Silicon nitride heating element and making method thereof

A silicon nitride heating element and silicon nitride powder technology, applied in the direction of heating element materials, can solve the problems of affecting the service life of the product, high manufacturing cost, and large safety hazards, so as to reduce finished products and improve environmental safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

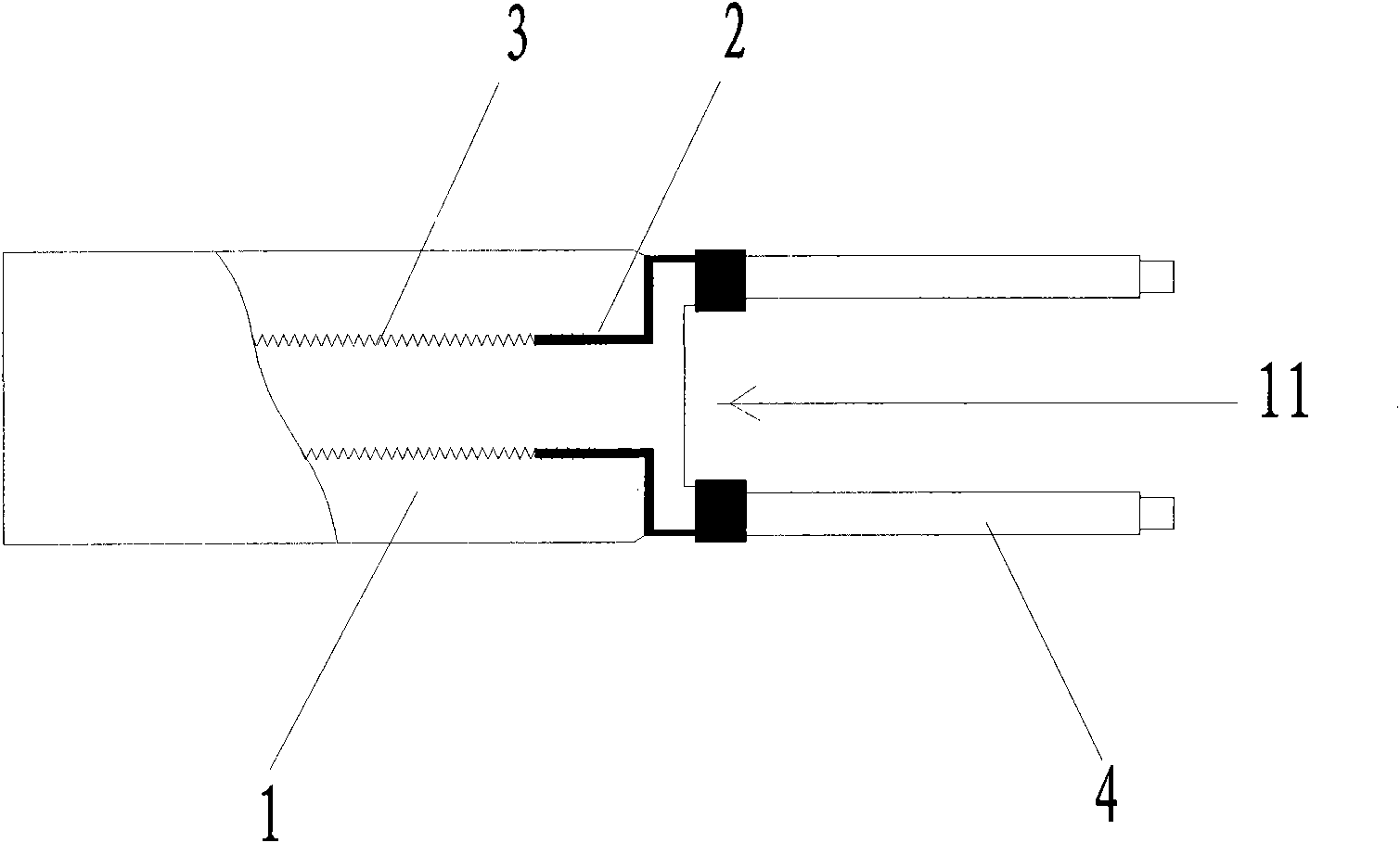

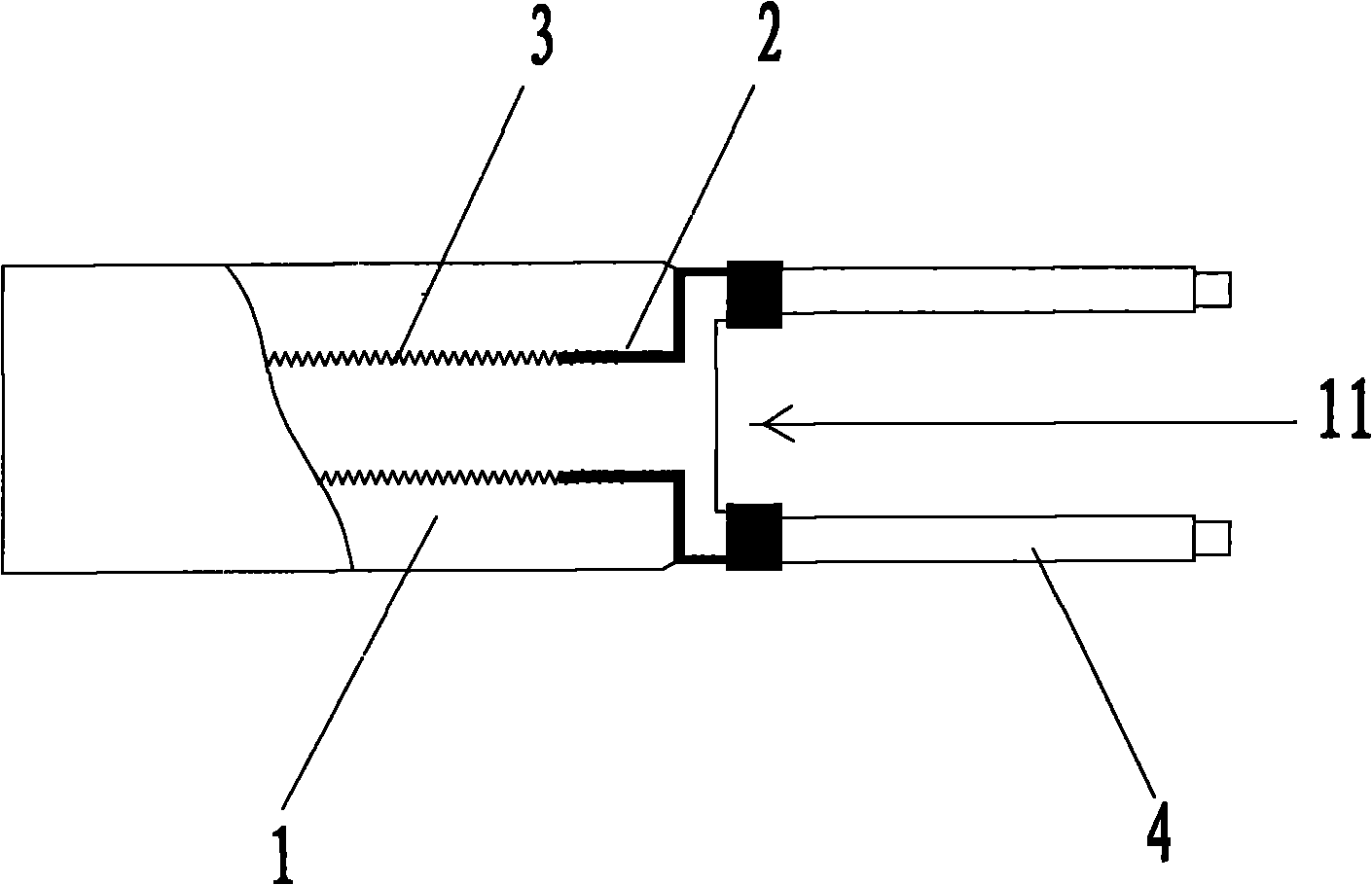

Embodiment 1

[0019] Take 90 grams of silicon nitride powder, 3 grams of yttrium oxide powder, 4 grams of lanthanum oxide powder and 3 grams of aluminum oxide powder into a nylon bucket, add distilled water, silicon nitride balls, ball mill for 4-20 hours, and then pour into the container , put it in an oven to dry, and sieve the powder for later use. Take one-half of the weight of the powder and pour it into the green mold, then scrape it flat, put the tungsten wire into the mold, add the other half of the powder and scrape it, put the upper head into the green mold, and use A 60-ton press presses the powder in the mold into a silicon nitride green body with a density of 45-50%.

[0020] Then the above-mentioned silicon nitride biscuits are clamped by two graphite backing plates from top to bottom to form a laminate, and the multiple laminates are stacked together, and the laminates are covered with graphite baffles around them, and placed in the mold Press it tightly, put it in a vacuum ...

Embodiment 2

[0023] The manufacturing steps are the same as in Example 1, except that the silicon nitride powder is 85 grams, the yttrium oxide powder is 5 grams, the lanthanum oxide powder is 9 grams, and the aluminum oxide powder is 1 gram.

Embodiment 3

[0025] The manufacturing steps are the same as in Example 1, except that the silicon nitride powder is 87 grams, the yttrium oxide powder is 1 gram, the lanthanum oxide powder is 2 grams, and the aluminum oxide powder is 10 grams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com