System and method for automatically replacing battery by robot without power interruption

An automatic replacement, battery system technology, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve problems affecting work efficiency, inability to achieve automation and intelligence, large equipment failure risks, etc., to reduce manual intervention, It is convenient to control information at any time, enhance the effect of continuity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

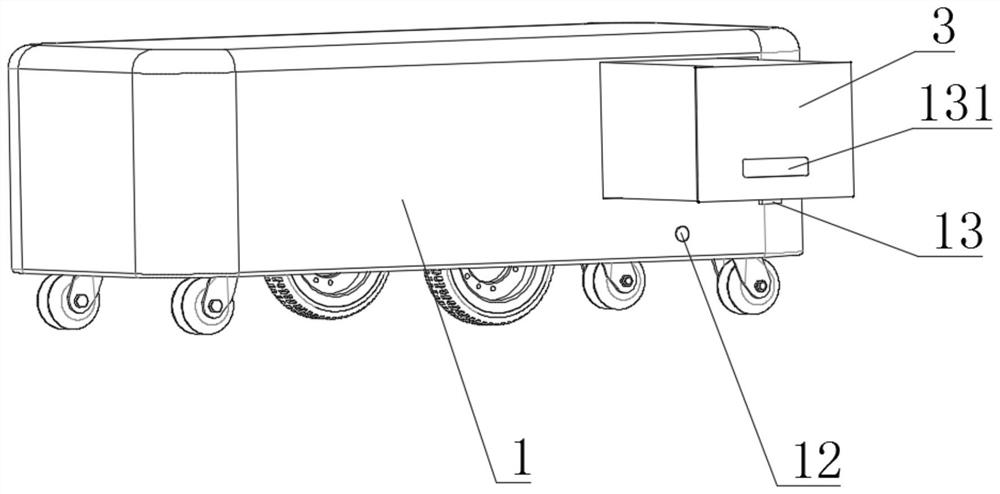

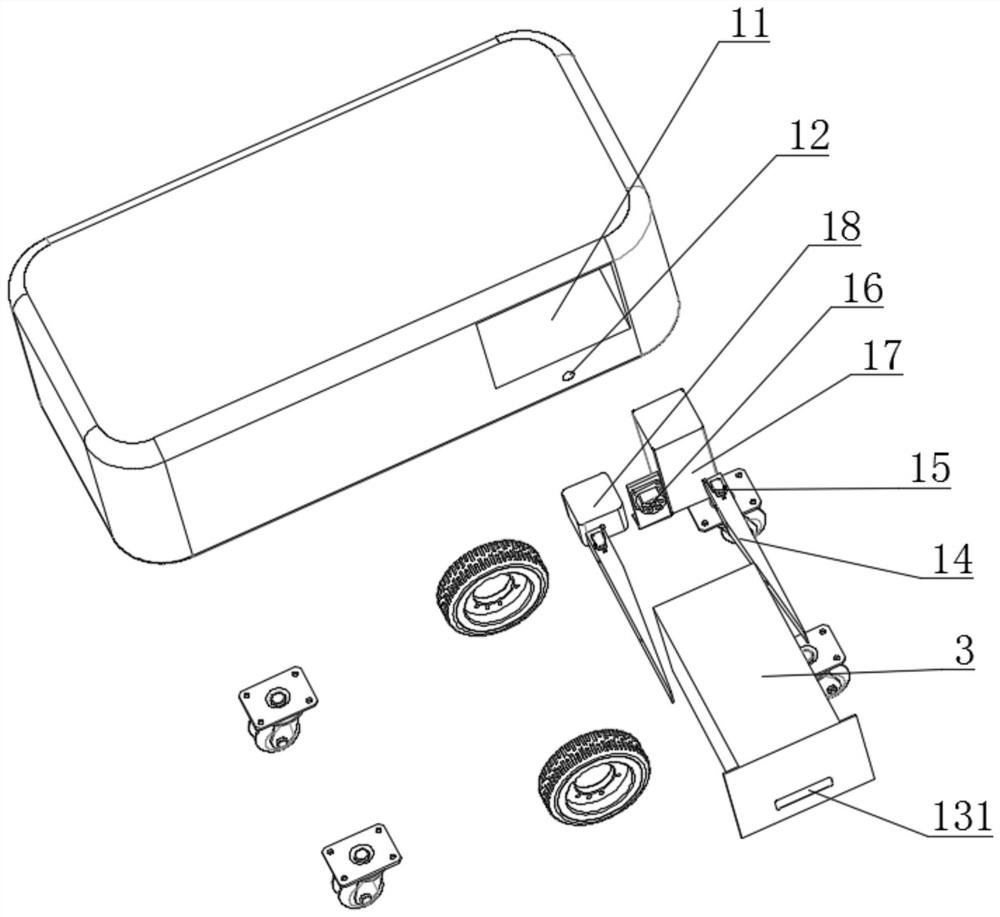

[0040] A battery replacement system for a robot without power interruption, comprising a robot body 1, a battery replacement storage device 2 and a dispatching background.

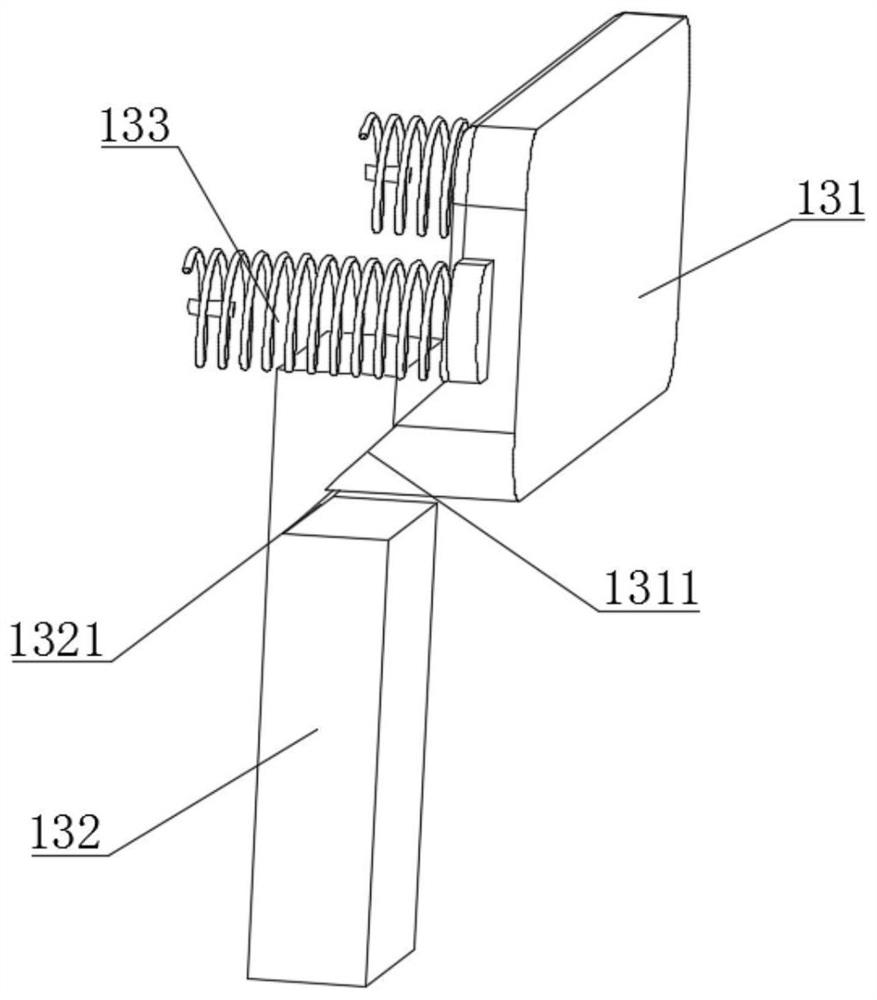

[0041] Such as figure 1 , figure 2 As shown, the robot body 1 is provided with a battery compartment 11, an auxiliary battery 17, a power supply joint 16 and a first communication module 18, the main battery 3 is disposed in the battery compartment 11, and the power supply joint 16 is disposed in the One end of the battery compartment 11, the main battery 3 is connected to the components on the robot body 1 by the power supply joint 16 to supply power to these components; meanwhile, the main battery 3 is connected to the auxiliary battery 17 by the power supply joint 16, and the main battery 3. Charge the auxiliary battery 17 through the power supply connector 16 during work. The auxiliary battery 17 is connected to the components on the robot body 1. When the main battery 3 is replaced, the auxiliary ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com