Patents

Literature

460results about How to "Realize unmanned operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

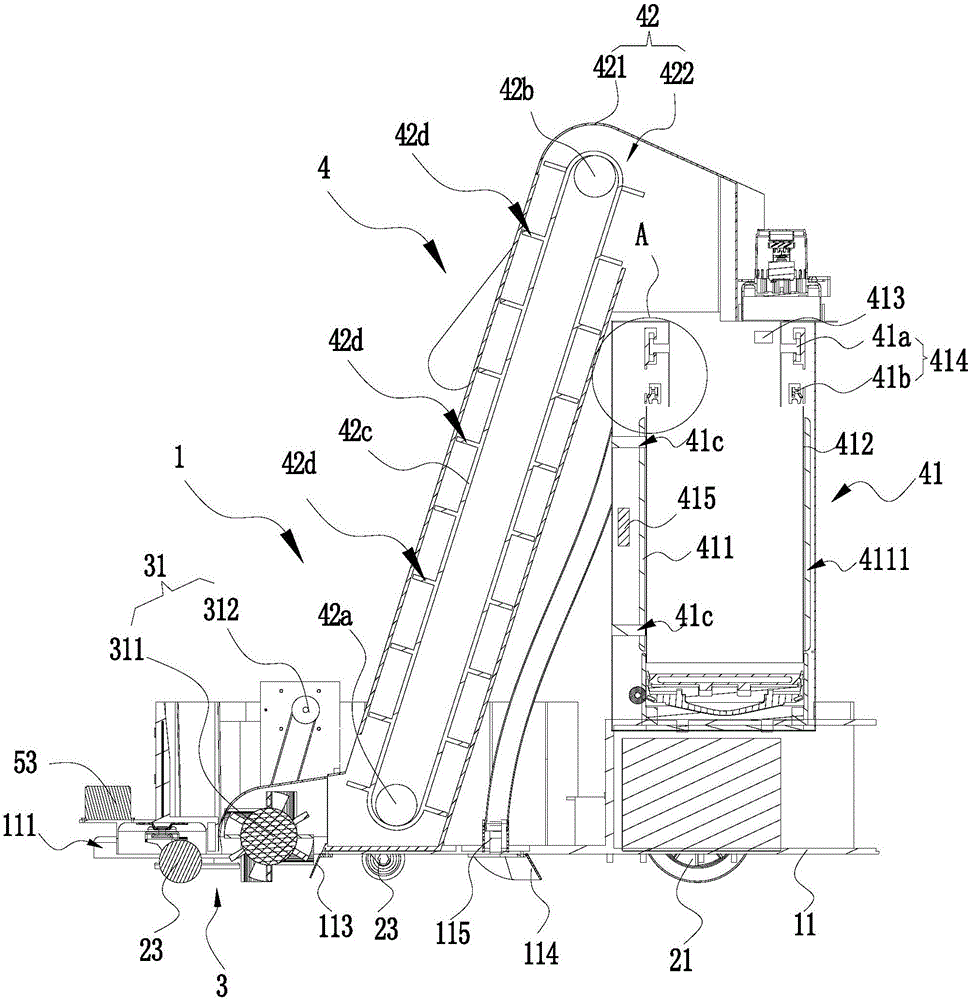

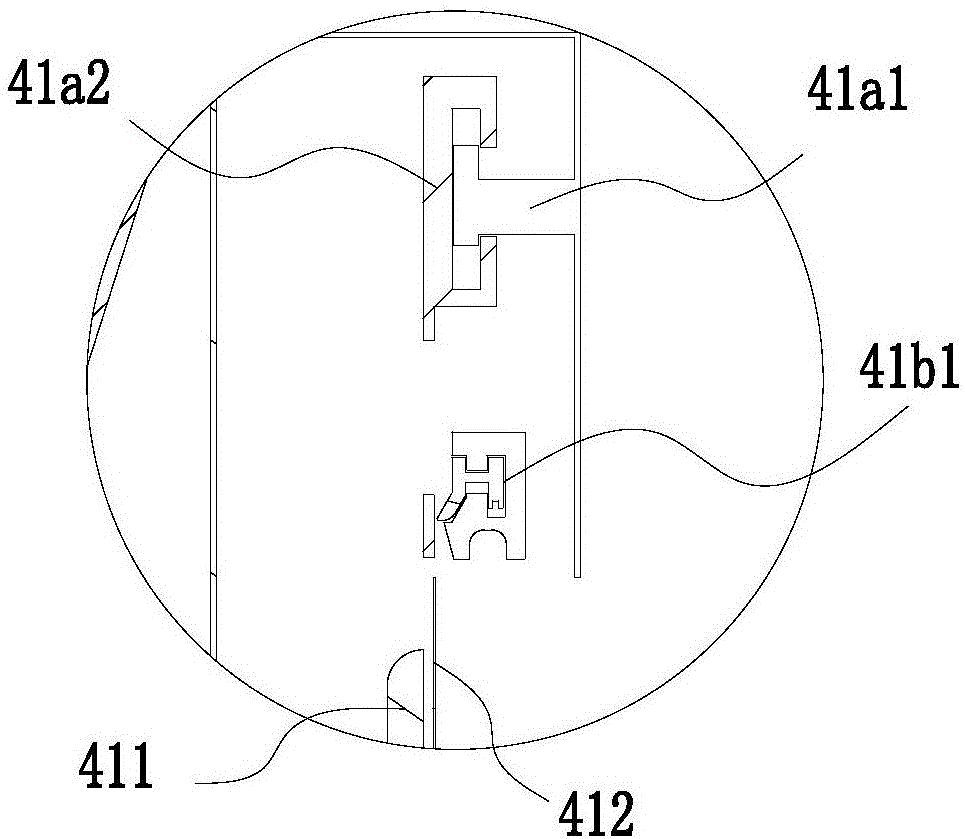

Tree planting machine and application of same

ActiveCN106538346AImprove work efficiencySave manpower and material resourcesPlantingFurrow making/coveringEngineeringContinuous operation

The invention relates to a tree planting machine and an application of the same. The tree planting machine comprises a traction car, wherein a pit digging mechanism is disposed on the front part of the traction car and used to dig tree pits used for tree seedling plantation; a seeding fetching mechanism is disposed at the middle part of the traction car, a seedling box used to store tree seedlings is disposed on one side of the traction car, and the seedling fetching mechanism is used take out the tree seedlings in the seedling box and place the seedlings into the dug tree pits; and a push and compression mechanism is disposed at the tail part of the traction car, used to push soil back to the tree pits in which the tree seedlings are placed and used to compact the soil. The tree planting machine provided by the invention is characterized in that whole courses of tree plantation are integrated; courses from pit digging and seedling placement to soil filling and compaction can be completed at a time, and ceaseless continuous operations can be achieved; the machine can completely take the place of traditional manual tree plantation; working efficiency is increased; and consumption of manpower and materials is reduced. In addition, transplantation line spacing can be adjusted to be adapted to tree plantation requirements of different trees for the line spacing; operation courses can better satisfy actual demands; the practicability is high; functions are obvious; and effects are significant.

Owner:SHANDONG UNIV OF SCI & TECH

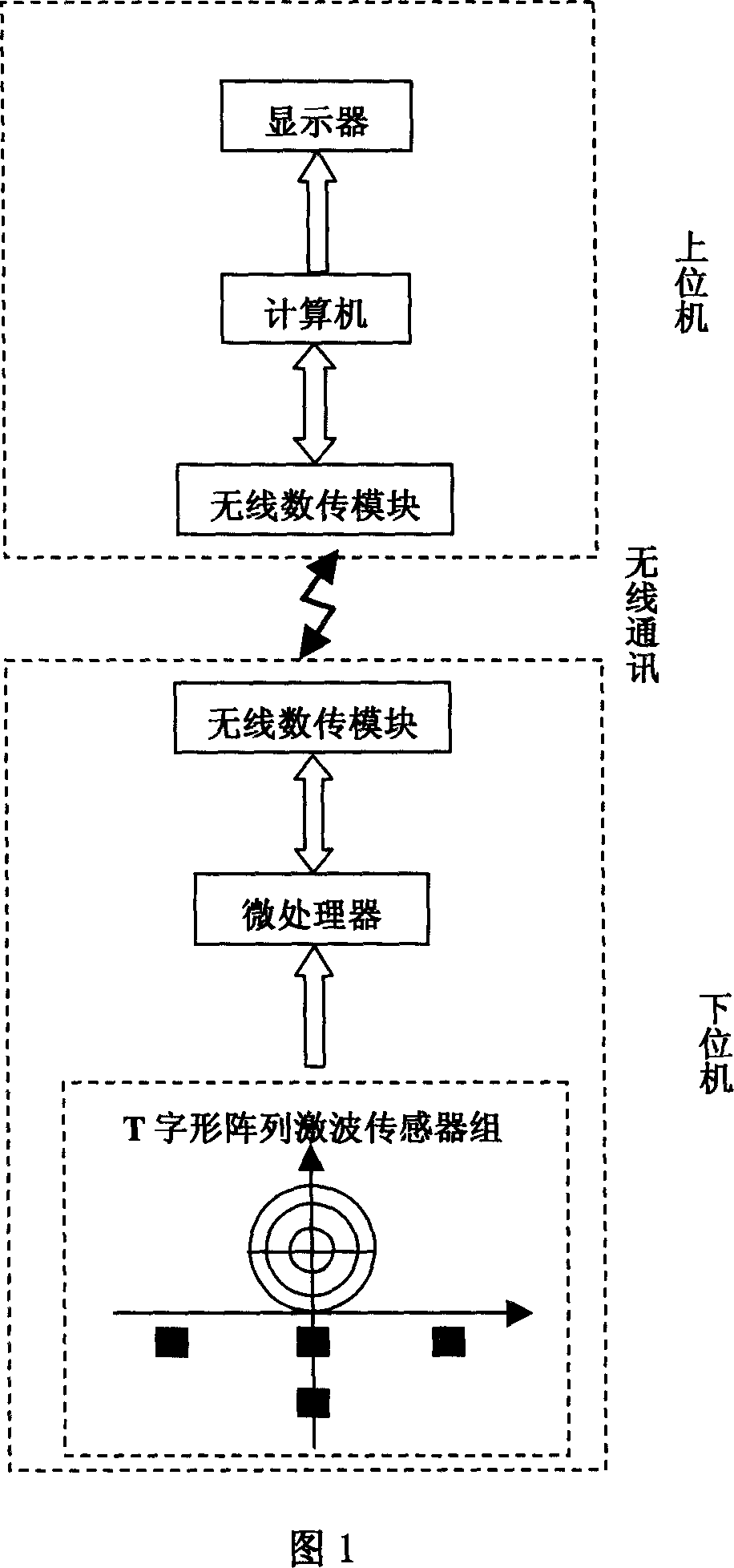

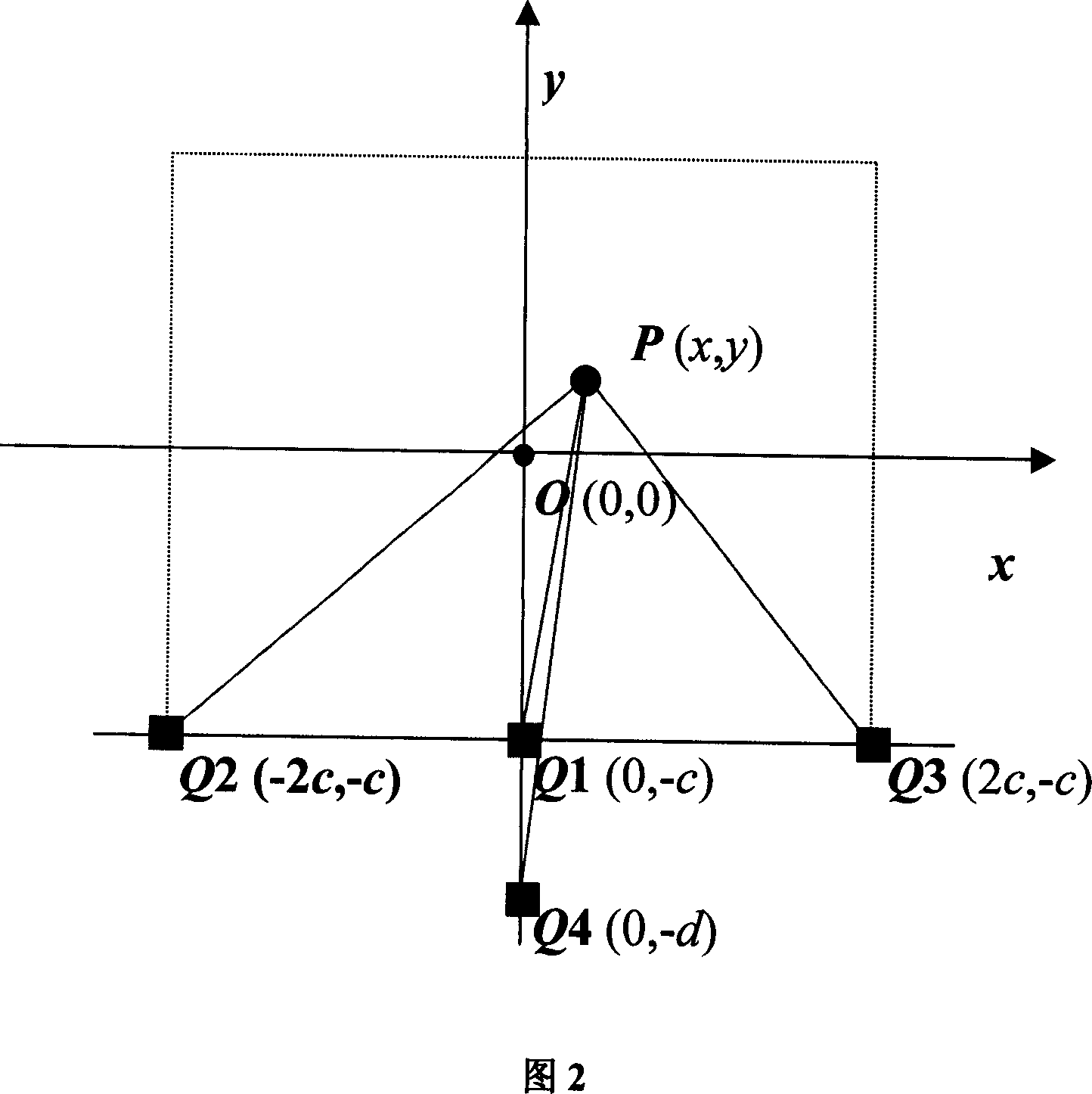

Shock wave target-reading system

InactiveCN1967136ARealize unmanned operationImplementation settingsTarget detectorsShock waveDisplay device

A shock wave target teller system comprises the top and bottom machines connected through wireless communications, with the bottom machine composed of T matrix shock wave sensing units, micro processor, wireless data transmission block, T matrix shock wave sensing unit made of 4 shock wave sensors Q1, Q2, Q3, and Q4 at the bottom and top of the target teller surface, entries of four shock wave sensors connecting with the entry of the micro processor, which in turn connects with the wireless data transmission block, with the top machine made of wireless data transmission block, computer, and display, wireless data transmission block connecting with the computer, and the output of the computer connecting with the display. It can realize dynamic target telling, no matter the shape of the target.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

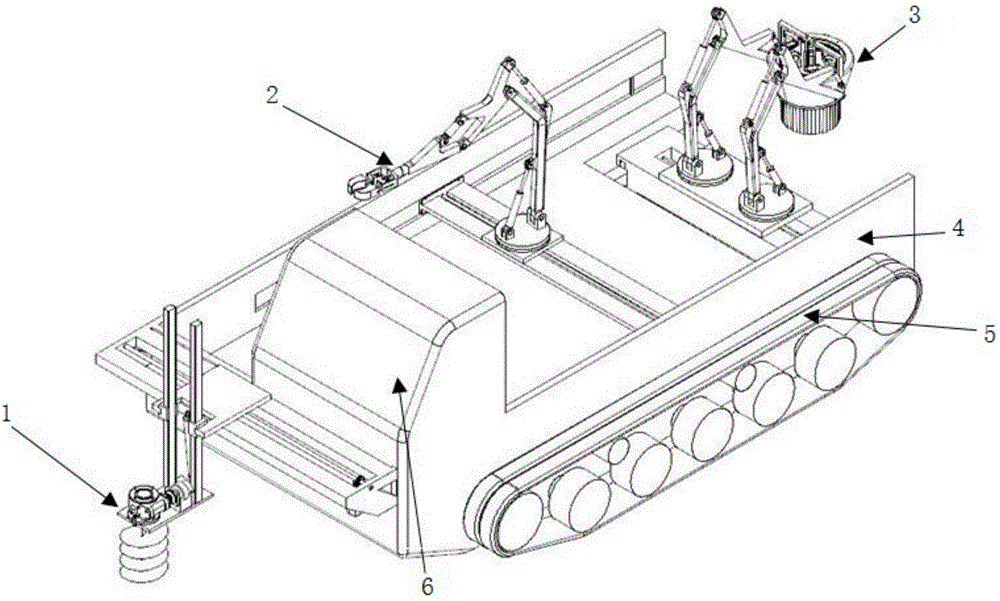

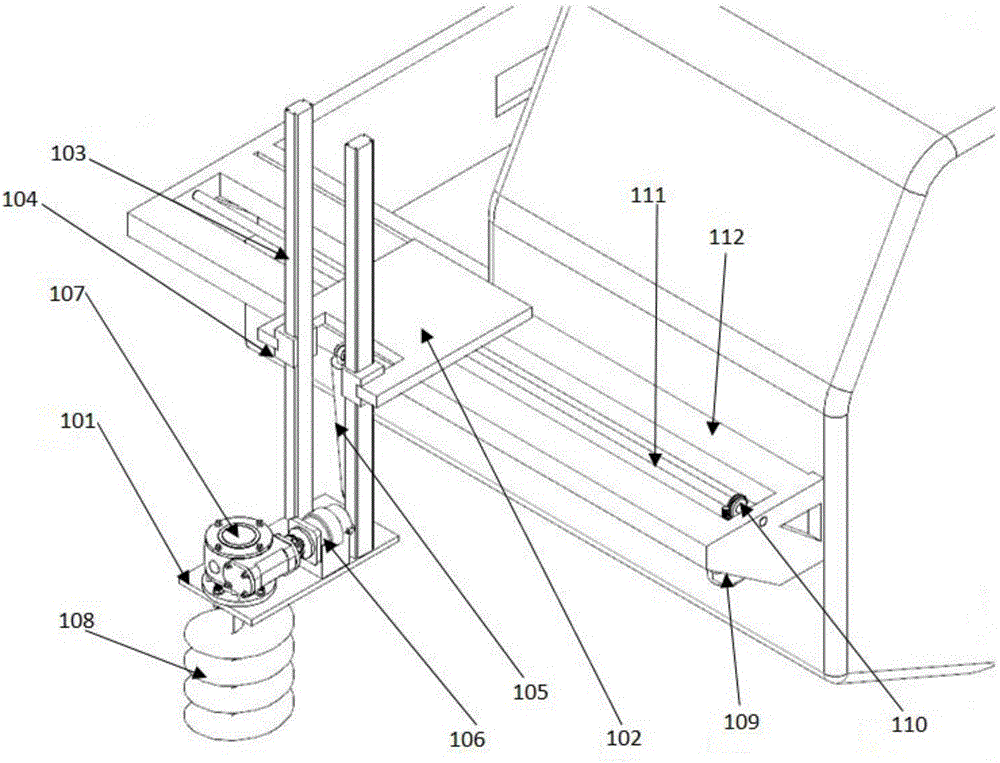

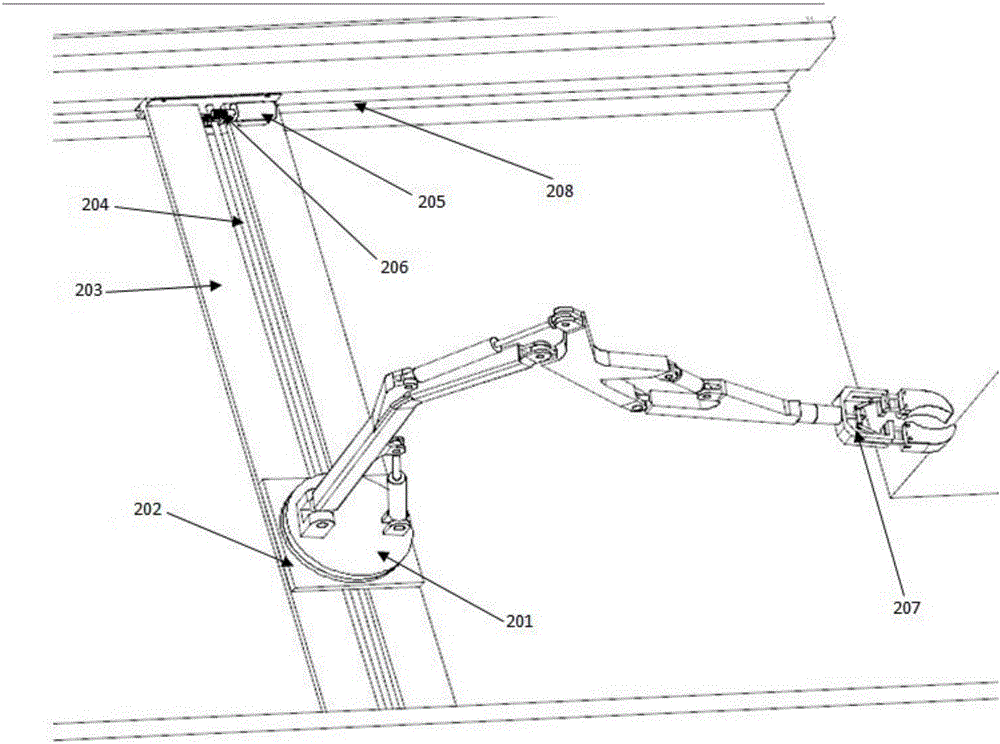

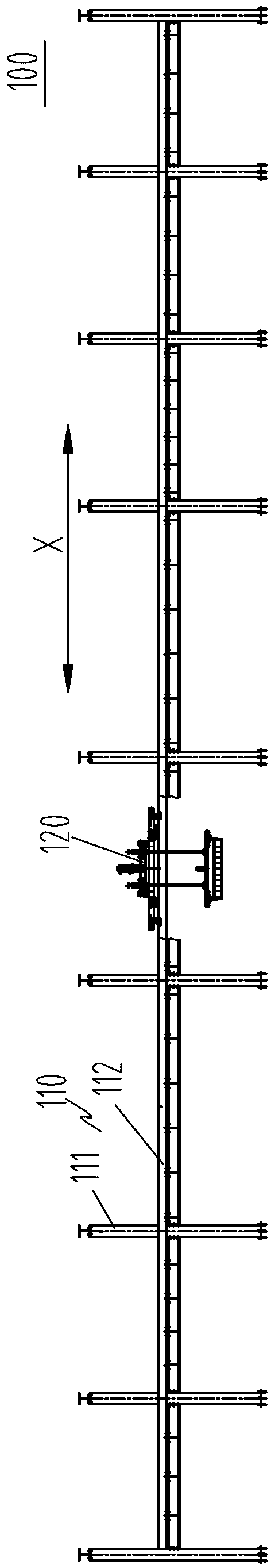

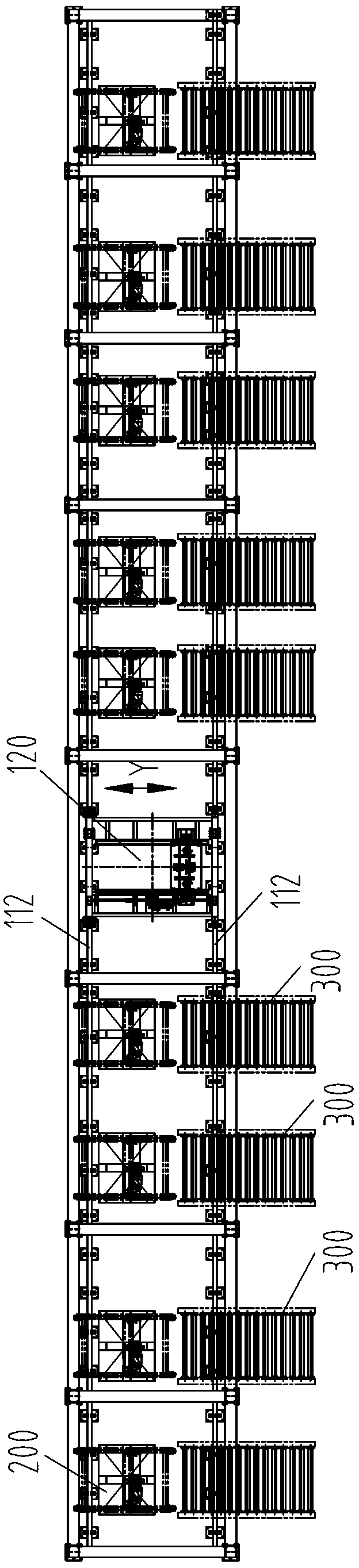

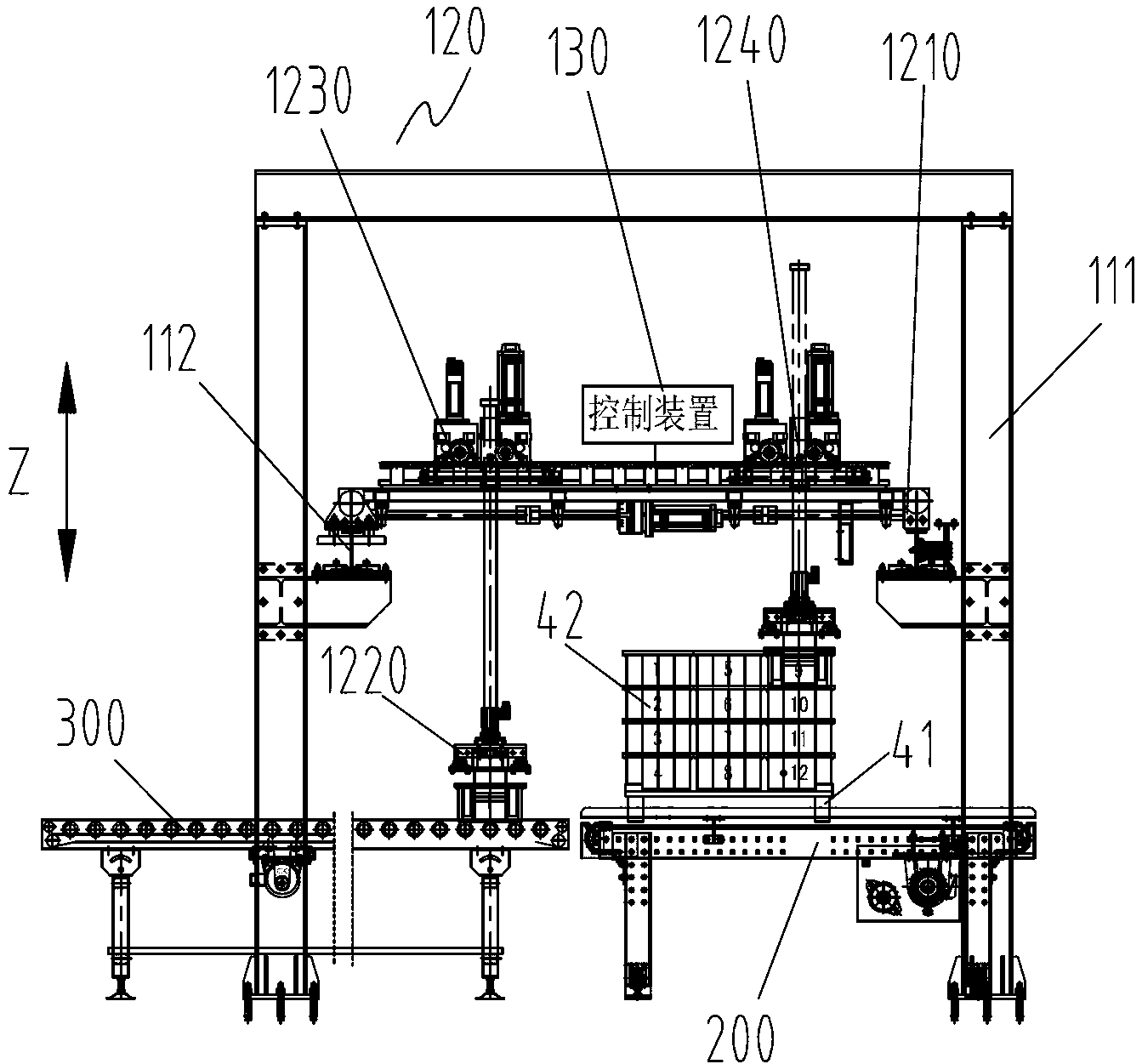

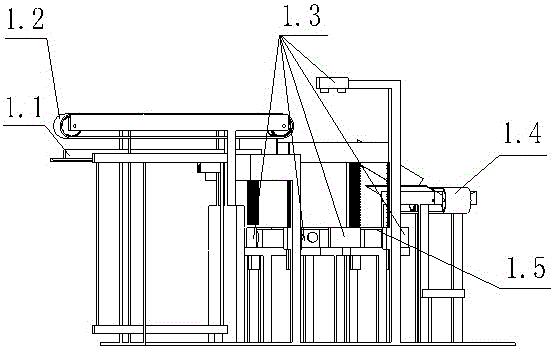

Automatic rock core box tray dismounting and stacking system and method

ActiveCN103303675ARealize disassemblyAutomatic accessStacking articlesDe-stacking articlesManipulatorEngineering

The invention relates to an automatic rock core box tray dismounting and stacking system and method. The automatic rock core box tray dismounting and stacking system comprises a track system, a carrying mechanical hand and a control device, wherein the track system comprises a track lifting frame and a track; the track lifting frame is erected between a rock core box tray conveying line and a rock core observation conveying line; the track is arranged on the track lifting frame and positioned above the rock core box tray conveying line and the rock core observation conveying line; the carrying mechanical hand is used for carrying a plurality of rock core boxes stacked in a way of N rows * M layers in trays onto the rock core observation conveying line in order when the trays are dismounted and carrying the plurality of rock core boxes on the rock core observation conveying line onto the trays on the rock core box tray conveying line in order and stacking the plurality of rock core boxes in the way of N rows * M layers when the trays are stacked; the control device is connected with the carrying mechanical hand; and a control module of the control device is used for controlling the movement of a grasp mechanism according to signals fed back by a horizontal position detection switch and a vertical position detection switch. The automatic rock core box tray dismounting and stacking system can meet the carrying, tray dismounting and tray stacking requirements of the rock core boxes from the tray conveying line to a plurality of observation conveying lines.

Owner:RIAMB (BEIJING) TECH DEV CO LTD

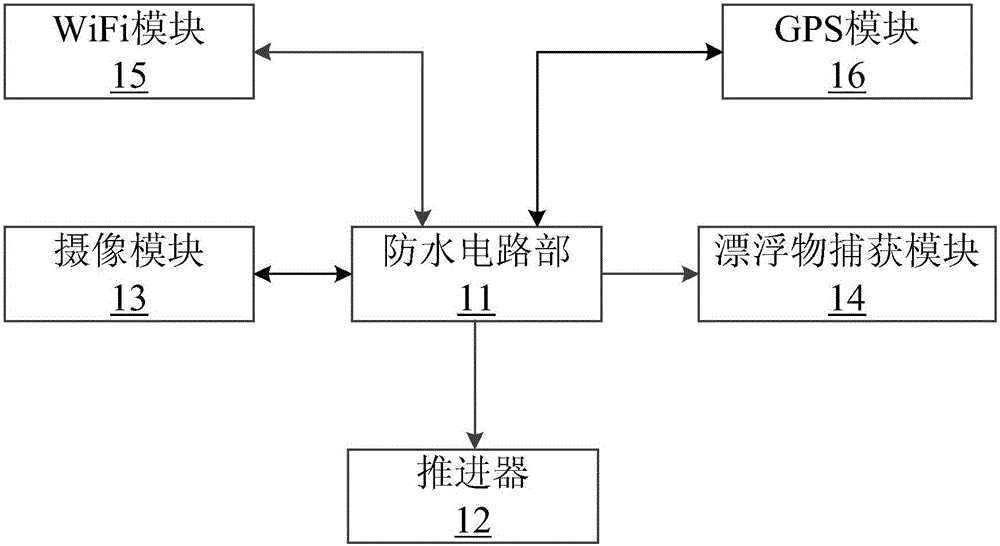

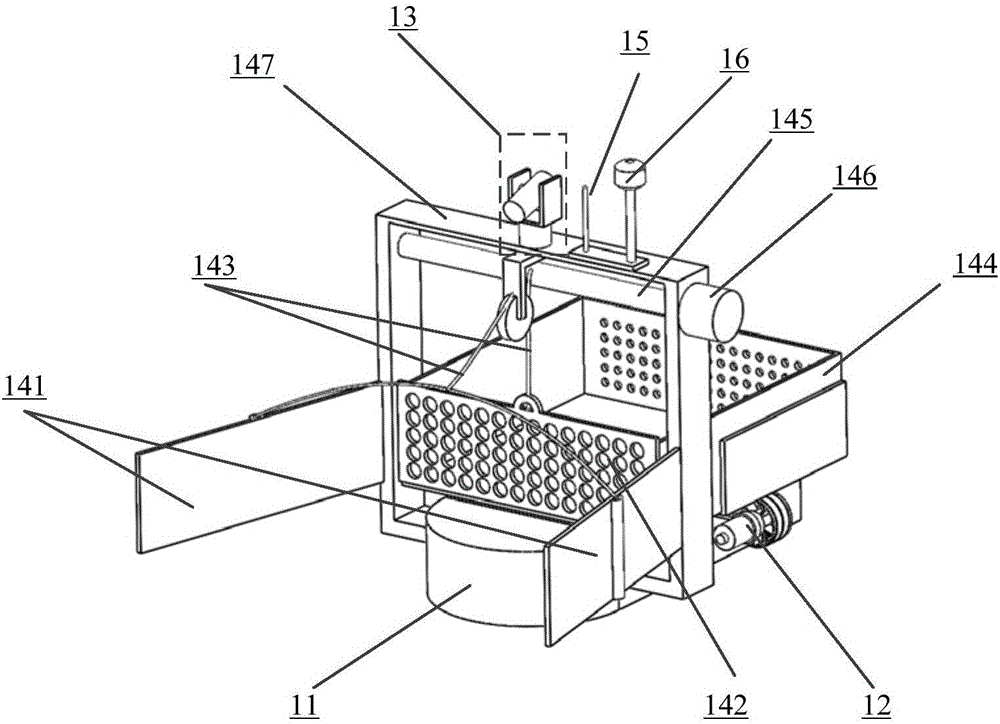

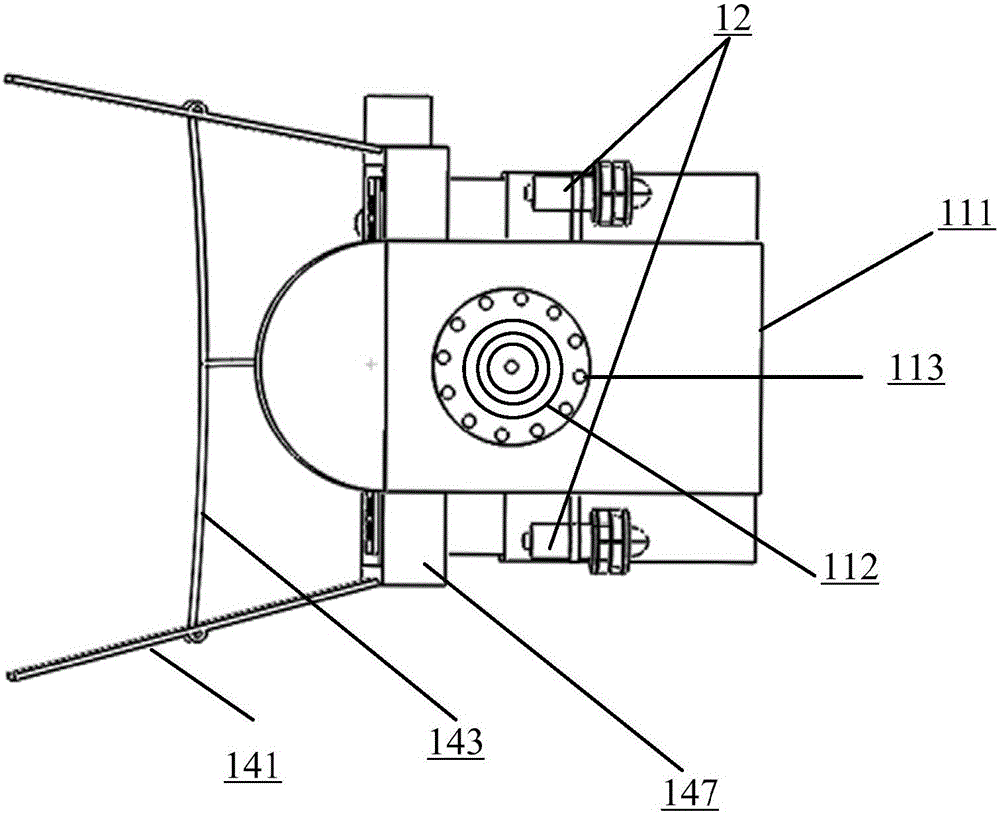

Wireless charging automatic water surface cleaning robot system

ActiveCN106347594AWith automatic dumping abilityNon-stop workWater cleaningWaterborne vesselsRobotic systemsSurface cleaning

The invention discloses a wireless charging automatic water surface cleaning robot system, which comprises a robot and a base station, wherein the robot comprises a waterproof circuit part, as well as a propeller, a photographic module, a floating object capturing module, a WiFi (wireless fidelity) module and a GPS (global positioning system) module, which are all connected with the waterproof circuit part; the base station comprises a bracket, a platform arranged at the front end of the bracket, a rotating shaft arranged on the bracket, a rotating rod fixedly connected with the rotating shaft in the perpendicular direction, an electromagnet arranged at the front end of the rotating rod and a target arranged above the rotating rod; a second coil and a second magnet array are arranged on the platform. The system has an autonomous floating object capturing capability and an autonomous returning and charging capability, can autonomously and continuously work completely without an operator, and is very suitable for floating object cleaning of a natural water surface such as a river channel, a lake and an ocean and an artificial water surface such as a reservoir and a swimming pool. In addition, the robot also has an automatic floating object dumping capability, and collected floating objects are concentrated at a floating object storage site on the base station on the bank to actually realize unmanned operation.

Owner:HANGZHOU DIANZI UNIV

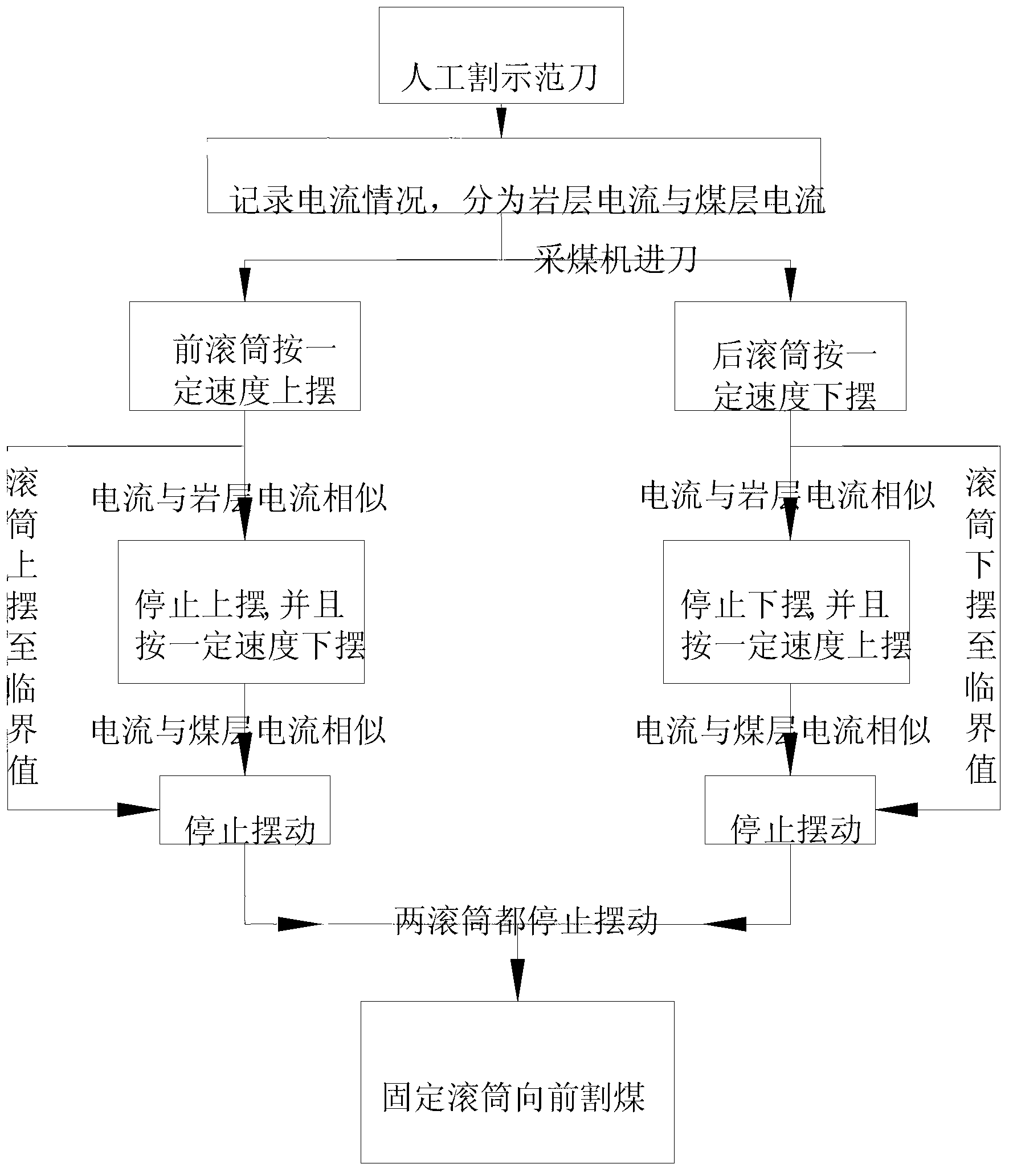

Method for identifying coal petrography interface of thin coal layer and automatically heightening expansion cylinder

ActiveCN103216233ARealize unmanned operationPromote recoverySlitting machinesCurrent limitingPower flow

The invention provides a method for identifying a coal petrography interface of a thin coal layer and automatically heightening an expansion cylinder. A current sensor is arranged on a slicing motor of a coal cutter. The method comprises the following step of: (1) firstly cutting for once to be taken as demonstration cutting by the slicing motor of the coal cutter, and recording the respective current value condition when the coal seam and the rock stratum are cut by the coal cutter, wherein the current value is taken as a coal seam / rock stratum current limiting value; (2) enabling a rocker arm of a front expansion cylinder to upwards swing automatically after the coal cutter is used for cutting, and enabling a back expansion cylinder of the coal cutter to downwards swing, identifying the coal petrography layer by detecting a current fluctuation range, and automatically adjusting the mining height according to the different current limiting values of the coal seam and the rock stratum; and (3) judging by the means that the current data generated when the coal petrography is cut by the coal cutter and recoded in the process of coal cutting by the demonstration cutting are taken as the standard value. Under the condition that the coal petrography interface is identified, the coal cutter can be used for automatically adjusting the mining height according to the thickness of the coal, so that the recovery ratio can be improved.

Owner:CHINA UNIV OF MINING & TECH

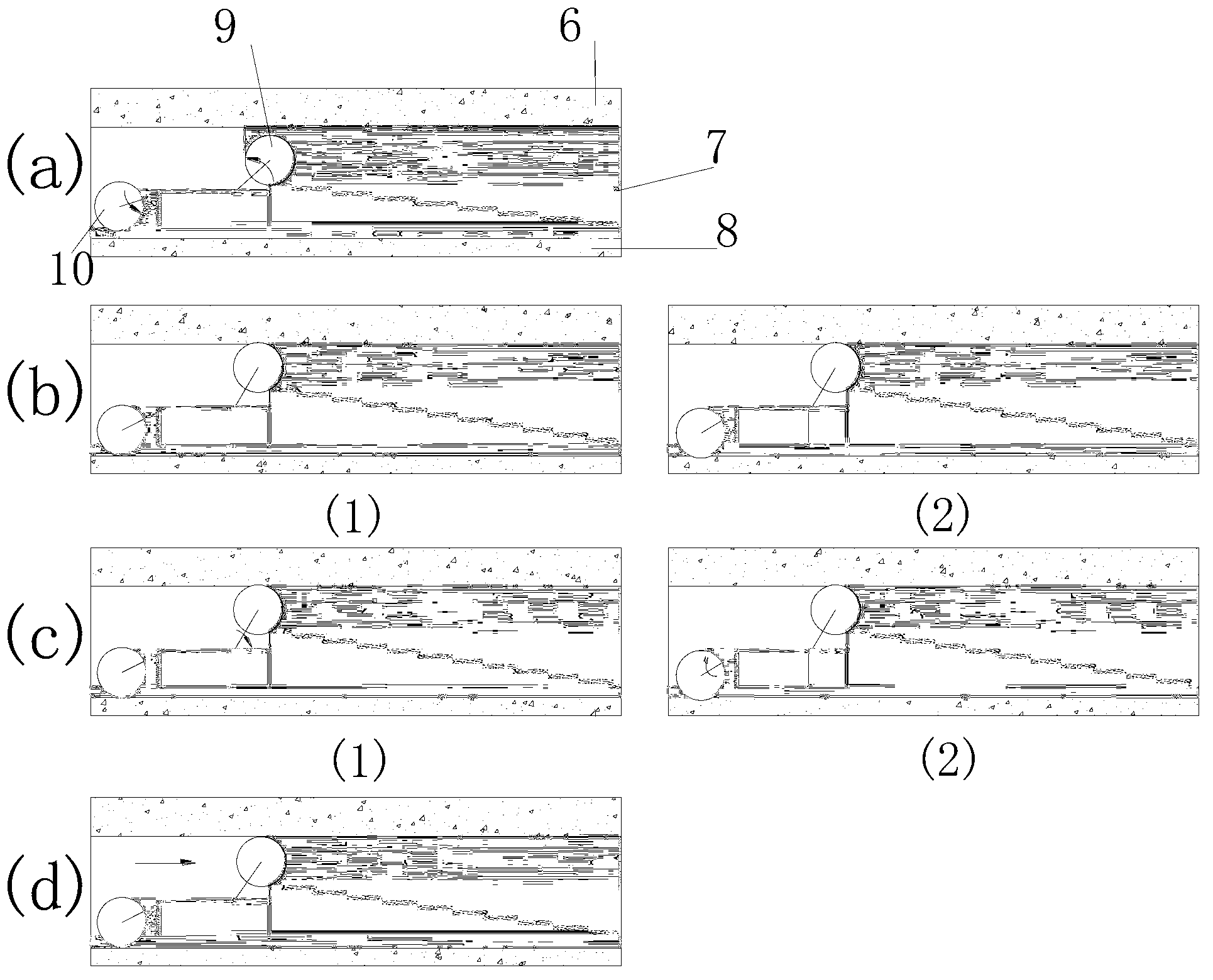

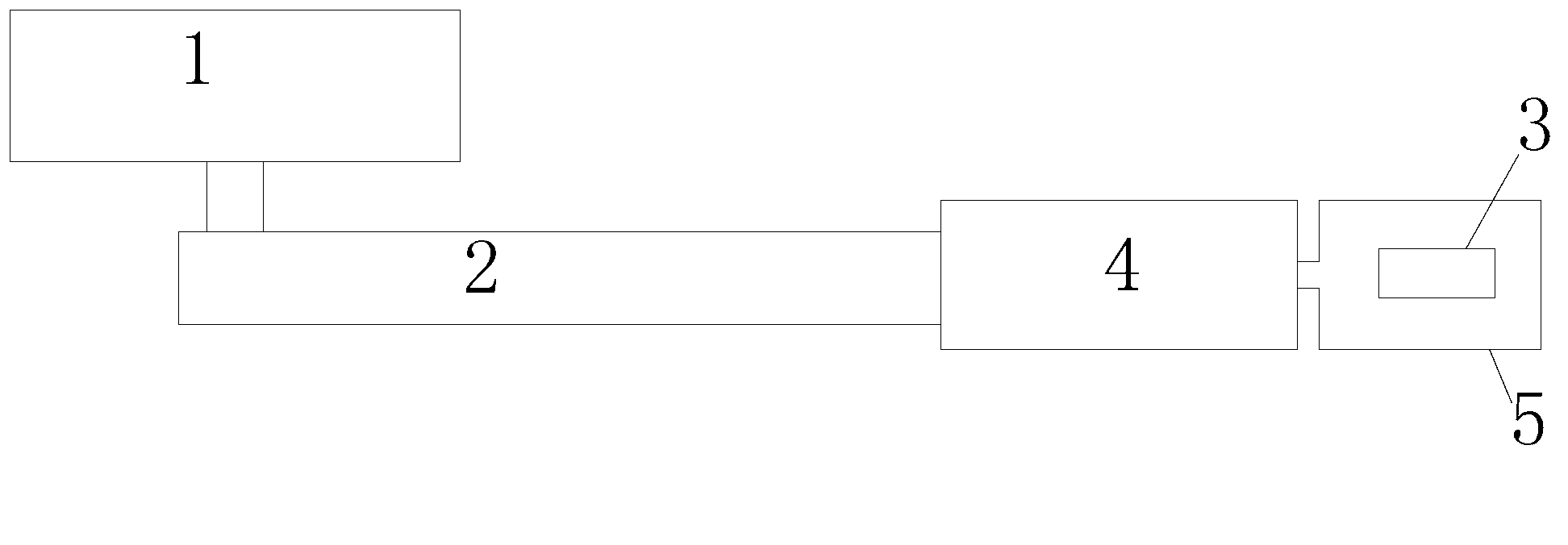

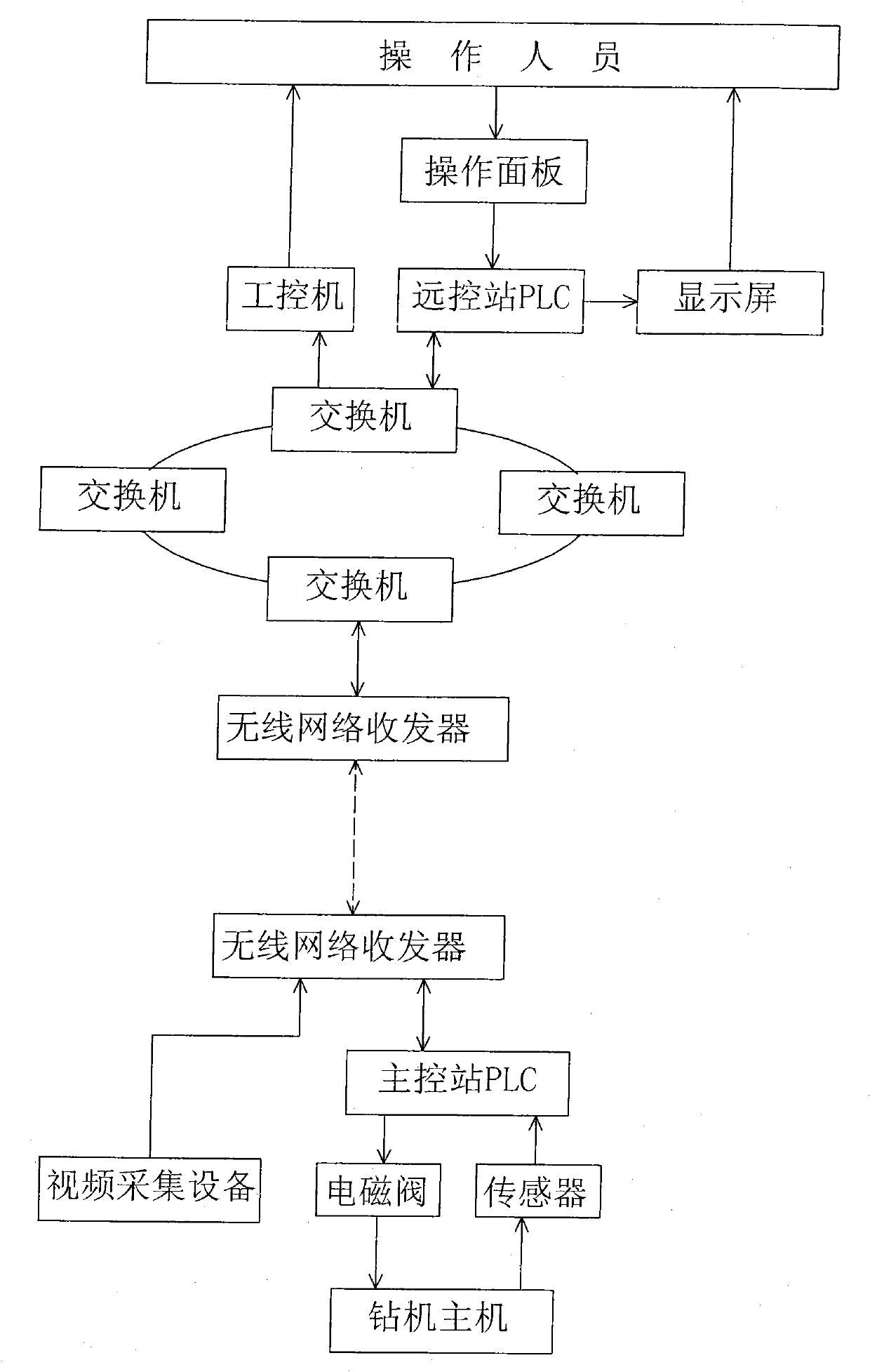

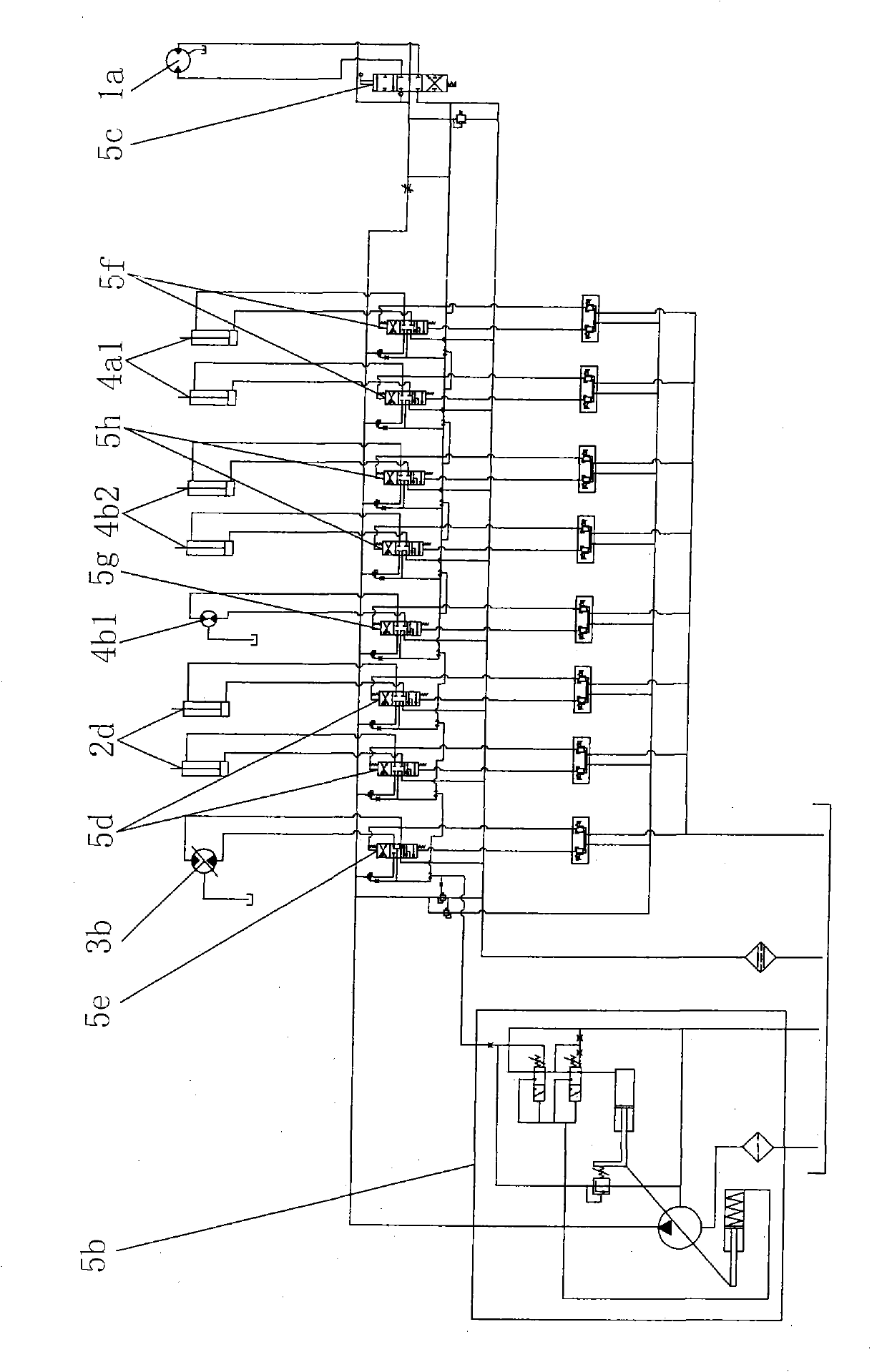

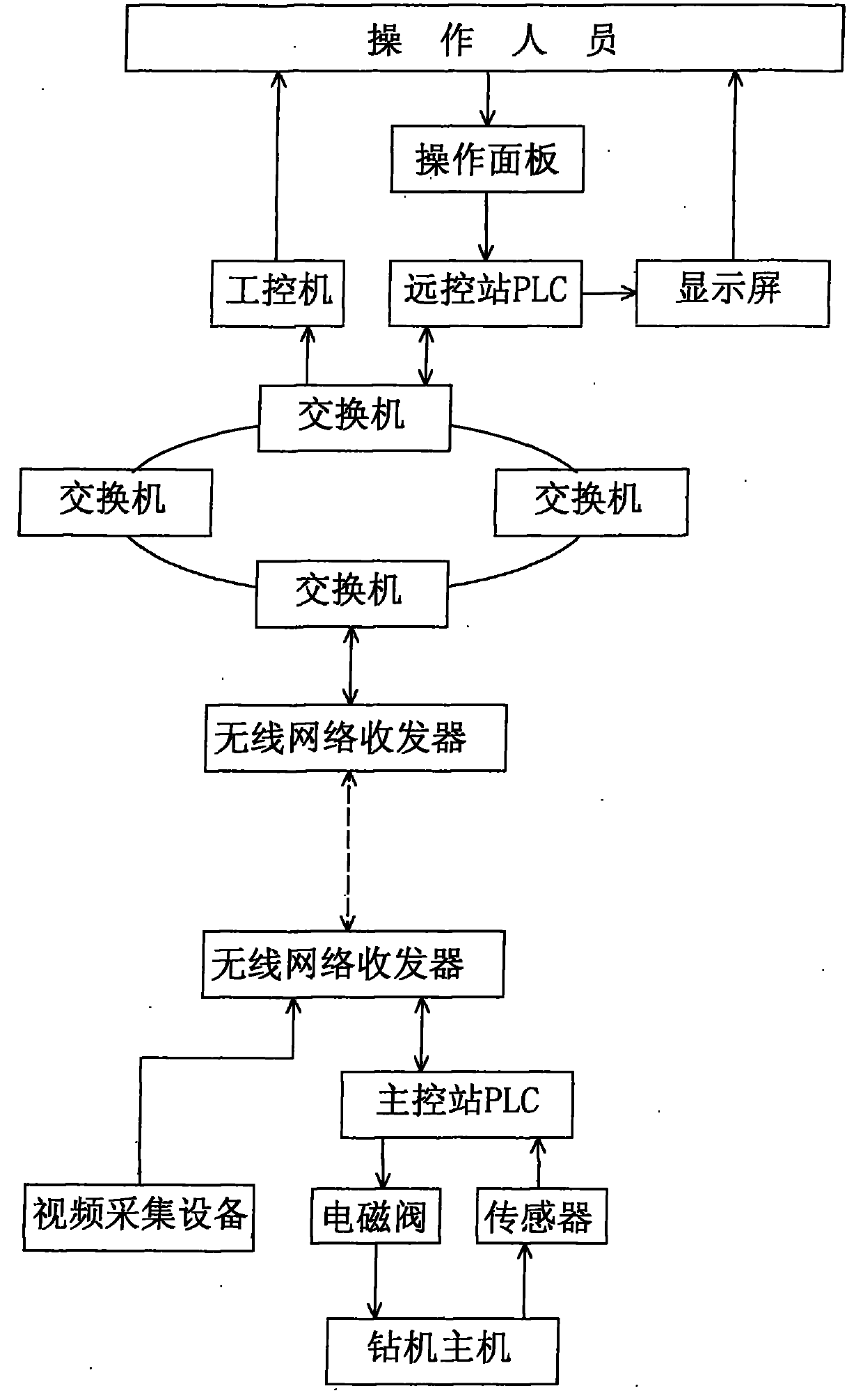

Remote-control underground gas extraction drilling machine

ActiveCN101906988ARealize unmanned operationGuaranteed uptimeDrilling rodsGas removalRemote controlEngineering

The invention discloses a remote-control underground gas extraction drilling machine. The drilling machine comprises a host machine of the drilling machine and an electric control system, wherein the electric control system is used for controlling the operation of the host machine of the drilling machine and comprises a main control station, a remote control station and a communication device; and the communication device is used for transferring information between the remote control station and the main control station. In the remote-control underground gas extraction drilling machine provided by the invention, the operation of the host machine of the drilling machine is controlled by the remote control station arranged on the ground, so unmanned operation of the host machine of the drilling machine is realized, an operator does not need to enter a site of a severe environment and the life safety of the operator is guaranteed; at the same time, the operation process of the host machine of the remote-control drilling machine is fully automatic operation, so the operation efficiency is high; and signals acquired by a video acquisition device and a sensor which are arranged on the host machine of the drilling machine can help the operator in the remote control station to know the operation condition of the host machine of the drilling machine at any time, so the reliable operation of the host machine of the drilling machine can be guaranteed.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

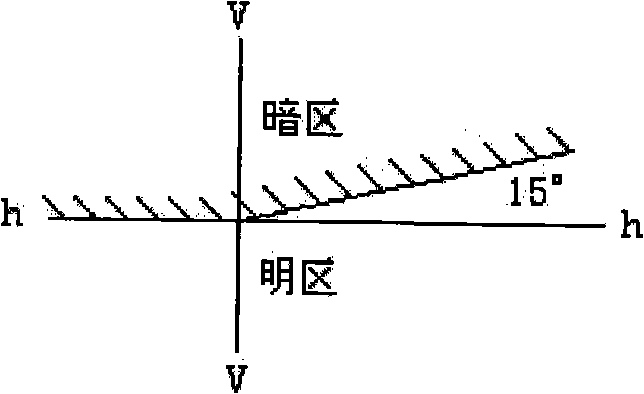

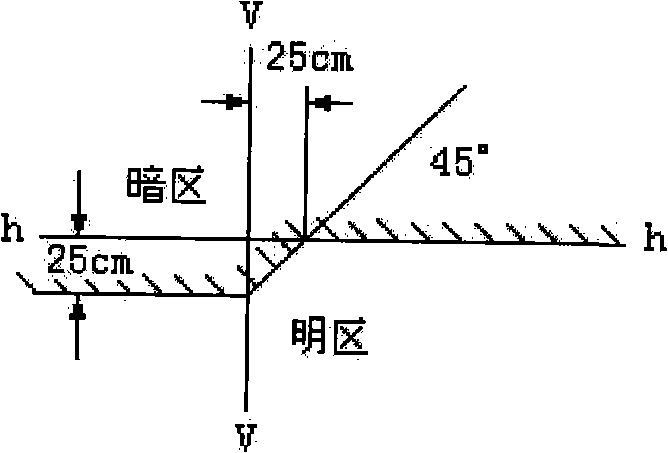

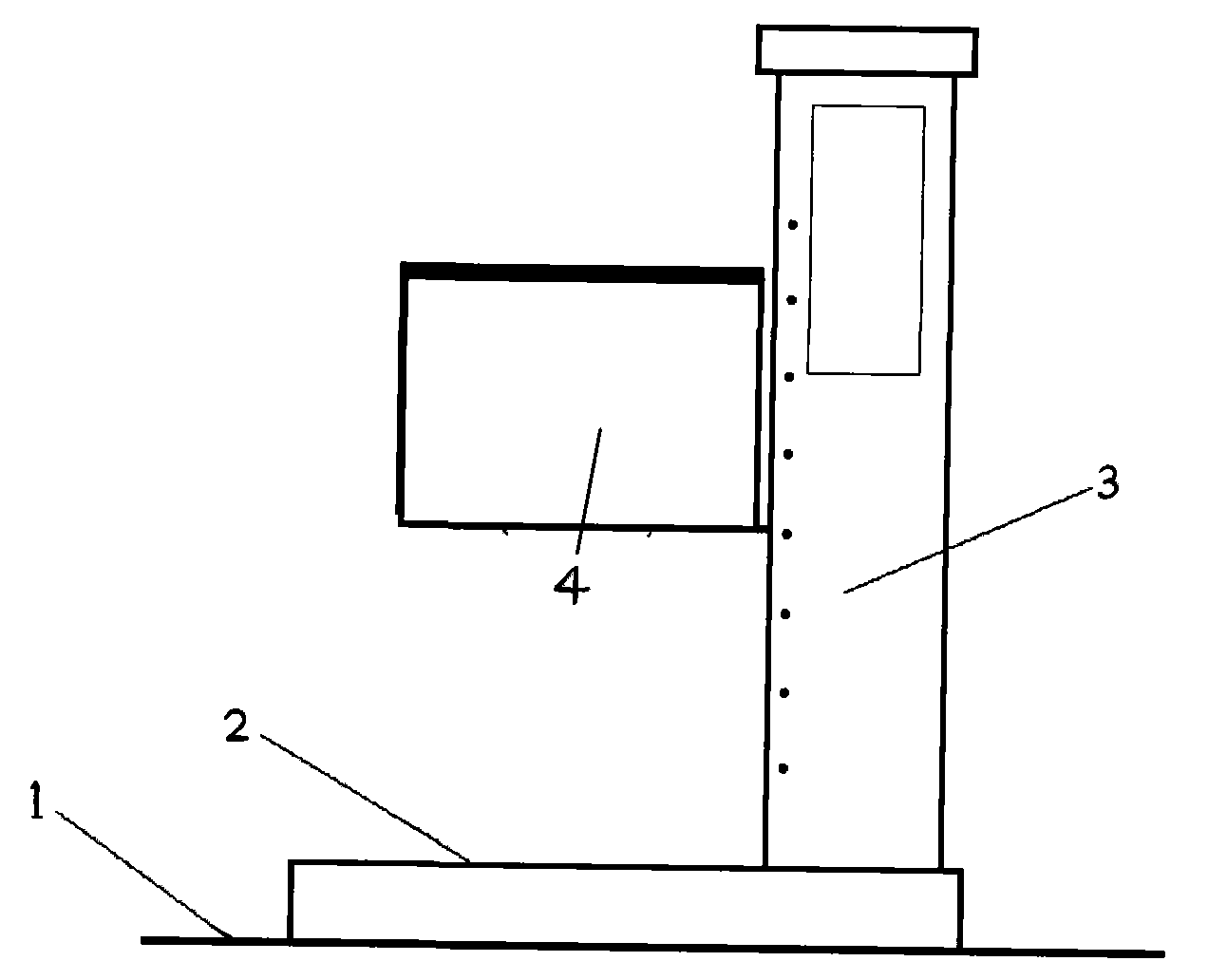

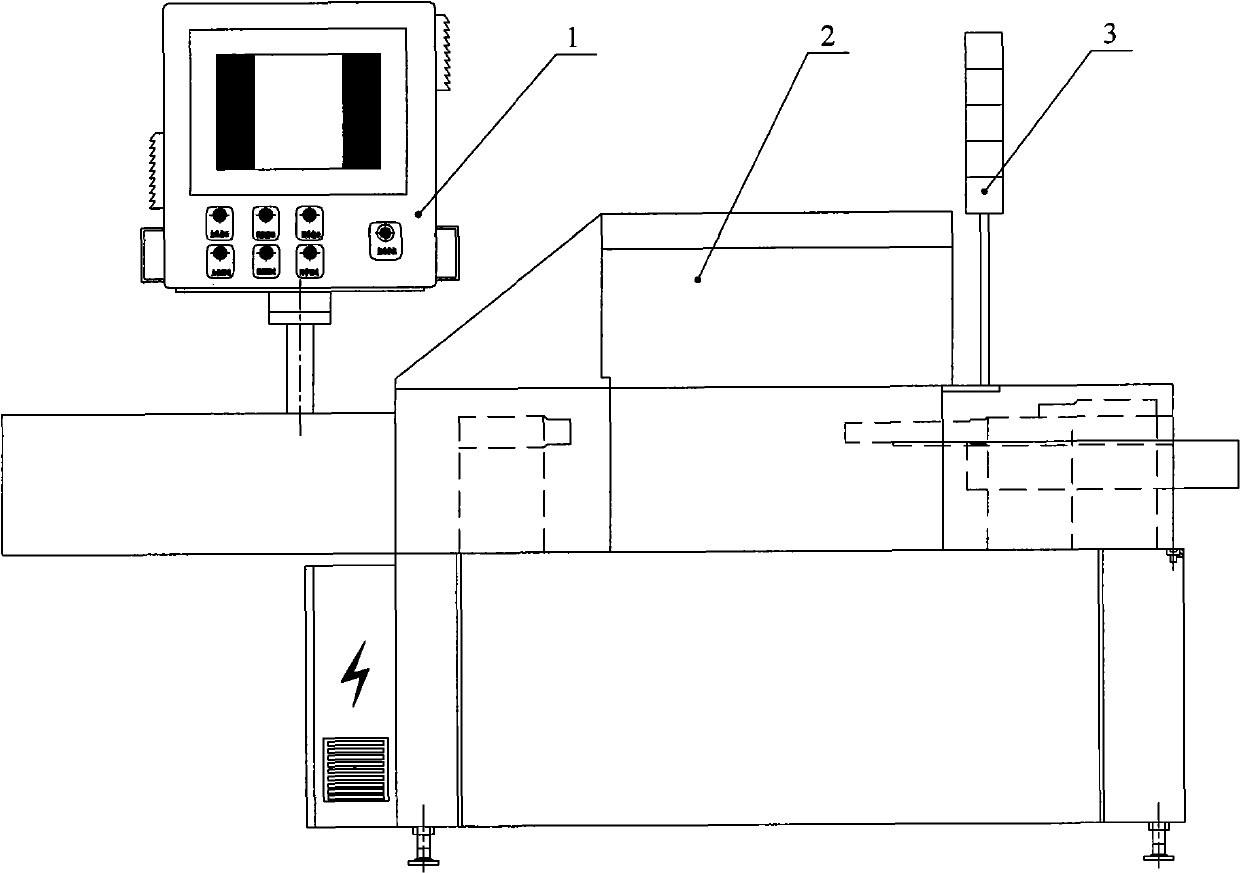

Intelligent lighting automatic detection and analysis system and detection method thereof

ActiveCN101556208AImprove automationCapable of intelligent image recognition and detectionTesting alignment of vehicle headlampsMicrocontrollerIntelligent lighting

The invention relates to an intelligent lighting automatic detection and analysis system and a detection method thereof. The intelligent lighting automatic detection and analysis system comprises a guide way, a base larry, an upright post, a photic box, an optical system, a CCD vidicon, a singlechip processing system and a DSP image processing system, wherein symmetry of high beam light spots is obtained from images photographed by the CCD vidicon in the photic box through pretreatment, isolux annulus extraction, isolux annulus centre calculation and symmetry check; and definition of low beam light spots on a dividing line of light and dark cutoff regions is obtained from the images through the pretreatment, low beam light and dark bend line extraction and light and dark dividing line bright band width calculation. The invention detects the lighting quality of high beam and low beam by adopting the method of judging the symmetry of the high beam light spots with the relative average offset of isolux annuluscentre coordinates to the centre of the light spots and the calculation method, and the method of judging definition of the low beam light spots on the light and dark bend positions with size of band width of the bright band of the images above the bend line and the calculation method of the band width of the bright band.

Owner:天津圣纳科技有限公司

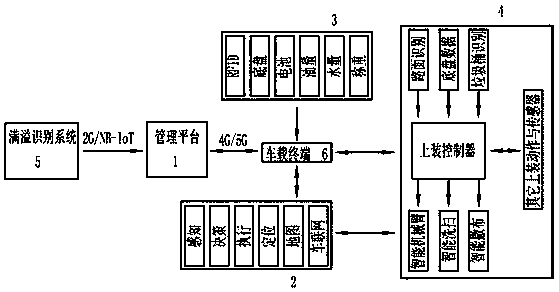

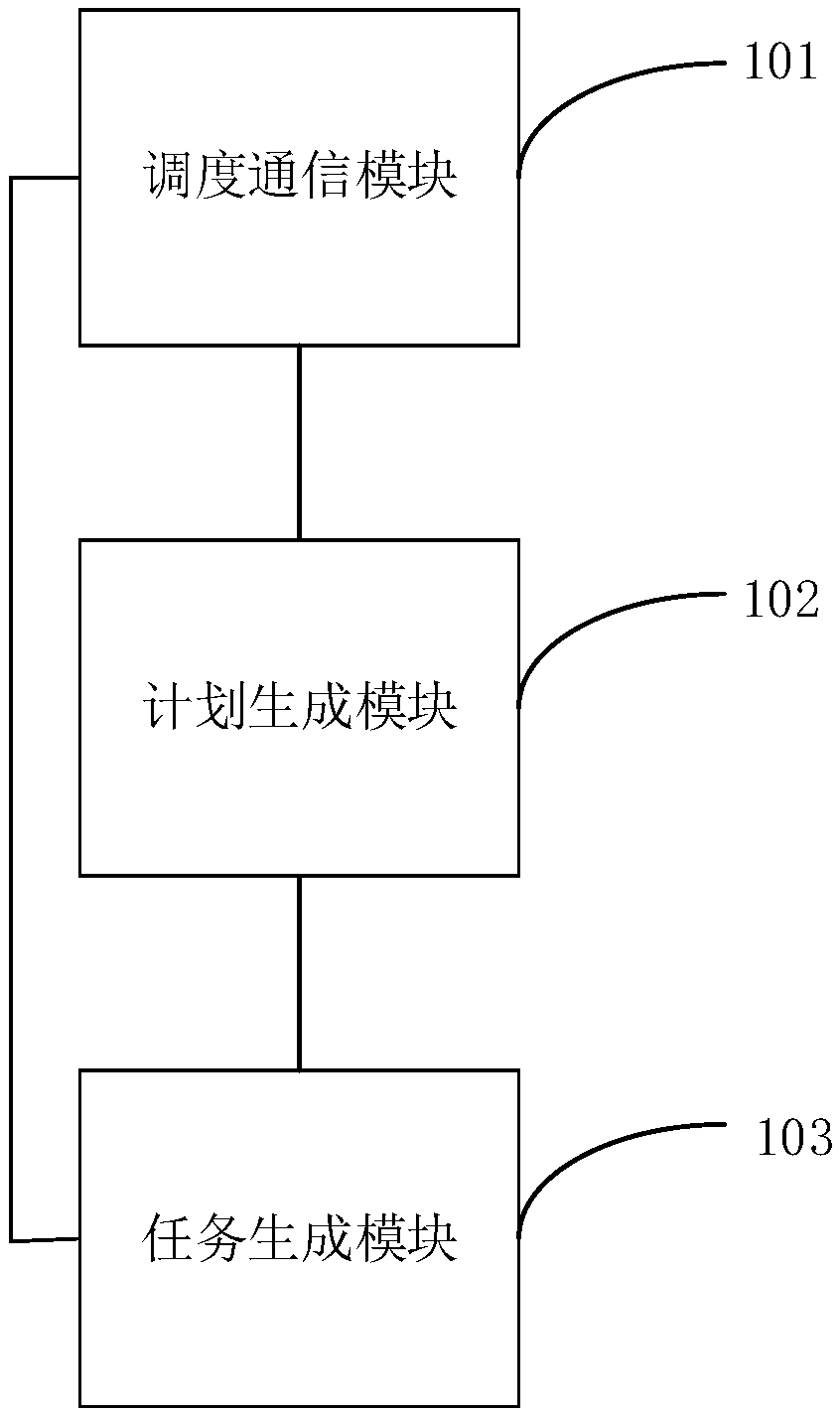

Unmanned operation system of sanitation vehicle

PendingCN108563228ARealize unmanned drivingRealize unmanned operationCharacter and pattern recognitionSatellite radio beaconingControl systemData acquisition

The invention provides an unmanned operation system of a sanitation vehicle. The unmanned operation system of the sanitation vehicle comprises a management platform, an unmanned driving system, a dataacquisition system, a loading control system, an overfilling recognition system and a vehicle-mounted terminal, wherein the management platform is connected with the vehicle-mounted terminal and theoverfilling recognition system through a communication network respectively; the data acquisition system is connected with the vehicle-mounted terminal through a bus; the loading control system is connected with the unmanned driving system through a bus / net line; the loading control system and the unmanned driving system are connected with the vehicle-mounted terminal through buses / net lines respectively; the management platform monitors the real-time state of the sanitation vehicle through the management platform and issues a control instruction through the vehicle-mounted terminal to controlthe running state of the vehicle. Through the unmanned operation system of the sanitation vehicle, the sanitation vehicle really achieves unmanned operation, so that the labor intensity of workers iseffectively reduced, a working environment is improved, and waste of resources is reduced; the automation degree and the intelligence degree of a sanitation operation mode are improved.

Owner:EGUARD NEW ENERGY AUTOMOBILE CO LTD

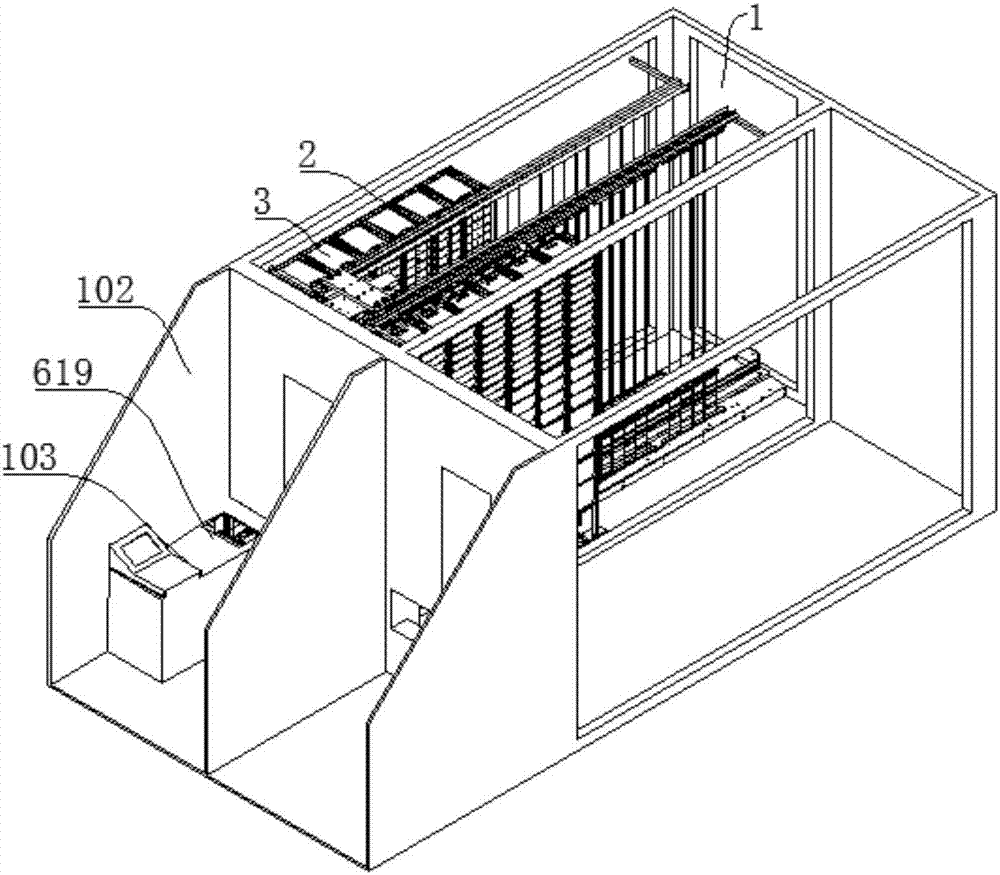

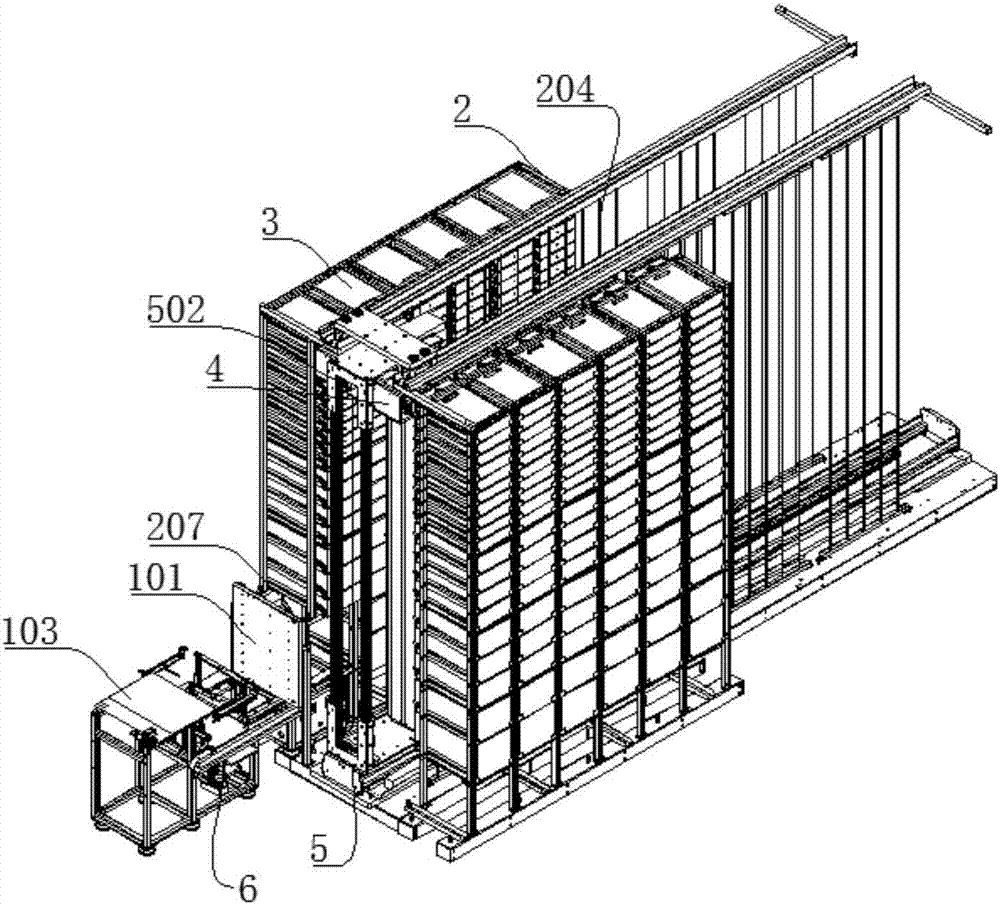

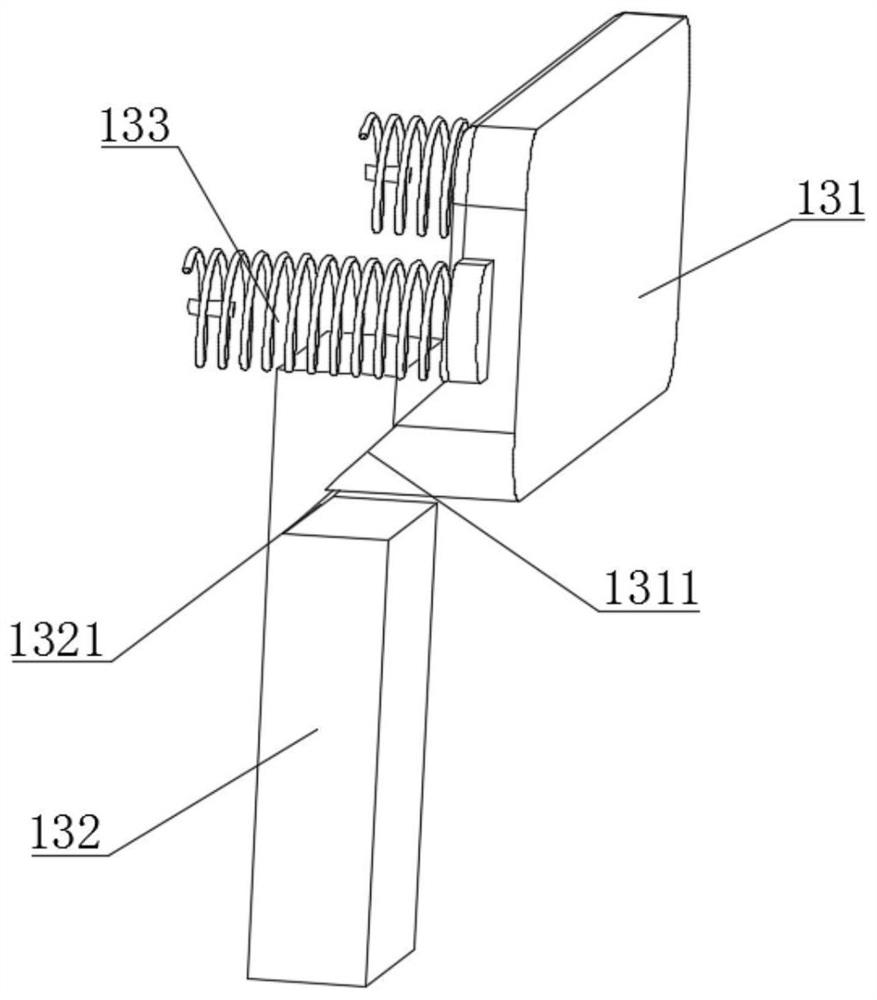

Safe deposit box system

PendingCN107512514ASimple processReduce intermediate linksStorage devicesStructural engineeringMechanical engineering

The invention discloses a safe deposit box system. The safe deposit box system comprises a safe deposit chamber, storage racks installed inside the safe deposit chamber, a plurality of safe deposit boxes on the storage rack, and a hooking device used for fetching the safe deposit boxes; protrusions are arranged on two sides of each safe deposit box; the hooking device comprises a shell with a safe deposit box inlet / outlet channel, and safe deposit box placement supports fixed inside the shell; grabbing hooks for hooking the protrusions of the safe deposit boxes are arranged on the two sides of the opposite placement supports inside the shell; a drive device for controlling the grabbing hooks to move is arranged inside the shell; and the drive device comprises a hooking jacking mechanism and a hooking horizontal moving mechanism. The hooking device directly hooks the safe deposit boxes, the intermediate steps and parts are reduced, the degree of automation is improved, the safe deposit box system is simple in structure, not prone to damage and small in number of faults, the hooking process is firm and stable, and the safe deposit boxes are not prone to falling off.

Owner:成都智安易智能设备有限公司

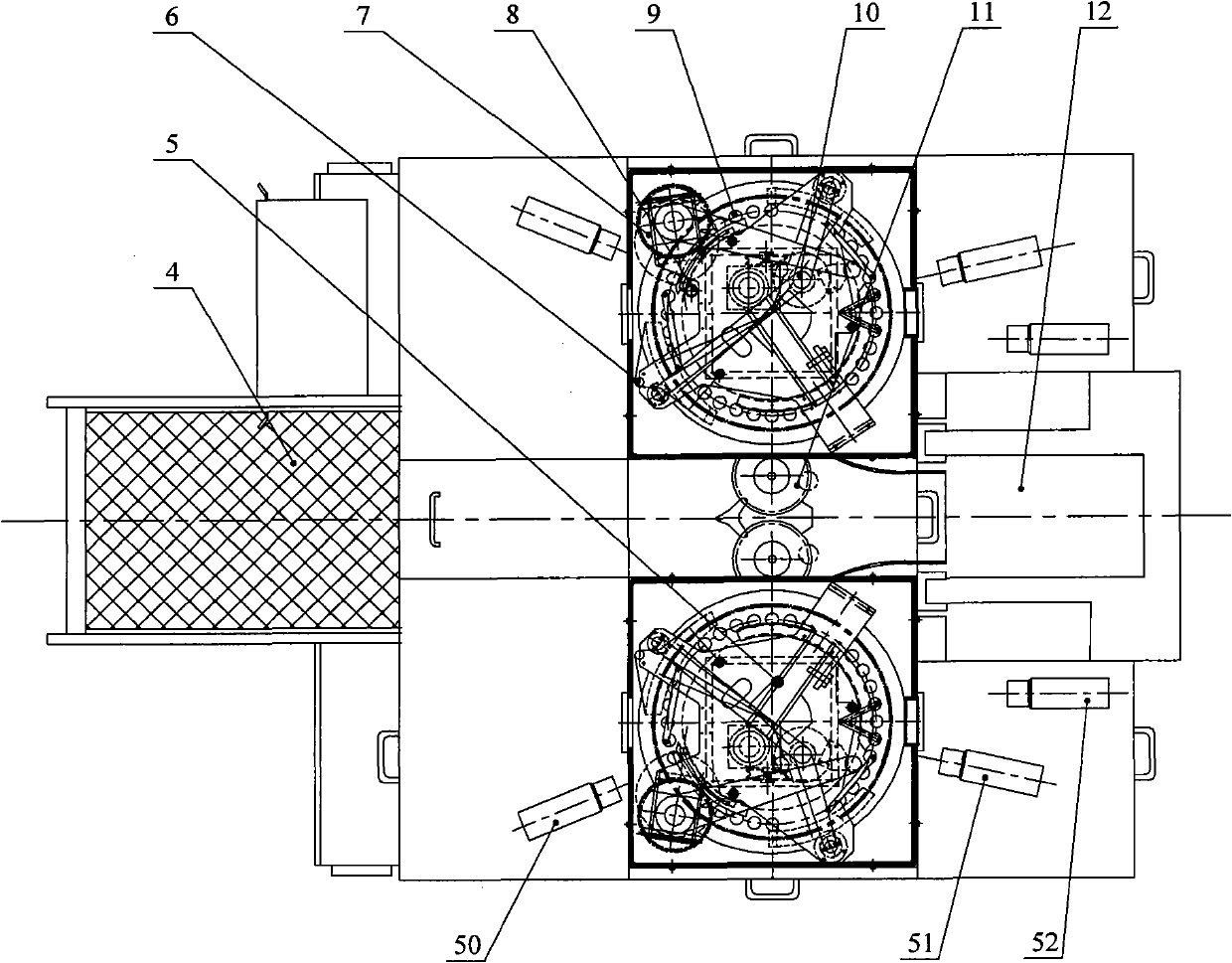

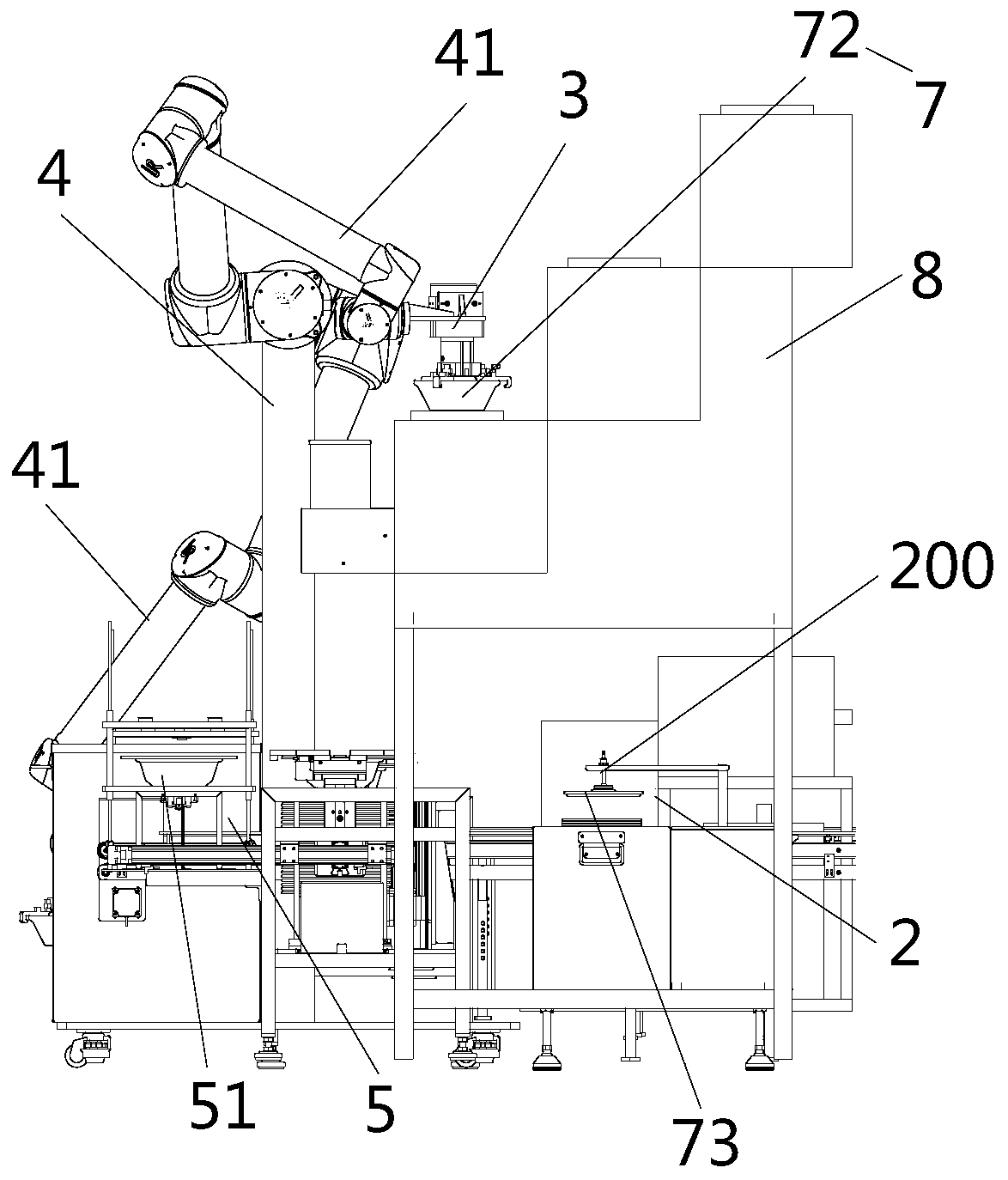

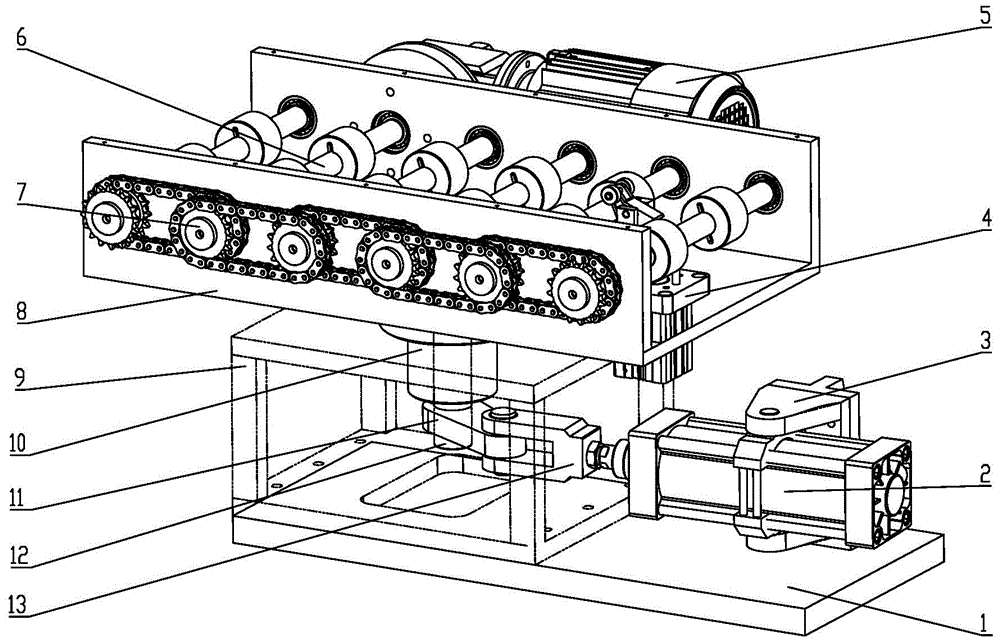

Intelligent on-line visual detection robot for visible foreign matters in bottled liquid

InactiveCN101793842ACompact structureHigh degree of automationProgramme-controlled manipulatorOptically investigating flaws/contaminationEngineeringForeign matter

The invention discloses an intelligent on-line visual detection robot for visible foreign matters in bottled liquid, which is characterized by comprising a bottle twisting mechanism and an intermittent transmission mechanism, wherein the bottle twisting mechanism is used for enabling a bottle body to rotate, and the intermittent transmission mechanism is used for enabling a main wheel disc to intermittently rotate; and the bottle twisting mechanism comprises a bearing seat, an arc-shaped supporting seat, a shaft, belt pulleys and a plurality of bearings. The bearing seat is installed on a rack of the intelligent on-line visual detection robot for the visible foreign matters in the bottled liquid along the upright direction; the arc-shaped supporting seat is installed on the bearing seat; the shaft is inserted into the bearing seat and connected with the bearing seat by the bearings; the number of the belt pulleys is five; a first belt pulley is connected with a bottle twisting motor by a belt; and a belt between a third belt pulley and a fourth belt pulley drives a bottle twisting belt pulley installed on a bottle clamping mechanism. The intelligent on-line visual detection robot for the visible foreign matters in the bottled liquid has the unique bottle twisting mechanism, a unique bottle rejecting mechanism and a unique intermittent rotating mechanism so as to guarantee the detection reliability of the bottle body.

Owner:长沙图创机电科技有限公司

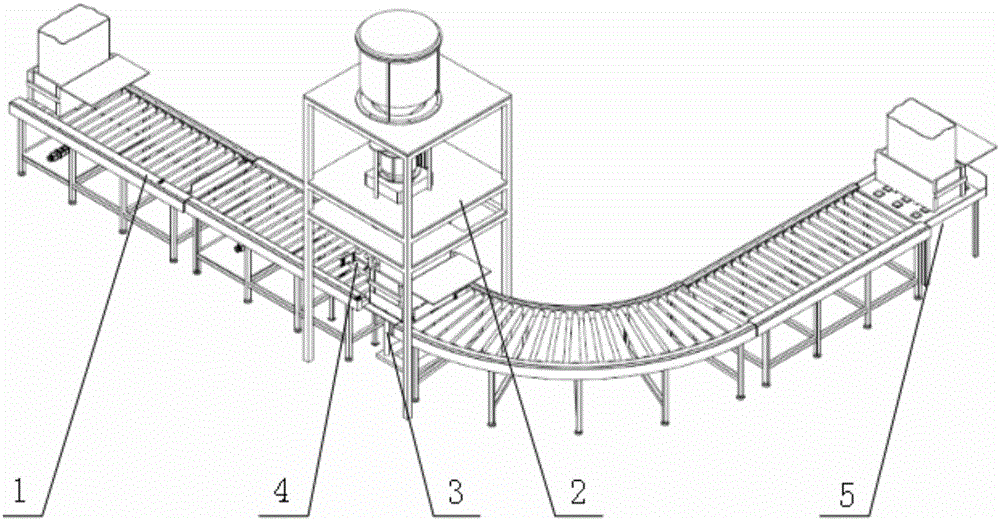

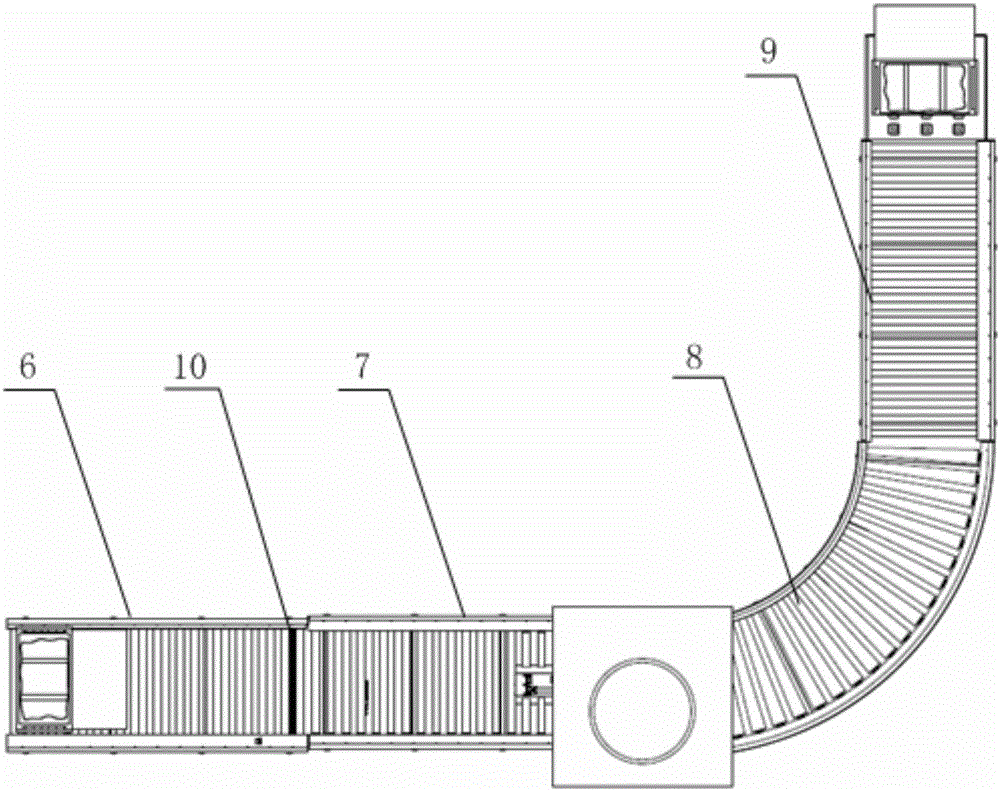

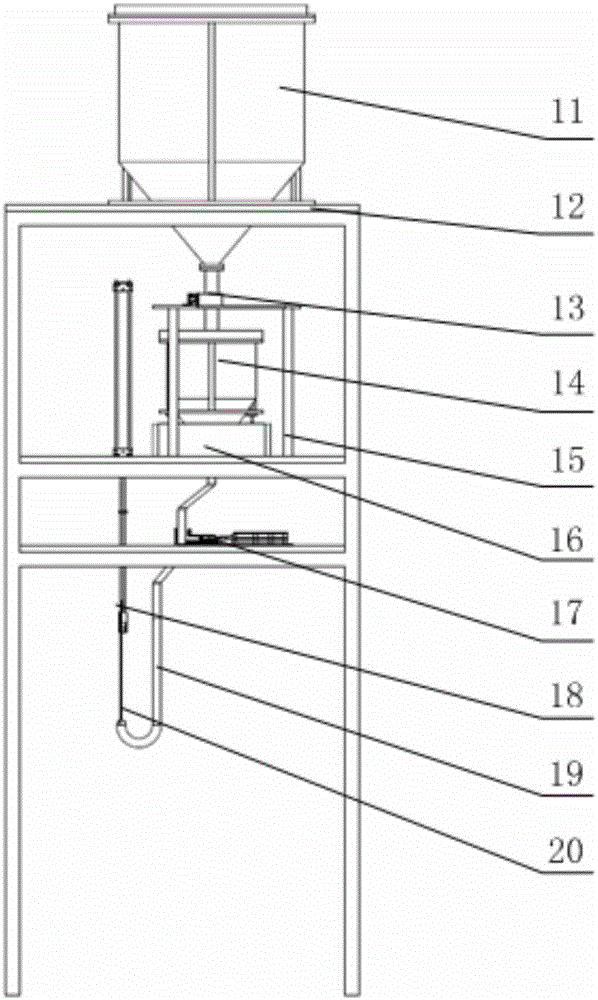

Automatic weighing and boxing device for powder blasting supplies

InactiveCN105857756ARealization of automatic weighingRealize automatic unloadingSolid materialMechanical engineeringAutomatic testing

The invention discloses an automatic weighing and boxing device for powder blasting supplies. The automatic weighing and boxing device is composed of a roller conveying line, a feeding and weighing device, a vibration platform, an auxiliary device and a finished product packaging table. Part of the roller conveying line and the finished product packaging table are installed outside a semi-closed workshop. The roller conveying line is formed by sequentially connecting a plurality of roller conveyors in the conveying sequence. An explosion-proof motor and power chain wheel type rollers are adopted by the roller conveyors, and the roller conveyors are subjected to dust-proof treatment, so that automatic conveying of products is achieved. Weighing of materials and automatic filling of the materials are completed by the feeding and weighing device. The vibration platform is used for jolt-ramming of the materials, the number of gaps between the materials is reduced, and the materials are prevented from being piled up. The auxiliary device is used for pushing material boxes onto the vibration platform and pushing the material boxes off the vibration platform after the material boxes are filled with the materials. The finished product packaging table is used for product packaging. The automatic weighing and boxing device is provided with pneumatic elements, the explosion-proof structure design is adopted, and unmanned operation is achieved; and the automatic weighing and boxing device has the characteristics of being simple in structure, high in weighing precision and convenient and fast to operate.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

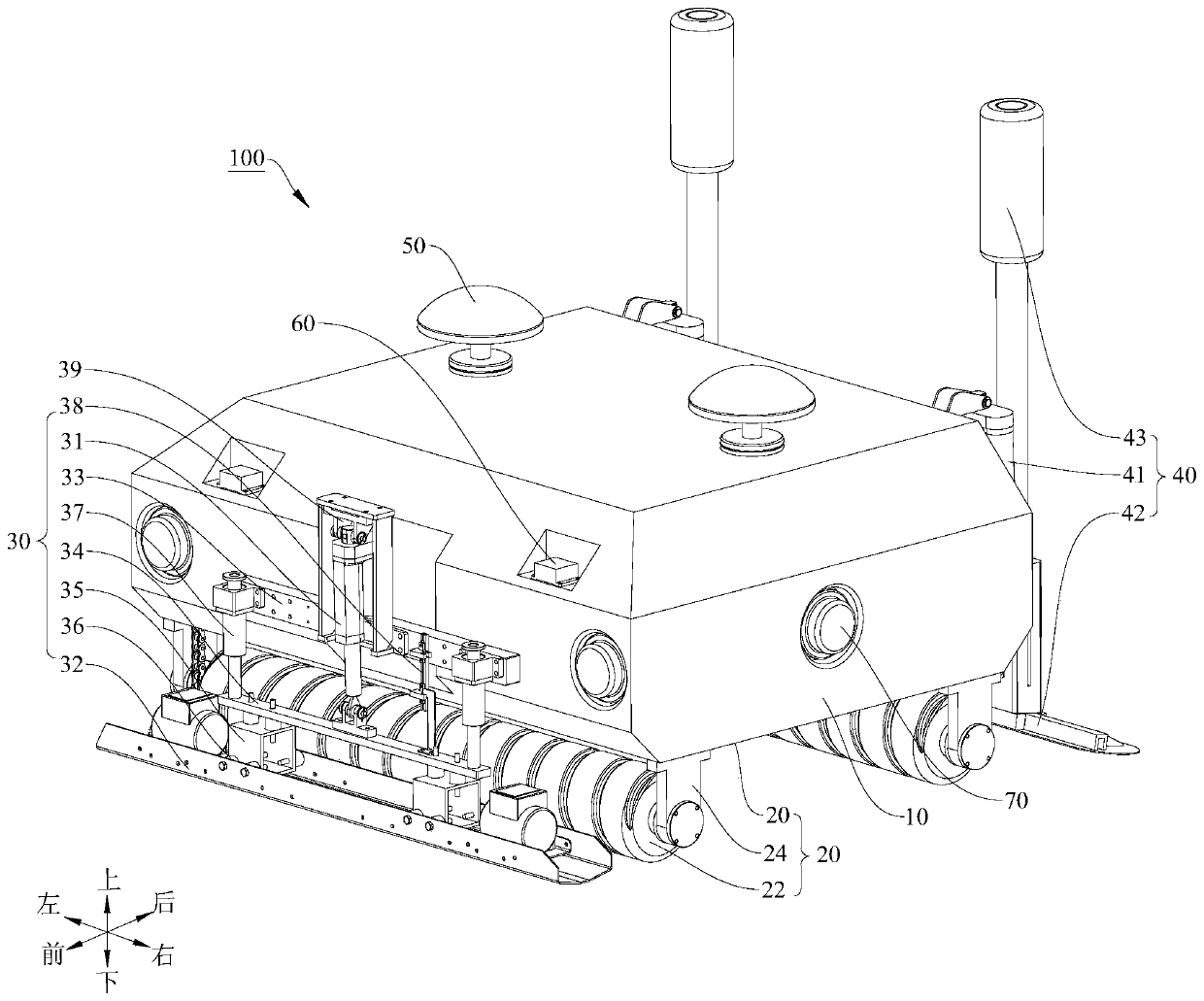

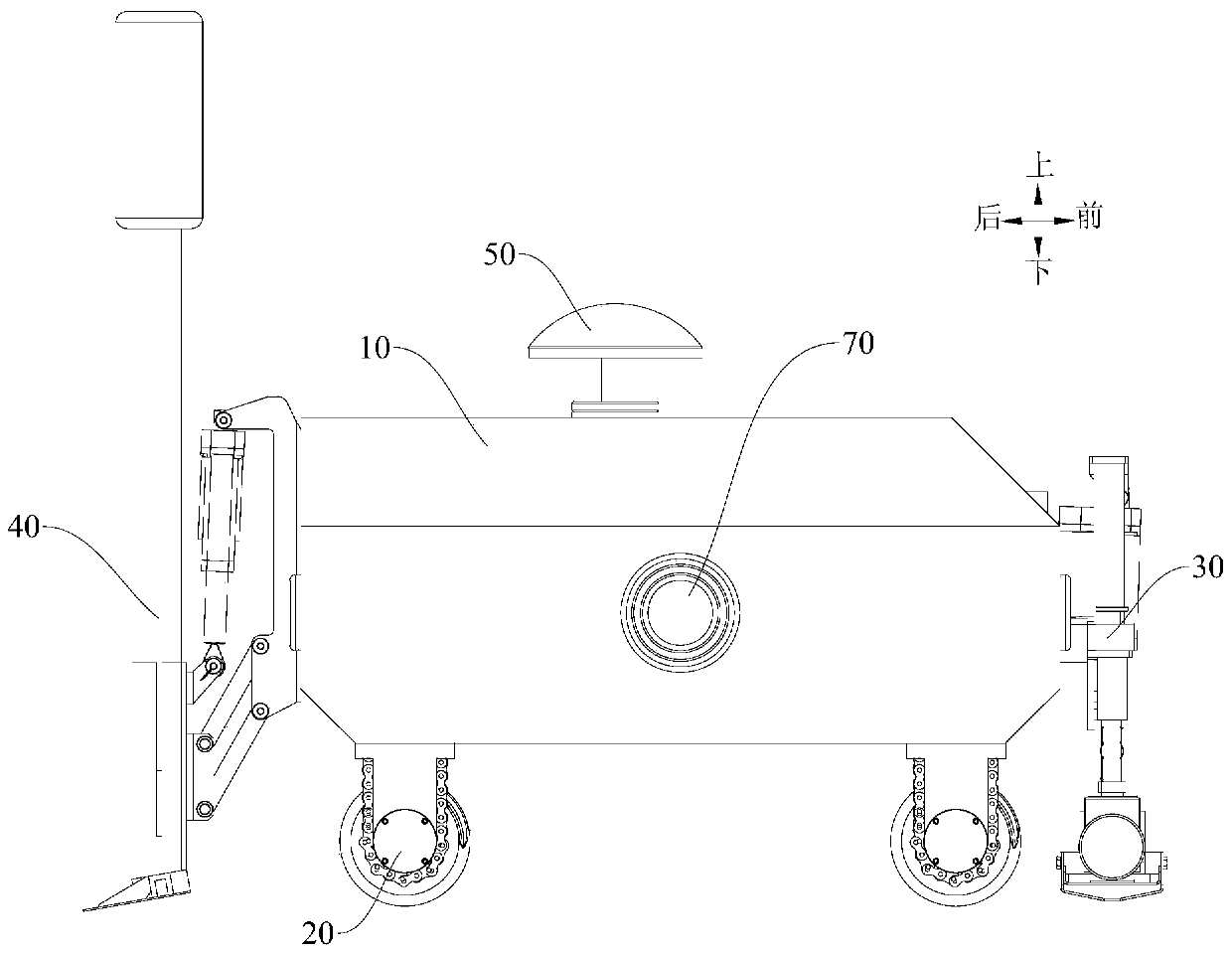

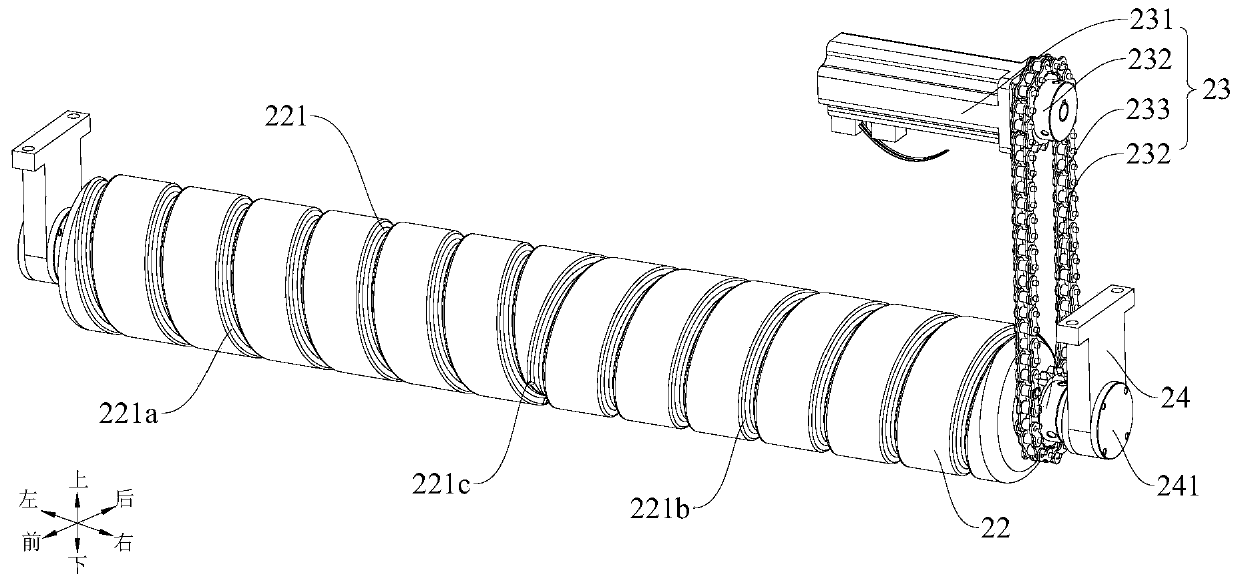

Leveling robot

ActiveCN110924686ARealize unmanned operationReduce manual operationsBuilding material handlingPath planManual handling

The invention discloses a leveling robot. The leveling robot comprises a chassis, a walking mechanism, a pulp lifting mechanism, a leveling mechanism and a navigation control module, wherein the walking mechanism is arranged on the chassis; the walking mechanism comprises a chassis and a roller; the roller is arranged on the chassis in a pivoted mode; a spiral groove in threaded extension around the axis of the roller is arranged on the surface of the roller; the pulp lifting mechanism comprises a first lifting piece and a vibration plate; the first lifting piece is connected with the vibration plate; the leveling mechanism comprises a second lifting piece, a scraper and a pavement detecting piece; the second lifting piece is connected with the scraper; the pavement detecting piece is electrically connected with the second lifting piece; and the navigation control module is arranged on the chassis for realizing the path planning and controlling the leveling robot to operate. The invention provides a new realization method for leveling treatment of concrete casting construction surfaces in the building industry, and facilitates realization of unmanned operation in the construction environment. The whole robot can save a lot of manual operations, and is low in labor intensity, low in cost and high in efficiency.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

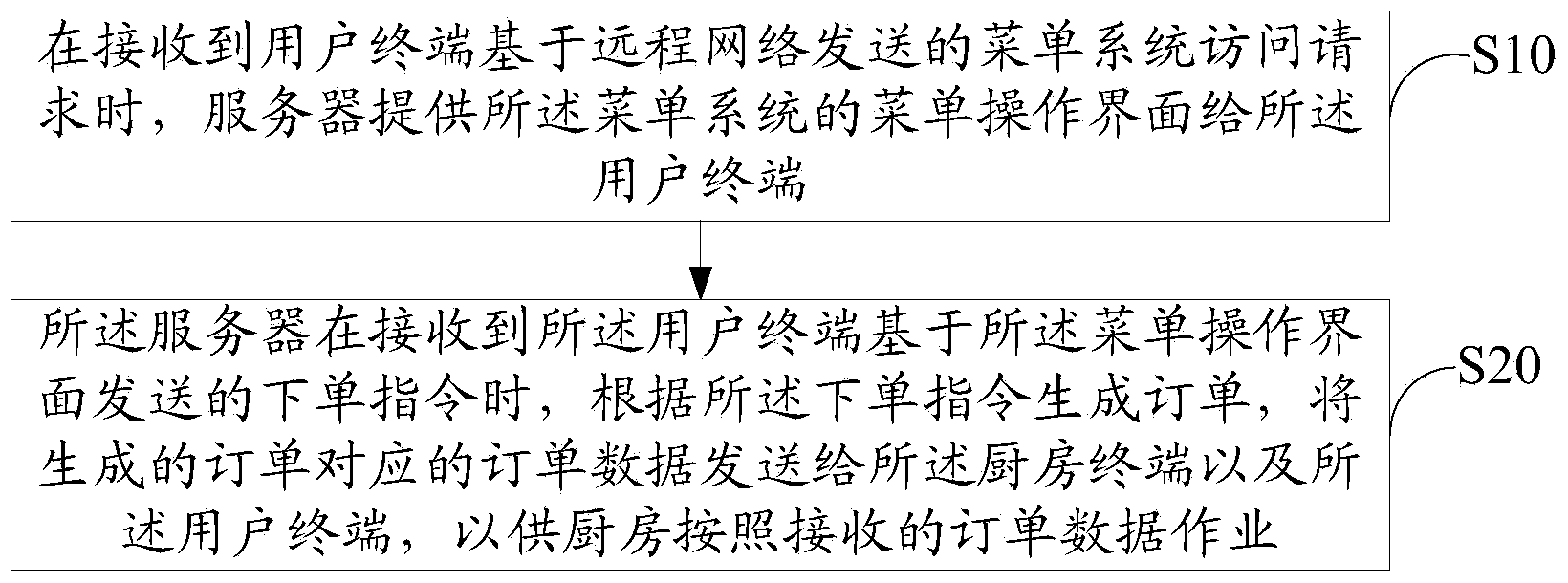

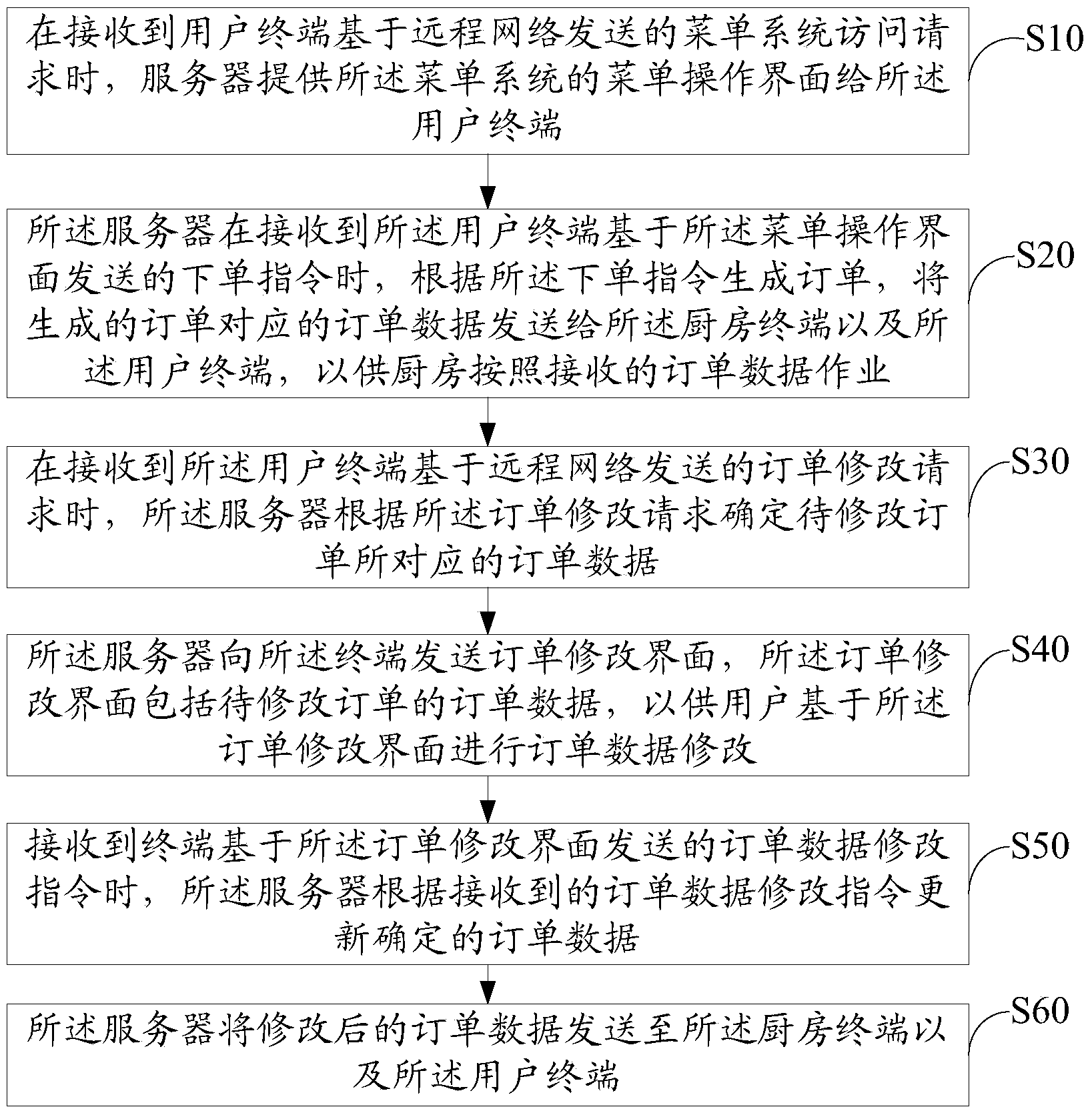

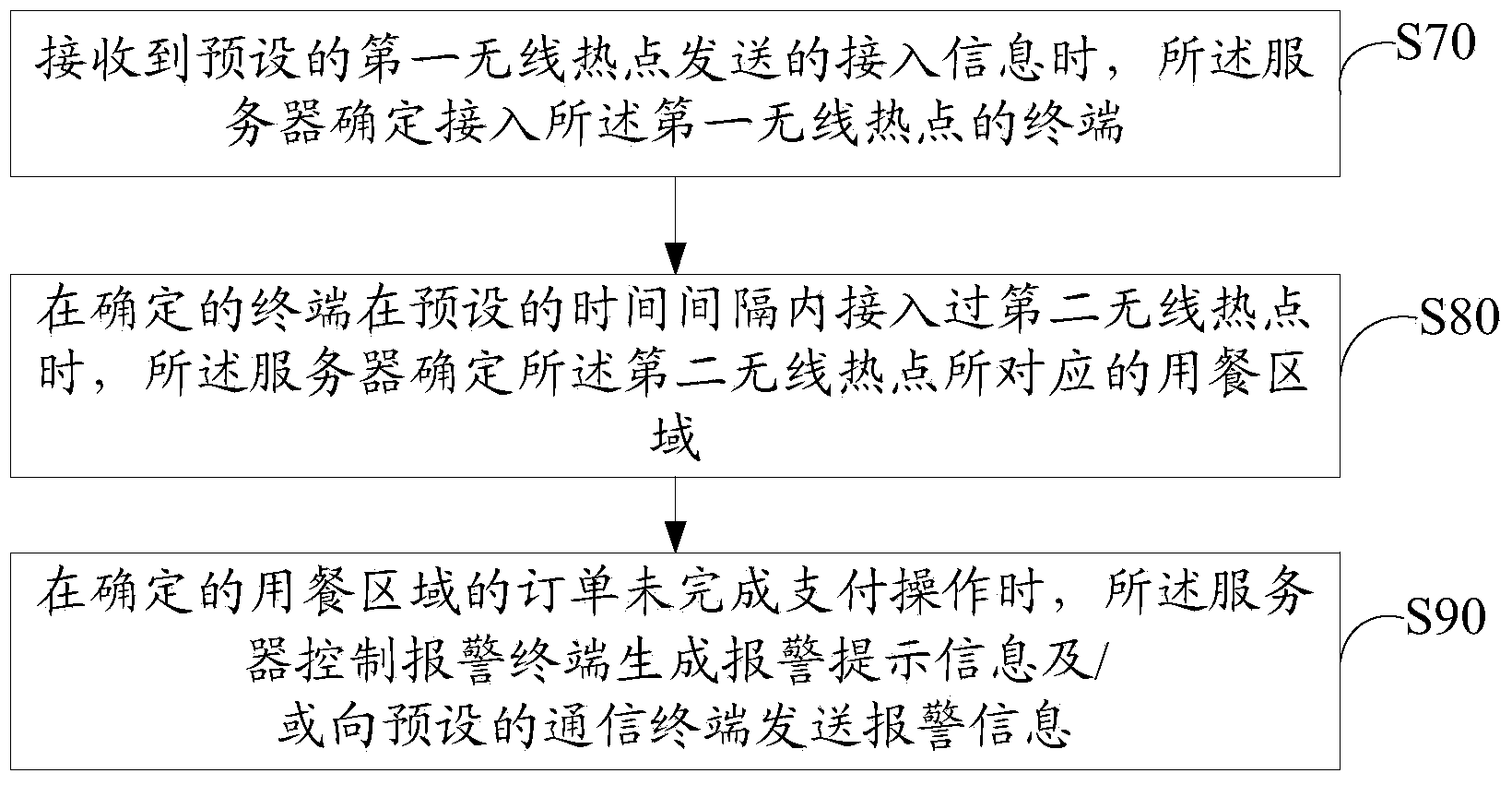

Method and system for realizing dining order-placing control

InactiveCN104036439ARealize unmanned operationLow costData processing applicationsTransmissionComputer scienceComputer terminal

The invention relates to a method and a system for realizing dining order-placing control. A user can use a terminal or a fixed terminal carried by the user himself / herselfto access a menu system operated in a server on the basis of a remote network, and can place an order via a menu operation interface provided by the server; when the server receives the order-placing command of a user terminal on the basis of the menu operation interface, an order is generated according to the order-placing command; order data corresponding to the generated order is linked to a kitchen terminal and the user terminal for a kitchen to operate according to the linked order data so as to realize the unmanned operation of an order-placing process and remote order placing; and cost is low.

Owner:西安祥泰软件设备系统有限责任公司

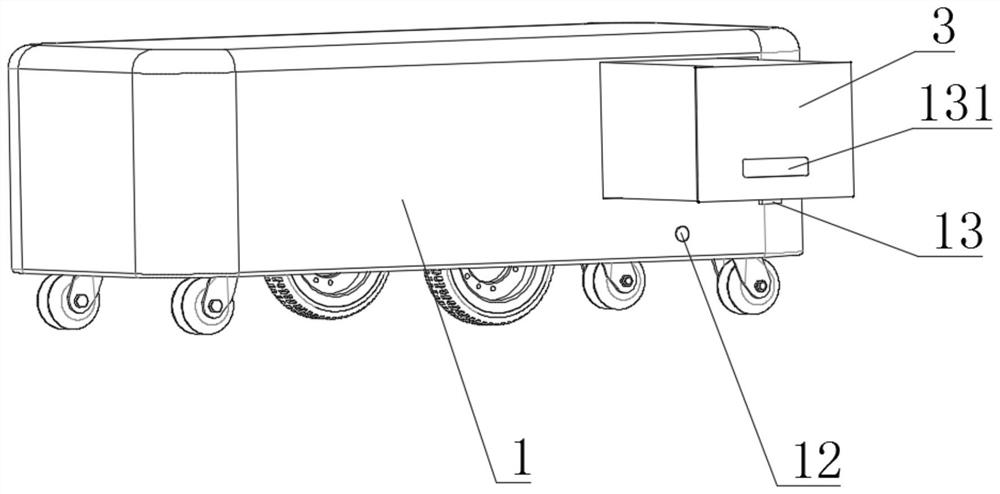

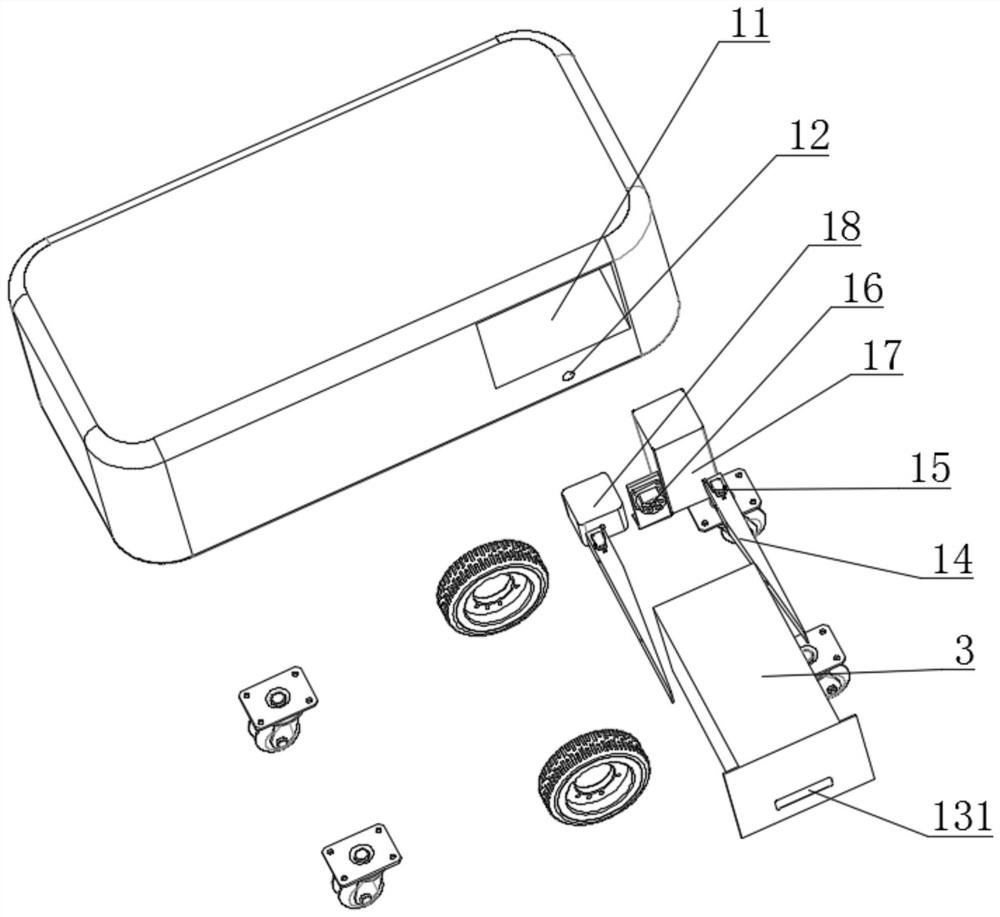

Intelligent express delivery device

ActiveCN107599938AThe process of sending and receiving express delivery is convenientGet rid of time constraintsProgramme-controlled manipulatorItem transportation vehiclesLogistics managementDelivery vehicle

The invention relates to an intelligent express delivery device and belongs to the technical field of logistics transport devices. The intelligent express delivery device solves the technical problemof low efficiency of package delivery and pick-up in the prior art. The technical solution comprises a storage area arranged in the front part of a carriage, wherein a storage area unfolding device isarranged on the top of the carriage; an automatic compartment door is also arranged on the top of the carriage; a package pick-up device is mounted at the middle of the bottom of the carriage; the rear part of the carriage is provided with an upper layer and a lower layer; the lower layer is a package sending and pick-up platform; the upper layer of the carriage is an unmanned aerial vehicle package delivery device; and a hydraulic lifting device is mounted between the bottom of the carriage and a carrying vehicle. The intelligent express delivery device applies the technical improvement of the automated storage and retrieval system to an express delivery vehicle so as to achieve a high intensive degree, free the package sending and pick-up from the time limitation, realize the intelligence and unmanned operation of the package sending and pick-up process, save human resources and solve the problem of "the last kilometer" of packages to a greater extent. The intelligent express delivery device conforms to the development trend of "Internet plus express delivery" and is worth popularizing and applying widely.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

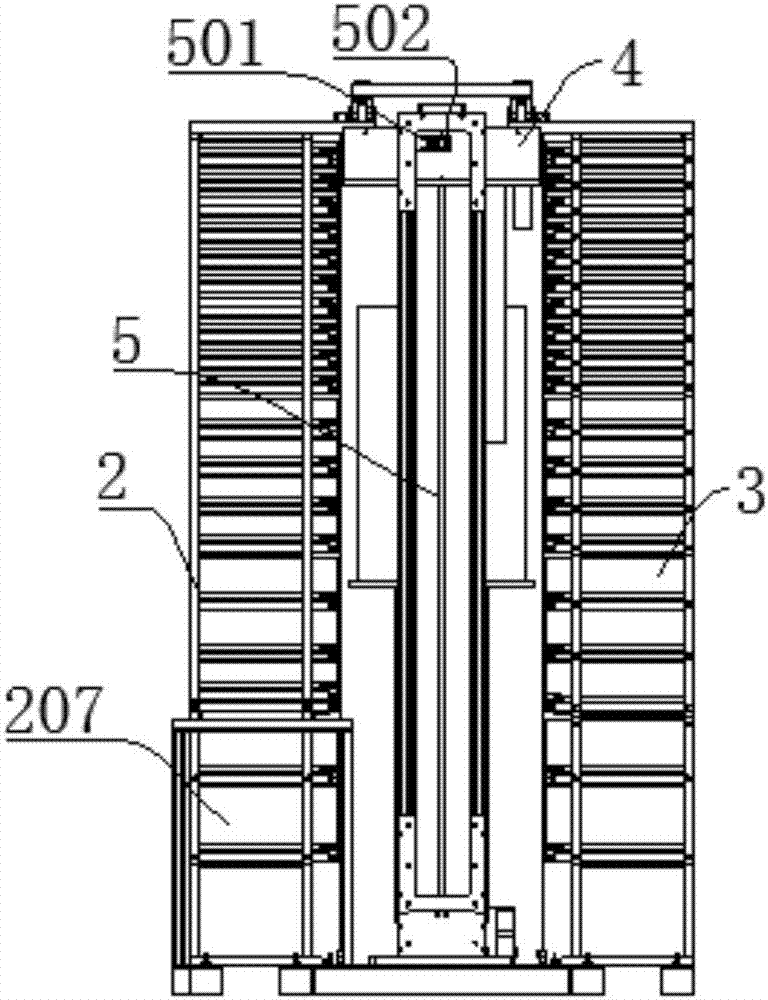

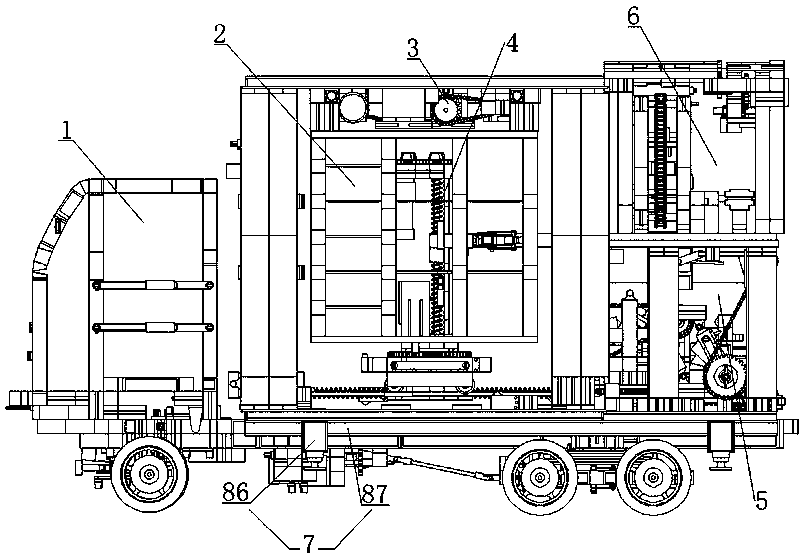

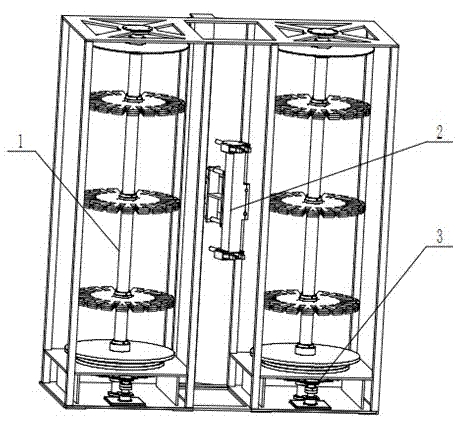

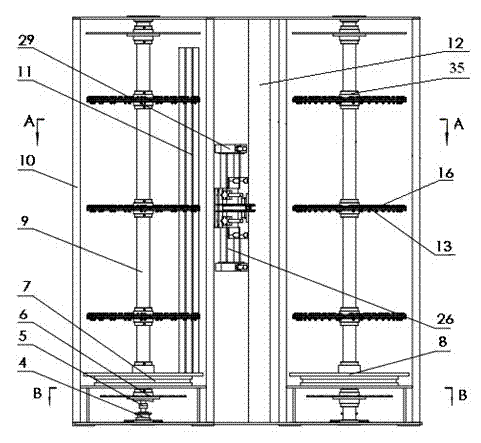

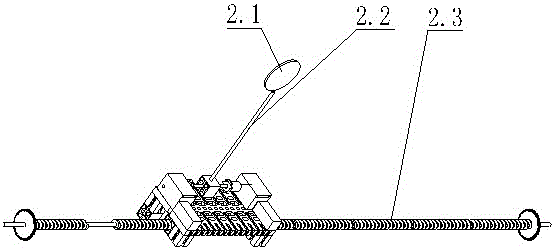

Automatic storage system for drill stem

InactiveCN102242612ALarge capacityAdjustable spacingDrilling rodsDrilling casingsWorking environmentPetroleum engineering

The invention relates to an automatic storage system for a drill stem. The automatic storage system comprises drill stem storerooms, a grab mechanism and a driving mechanism, wherein the drill stem storerooms are two and are mainly used for storing various drill stems, and each drill stem storeroom can store 60 drill stems; the driving mechanism is mainly used for driving the drill stems in the drill stem storerooms to rotate intermittently to ensure that the drill stems in the drill stem storerooms can rotate a certain angle each time; the grab mechanism is used for storing the drill stems and realizing the assembly and disassembly of the drill stems, so that a drilling tool moves among three positions, namely the left drill stem storeroom, the right drill stem storeroom and a power head; and actions such as the storage, take-off, clamping, assembly and disassembly and the like of the drill stems can be completed accurately by the matching among the drill stem storerooms, the grab mechanism and the driving mechanism. The storage system has a simple structure, is large in capacity, convenient to operate and high maintainability, and offers a reliable performance; and when the storage system is used, unmanned operation is realized, the work efficiency is high, and the automatic storage or remote control of the drill stems can be realized in special severe work environment.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

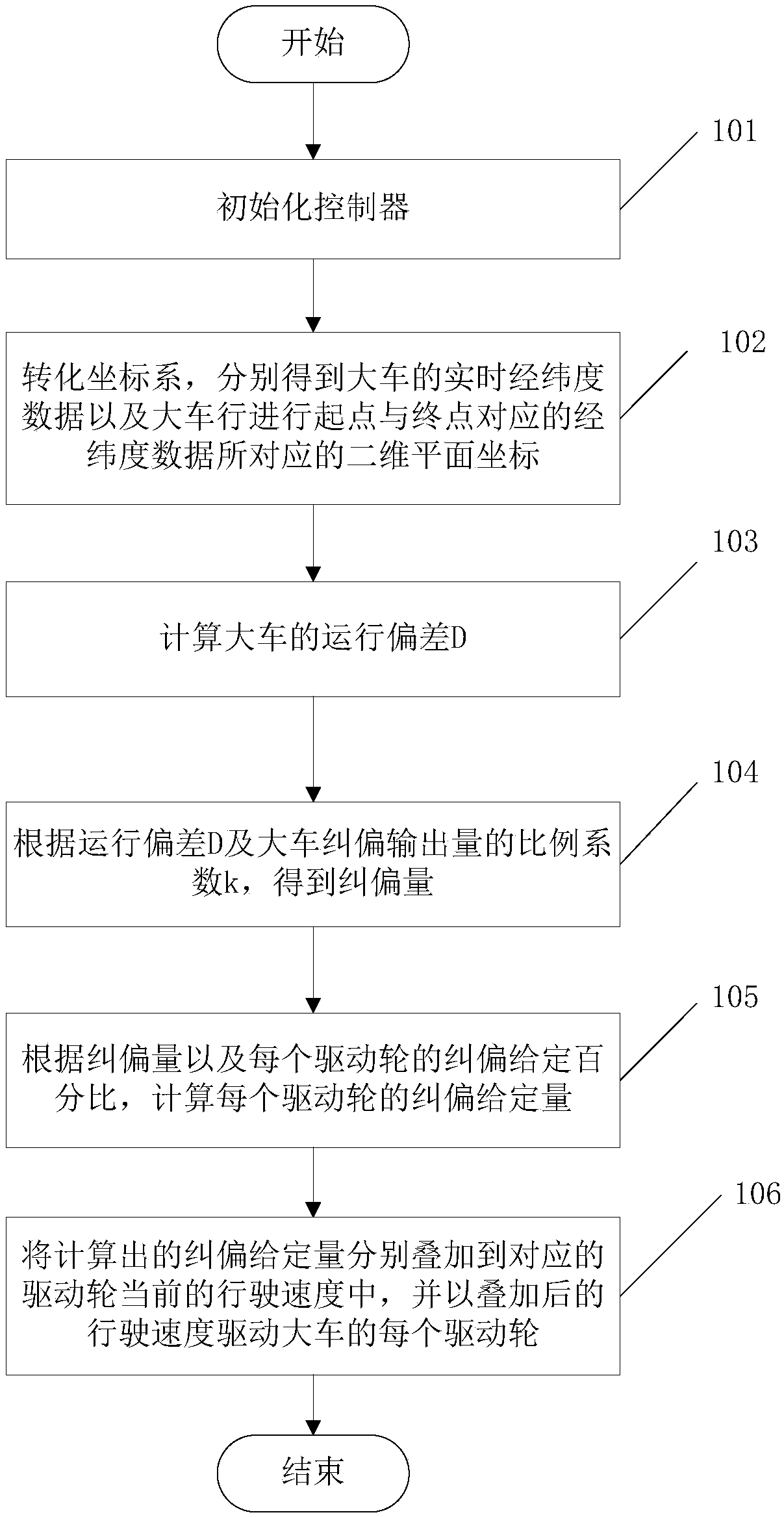

Tire crane cart automatic deviation correcting method

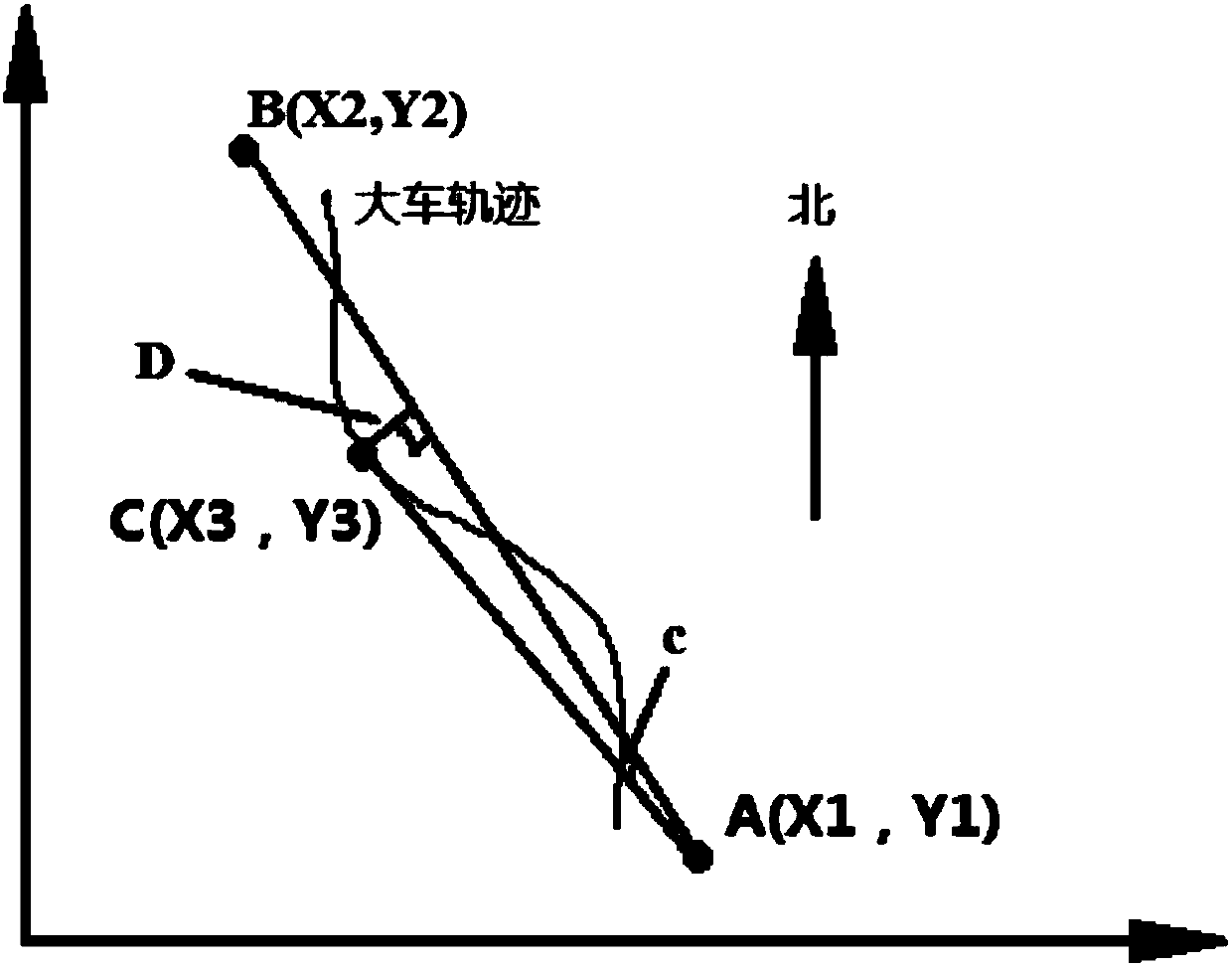

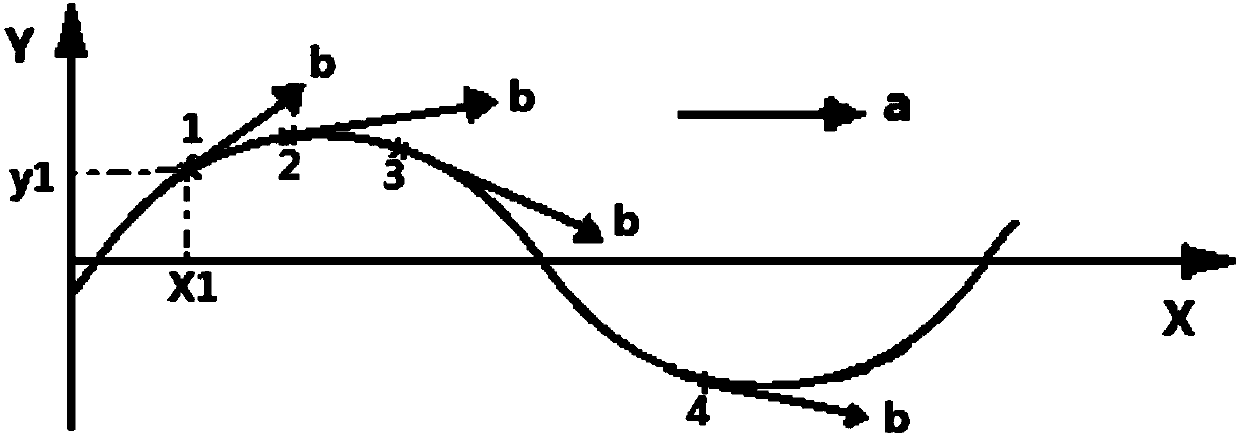

ActiveCN107943020AJudgment of operabilityJudgment bias trendLoad-engaging elementsPosition/course control in two dimensionsSimulationReference line

An embodiment of the invention relates to the field of port machinery, and discloses a tire crane cart automatic deviation correcting method. The tire crane cart automatic deviation correcting methodcomprises the steps of: calculating a current running deviation D of a tire crane cart, wherein the running deviation D is a distance between a real-time coordinate point of the current cart and a trajectory reference line; acquiring a deviation correcting quantity according to the running deviation D and a proportional coefficient k of a cart deviation correcting output quantity; and controllingdriving wheels of the cart according to the deviation correcting quantity, so that the cart can run straight. Compared with the prior art, the tire crane cart automatic deviation correcting method calculates the deviation correcting quantity by combining with the real-time running deviation of the cart, and can judge a real-time running direction and a deviation trend of the card more precisely, so as to conduct calculation of the deviation correcting quantity more precisely, and control the driving direction of the cart more precisely; meanwhile, the automatic deviation correcting method saves labor, reduces the labor intensity of related staff, and is conducive to realizing on-site unattended operation.

Owner:SHANGHAI SIGRINER STEP ELECTRIC

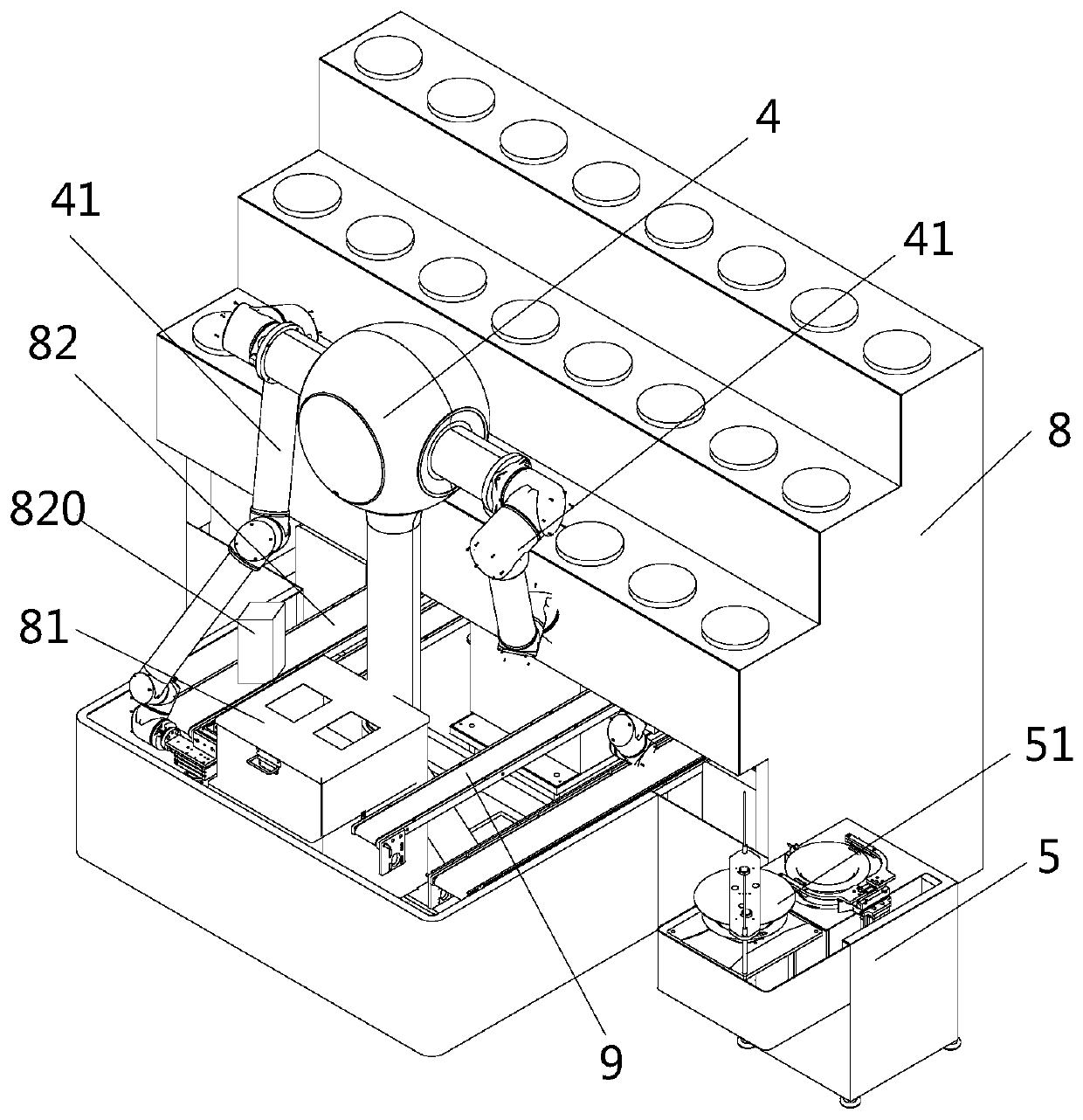

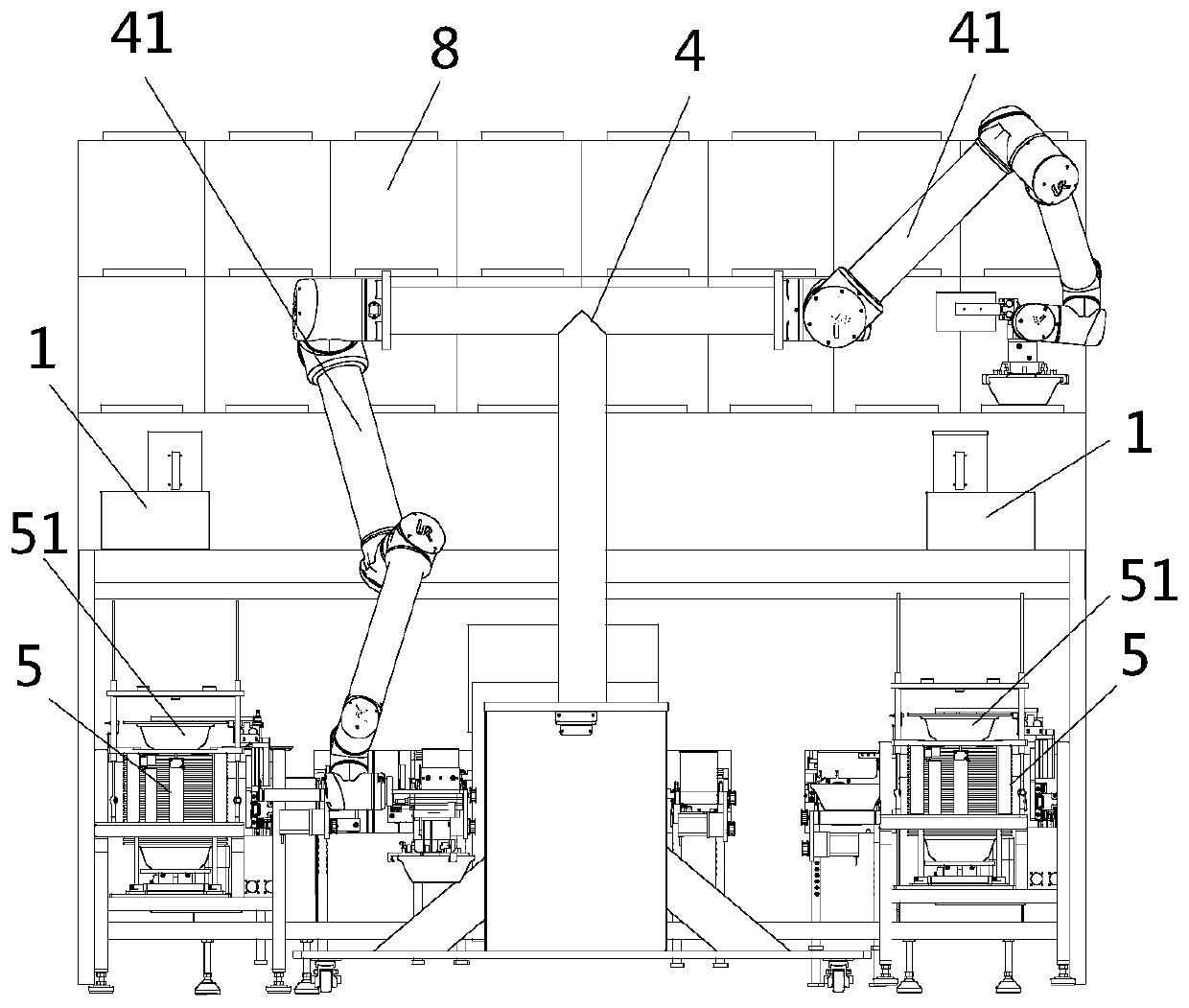

Food material cooking equipment and food material cooking method

ActiveCN110558833AImprove processing efficiencyRealize unmanned operationCooking vesselsFood materialEngineering

The invention provides food material cooking equipment and a food material cooking method. The food material cooking equipment comprises a food material conveying line used for conveying food materialcontaining parts containing food materials, a cooking device used for cooking the food materials located in the food material containing parts, and an operation robot provided with a mechanical arm,wherein the working end of the mechanical arm is provided with a clamp mechanism; and the clamp mechanism is used for clamping or releasing the food material containing parts. The clamp mechanism andthe mechanical arm are matched with each other so as to transfer the food material containing parts located on the food material conveying line to or from the cooking device; and the problem of low food preparation efficiency in the prior art is solved.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

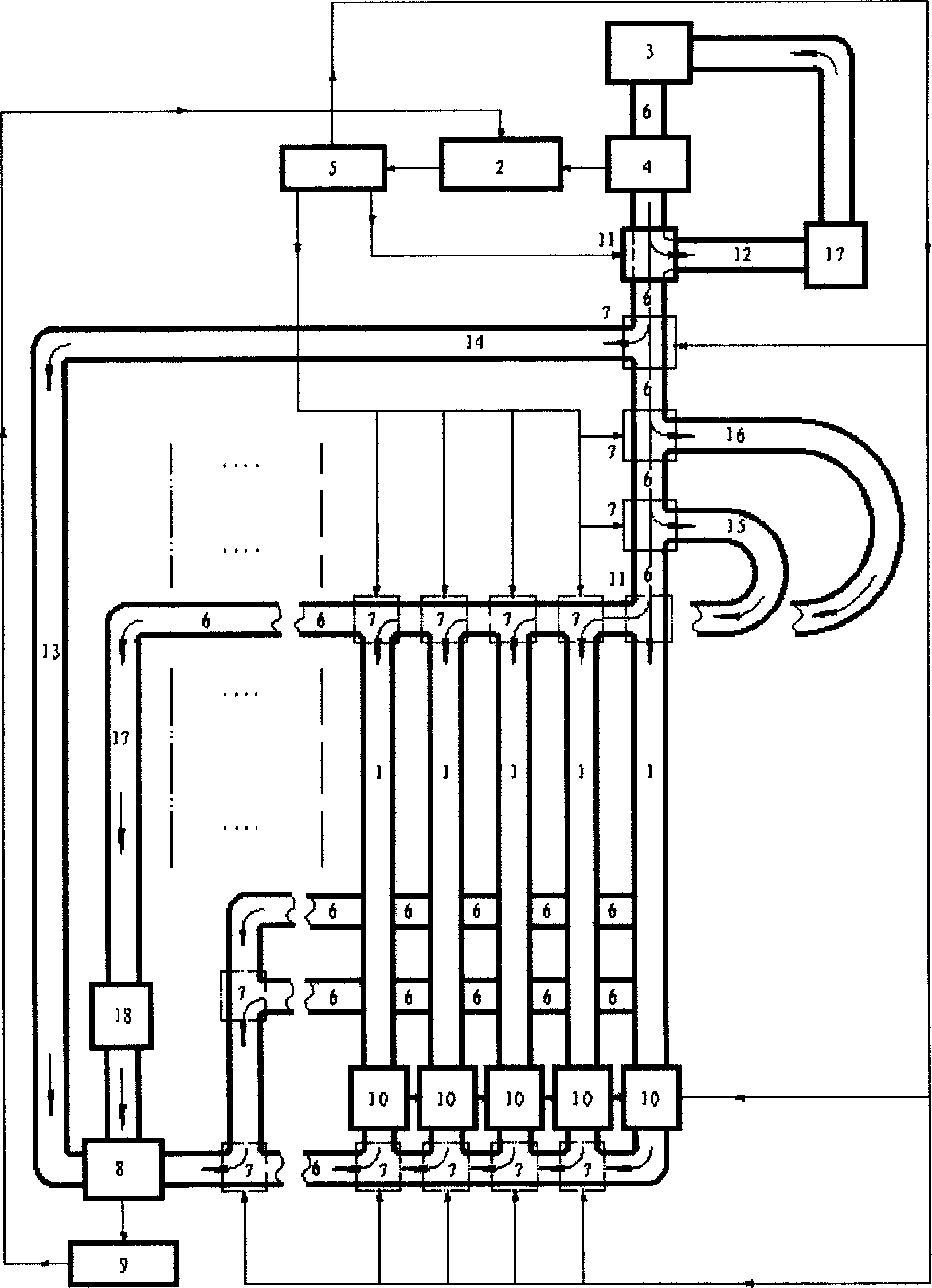

Channel type automatic cigarette-sorting and -storing method and apparatus thereof

InactiveCN1843869AImprove flow and efficiencyReduce errorsStorage devicesAutomatic controlTraffic volume

The invention discloses a channel-type tobacco automatic classify storage method and relative device, which comprises: several layers and several tobacco storage channels (1). The whole process of feeding, storing and discharging are automatically controlled by computer (2). The invention can realize unattended operation of tobacco, to improve efficiency and flux, which replaces the disc unit with tobacco unit as transmission unit, to realize automatic tobacco feeding and selecting. And it can improve the safety of storehouse and reduce the labor intensity of worker.

Owner:GUIYANG PUTIAN LOGISTICS TECH

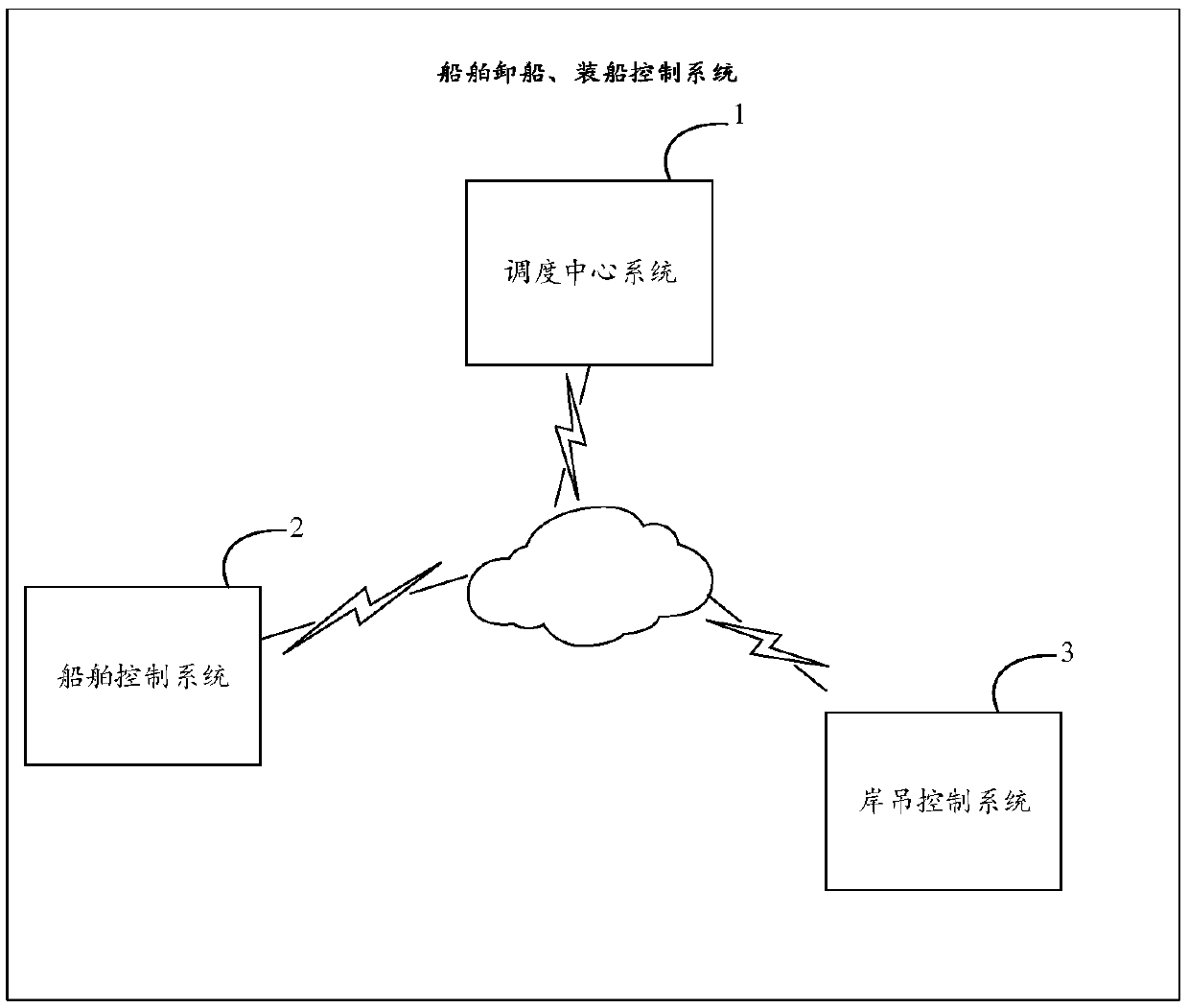

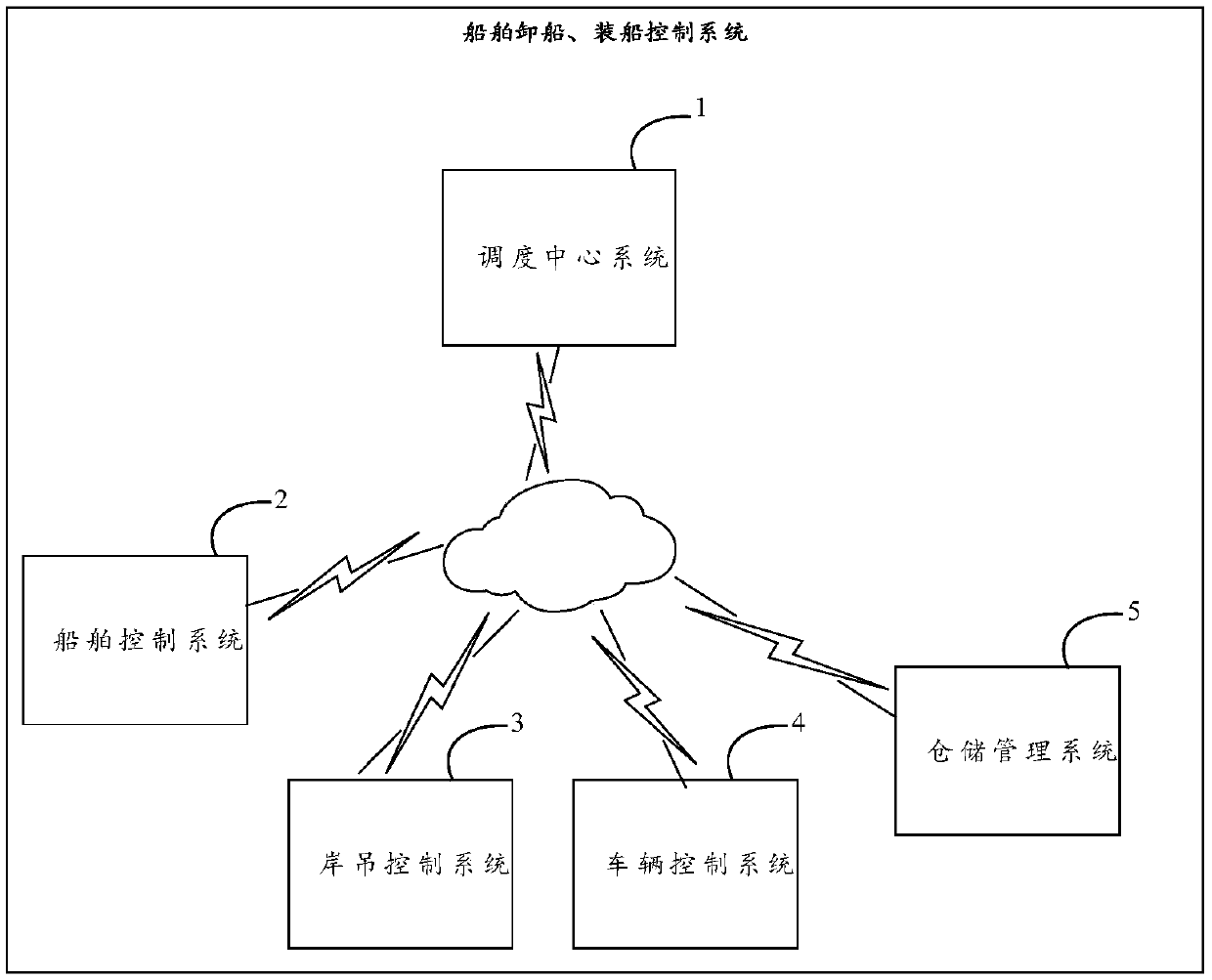

Ship unloading and loading control system and related system and device

PendingCN109685435AReduce human resource investmentReduce labor cost investmentSteering initiationsOffice automationShoreCrane Equipment

The invention discloses a shipping unloading and loading control system and related systems and devices, which can achieve full automation of ship loading and unloading; The ship unloading control system comprises the dispatching center system generates a ship unloading plan according to the ship information of the target ship, the container information and the shore crane equipment information, generates a ship unloading task and a ship berthing task according to the ship unloading plan, and sends the ship berthing task and the ship unloading task to a ship control system of the target ship and a shore crane control system of the target shore crane equipment respectively; The ship control system sends ship information and container information to the dispatching center system, controls atarget ship to run to an operation area corresponding to the target shore crane equipment according to the received ship berthing task, and sends a ship in-place notification message to a shore cranecontrol system of the target shore crane equipment; And when the shore crane control system receives the ship in-place notification message from the ship control system, the shore crane control systemcontrols the target shore crane equipment to load the container on the target ship to the vehicle according to the ship unloading task.

Owner:BEIJING TUSEN ZHITU TECH CO LTD

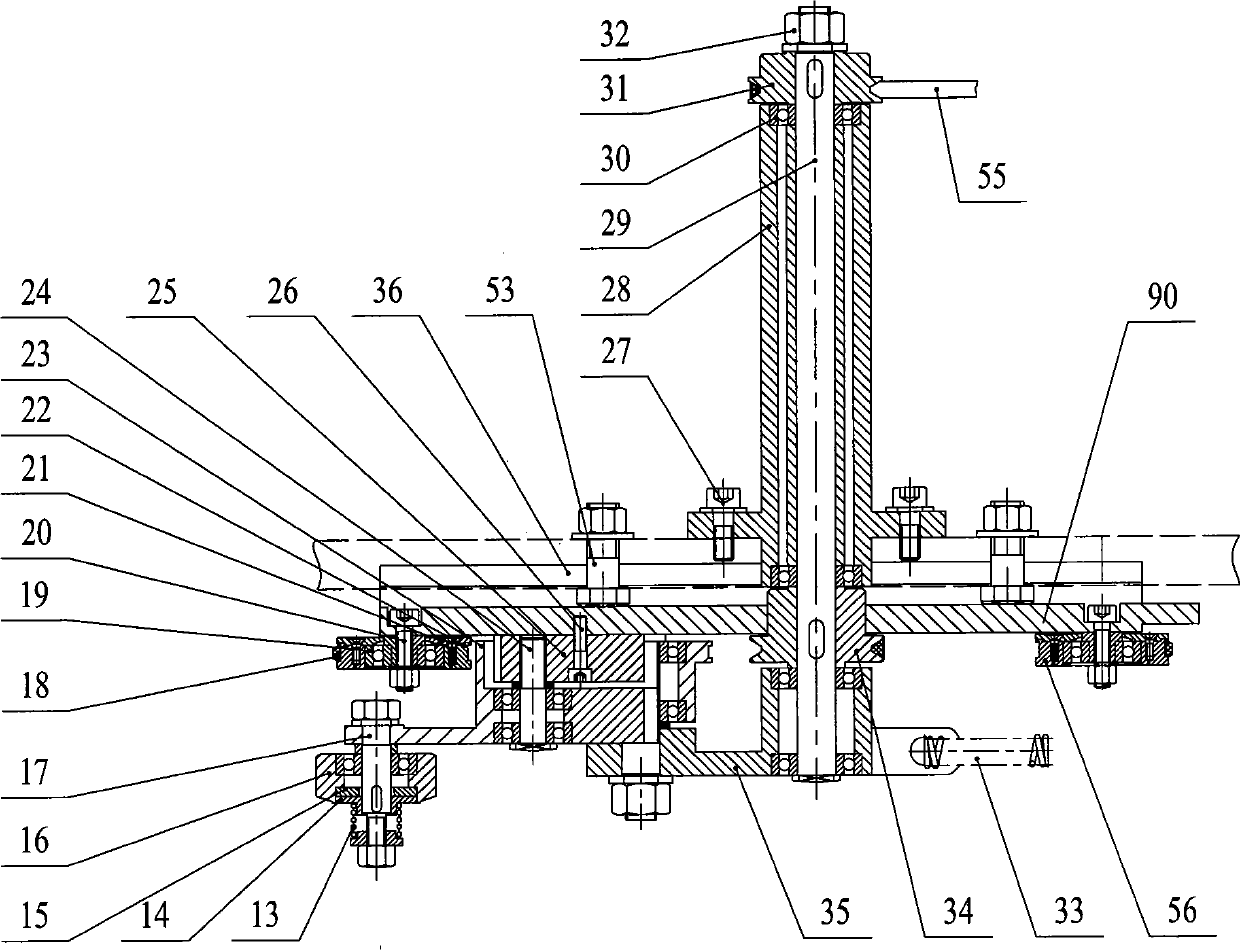

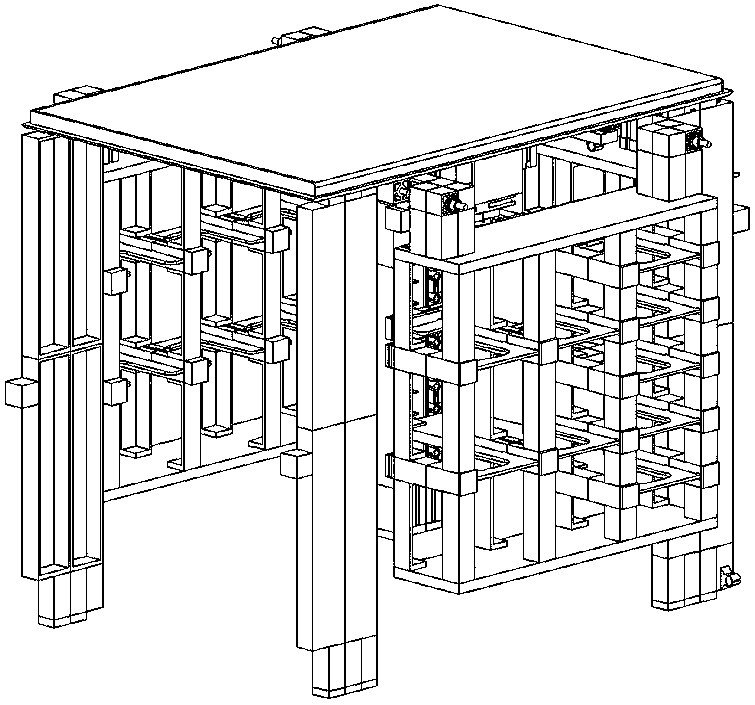

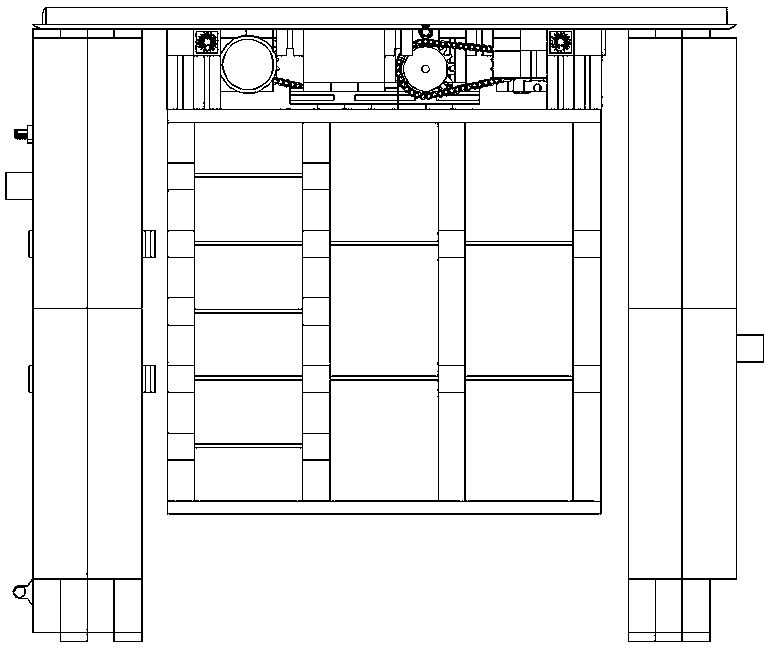

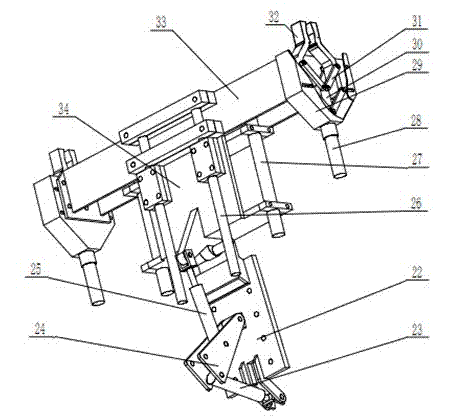

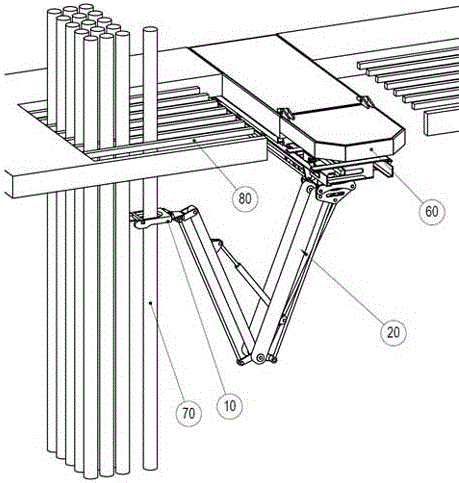

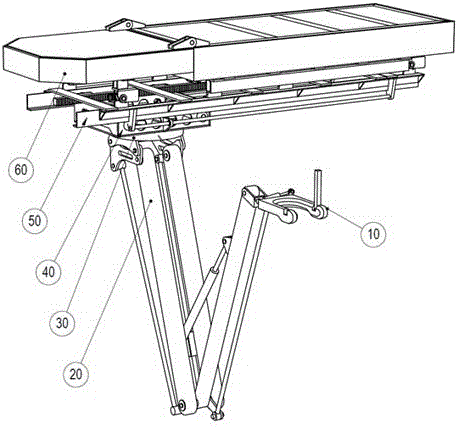

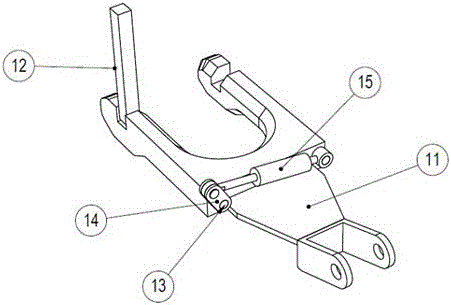

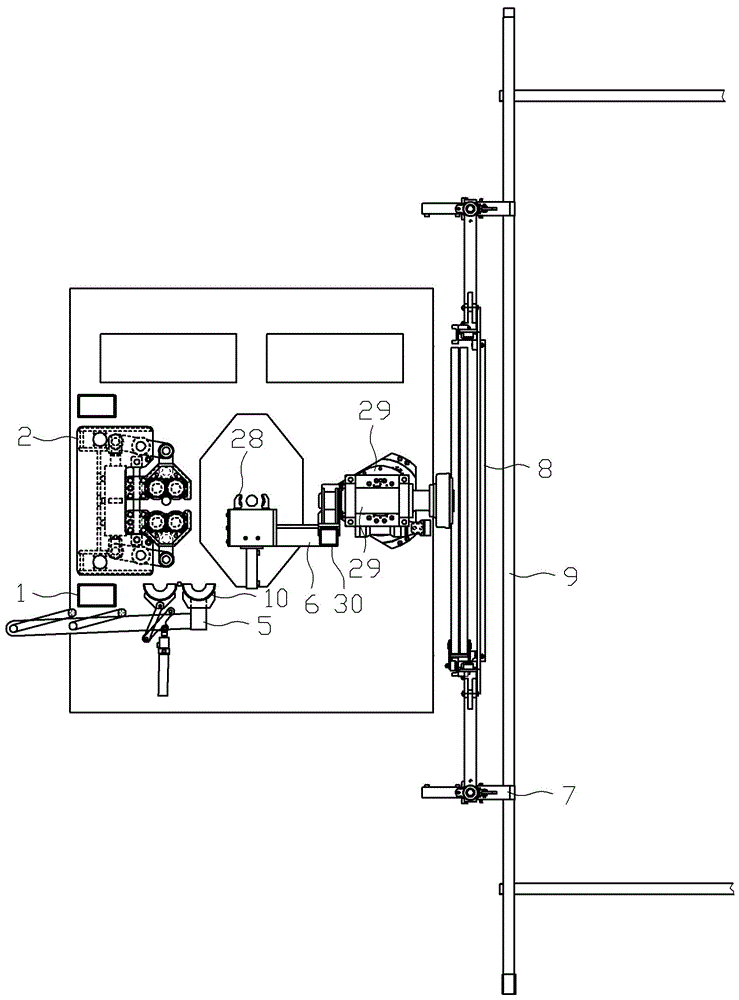

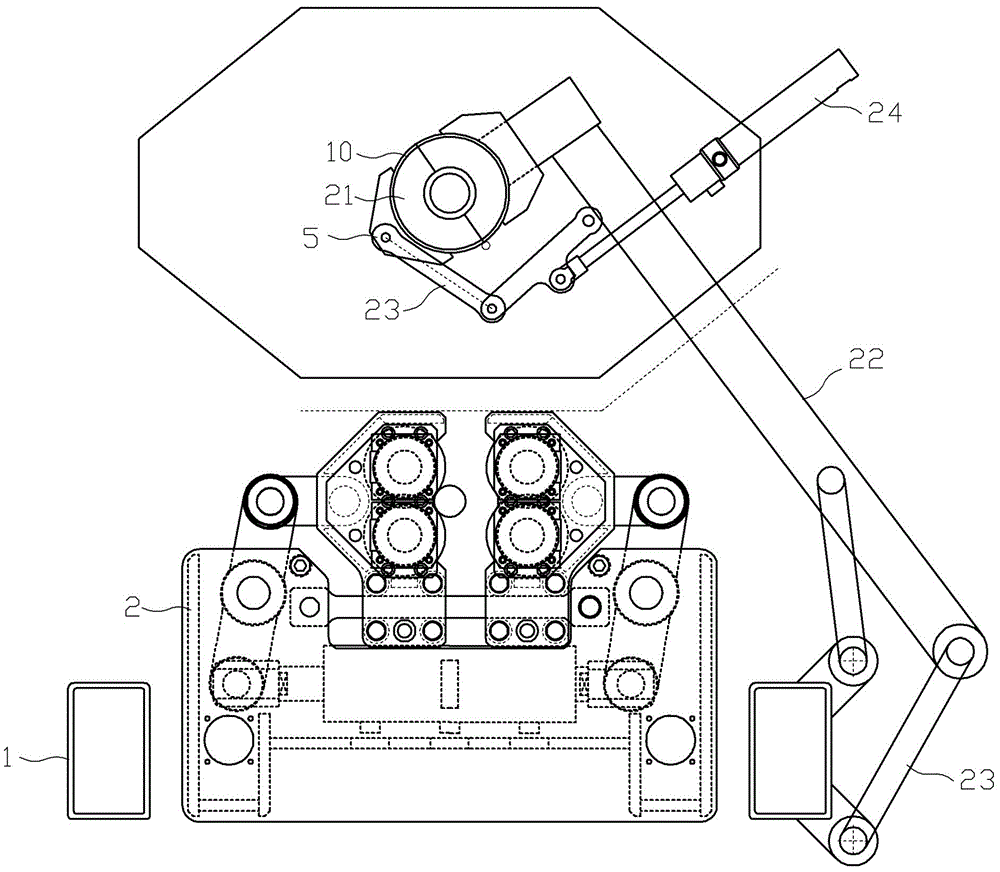

Tube-arraying robot for racking platform of petroleum well drill and method

ActiveCN106593324ARealize unmanned operationReduce labor intensityDrilling rodsDrilling casingsRackingContinuous operation

The invention relates to a tube-arraying robot for a racking platform of a petroleum well drill and a method. According to the technical scheme, the tube-arraying robot comprises a tubular column claw, a telescopic boom, a rotating mechanism, a sliding base, a stretchable guide rail and an overturning racking platform, wherein the tubular column claw is hinged at one end of the telescopic boom; the upper end of the telescopic boom is connected with the rotating mechanism; the rotating mechanism is arranged on the sliding base; the sliding base can move on the stretchable guide rail; and the stretchable guide rail is arranged at the bottom of the overturning racking platform. The tube-arraying robot has the beneficial effects that the full mechanical continuous operation for automatically arraying and placing the tubular columns of the racking platform is realized; the labor intensity of the operator is greatly reduced; the accident rate of the drilling operation is greatly reduced; the work danger of the worker is reduced; the safety is greatly promoted; the labor cost is saved; the tube-arraying robot is coordinated with a power elevator, so that the unmanned operation of the racking platform is realized and the problem that the space is occupied by the racking platform and the guide rail which are released on specific positions under a special state is effectively solved.

Owner:DONGYING RUIAO IND & TRADE CO LTD

Automatic filling system for radioactive isotope medicament

ActiveCN106800268AReduce the risk of radiation exposureFully automatedCapsSynchronising machinesIsotopeMechanical engineering

The invention relates to an automatic filling system for a radioactive isotope medicament. The automatic filling system comprises a filling worktable and a control table. The filling worktable is arranged in a protective box. The control table is arranged outside the protective box and connected with the filling worktable. The automatic filling system further comprises a medicament pot storage module arranged at a feeding inlet of the filling worktable, an automatic grabbing module, a medicament pot processing module, a weighing and filling module and a finished product conveying module, wherein the automatic grabbing module, the medicament pot processing module and the weighing and filling module are arranged on the filling worktable, the finished product conveying module is located at a discharging outlet of the filling worktable, and all the modules are connected with the control table. Firstly, the automatic grabbing module grabs a medicament pot in the medicament pot storage module to the medicament pot processing module to be unsealed, next, the medicament pot is conveyed to the weighing and filling module to be filled automatically, then, the medicament pot is conveyed to the medicament pot processing module to be sealed, and finally, the medicament pot is conveyed to the finished product conveying module for conveying process. Compared with the prior art, the automatic filling system has the advantages of high filling accuracy, safety, reliability and the like.

Owner:SHANGHAI ATOM KEXING PHARMA +1

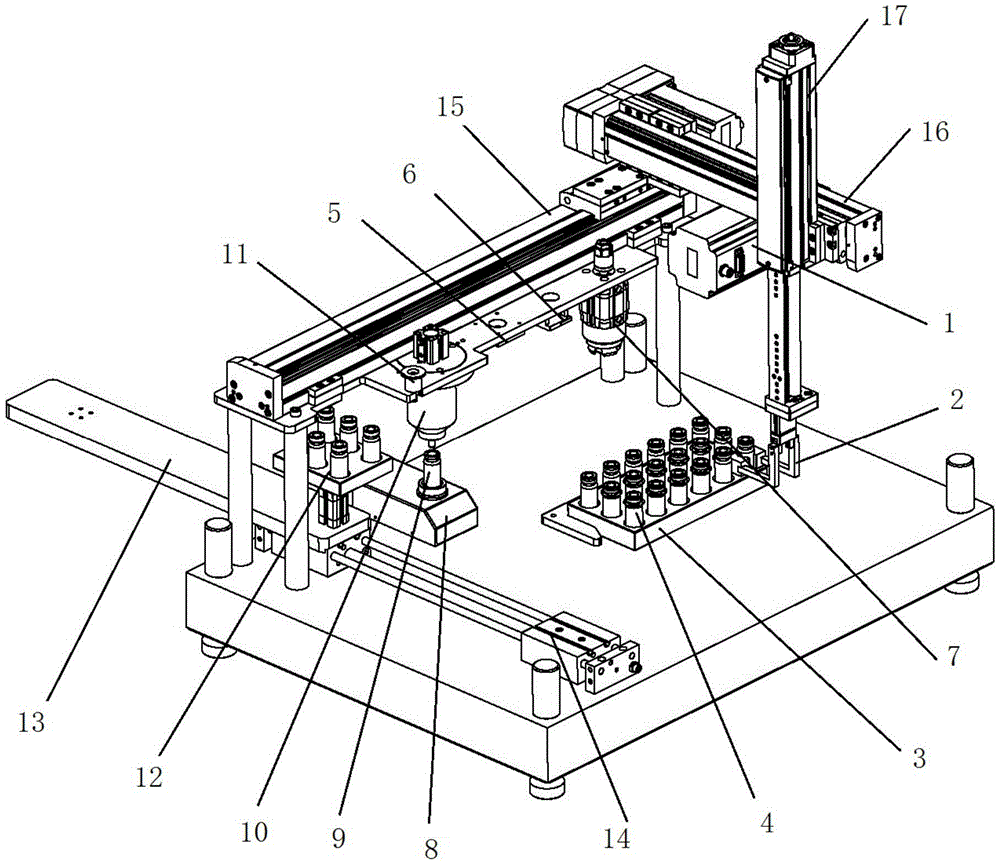

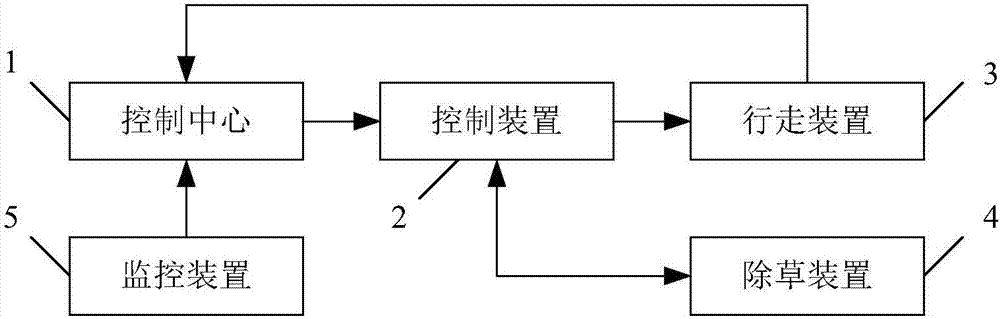

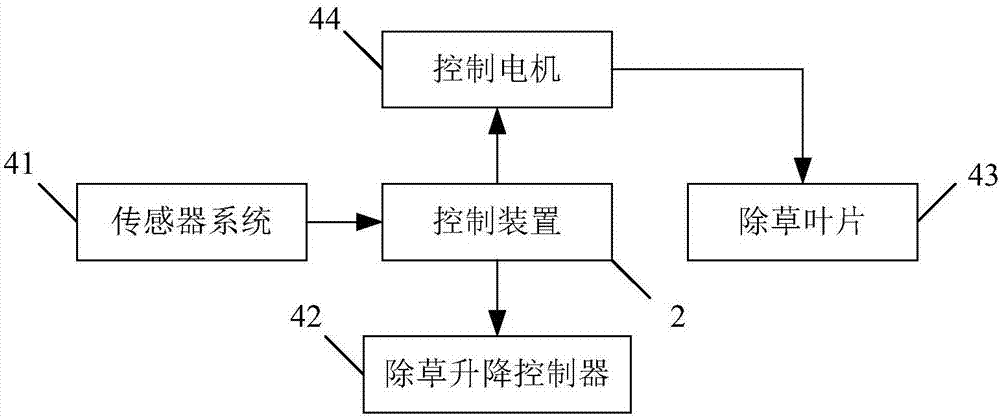

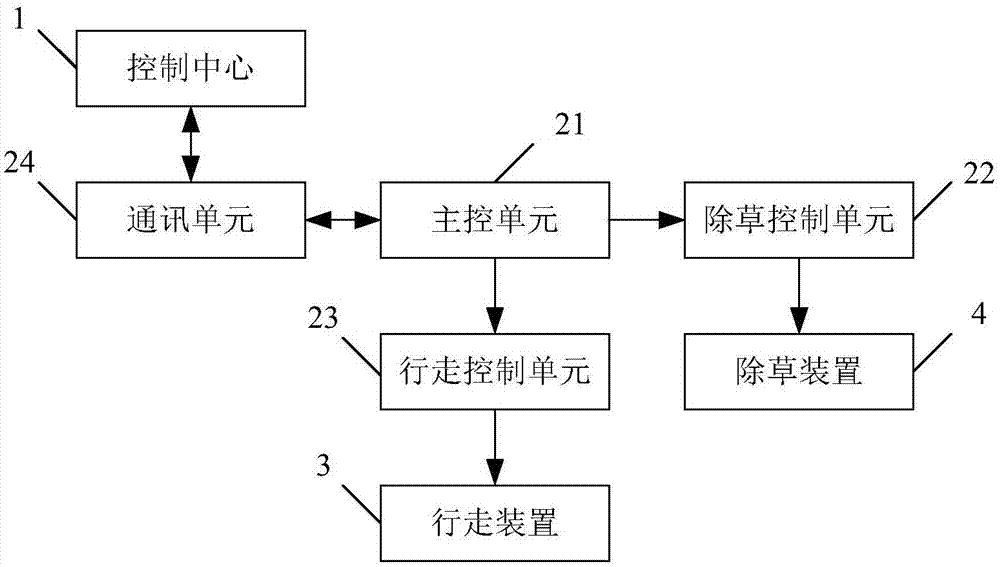

Intelligent agricultural weeding system and a weeding method

InactiveCN107343494AReach the goal of weedingImprove efficiencyWeed killersProgramme control in sequence/logic controllersMonitoring systemAgricultural engineering

The embodiments of the invention disclose an intelligent agricultural weeding system and a weeding method. The system comprises a control center, a control device, a walking device, a weeding device and a monitoring device. The control center is wirelessly connected with the control device; the control device is connected with the walking device and the weeding device; the monitoring device is wirelessly connected with the control center. The intelligent agricultural weeding system disclosed by the invention is used for detecting the density and heights of weeds through a sensor system, then the weeding speed and height of the weeding device are then set by the control device, the objective of weeding is achieved by changing the weeding speed and height in real time; the use efficiency of the product is improved, the loss of the product is reduced, a monitoring system can monitor weeding area environment, weeding quality and obstacles, so that the control center can reasonably adjust a walking path and the weeding effect is improved.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL

System and method for automatically replacing battery by robot without power interruption

ActiveCN112297943AImprove continuity and efficiencyReduce manual interventionCharging stationsElectric vehicle charging technologyAutomotive engineeringElectrical and Electronics engineering

The invention discloses a system and method for automatically replacing a battery by a robot without power interruption. The system comprises a robot body, a battery replacing and storing device and adispatching background, the robot body is provided with a battery bin, an auxiliary battery, a power supply connector and a first communication module, and the auxiliary battery supplies power when amain battery is replaced; the battery replacing and storing device comprises battery storage bins, a battery dismounting and transporting mechanism, a lifting mechanism, a second communication moduleand a control module, each battery storage bin is provided with a charging connector, the battery dismounting and transporting mechanism can be driven by the lifting mechanism to be in butt joint with each battery storage bin, and the other end of the battery dismounting and transporting mechanism is in butt joint with the battery bin on the robot body; the system is used for dismounting and conveying main batteries. The battery can be quickly and automatically replaced within a few minutes under the condition that the robot is not powered off, and completely unmanned operation is achieved; the structure of the battery replacing and storing device has rapid expansibility, a simple structure is adopted, the cost is low, the stability is high, the maintenance is easy, and the safety is high.

Owner:GUANGZHOU SAITE INTELLIGENCE TECH CO LTD

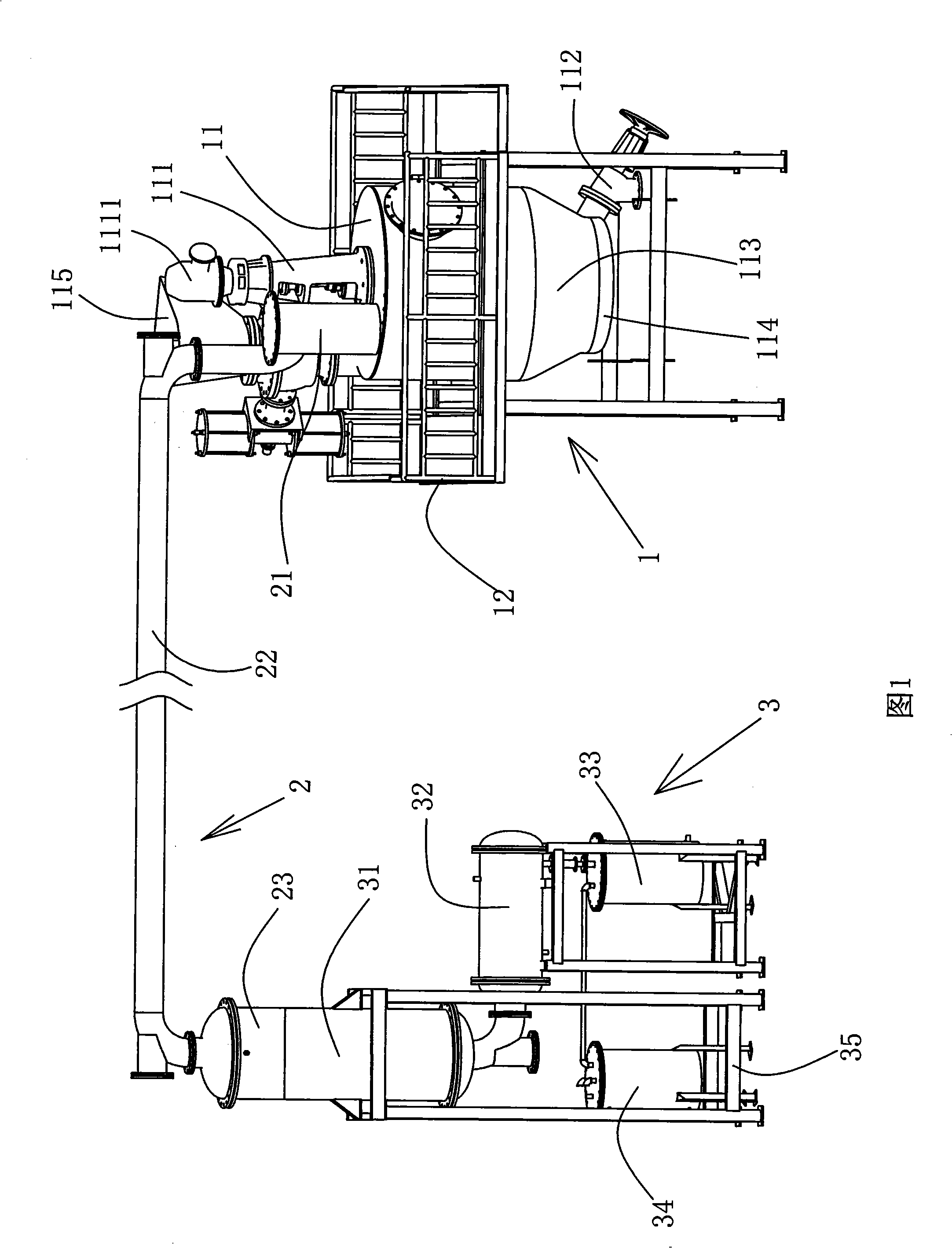

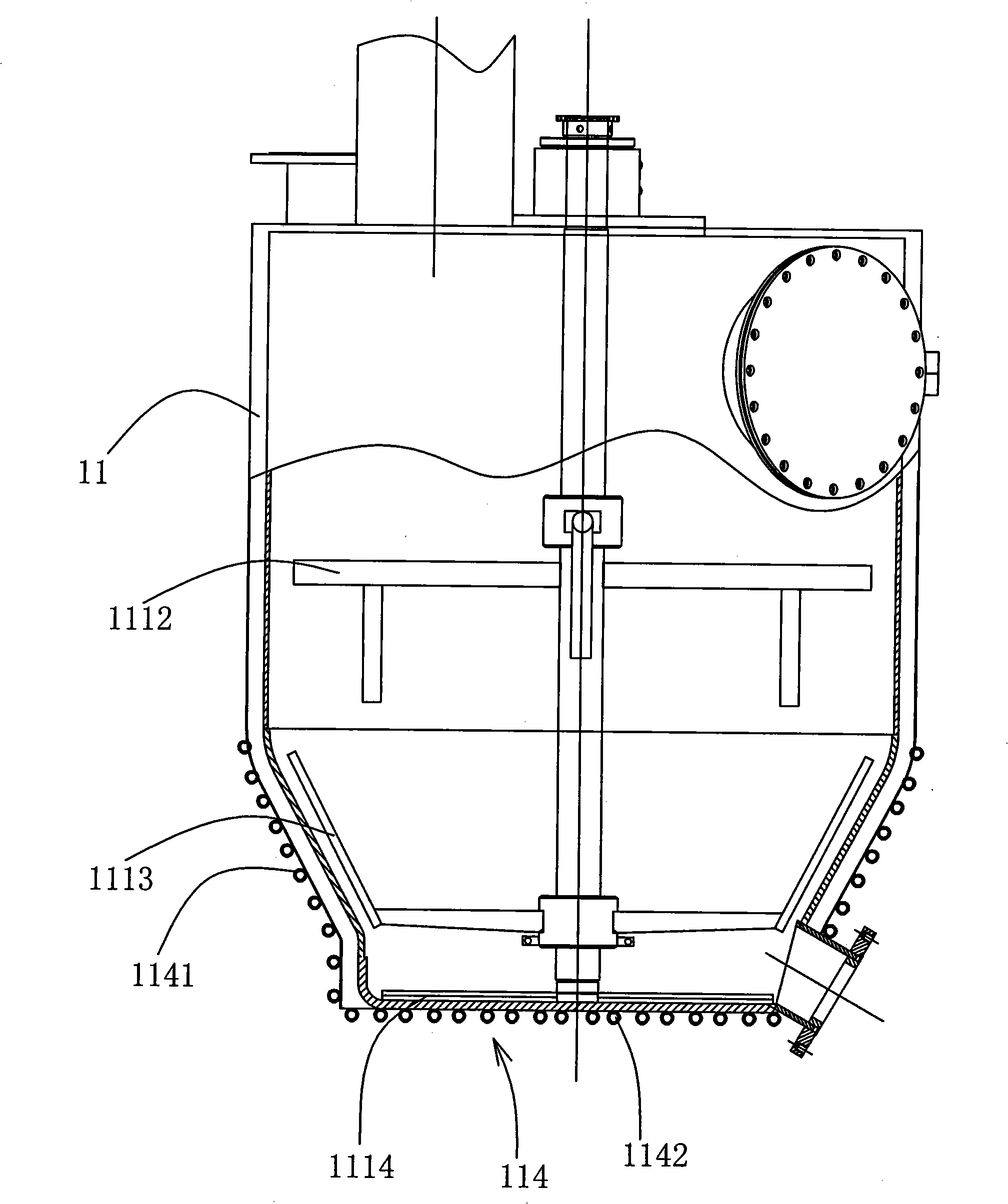

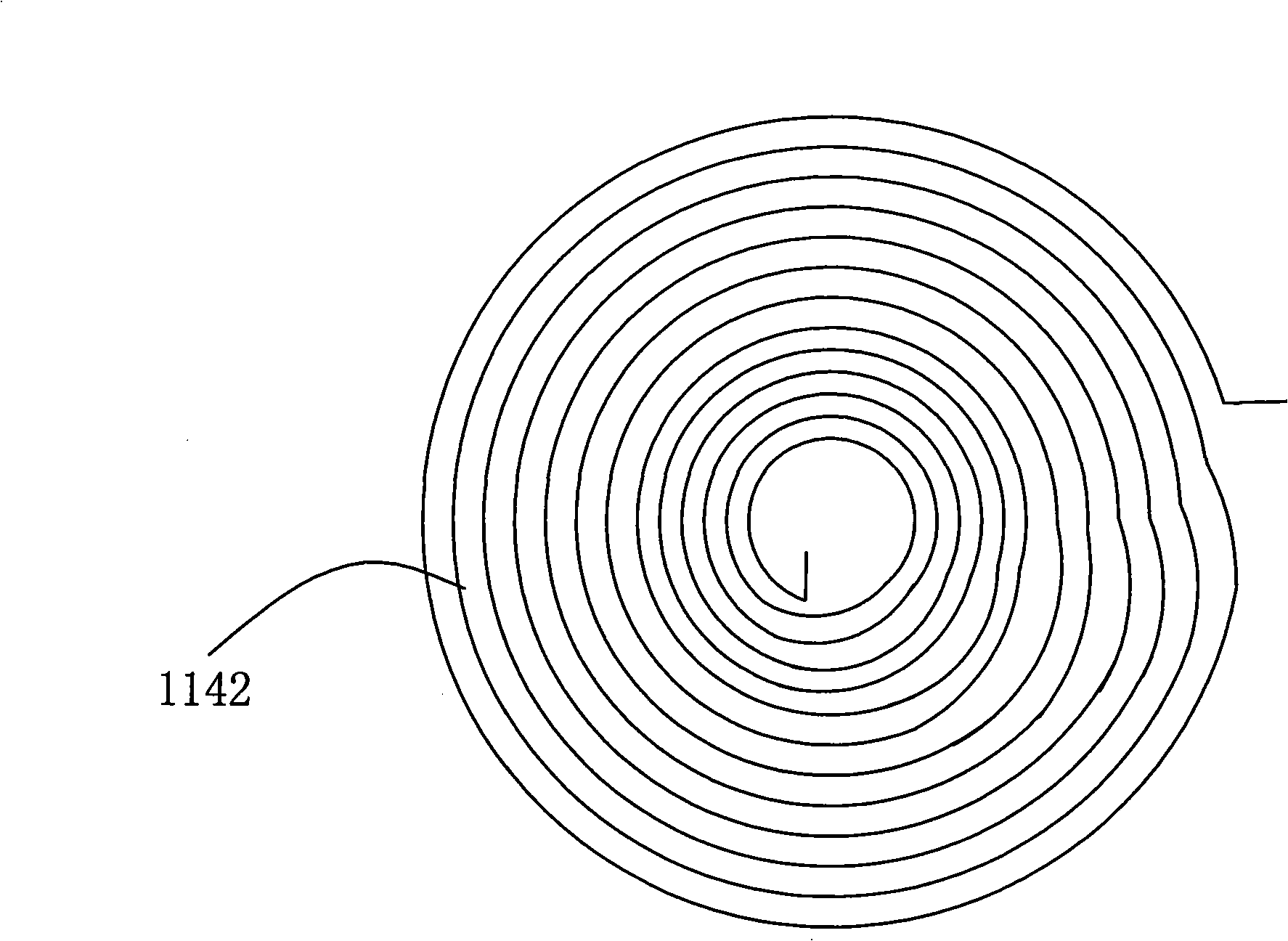

Reduction method for processing waste plastic and system thereof

ActiveCN101302432AGood load adaptabilityQuality improvementElectrical coke oven heatingProductsCatalytic pyrolysisLiquid fuel

The invention relates to a reduction method and a reduction system for processing waste plastics. The method and the system take an IGBT heating module as the core, and can save over 40 percent of energy compared with the prior vacuum tube high-frequency equipment and the prior thyristor induction heating equipment. The method and the system adopt the novel catalytic pyrolysis method, namely the prior mode of directly placing catalyst zeolite into the waste plastics is changed and the waste plastics are gasified into oil gas and then degraded by Y-shaped molecular sieves. Therefore, the pyrolysis effect of the method and the system is more obvious; the quality of liquid fuel gasoline and diesel fuel produced is better; and the gasoline and the diesel fuel produced reach or exceed the national standards of No.70 gasoline SHO 42-92 and No. 0 diesel fuel GB 252-94. Moreover, No. 90 to No. 93 unleaded gasoline can be modulated by utilization of the gasoline.

Owner:吴振奇

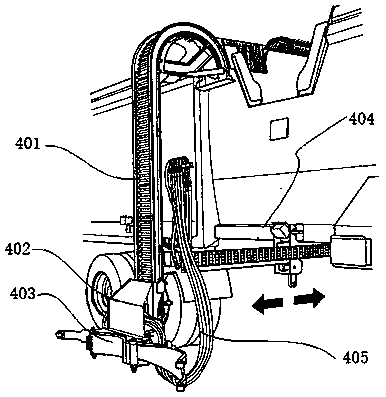

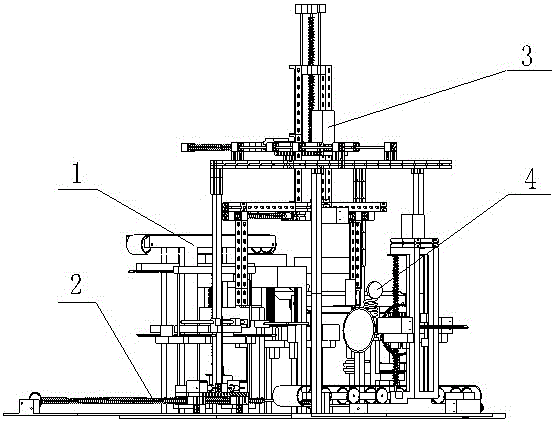

Intelligent tripping pipe system for under-pressure workover rig

ActiveCN106285513ARealize unmanned operationRealize intelligent operationDrilling rodsDrilling casingsRoughneckManipulator

The invention relates to petroleum machines, in particular to an intelligent tripping pipe system for an under-pressure workover rig. The under-pressure workover rig is provided with a rack (1), a tubular column lifting device and an iron roughneck device (2). The iron roughneck device (2) comprises a back-up wrench mechanism (3) and a spinning wrench mechanism (4), and further comprises a coupling detection part used for detecting the coupling positions of oil tubes, a residual liquid collecting device (5) used for collecting discharged oil tube residual liquid, a horizontal and vertical tube state conversion device (6) for the oil tubes, an oil tube lifting device (8) provided with a grabbing mechanical arm (7) and a control device used for controlling all the parts to act. The iron roughneck device (2) is fixed on a sliding table (11) capable of moving front and back in the horizontal direction. The intelligent tripping pipe system for the under-pressure workover rig has the advantages of being reasonable in structural design, convenient and reliable to use, high in positioning precision and high in automation degree.

Owner:牡丹江新辉石油机械有限公司

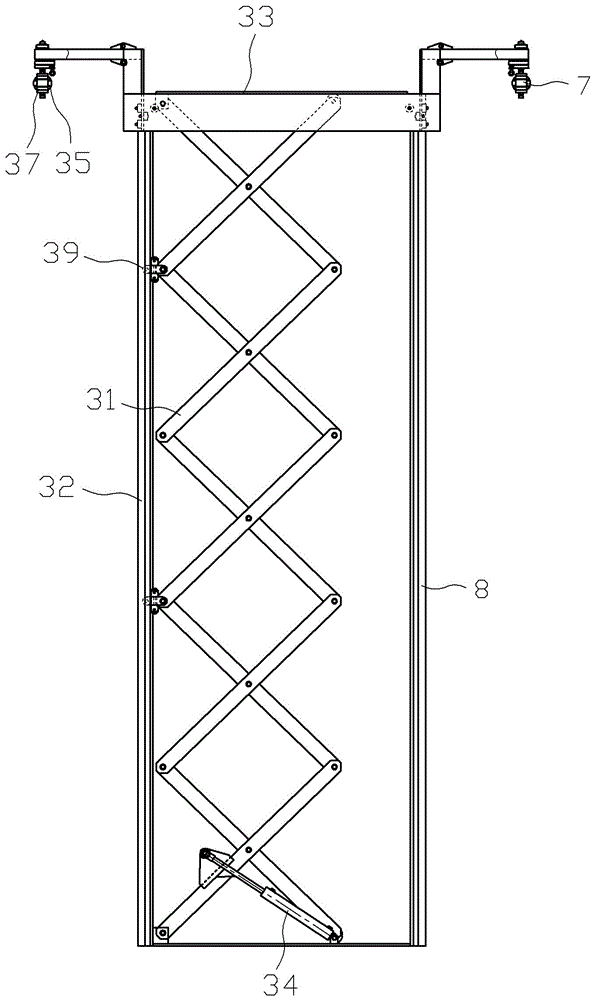

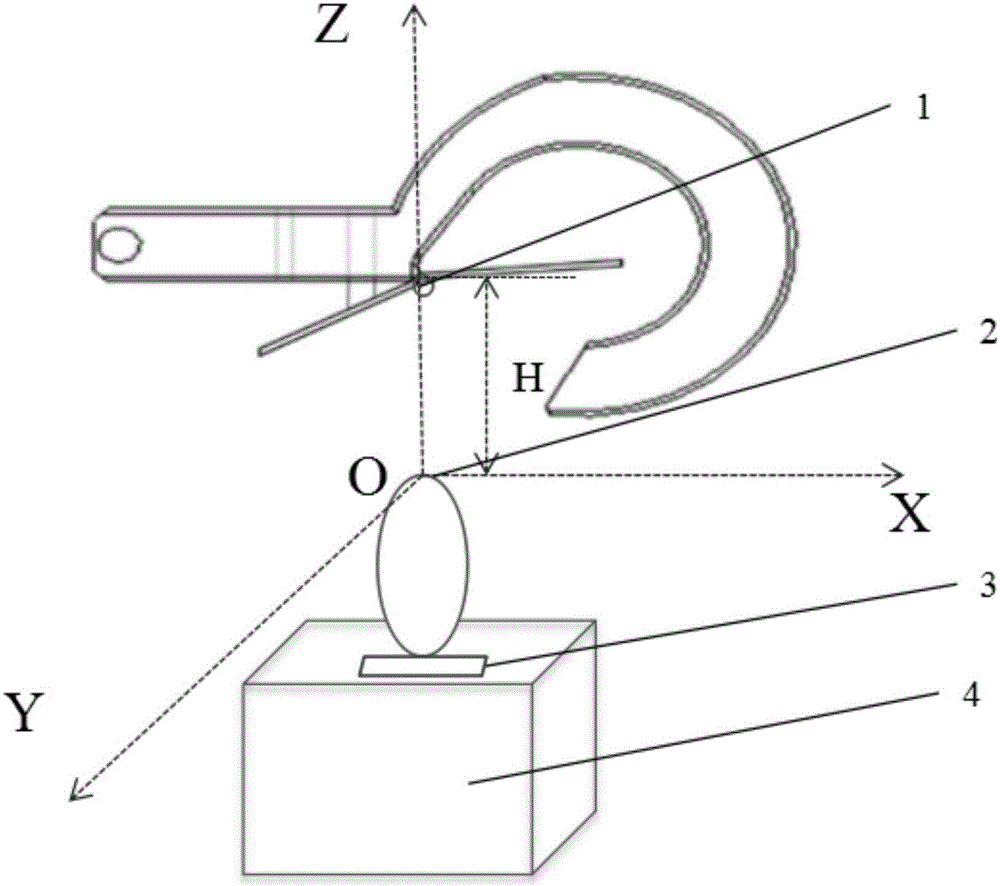

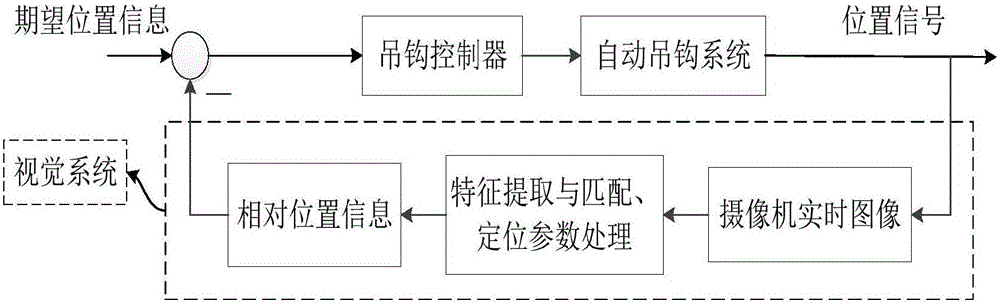

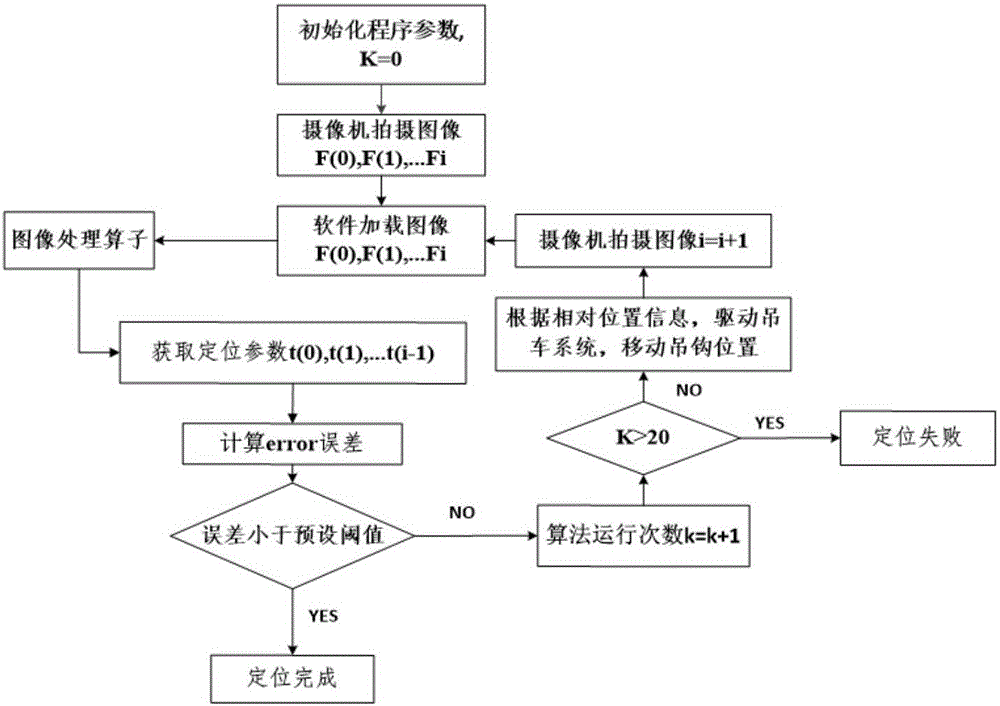

Positioning method based on automatic lifting hook system

ActiveCN105800464APrecise positioningSafe and reliable workLoad-engaging elementsReturn timeFeature matching

The invention relates to a positioning method based on an automatic lifting hook system. The method is the positioning method based on the automatic lifting hook system combining ultrasonic ranging and machine vision. The automatic lifting hook system is designed, and therefore accurate positioning of a lifting hook positioning point and a load positioning point is achieved. Z-direction positioning is achieved through an ultrasonic ranging method. A sensor is connected with a lifting hook main controller, the lifting hook main controller sends out a ranging command, a timer obtains the return time of ultrasonic waves, and the system calculates the distance H of a lifting hook in the Z direction. A visual positioning method is adopted to achieve positioning in the X direction and the Y direction. A visual positioning algorithm is designed by using load information in a known scene, expected positional information for work of the lifting hook system serves as a reference road sign, a road sign database is built to serve as reference conditions, real-time images and video information are subject to object identification and feature matching treatment, relative positional information needed by the lifting hook system is obtained, and accurate positioning of the lifting hook in the X direction and the Y direction is achieved.

Owner:NANKAI UNIV

Electric energy meter single meter sealing device

InactiveCN103093692AAvoid modificationRealize unmanned operationStampsElectrical measurementsAssembly lineElectric energy

The invention discloses an electric energy meter single meter sealing device which comprises a machine frame. A pressing cover device, a base seat feeding mechanism, a full-automatic screwdriver device, a jacking device and an assembly line body which extends horizontally are arranged on the machine frame, wherein the assembly line body is used for supporting a meter support of an electric energy meter, the edge of the meter support extends out of two sides of the assembly line body, the pressing cover and the base seat feeding mechanism are arranged over the assembly line body and are respectively arranged on the left side and right side of the assembly line body, the full-automatic screwdriver device is arranged over the base seat feeding mechanism, and the jacking device is arranged on the lower side of the assembly line body and below the base seat feeding mechanism correspondingly. The electric energy meter single meter sealing device is suitable for being used in electric energy meter automatic assembly lines and has the advantages of reducing steps of original sealing process, simplifying working procedures, improving efficiency of automatic sealing, saving labor force greatly and reducing sealing cost.

Owner:ZHENGZHOU SMS ELECTRIC

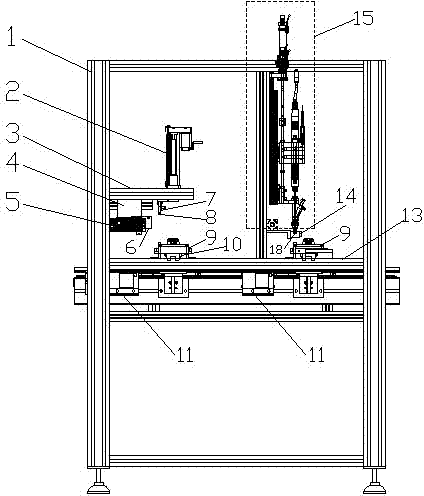

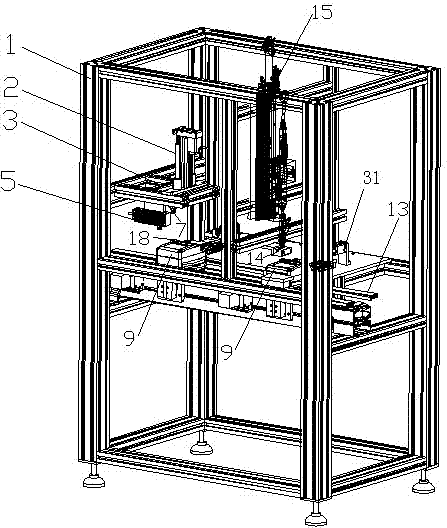

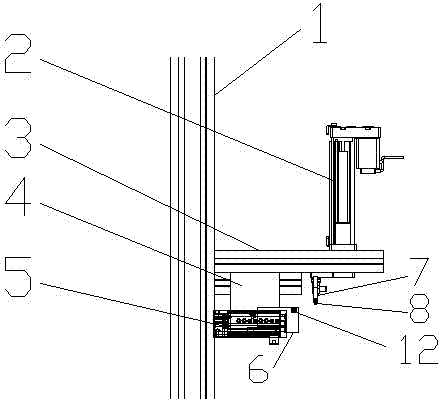

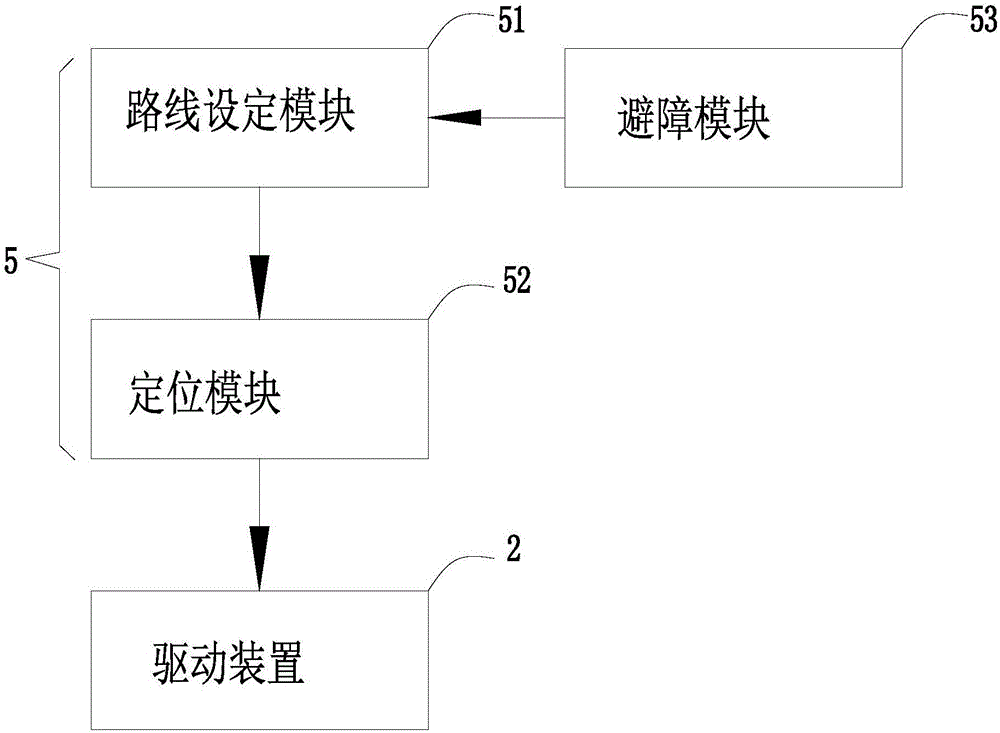

Garbage cleaning robot

InactiveCN106320237AImprove autonomous control functionsRealize unmanned operationRoad cleaningElectricityAutomatic control

The invention relates to the technical field of garbage cleaning equipment and provides a garbage cleaning robot. The garbage cleaning robot comprises a main body, a driving device, a road surface cleaning system and a navigation system, wherein the road surface cleaning system is arranged at the bottom of the main body; the navigation system comprises a path setting module used for drawing up a walking path of the main body in a designated area and a positioning module used for driving the main body to move according to the drawn-up walking path, and the path setting module and the driving device are both electrically connected to the positioning module. The navigation system is arranged additionally, and the operating principle of the navigation system comprises steps as follows: firstly, maps in the designated area are input into the path setting module, and a primary walking path is drawn up by the path setting module according to the maps; secondly, the positioning module transmits signals to the driving device according to the drawn-up walking path, so that the main body is enabled to move along the walking path, the automatic control function of the garbage cleaning robot is further improved and the purpose of unmanned operation is achieved.

Owner:深圳市女娲机器人科技有限公司

90-degree automatic cylinder rotating and material receiving mechanism

InactiveCN104555389AShorten delivery timeImprove processing timeConveyor partsDrive shaftElectric machinery

The invention relates to a 90-degree automatic cylinder rotating and material receiving mechanism, and belongs to the technical field of mechanisms. The mechanism comprises a bottom plate; a bracket and a cylinder seat are arranged on the bottom plate; a rotating cylinder is arranged on the cylinder seat; a piston rod of the rotating cylinder is connected with a cylinder connector; the cylinder connector is hinged to a connecting rod; the other end of the connecting rod is fixedly connected with a rotating shaft; a rotating seat is mounted at the upper end of the rotating shaft; a rotating frame is mounted on the rotating seat; a plurality of driving shafts are arranged in parallel in the rotating frame; a limiting cylinder for stopping a cylinder to be rotated is arranged at one end of the rotating frame, wherein the limiting cylinder can be lifted; one end of one of the driving shafts is connected with a driving motor; a driving chain wheel is mounted at one end of each driving shaft, far away from the driving motor. According to the mechanism, the cylinder can be automatically rotated and receive materials under the effect of motor and pneumatic driving, and therefore, the conveying time is reduced, the processing frequency is increased, the damage by bumping due to manual conveying can be avoided, and as a result, the processing quality is improved, and automatic operation is achieved; the mechanism is simple and reliable in structure, and convenient to repair.

Owner:WUXI BEST PRECISION MACHINERY

Intelligent commodity packaging system

PendingCN106144055AIntelligent packagingAvoid the error of human subjective consciousnessWrapper twisting/gatheringSoftware engineeringSystems engineering

The invention belongs to the field of mechanical transmission and discloses an intelligent commodity packaging system. The intelligent commodity packaging system is characterized in that packaging boxes can be selected for commodities intelligently and can be automatically sealed. The intelligent commodity packaging system adopts modular design and comprises an ultrasonic measuring module, a multi-specification packaging box picking module, a four-direction box sealing module and a 360-degree adhesive tape adhesion module. According to the system, the sizes of the commodities can be measured, the packaging boxes of appropriate sizes can be selected according to the sizes of the commodities, uniform arrangement and encasement can be carried out, and the packaging boxes can be sealed by adhesive tape. The intelligent commodity packaging system is designed for network businessmen, realizes intelligent packaging of the different commodities and avoids personal errors and heavy and repeated labor, and therefore the commodity delivering speed can be increased and the commodity efficiency can be improved.

Owner:CHANGCHUN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com