Intelligent commodity packaging system

A packaging system and product technology, applied in the field of mechanical transmission, can solve problems such as high labor costs, low work efficiency, and inability to meet the speed of online business operations, so as to avoid human subjective errors, improve work efficiency and quality, and save money. Resource and Labor Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further illustrate the technical means adopted by the present invention to achieve the intended purpose of the invention, the specific implementation, structure and features proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and the fischer model lap joint example.

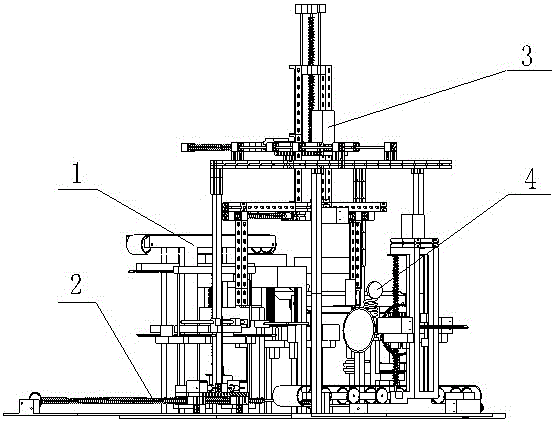

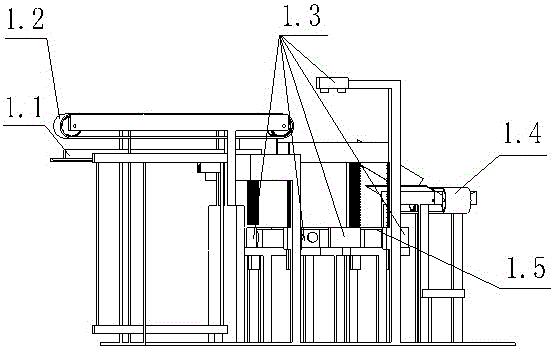

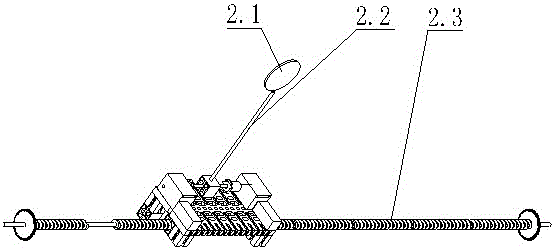

[0017] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , The product intelligent packaging system described in the patent of the present invention includes: an ultrasonic measurement module 1, a multi-standard packaging box picking module 2, a four-way sealing module 3 and a 360° adhesive tape module 4. Make sure that the goods to be packaged are transported into the five-way measurement module 1.3 through the goods transported into the conveyor belt 1.2. The ultrasonic sensors on the front, back, left, and right sides of the five-way measurement module 1.3 measure the distances in the five directions of the object, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com