Intelligent tripping pipe system for under-pressure workover rig

A workover rig and pipe system technology, applied in drilling pipes, casings, drilling equipment, etc., can solve problems such as unsolved problems, complex intelligent control system technology, and many key technologies, and achieve reasonable structural design, convenient and reliable use. , reduce the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

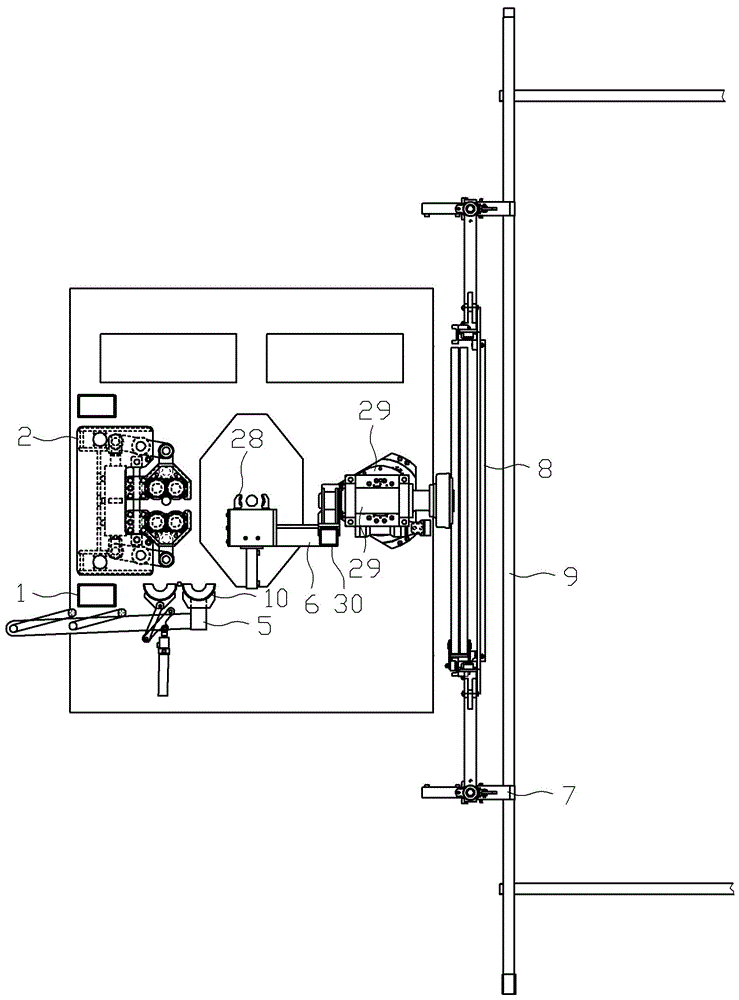

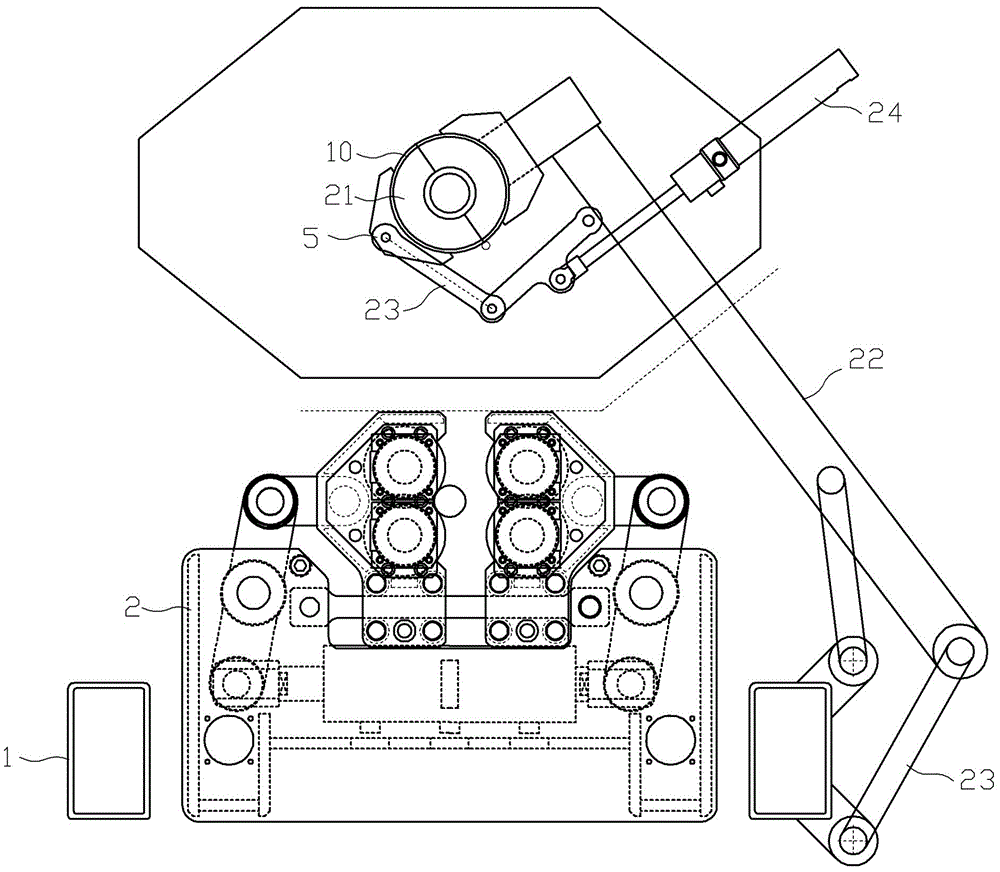

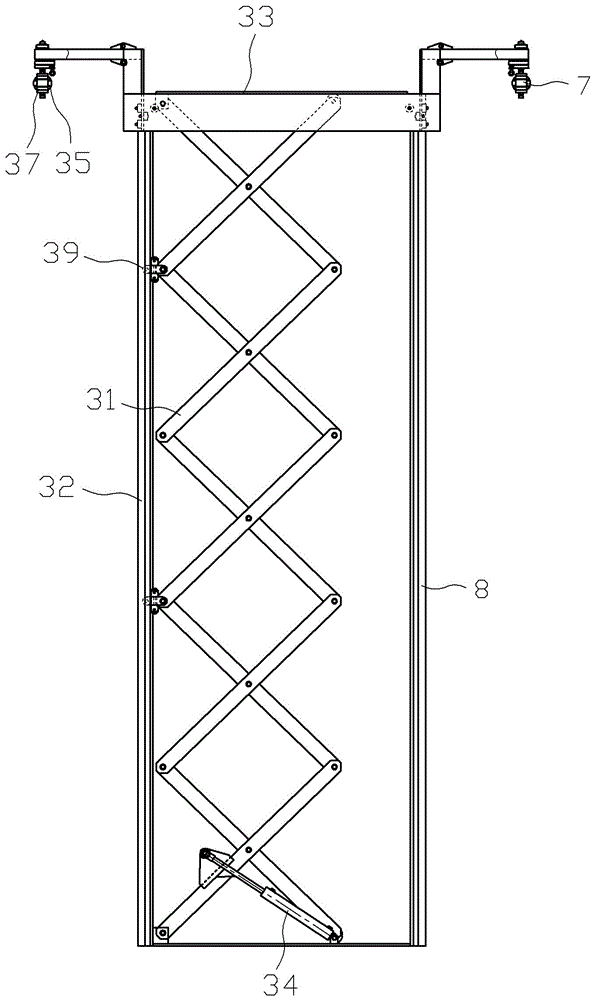

[0017] like Figures 1 to 11 As shown in the figure, the present invention is an intelligent manipulator lifting and lowering system of a pressurized workover rig, which adopts a large-scale lifting hydraulic cylinder equipped with a fixed guide column, and is installed on the top of the piston rod, which can rotate 180° in the horizontal direction and rotate 180° vertically. A dual manipulator mechanism with a 90° direction rotation, and a strain gauge pressure sensor for sensing the manipulator pressure, an iron driller system, a hoist manipulator system, and a 400mm position of the load platform on the workover rig to detect the coupling. The open eddy current testing device, the automatic residual liquid collection mechanism and the pressurized workover rig device are installed together, and under the control of the PLC, the unmanned operation of the wellhead can be realized in the process of raising and lowering the tubing.

[0018] The intelligent tripping and tripping s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com