Light-emitting diode (LED) automobile headlamp

A technology for LED lamps and automobiles, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., and can solve the problems of low LED power and poor heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

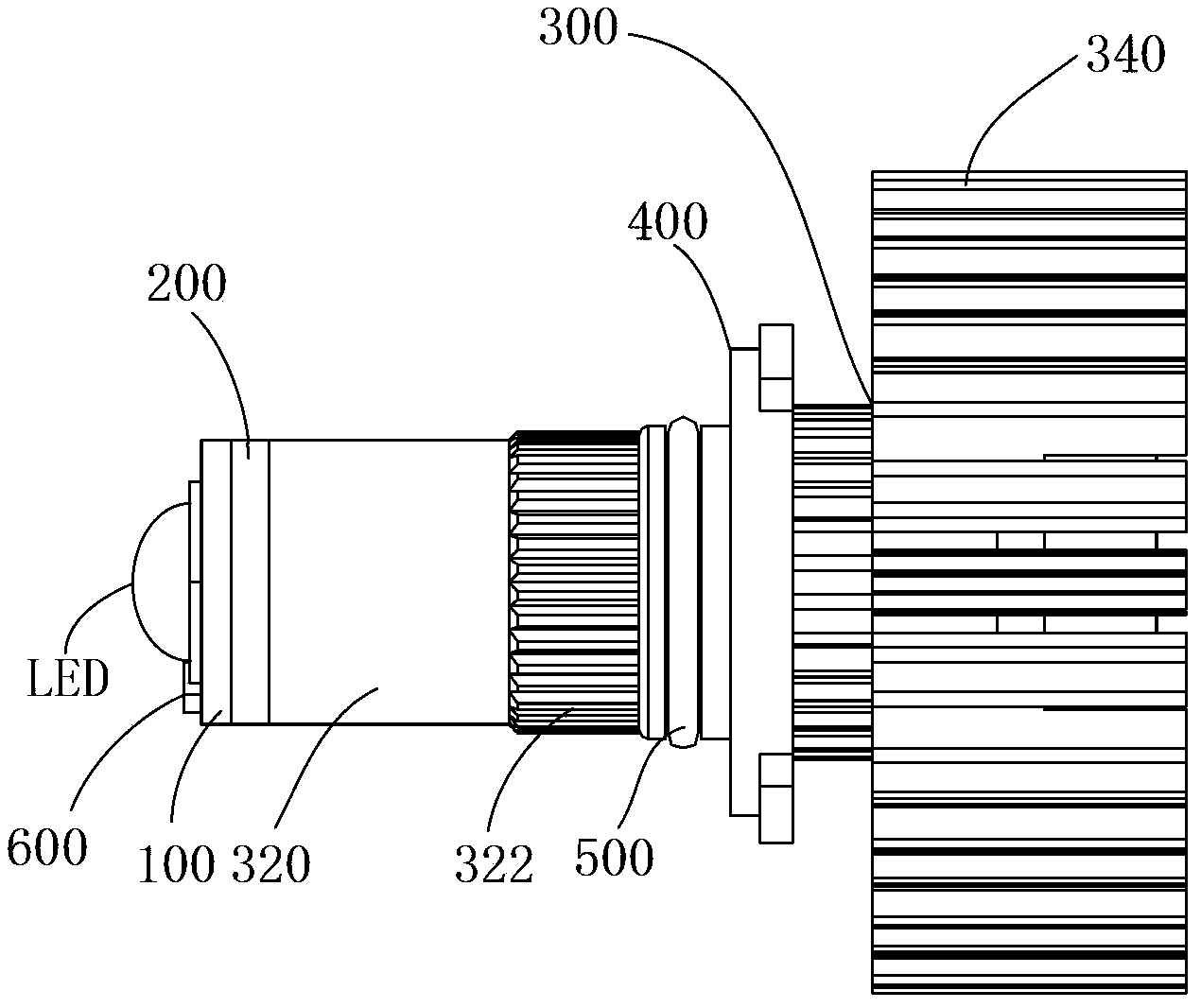

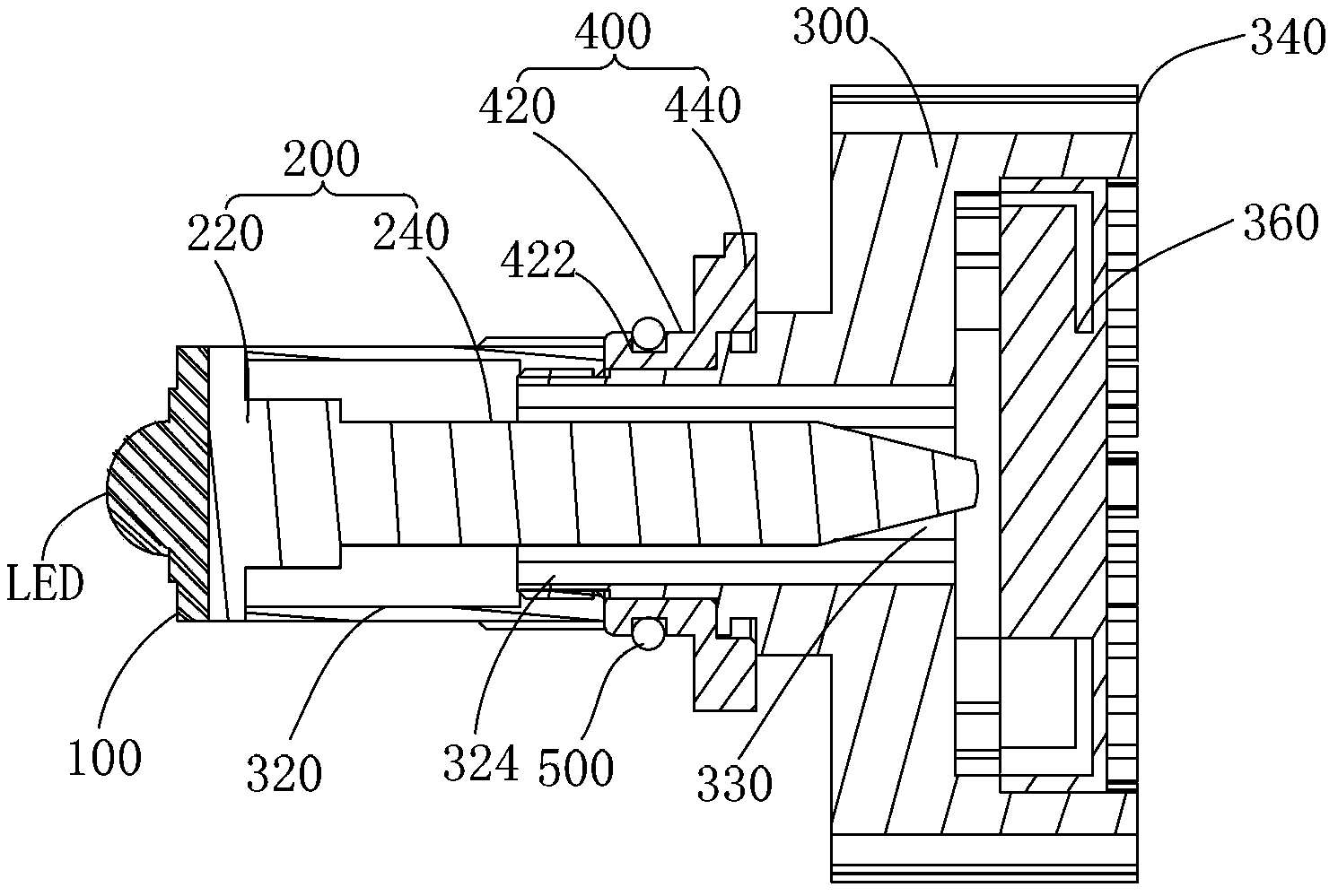

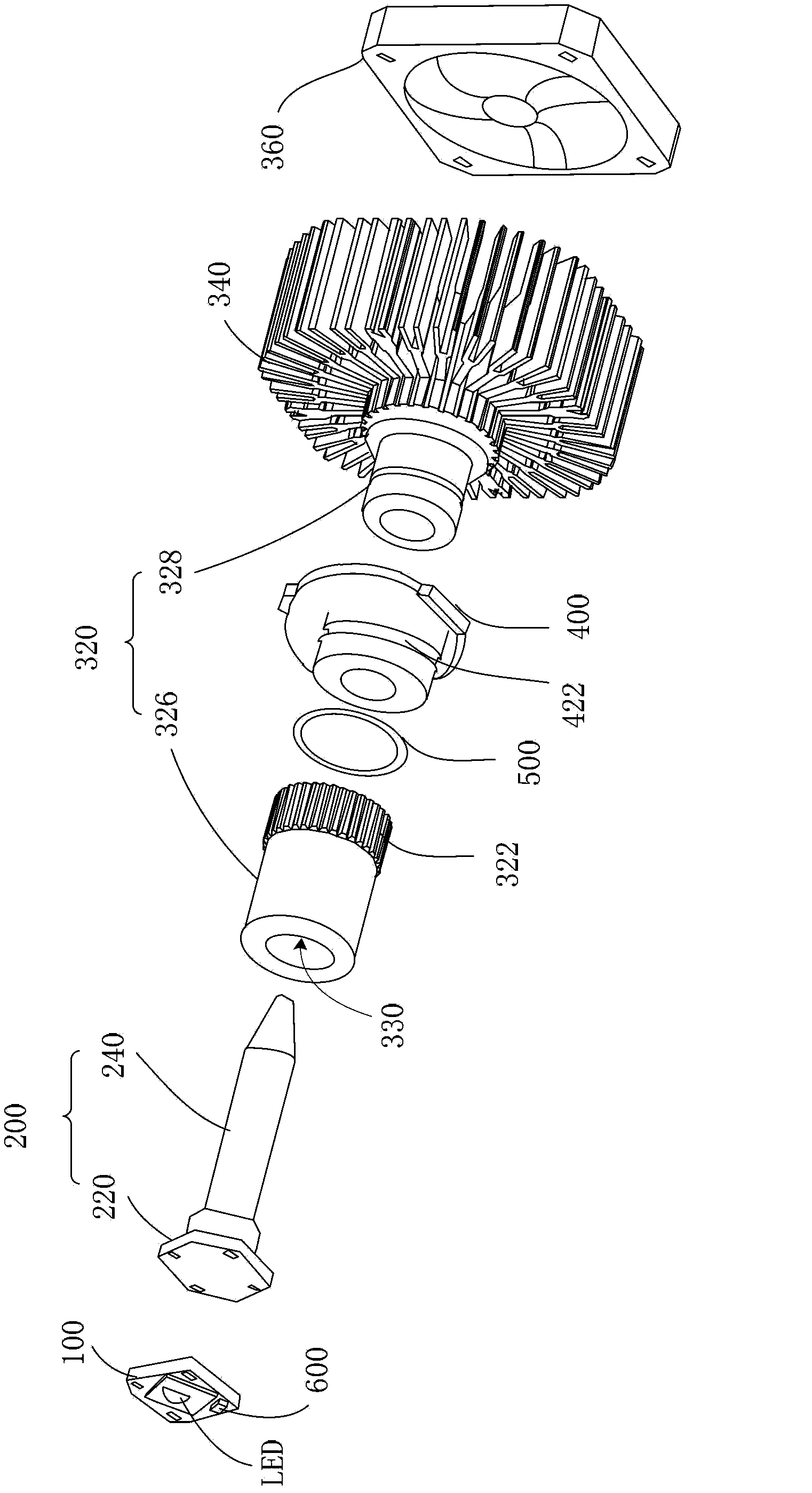

[0033] Such as figure 1 Shown is an LED automobile headlight in an embodiment, including: an LED lamp, a substrate 100 , a heat conduction member 200 , a heat dissipation member 300 and a locking member 400 .

[0034] The LED lamp is arranged on the substrate 100, and the substrate 100 is a PCB board (Printed circuit board, printed circuit board). In this embodiment, there can be one LED lamp or multiple LED lamps. Of course, multiple substrates 100 may also be provided on the same substrate 100 . Multiple LED lights can increase the brightness of LED car headlights.

[0035] The heat conduction member 200 is elongated, that is, cylindrical, cuboid, polyhedron elongated, etc. The substrate 100 is fixed on one end of the heat conduction member 200. When the LED automobile headlight is working, the LED lamp on the substrate 100 emits heat, and the heat conduction The member 200 transfers heat from one end provided with the substrate 100 to the other end.

[0036] In a preferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com