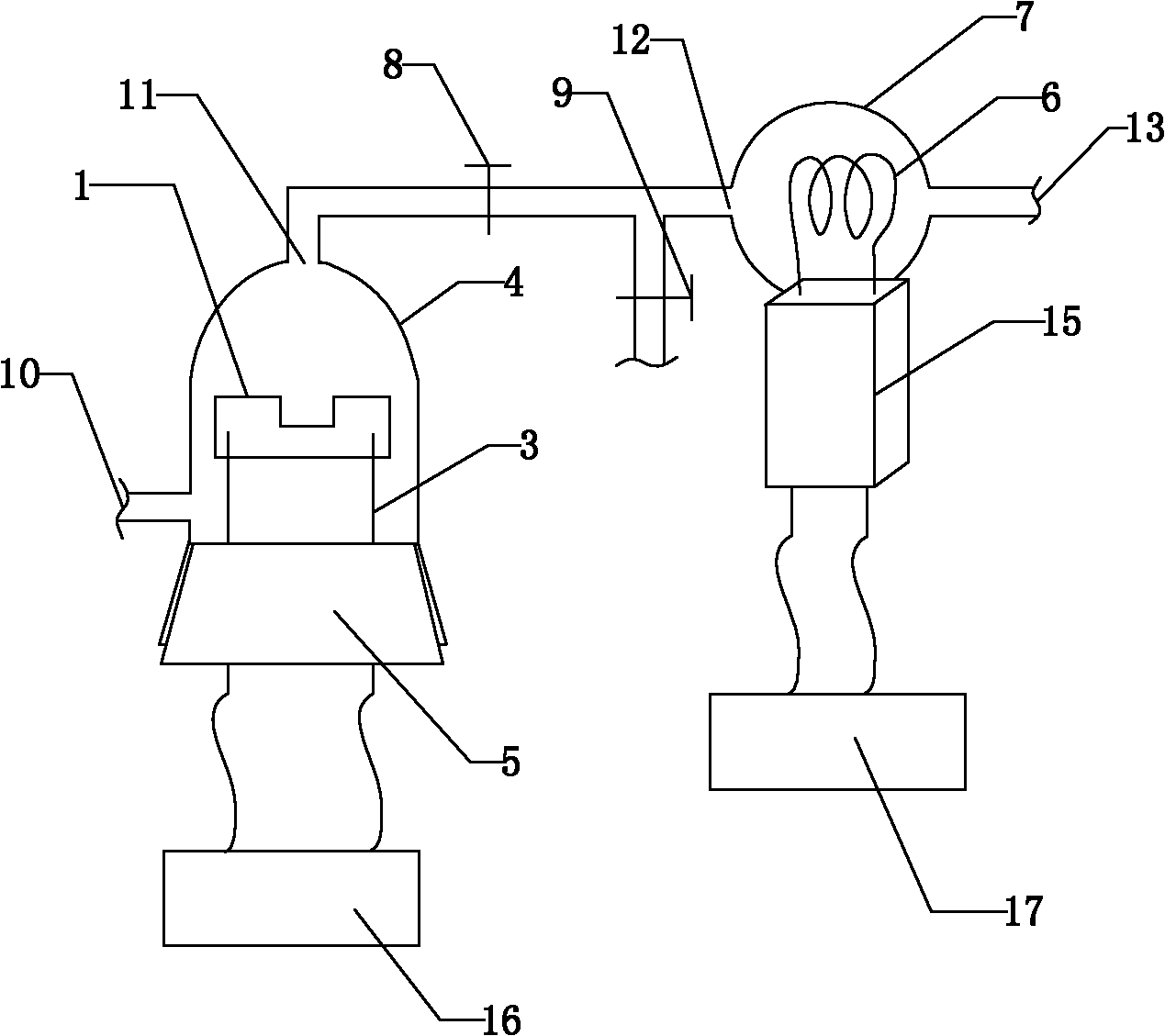

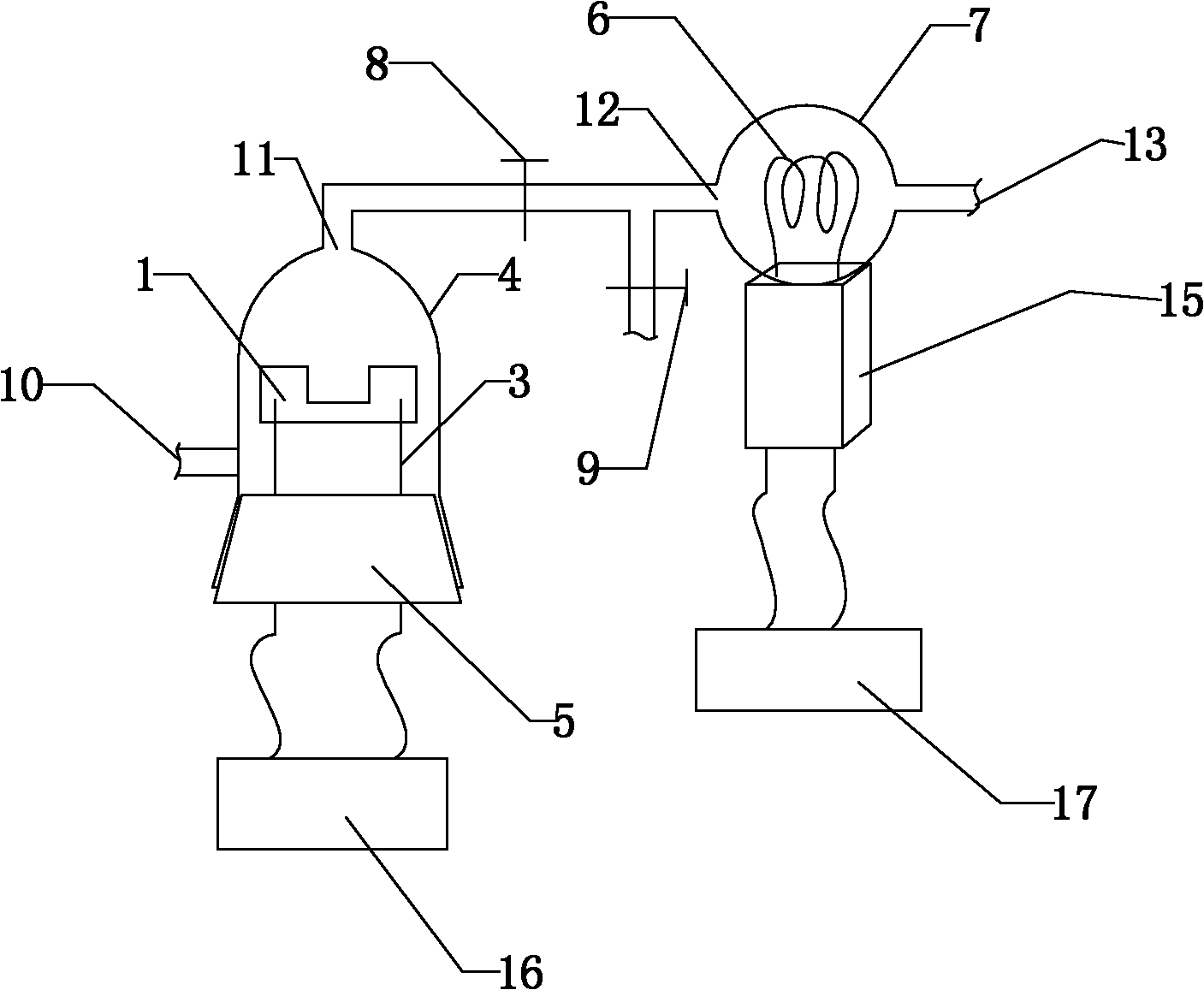

Direct sample introduction type method and instrument for simultaneously measuring mercury and cadmium

ActiveCN102967590ASimple structureConvenient for routine analysisGas treatmentRaman/scattering spectroscopyTemperature controlHydrogen

The invention relates to a direct sample introduction type method and a direct sample introduction type instrument for simultaneously measuring mercury and cadmium, which do not need to digest a sample. The direct sample introduction type method for simultaneously measuring mercury and cadmium comprises the steps of heating a sample in an aerobic environment, controlling the temperature in the scope from 120 DEG C to 500 DEG C, and separating most Hg and a decomposer out from the sample; loading Hg (mercury) and the decomposer into a catalytic furnace by an air flow to be further decomposed, absorbing Hg with Au, and keeping Cd (cadmium) be in the sample; putting the processed sample into a cracking furnace to be further thermally decomposed, and vaporizing Cd and residual H in the sample at a high temperature; loading the vaporized Cd and residual Hg into a Cd atom trap by argon, selectively trapping the Cd by a tungsten filament, and absorbing the residual Hg by a Hg trap; and heating the tungsten filament or a molybdenum filament and gold amalgamation in the argon and hydrogen gas to release Cd and Hg, and carrying Cd and Hg into an atomic fluorescence spectrometer by the argon and the hydrogen. On the basis of realizing the function of simultaneously measuring Hg and Cd, the direct sample introduction type method and direct sample introduction type instrument for simultaneously measuring mercury and cadmium have the advantages that the structure of the entire measurement instrument is simplified so as to miniaturize the instrument, so that the instrument can conveniently meet the requirements of the conventional analysis and emergencies, and can be carried to the field by a vehicle. Moreover, the direct sample introduction type method and the direct sample introduction type instrument for simultaneously measuring mercury and cadmium have application prospect in the field detection.

Owner:BEIJING JITIAN INSTR CO LTD

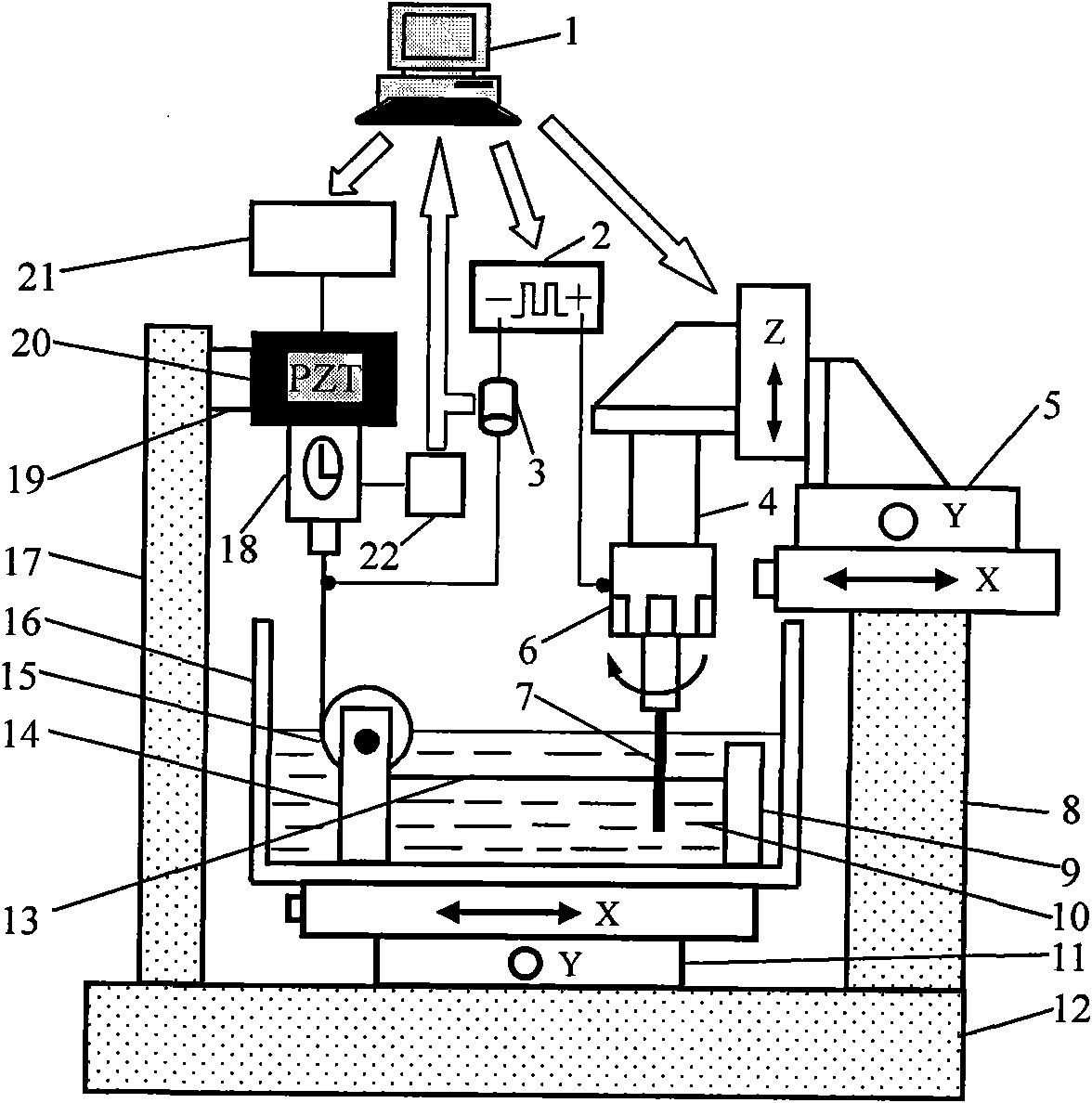

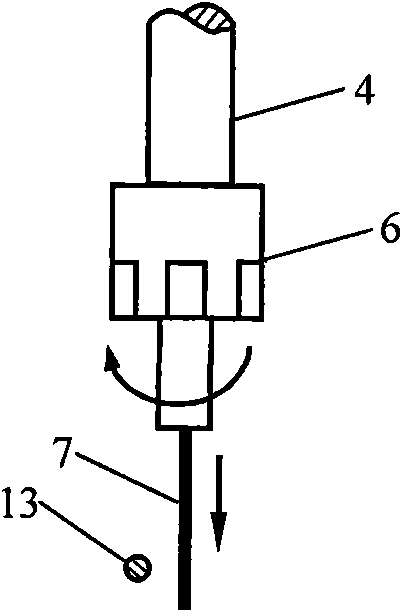

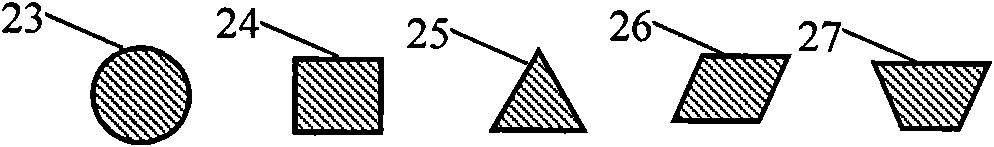

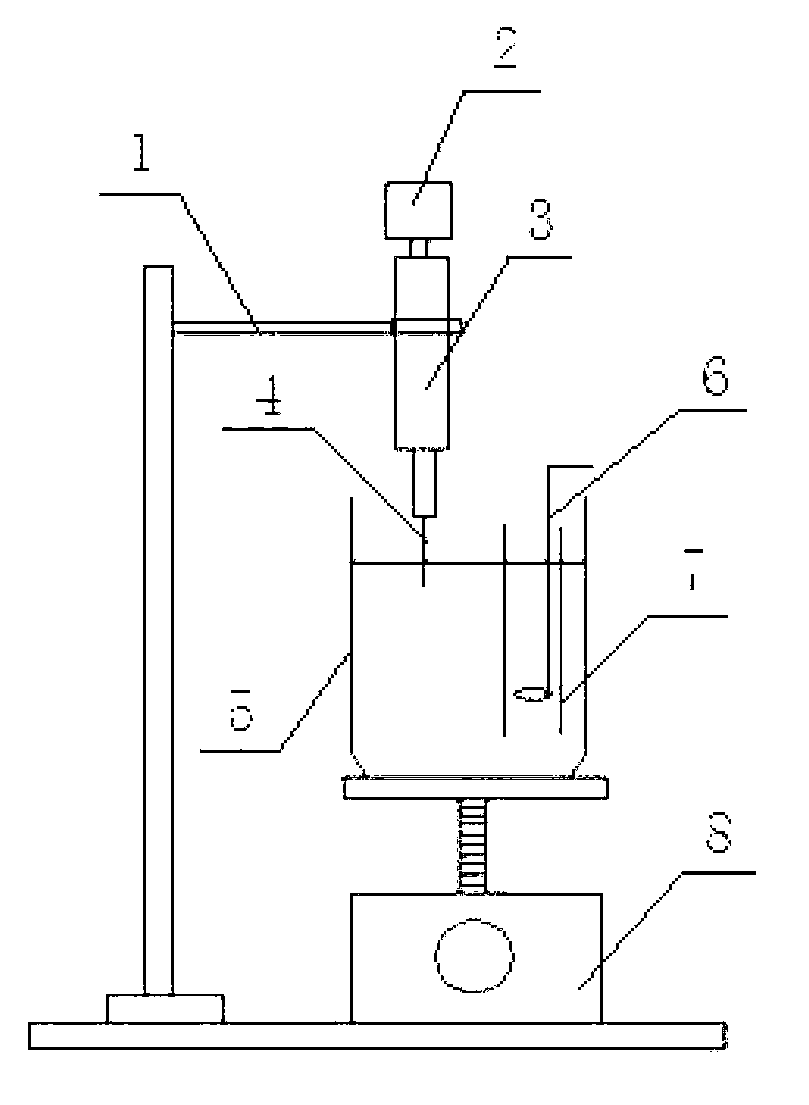

Online preparing system and method for electrochemical grinding micro tool for line electrode

ActiveCN102019474AStrong processing localization abilityGood process compatibilityElectrolytic agentNumerical control

The invention relates to online preparing system and method for an electrochemical grinding micro tool for a line electrode, belonging to the field of micro electrochemical machining. A microscale line electrode is fixed in an electrolyte tank and is tensioned by a micro tension device, and a tool electrode is connected onto a numerical-control rotary main shaft; the electrolyte tank is filled with electrolyte, the microscale line electrode and the tool electrode are immersed in the electrolyte, both the microscale line electrode and the tool electrode maintain a machining gap, and a pulse width power supply is connected; and by utilizing a principle that metal generates electrochemical anodic dissolution in the electrolyte, the tool electrode is corroded for molding. In the machining process, the numerical-control rotary main shaft is utilized to enable the tool electrode to generate rotation of certain angular speed or perform indexing, meanwhile a three-axis motion platform is utilized to generate uniform-speed feeding in a Z-axis direction so as to obtain the micro tool with a needed section shape. In size control, a current sensor is used for collecting and machining current in a loop, the size change of tungsten filaments in the corrosion process is reflected by utilizing the corresponding relationship of machining current and tungsten filament resistance, and therefore the size is accurately controlled.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

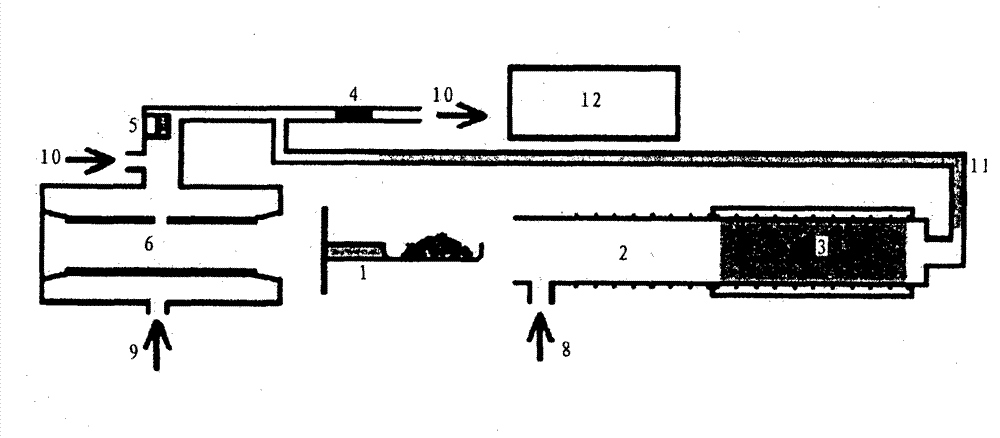

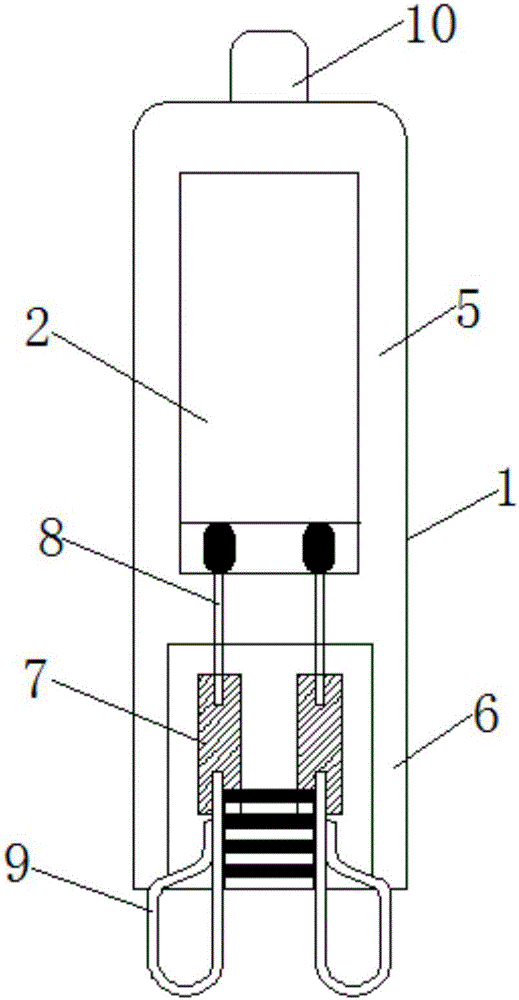

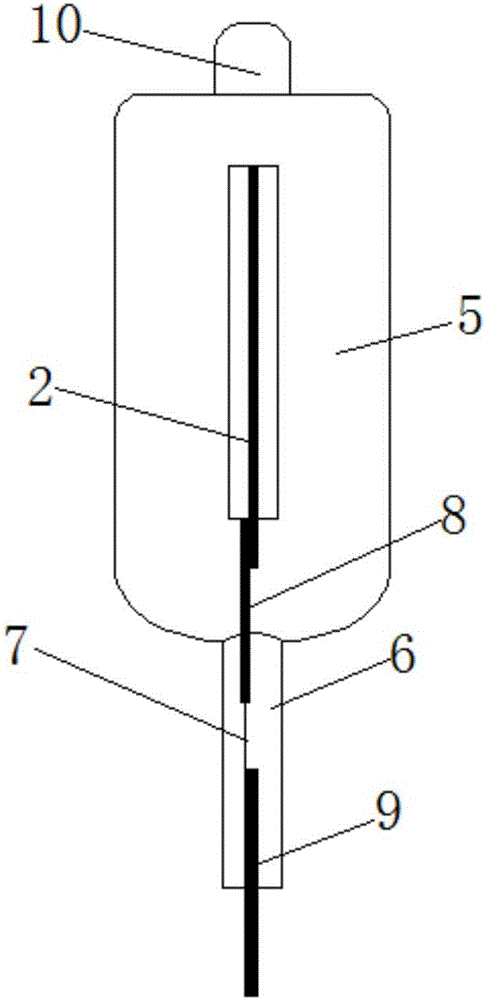

Electro-thermal vaporization atomic fluorescence spectrometry method and spectrometer used for determining cadmium

ActiveCN102338745AAccurate measurementEliminate distractionsAnalysis by thermal excitationHydrogenArgon atmosphere

The invention discloses an electro-thermal vaporization atomic fluorescence spectrometry method and a spectrometer used for determining cadmium. An atomizer of the electro-thermal vaporization atomic fluorescence spectrometer comprises an atomizing apparatus and a collecting trap. The collecting trap is composed of a tungsten filament or a molybdenum filament, a support, a housing and a power source. A sealed space is formed by the housing and the support. The tungsten filament or the molybdenum filament is arranged on the support. The tungsten filament or the molybdenum filament is positioned in the sealed space formed by the housing and the support. An inlet and an outlet are arranged on the housing. The electro-thermal vaporization atomic fluorescence spectrometry method used for determining cadmium comprises steps that: a sample requiring testing is dried in air, and is cinerated, such that ash is obtained; under an argon atmosphere, the ash is heated to 1600 to 2000 DEG C, and the obtained vapor contacts the tungsten filament or the molybdenum filament; under an atmosphere of hydrogen and argon, the temperature of the tungsten filament or the molybdenum filament is increased to 1600 to 2000 DEG C, cadmium atoms are released, and the content of the cadmium atoms are analyzed by using a fluorescence spectrometry method. With the electro-thermal vaporization atomic fluorescence spectrometry method and the spectrometer used for determining cadmium provided by the invention, matrix interference can be effectively eliminated, and accurate measuring of cadmium can be realized.

Owner:BEIJING JITIAN INSTR CO LTD

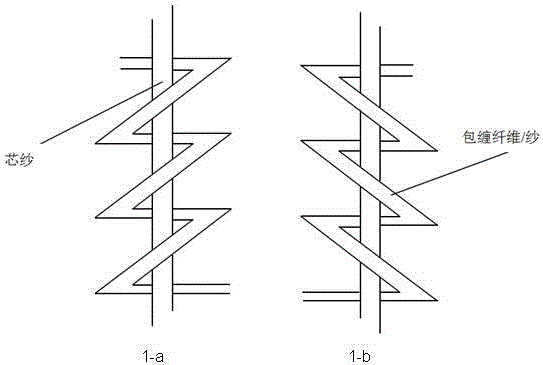

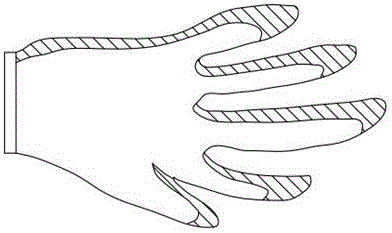

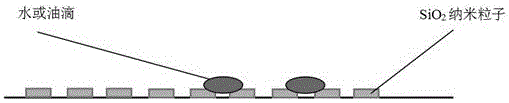

Novel cut-resistant yarn and production method of cut-resistant articles of novel cut-resistance yarn

InactiveCN106087171AImprove cut resistanceWaterproofWarp knittingGlovesEngineeringElectromagnetic shielding

The present invention discloses a novel cut-resistant yarn and production method of cut-resistant articles of the novel cut-resistance yarn; the novel cut-resistant yarn is woven by: using a high-strength high-count tungsten filament yarn as a core yarn, covering the core yarn with wrapping fiber / yarn, and spinning; wherein, core yarn count is 3-250 tex, and the tungsten filament yarn is 20-80% by weight of total weight of the novel cut-resistant yarn. The cut-resistant articles made with the novel cut-resistant yarn have good cut resistance, electromagnetic shielding performance, self-extinguishment, flame retardancy, tolerance to high temperature, flexibility, wearing comfort and good processibility, and the production method is simple, convenient to operate and low in production cost and has a promising market application prospect.

Owner:上海固甲新材料科技有限公司

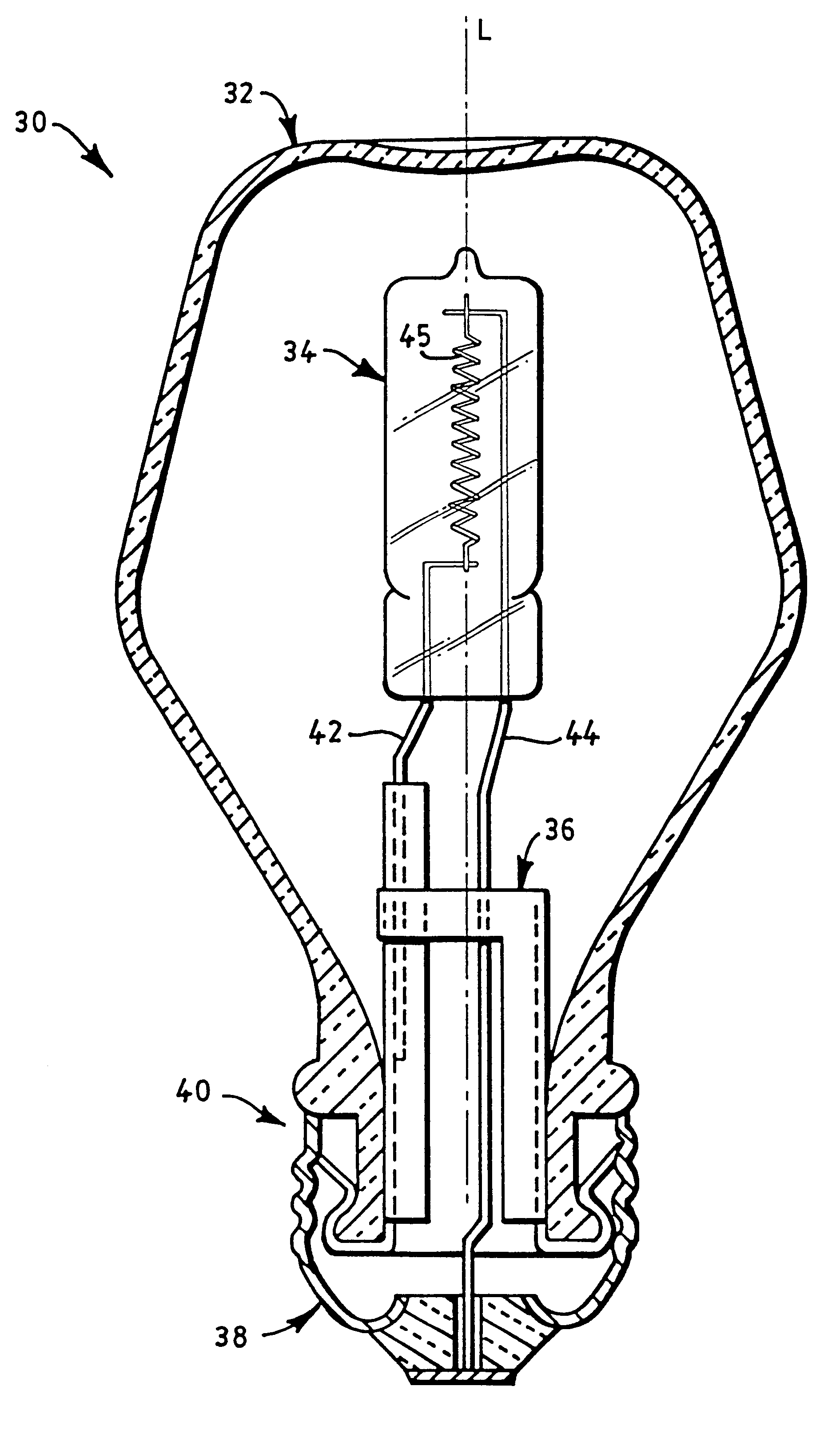

Long life halogen cycle incandescent lamp and glass envelope composition

InactiveUS6373193B1Improve performanceIncandescent lamp energy savingSolid cathode detailsHalogenEngineering

A long life, halogen cycle, incandescent lamp (30) for operation in excess of 85 volts. The lamp comprises a transparent glass envelope (34) having sealed therewithin a tungsten filament (45); a pair of electrical lead-ins (42, 44) connecting the filament and extending exteriorly of the envelope for connection to a supply voltage greater than 100 V; and a fill gas within the envelope, including a halogen, at a pressure of at least three atmospheres. The envelope is constructed of a five component alkaline earth aluminosilicate glass having a composition consisting essentially of, in weight percent from >58 to about 64% SiO2, from about 14 to about 17% Al2O3; from 0 to about 1% B2O3, from 1 to about 6% MgO, from about 6 to about 12% CaO, from about 7 to about 17% BaO and from 0 to about 1.5% ZrO2.

Owner:SCHOTT AG +1

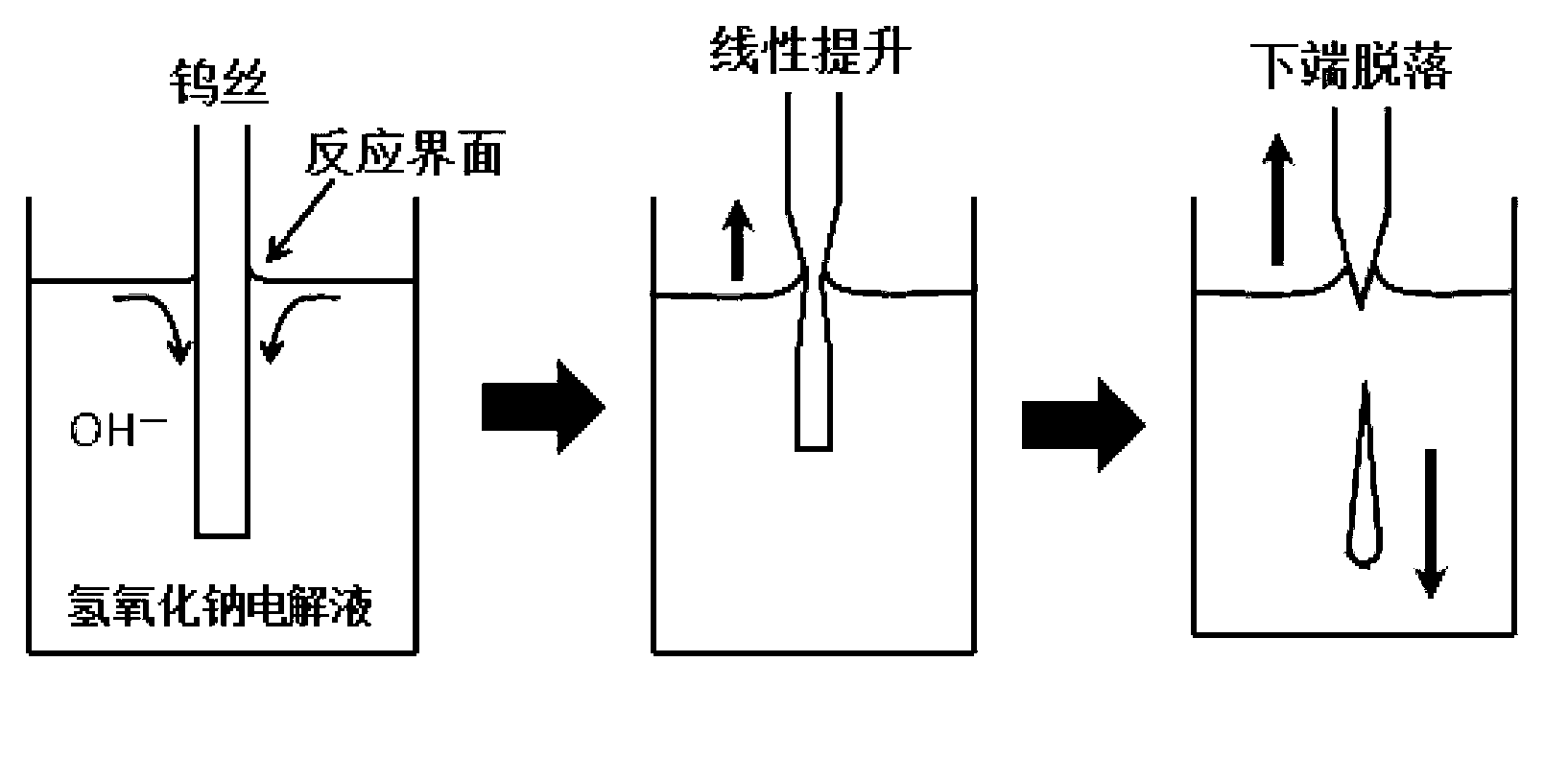

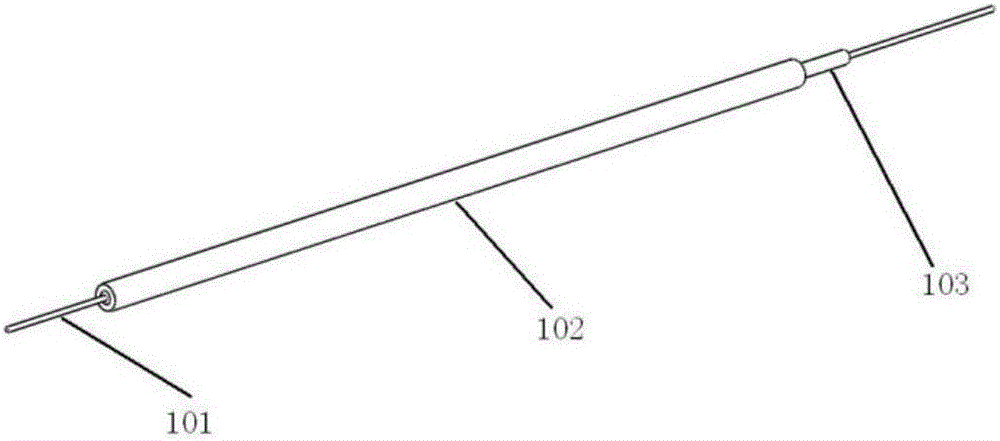

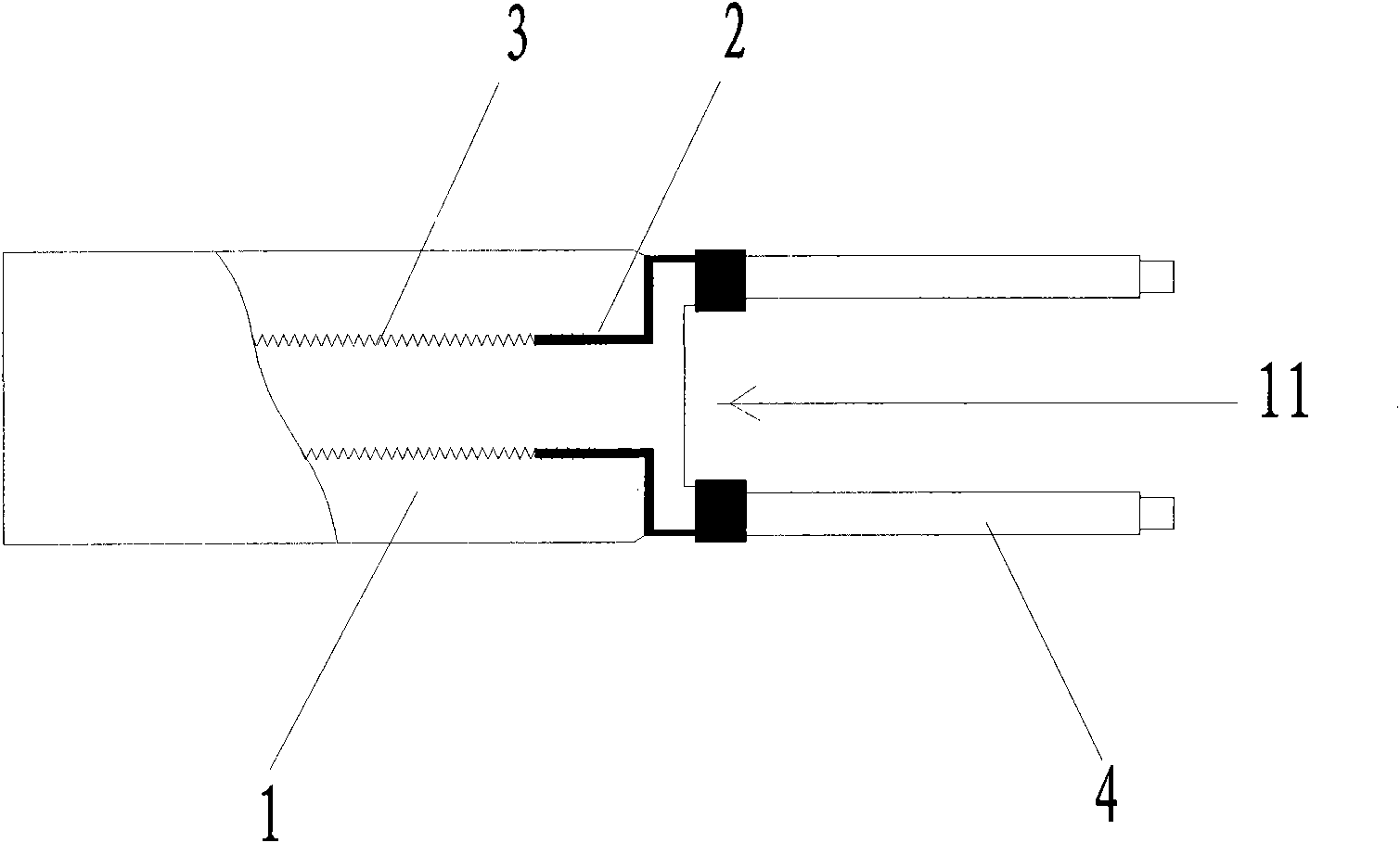

Preparation method and preparation device of tungsten probe for electrical measurement of nanometer device

The invention discloses a preparation method and a preparation device of a tungsten probe for electrical measurement of a nanometer device. The principle of the method is to obtain the tungsten probe by an electrochemical corrosion tungsten filament, wherein the tungsten filament is taken as an anode and soaked in electrolyte; the tungsten filament is lifted when the current of the tungsten filament is reduced to 20mA; and the tungsten filament is taken as a cathode by reverse current and lifted to depart from the electrolyte at the moment when the tungsten filament is cut off by corrosion, so as to obtain the tungsten probe. The tungsten tipped probe with large draw ratio can be prepared by the preparation method; meanwhile, the reverse current when the tungsten filament is cut off is detected; and the taper corner at the tip of the tungsten probe can be estimated in advance, so as to save the time and cost needed in subsequent procedure that an electron scanning microscope is needed to observe and confirm in the traditional method.

Owner:SOUTHEAST UNIV

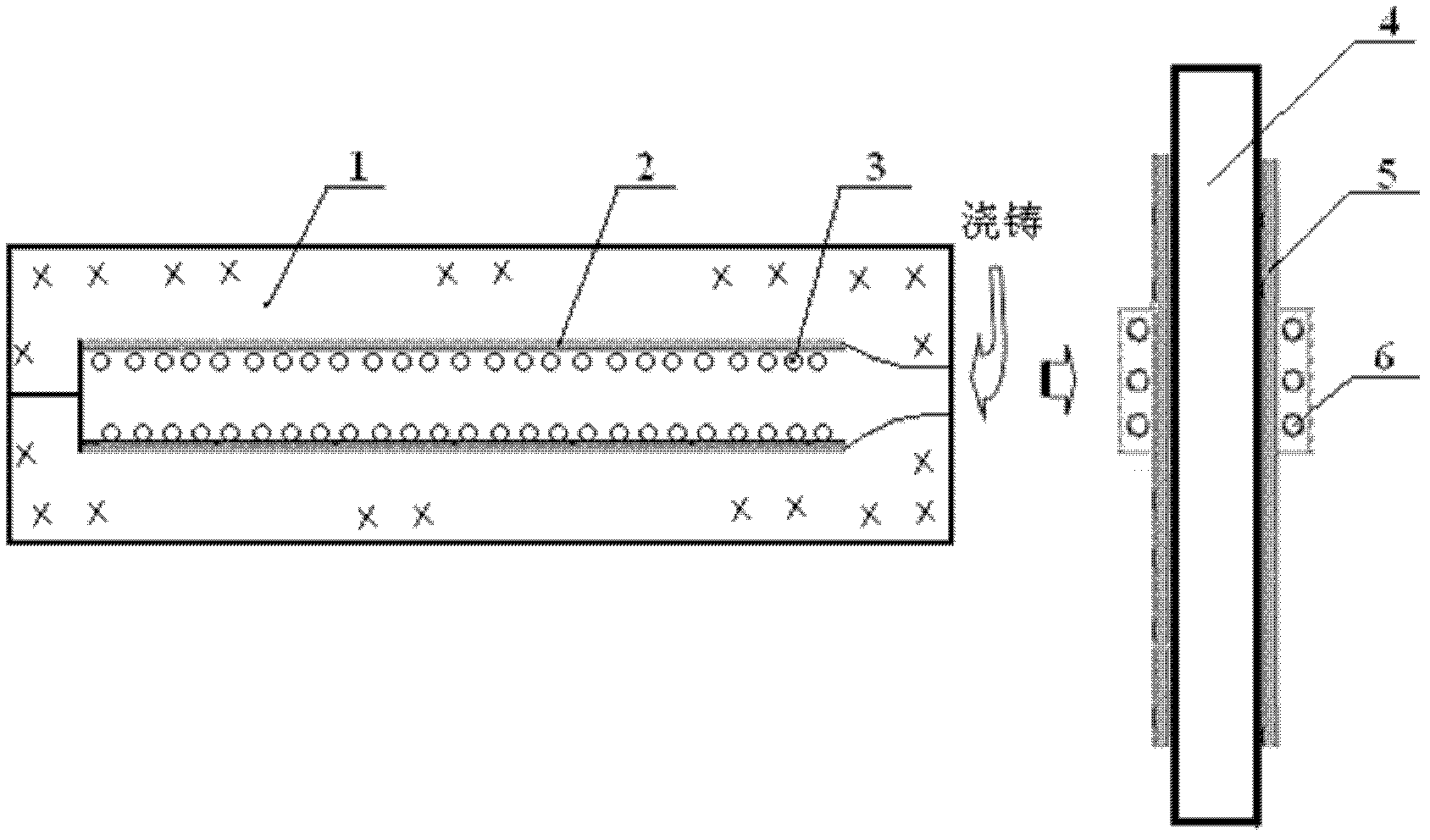

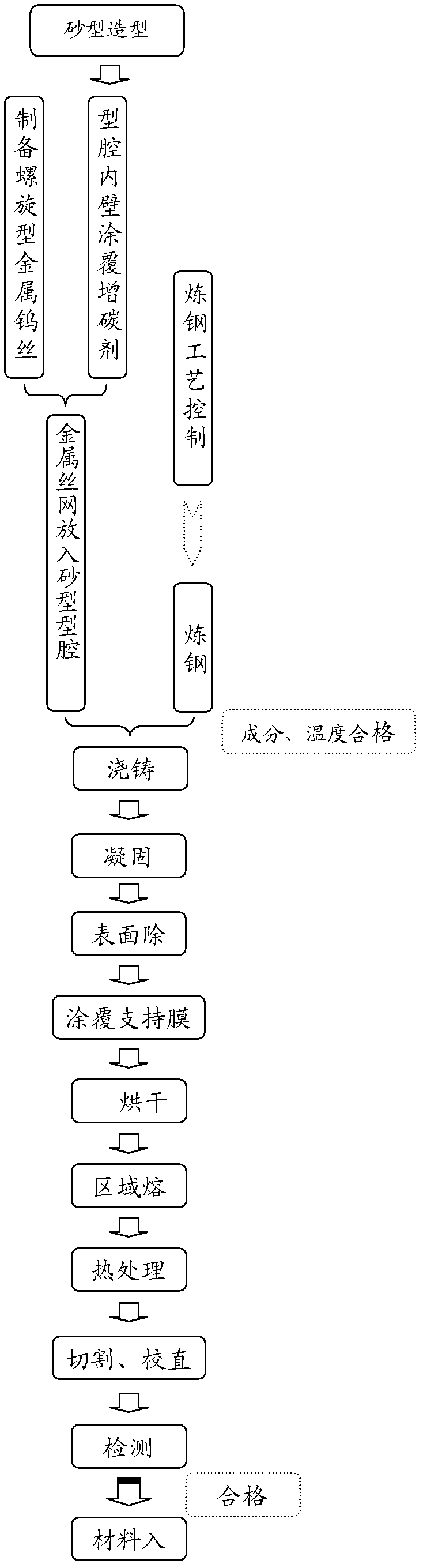

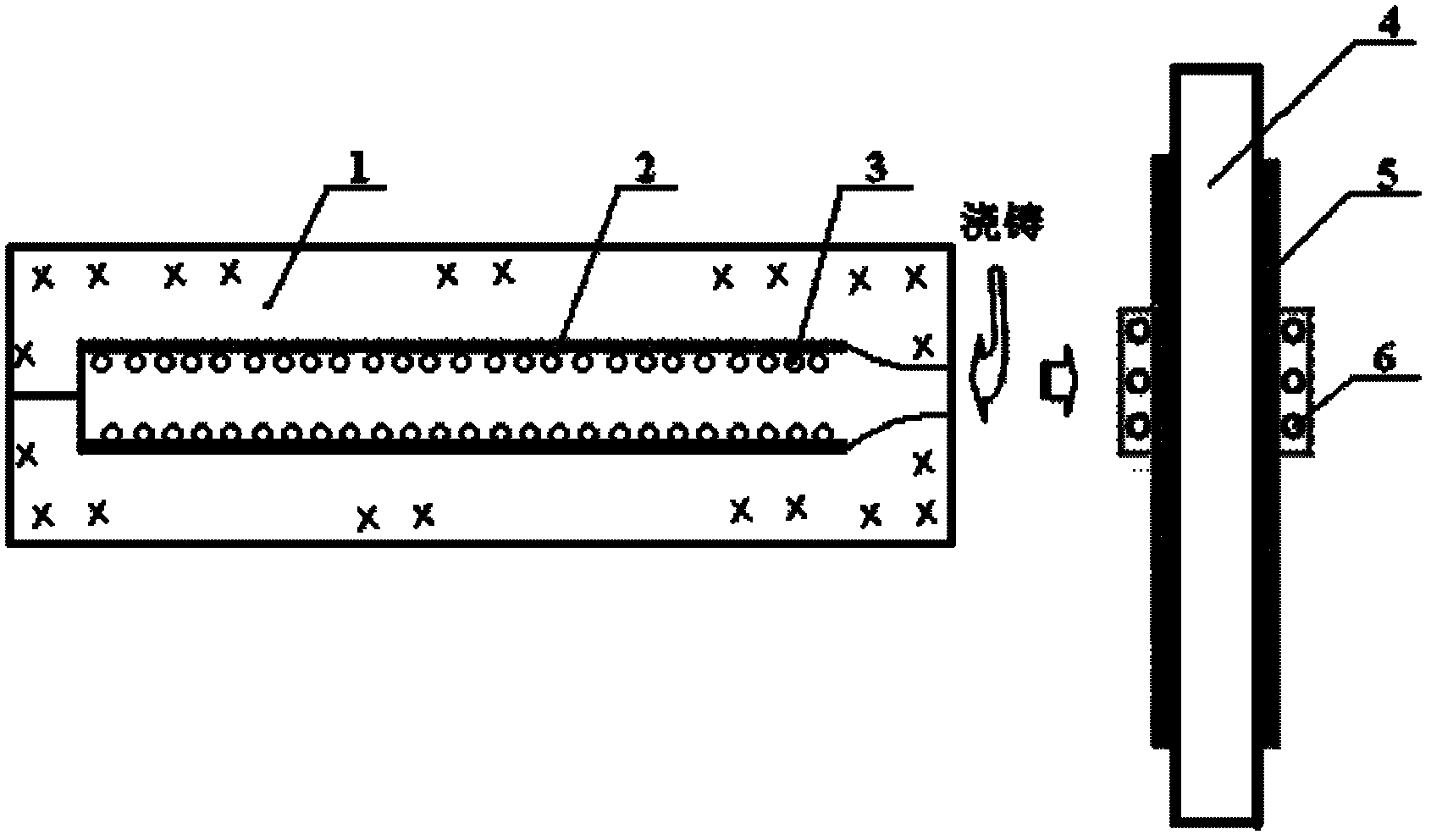

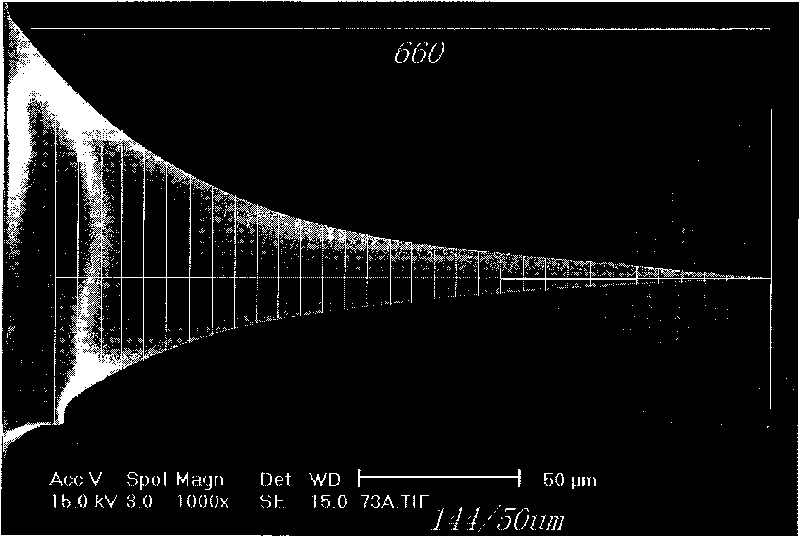

Preparation method of tungsten carbide particle enhanced steel-base surface layer composite bar

The invention discloses a preparation method of a tungsten carbide particle enhanced steel-base surface layer composite bar. The method comprises the following steps of: coating recarbonizer on the cavity surface of a sand mould; acid-washing the tungsten filament to be used as a strengthening phase and making into a spiral shape; placing the spiral-shaped tungsten filament in the cavity, and pouring, wherein after the metal liquid is solidified to room temperature, a metal steel bar is obtained; removing rust of the surface of the metal bar; then coating a support film on the outer surface of the metal bar; after the support film is dried, performing surface rapid zone melting through a zone melting sensor, and performing rapid solidification, wherein the heating temperature for the surface rapid zone melting is controlled to be 20-30 DEG C higher than the melting point of the base material; after the zone melting, performing thermal treatment on the metal bar; and then performing cutting, mechanical straightening and the like to achieve the required size to finally obtain the tungsten carbide particle enhanced steel-base surface layer composite bar. The tungsten carbide particleenhanced steel-base surface layer composite bar not only maintains the characteristics of good toughness and plasticity of metal materials, but also has strong wear resistance. The thickness of a WC composite layer can reach 10-15 mm, and the hardness HRC can reach 50-56. The invention is easy to realize large-scale industrial production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

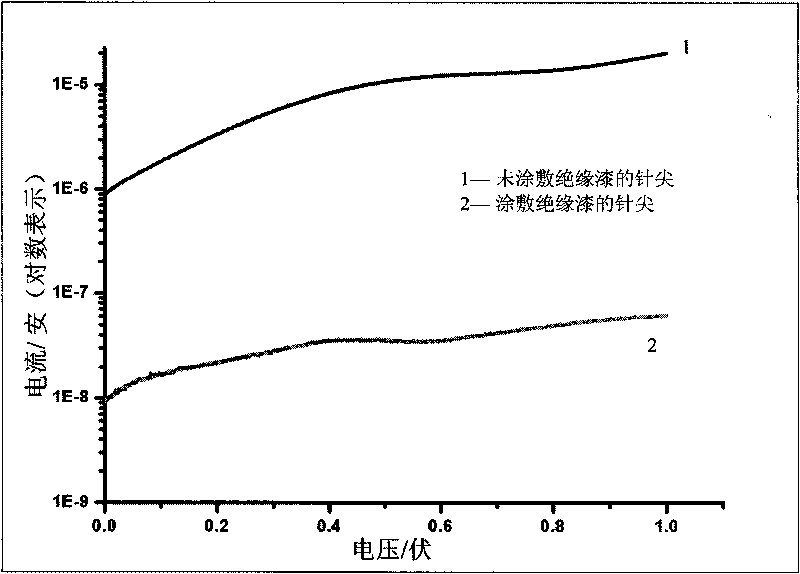

Method for preparing pinpoint of nano-tungsten probe

InactiveCN101696980ASimple and Quick Override MethodSimple and efficient overlay methodNanostructure manufactureScanning probe microscopyAlcoholLacquer

The invention discloses a method for preparing a pinpoint of a nano-tungsten probe, which comprises the following steps: 1) after removing an oxide layer on the surface of a tungsten filament by using an etching solution, inserting the tungsten filament into the etching solution, energizing the etching solution, and corroding the tungsten filament; 2) after washing the tungsten filament corroded in the step 1) by using deionized water and performing ultraphonic treatment, washing and drying the tungsten filament by using alcohol; and 3) coating an insulating varnish on the surface of the tungsten filament processed in the step 2), and drying and standing the tungsten filament to prepare the pinpoint of the nano-tungsten probe. The radius of curvature of the tip of the pinpoint of the nano-tungsten probe can reach about 20 nanometers minimally, and the pinpoint of the nano-tungsten probe can form tip conduction at a small voltage (1 mV magnitude). The method has a low preparation cost, and has a good application prospect in the study fields of nanometer channels, nano fluidonics, subcellular electrical measurement and the like.

Owner:PEKING UNIV

Uncontinuous high-metallic coating method

InactiveCN101565815AStrong metal textureHigh light transmittanceVacuum evaporation coatingSputtering coatingIndiumSpray coating

The invention belongs to the technical field of vacuum coating, and in particular relates to an uncontinuous high-metallic coating method, which comprises the following steps: firstly, spray coating of a UV primer, namely coating the UV primer on the coated surface of a product, roasting the coated product in an oven, and curing the roasted product in a UV furnace; secondly, stannum-indium coating, namely placing a tungsten filament of a coating machine into a stannum-indium coating material, placing the product after spray coating of the UV primer into a vacuum furnace turntable of the coating machine for electrostatic dust collection of the product, performing vacuum pumping after sealing the coating machine, performing preheating after vacuum pumping, and evaporating the stannum-indium coating material for coating; and thirdly, spray coating of a UV finishing coat, namely coating the UV finishing coat on the coated surface of the product after stannum-indium coating, roasting the coated product in the oven, and curing the roasted product in the UV furnace. The product coated by the method is not conductive; the membrane layer is white and bright; the light transmittance is good; the metallic texture is strong; and the weathering resistance is good.

Owner:GUANGDONG JANUS SMART GRP CO LTD

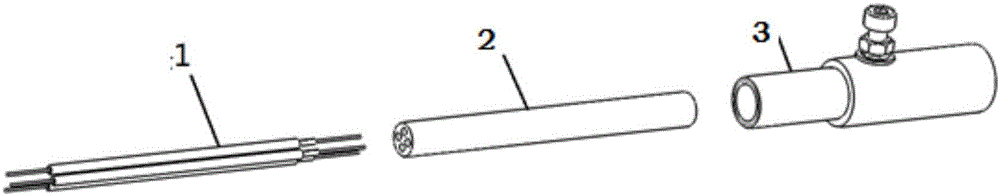

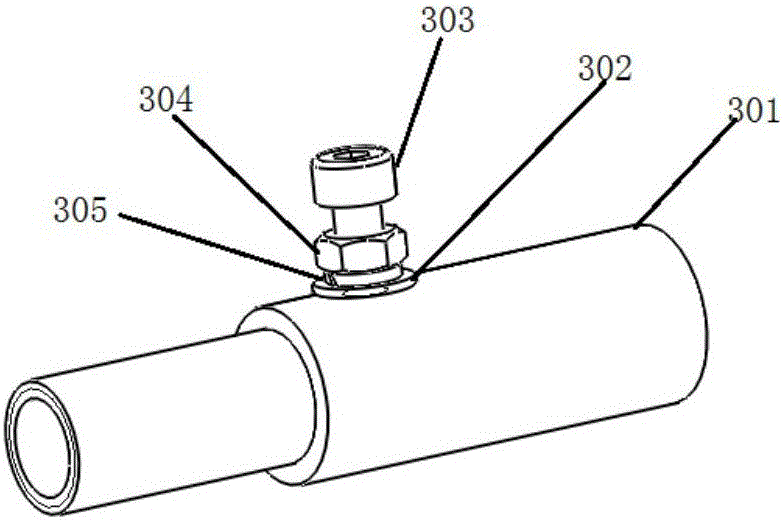

Cylindrical probe used for plume measurement of magnetic plasma thrustor

The invention discloses a cylindrical probe used for plume measurement of a magnetic plasma thrustor. The cylindrical probe includes single probe modules, a four-hole ceramic tube and a Langmuir probe protection tube module. The single probe module includes a thick single-hole ceramic tube, a thin single-hole ceramic tube and a tungsten filament. One end of the thin single-hole ceramic tube and one end of the thick single-hole ceramic tube are flush to each other and are fixed to each other. The tungsten filament is inserted to the thin single-hole ceramic tube. An end face of the four-hole ceramic tube is provided with four through holes. Three identical single probe modules are inserted into three of the four through holes. The Langmuir probe protection tube module includes a protection tube, a flat gasket, a fastening screw, a nut and a spring gasket. The four-hole ceramic tube with the fixed single probe modules is inserted from the protection tube and gets fixed. The cylindrical probe provided by the invention has advantages that the four-hole ceramic tube, the thick single-hole ceramic tube, the thin single-hole ceramic tube and the tungsten filament made of aluminum oxide which is common in market can bear plume temperature of the magnetic plasma thrustor; structural stability can be kept through clearance fit; and the cylindrical probe is simple in structure.

Owner:BEIHANG UNIV

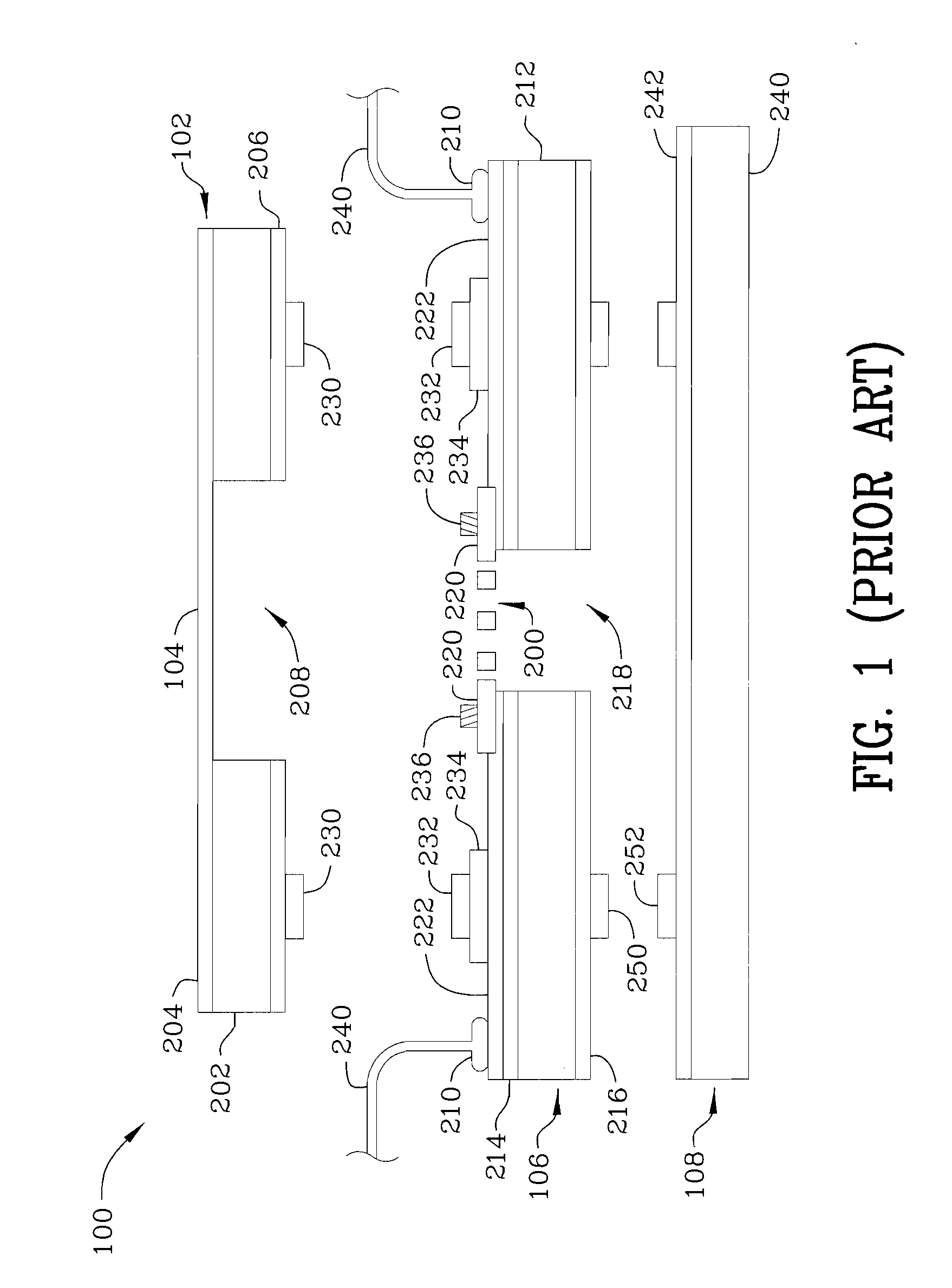

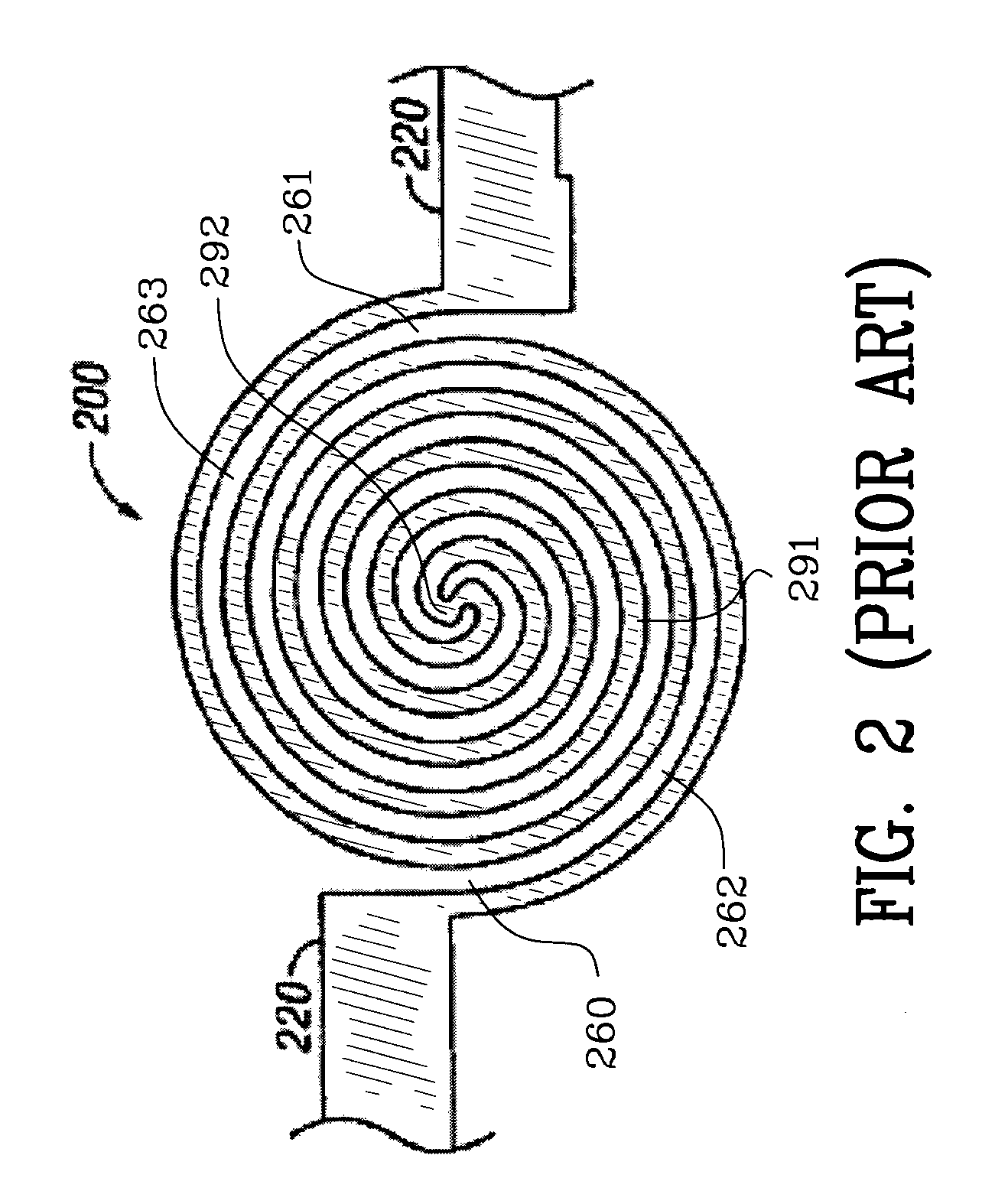

Ultraminiature broadband light source and method of manufacturing same

InactiveUS7755292B1Improve sealingEfficient couplingVacuum tubesIncadescent body mountings/supportEngineeringBroadband light source

An ultraminiature light source using a double-spiral shaped tungsten filament includes end contact portions which are separated to allow for radial and length-wise unwinding of the spiral. The double-spiral filament is spaced relatively far apart at the end portions thereof so that contact between portions of the filament upon expansion is avoided. The light source is made by fabricating a double-spiral ultraminiature tungsten filament from tungsten foil and housing the filament in a ceramic package having a reflective bottom and a well wherein the filament is suspended. A vacuum furnace brazing process attaches the filament to contacts of the ceramic package. Finally, a cover with a transparent window is attached onto the top of the ceramic package by solder reflow in a second vacuum furnace process to form a complete hermetically sealed package.

Owner:NASA

Method for producing thorium-tungsten wire

InactiveCN101004995AUniform distribution of internal stressImprove the winding effectCold cathode manufactureThorium nitrateTungsten filament

The method includes following steps: adding certain quantity of solution of thorium nitrate into tungsten oxide so as to prepare doped powder of tungsten oxide; deoxidizing the obtained doped powder of tungsten oxide to obtain powder of thorium - tungsten; acid cleaning powder of thorium - tungsten to remove impurity, and producing sintered body of powder of thorium - tungsten; using press work to obtain thorium -tungsten filament with needed diameter, and content of thorium dioxide being 0.7-1.1 wt%, and enwinding thorium -tungsten filament by using wire coil; Finally, straightening filament. The invention raises the rate of finished products, and optimizes working performance of tungsten winding.

Owner:兆恒威勒(石门)钨业有限公司

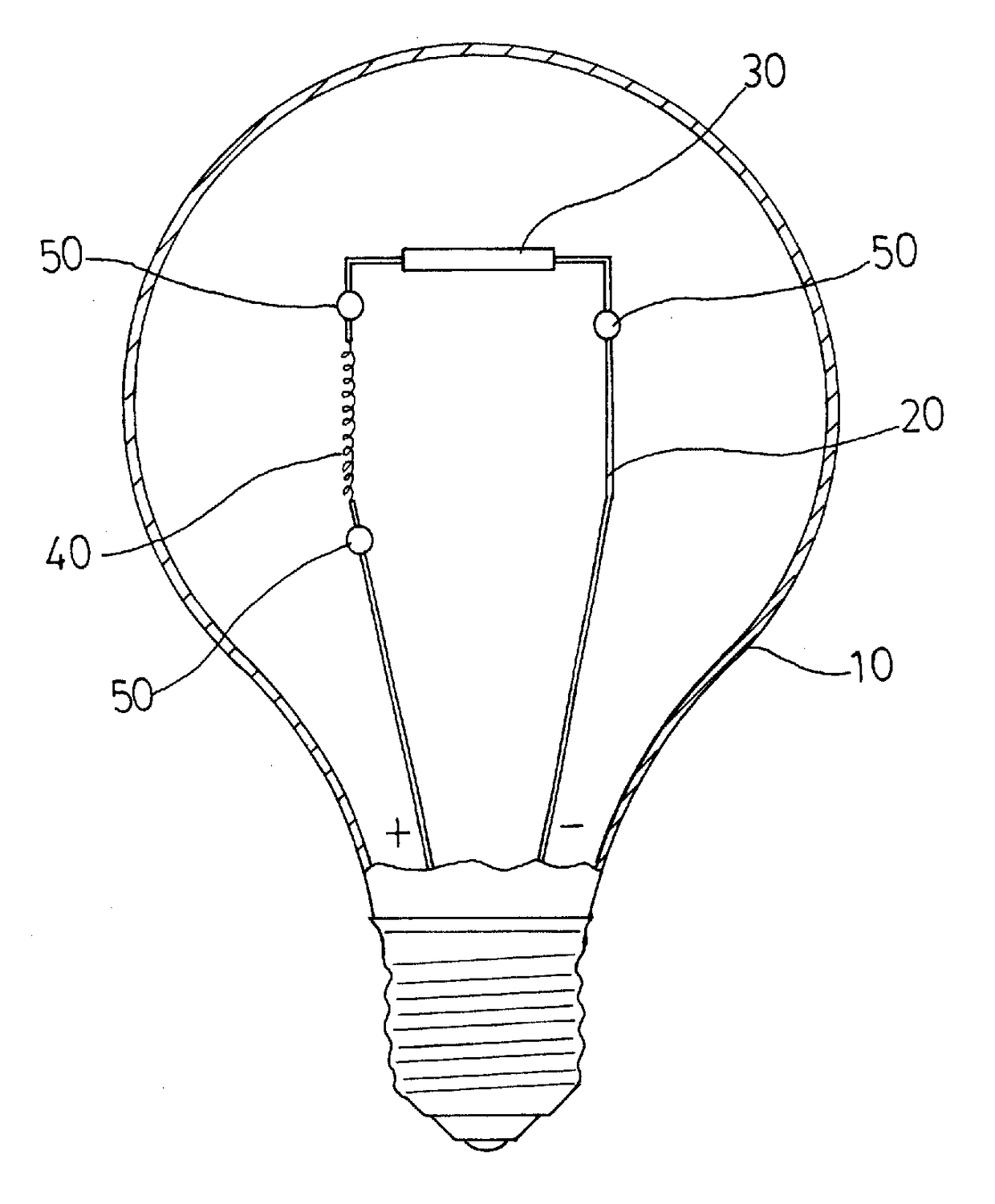

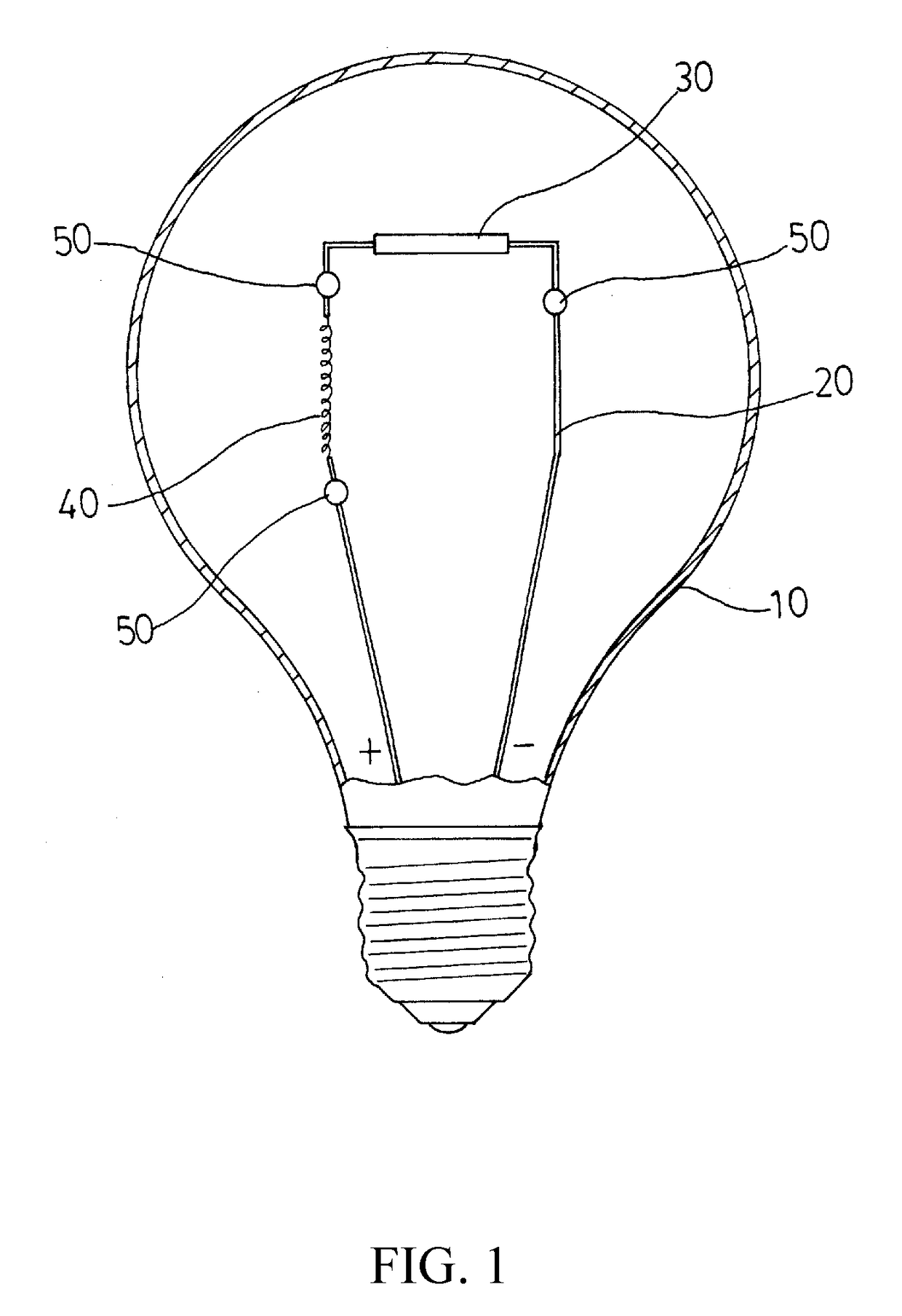

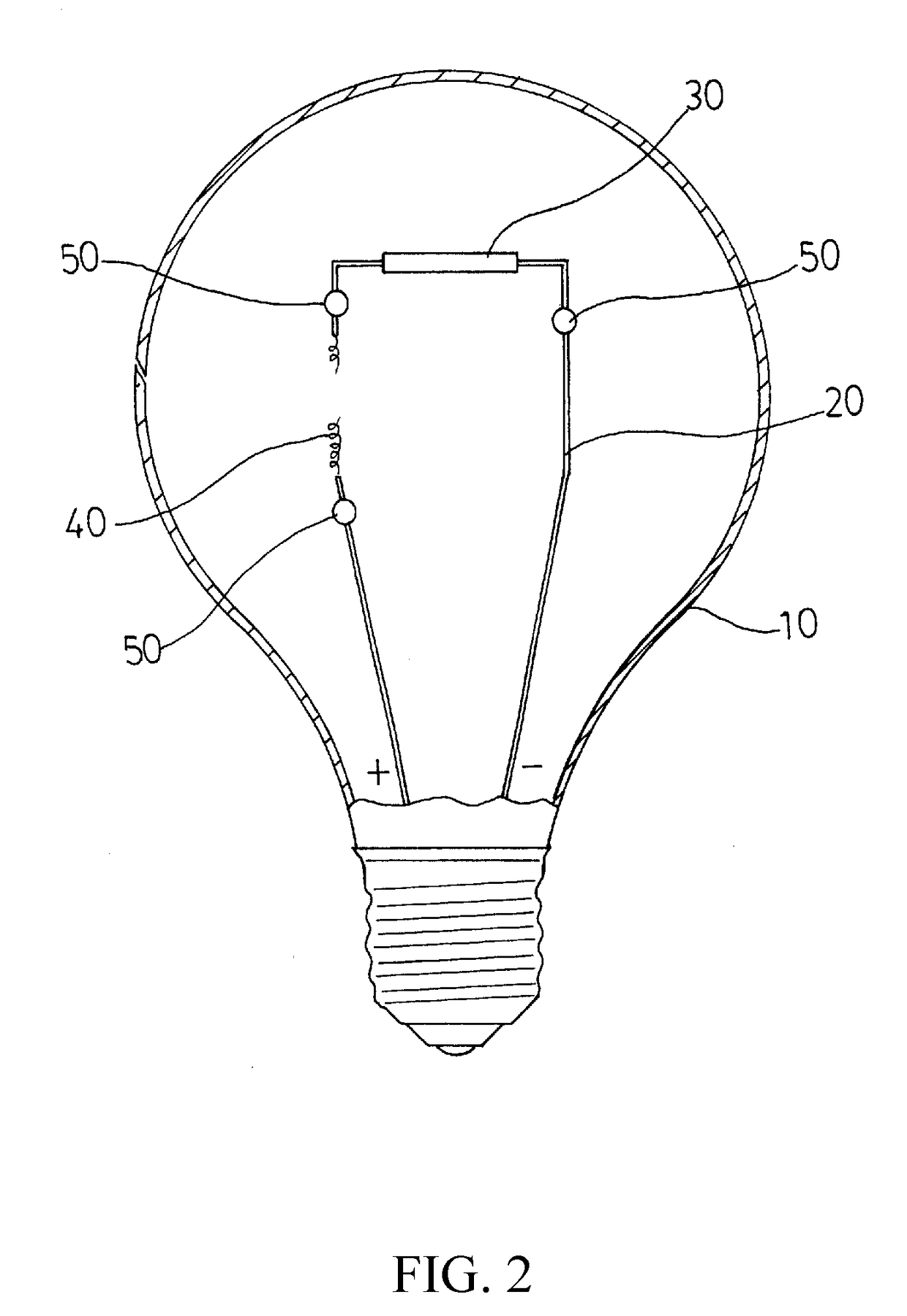

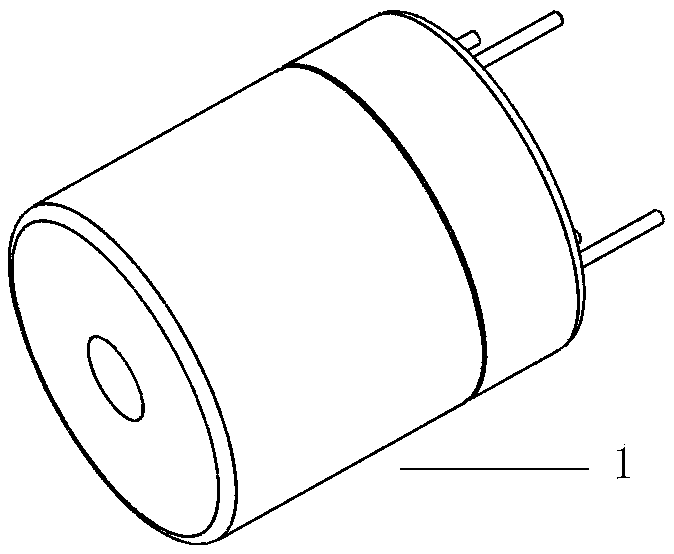

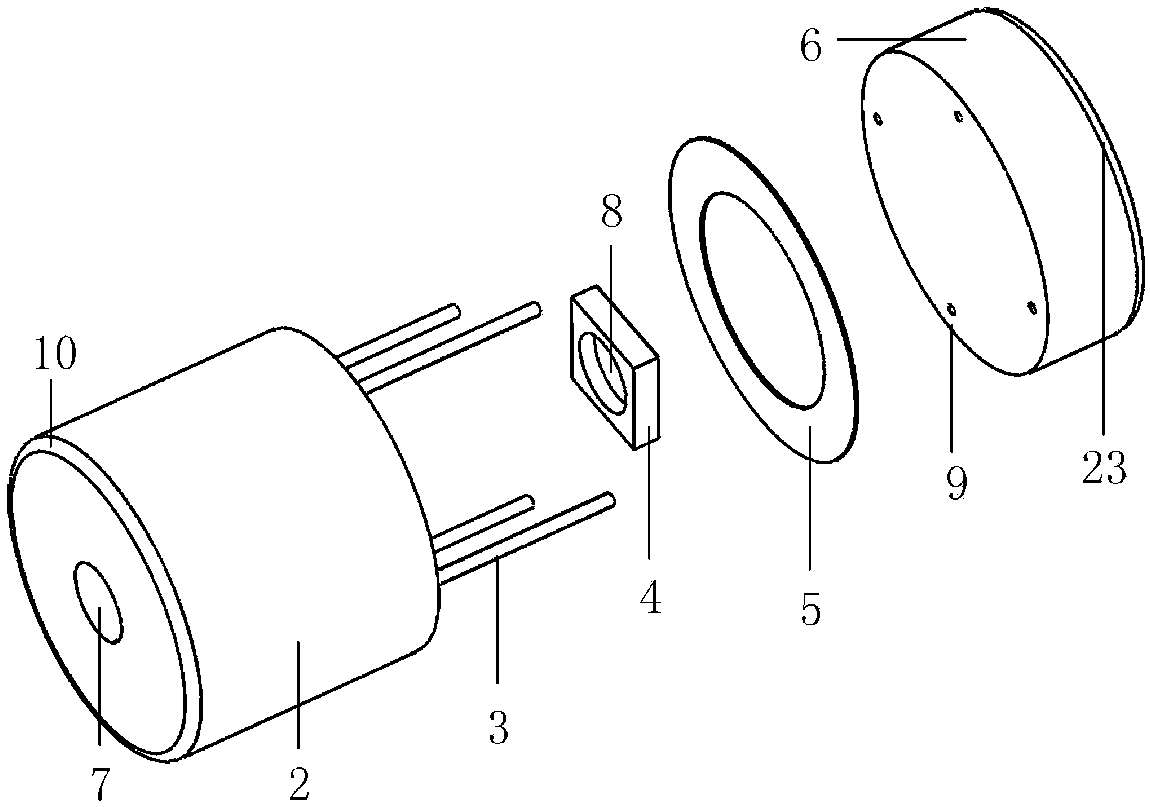

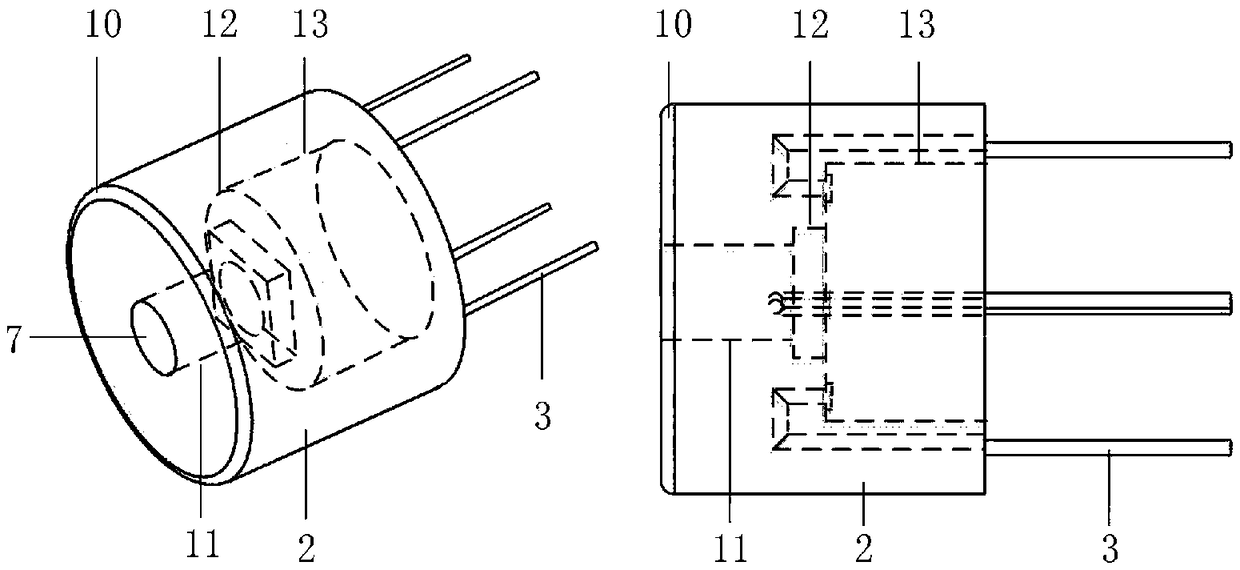

LED bulb structure

An LED bulb structure includes a glass envelope, support, LED light emitting body, tungsten filament light emitting body and electronic element units, where the glass envelope is vacuum-sealed, the support formed by a conducting wire is fixed inside it, both LED and tungsten filament light emitting bodies are configured on the support, the necessary electronic element units are configured on the support between the LED light emitting body and tungsten filament light emitting body, and one side of the support is set to a positive pole and another side thereof a negative pole. As arranged, air will enter the glass envelope of a broken LED bulb to cause the tungsten filament to be burned to break to extinguish, and thus to cause the LED light emitting body to extinguish in such a way to remind users that the broken LED bulb must be replaced with a new one.

Owner:LIN CHIN SAN

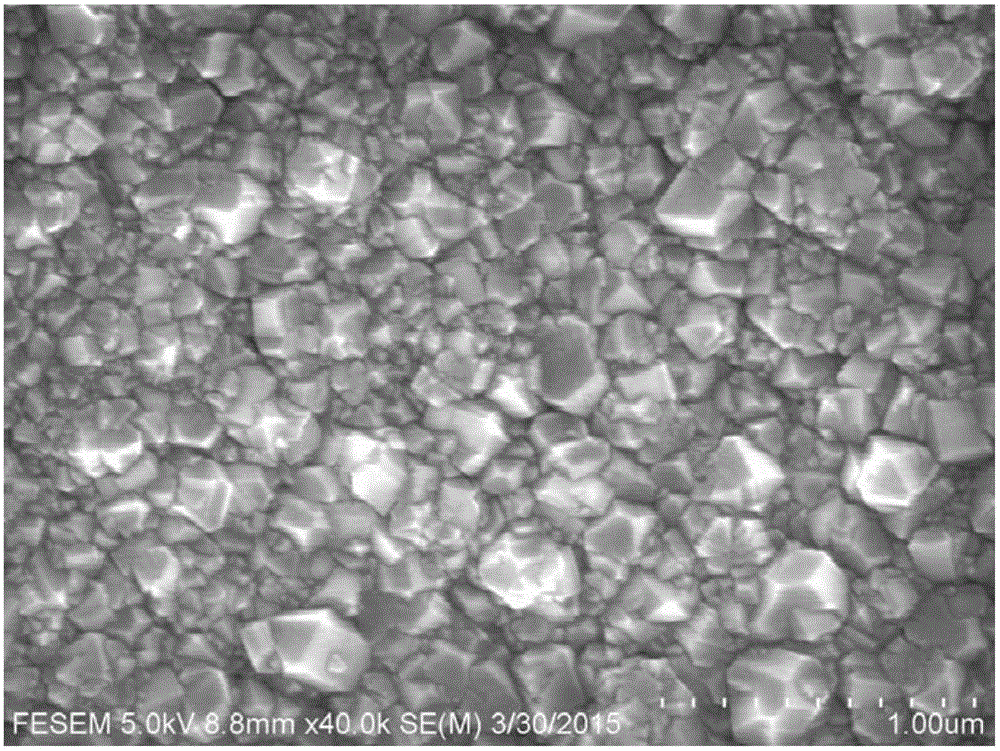

Electrochemical reduction CO2 catalyst based on boron and nitrogen co-doped nano-diamond and preparation method and application of catalyst

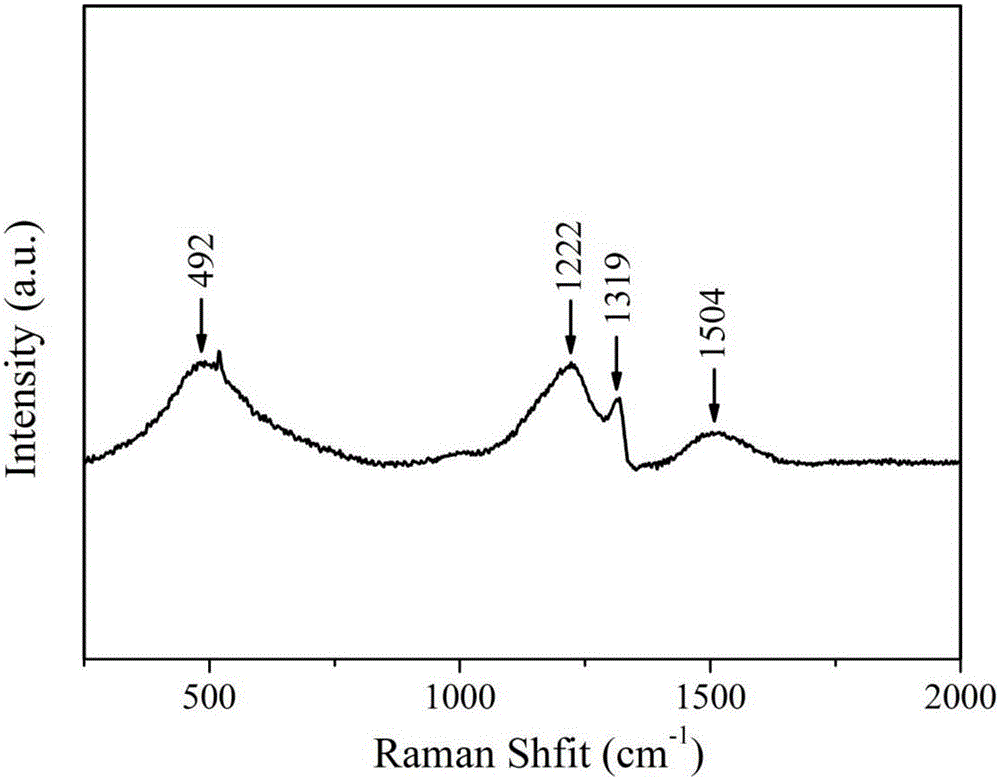

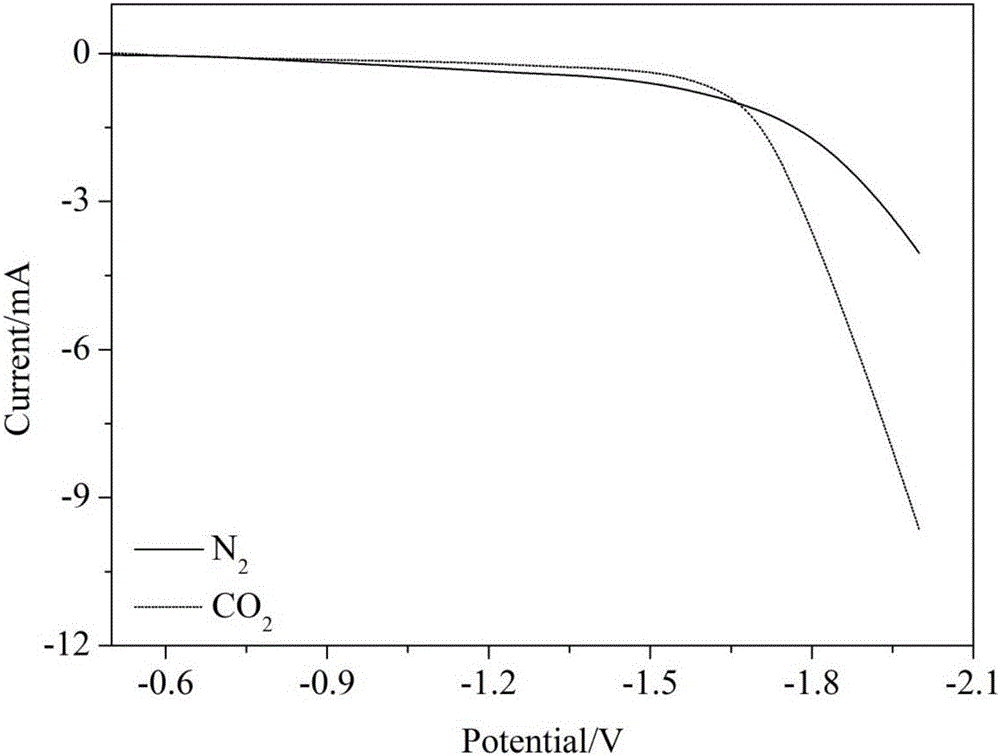

ActiveCN105688971AHigh catalytic activityLow background currentPhysical/chemical process catalystsElectrolytic organic productionGas phaseElectrochemistry

The invention belongs to the field of electrochemistry, and relates to an electrochemical reduction CO2 catalyst based on boron and nitrogen co-doped nano-diamond. A doping agent in the nano-diamond has the nitrogen content of 0-10 at%, the boron content of 0-5 at% and the granularity of 10-500 nm. The nano-diamond is prepared by depositing for 10-20 hours through a hot wire chemical gas-phase depositing method at the tungsten filament temperature of 1900-2200 DEG C and the pressure of 200-2000 Pa, wherein the volume percentage of N2 is 2.5-25%, and the volume percentage of CH4 is 0.5-20%. The catalyst has the advantages of being high in electro-catalysis activity, C2 product selectivity and material stability and the like for electrochemical reduction CO2 reaction, is a nonmetallic electro-catalysis material excellent in performance and low in price, and can be applied to the field of CO2 resourceful utilization.

Owner:DALIAN UNIV OF TECH

Tungsten-copper composite material and preparation method thereof

The invention relates to a tungsten-copper composite material, wherein tungsten and copper are mutually clad and through, and the tungsten-copper composite material comprises the following components in percentage by weight: 60-90 percent of tungsten and the balance of copper. A preparation method of the tungsten-copper composite material comprises the following steps of: washing a tungsten filament with acid, cleaning, and carrying out three-dimensional or two-dimensional braiding to obtain a tungsten filament braided body; placing a copper material into a graphite container, placing the obtained tungsten filament braided body on the copper material, and holding a temperature of 1200-1350 DEG C for 0.5-2h under a vacuum environment with the vacuum degree being larger than 1*10<-3>Pa; cooling to the room temperature in a furnace, and then removing redundant copper from the surface of the obtained green body to obtain the tungsten-copper composite material. The tungsten-copper composite material prepared with the preparation method has the advantages of avoiding the problem of nonuniform texture caused by nonuniform mixing of tungsten and copper alloy prepared by applying a traditional process.

Owner:SHANGHAI UNIV OF ENG SCI

Preparation method of CuInxGa1-xSe2 powder

InactiveCN101531529AShort preparation timeQuick responseFinal product manufactureSemiconductor devicesSelf-propagating high-temperature synthesisArgon atmosphere

The invention relates to a preparation method of CuInxGa1-xSe2 powder which is material of absorption layer material of film solar battery, characterized in that the method comprises the following steps: step 1) of selecting raw materials: weighing Cu powder, In powder, Ga powder and Se powder according to molar ratio of 1:0.7:0.3:(2.1-2.5); step 2) of mixing; step 3) of molding to shape so as to obtain a mixture billet; step 4) of synthesizing: adopting self-propagating high-temperature synthesis, switching on power of igniting tungsten filament under condition of argon atmosphere at 0.1-0.6MPa, igniting the mixture billet to carry out self-propagating high-temperature synthesizing reaction at synthesizing reaction speed of 2-3mm / s; after the reaction, cooling in the furnace, ball milling to obtain the CuInxGa1-xSe2 powder. The preparation method has the features of short preparation time, stable stoichiometric proportion, controllable stoichiometric proportion of product, simple process, high production efficiency and low cost.

Owner:WUHAN UNIV OF TECH

LED lamp bead capable of replacing halogen lamp and manufacturing process thereof

PendingCN106594544AAvoid discolorationExtended service lifeElectric circuit arrangementsSemiconductor devices for light sourcesEngineeringTungsten filament

The invention discloses an LED lamp bead capable of replacing a halogen lamp and a manufacturing process thereof. The LED lamp bead comprises a housing, a base plate, LED wafers and a power supply component. The housing is a transparent glass housing which comprises a cylindrical upper portion and a flat lower portion, the base plate is arranged in the upper portion, the LED wafers are uniformly arranged on front and back surfaces of the base plate, the power supply component is arranged at the lower end of the front surface of the base plate, a molybdenum sheet is arranged at the lower end of the base plate, the molybdenum sheet is connected to the base plate through a molybdenum rod, a contact pin is arranged at the lower end of the molybdenum sheet, the upper end of the contact pin and the molybdenum sheet are arranged in the lower portion, and the lower end of the contact pin is exposed to the outer side of the housing. A conventional tungsten filament halogen lamp is replaced by the LED wafers, and the housing is the glass housing, so that the G9 lamp bead is good in light-emitting effect, low in cost and safe and environmental-friendly, and the service life of the lamp bead is prolonged.

Owner:张健

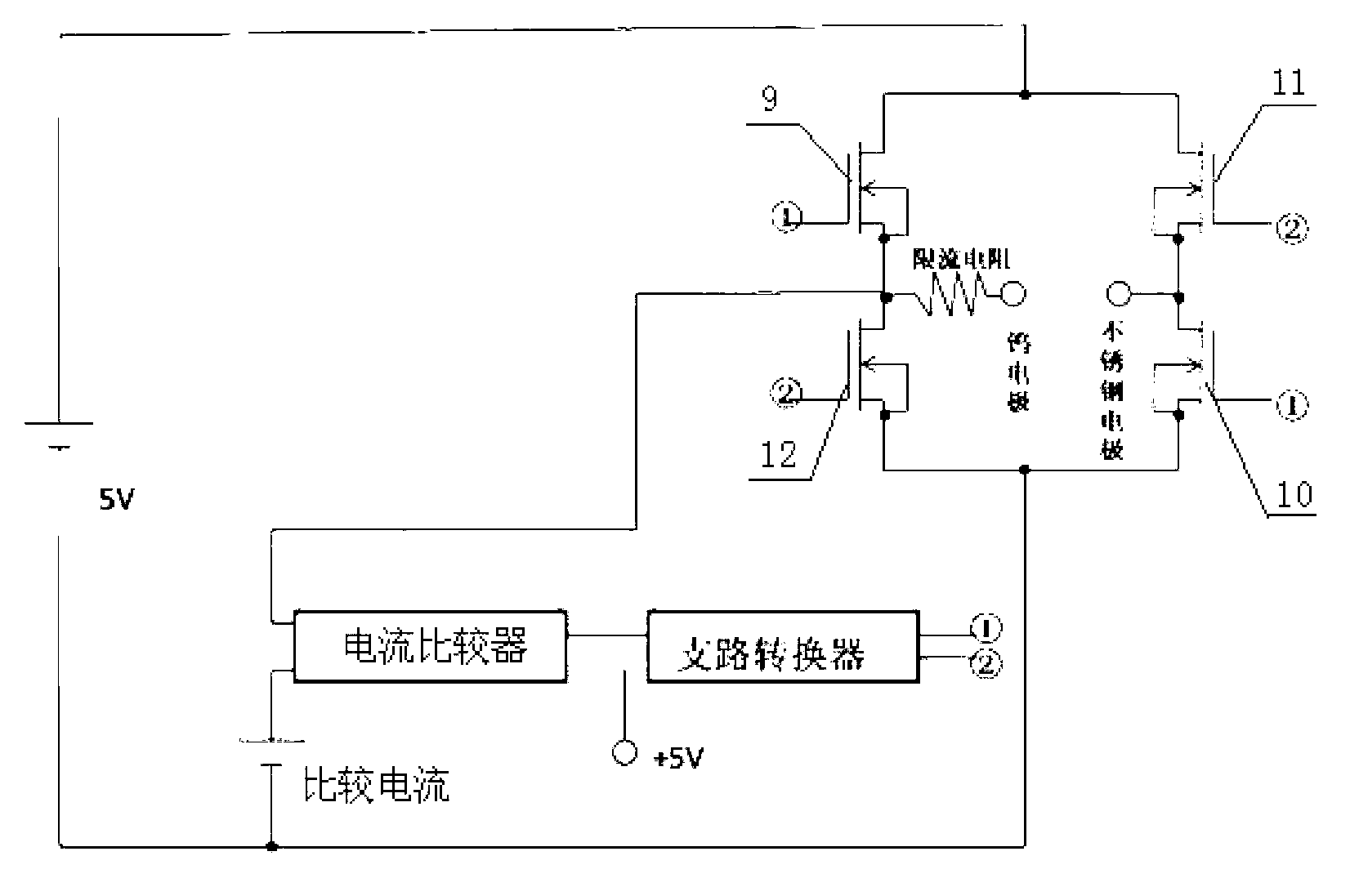

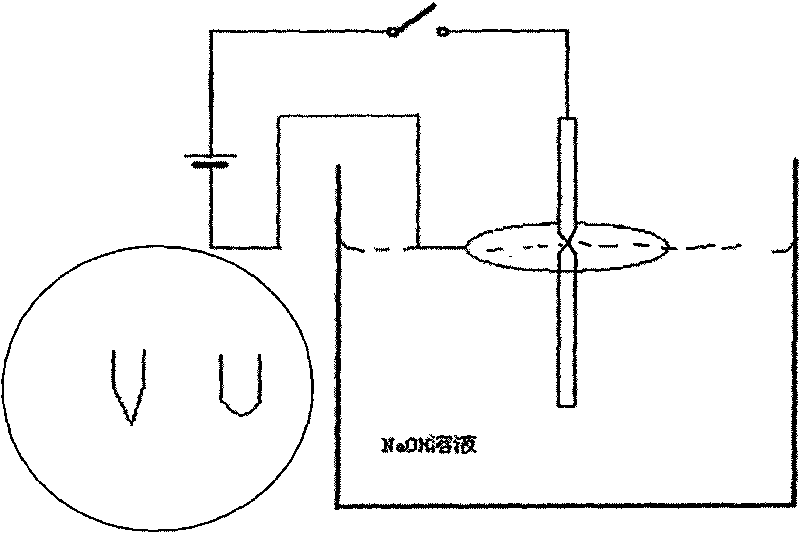

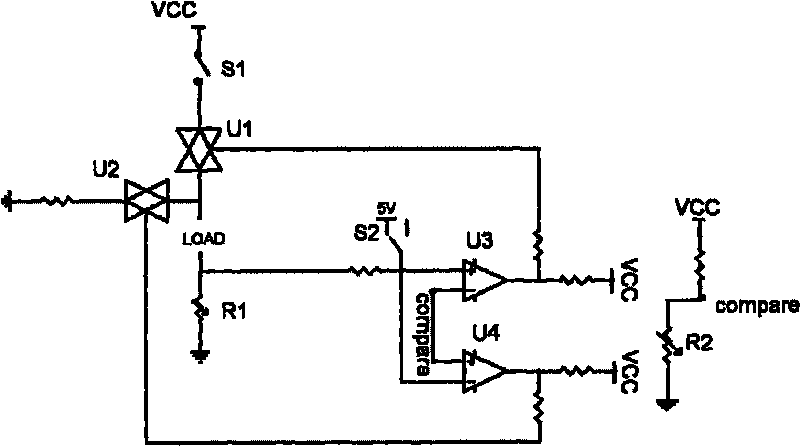

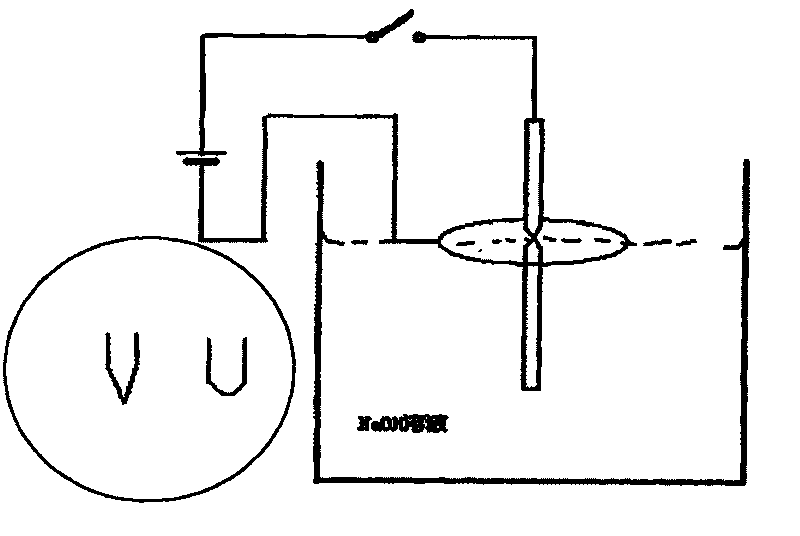

Method and device for preparing pinpoint of scanning tunnel microscope (STM)

InactiveCN101692100ANot let dullEasy to controlNanostructure manufactureScanning probe microscopyScanning tunneling microscopeScanning electron microscope

The invention provides a method for preparing a pinpoint of a scanning tunnel microscope (STM). The invention adopts the method of electrochemical corrosion, wherein the NaOH solution is taken as etchant solution; the copper electrode is taken as the negative pole; the tungsten filament is taken as the positive pole; in the electrochemical corrosion process, the tungsten filament at the liquid surface of the etchant solution is thinner and thinner and finally cracks to form a pinpoint, and the power circuit of the electrochemical corrosion is cut off in the instant that the tungsten filament is disconnected; a tungsten filament positive pole is arranged to string into the circuit of electrochemical corrosion to prepare the negative pole copper electrode into a ring shape; and simultaneously, the positive electrode tungsten filament is placed in the center of the ring-shaped circle and placed in the corrosion solution evenly; and the condition of the electrochemical corrosion is that the pressure of the pinpoint is 7-8V.

Owner:NANJING UNIV

Miniaturized heat-resistant and high-dynamic pressure sensor

ActiveCN108871652ASolve the problem of high temperature failureImprove high temperature stabilityFluid pressure measurement by electric/magnetic elementsAdhesiveEngineering

A miniaturized heat-resistant and high-dynamic pressure sensor comprises a sensor probe which is internally provided with a sensor chip, the sensor chip is fixed through a heat-resistant ceramic adhesive, the sensor probe is connected with a metal tungsten filament which passes through a seal plate, and the seal plate is connected with the sensor probe; the front end face of the sensor probe is provided with a pressure guidance hole which communicates with a pressure channel and a square sensor chip in the sensor probe, the rear end of the sensor chip installation groove is provided with a sensor vacuum chamber, and the side wall of the sensor probe is internally provided with a the metal tungsten filament taken as a lead terminal of the pressure sensor; the sensor chip is square-shaped, four sensitive resistors are arranged at the front surface of the sensor chip in the same direction, the back surface of the sensor chip is a square cavity corresponding to a square sensitive film, andthe pressure is applied to the square sensitive film through the pressure guidance hole. The miniaturized heat-resistant and high-dynamic pressure sensor is small in volume, resistant to heat and fast in response, and can be used for measurement of the total pressure and the static pressure.

Owner:XI AN JIAOTONG UNIV

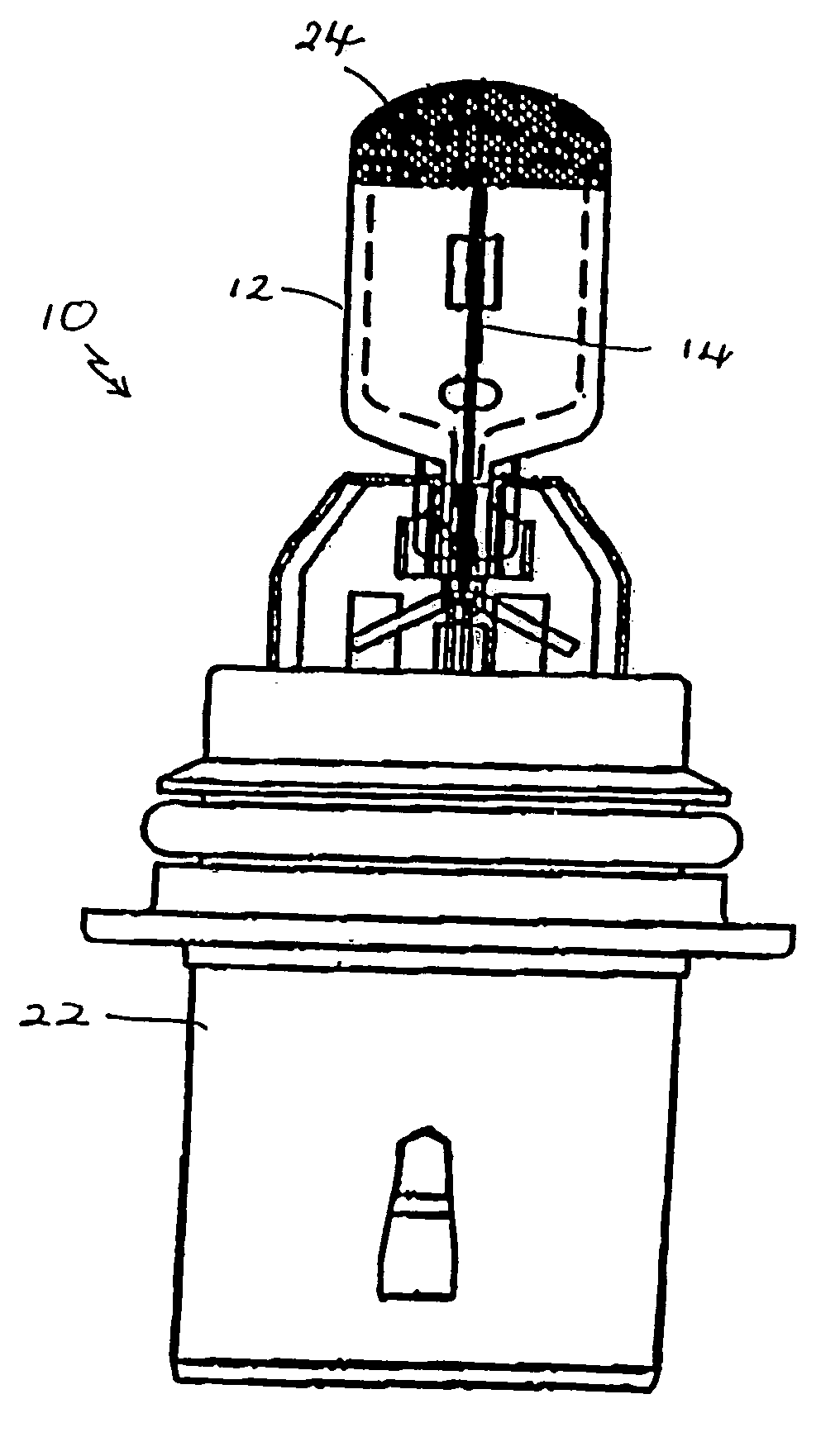

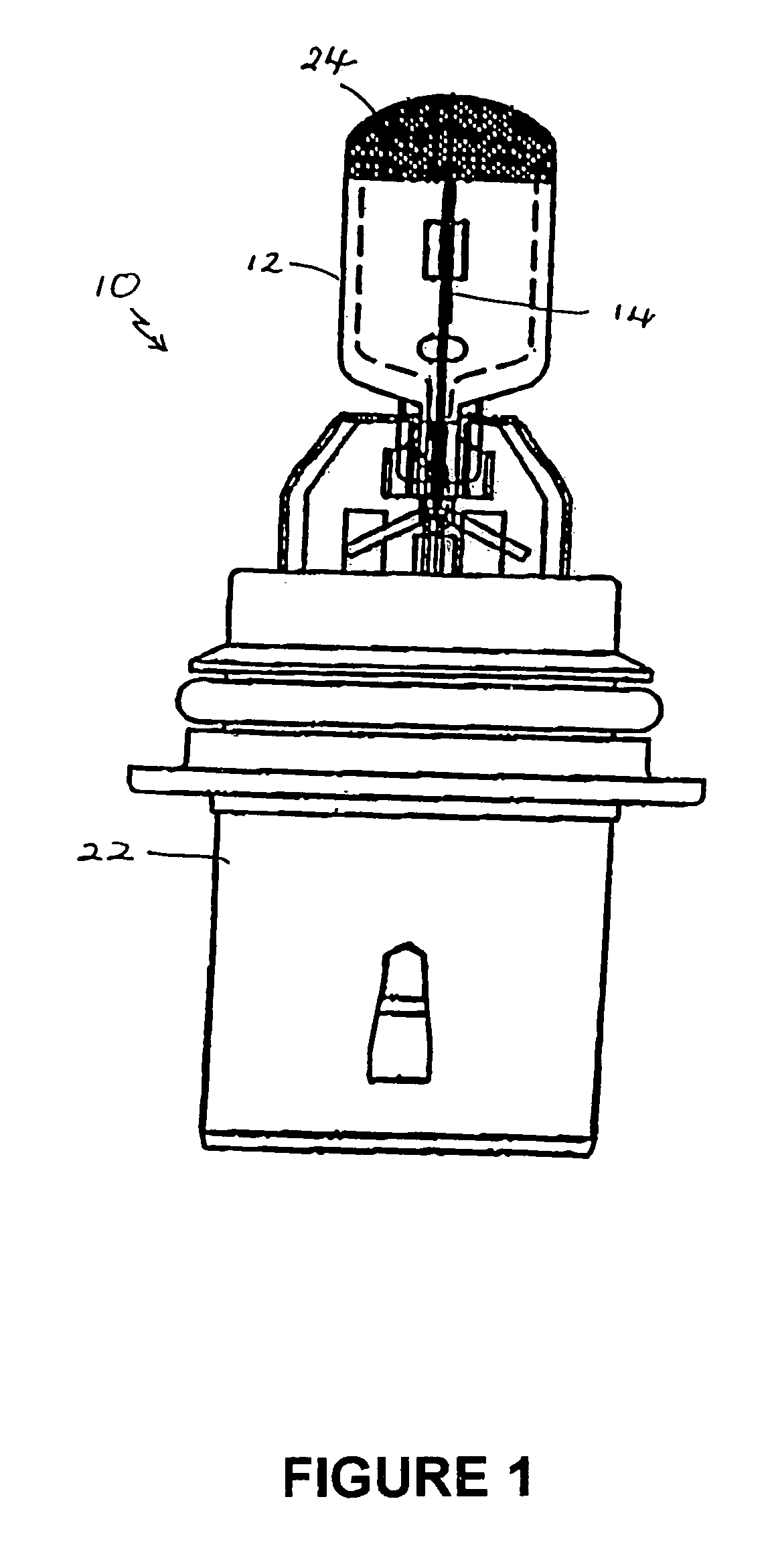

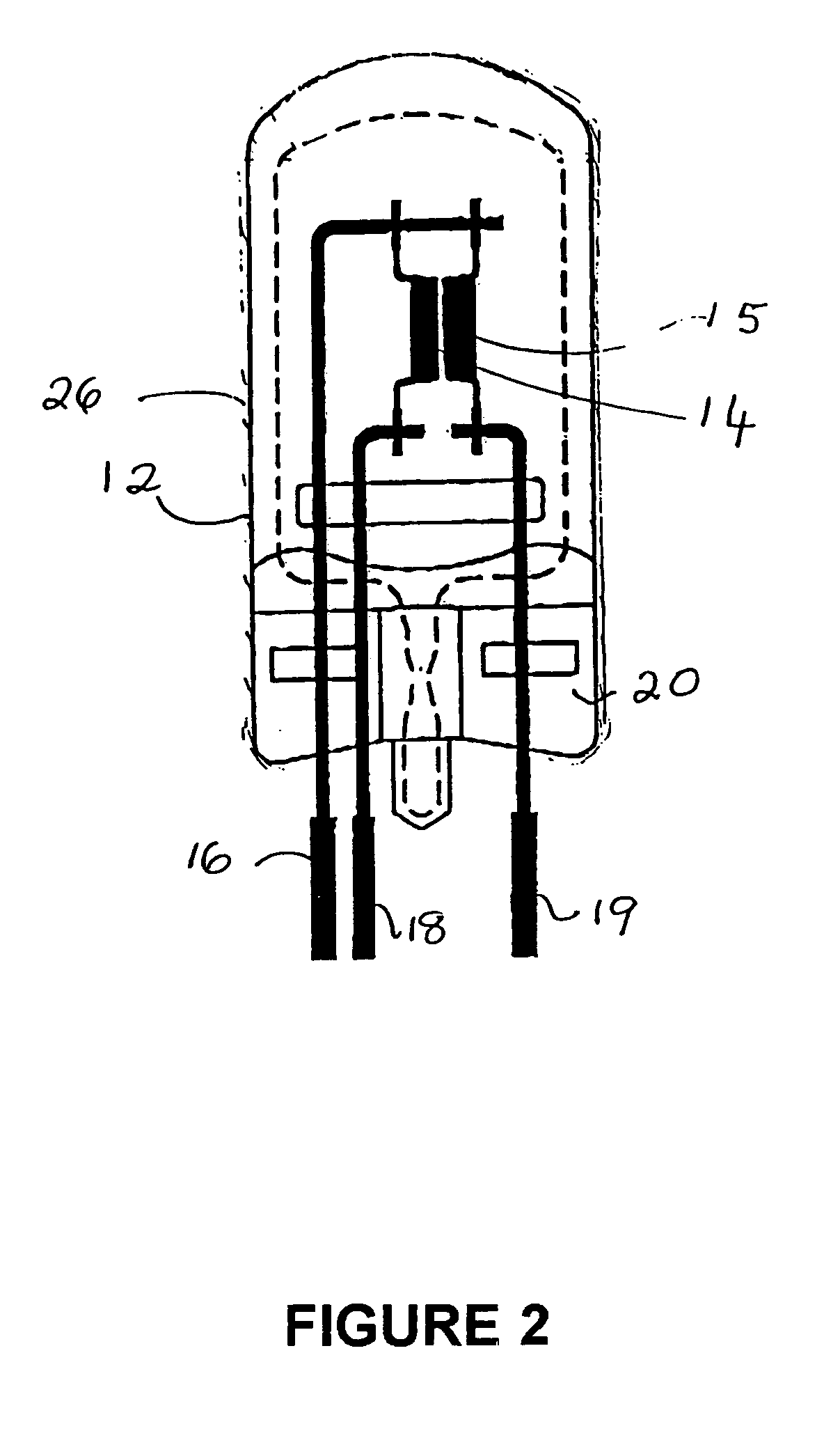

Tungsten halogen lamp with halogen-containing compound and silicon-containing compound

InactiveUS6956328B1Easy maintenanceObvious advantagesIncandescent lamp energy savingSolid cathode detailsCompound aHalogen

A tungsten halogen lamp (10) includes a light transmissive envelope (12), which encloses a tungsten filament (14) and a gaseous fill comprising an inert gas and a halogen-containing gas, such as an alkyl halide. In addition the fill includes a silicon-containing compound capable of gettering oxygen within the envelope. The atomic ratio of silicon to halogen in the envelope is selected so as to remove most, but not all of the oxygen present in the envelope A silicon:halogen ratio of less than about 0.5 more preferably, below about 0.4 has been found to be effective in this respect.

Owner:GENERAL ELECTRIC CO

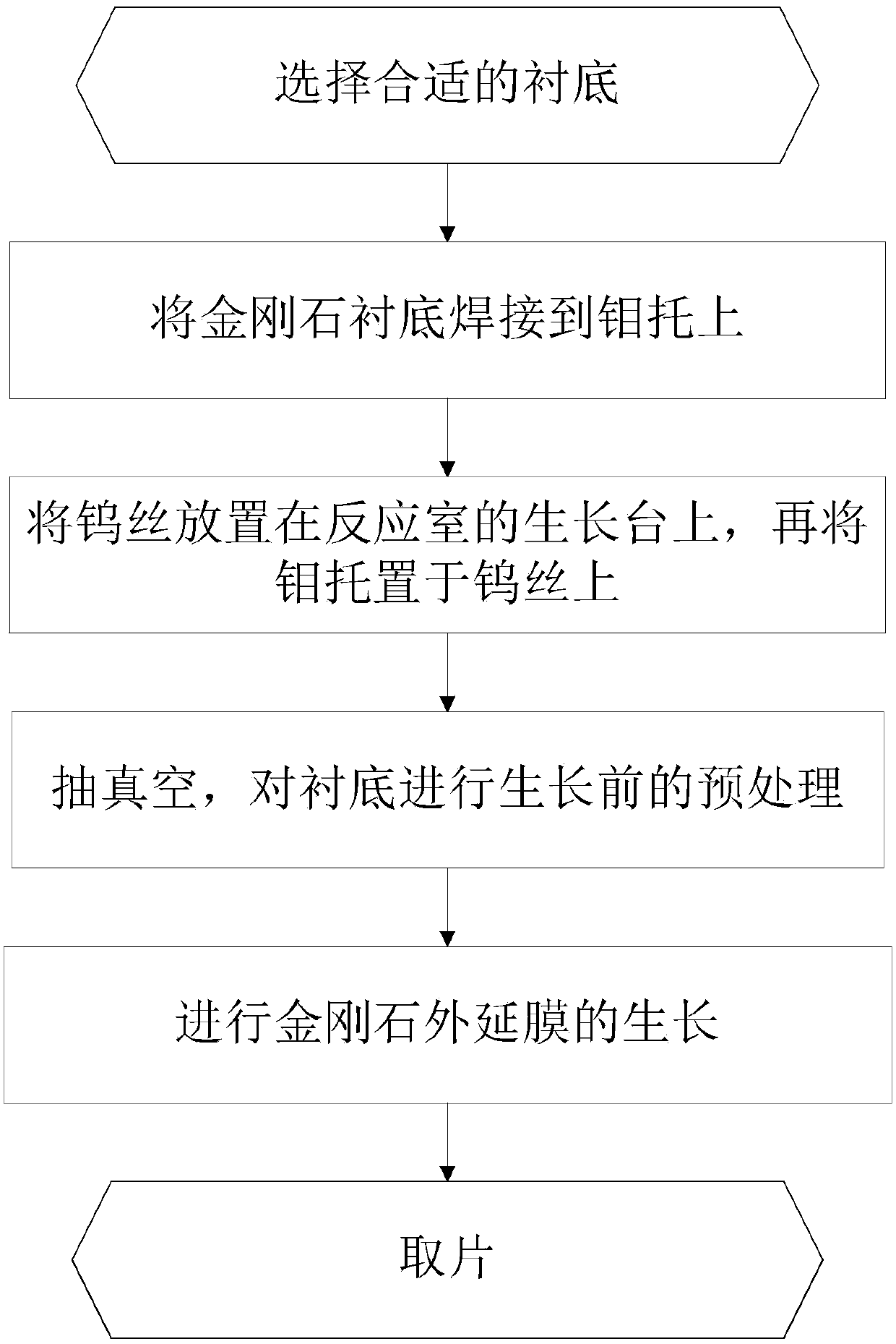

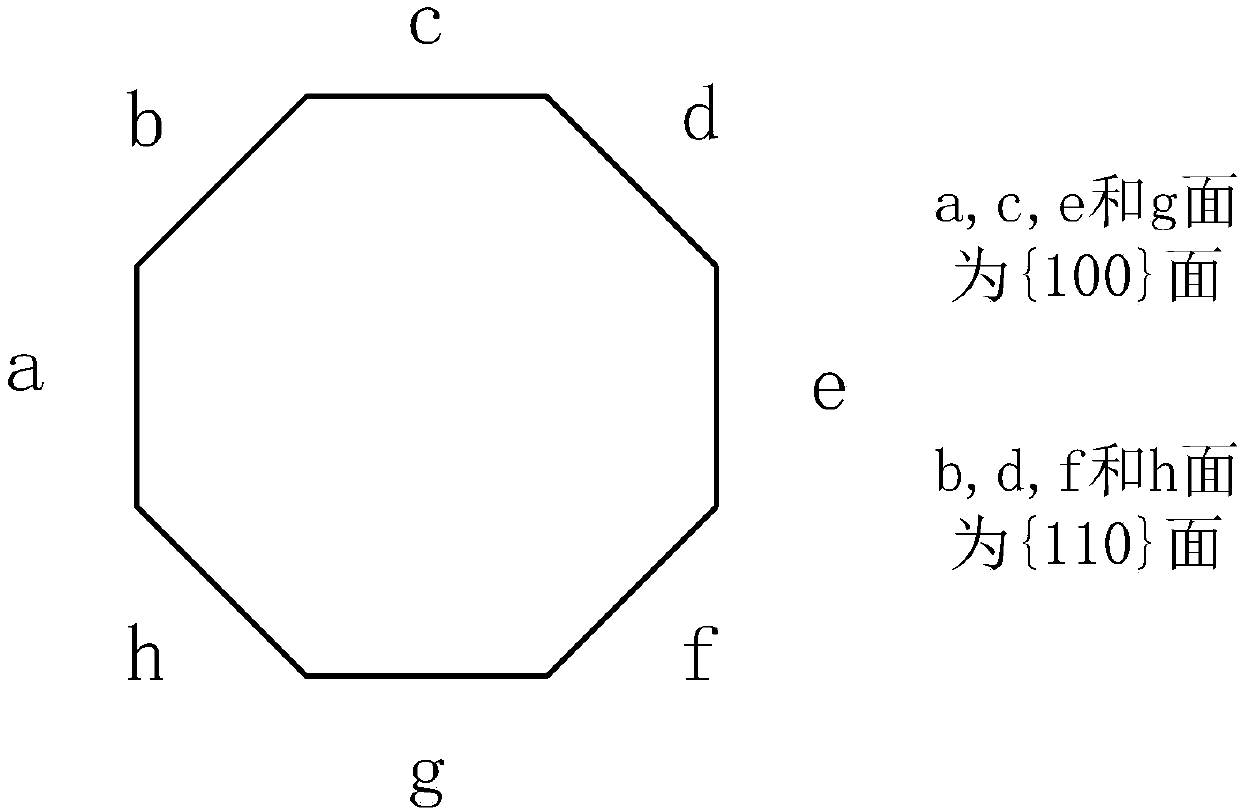

Diameter enlarging growth method of monocrystal diamond

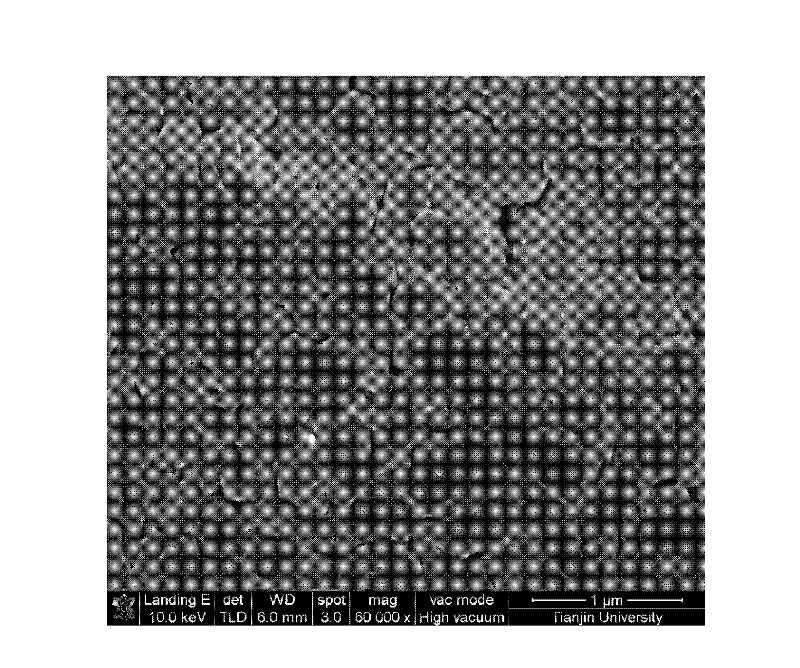

ActiveCN107675249AReduce polycrystalline contentEffective diameter expansionPolycrystalline material growthFrom chemically reactive gasesSingle crystalField-effect transistor

The invention discloses a diameter enlarging growth method of monocrystal diamond. The diameter enlarging growth method of monocrystal diamond comprises following steps: 1, an octagonal high temperature high pressure diamond substrate is selected, wherein the side surfaces of the octagonal high temperature high pressure diamond substrate are designed to be alternatively arranged {100} crystal faces and {110} crystal faces; 2, a molybdenum support is introduced into a reaction chamber, a piece of gold foil is placed on the molybdenum support, the octagonal high temperature high pressure diamondsubstrate is placed on the molybdenum support, the reaction chamber is vacuumized, the octagonal high temperature high pressure diamond substrate is heated in the reaction chamber until the gold foilis melted, and then the octagonal high temperature high pressure diamond substrate is welded onto the molybdenum support; 3, tungsten filaments are placed on a growth platform in the reaction chamber, and the molybdenum support welded with the octagonal high temperature high pressure diamond substrate is placed on the tungsten filaments for surface defect and injury etching pretreatment; and 4, the pressure, the temperature, microwave frequency, methane concentration, and growth time in the reaction chamber are controlled, so that growth of monocrystal diamond epitaxial film with a thicknessranging from 0.5 to 2.5mm on the octagonal high temperature high pressure diamond substrate obtained via pretreatment is realized. The diameter enlarging growth method is capable of reducing the content of polycrystal in the monocrystal diamond epitaxial film, and ensuring diameter enlarging effectiveness, and can be used for manufacturing of diamond field effect transistors.

Owner:湖州中芯半导体科技有限公司

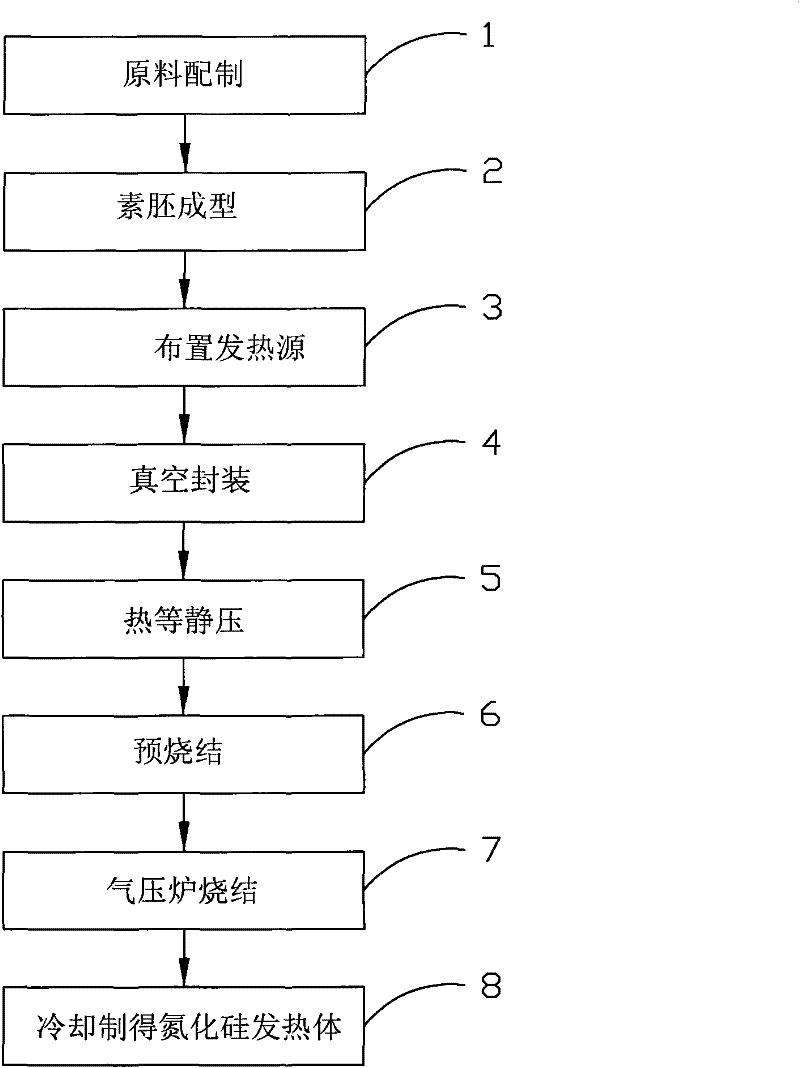

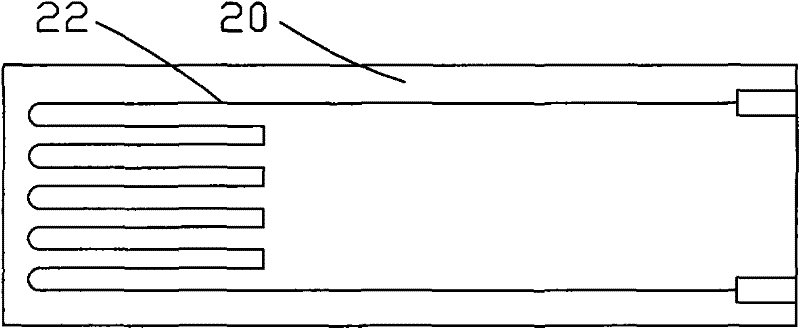

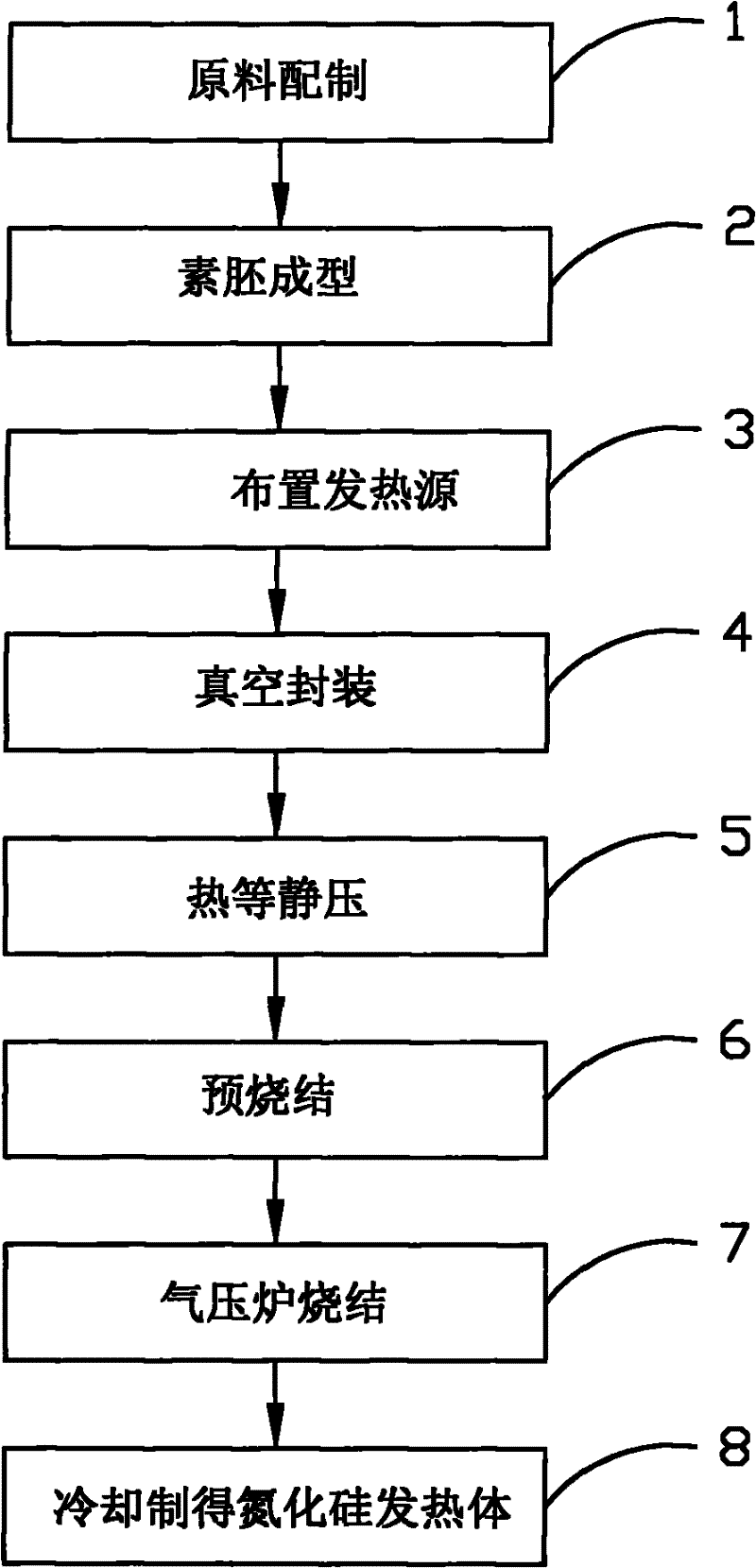

Silicon nitride heat generator and manufacturing method thereof

InactiveCN101754497AImprove thermal shock performanceImprove pass rateHeating element materialsHeat conductingTungsten filament

The invention provides a silicon nitride heat generator and a manufacturing method thereof. The silicon nitride heat generator comprises a heat generating source and a heat generating main body, wherein the heat generating source is a tungsten filament; the heat generating main body is prepared from the following components in part by weight: 88-92 parts of silicon nitride, 6.5-8.5 parts of aluminum oxide and 1.5-3.5 parts of yttrium oxide. The invention has the advantages that the manufacture processing is simple, and the operation process is easy to control; the silicon nitride heat generator manufactured by the method has higher qualified rate of the finished product, higher heat conducting property and higher heat efficiency; and the silicon nitride also has good thermal shock property.

Owner:贺连英

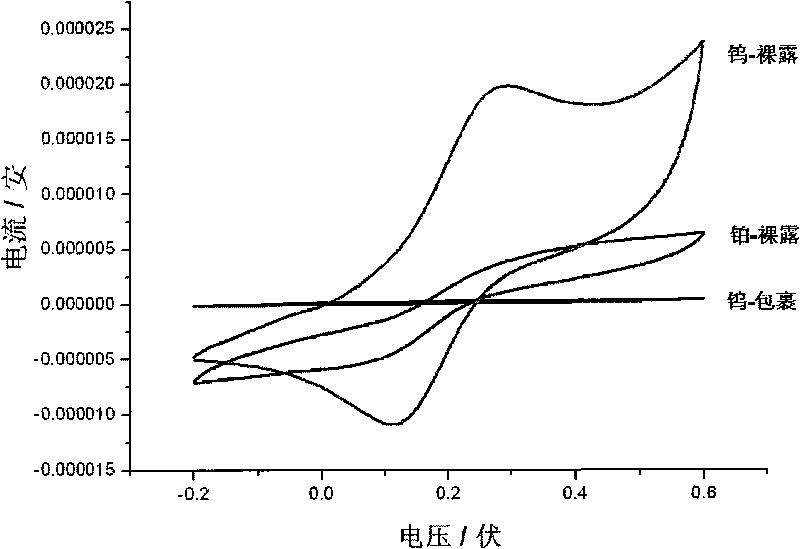

Method for preparing boron-doped diamond film electrode for detecting dopamine

InactiveCN102520042AImprove performanceHigh impedanceMaterial analysis by electric/magnetic meansTyrosinaseIn vivo

The invention discloses a method for preparing a boron-doped diamond (BDD) film electrode for detecting dopamine (DA), characterized by using a sharp tip-shaped tungsten filament as a substrate, depositing a BDD film on the tungsten filament, activating the surface amino groups of the diamond film, then directly preparing a tyrosinase modification layer on the BDD film, wherein the tungsten filament is connected with a guide wire through a silver paste. The BDD film electrode is used as a biological probe, cyclic voltammetry is used to detect the DA content, and the concentration of DA in vivo can be detected in real time. According to the invention, the electrode prepared by the invention has good repeatability and electrochemical stability for detecting DA, has high sensitivity and strong selectivity, the modified BDD electrode can effectively separate oxidation peaks of DA and ascorbic acid (AA) in a solution containing AA that is many times DA and an ideal linear response relation is obtained in a wide range; the prepared electrode has extremely good anti pollution capability and long life, can not generate passivation pollution, and the needle-type electrode is beneficial for implanting operation of sensors in surgery.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Silicon nitride heating element and making method thereof

The invention provides a silicon nitride heating element and a making method thereof. The silicon nitride heating element comprises a carrier, a heating tungsten filament with an electrode and a conducting wire, wherein the carrier is prepared from 85-93wt% of silicon nitride powder, 0.4-6wt% of yttrium oxide powder, 1.5-10wt% of lanthanum oxide powder and 0.1-12wt% of aluminum oxide powder, the heating tungsten filament is embedded in the carrier, the electrode of the heating tungsten filament is arranged at one end of the carrier, and the conducting wire is in welding connection with the electrode of the heating tungsten filament. The making method of the silicon nitride heating element comprises the steps of making a silicon nitride biscuit, making a silicon nitride heating element matrix, welding the conducting wire and the like. The carrier of the silicon nitride heating element is made by mixing the silicon nitride powder, the aluminum oxide powder, the yttrium oxide powder and the lanthanum oxide powder so that the high-temperature (higher than 1300 DEG C) fracture toughness of the carrier is higher than that of a carrier made by mixing the silicon nitride powder, the yttrium oxide powder and the aluminum oxide powder, and absolute ethyl alcohol is replaced by distilled water as a mixed powder blender in the making process so that the making cost can be reduced, and the environmental potential safety hazard can be improved.

Owner:浙江美工精细陶瓷科技有限公司

Halogen tungsten lamp bulb having lamp bulb-contained lamp bulb structure

InactiveCN102354655AEasy to useNot easy to fuseEnergy efficient lightingGas filling substancesKryptonEngineering

The invention discloses a halogen tungsten lamp bulb having a lamp bulb-contained lamp bulb structure. The halogen tungsten lamp bulb comprises: a lamp bulb housing; a lamp socket; and tungsten filament leads, which is connected on a joint of the lamp socket. Besides, the tungsten filament leads are connected with tungsten filaments through aluminium molybdenum sheets; a halogen bulb is arranged outside the tungsten filaments and is filled with krypton gases. According to the invention, a halogen bulb is arranged outside tungsten filaments and is filled with krypton gases, so that a using efficacy of the tungsten filaments is improved; and thus a brightness of the lamp bulb on the equal power condition is enhanced to over 30%. Moreover, due to protection of the krypton gases, the tungsten filaments are not easy to fuse, even if the tungsten filaments have been used for a long time, so that service life the lamp bulb is improved.

Owner:宿迁市亚明电器有限公司

Method for producing tungsten bar serving as halogen tungsten lamp tungsten filament

ActiveCN102198507AFine and uniform crystals on the cross-sectionAvoid spikesHalogenAmmonium paratungstate

The invention provides a method for producing a tungsten bar serving as a halogen tungsten lamp tungsten filament, comprising the following steps of: material selecting, pre-reducing, high potassium doping, reducing, acid rinsing, powder preparing, cold static pressure shaping, high temperature sintering and the like. Compared with the conventional technology, the method is characterized in that two crystal ammonium paratungstates are utilized to prepared raw materials, high potassium doping is adopted, preparation of middle granule tungsten powder is added, a powder distribution scheme is optimized by the middle granule tungsten and a unique incipient fusion high temperature sintering process is utilized. In the method, the granularity distribution of the tungsten powder avoids the peak or double peak phenomenon and has good normal distribution, after being sintered at high temperature, the cross section crystal of the tungsten bar is thin and uniform; the tungsten bar is pressed by a powder mixing scheme; according to a forming mechanism of potassium foams, the number of tungsten bar cross section crystal grains is increased; and the partial growth of the crystal grains is avoided so that the potassium foam is small in aperture, large in density, multiple in crystal boundary, long in line and uniform in distribution.

Owner:GANZHOU HONGFEI TUNGSTEN & MOLYBDENUM MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com