Embedded type system-based control device for horizontal directional drill

An embedded system and horizontal directional drilling technology, applied in directional drilling, drilling automatic control system, drilling equipment, etc., can solve the problems of difficult reliability and high cost, solve communication problems, reduce operation difficulty, and facilitate input and the effect of viewing related information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

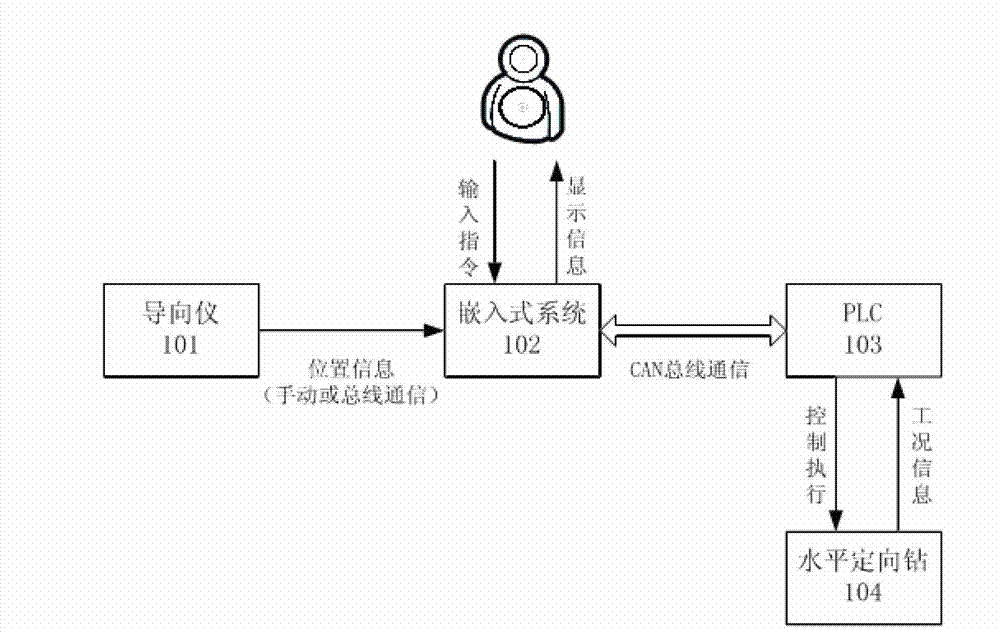

[0032] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0033] Such as figure 1 Shown: the horizontal directional drilling control device based on the embedded system, including the guide instrument 101, the embedded system 102 and the programmable logic controller (PLC) 103, the guide instrument 101 is used to obtain the current drill bit position information, and the drill bit position information Feedback to the embedded system 102; considering the diversity of the guide instrument 101 products and the closedness of the internal protocol, in a specific embodiment, if the guide instrument 101 cannot provide any interface, then the manual input method is adopted, that is, the operator reads the Get the current dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com