Preparation method of tungsten carbide particle enhanced steel-base surface layer composite bar

A technology of tungsten carbide particles and composite rods is applied in the field of preparation of tungsten carbide particles reinforced steel-based surface layer composite metal rods, which can solve the mechanical property damage of the overall composite material, difficult to control the volume fraction of ceramic particles, uneven dispersion of ceramic particles, etc. problems, to achieve the effect of a wide range of use, dense organization, and uniform distribution of the second phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

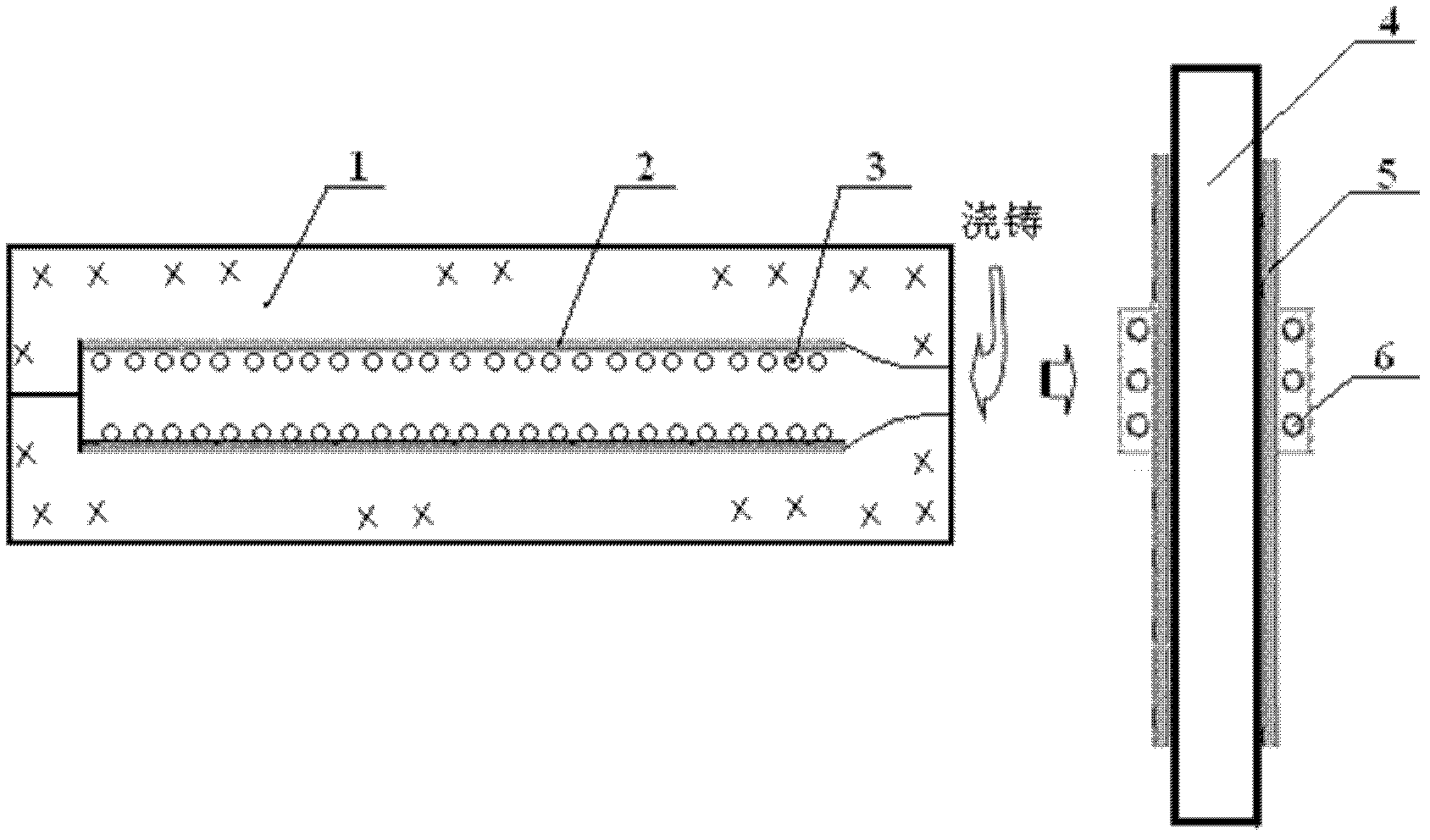

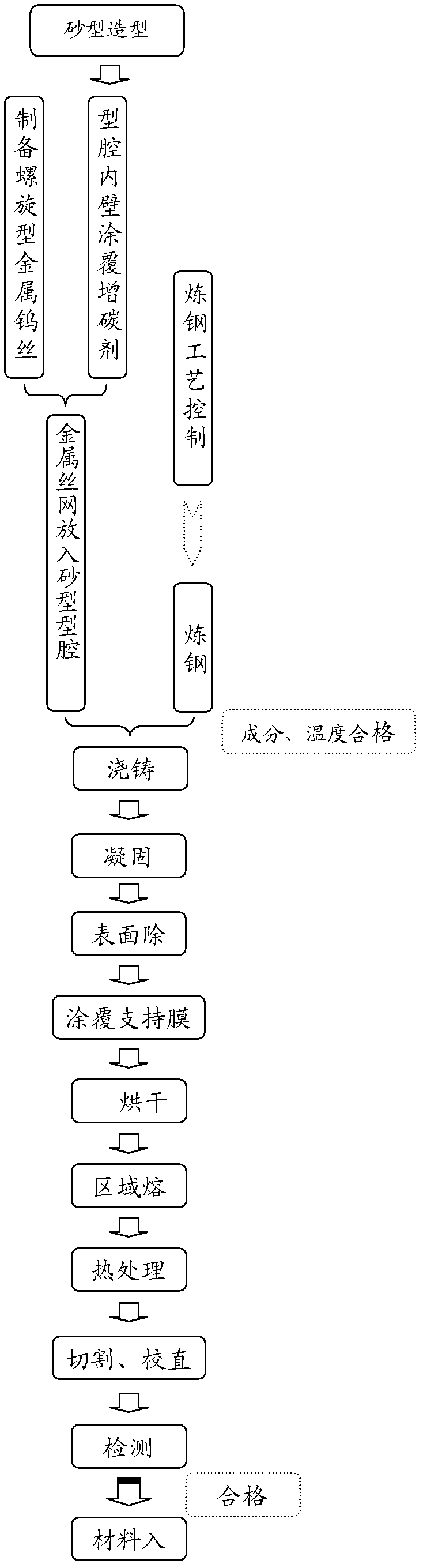

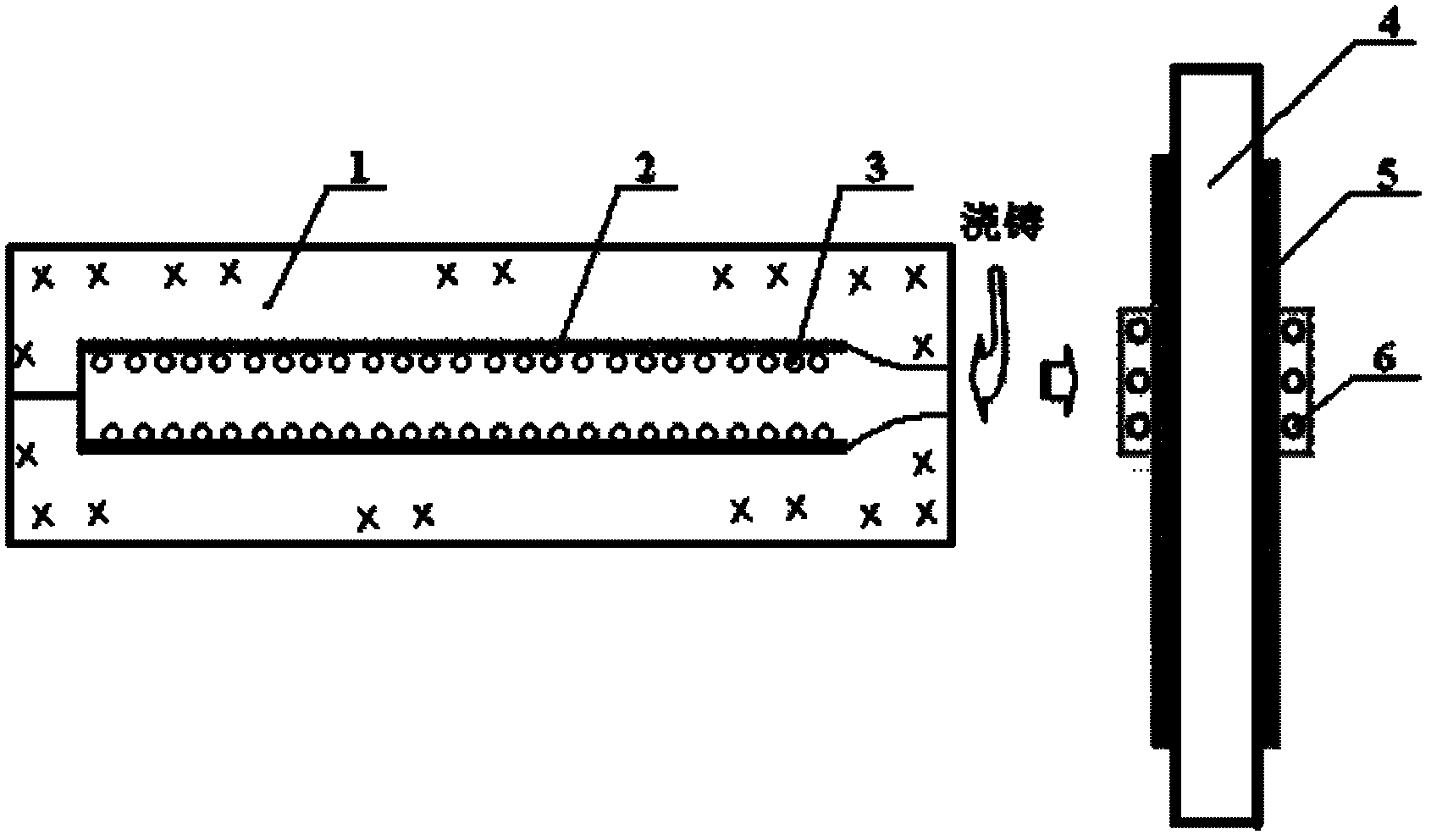

[0020] Example 1: Preparation of tungsten carbide particle-reinforced steel-based surface layer composite metal rod

[0021] In this example, a micron-sized diameter tungsten wire is used to in-situ synthesize a hard reinforcing phase WC with high hardness and high elastic modulus in the metal matrix through the reaction between W element and C, thereby forming a high-strength and high-toughness alloy steel WC particle / metal matrix composite rod with a certain volume fraction of WC particles as the wear-resistant hard phase. In this way, not only the toughness and plasticity of metal materials are maintained, but also the characteristics of high hardness reinforced materials are good in wear resistance, so the application prospect is very broad. Moreover, the size, distribution, quantity and thickness of the composite layer of the reinforcing particles WC can be effectively controlled by choosing a reasonable preparation process.

[0022] The specific production operation pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com