Patents

Literature

34results about How to "Improve work efficiency and quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Municipal drainage pipe network design system and method based on GIS (Geographic Information System) technology

InactiveCN102592008AImprove effectivenessImprove work efficiency and qualitySpecial data processing applicationsGeographic information systemDesign systems

The invention discloses a municipal drainage pipe network design system based on GIS (Geographic Information System) technology, comprising a pipe network element drawing module, a sewage quantity predicting module, a pipe network optimization design module and other modules. The invention also provides a GIS technology based running method of a municipal drainage pipe network design system, according to the method, under a condition that the charting edition, the data management, storage and the like of a geographic information system are fully utilized, the distribution of the pipeline can be drawn and adjusted, the corresponding hydraulic calculation and the pipe diameter optimization can be conducted on the pipeline in the design scheme, the drainage pipe network planning scheme can be designed scientifically and reasonably.

Owner:EAST CHINA NORMAL UNIVERSITY

Pose-synchronous six-axis industrial robot track smoothing method

ActiveCN110900612ASimple calculationImprove work efficiency and qualityProgramme-controlled manipulatorProcess engineeringControl engineering

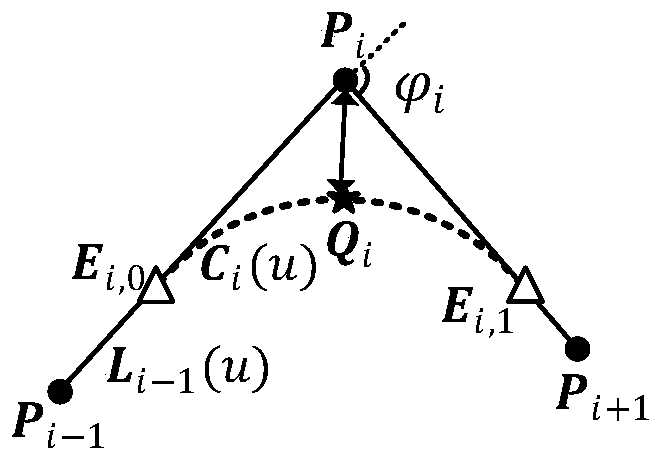

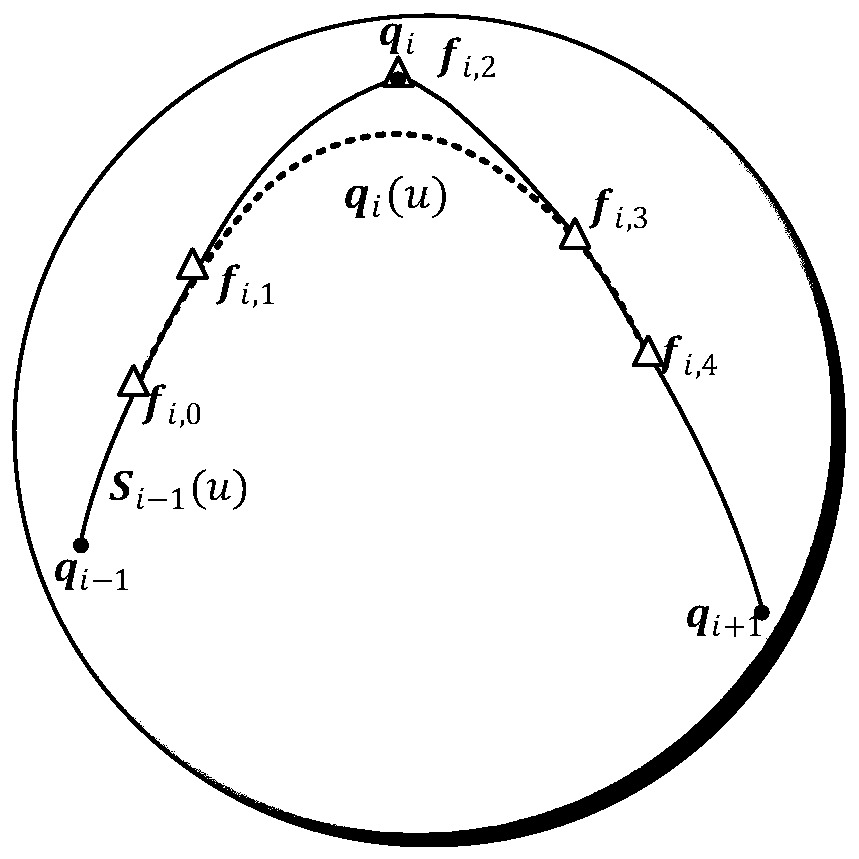

The invention discloses a pose-synchronous six-axis industrial robot track smoothing method, which adopts an arc curve to transit a position track and adopts a quaternion B spline to transit an attitude track. The position and attitude tracks after transition have high-order continuity, transition errors of the position and attitude can be restrained at the same time, and the position and attitudetracks after transition have parameter synchronism. The method comprises the following two steps: step 1, determining transition parameters according to a transition error threshold value, a continuity condition and a pose synchronization condition of the position and attitude; 2, calculating transition tracks of the position and the attitude respectively according to the transition parameters; according to the smoothing method provided by the invention, the smooth and precision-controllable six-axis robot track can be generated, so that the operation efficiency and precision of the six-axisrobot are improved.

Owner:GUANGDONG SAMSUN TECH CO LTD

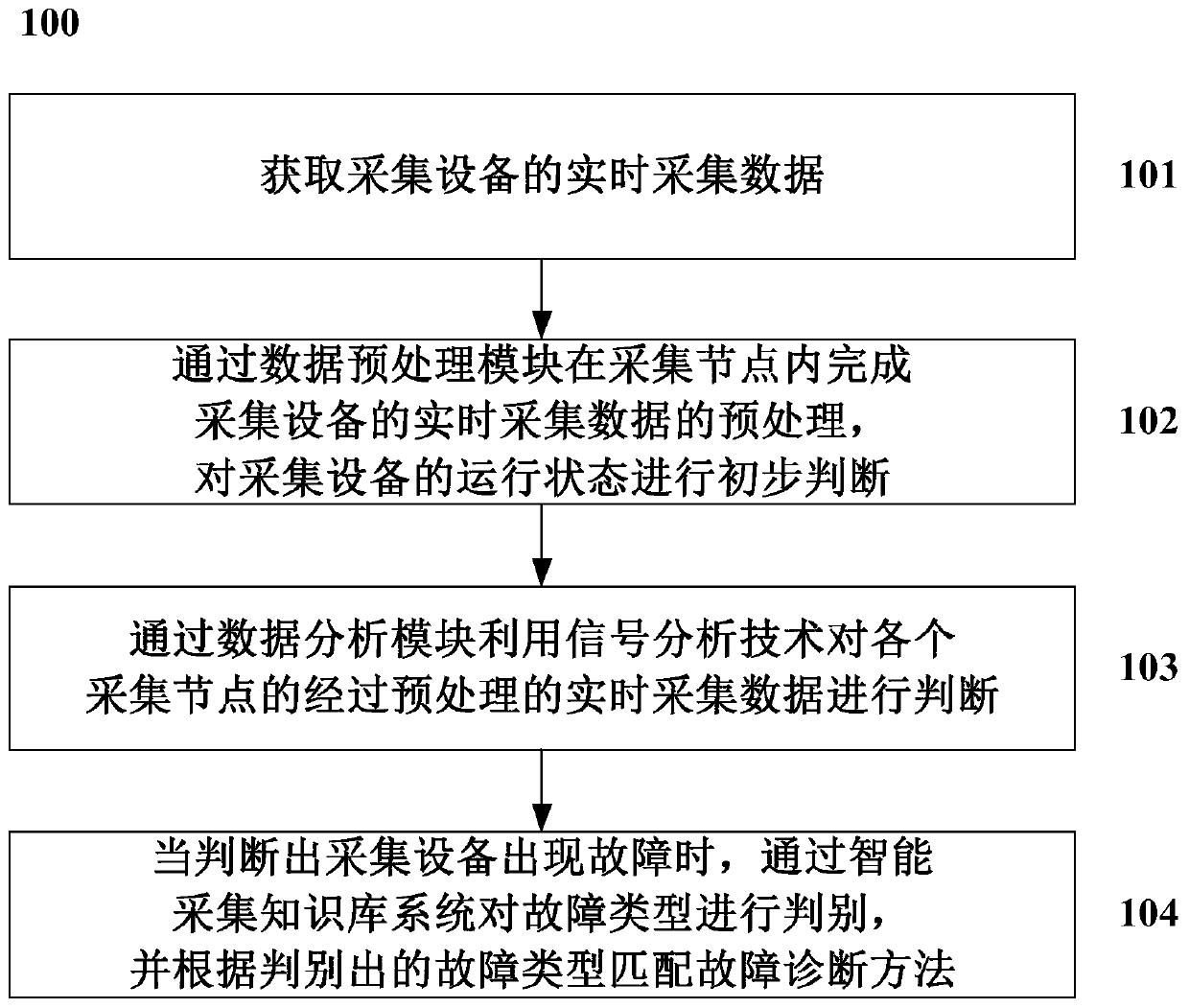

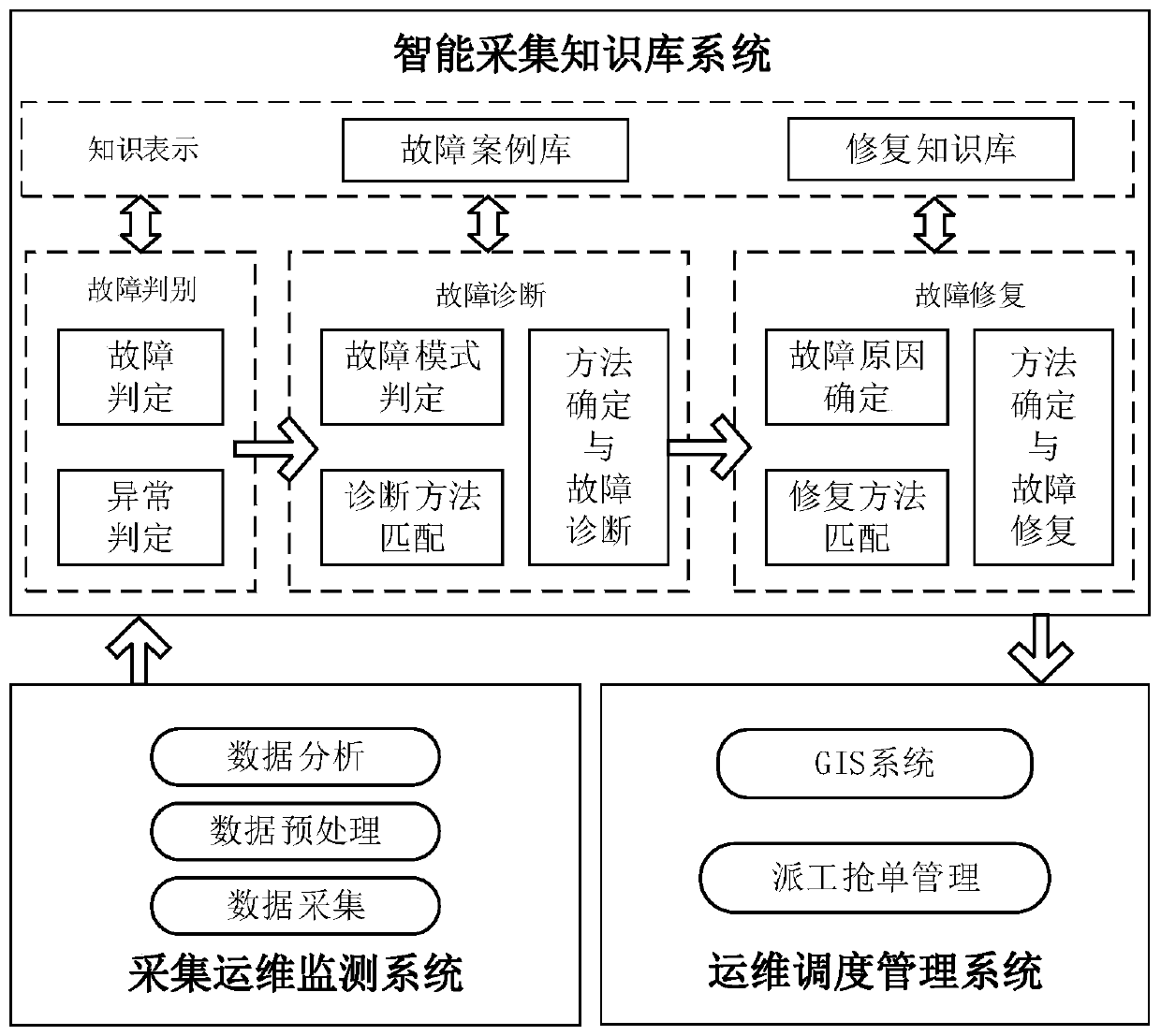

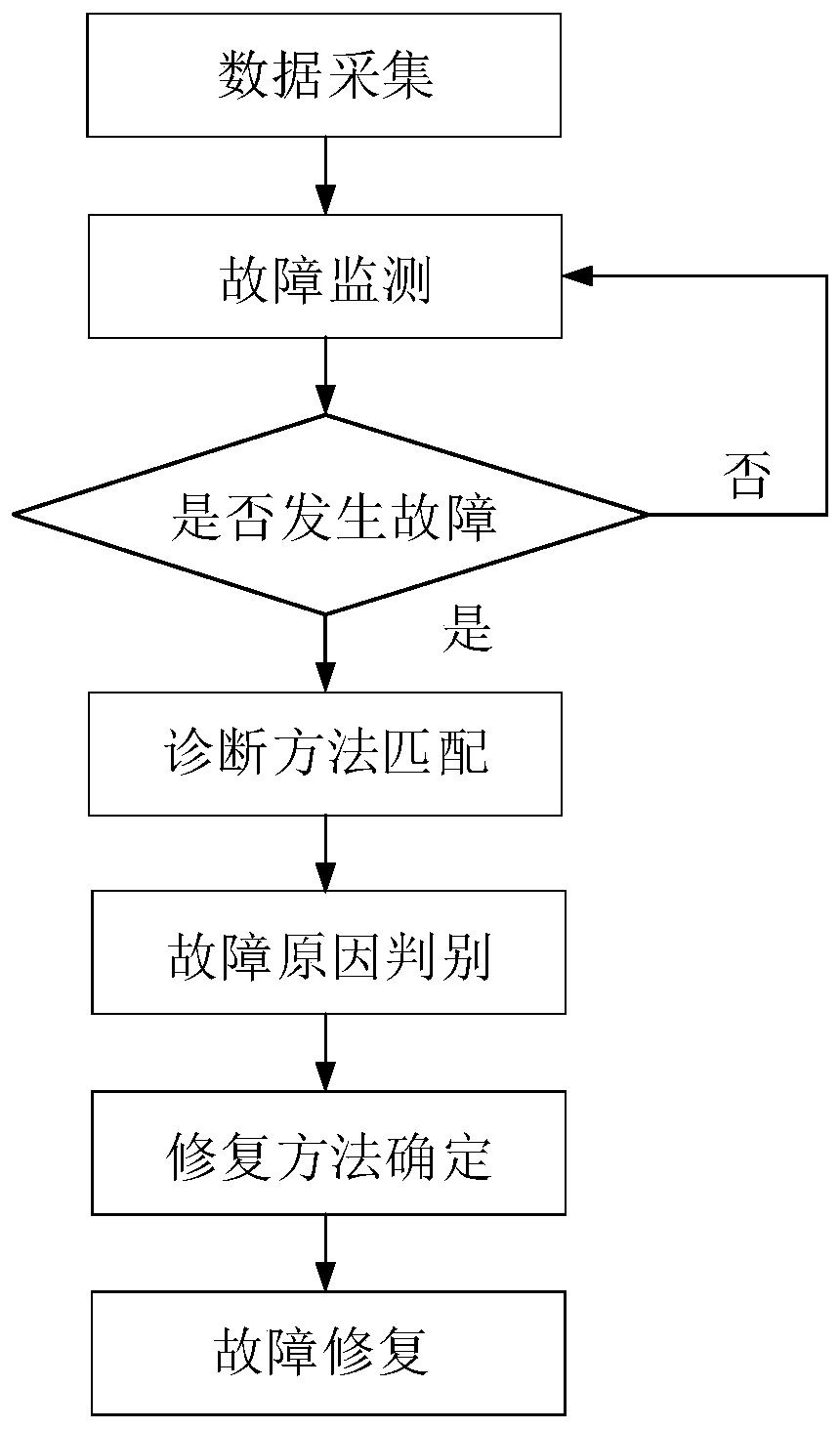

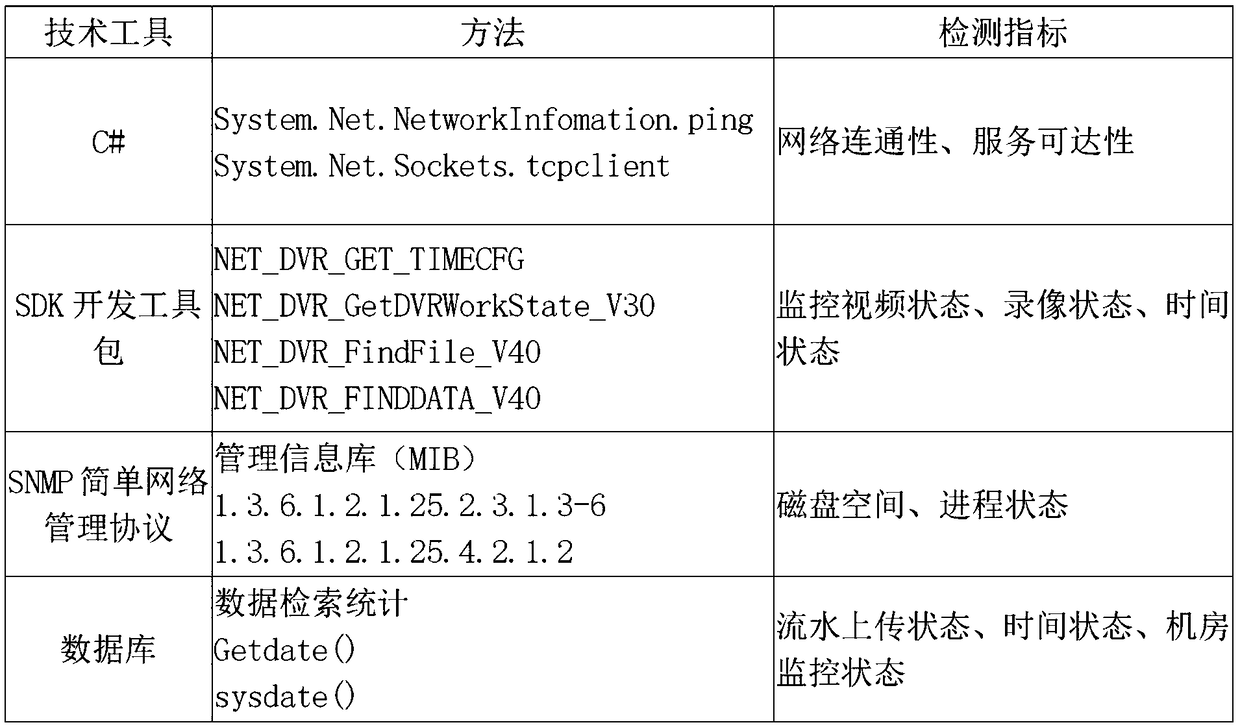

Method and system for monitoring collecting equipment based on real-timely collected data

InactiveCN109885021AImprove work efficiency and qualityAccurately determine the cause of the failureElectric testing/monitoringKnowledge-based systemsData profiling

The invention discloses a method and system for monitoring collecting devices based on real-timely collected data. The method comprises the steps that the real-timely collected data of the collectingdevices are obtained; the real-timely collected data of the collecting devices are preprocessed in collecting nodes through a data preprocessing module, operation states of the collecting devices arepreliminarily judged, and the preprocessed real-timely collected data are sent to a data analyzing module; the data analyzing module receives the preprocessed real-timely collected data sent by the collecting devices at all the collecting nodes, and the data analyzing module utilizes a signal analyzing technology to judge the preprocessed real-timely collected data of all the collecting nodes; when it is judged that the collecting devices break down, an intelligent collecting knowledge base system distinguishes the breakdown type, and a breakdown diagnosis method is matched according to the distinguished breakdown type; and a breakdown repairing method of the collecting devices is determined according to the breakdown diagnosis method.

Owner:CHINA ELECTRIC POWER RES INST +3

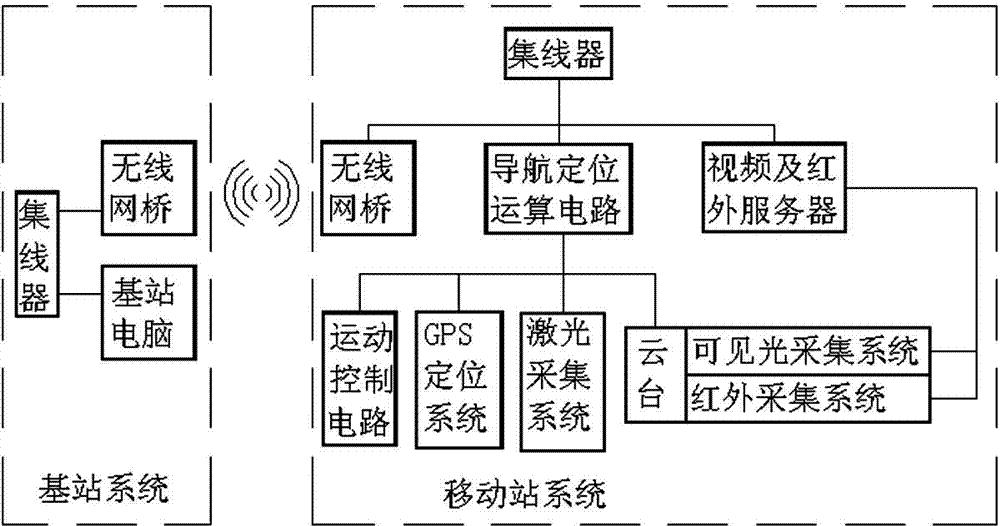

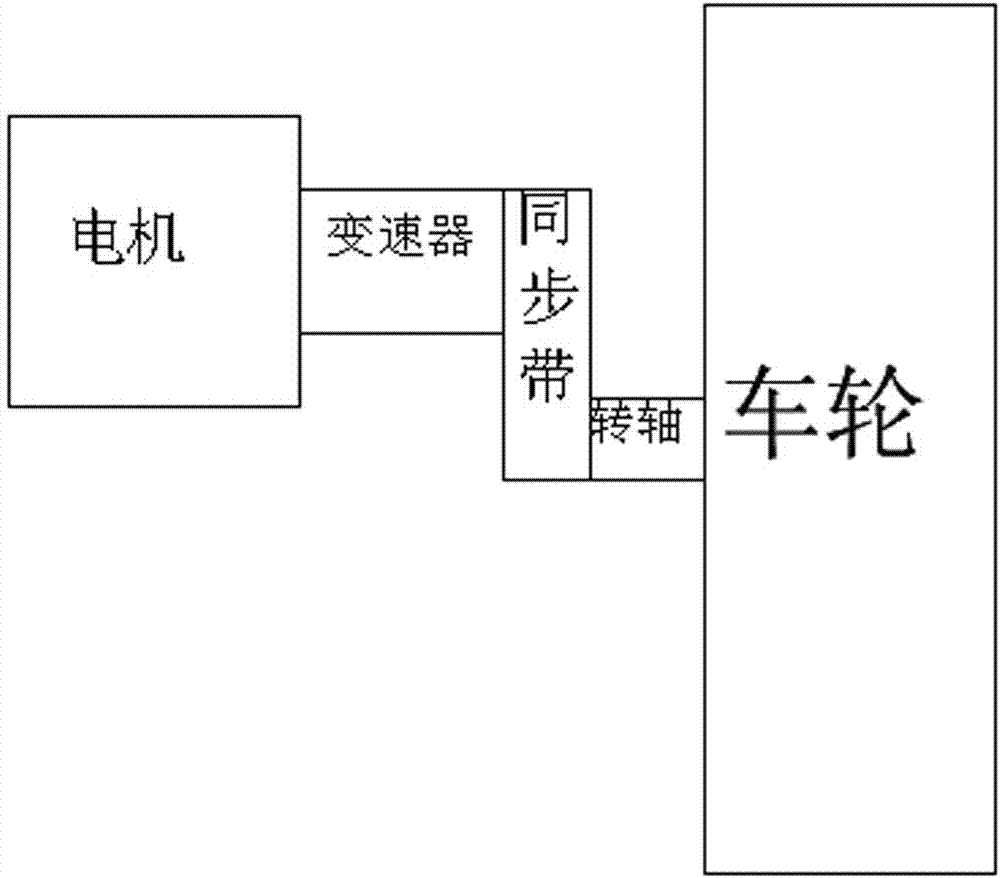

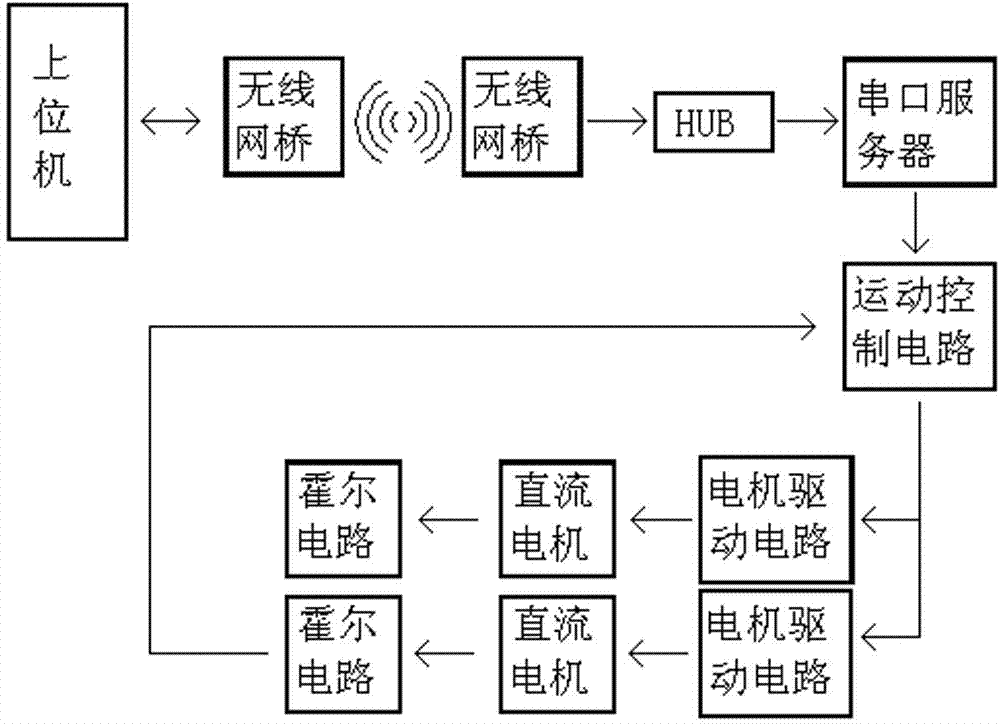

Remote monitoring device of power station equipment

InactiveCN103199618AImprove work efficiency and qualityIncrease the level of automationCircuit arrangementsSustainable buildingsRobotic systemsThermographic camera

The invention provides a remote monitoring device of power station equipment. A mobile robot comprises a base station control system, a mobile station control system and an infrared thermal imager, the base station control system and the mobile station control system are wirelessly connected, and the mobile station control system is installed on a track robot. The remote monitoring device of the power station equipment provides a brand-new solution for detection of substation equipment, and promotes development progress of automation in an electric system, and meanwhile brings a civil robot system to a new development area. According to the application of the remote monitoring device of the power station equipment, the detection period of the substation equipment is greatly shortened, under the condition that personal safety of workers is ensured, detection quality is ensured better, and a good guarantee is provided for safe running of the electric system and reliable electricity utilization of power consumers.

Owner:MAINTENANCE BRANCH STATE GRID LIAONING ELECTRIC POWER +1

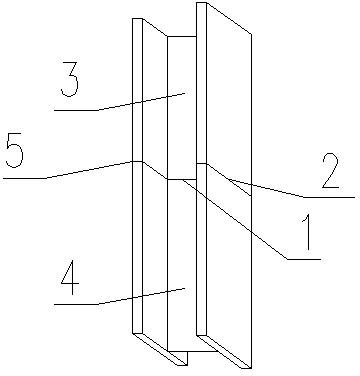

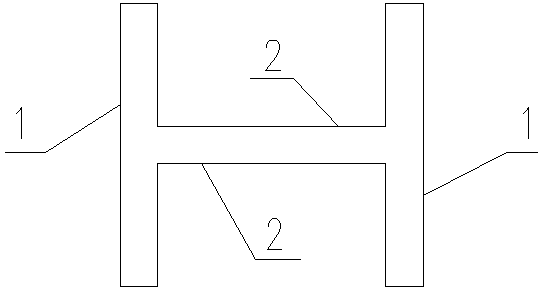

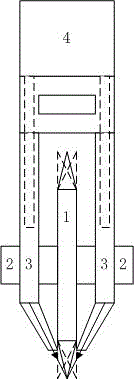

Butt welding method for workshop columns under humid environment

ActiveCN104259622AImprove work efficiency and qualityReduce quality defectsArc welding apparatusUpset weldingOxide

The invention discloses a butt welding method for workshop columns under the humid environment. The butt welding method is characterized by comprising the following technological steps of (1) construction preparation, wherein before welding, a welding area is cleaned, the cleaning range is the area 30 mm to 50 mm away from a welding line, a grinding wheel is adopted to carry out grinding to remove oxide scales, metallic luster is exposed out, and impurities such as water, rust and oil contamination affecting the welding quality are removed; (2) initial positioned welding, wherein before main welding, initial positioned welding is carried out, integral combined tack welding is carried out, and the positioned welding quality should be consistent with the quality of the main welding line; (3) technology and butt welding determining, wherein according to the butt welding technology of H-type steel workshop columns, butt welding is carried out on an upper column (3) and a lower column (4) along a butt welding line (5), and according to the butt welding sequence, flange plates (2) are firstly welded, and then a web (1) is welded. The butt welding method has the advantages that due to effective combination of the welding process and the welding method, the welding quality and the working efficiency are improved, quality defects are reduced, and one-time welding percent of pass is improved.

Owner:CHINA MCC17 GRP

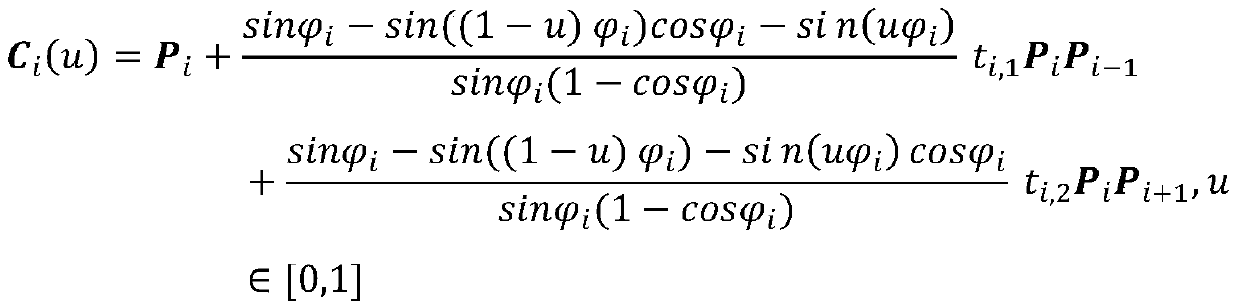

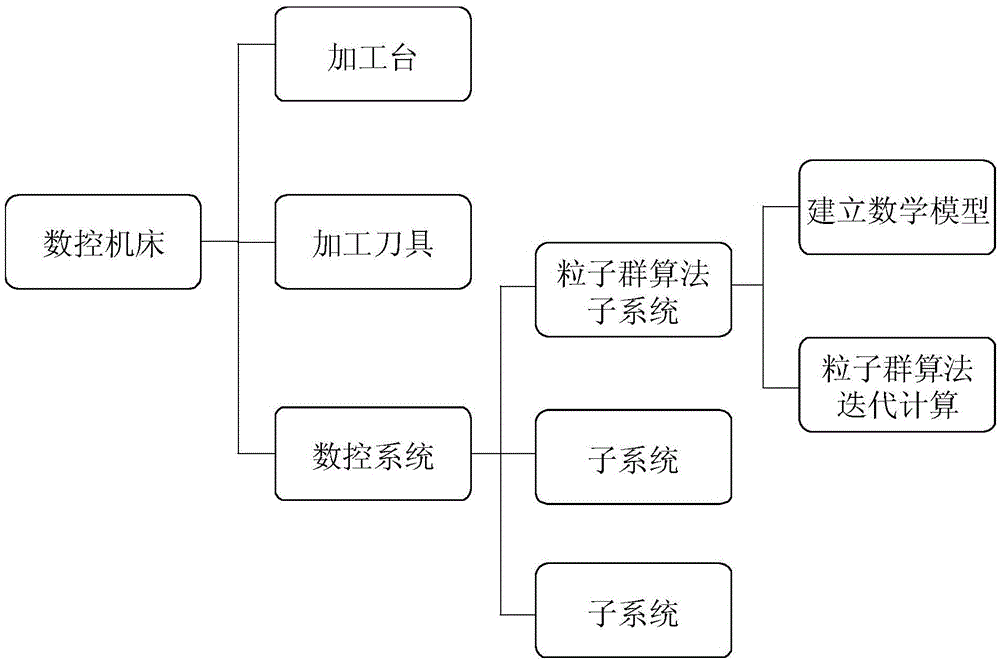

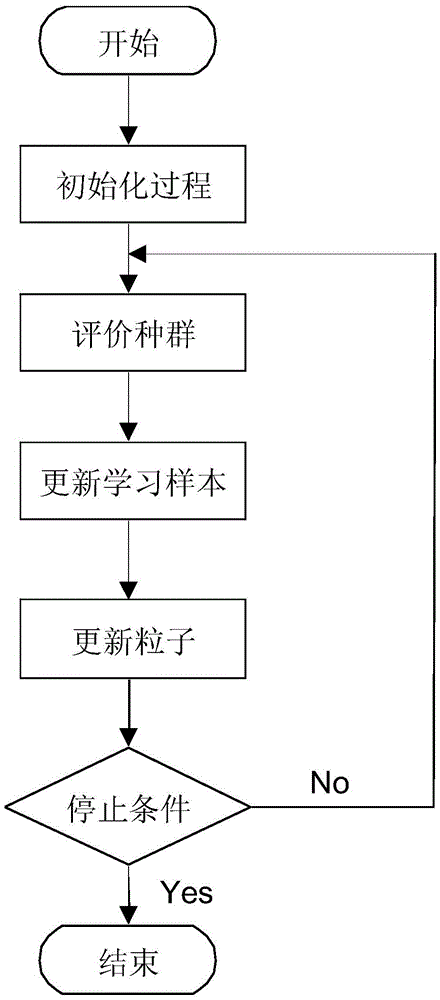

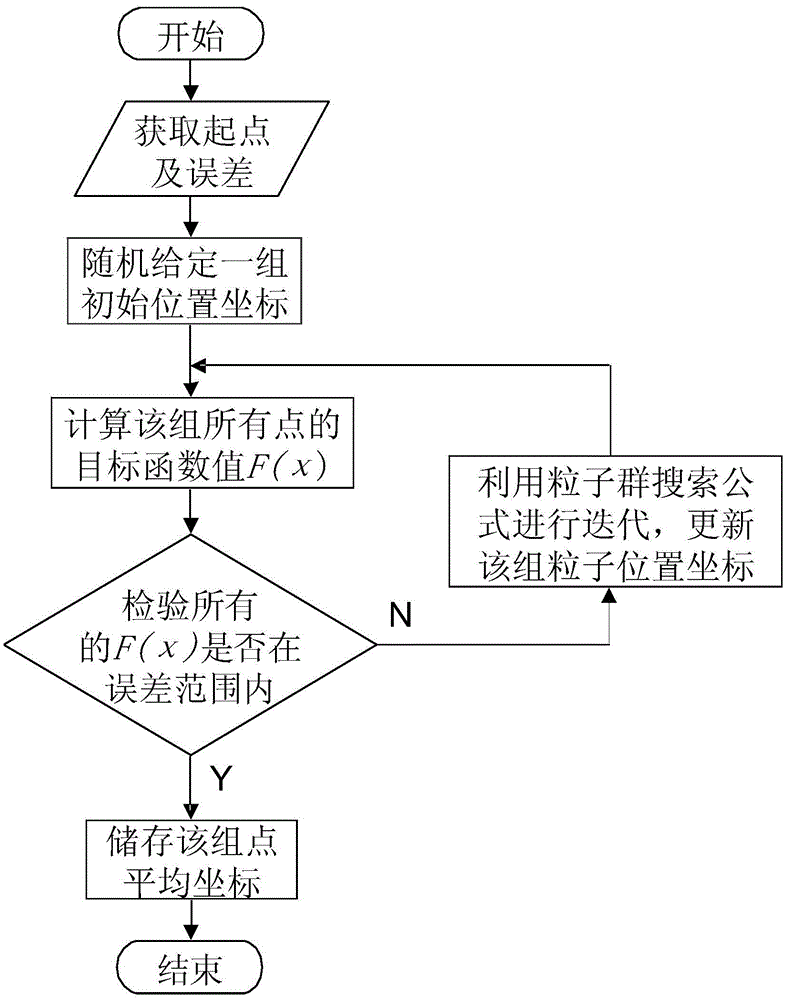

Profile curve numerical control code generation method based on particle swarm algorithm and numerical control machine tool

ActiveCN105676776AImprove work efficiency and qualitySimple and direct operationNumerical controlProcessing accuracyNumerical control system

The invention relates to a profile curve numerical control code generation method based on a particle swarm algorithm and a numerical control machine tool. The profile curve numerical control code generation method based on the particle swarm algorithm is used for a numerical control machine tool, and includes the steps of: (1) building a mathematical model for a profile curve of a machining workpiece in a numerical control system; (2) using the particle swarm algorithm to program iterative computation in a computer, and obtaining an approximation node; (3) generating and outputting a machining curved surface tool path numerical control code of a machining tool; (4) putting the machining workpiece on a machining table, and positioning and fixing the machining workpiece through a clamp; (5) providing a tool by a tool magazine and performing tool setting, and positioning the position of a machining starting point; and (6) using the machining tool to machine the machining workpiece on the machining table according to the acquired machining curved surface tool path numerical control code. The invention provides the profile curve numerical control code generation method based on the particle swarm algorithm which is applied to the numerical control machine tool, thereby enabling the machining tool to effectively and accurately complete numerical control machining of the profile curve of the workpiece, improving work efficiency and quality of the numerical control machine tool, the operation is simple and direct, and the machining precision is high.

Owner:GUANGDONG UNIV OF TECH

Oil field production management system

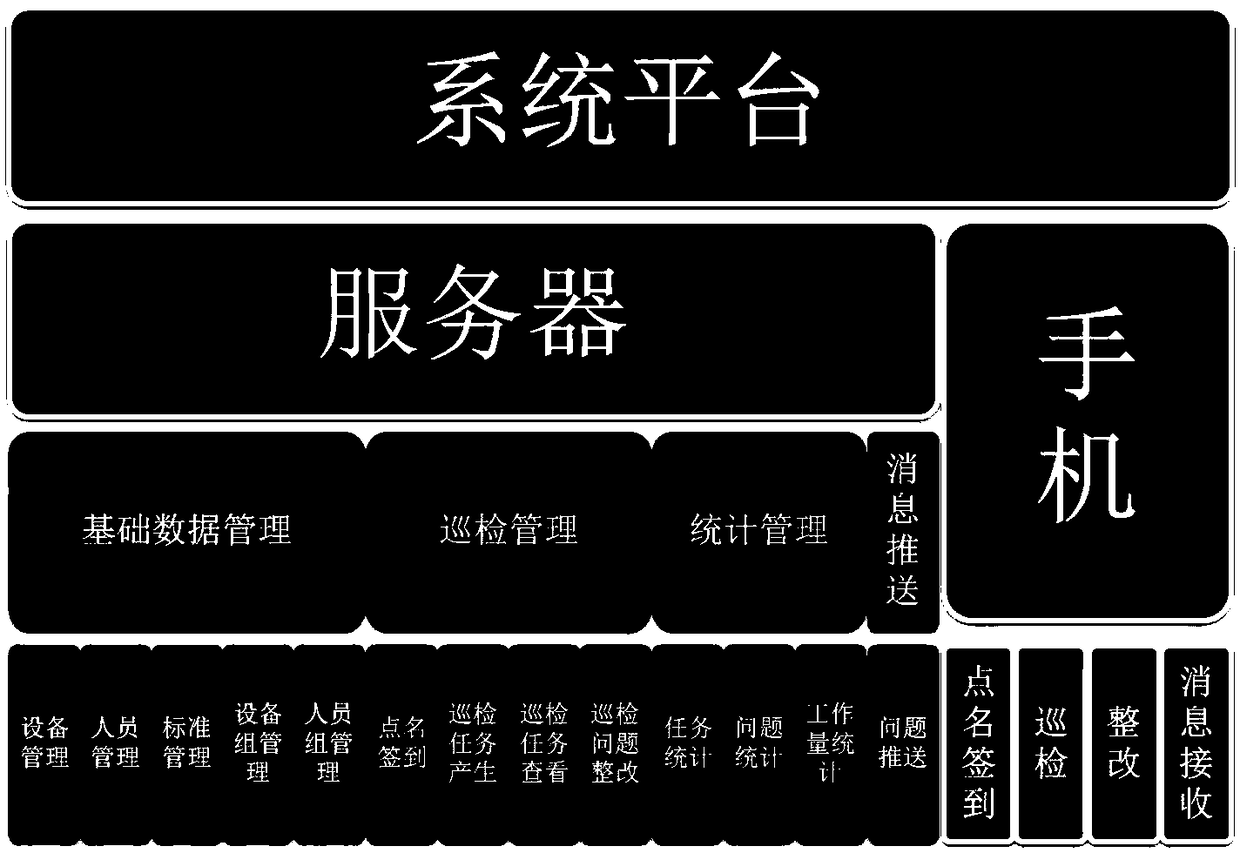

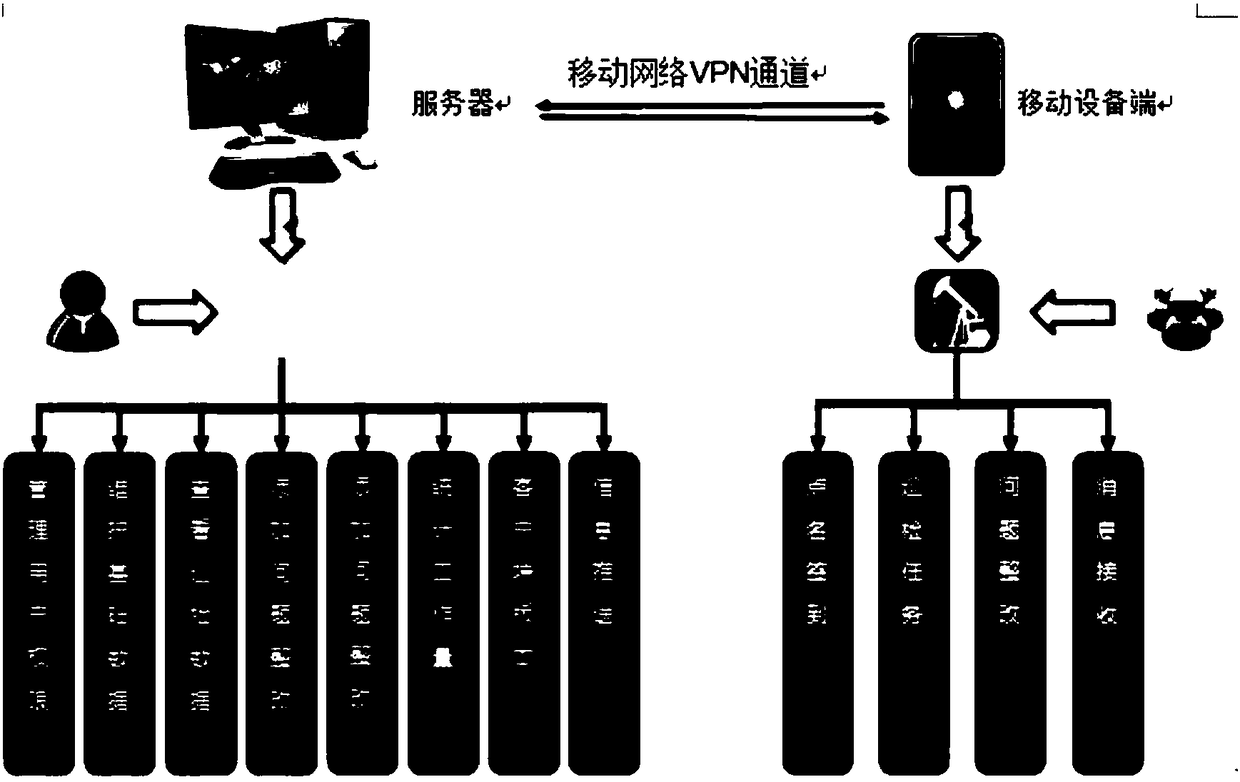

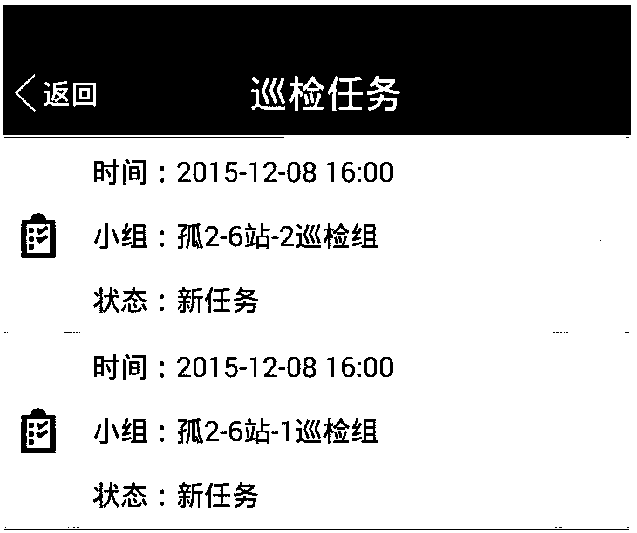

ActiveCN108492034ARealize informatizationImprove work efficiency and qualityChecking time patrolsResourcesSystem configurationManagement system

The invention provides an oil field production management system comprising a terminal device application end and a WEB application end. The terminal device application end comprises a task allocationmodule, a device inspection module, a device positioning module and a process display module. The WEB application end includes a system configuration management module and a patrol operation module.The above technical solution proposes the oil field production management system, the informationization, standardization and streamline of grassroot production management can be achieved, and the efficiency and quality of grassroots management are improved. At the same time, by using the oil field production management system of the embodiment of the invention, the timely and accurate reporting of problems can be ensured, and the rectification of the reported problems is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

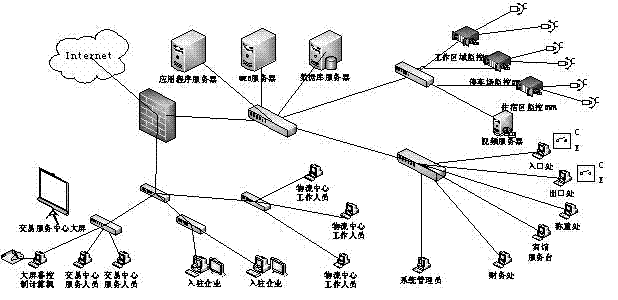

Logistic information management platform

InactiveCN102789604AImprove work efficiency and qualityImprove work efficiencyLogisticsTime dynamicsInformation technology

The invention relates to a logistic information optimization system, particularly relates to a logistic information management platform and belongs to the field of computer information technology. In order to solve the problems that in the current, the logistic information management is disordered, the logistic information communication is inconvenient, the transaction cost is high, and the operation efficiency of a freight market is low, the logistic information management platform is provided. The platform comprises a login information management system, a basic information management system and an enterprise platform information management system. According to the platform, the customer service in freight stations is humanized, the business process is informationized, the information processing is automated, and reasonable requirements are met. Real-time dynamic supervision of all links is achieved, the working efficiency and the quality of freight stations and business owners in the station are improved, and the platform is safe, accurate, high-efficient and scientific.

Owner:南京索弗威信息技术有限公司

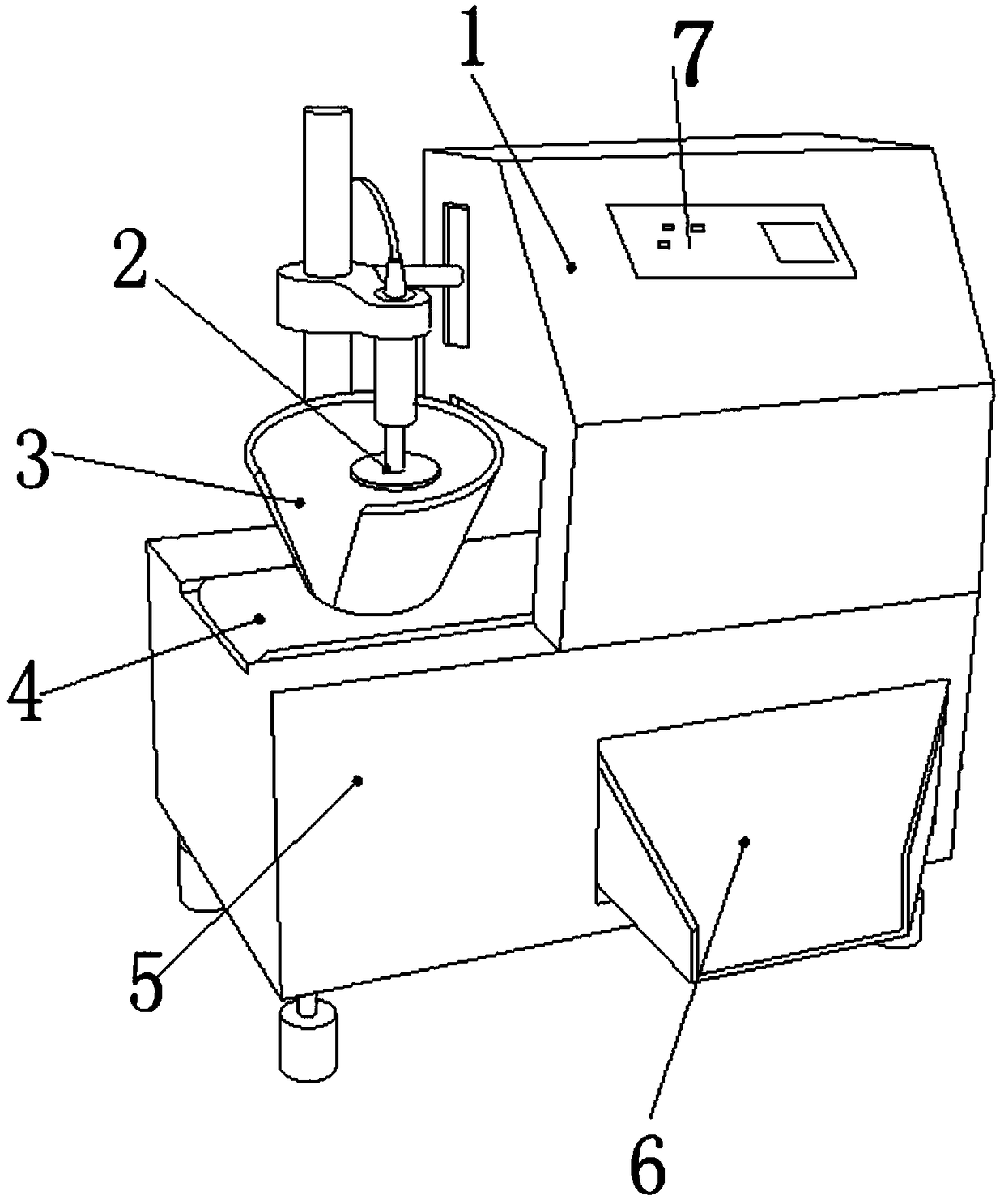

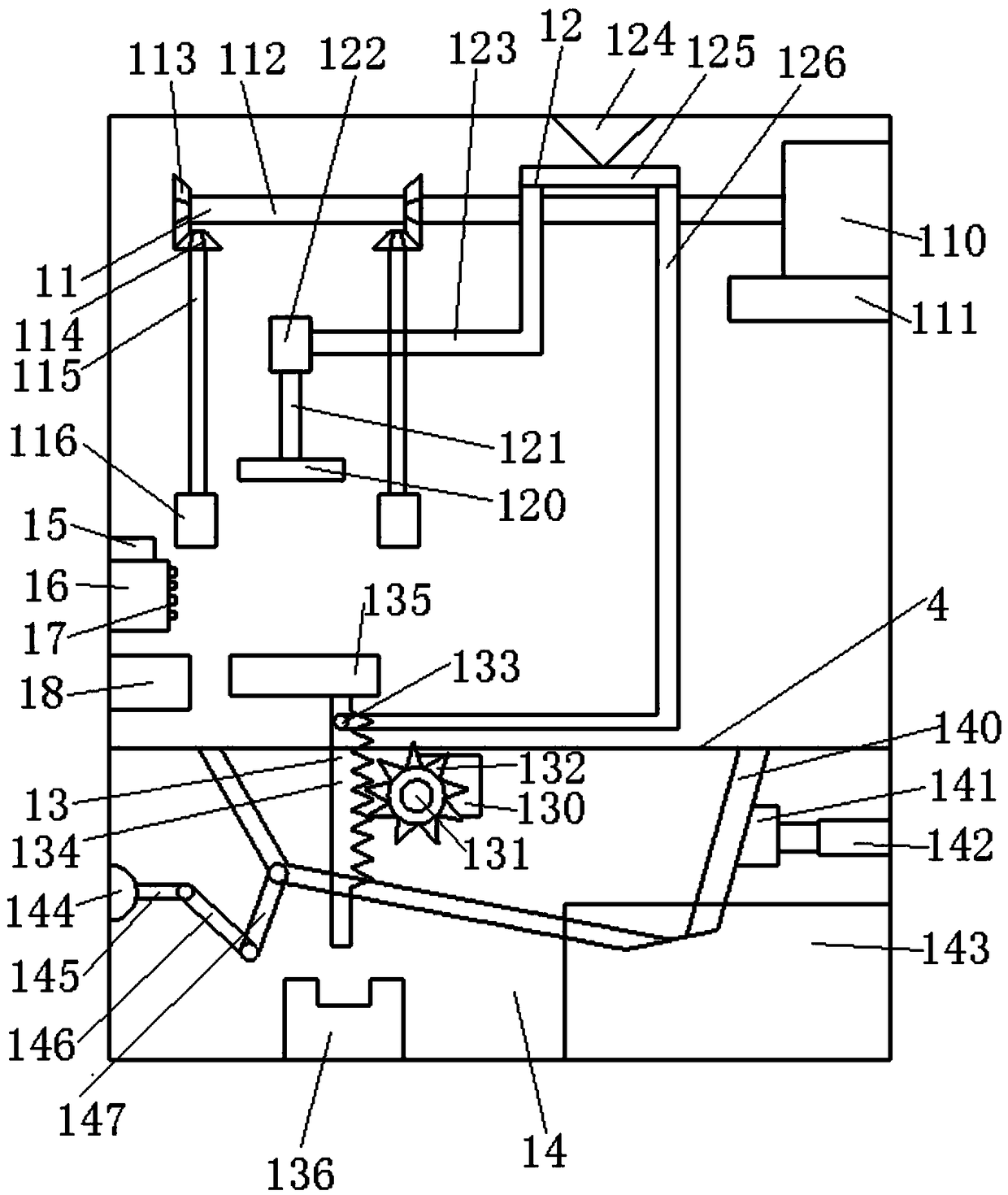

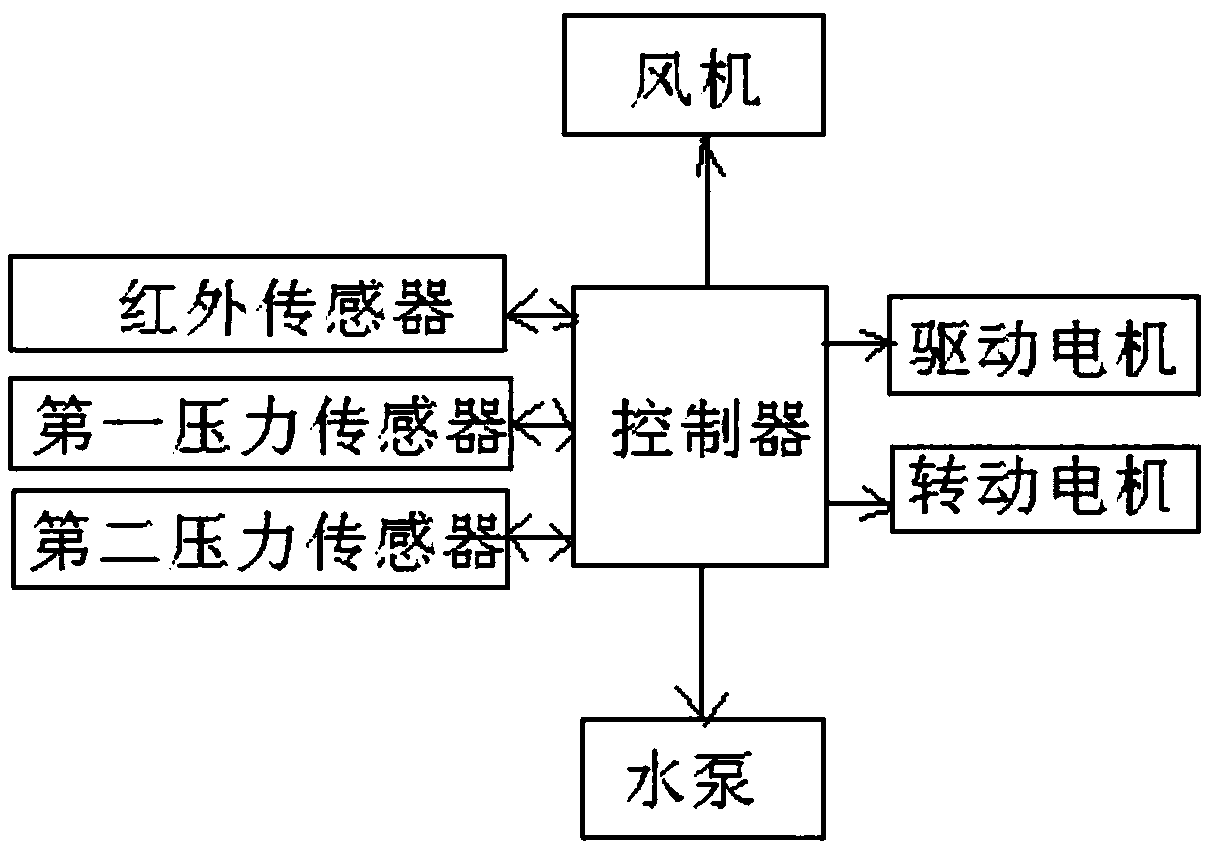

Grinding device for grinding glass end surface

ActiveCN108687603AHigh degree of automationImprove work efficiency and qualityEdge grinding machinesGrinding drivesSurface grindingMachining process

Owner:安徽国隆玻璃科技有限公司

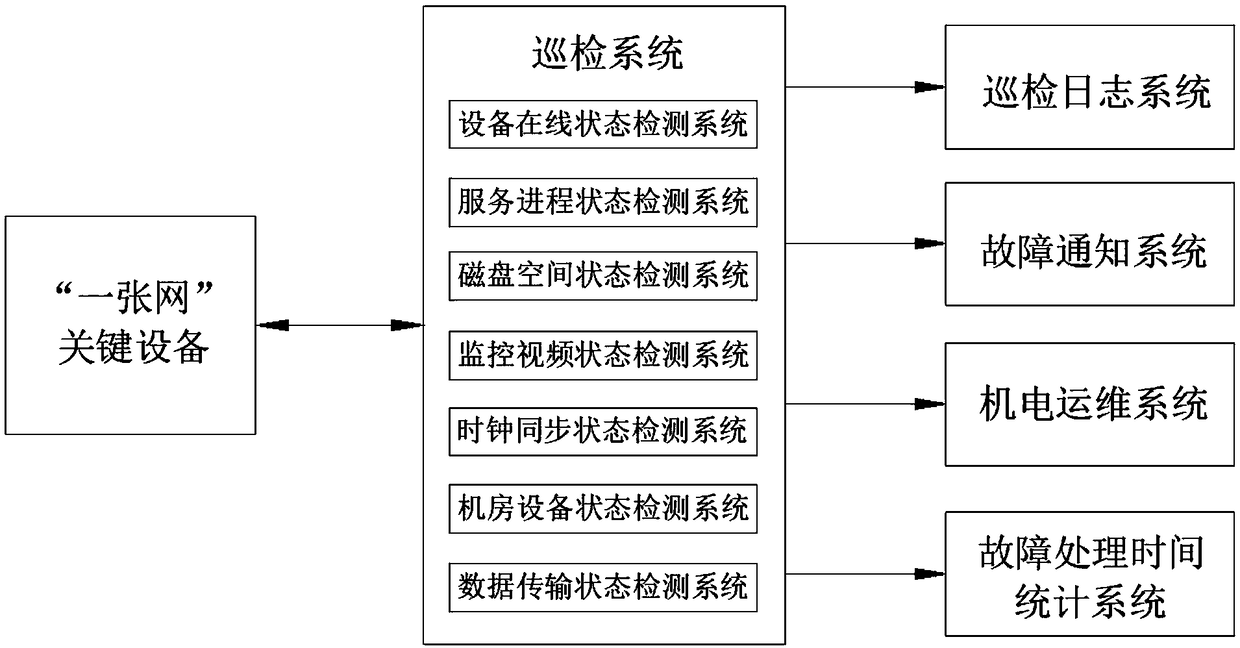

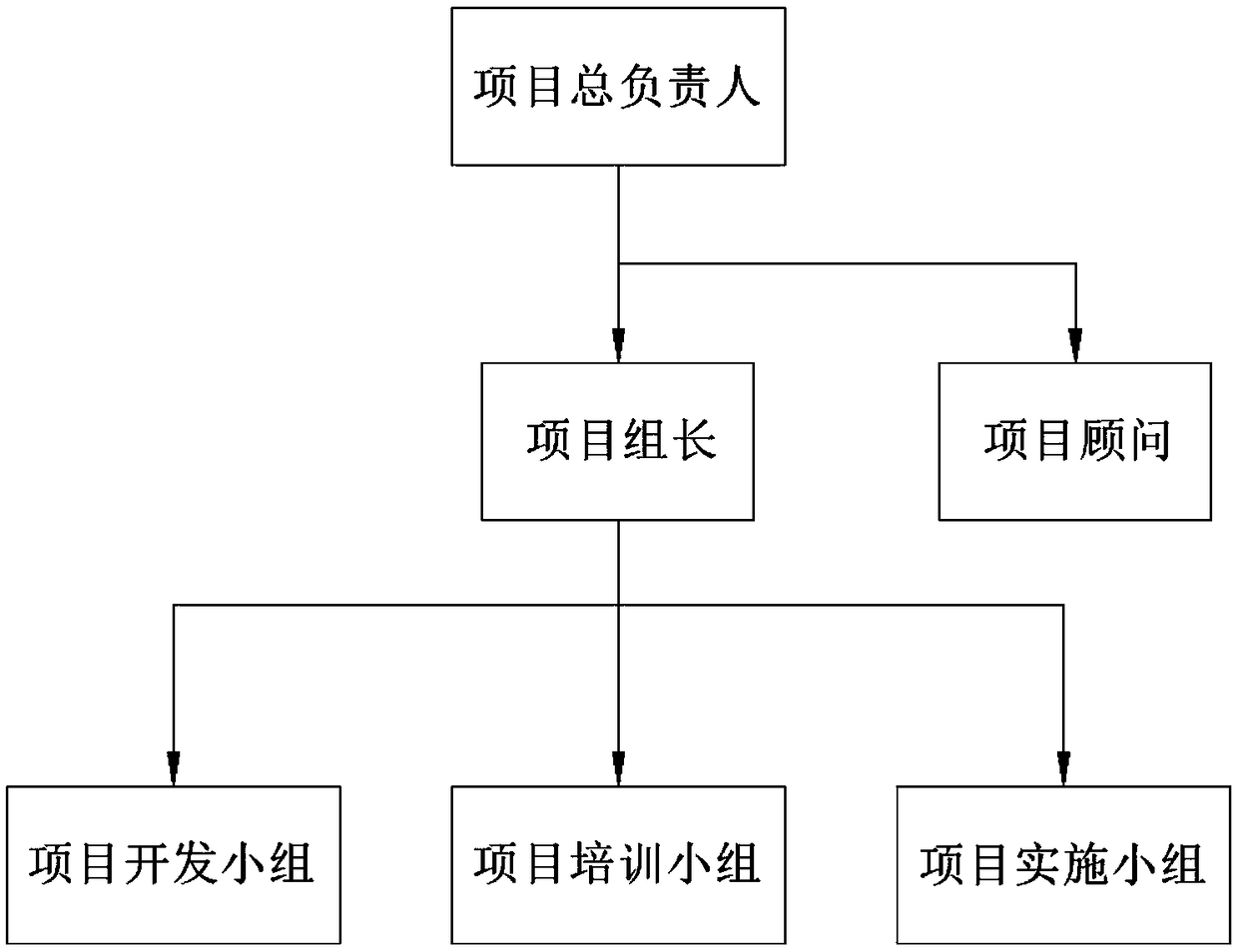

An intelligent patrol inspection system for expressway equipment

InactiveCN109376876AImprove work efficiency and qualityFree up staff workloadTicket-issuing apparatusData transmissionCritical system

The invention discloses an intelligent patrol inspection system for expressway equipment, belonging to the field of intelligent patrol inspection system. The system comprises a network key device, andan inspection system comprises a device online state detection system, a service process state detection system, a disk space state detection system, a monitoring video state detection system, and aclock synchronization state detection system, an equipment room condition detection system and a data transmission status detection system, the inspection system can realize the automatic detection and statistics of most mechanical and electrical key equipment faults, which can improve the efficiency and quality of daily patrol inspection of mechanical and electrical system, devote the maintainer's main energy to the repair and treatment of mechanical and electrical equipment faults, and reduce the risk of management responsibility. It can ensure the normal operation of the key system and facilities of the networked toll collection to the maximum extent; it is convenient for statistical analysis of fault treatment, evaluation of mechanical and electrical maintenance work, and further improve the quality of mechanical and electrical maintenance work.

Owner:广东广凌信息科技股份有限公司

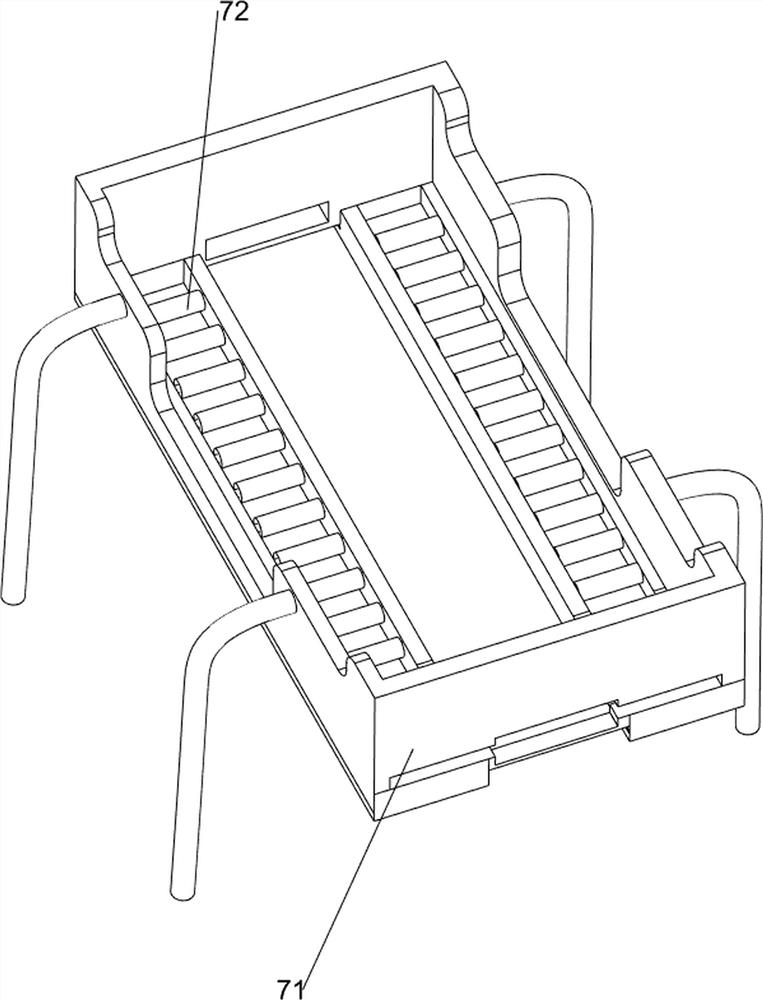

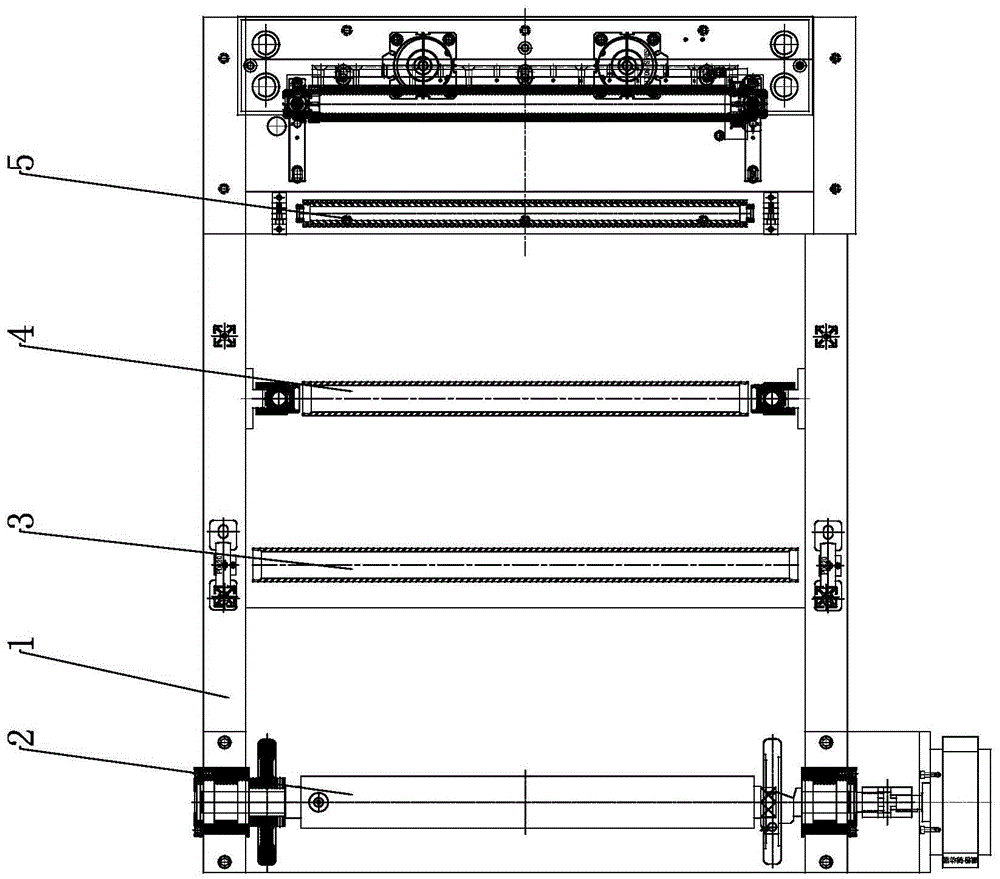

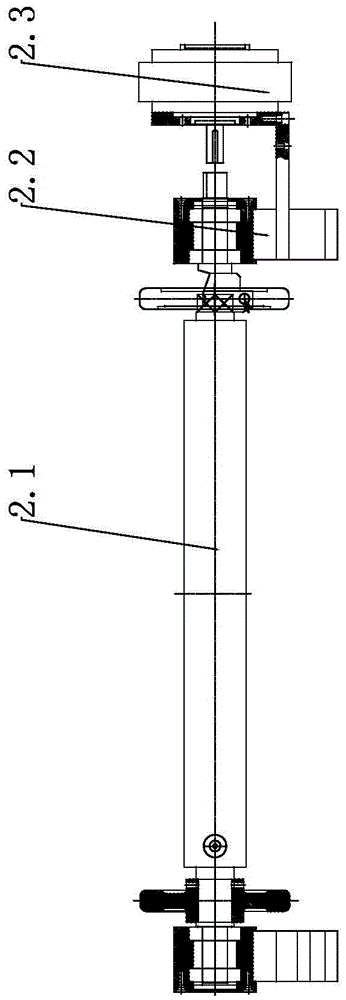

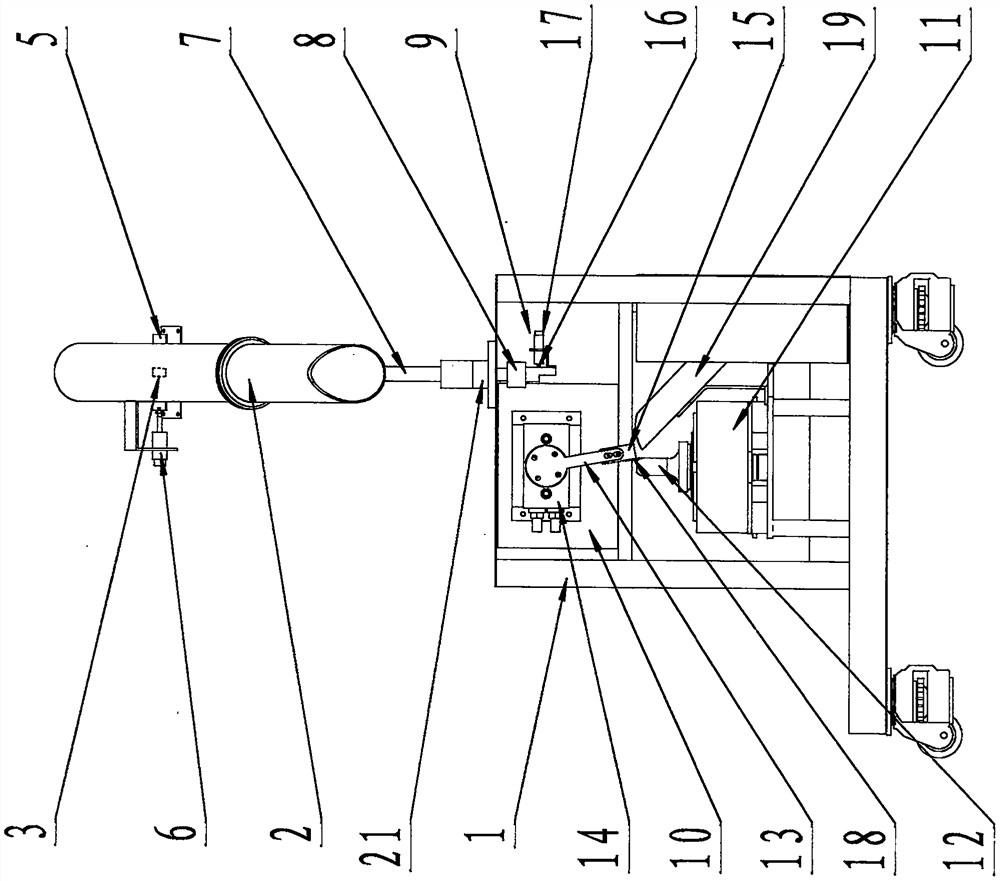

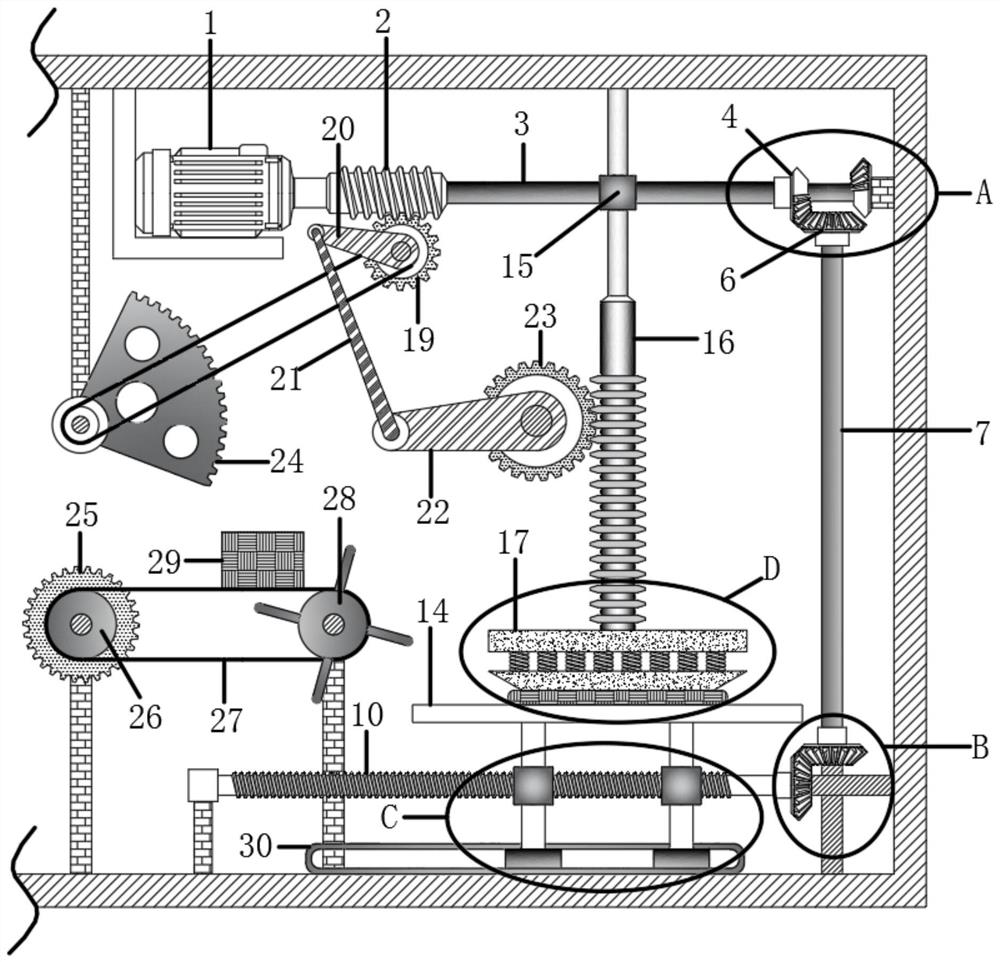

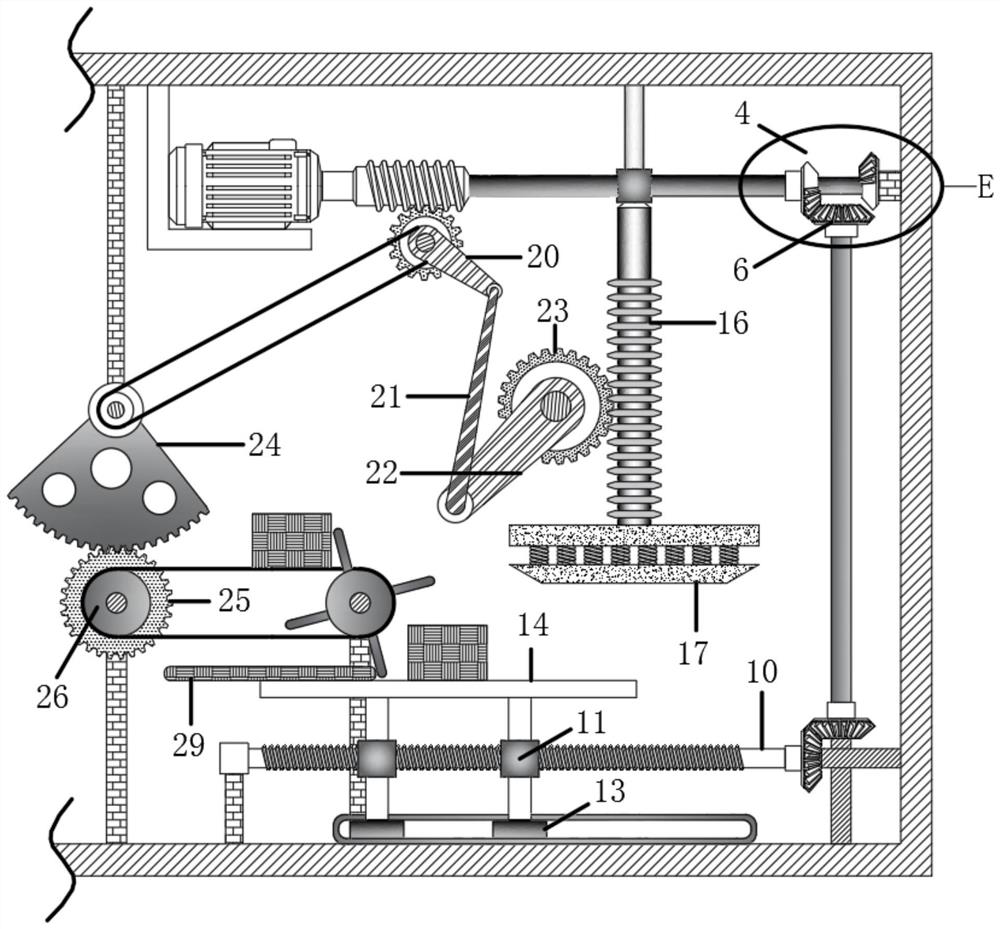

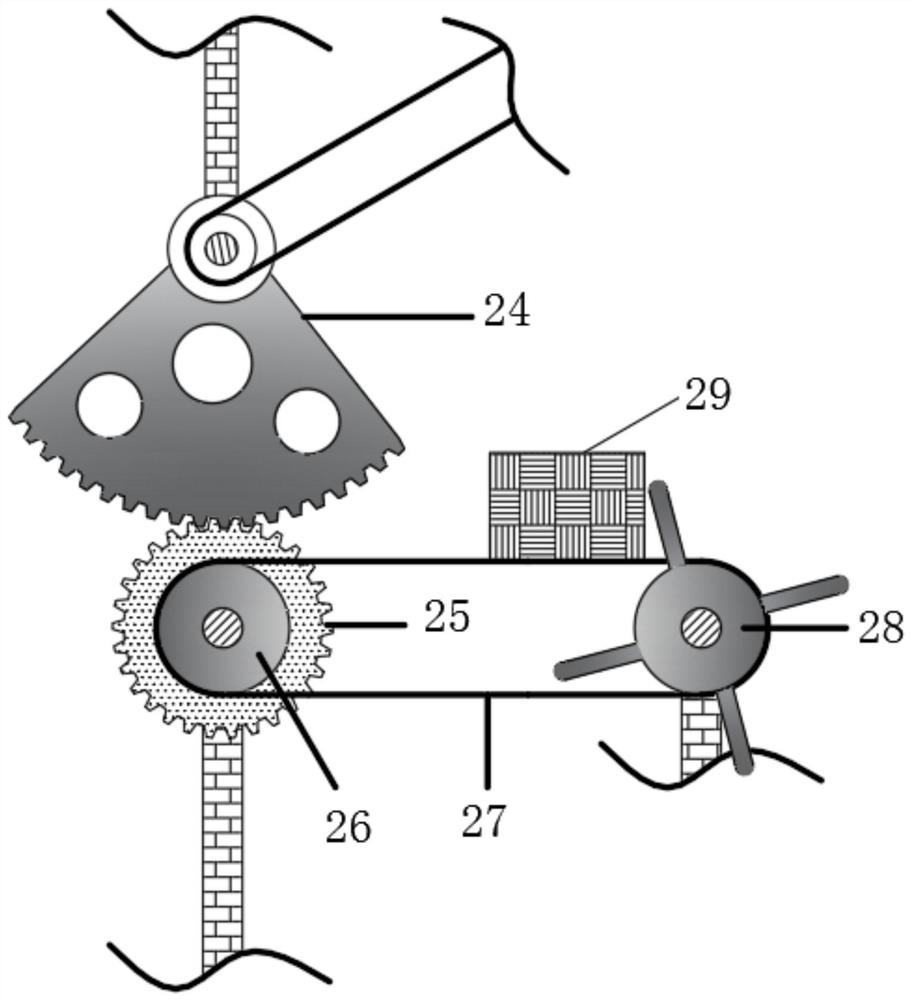

Iron plate continuous bending machine

ActiveCN111872173AImprove work efficiency and qualityRealize the bending effectMetal-working feeding devicesPositioning devicesElectric machineryStructural engineering

The invention relates to a bending machine, in particular to an iron plate continuous bending machine. The iron plate continuous bending machine can fix an iron plate and achieve the function of conveying the iron plate. According to the technical scheme, the iron plate continuous bending machine comprises a base, a motor, a bending mechanism and a pressing mechanism, wherein a workbench is arranged on one side of the base. The motor is arranged at the top of the workbench; the bending mechanism is connected between an output shaft of the motor and the workbench; and the workbench is connectedwith the pressing mechanism, and the pressing mechanism is connected with the bending mechanism. Through cooperation of the motor and the bending mechanism, the effect of bending the iron plate can be achieved, the iron plate does not need to be bent manually, the working efficiency and quality are improved, through cooperation of the pressing mechanism, the iron plate can be fixed in the bendingprocess, and product damage caused by errors generated in the bending process is avoided.

Owner:ZHONGTIAN BROADBAND TECH

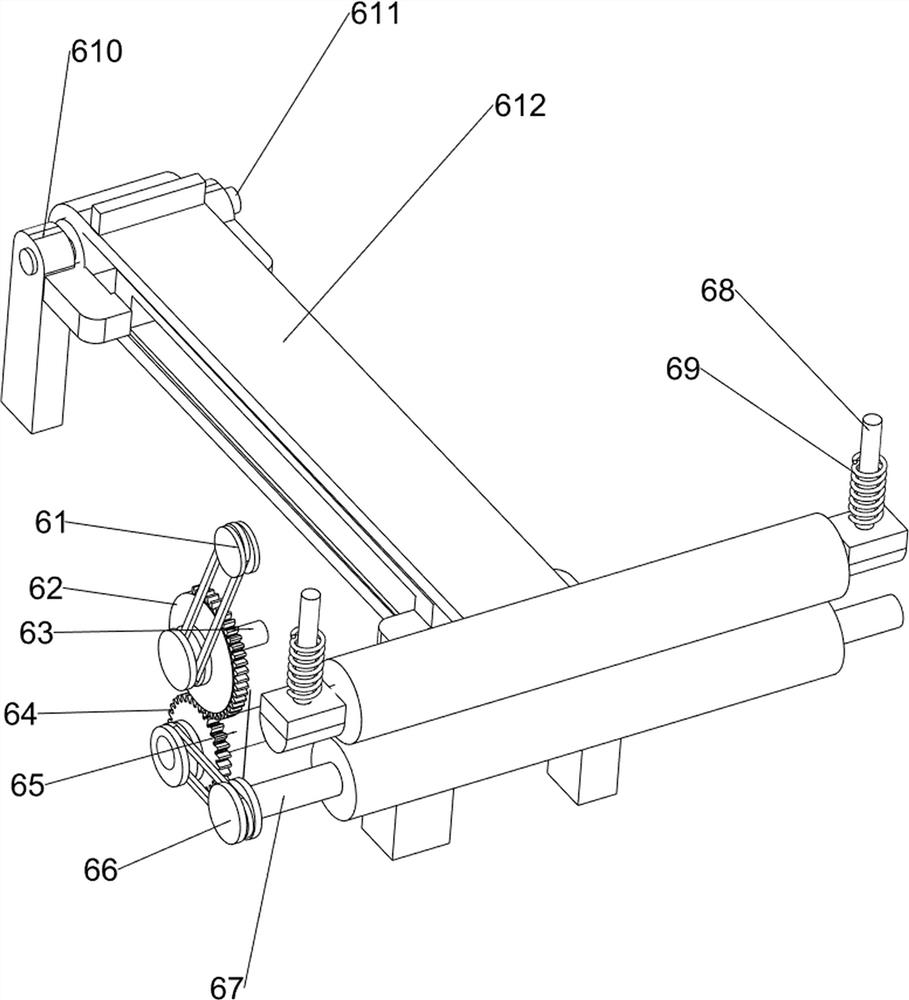

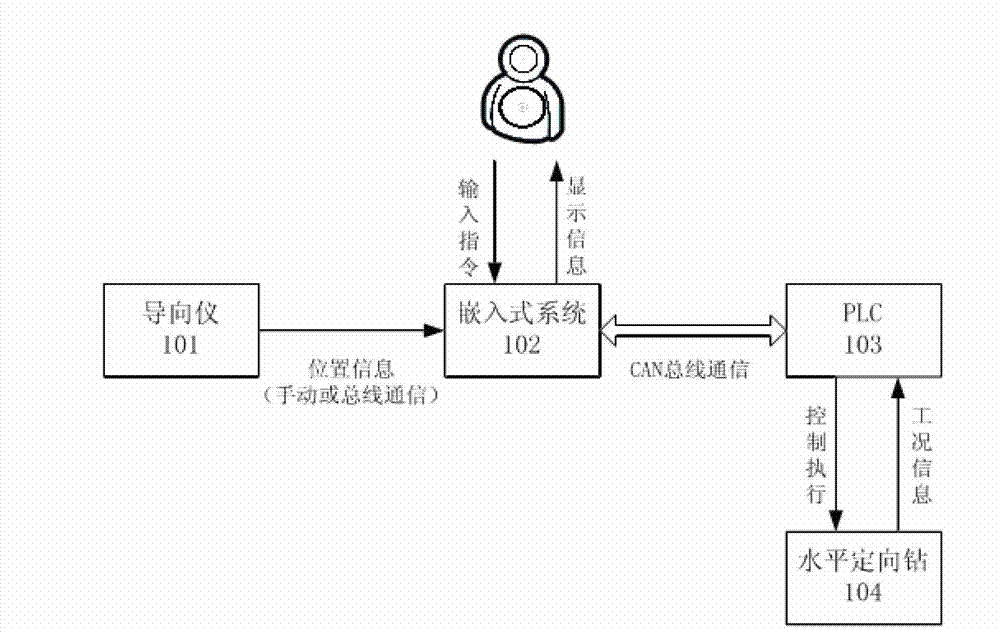

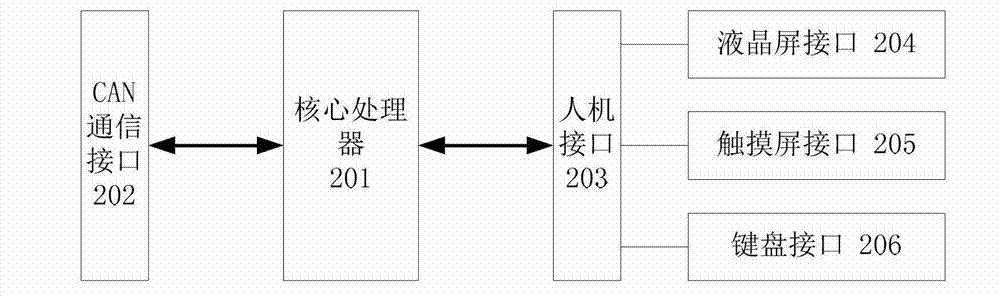

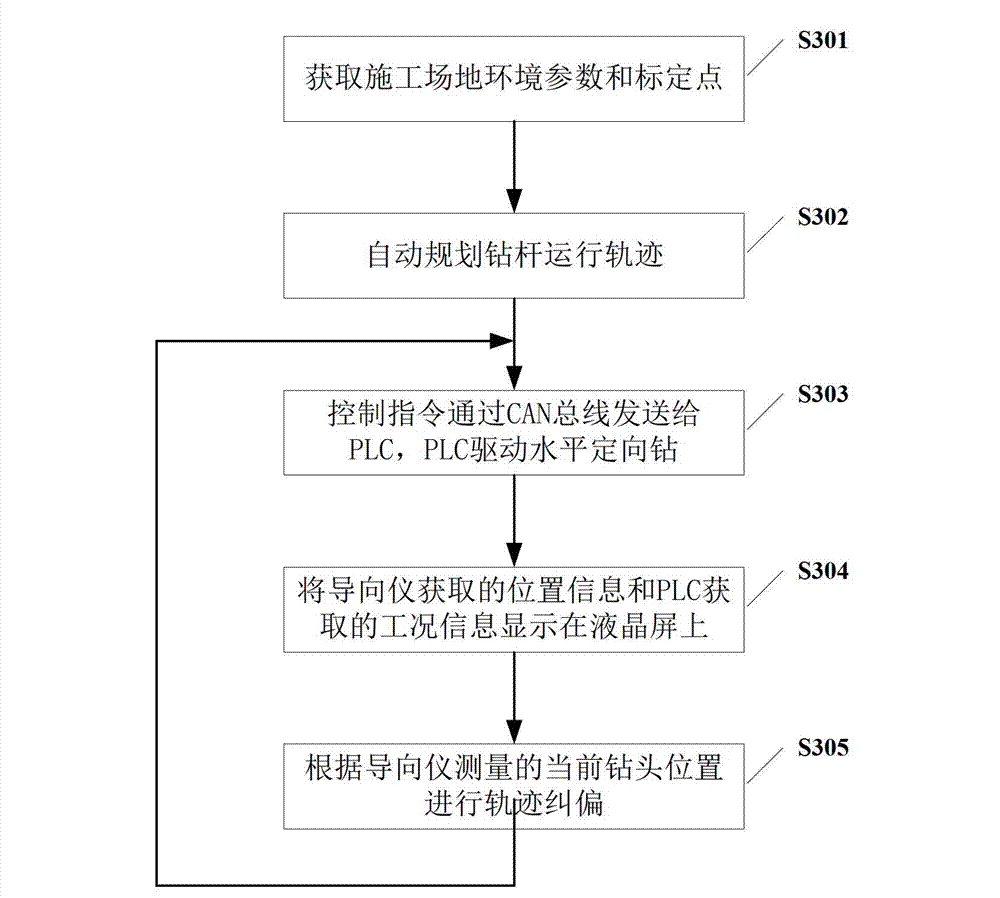

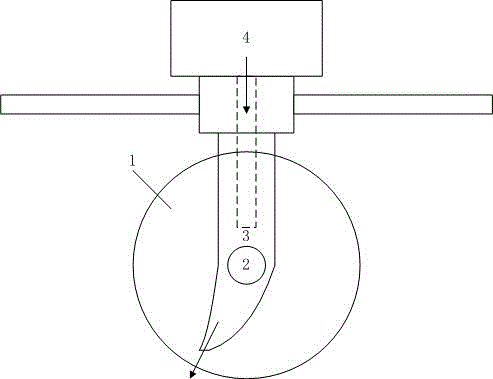

Embedded type system-based control device for horizontal directional drill

ActiveCN102900365AImprove work efficiency and qualitySolve communication problemsDirectional drillingAutomatic control for drillingEmbedded systemProgrammable logic controller

The invention relates to an embedded type system-based control device for a horizontal directional drill, which comprises an orientating instrument, an embedded type system and a programmable logic controller, wherein the orientating instrument is used for obtaining current drill bit position information and feeding back the drill bit position information to the embedded type system; the embedded type system is used for automatically planning the operation track of the horizontal directional drill, correcting the deviation of the operation track according to the drill bit position information fed back by the orientating instrument, transmitting a control instruction to the programmable logic controller, receiving a data packet of working condition information of the programmable logic controller and displaying the working condition information to operation personnel; and the programmable logic controller is communicated with the embedded type system through a CAN (controller area network) bus and is used for driving the horizontal directional drill to operate and monitoring the working condition information of each part of the horizontal directional drill. With the adoption of the control device, the automatic track planning and deviation correction of the horizontal directional drill are realized, the operation mode of the horizontal directional drill is simplified, and the working efficiency and the quality are improved.

Owner:SOUTHEAST UNIV +1

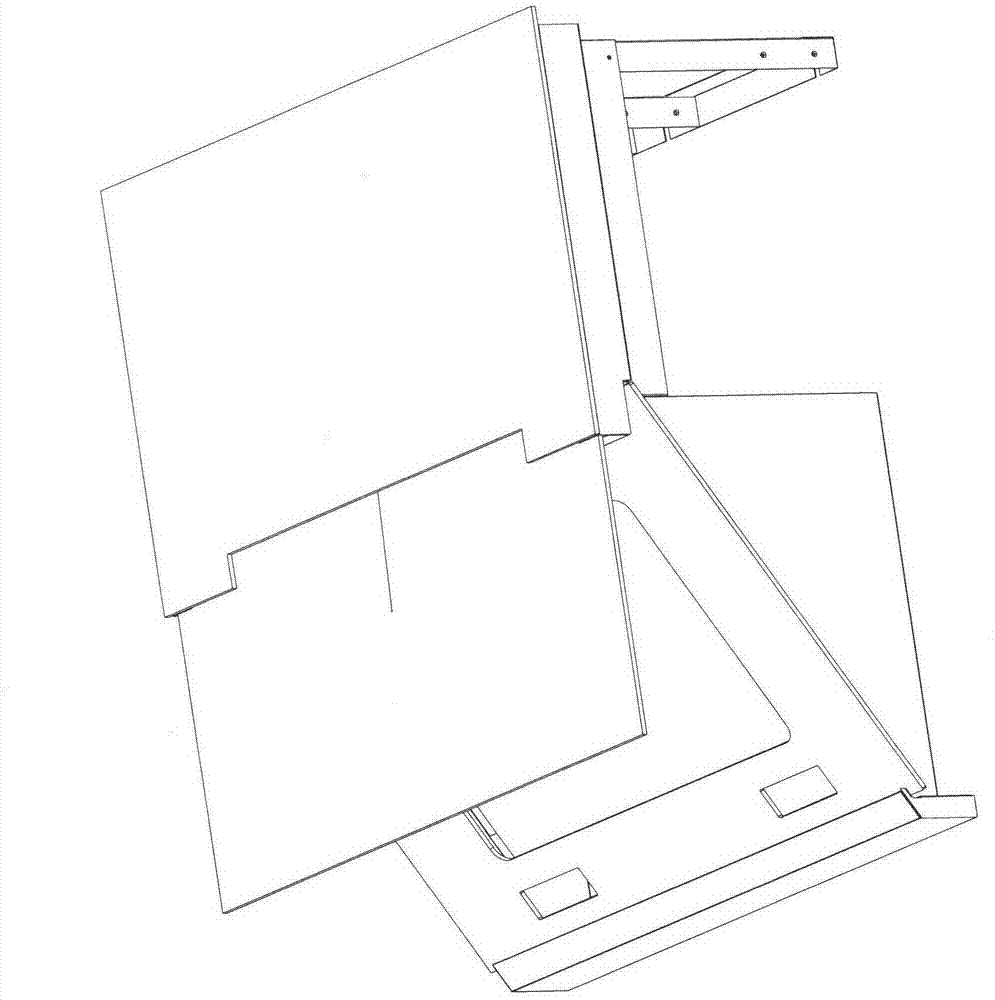

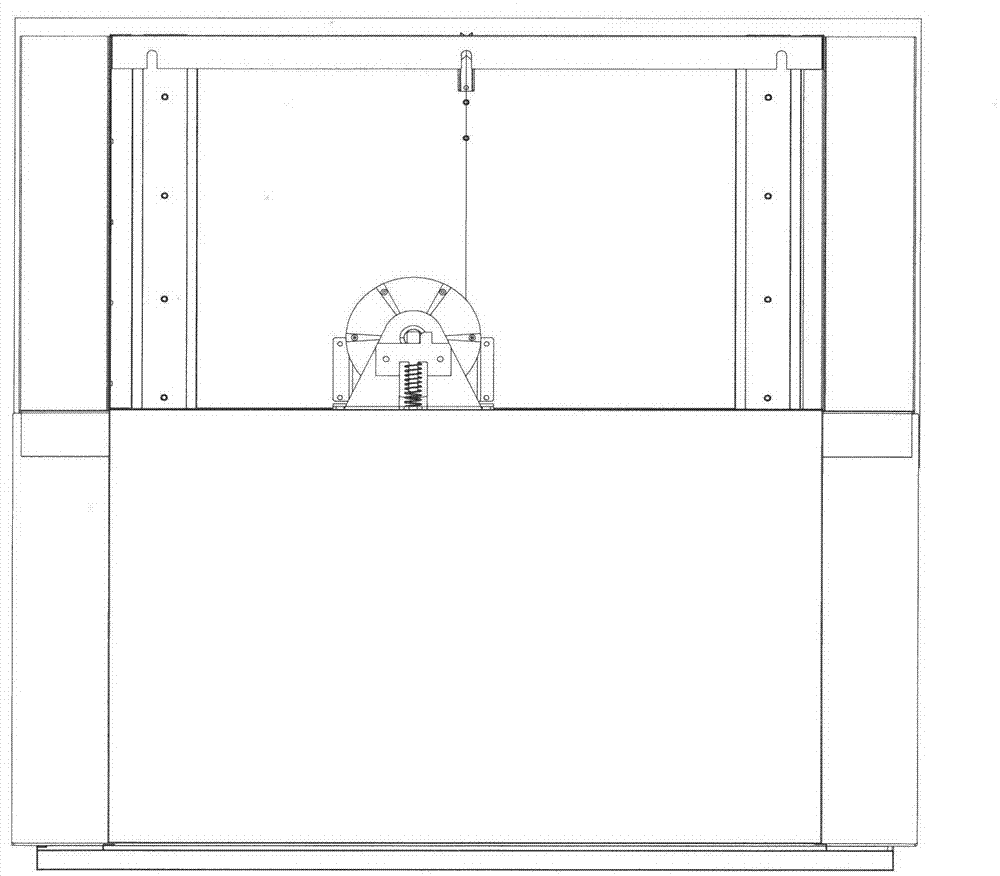

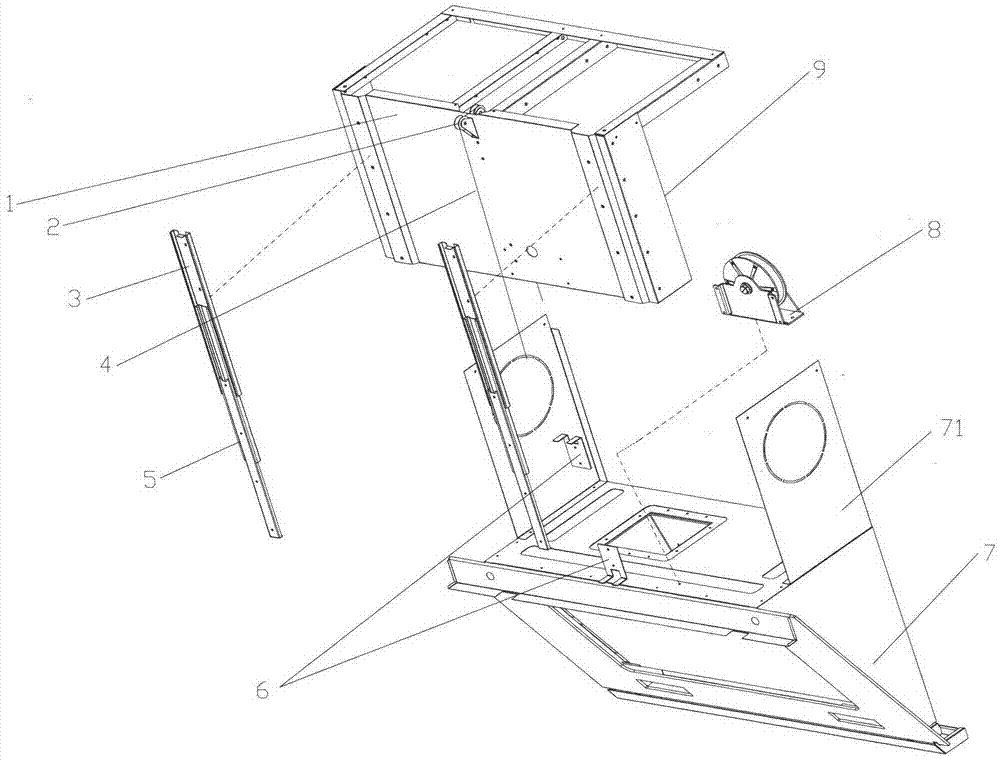

Range hood

InactiveCN102966989AImprove work efficiency and qualityMove up and down steadilyDomestic stoves or rangesLighting and heating apparatusAdhesivePulley

The invention provides a range hood comprising a main body and also comprises a bracket, wherein the bracket is an inverted L-shaped bracket from a side view, baffle plates are arranged on the two sides of the top of the range hood main body, the bracket is arranged above the range hood main body and is provided with a hoarding plate, outer sliding rails arranged longitudinally are respectively fixed on the left side and the right side of the front surface of the hoarding plate by screws, inner sliding rails are installed in the outer sliding rails in a matching manner, the inner sliding rails are matched with movable glass by adhesive, pulleys are respectively arranged on the front surface and the back surface in the middle of the upper edge of the hoarding plate, steel wire ropes are arranged on the pulleys in a penetrating manner, the steel wire rope in front of the hoarding plate is connected with the movable glass, the steel wire rope on the back surface of the hoarding plate is connected with a scrolling spring assembly, and the scrolling spring assembly is arranged at the top of the range hood main body. According to the range hood, the work efficiency and the quality of the range hood are improved.

Owner:米永峰

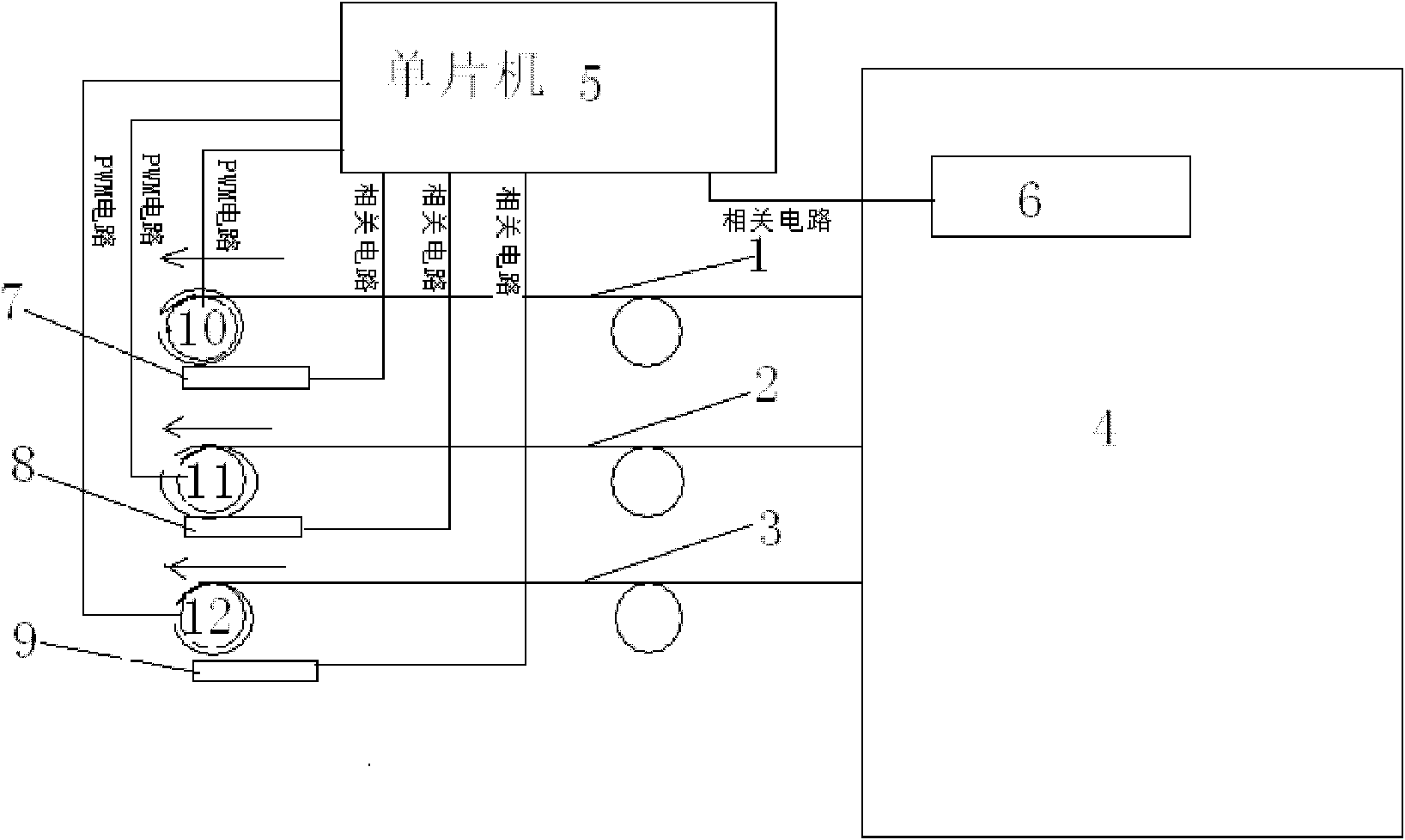

Automatic traveling speed control device of gluing machine and gluing machine with same

InactiveCN102323768AGlue evenlyImprove work efficiency and qualityProgramme controlComputer controlAutomatic controlMicrocomputer

The invention discloses an automatic traveling speed control device of a gluing machine. The automatic traveling speed control device is characterized by comprising a temperature sensor, at least one rotation speed sensor and a singlechip microcomputer, wherein the temperature sensor is arranged inside a glue tank of the gluing machine and is used for measuring the temperature of glue; the rotation speed sensor is arranged on a motor of a winding coil of the gluing machine and is used for measuring the rotation speed of the motor; the temperature sensor, the rotation speed sensor and the motor of the winding coil of the gluing machine are connected with the singlechip microcomputer through corresponding circuits; and the singlechip microcomputer is used for presetting optimal motor rotation speed data of a material to be glued at a specific glue temperature, and comparing the rotation speed detected by the rotation speed sensor with the preset optimal motor rotation speed according to the temperature, detected by the temperature sensor, of the glue in the gluing machine, so as to control the motor of the winding coil of the gluing machine. In the invention, according to the temperature detection of the gluing machine, a singlechip microcomputer control system can be used for realizing the automatic tracking of the temperature specific to winding linear speeds of different materials, so as to control the rotation speed of the motor of the winding coil and achieve the purpose of automatically controlling the traveling speed of the material to be glued.

Owner:杭州奇力企业管理咨询有限公司

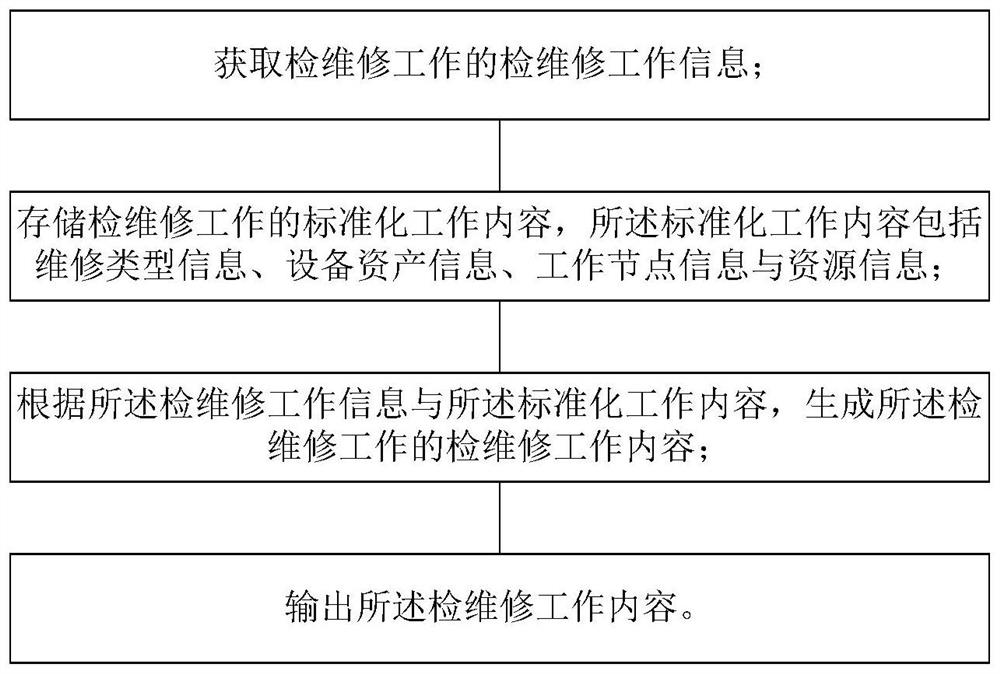

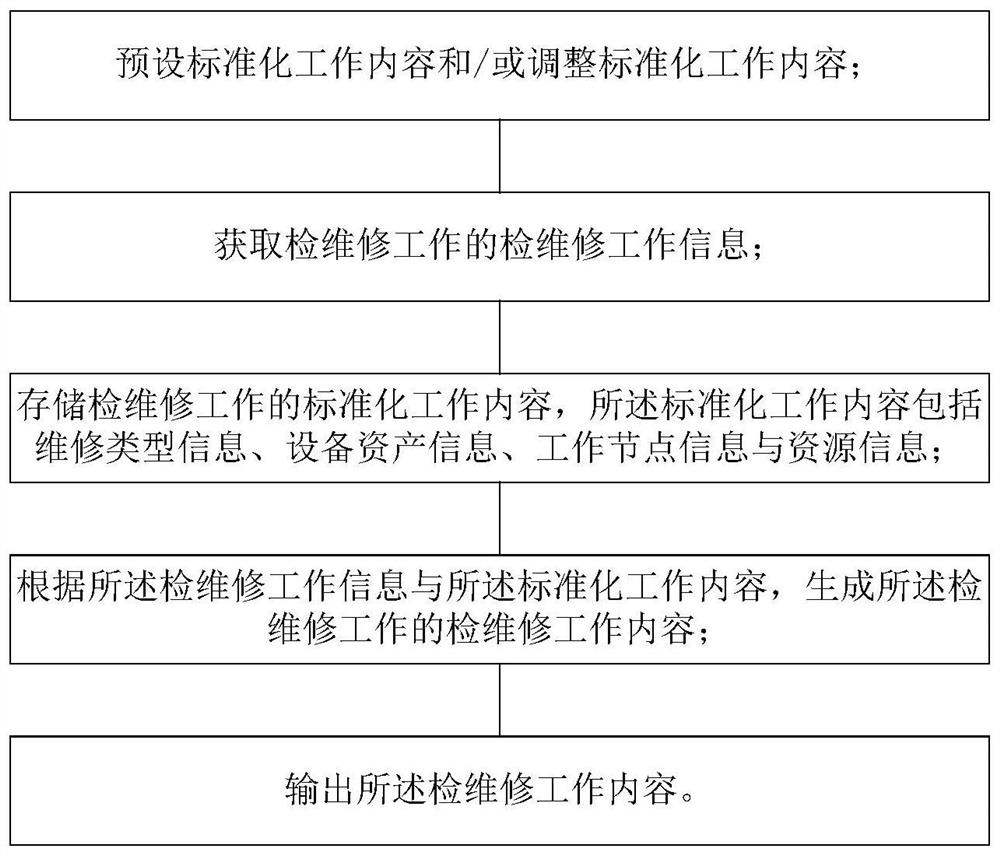

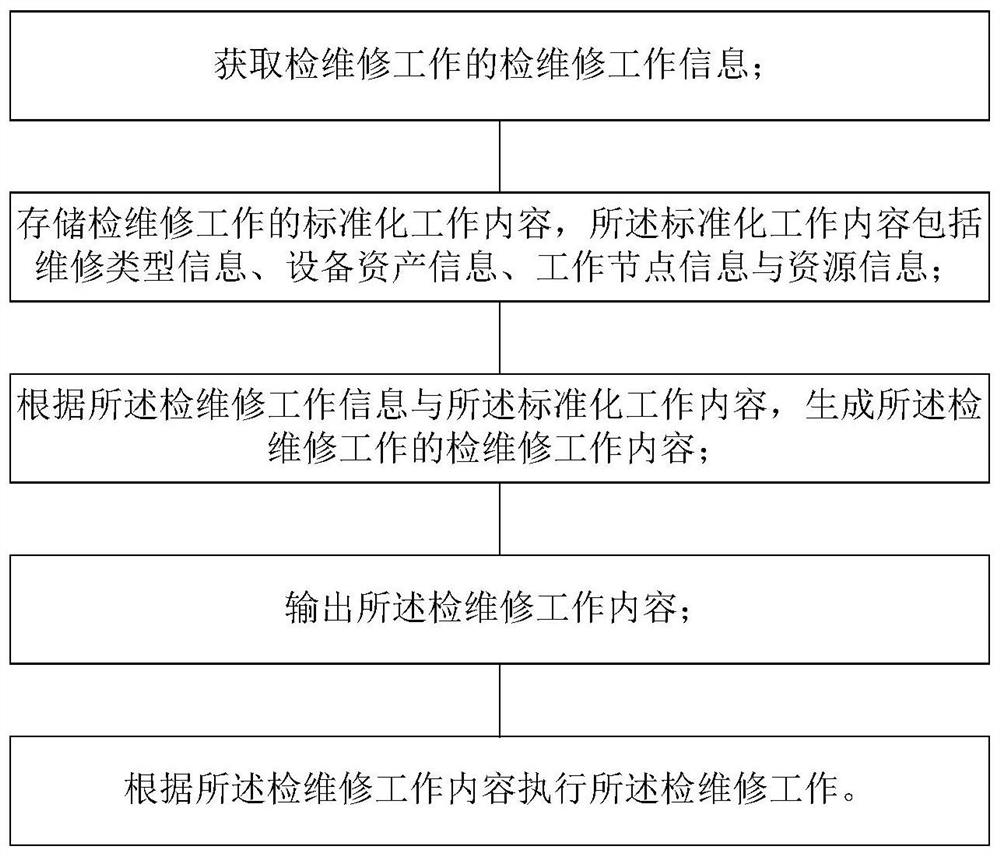

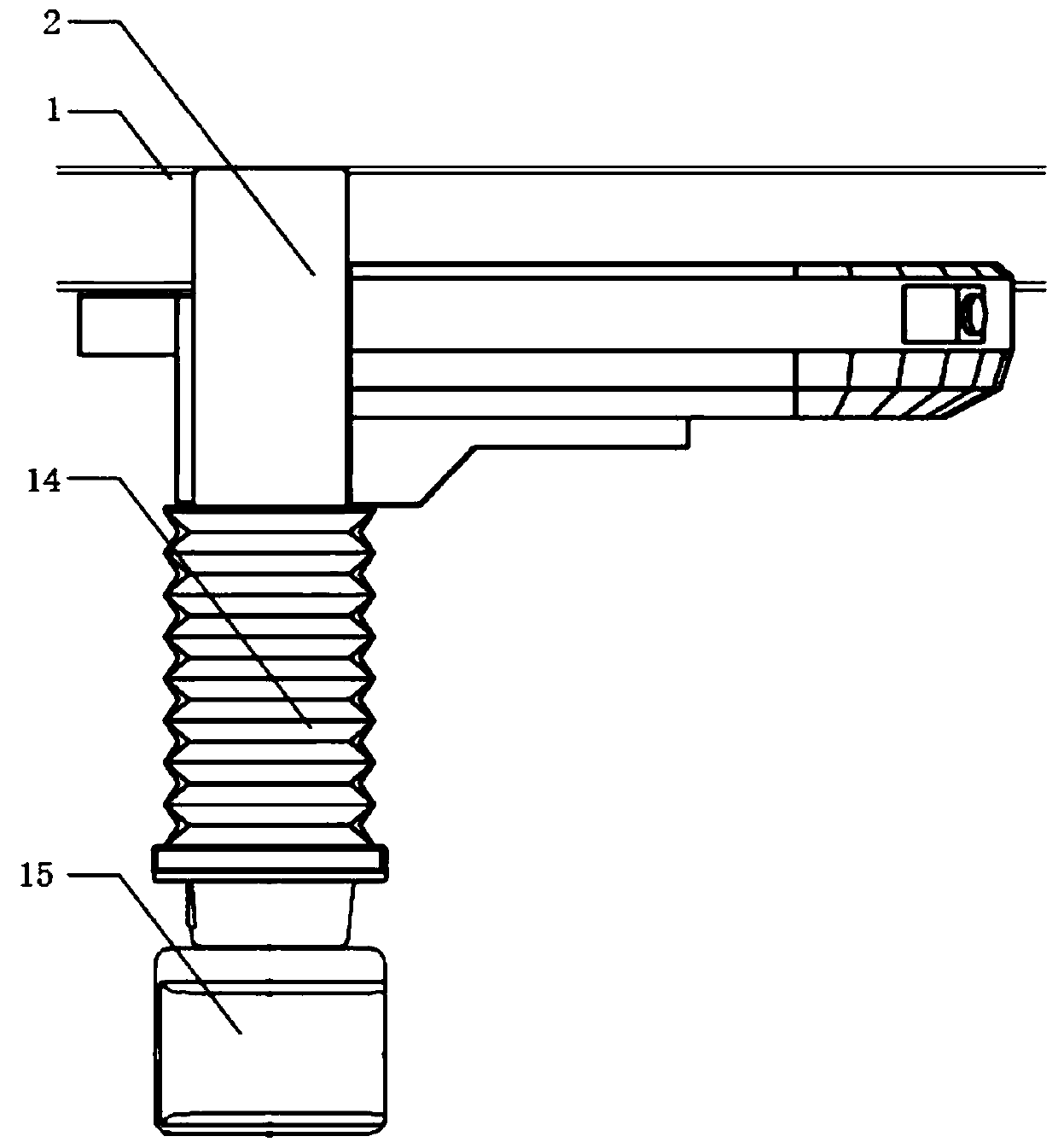

Inspection and maintenance standardization implementation method and system

PendingCN112101580AAchieve standardizationAchieve normalizationInstrumentsResource informationBusiness enterprise

The invention discloses an inspection and maintenance standardization implementation method and system. The inspection and maintenance standardization implementation method comprises the following steps: acquiring inspection and maintenance work information of inspection and maintenance work; storing standardized work content of the inspection and maintenance work, wherein the standardized work content comprises maintenance type information, equipment asset information, work node information and resource information; generating inspection and maintenance work content of the inspection and maintenance work according to the inspection and maintenance work information and the standardized work content; and outputting the inspection and maintenance work content. By adopting the scheme, the inspection and maintenance work content corresponding to the inspection and maintenance work can be generated according to the inspection and maintenance work information and the standardized work content to standardize the inspection and maintenance work, standardization and normalization of the inspection and maintenance work are achieved, the randomness of inspection and maintenance work management is reduced, and the work efficiency and quality are improved; consistency of operation quality is achieved, a good foundation is laid for enterprise inspection and maintenance work, and safe and efficient execution of on-site work can be guaranteed on the basis.

Owner:北京昊恩星美科技有限公司

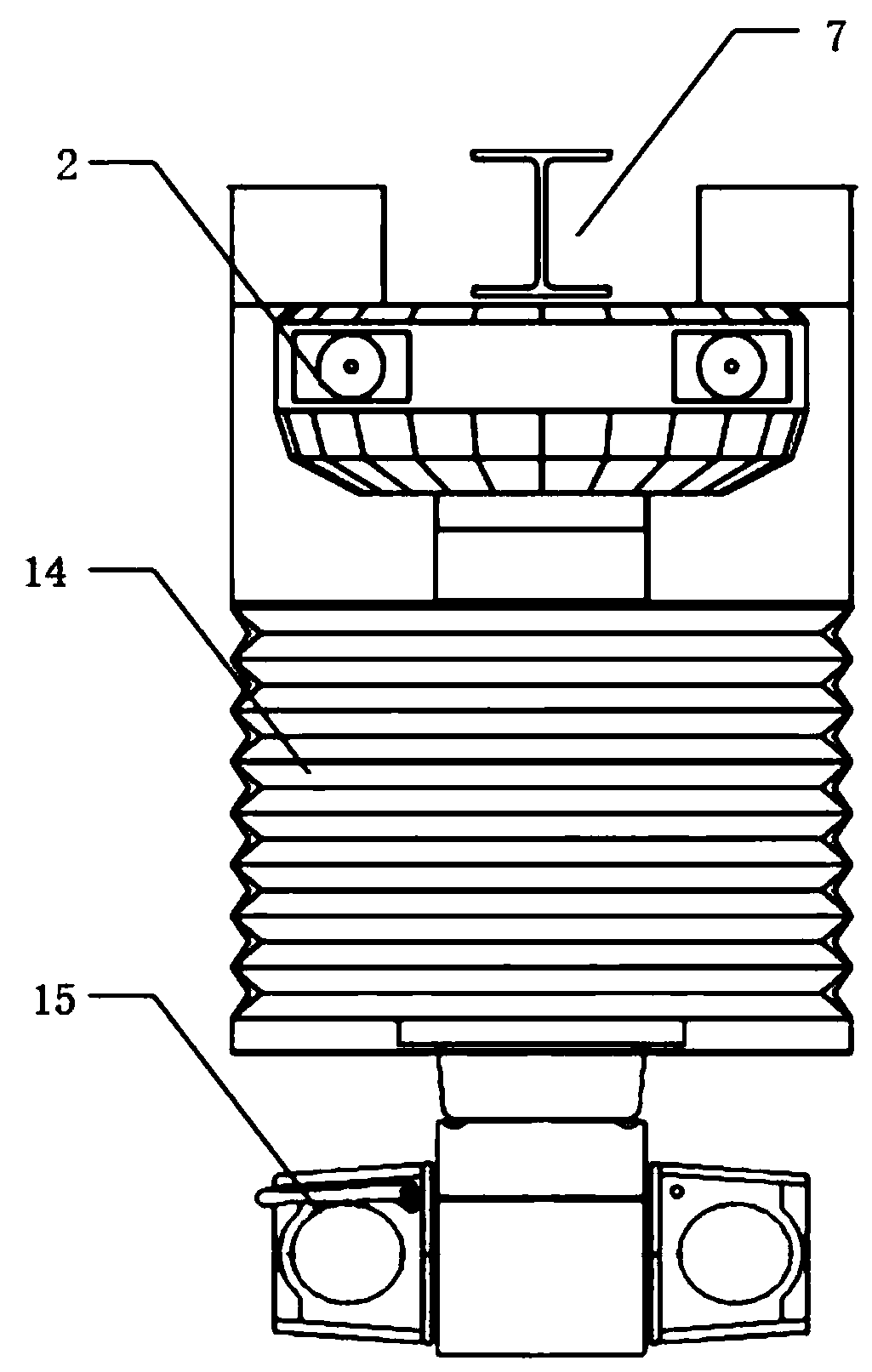

Intelligent inspection robot for power equipment

InactiveCN110649706AImprove work efficiency and qualityFlexible and free to operateCircuit arrangementsSustainable buildingsPower equipmentCommunication unit

The invention provides an intelligent inspection robot for power equipment, which comprises a track assembly, a track robot and an upper computer control system. The track robot is arranged on the rail assembly in a sliding mode. The upper computer control system comprises a local control unit, a communication unit and a man-machine interaction unit. The local control unit is used for issuing various operation instructions to the track robot. The communication unit is used for realizing data intercommunication between the local control unit and the man-machine interaction unit. The man-machineinteraction unit is used for realizing remote control of the track robot. Real-time acquisition and intelligent analysis of operation condition information such as the state of the track robot and device signals can be realized, environmental quality factors such as temperature and humidity can also be monitored, and the requirement for inspection operation of power equipment can be met.

Owner:北京国电光宇机电设备有限公司

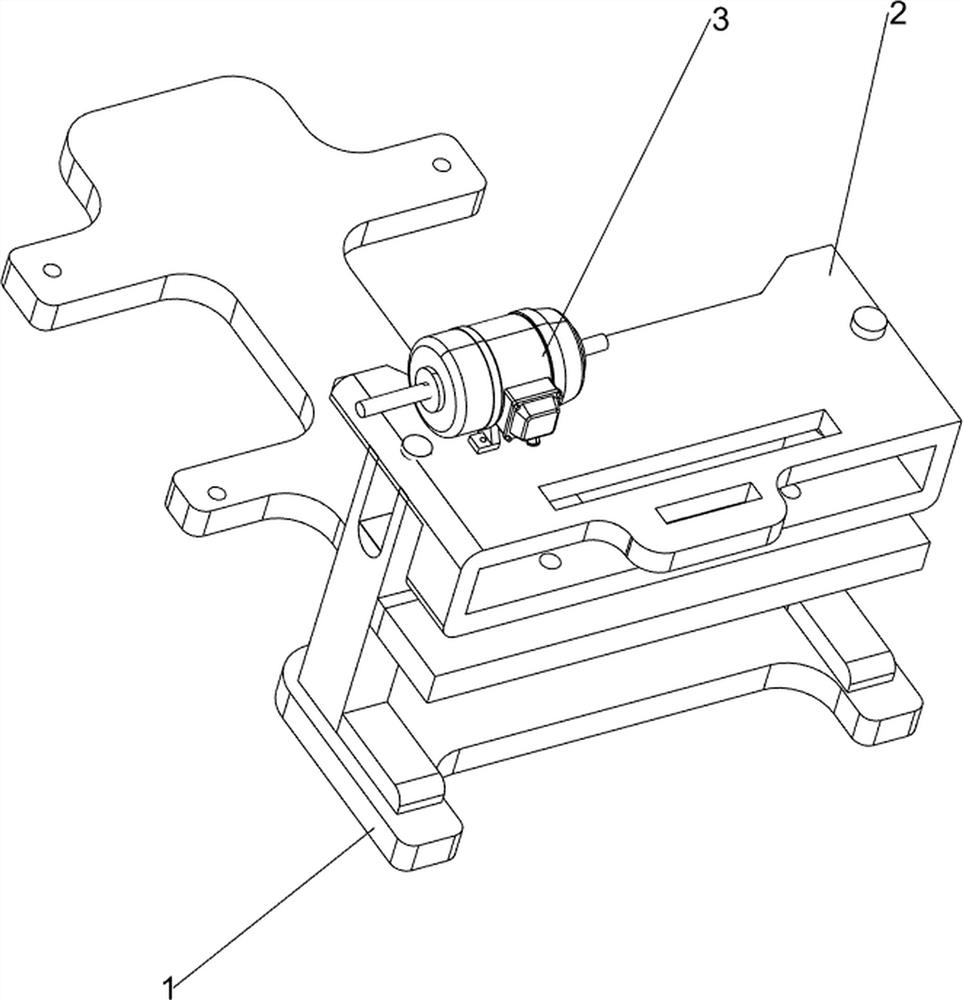

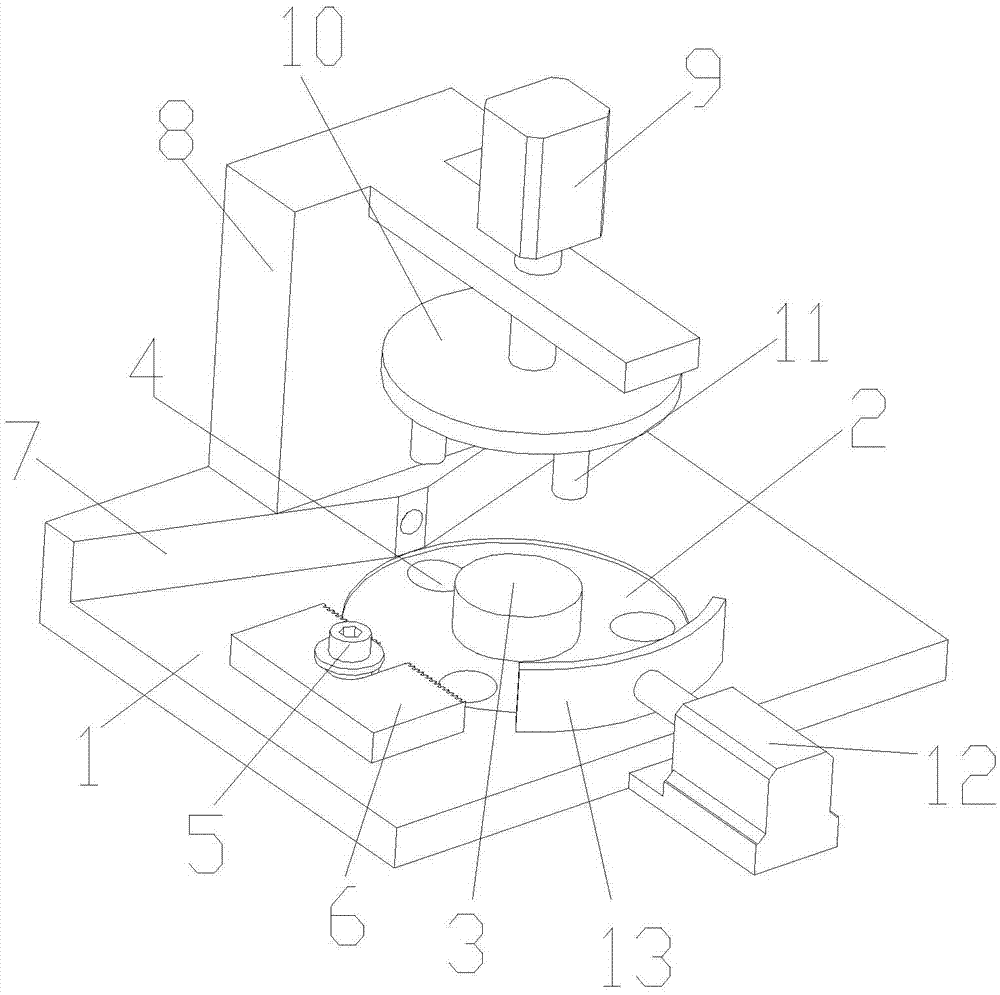

Double-pneumatic disc fixing and punching clamp

InactiveCN105436949APrecise punchingImprove work efficiency and qualityWork clamping meansPositioning apparatusTelescopic cylinderEngineering

The invention discloses a double-pneumatic disc fixing and punching clamp, which comprises a base, wherein a disc groove is formed in the base; a positioning pillar is arranged in the center of the disc groove; ejector rod holes are uniformly distributed in the disc groove; a clamping block is connected with one end of the disc groove by a bolt and the clamping block can rotate by taking the bolt as the center; a baffle is arranged on one end of the base; a telescopic cylinder which is fixed by a supporting plate is arranged above the baffle; a punching disc is arranged on a piston rod of the telescopic cylinder; a punching needle is arranged under the punching disc; and an arc-shaped plate which is controlled by a clamping cylinder is also arranged outside the disc groove. The positioning pillar is arranged in the center of the disc groove; the clamping block rotates for adjustment and is clamped on the disc; the baffle on one side abuts against the disc; the arc-shaped plate can press a product under the control of the clamping cylinder; after the disc is fixed from three aspects, the punching disc is controlled by the telescopic cylinder to punch the product, so the precise punching of the disc is realized, and the quality and work efficiency of the product are improved.

Owner:SUZHOU WUZHONG DISTRICT DALU ELECTRIC EQUIP FACTORY

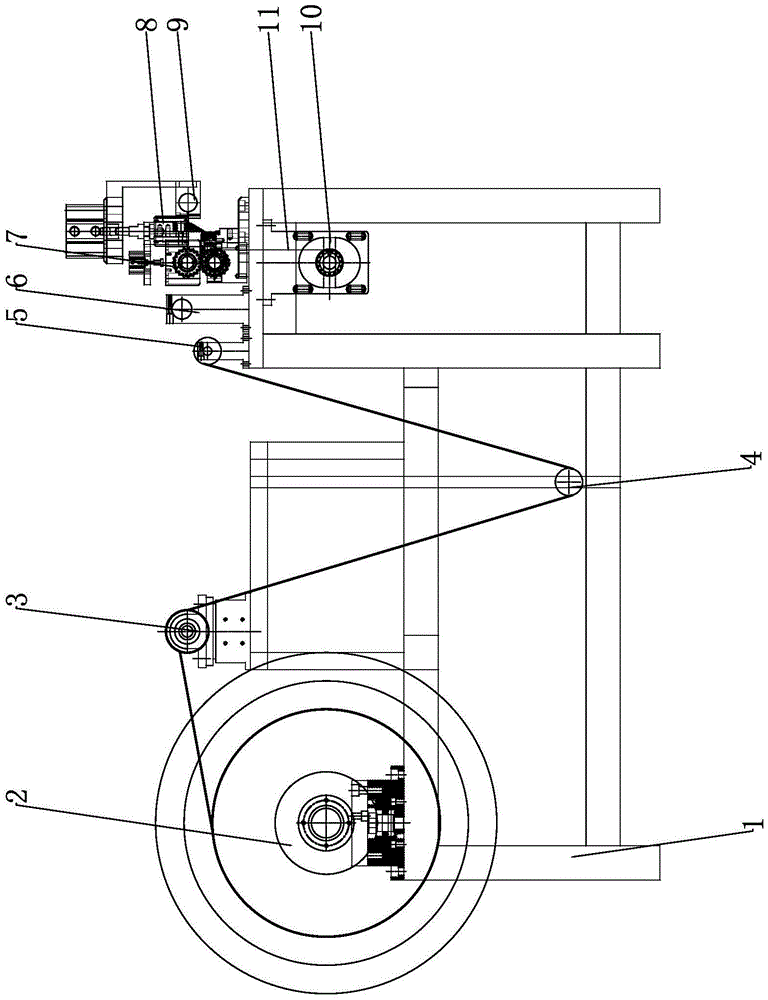

Automatic PI film cutting machine

InactiveCN105599025ASimple structureImprove work efficiency and qualityMetal working apparatusElectrostatic chargesGear driveStatic electricity

The invention relates to an automatic film cutting machine, in particular to an automatic PI film cutting machine, and belongs to the technical field of film cutting machines. The automatic PI film cutting machine comprises a main support, a feeding device, a tension detector, a buffer roller, a gear conveying device, an upper-lower cutter device and a gear driving device. The feeding device, the tension detector, the buffer roller, the gear conveying device and the upper-lower cutter device are arranged on the main support from left to right in sequence. The gear driving device is arranged at the lower end of the gear conveying device. The gear driving device is connected with the gear conveying device through a transmission chain and drives the gear conveying device. The automatic PI film cutting machine is simple, compact and reasonable in structure, the quality of PI film edge cutting work and working efficiency can be improved, and the production cost is reduced; a static electricity removing device can well eliminate static electricity in the unreeling process, and the film cutting quality is improved.

Owner:珠海市光环自动化科技有限公司

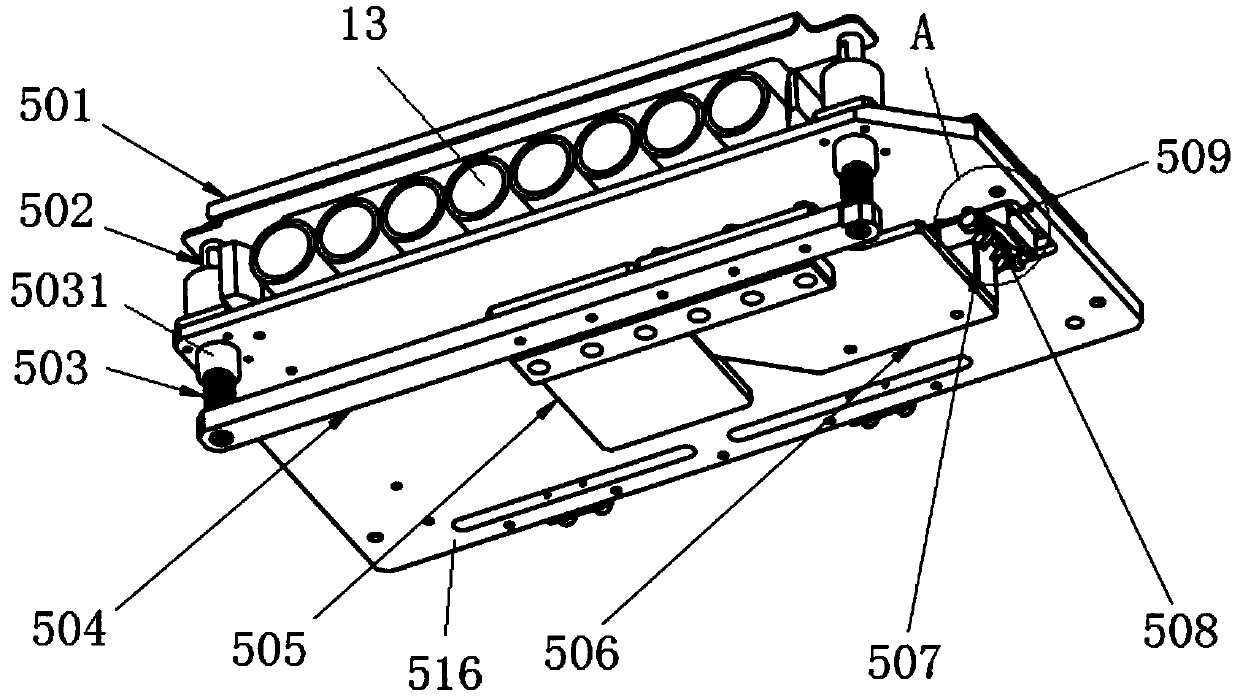

Vibration arrangement appearance detection carrier tape packaging device

PendingCN112623317AImprove work efficiency and qualityConducive to appearance quality inspectionWrapping material feeding apparatusPackaging automatic controlPhysicsEngineering

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Separation and comparison device for integrated circuit chip production

PendingCN113941516AAvoid low productivityImprove work efficiency and qualityCleaning using gasesSortingProcess engineeringIntegrated circuit

The invention relates to the field of circuit chip production, in particular to a separation and comparison device for integrated circuit chip production. The separation and comparison device comprises a conveyor belt, a cleaning mechanism comprises a fixed box, a ventilation net and a fan, the other side of a comparison mechanism is provided with a placement mechanism with a sensing function, and the other side of the conveyor belt is provided with a slidable grabbing mechanism. According to the separation and comparison device for integrated circuit chip production, through arrangement of a comparison plate and positioning pins, circuit chip distinguishing and separation do not depend on naked eye distinguishing manually, the situations that the working efficiency is low and the body health of workers is harmed are avoided, the working efficiency and quality are improved, through the arrangement of the cleaning mechanism, sundries in circuit chip holes can be blown off, the situation that the sundries in the holes affect the comparison and separation precision to affect the working efficiency is avoided, through the arrangement of a feeding mechanism and the grabbing mechanism, the circuit chips are taken and reset no longer through manual work, and the labor intensity of the workers is lowered.

Owner:成芯半导体(江苏)有限公司

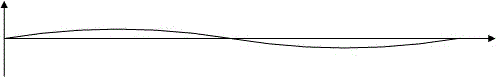

Cutter for marten processing

InactiveCN106521044ASimplify workImprove work efficiency and qualityLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusMartenMechanical engineering

The invention provides a cutter for marten processing and belongs to tools for garment manufacturing and processing. The cutter for marten processing comprises a disc-shaped blade and a rotary shaft penetrating through the center of the blade. A fork capable of moving horizontally is installed on the rotary shaft. The cutting portion of the blade is in the shape of a sine curve after being unfolded in the circumferential direction. The cycle T of the sine curve is larger than the amplitude value by over 20 times. The fork passes through the rotary shaft and protrudes forwards. A vent hole is formed in the front end of the fork, and air of the vent hole is supplied by an air pump. The blowing direction of the vent hole is in the plane where the blade is located, is in the range defined by rotating by 10-30 degrees clockwise from the downwards vertical direction , is in the plane where the vertical blade is located and points to the edge of the blade. According to the cutter for marten processing, curve cutting is conducted on marten, so that alignment work becomes easy; and meanwhile, the situation that furs are cut off is avoided to a great extent, and the cutting edge can be protected.

Owner:蠡县中圣皮业有限公司

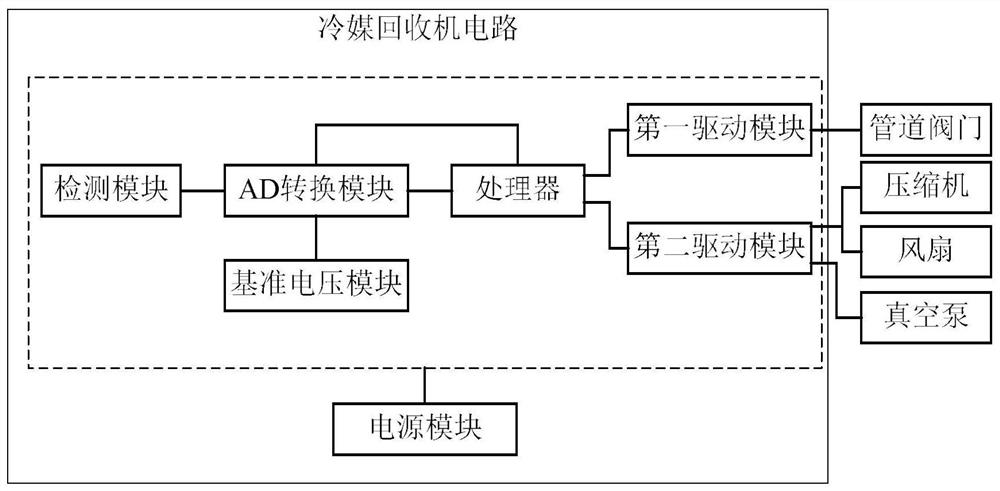

Refrigerant recoverer circuit

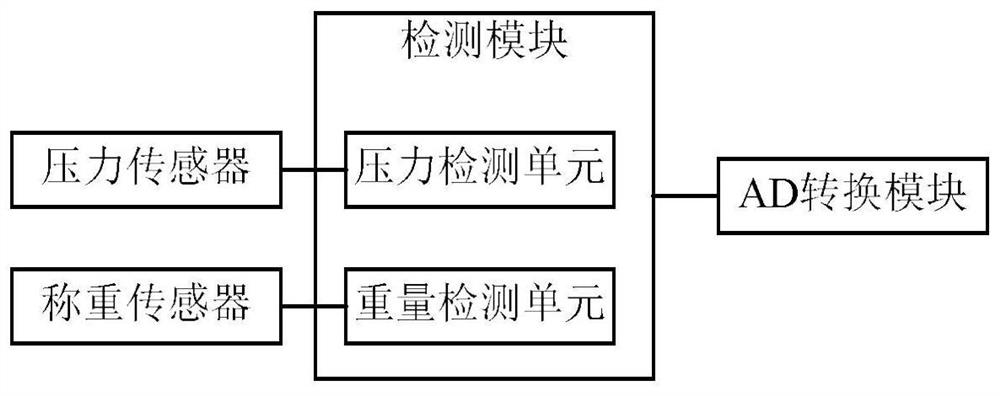

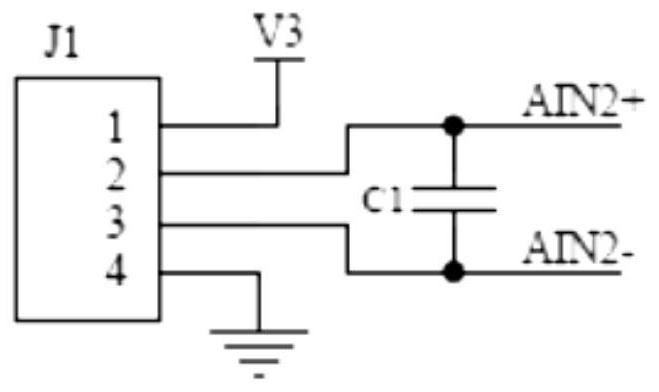

PendingCN112577223AAvoid human errorImprove work efficiency and qualityWeighing apparatus for materials with special property/formApparatus for force/torque/work measurementRefrigerantVacuum pumping

The invention provides a refrigerant recoverer circuit. The refrigerant recoverer circuit comprises a detection module, an AD conversion module, a reference voltage module, a processor, a first driving module and a second driving module, wherein the input end of the detection module is connected with an external sensor, and the output end of the detection module is connected with the input end ofthe AD conversion module; the input end of the AD conversion module is also connected with the output ends of the reference voltage module and the processor; the processor is connected with the inputends of the AD conversion module, the first driving module and the second driving module respectively; the output end of the first driving module is connected with the control ends of a plurality of pipeline valves; and the output end of the second driving module is connected with the power supply ends of a compressor and a vacuum pump. According to the refrigerant recoverer circuit, the state ofrecovered refrigerant is automatically obtained, and in combination with the state of the recovered refrigerant, various functions of vacuum pumping, refrigerant filling, refrigerant oil filling, airconditioner pipeline cleaning and the like can be realized, so that various use requirements of users are met, manual misoperation is avoided, and the working efficiency and quality are improved.

Owner:张家港市智恒电子有限公司

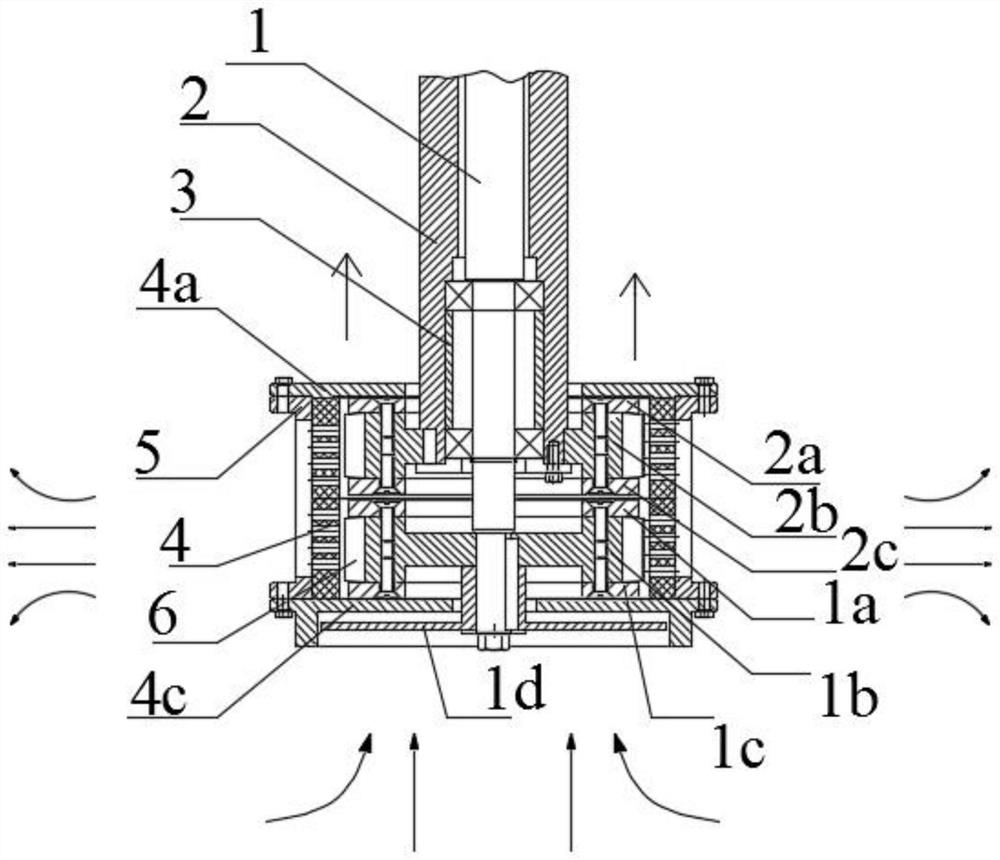

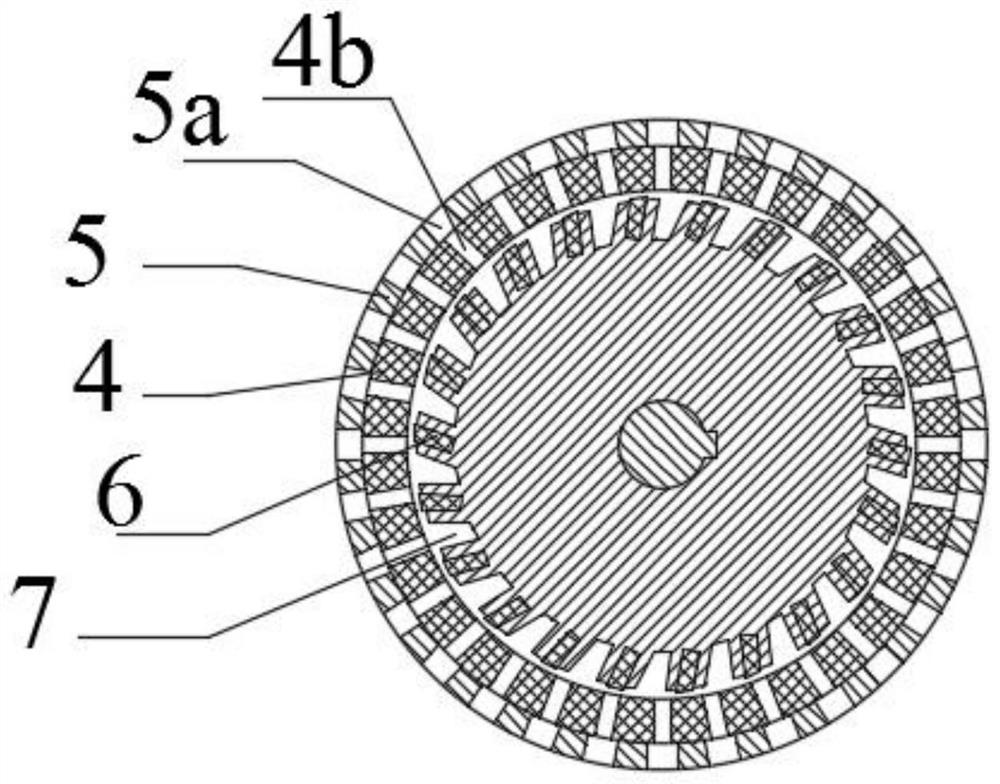

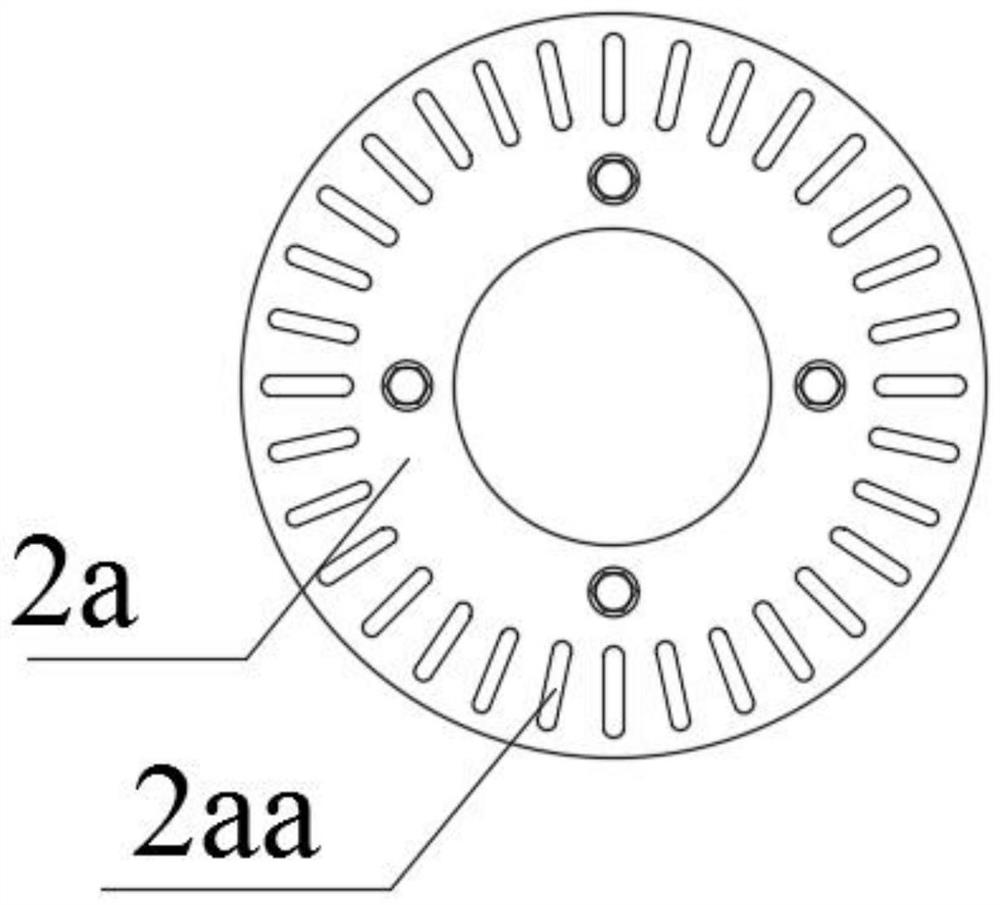

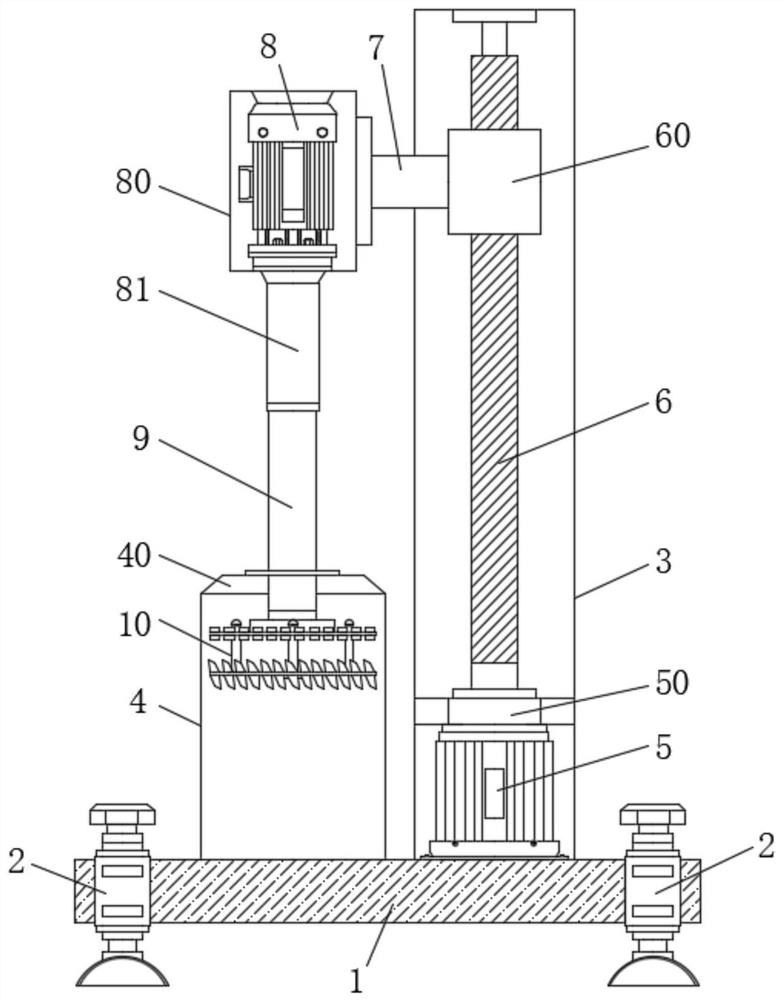

Gapless shearing ceramic crushing, dispersing, homogenizing and emulsifying device

PendingCN112973897AIncrease throughputImprove work efficiency and qualityGrain treatmentsPhysicsStator

The invention discloses a gapless shearing ceramic crushing, dispersing, homogenizing and emulsifying device. The device comprises a homogenizing shaft, a stator shell, centrifugal rotor blades, a stator ring and a connecting end plate, wherein the centrifugal rotor blades are a plurality of centrifugal rotor blades arranged on the circumferential surface of the homogenizing shaft along the circumferential direction of the homogenizing shaft; the stator ring is arranged on the circumferential inner wall of the stator shell; and a plurality of stator shearing holes which are matched with the centrifugal rotor blades and communicate with a discharge hole of the stator shell are formed in the inner circumferential wall of the stator ring. According to the device, a clockwise cutter head rotates clockwise at a high speed, an anticlockwise cutter head rotates anticlockwise, and the clockwise cutter head and the anticlockwise cutter head form a 'shearing opening' together with the stator shearing holes, so that materials are sheared and crushed, and comprehensive effects such as strong and reciprocating hydraulic shearing, friction, centrifugal extrusion, liquid flow collision and the like can be formed. According to the device, the treatment capacity of the materials is increased in the same working time, and the product quality and the working efficiency are remarkably improved.

Owner:南通市通州区三槐机械制造有限公司

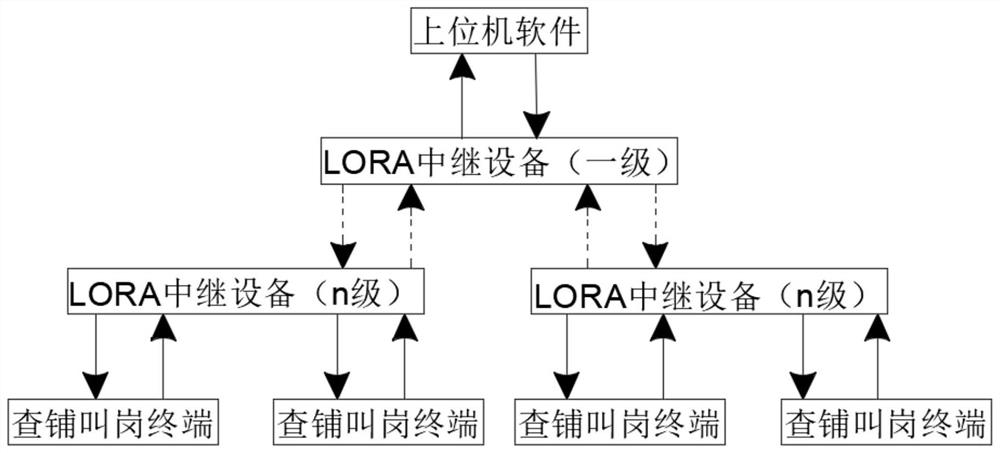

Intelligent checking and duty-calling system

PendingCN113436421AImprove work efficiency and qualityCost-effectiveChecking time patrolsTactile signalling systemsTrunkingEmbedded system

The invention discloses an intelligent checking and duty-calling system. The system comprises a control terminal provided with upper computer software, at least one stage of relay equipment and a plurality of checking and duty-calling terminals, and is characterized in that a plurality of stages of relays can be arranged according to actual conditions, so the number of stages of the LORA relay equipment is increased to enlarge the network transmission distance; the checking and duty-calling terminals receives a control command of the nth level Lora relay equipment and responds, the first-level LORA relay equipment receives a control instruction of upper computer software and transmits the response of the checking and duty-calling terminal back to the upper computer software, and the big data analysis technology, the artificial intelligence technology, the modern computer network technology and other technologies are utilized, digitization and automation of checking management of dormitory management personnel are achieved, defects of a traditional checking and post calling system can be overcome, working efficiency and quality of dormitory management are improved, the checking personnel can complete checking tasks in own offices, a checking system is implemented, and rest of room personnel is not disturbed.

Owner:济南志欣科技发展有限公司

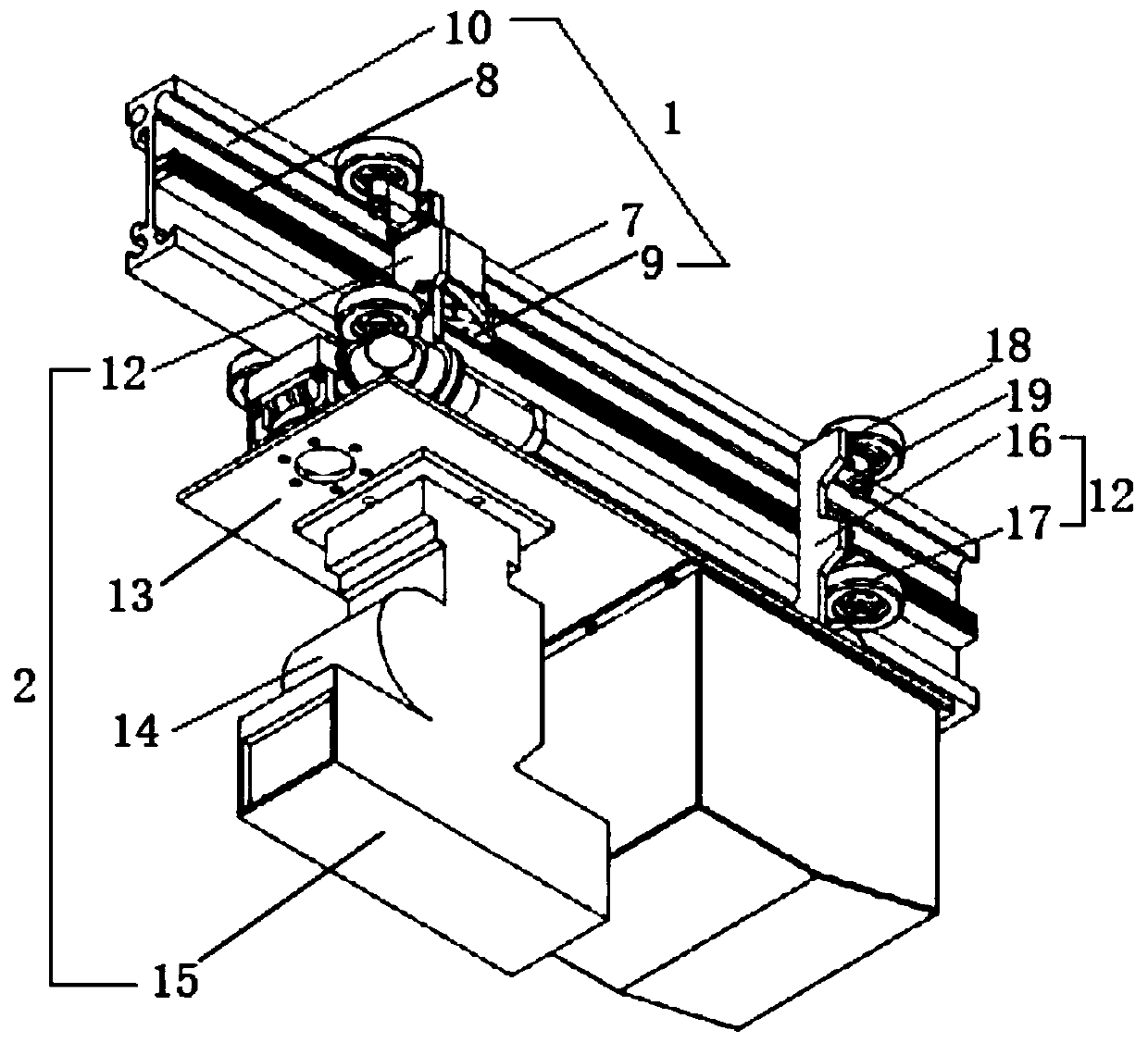

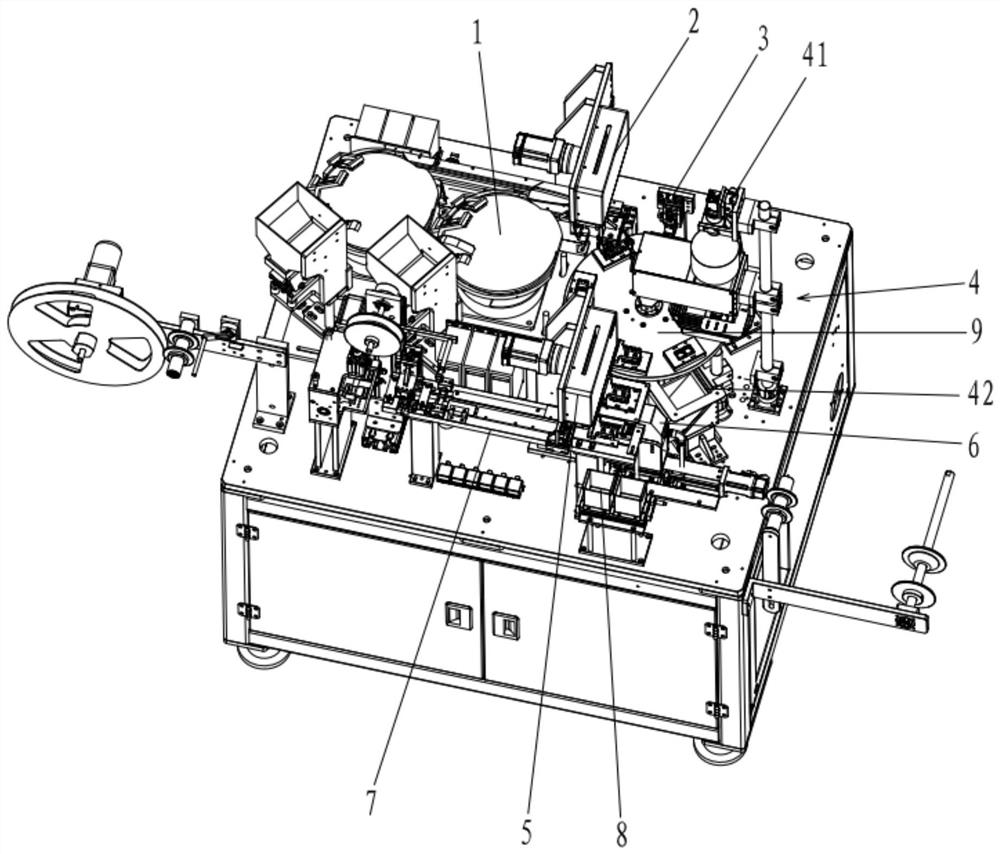

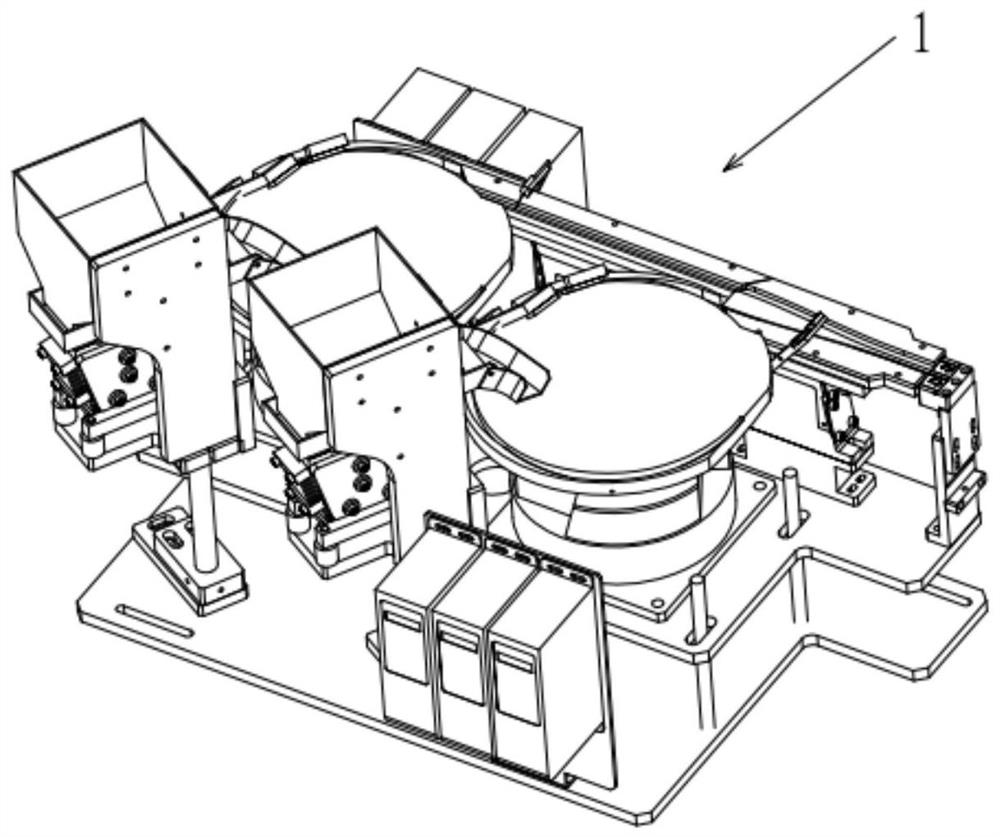

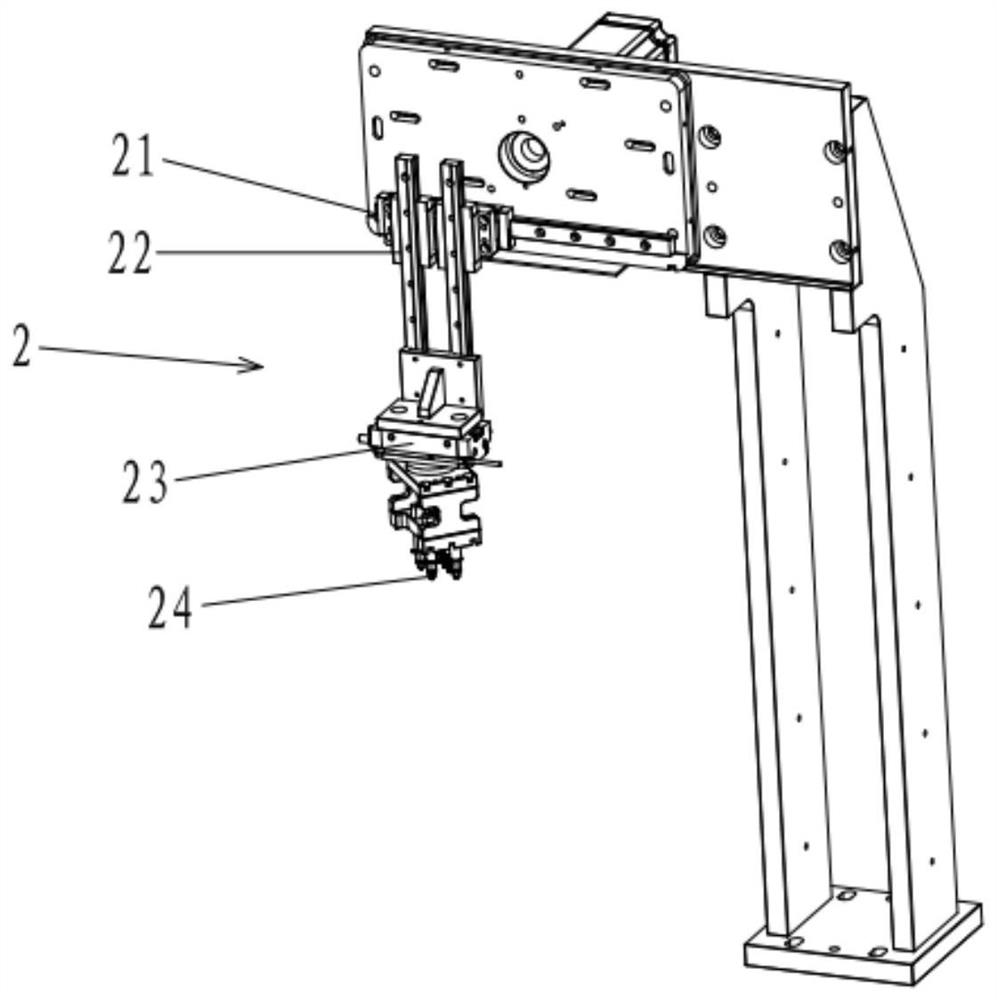

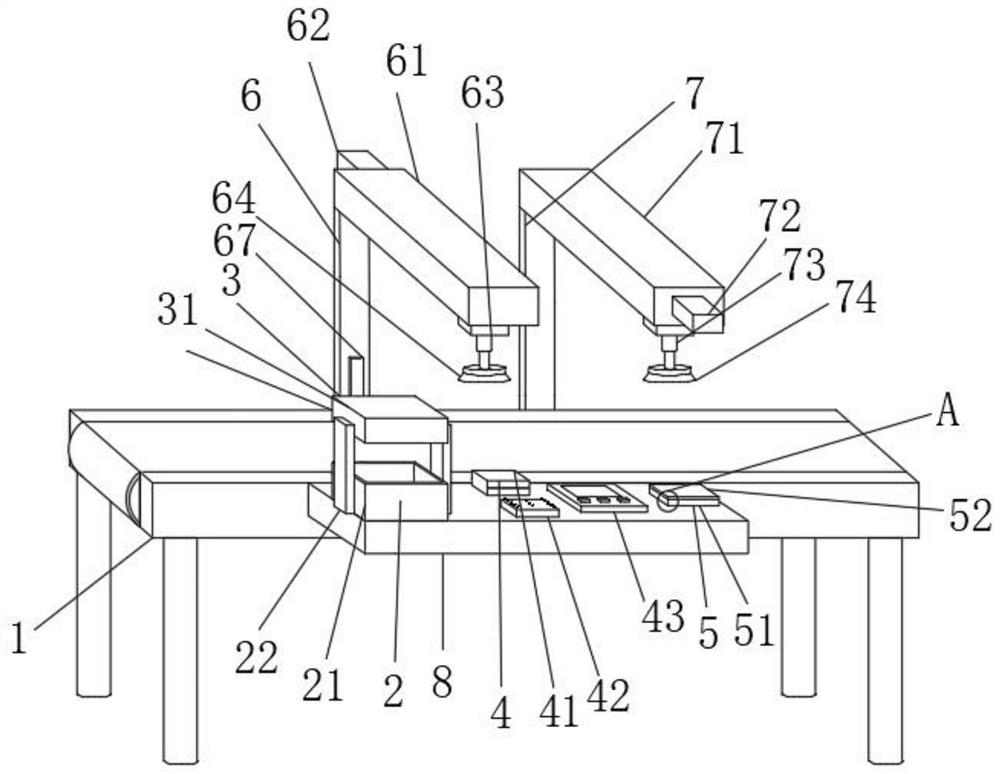

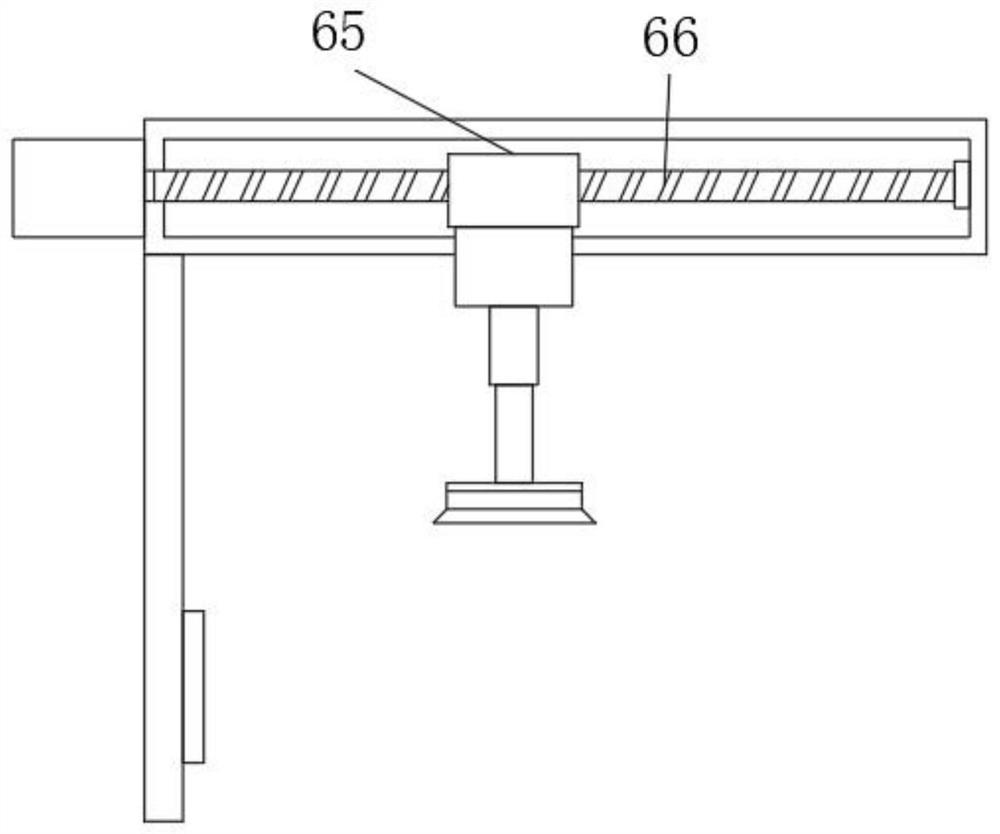

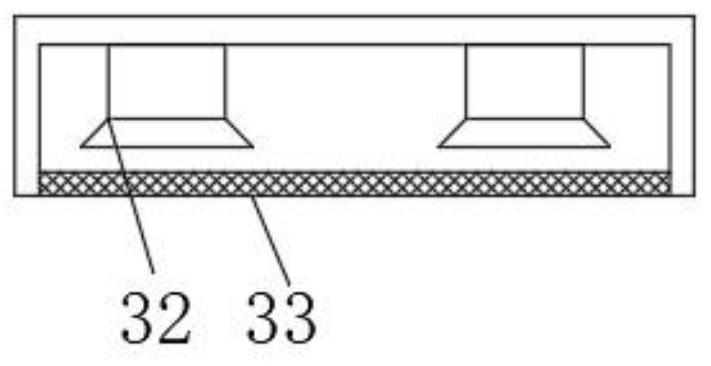

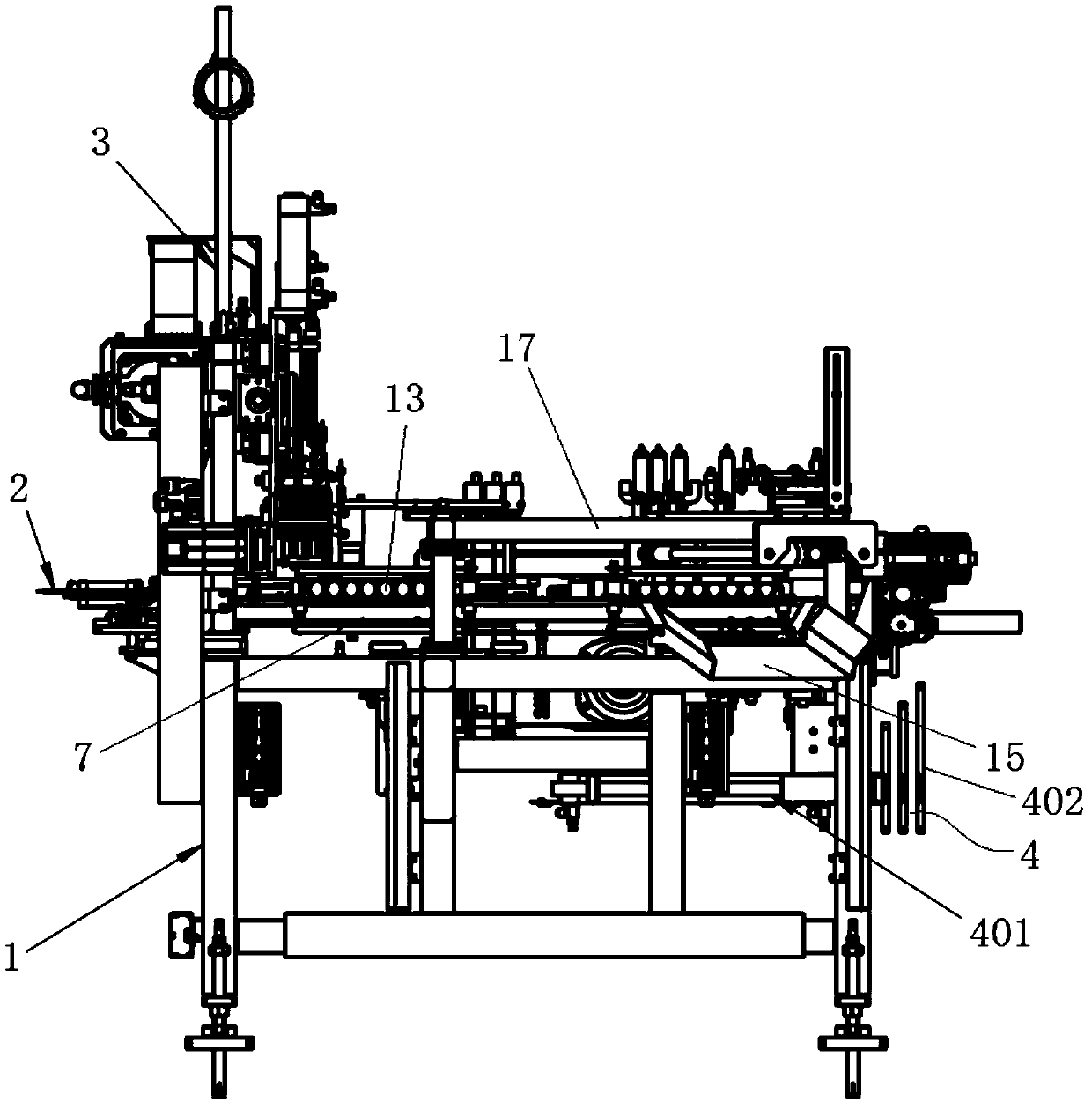

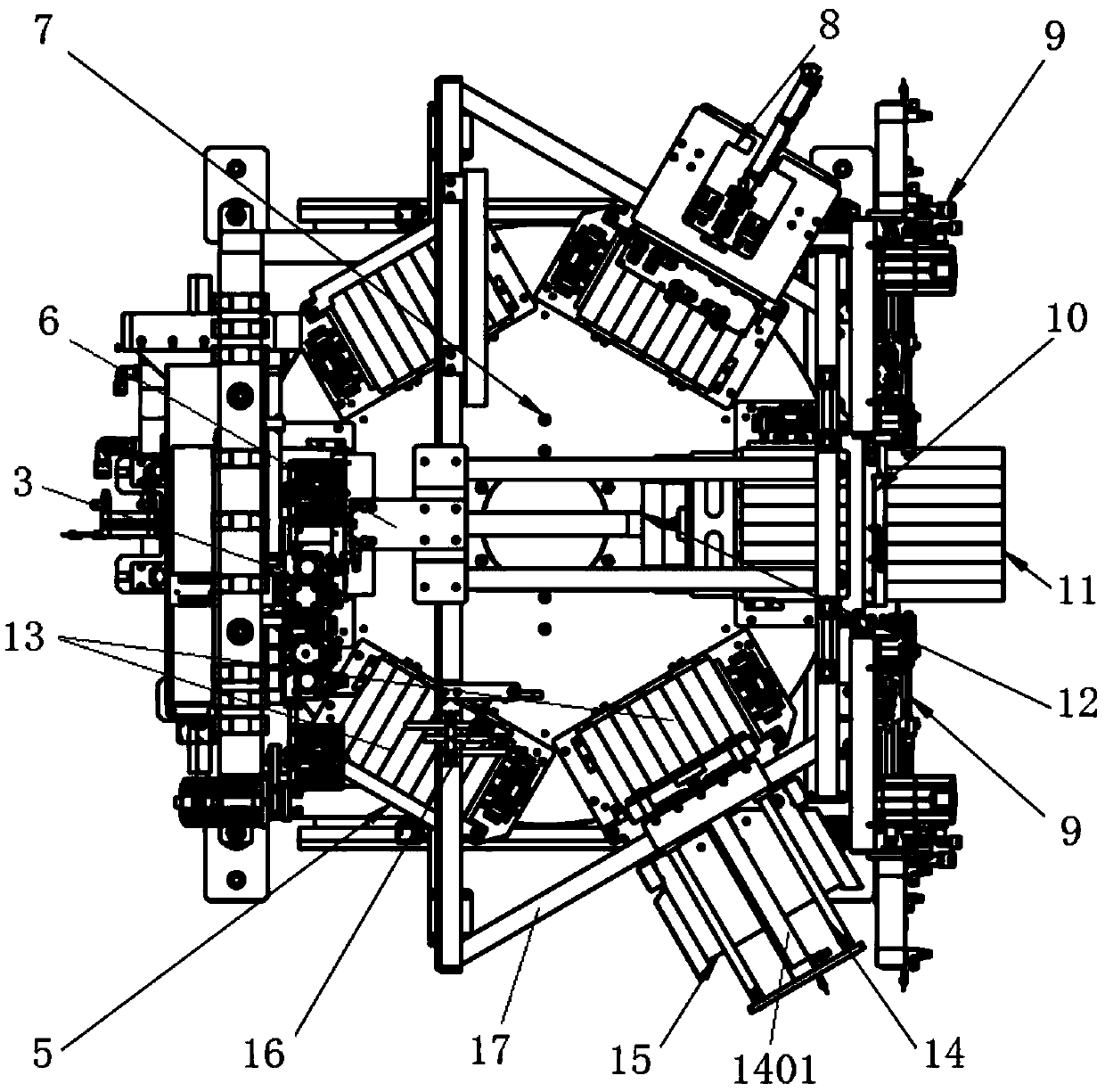

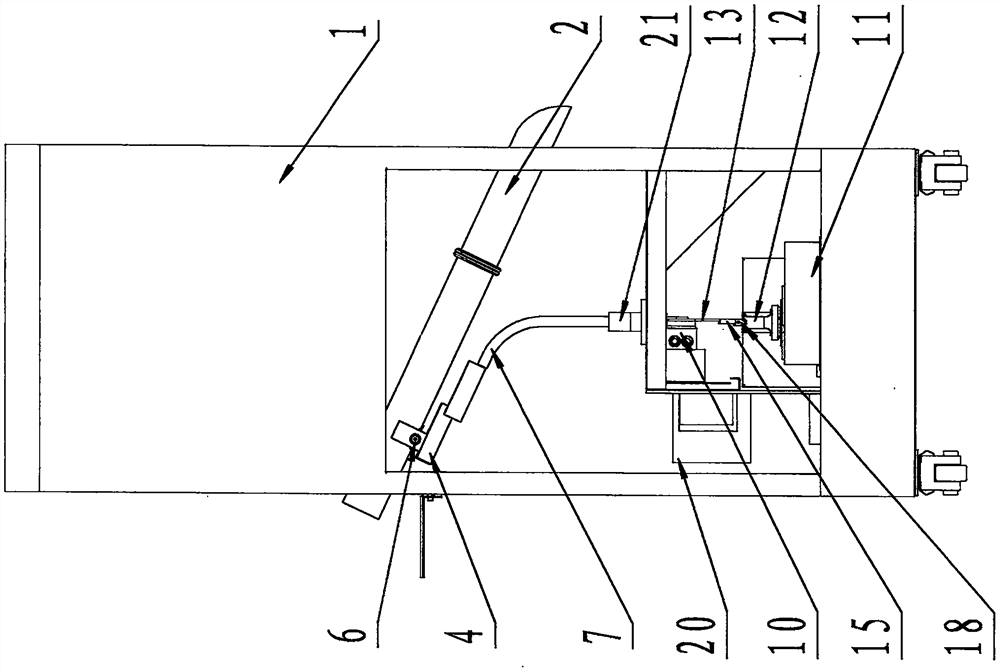

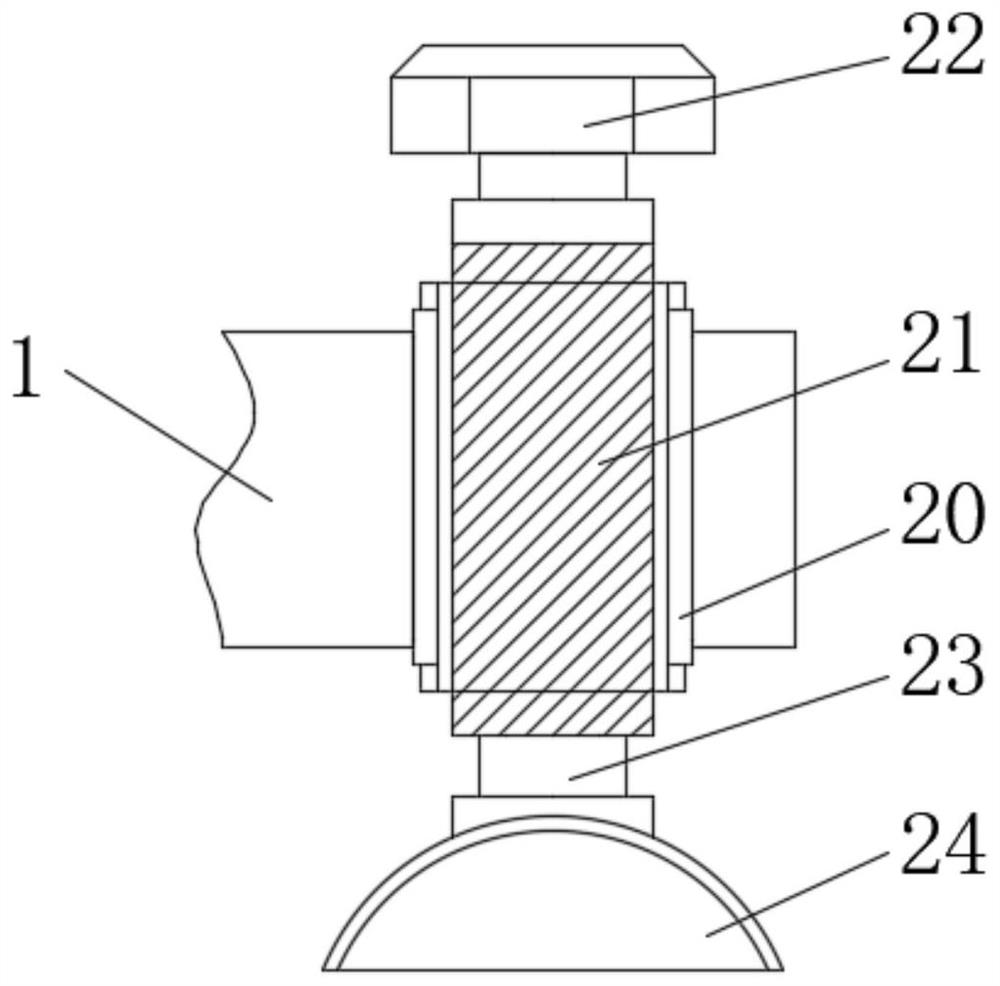

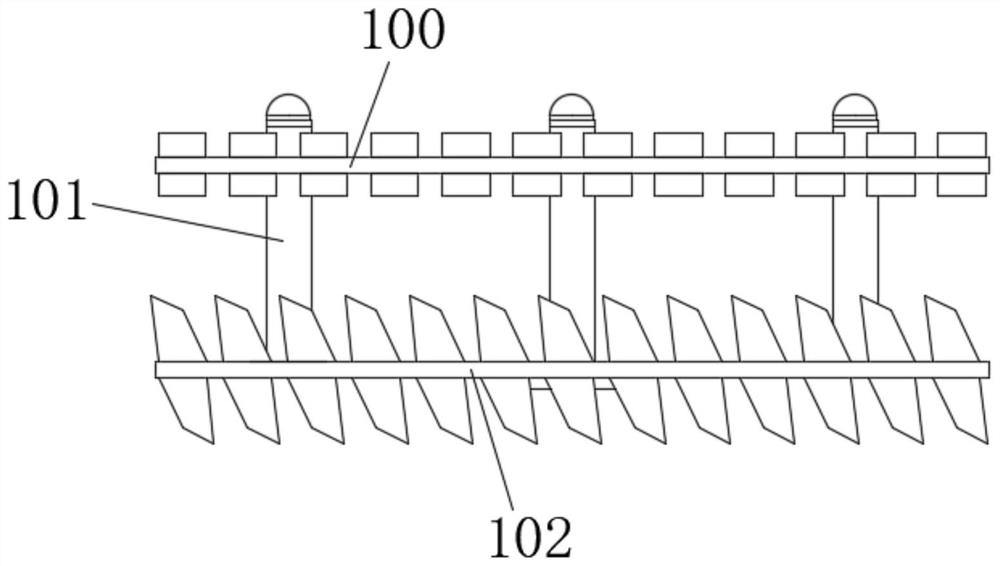

Rotating disc type multi-station connection lead inserting device

ActiveCN111121550AHigh degree of automationImprove work efficiency and qualityFireworksWorkbenchRotating disc

The invention relates to the technical field of firework production, in particular to a rotating disc type multi-station connection lead inserting device. The device comprises a workbench support andan indexing disc workbench, wherein the indexing disc workbench is rotatably arranged on the workbench support; a feeding station, a detecting station, a lead inserting station, a glue spraying station and a pushing-out station are sequentially arranged on the workbench support; a lead inserting mechanism is arranged on the lead inserting station, and the lead inserting mechanism comprises a leadinserting assembly, a lead guiding assembly and a cutter assembly; a puncturing needle and a lead punch are arranged on the lead inserting assembly; an outer barrel pushing-out mechanism, a side leadinserting mechanism, a lifting mechanism and a potted firework pushing-out mechanism are arranged at the pushing-out station; a lifting plate is arranged in the lifting mechanism; single-layer outer barrels are sequentially pushed out and stacked on the lifting plate through the outer barrel pushing-out mechanism to form a potted firework assembly; upper and lower adjacent outer barrels of the potted firework assembly are in lead inserting connection through the side lead inserting mechanism; and the potted firework assembly is pushed out through the potted firework pushing-out mechanism afterthe side lead inserting is finished. According to the device, the quality and the working efficiency of inserting a connection lead to potted firework are improved, and the production safety is ensured.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

On-line sampling, blanking, conveying and weighing device for capsules

PendingCN113483865ASave human resources and maintenance timeImprove work efficiency and qualityWeighing apparatus for materials with special property/formStructural engineeringMechanical engineering

The invention discloses an on-line capsule sampling, blanking, conveying and weighing device capable of being connected with a capsule filling machine, a blanking hole is arranged on a capsule conveying pipe and at a feeding position, a capsule slide way is arranged in a box body and below the blanking hole of the capsule conveying pipe, and a sampling emptying plate and an emptying power source are arranged between the capsule slide way and the blanking hole of the capsule conveying pipe; and the capsule slide way is downwards in butt joint with a hollow pipe, a material intercepting assembly is arranged at the lower end of the hollow pipe, a material suction side swing assembly is arranged in the box body and located on the side edge of the lower end of the hollow pipe, and an electronic scale is arranged in the box body and located below the material suction side swing assembly. The full process of sampling inspection discharging, conveying, material intercepting, single-particle sucking, weighing and discharging of the capsule finished products is completed in sequence, and online sampling inspection weighing of the capsule finished products is achieved. The capsule weighing device has the advantages of ensuring stability, reliability, unattended operation, automatic optimization control and the like of capsule weighing, improves the quality of medicines, and ensures that the public medicines are safer.

Owner:瑞安市华仕力科技有限公司

Textile assistant dispersing machine

InactiveCN112546922AGood emulsification and dispersionImprove work efficiency and qualityShaking/oscillating/vibrating mixersTransportation and packagingElectric machineryEngineering

The invention belongs to the technical field of dispersing machines, and discloses a textile assistant dispersing machine, which comprises a base, a stabilizing device is arranged on one side of the interior of the base in the vertical direction, a driving bin is arranged on one side of the upper portion of the base in the vertical direction, and a pedestal of the driving bin is fixedly connectedto the base, and a generating barrel is disposed above the other side of the upper part of the base. According to the textile assistant dispersing machine, a lifting mechanism and a rotating mechanismare arranged, and a second motor drives a stirring rod to rotate at a high speed, so that a dispersing disc can fully and completely stir textile assistants in the generating barrel; a first motor ina driving bin works to drive a rotating device to perform translational motion in the vertical direction, so that the dispersing disc can perform vertical large-range stirring work in the generatingbarrel, and the textile assistants can be uniformly and better emulsified and dispersed, and the working efficiency and quality of the dispersing machine are improved.

Owner:江门市美亚纺织材料有限公司

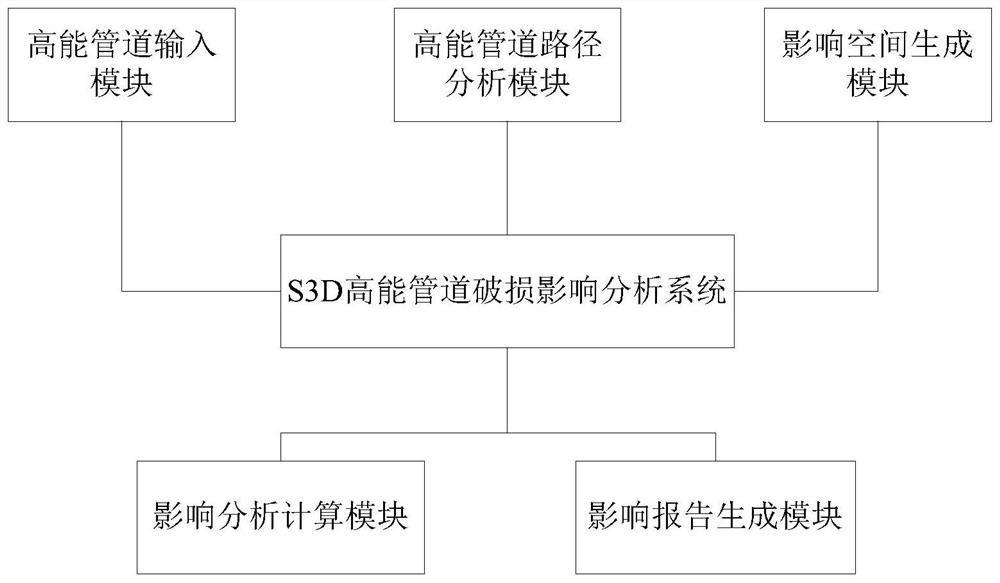

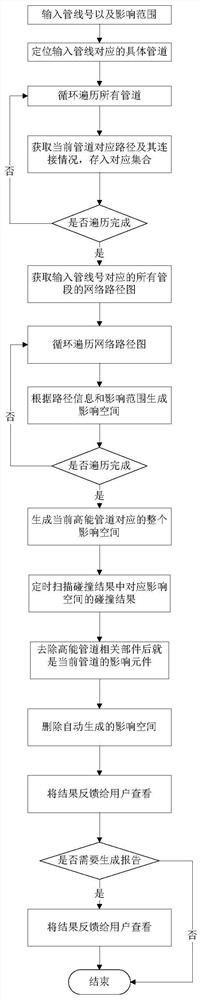

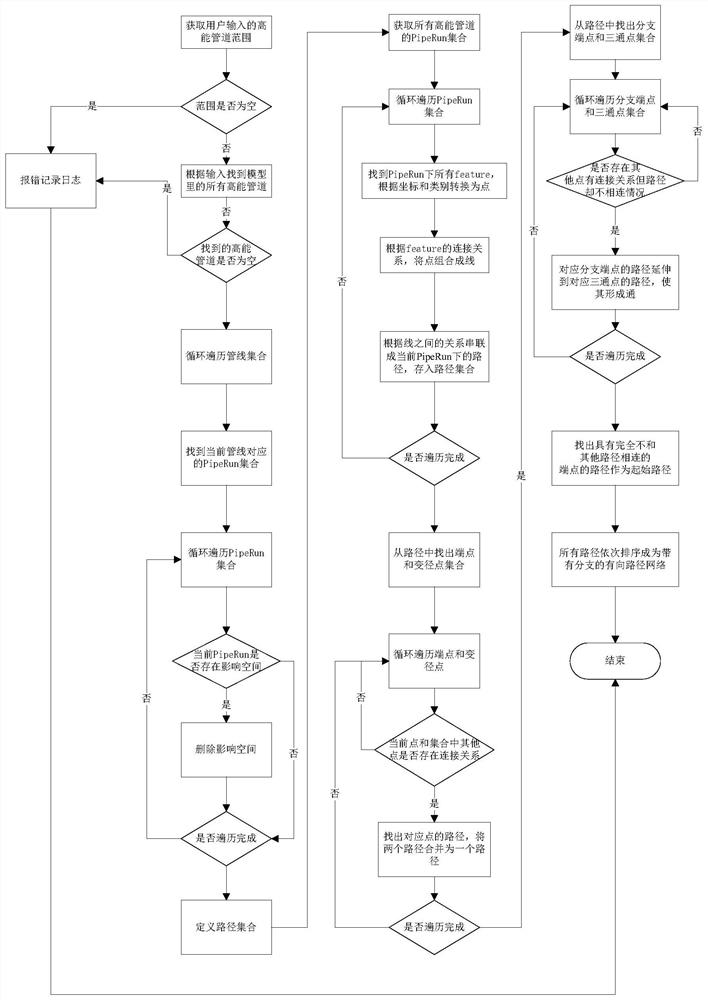

S3D high-energy pipeline damage influence analysis system and implementation method

PendingCN113946926AImprove work efficiency and qualityVersatileGeometric CADSpecial data processing applicationsProcess engineeringSystems engineering

The invention relates to the related field of high-energy pipeline damage influence analysis, in particular to an S3D high-energy pipeline damage influence analysis system and an implementation method. A high-energy pipeline input module, a high-energy pipeline path analysis module, an influence space generation module, an influence analysis module and a report generation module are compiled, all related elements which can be influenced once the high-energy pipeline is broken can be automatically calculated according to the high-energy pipeline set by a user and the influence range of the high-energy pipeline, and a corresponding influence list can be automatically generated; the process that an analyst manually creates a high-energy pipeline influence space and manually analyzes the influence of the high-energy pipeline is omitted, the working efficiency is greatly improved, meanwhile, interference of human factors is avoided through the automatic calculation process, and the analysis result is more accurate.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

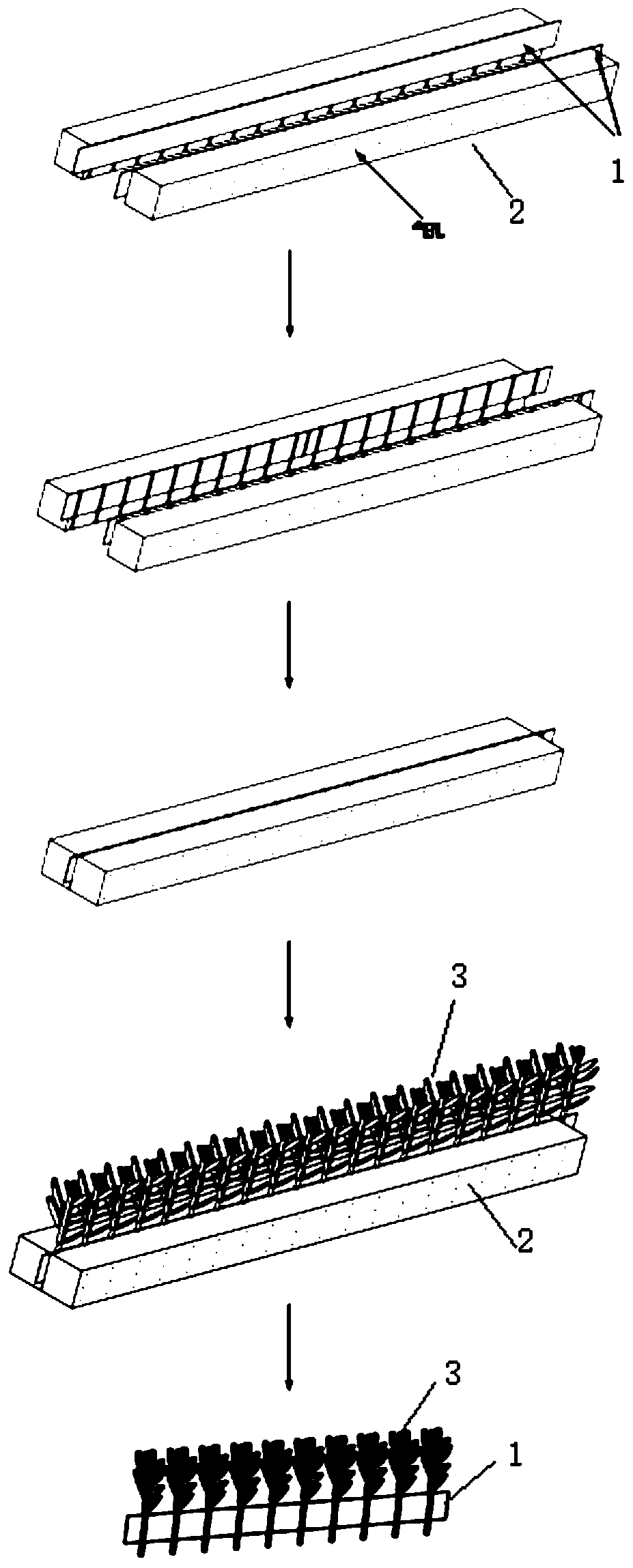

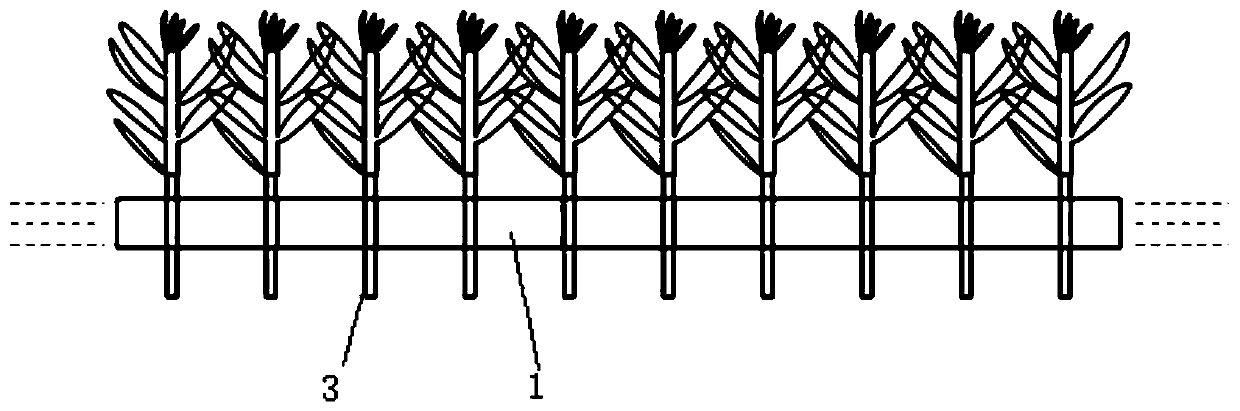

Seedling growing belt and seedling growing method for stevia rebaudiana

ActiveCN111226619AImprove work efficiency and qualityImprove quality and efficiencyGrowth substratesCulture mediaTransplantingEnvironmental geology

The invention provides a seedling growing belt and a seedling growing method for stevia rebaudiana. A paper strip is soaked in a prepared vegetable gum solution, taken out and aired to 30% humidity, so that the seedling growing belt is obtained. The seedling growing method comprises the steps of shearing cutting slips from stock plants which grow robustly; placing taken-out seedlings between the two seedling growing belts, and adjusting the spacing between the seedlings according to the seedling growing density requirement; and integrally cutting the seedling growing belts and the seedlings ina seedling growing tray paved with soil in rows, watering enough water, and performing seedling growing management in the later period. According to the seedling growing method, seedling separation and seedling arrangement in the seedling growing link are completed outside the seedling growing tray, the seedling growing quality and working efficiency of the seedling growing tray can be greatly improved, and meanwhile, conditions are created for mechanical transplanting.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Anti-excessive squeezing express box compression device with higher automation degree

InactiveCN111959018AHigh degree of automationImprove work efficiency and qualityPressesElectric machineryStructural engineering

The invention relates to the technical field of electronic commerce, and discloses an anti-excessive squeezing express box compression device with higher automation degree. The express box compressiondevice comprises a motor, the output end of the motor is fixedly connected with a worm, and the right end of the worm is fixedly connected with a first rotating rod; the right end of the first rotating rod is provided with a first semicircular bevel gear and a second semicircular bevel gear, a first bevel gear is arranged below the first semicircular bevel gear and the second semicircular bevel gear, and a second rotating rod is fixedly connected to the lower portion of the first bevel gear; and a second bevel gear is fixedly connected to the lower end of the second rotating rod, and a thirdbevel gear is connected to the lower portion of the second bevel gear in a meshed manner. According to the anti-excessive squeezing express box compression device with the higher automation degree, anobject bearing plate and a box pressing device are driven by the motor to do intermittent reciprocating motion, and high-stiffness-coefficient springs are arranged in the box pressing device, so thatthe effects of obtaining the higher automation degree, preventing excessive compressing and improving the working efficiency and quality are achieved.

Owner:浙江格锐特包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com