Diameter enlarging growth method of monocrystal diamond

A single crystal diamond and growth method technology, applied in the field of microelectronics, can solve problems such as hindering the effective diameter expansion of the upper surface of a single crystal epitaxial film, and achieve the effects of reducing the content of polycrystals, effective diameter expansion growth, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

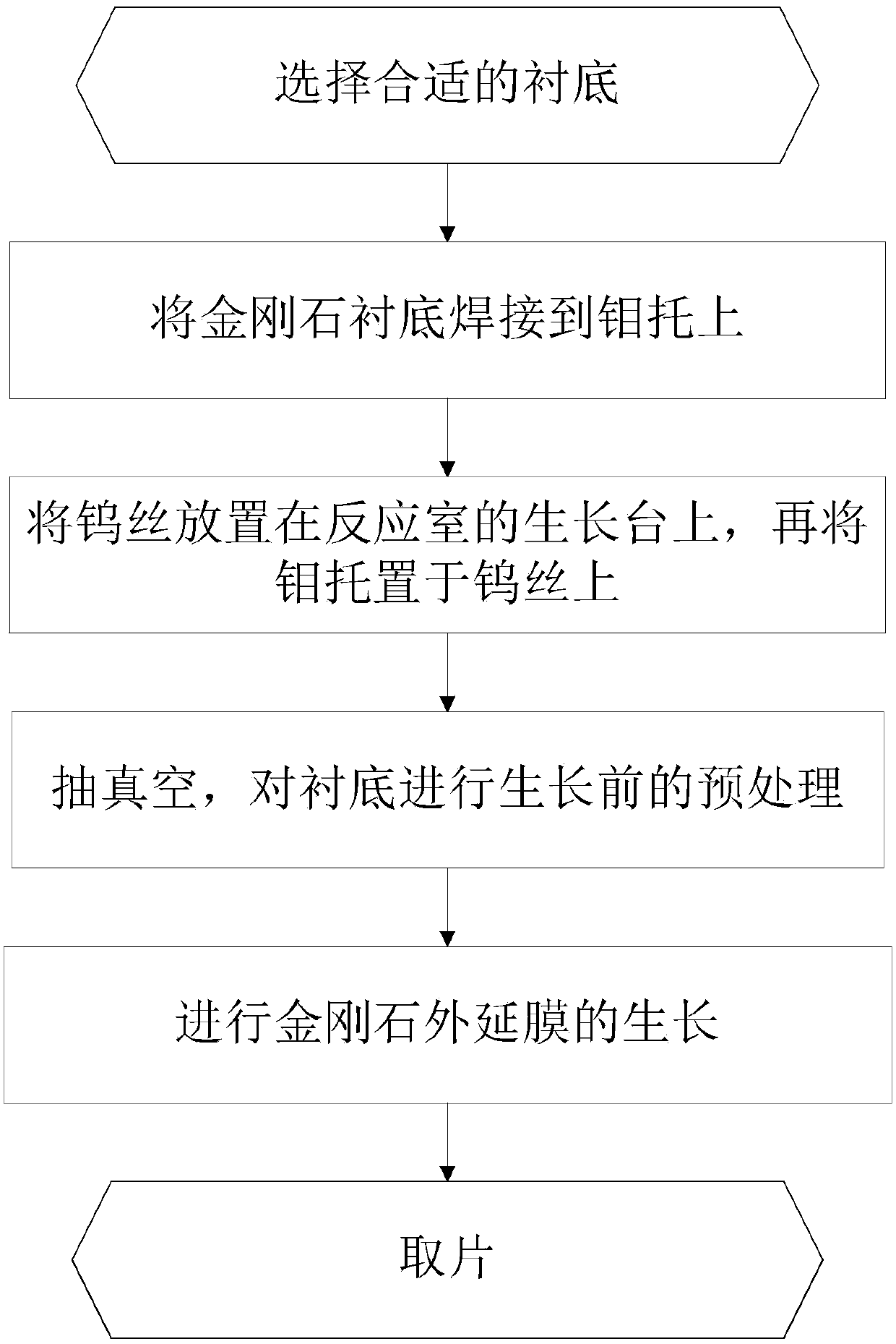

Method used

Image

Examples

Embodiment 1

[0018] Example 1, based on an octagonal HPHT diamond substrate, a diamond epitaxial film with a (001) crystal plane and a thickness of 0.5 mm was grown.

[0019] Step 1, select the substrate.

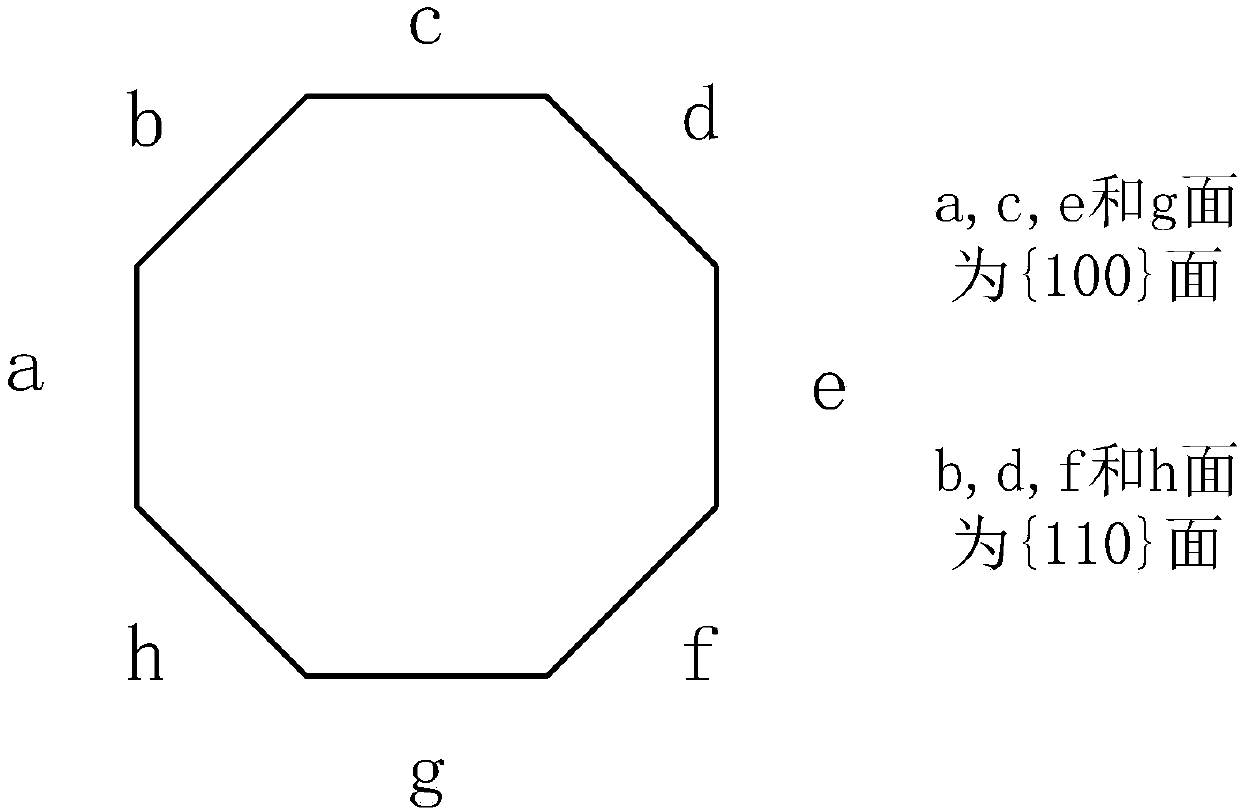

[0020] refer to figure 2 In this example, octagonal high-temperature and high-pressure HTHP diamond is selected as the substrate. The upper surface of the substrate is a (001) crystal plane, and the side surface is a {100} crystal plane alternated with a {110} crystal plane, that is, a plane, c plane, e plane The plane and g plane are {100} crystal planes, and the b, d, f and h planes are {110} crystal planes.

[0021] Step 2, welding the diamond substrate to the molybdenum support.

[0022] Place the molybdenum holder in the MPCVD reaction chamber, place a 25 μm thick gold foil on the molybdenum holder, and then place the selected high-temperature and high-pressure HPHT diamond substrate on the gold foil;

[0023] Evacuate the reaction chamber to a vacuum value of less than 10 -6 ...

Embodiment 2

[0030] Example 2, based on an octagonal HPHT diamond substrate, a diamond epitaxial film with a (001) crystal plane and a thickness of 1.2 mm was grown.

[0031] Step A, select the substrate.

[0032] The specific implementation of this step is the same as step 1 of Example 1.

[0033] Step B, welding the diamond to the molybdenum support.

[0034] Place a molybdenum holder in the MPCVD reaction chamber, place a 50 μm thick gold foil on the molybdenum holder, place the selected high-temperature and high-pressure HPHT diamond substrate on the gold foil, and vacuum the reaction chamber to make the vacuum degree of the reaction chamber less than 10 -6 mbar, the substrate is heated in the reaction chamber until the gold foil is melted, and the diamond substrate is welded to the molybdenum holder.

[0035] Step C, placing a tungsten wire with a diameter of 200 μm on the growth stage of the MPCVD reaction chamber, and placing the molybdenum holder welded with the substrate on the ...

Embodiment 3

[0041] Example 3, based on an octagonal HPHT diamond substrate, a diamond epitaxial film with a thickness of 2.5 mm and a (001) crystal plane was grown.

[0042] The implementation steps of this example are as follows:

[0043] Step 1, select the substrate.

[0044] The specific implementation of this step is the same as step 1 of Example 1.

[0045] Step 2: Place the molybdenum holder in the MPCVD reaction chamber, place the gold foil on the molybdenum holder, and then place the selected high-temperature and high-pressure HPHT diamond substrate on the gold foil. After the MPCVD reaction chamber is evacuated, the substrate is heated until the gold foil melts, and the diamond substrate is welded to the molybdenum support, wherein:

[0046] Gold foil thickness is 100μm;

[0047] The initial vacuum degree of the reaction chamber is less than 10 -6 mbar;

[0048] Step 3, place a tungsten wire with a diameter of 250 μm on the growth table of the MPCVD reaction chamber, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com