Patents

Literature

178results about How to "Good emulsification and dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whipped cream powder, preparation method and application

ActiveCN103039631AHigh foaming rateImprove plasticityEdible oils/fats production/working-upSodium CaseinateAnticaking agent

The invention relates to a preparation method of whipped cream powder. The method comprises the following steps that (1) vegetable fat and an emulsifying agent are mixed uniformly to form mixed liquid 5; white granulated sugar, sodium caseinate, whey protein and milk powder are mixed with water to form mixed liquid 1; the mixed liquid 1 is mixed with glucose syrup to form mixed liquid 3; a water retention stabilizer and a thickener are mixed with the water to form mixed liquid 2; the mixed liquid 2 is mixed with the mixed liquid 3 to form mixed liquid 4; the mixed liquid 5 is mixed with the mixed liquid 4 to form oil-water mixed pulp; the oil-water mixed pulp is stirred, sheared and emulsified to form uniform light-milk yellow pulp; (2) the pulps obtained in Step (1) are homogenized to form homogenized pulp; and (3) the homogenized pulp is pasteurized and subjected to spray drying; an anticaking agent is added to powder obtained through the spray drying, and mixed uniformly to form the whipped cream powder. The whipped cream powder can serve as a principal raw material of preparation of decorative cakes, mousse cakes and puffs.

Owner:无锡超科食品有限公司

Synthetic method for preparing colorless transparent alkyl polyglucoside

InactiveCN101696226AQuick responseGood emulsification and dispersionSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsGlycosideGlucose polymers

The invention relates to a synthetic method for preparing colorless transparent alkyl polyglucoside, which comprises the following steps: adding glucosum anhydricum or glucose containing one crystal water and aliphatic alcohol with 8 to 20 carbon atoms into a reaction kettle in the weight ratio of 1:2.8-6.5; adding a composite catalyst containing dodecyl benzene sulfonic acid under the agitation of an emulsifying agitator; after undergoing a reaction for 4 to 8 hours at a temperature of between 80 and 120 DEG C under the vacuum condition of between -0.093 and -0.098 MPa, reducing the temperature to between 70 and 80 DEG C; adding neutralizer alkaline hydroxide, adjusting the pH value between 6 and 8 to obtain a flaxen mixture of alkyl polyglucoside and the aliphatic alcohol; and performing dealcoholization and blanching on the mixture to obtain a product of the colorless transparent alkyl polyglucoside. The method has a simple process and convenient operations. The process of the method not only can use the glucosum anhydricum, but also can use the glucose containing one crystal water, has a low cost and good quality; and the method adopts the composite catalyst, has a mild temperature, smooth water yielding and no phenomenon of foam overflow.

Owner:石家庄金莫尔化学品有限公司

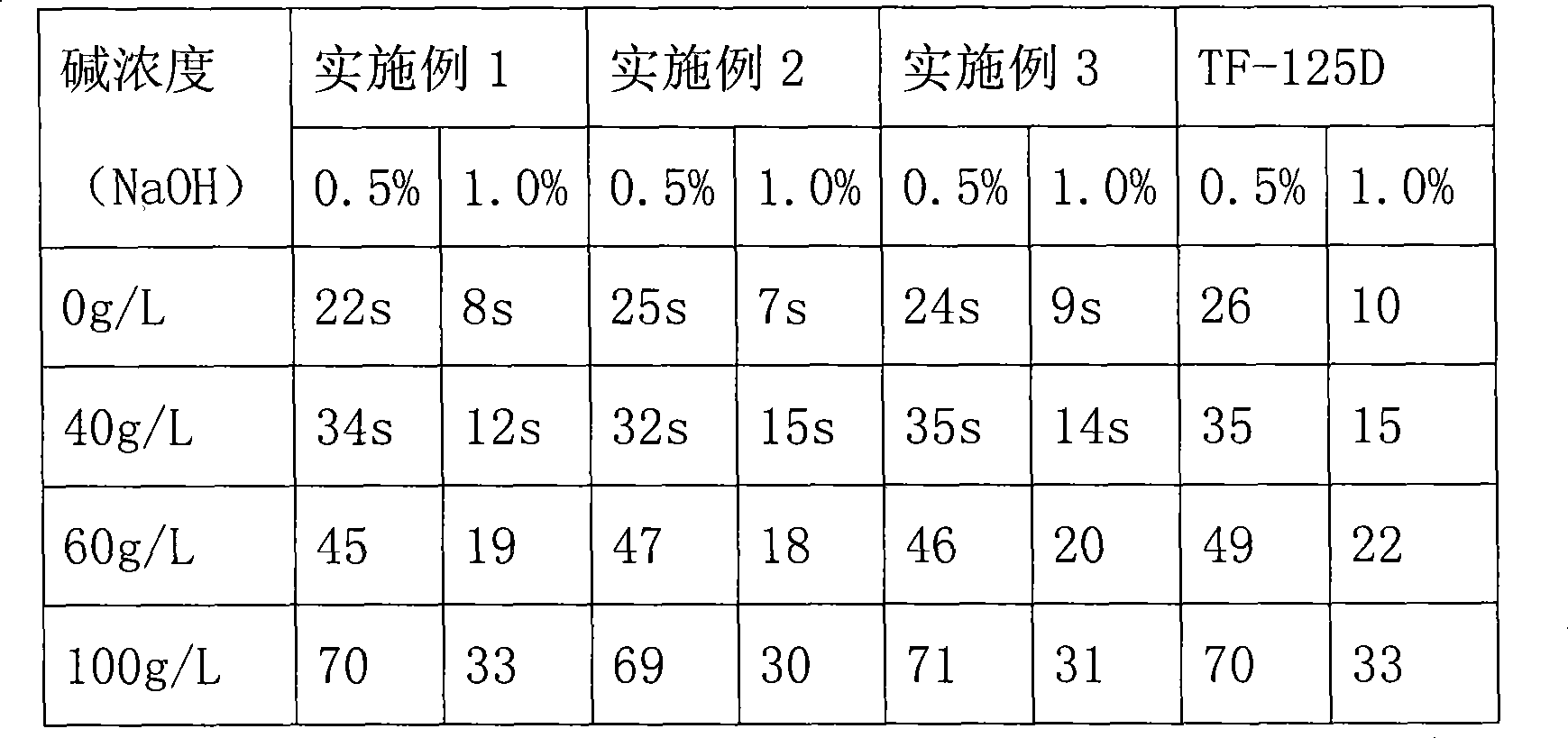

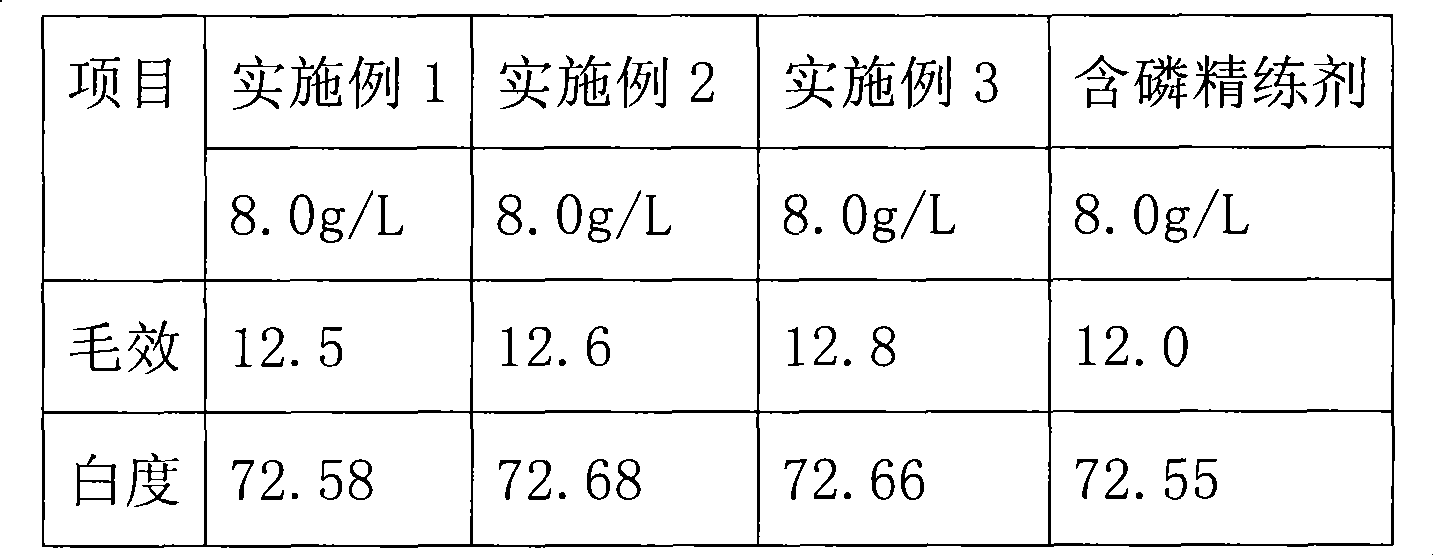

Non-phosphate scouring agent and preparation thereof

InactiveCN101498101AGood alkali resistanceGood emulsification and dispersionFibre treatmentEutrophicationEther

The invention discloses a scouring agent for fabric pretreatment and a preparation method thereof. Most of the existing products contain phosphate or other phosphorus substances which directly causes phosphorus environment pollution and water body eutrophication. The preparation method comprises the following steps: putting isomerous alcohol ether carboxylate, alkyl glucoside, isomerous polyoxyethylene ether and water into a reaction kettle according to a formulation proportion, stirring and mixing the mixture for 20 to 40 minutes within 40 to 50 DEG C at normal pressure, and preparing the non-phosphate scouring agent. The scouring agent does not contain phosphorus elements or APEO and has excellent alkali resistance, excellent alkali penetrability and excellent emulsifying dispersivity, therefore, the non-phosphate scouring agent has high efficiency and protects the environment.

Owner:传化智联股份有限公司

Summer using type automobile windscreen cleaning agent

InactiveCN101041791AWith hydrophobic and dust-repelling effectImprove permeabilityNon-ionic surface-active compoundsOrganic detergent compounding agentsAlcoholEther

The invention discloses a summer type windscreen cleaning agent, which is characterized by the following: allocating fatty alcohol polyoxyethylene ether, polyether, inhibitor, ethylene glycol monobutyl ether, alcohol and water; producing the cleaning agent. This invention possesses good penetrability, emulsibility and dewatering and lean dust behavior, which can drop the tensile force of each phase interface.

Owner:BEIJING JIAOTONG UNIV

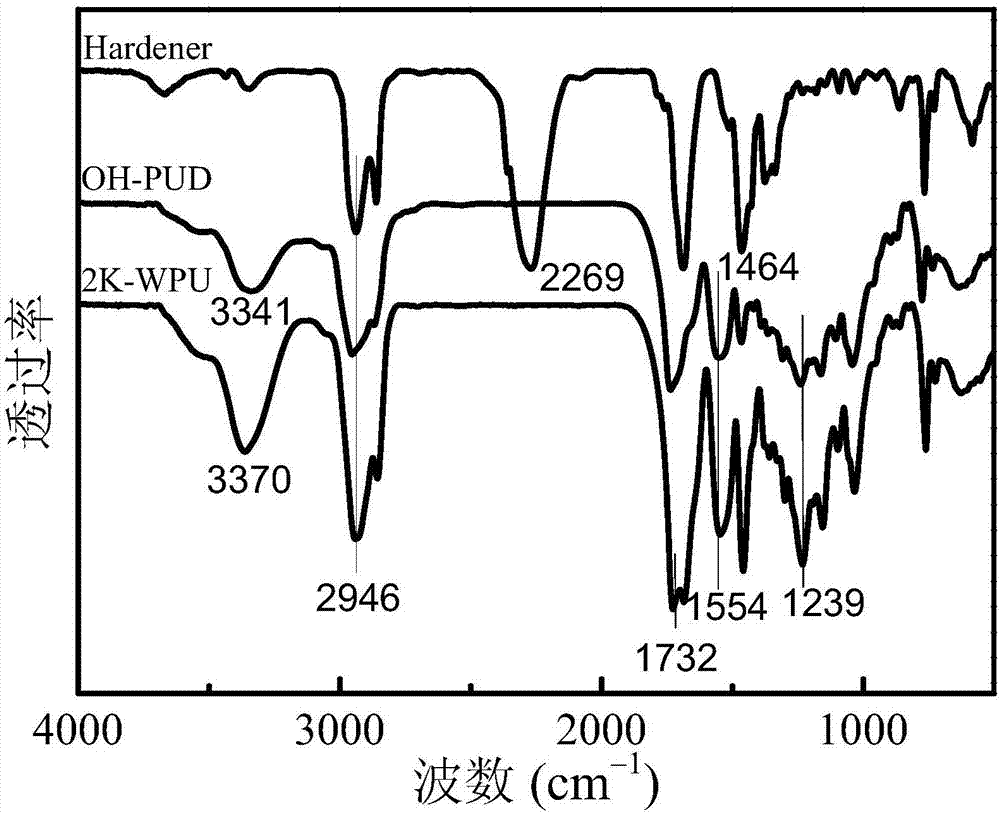

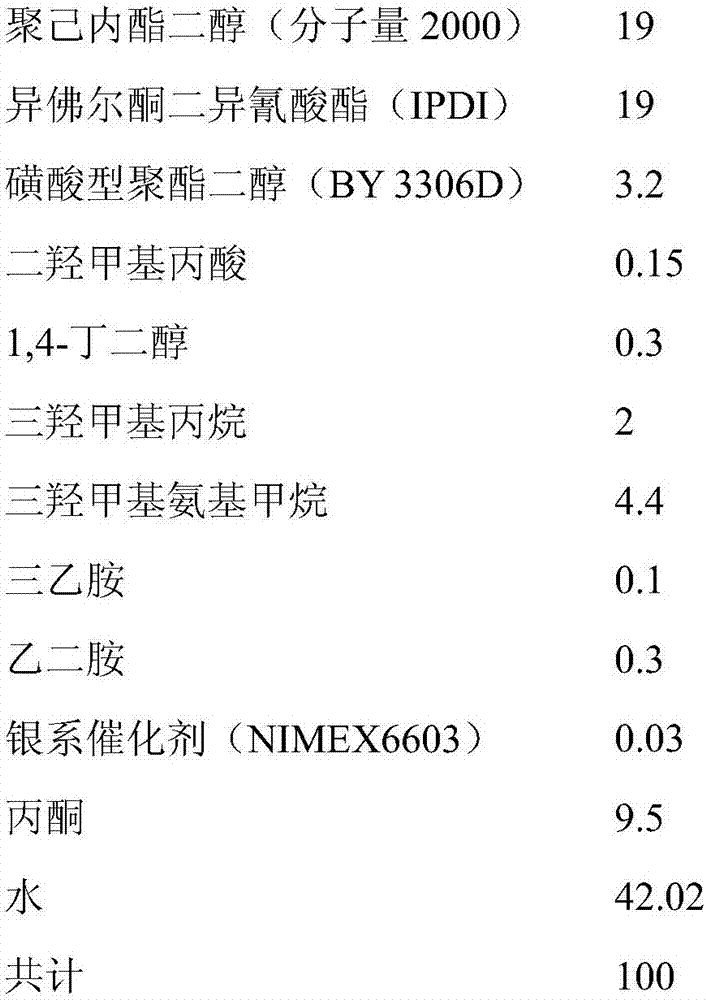

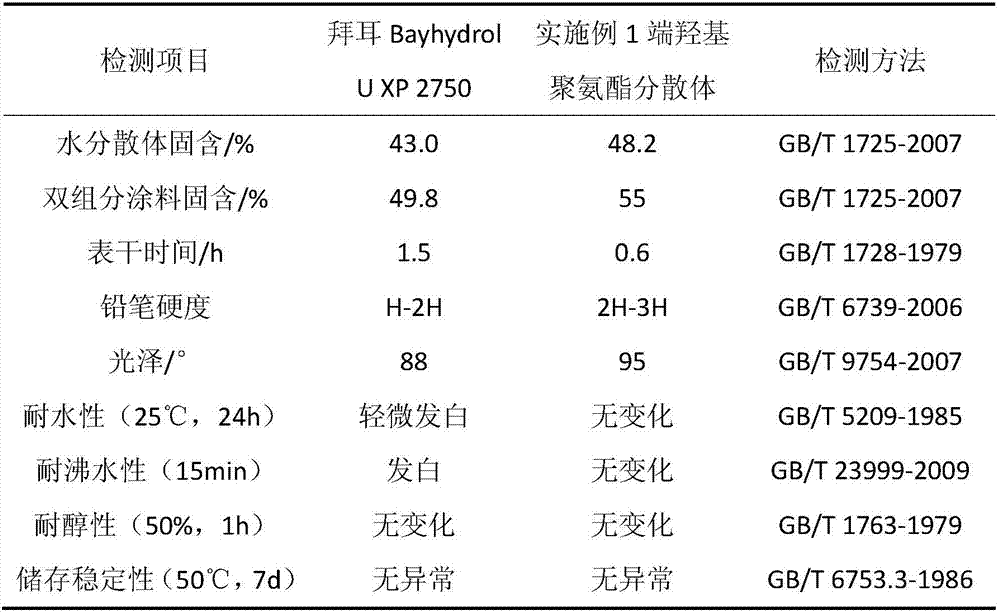

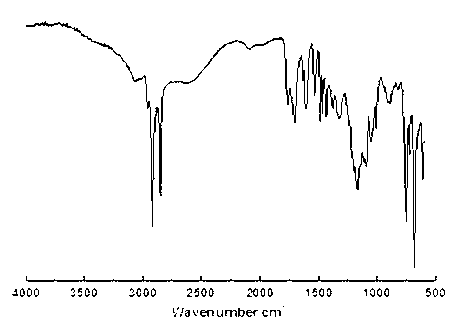

High-functionality hydroxyl-terminated polyurethane aqueous dispersion as well as preparation method and application thereof

InactiveCN106866923AIncreased average hydroxyl functionalityIncrease crosslink densityPolyurea/polyurethane coatingsEthylenediamineNitrogen gas

The invention discloses a high-functionality hydroxyl-terminated polyurethane aqueous dispersion as well as a preparation method and application thereof. The preparation method comprises the following steps: adding aliphatic diisocyanate, polyvalent alcohol, a hydrophilic chain-extending agent and a catalyst into a reaction kettle; carrying out temperature rise reaction under the protection of nitrogen gas and cooling when the NCO percent of a system reaches a theoretical value; dropwise adding an acetone solution of a dihydric alcohol chain-extending agent and a crosslinking agent, continuously reacting and diluting with acetone when the NCO percent of the system reaches the theoretical value; cooling, and adding triethylamine for neutralizing; adding water for dispersing, and adding alcamines compounds for terminating; finally, carrying out post chain extending by using ethidene diamine to obtain the hydroxyl-terminated polyurethane aqueous dispersion. According to the high-functionality hydroxyl-terminated polyurethane aqueous dispersion disclosed by the invention, an alcamines terminating agent with polyhydroxy functionality is adopted, and a polyhydroxy functional group is introduced on a polyurethane chain segment by a terminating reaction of an amine group and an NCO group; the obtained aqueous dispersion has the advantages of high solid content, small particle size and stable storage; a two-component waterborne polyurethane coating prepared by the high-functionality hydroxyl-terminated polyurethane terminating dispersion has the characteristics of high drying speed of the coating, excellent medium resistance and environment friendliness of a product.

Owner:SOUTH CHINA UNIV OF TECH

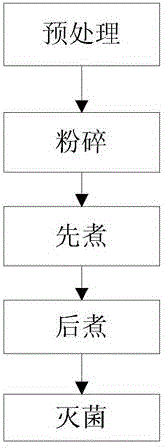

Preparation method of nano pearl proteins

InactiveCN103804468AUniform particlesKeep naturalNanomedicinePeptide preparation methodsCrystallographyHuman body

The invention relates to a preparation method of nano pearl proteins. The preparation method comprises the following steps: crushing pearls into pearl micropowder with the average grain size of 1-4 microns, carrying out acidolysis, filtering, washing the filter residues by purified water to obtain coarse pearl proteins, adding a dispersant into the coarse pearl proteins to grind, and carrying out ultrasonic concussion in the period; and concentrating the grinded liquid by a membrane, and heating, sterilizing and storing to obtain the nano pearl proteins. The preparation method provided by the invention is simple in process, organically combines the nano grinding technology with the emulsifying and dispersing technology, and further enhances the emulsifying and dispersing effect by means of ultrasonic waves, so that the pearl protein particles effectively reach nanoscale. The pure nature and integrity of the pearl protein component can be maintained by pure physical processing, and the nano pearl proteins are uniform in particle and are easily assimilated by human body and further by skins, so that the nano pearl proteins are suitable for being used as an additive of medicines, nutrients and skin care products.

Owner:HAINAN JINGRUN PEARL BIOTECH

Low-temperature deoiling scouring agent and preparation method thereof

InactiveCN105002022AGood degreasing effectGood emulsification and dispersionSurface-active non-soap compounds and soap mixture detergentsAlcoholSolvent

The invention discloses a low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent comprises, by weight friction, 10-20% of fatty alcohol-polyoxyethylene ether (EO9), 10-20% of fatty amine alcohol-polyoxyethylene ether (EO15), 5-10% of Isomeric ten alcohol-polyoxyethylene ether (EO5), 5-15% of secondary alcohol-polyoxyethylene ether (EO9), 3-6% of solubilizer, and the allowance is deionized water. The invention further discloses a preparation method for the low-temperature deoiling scouring agent. The low-temperature deoiling scouring agent is applied to the pretreatment processes of refining, deoiling, detergent washing and the like, the deoiling problem of fabric (especially the fabric containing spandex) in the process of pretreatment is solved, and oil stain and impurities in the fabric are guaranteed to be removed effectively. The functions of dispersing, emulsifying and wetting are achieved, the permeability is good, the form is little, and detergency is strong.

Owner:BONUS FUJIAN TEXTILE IND CO LTD

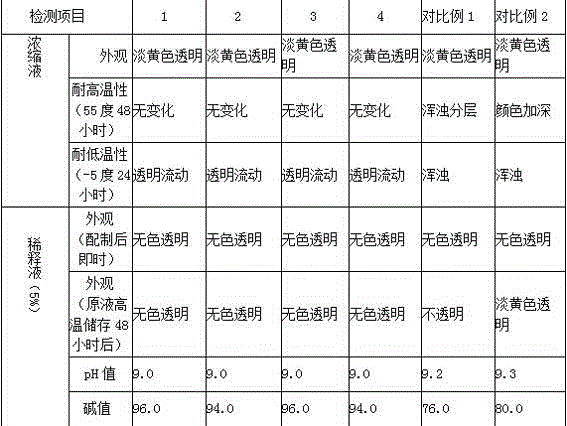

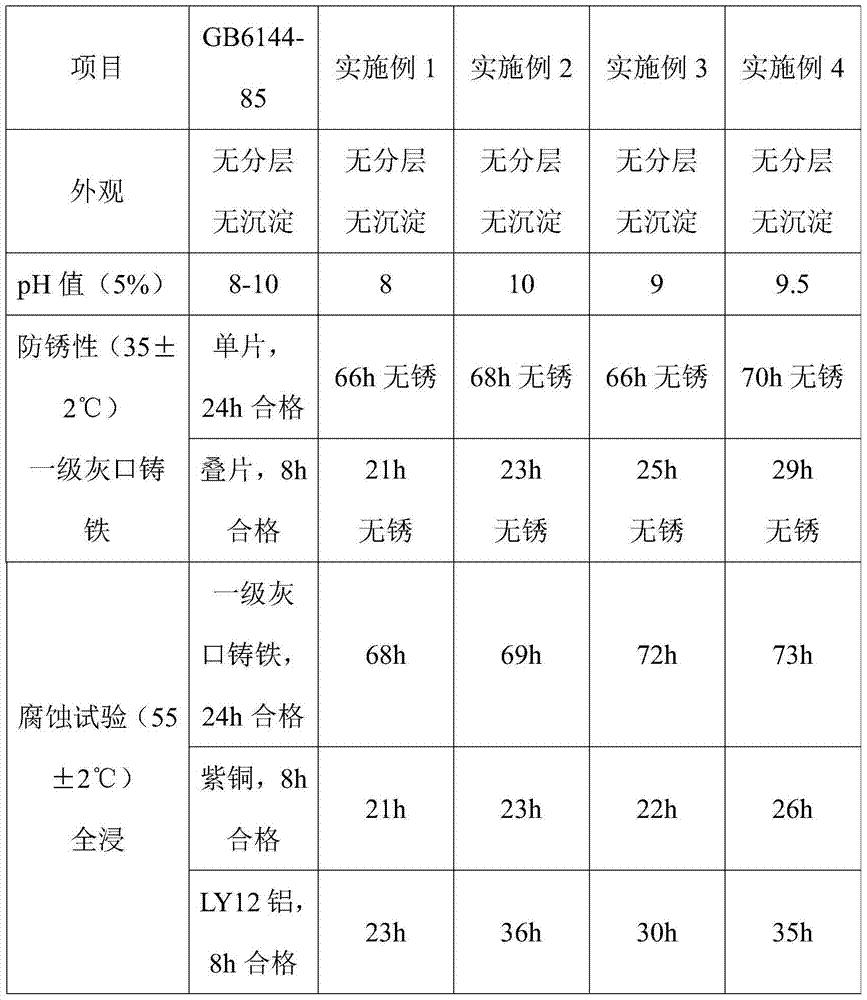

High-efficiency safe environment-friendly all-synthetic cutting fluid and preparation method thereof

InactiveCN104479833AImprove the lubrication effectExcellent rust and corrosion inhibition performanceLubricant compositionEnvironmental resistanceWork in process

The invention discloses a high-efficiency safe environment-friendly all-synthetic cutting fluid and a preparation method thereof. The cutting fluid consists of the following components in percentage by weight: 20-30% of synthetic ester, 4-8% of surfactant, 5-15% of antirust agent, 2-10% of pH regulator, 0-3% of corrosion inhibitor and the balance of deionized water. The preparation method comprises the following specific steps: adding the pH regulator into part of the deionized water and stirring uniformly; adding the corrosion inhibitor and the antirust agent in turn and stirring until solid powder is completely dissolved; after uniformly mixing and stirring the synthetic ester, adding the surfactant of the proportion and stirring for 15 minutes till uniformity; pouring a semi-finished product into the reaction system and stirring uniformly; repeatedly flushing the preparation container with the rest deionized water, and completely beating the flushing liquid back into the reaction system; and continuously stirring the reaction system until the solution is uniform and transparent to obtain a finished product. In the invention, the prepared all-synthetic cutting fluid has excellent lubricating and antirust and corrosion inhibition properties as well as good stability at high and low temperature to avoid color change, and avoids stimulation to the skin of a human body; and moreover, the all-synthetic cutting fluid has good biological stability and is safe, environment-friendly and non-irritant.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

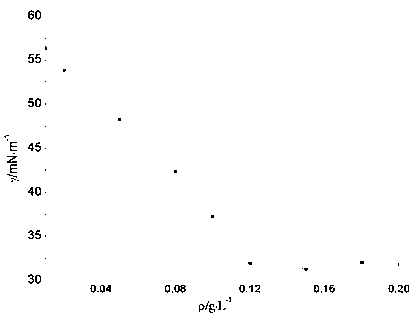

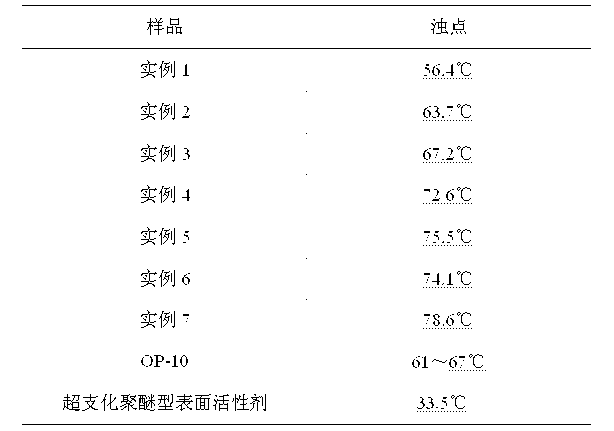

Aromatic hyperbranched polymer surfactant and preparation method thereof

ActiveCN102936333AImprove the disadvantage of low cloud pointGood self stabilityTransportation and packagingMixingPolymeric surfacePolymer science

Owner:GUANGZHOU FANGZHONG CHEM CO LTD

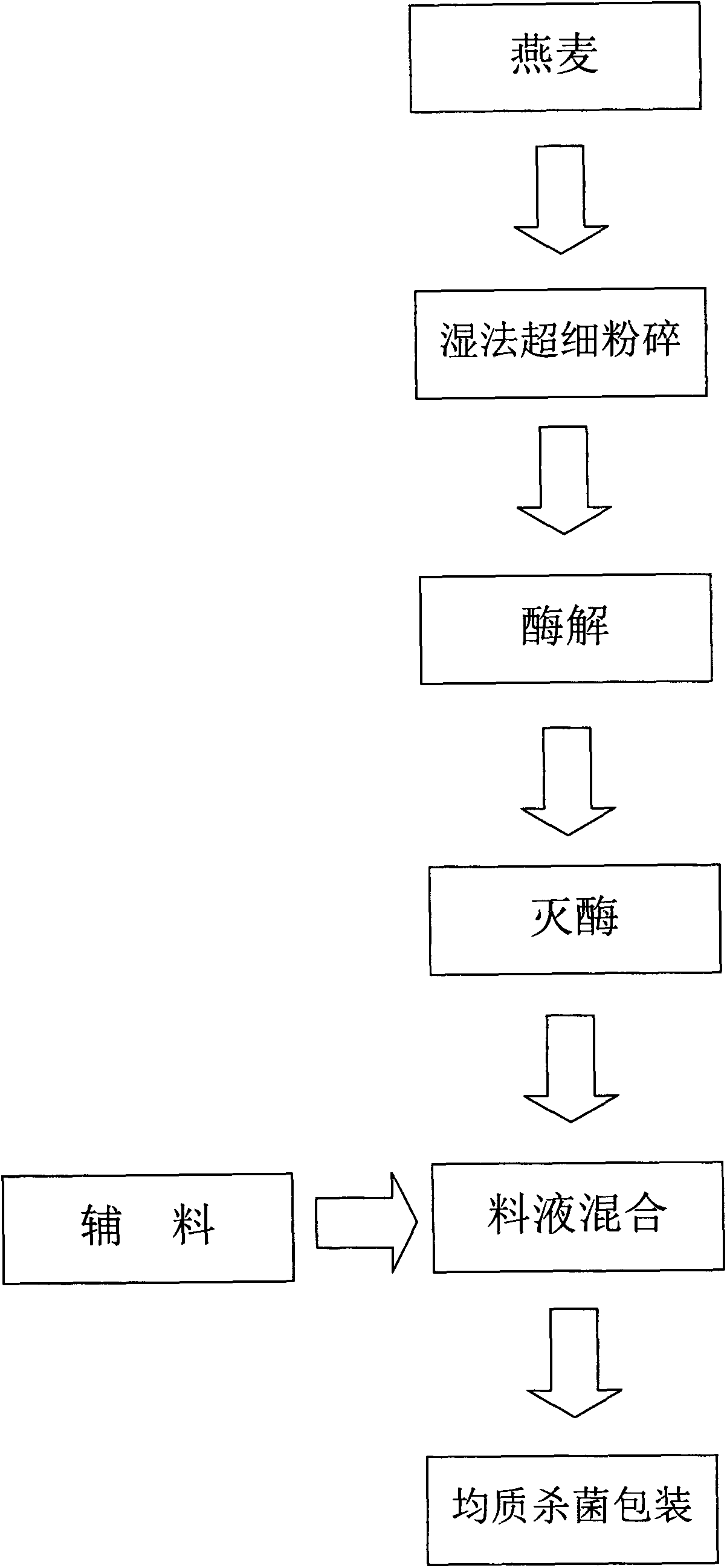

Method for preparing whole oat healthy drink through wet process ultrafine grinding

InactiveCN103519307AEfficient use ofFragrance and sweetnessFood homogenisationFood hydrolysisSucroseCereal grain

The invention relates to a method for preparing a whole oat healthy drink through wet process ultrafine grinding, belonging to the field of cereal deep processing. According to the method, oat is ground to be fine enough through wet process ultrafine grinding, the viscosity, stability and external property of the oat water system are improved by means of emulsification and homogeneity, so that the purpose of fully utilizing the oat is reached, and the prepared oat drink maintains all proteins, beta-glucan, mineral substances, vitamins and the like of the oat, furthermore, a part of the starch in oat is converted into glucose through enzyme reaction and is further converted into fructose, so that the content of glucose in the drink is low, but the sweetness of the drink is proper and saccharose or other sweetening agents do not need to be added, therefore, the whole oat healthy drink is rich in nutrients, has good fragrance and taste, and also has health care function. The method is scientific and reasonable, and can improve the comprehensive use value of oat resource and the economic benefit of food production.

Owner:JIANGNAN UNIV

Dyeing and retanning tanning process

ActiveCN102051419AReduce usageEmission reductionTanning treatmentPre-tanning chemical treatmentManufacturing cost reductionSodium bicarbonate

The invention relates to a dyeing and retanning tanning process, which comprises a softening and through-dyeing process and a color fixing and fixing process. The dyeing and retanning tanning process is characterized in that: the softening and through-dyeing process comprises the steps of adding normal-temperature water, wet blue leather, MND1717, MND3009, MND2031, MND2010, MND7010, sodium formate or sodium acetate, sodium bicarbonate, ammonium bicarbonate and dye by weight into a revolving drum, revolving for more than 2 hours, checking that the center of the obtained product is penetrated, stopping the drum, and keeping stand the obtained product overnight; and the color-fixing and fixing process comprises the steps of adding methanoic acid and MND1717 into a drum provided with a leather blank subjected to softening and through-dyeing treatments in the softening and through-dyeing process, in the same bath, adjusting the pH value, adding a chrome tanning agent, MND3009, MND2031, MND2010, glutaraldehyde or fatty aldehyde, and a mildew inhibitor into the drum, revolving for more than 4 hours, rinsing, taking the obtained product out of the drum, coating and finishing according to the conventional process. Compared with the prior art, the dyeing and retanning tanning process has the advantages of simple process, wide scope of application, capability of improving the quality of finished leather, raw material and labor saving, reduction of labor intensity, energy saving, effective reduction of wastewater discharge, and lower manufacturing cost.

Owner:禾瑞(漳州)助剂有限公司

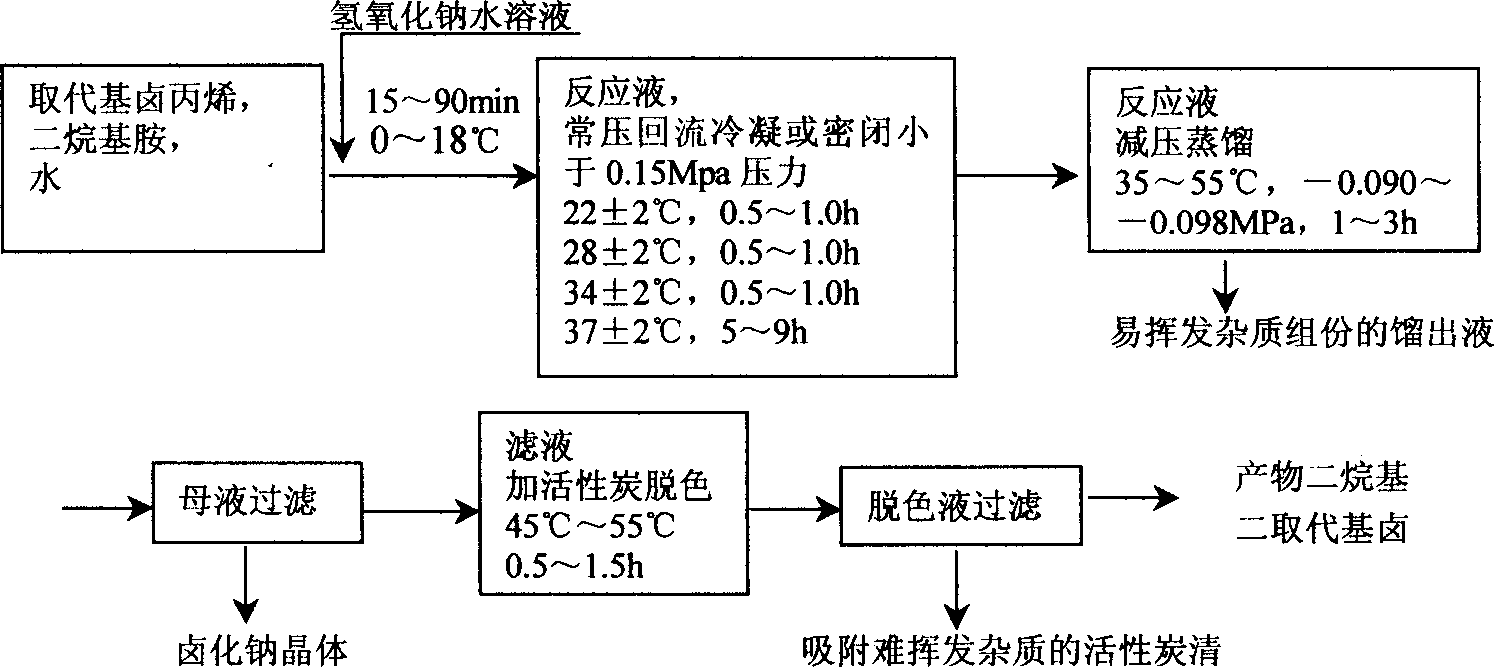

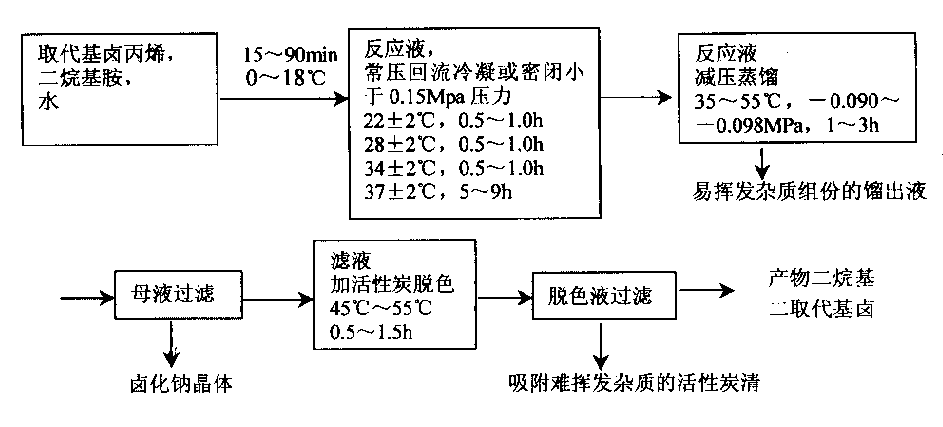

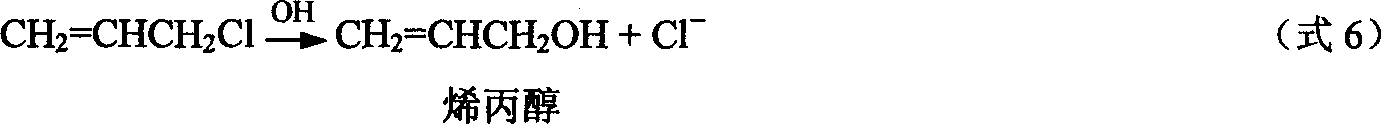

Prepn of cationic monomer dialkyl disubstituent propyl ammonium halide

InactiveCN1362401AReduce generationMaterial ratio is stableAmino preparation from aminesDistillationOil phase

The preparation method of high-purity cationic monomer dialkyl disubstituent allyl ammonium halide includes tertiary amination, neutralization reaction and tertiary amination reaction and quaterisation, in the reactor still with back-flow condensation device adding substituent halopropylene and dialkyl amine aqueous solution, adding a certain quantity of water to regulate water-phase and oil-phase, drop-adding sodium hydroxide aqueous solution, uniformly mixing, heating and heat-insulating, reduced pressure distillation, reduced pressure filtering of centrifugal filtering to remove crystal sodium chloride, decolouring said solution by using active carbon, then filtering to remove action carbon to obtain the invented product. Said invented reactions can be implemented under the condition of low temperature.

Owner:NANJING UNIV OF SCI & TECH

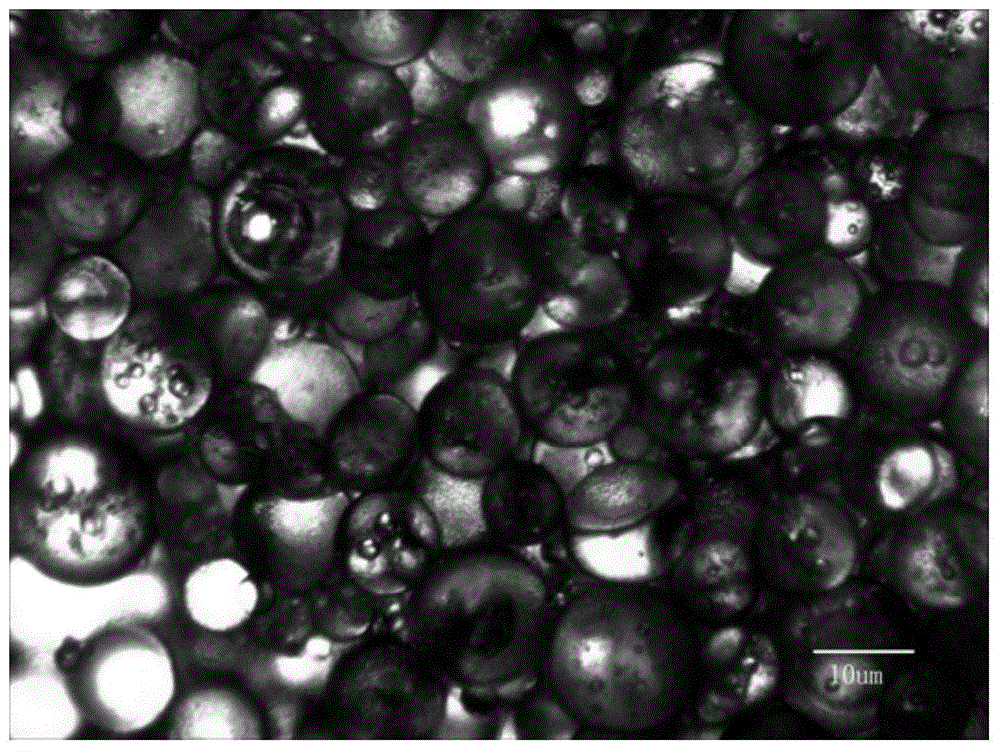

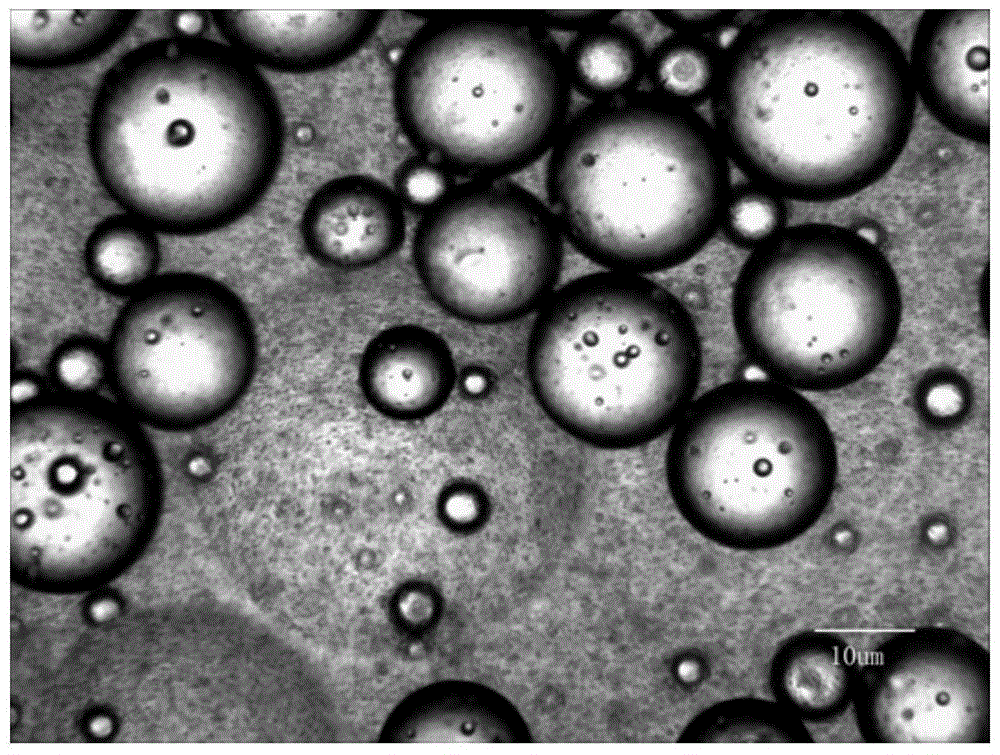

Self-repairing microcapsule, preparation method and application thereof

ActiveCN105964194AHas a repairing effectThe synthesis method is simpleMicroballoon preparationMicrocapsule preparationMedicineStyrene maleic anhydride

The invention relates to a self-repairing microcapsule, a preparation method and an application thereof. The microcapsule comprises a capsule core and a repairing microcapsule wall on the external surface of the capsule core, the capsule core is a repairing agent, the repairing microcapsule wall is composed of styrene-maleic anhydride and gelatin, wherein, the mass ratio of the repairing agent to styrene-maleic anhydride to gelatin is 5-15:1-2:1-5; the self-repairing microcapsule is prepared by employing a complex coacervation method; and the self-repairing microcapsule is used for repairing the cracks of cement-based materials. Compared with the prior art, the synthetic method is simple, synthetic efficiency is high, adverse impact of the noxious material and the additionally added emulsifier during a synthesis process can be better solved, the self-repairing microcapsule has environmental protection, and can be widely used for repairing the cracks of cement-based materials.

Owner:TONGJI UNIV

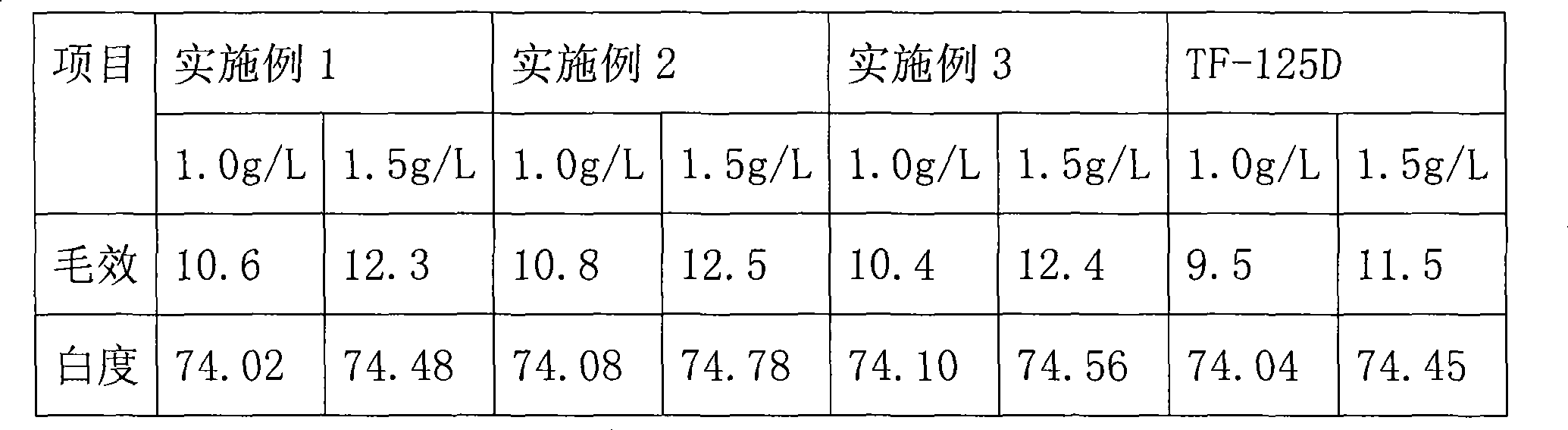

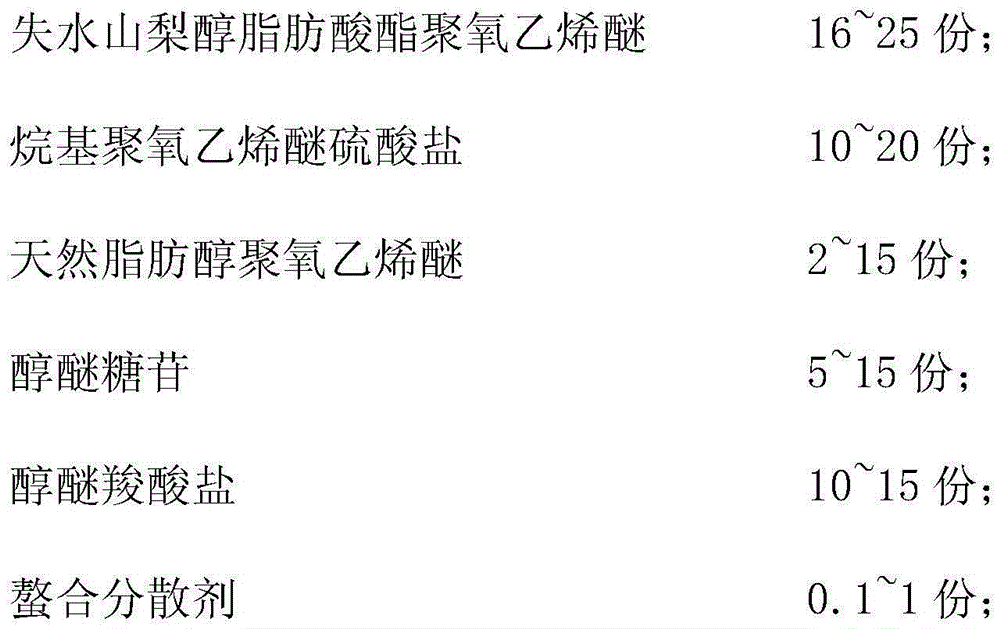

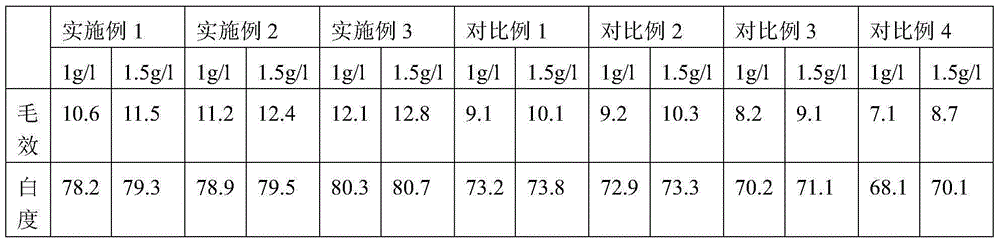

Environment-friendly scouring agent and preparation method thereof

InactiveCN105155273AGood alkali resistanceGood emulsification and dispersionFibre treatmentEtherHigh concentration

The invention discloses an environment-friendly scouring agent which comprises the following components: sorbitan fatty acid ester polyoxyethylene ether, alkyl polyoxyethylene ether sulfate, natural fatty alcohol polyoxyethylene ether, alkylethoxyglucoside, alcohol ether carboxylate, a chelating dispersant, an activating agent, an organic silicon defoamer and water, wherein the saponification value of sorbitan fatty acid ester polyoxyethylene ether is 80-120, and the proportion of sorbitan fatty acid ester polyoxyethylene ether of which the saponification value is 85-110 is 80 mol or above, the scouring agent has high concentration alkali resistance, so that the process time can be reduced, and the production efficiency is improved; the raw materials and by-products are environment-friendly, and do not cause water body nutrification problem; processed fabric can obtain the satisfying capillary effect and whiteness so as to meet follow-up process requirements of dyeing, printing and the like.

Owner:WUJIANG CITY QIDU TOWN MIAOGANG YADI KNITTING GARMENT FACTORY

Preparation method of powdered oil feed

The invention relates to a feed, in particular to a preparation method of a powdered oil feed. The preparation method mainly solves the technical problems that the powdered oil feed in the prior art is easy to melt, oxided and deteriorated and is difficult to preserve, a carrier of the traditional oil powder is a non-nutritive substance such as furfur, corn (cob) flour, modified starch, powder fiber and the like, only fat is provided, other nutritional ingredients are low, and the powdered oil feed can only serve as energy feed on an aspect of animal demand. By a special method, the carrier in the oil powder is replaced to animal and vegetable protein from the non-nutritive substance. The method comprises the following steps of: adding and mixing animal fat and vegetable fat according to proportion; adding an emulsifier into a mixture according to proportion, and performing high-speed emulsification; homogenizing the emulsified mixture by a homogenizing machine; and adding animal protein, vegetable protein, vitamin, mineral substances and trace elements into the homogenized mixture according to proportion, mixing in a solid-liquid stirring and mixing machine; and packaging.

Owner:HANGZHOU XIANGBAO FEED

Preparation method of water-based fast dry low VOC alkyd paint

The invention discloses a preparation method of water-based fast dry low VOC alkyd paint, and relates to the field of paint. The preparation method is as follows: fast dry type alkyd resin is first synthesized, and then emulsified to obtain the alkyd resin, and finally the water-based fast dry low VOC alkyd resin paint is produced using the emulsion as raw material. By adopting a high polymerization method in the alkyd resin synthesizing technology, the hard drying time of the alkyd resin can be effectively shortened, then the drying time of the final water-based paint product is shortened, and the customer's construction cycle is shortened. The emulsion has low VOC content, excellent water resistance property, stability and film formation property. During the whole technological process, the self-made fast dry type alkyd resin is selected, and the content reaches 99% or above. In the process of emulsification and paint preparation, no organic solvent is added; the VOC content in the final paint is controlled to be 60 g / L or below, and the low VOC content water-based alkyd paint is actualized.

Owner:CHANGSHA WEIYI CHEM PAINT

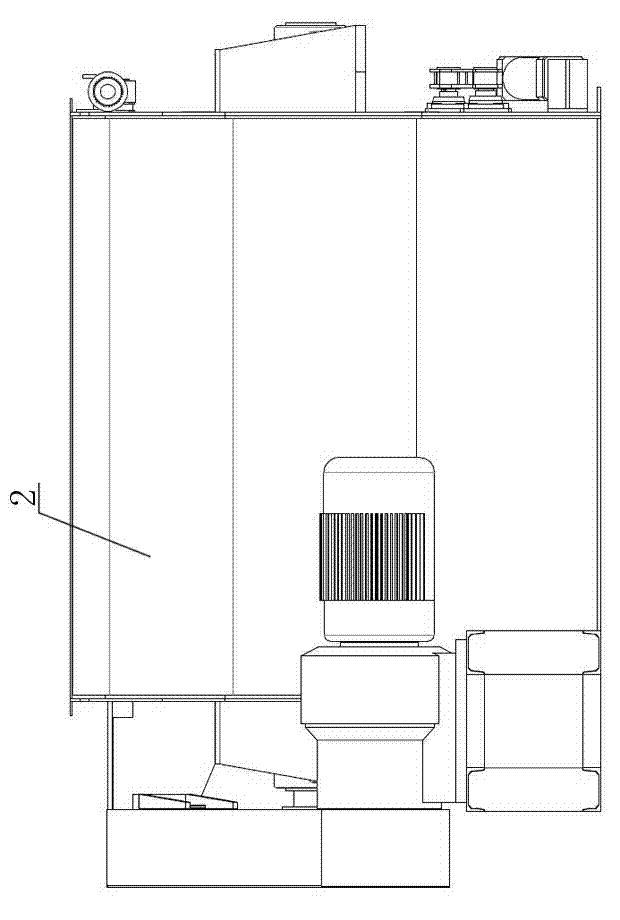

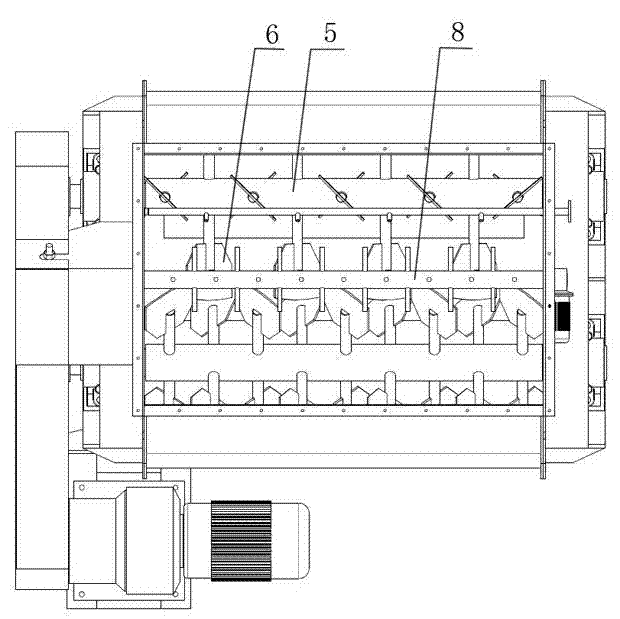

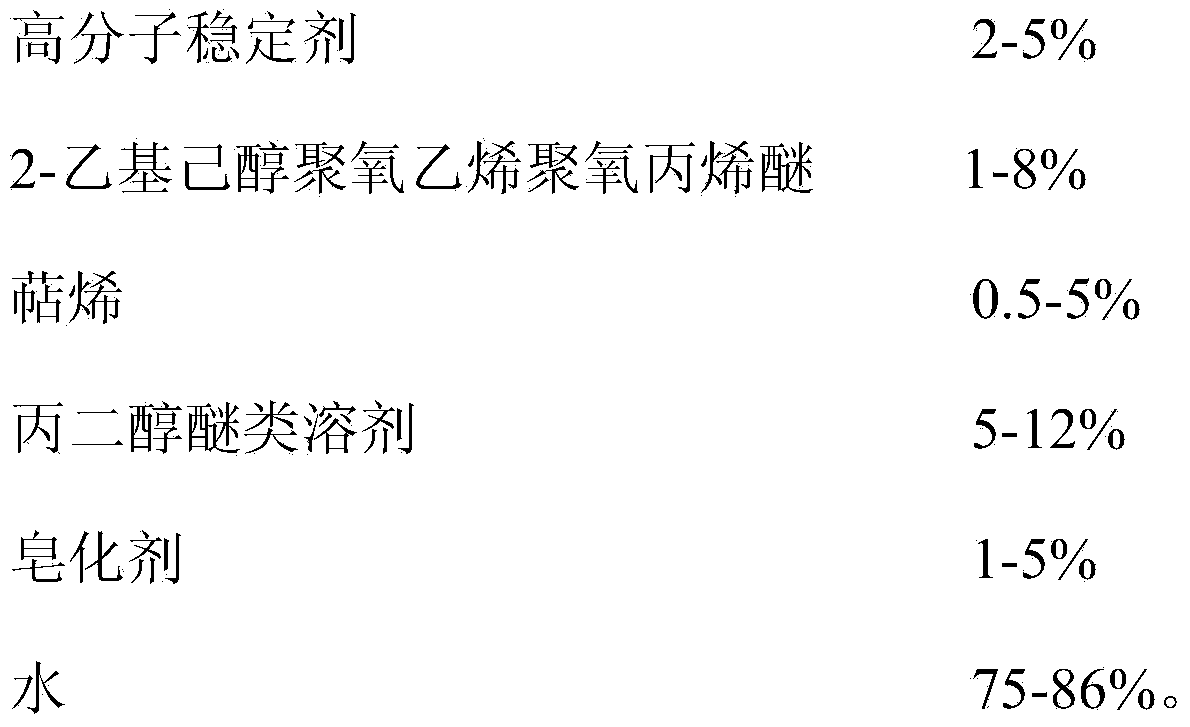

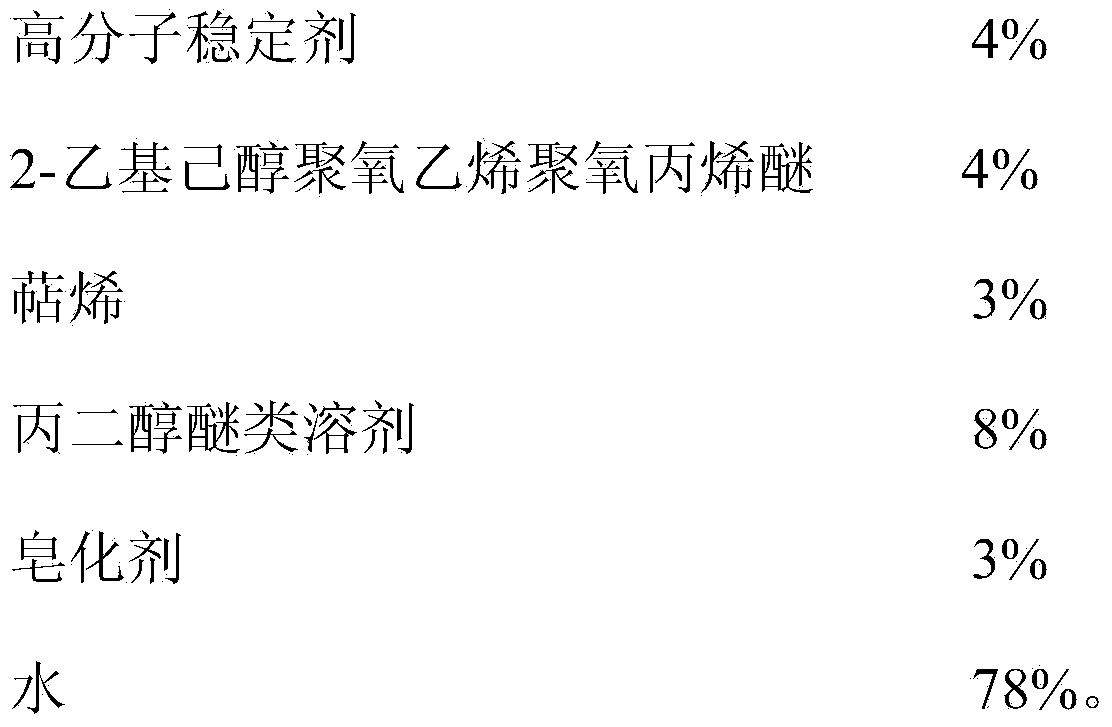

Micro-emulsion cleaning agent for welding jigs

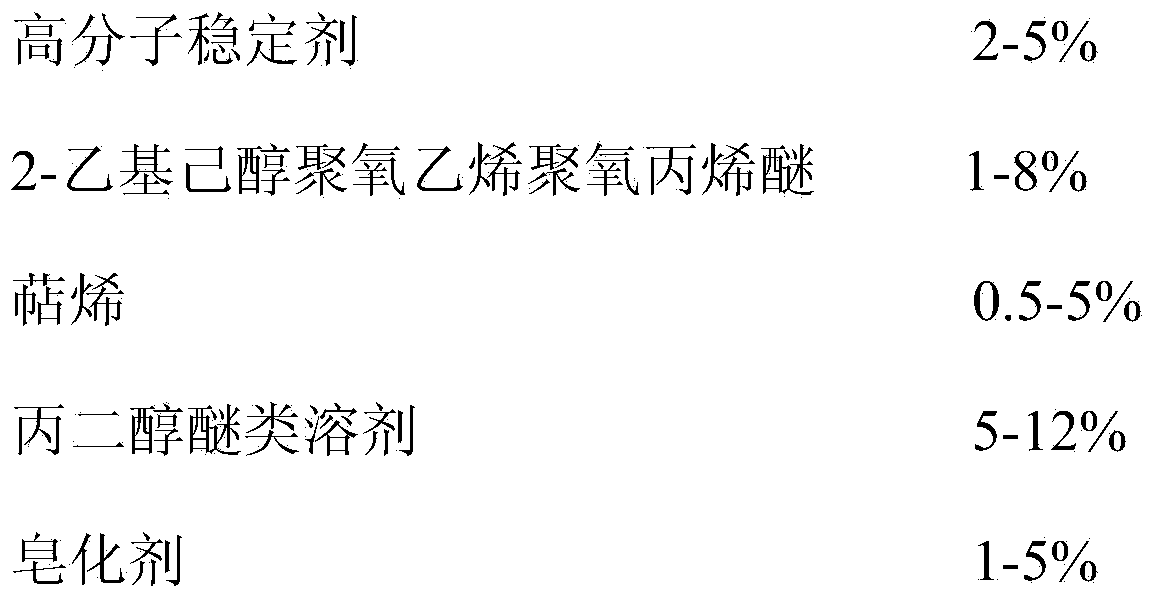

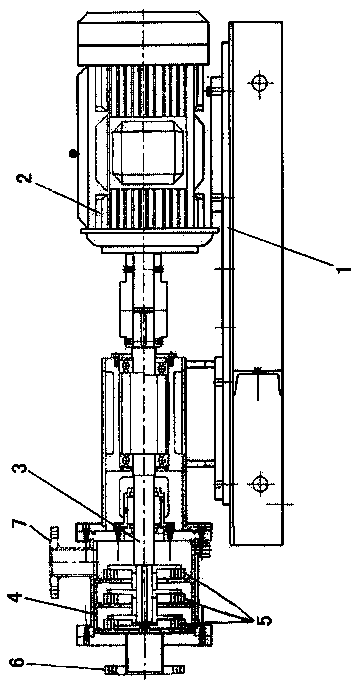

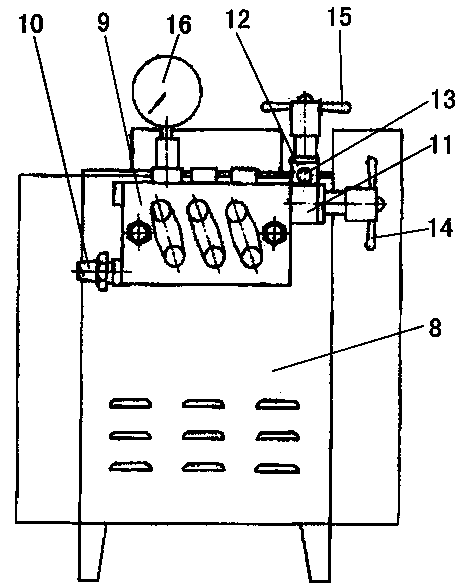

ActiveCN104194971AImprove cleaning abilityEasy to rinseOrganic detergent compounding agentsSurface-active detergent compositionsEmulsionEther

The invention provides a micro-emulsion cleaning agent for welding jigs. The micro-emulsion cleaning agent comprises the following components in percent by weight: 2-5 percent of polymer stabilizer, 1-8 percent of 2-ethyl hexanol polyoxyethylene polyoxypropylene ether, 0.5-5 percent of terpene, 5-12 percent of propylene glycol ether solvent, 1-5 percent of saponifier and 75-86 percent of water. The micro-emulsion cleaning agent provided by the invention has a good cleaning effect, low toxicity and less influence on environments, and is safe.

Owner:深圳市唯特偶新材料股份有限公司

Preparation method of powdered oil feed with whey powder

ActiveCN103380945AIncrease contact areaBarrier-free absorptionFeeding-stuffBacterial virusOil and grease

The invention relates to a feed, in particular to a powdered oil feed with whey powder and a preparation method thereof, which mainly solve the technical problems that in the prior art, protein, whey powder and oil all in the conventional feed are simply mixed and stirred, so that oil and protein digestion utilization of animals is low, the protein, the whey powder and the oil carry bacterial viruses easily and insanitation is caused, the storage time is short, the application is poor and the like. According to the preparation method, whey powder, plant protein, animal protein and plant oil are mixed in proportion, added into water and heated, then emulsifier is added, and the mixture is fully stirred and then gets into an emulsifying machine for treatment, the homogenization treatment is performed to the product subjected to emulsification through a homogenizer, spray drying is performed to the product through the variable frequency drying technology and via a spray drying tower, and the dried mixture is subjected to sieving, metering and packing, so that a finished product is obtained.

Owner:杭州禾太生物科技有限公司

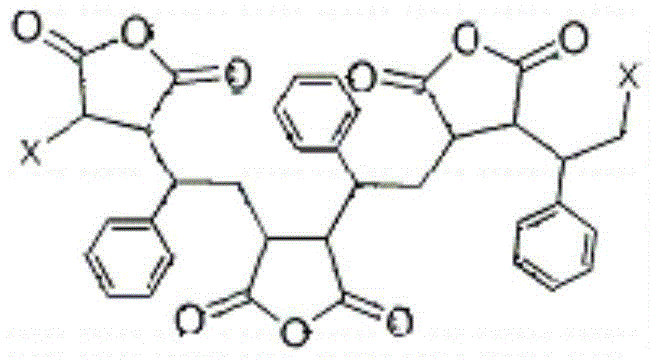

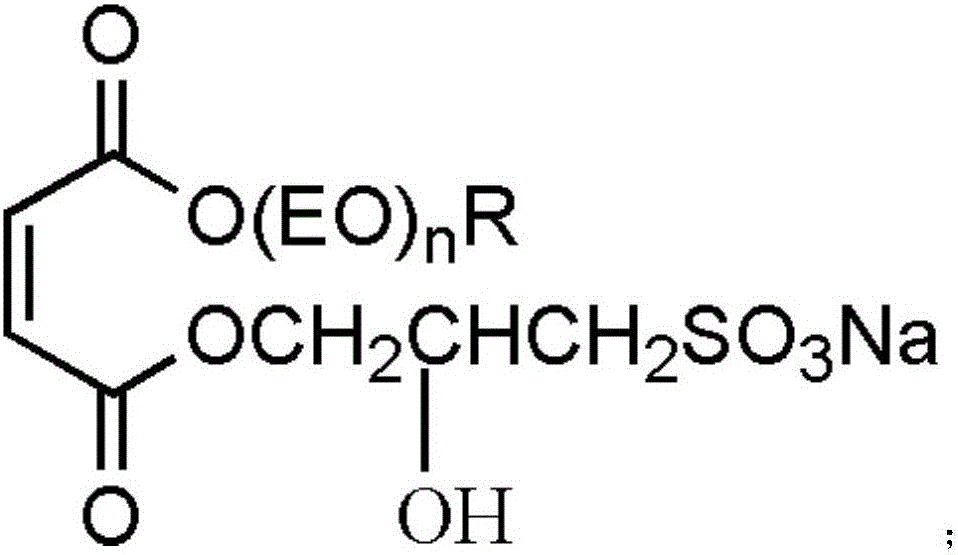

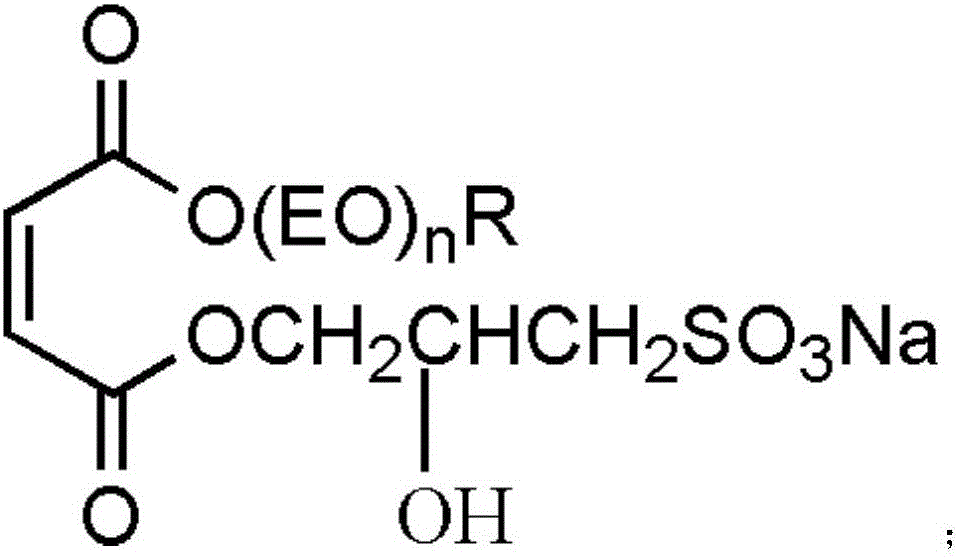

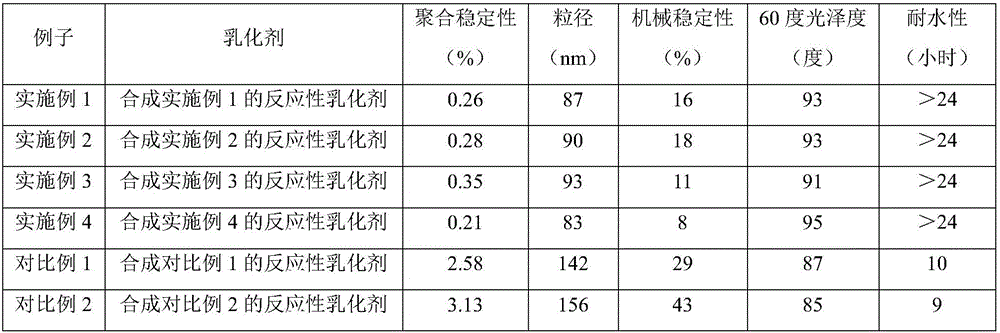

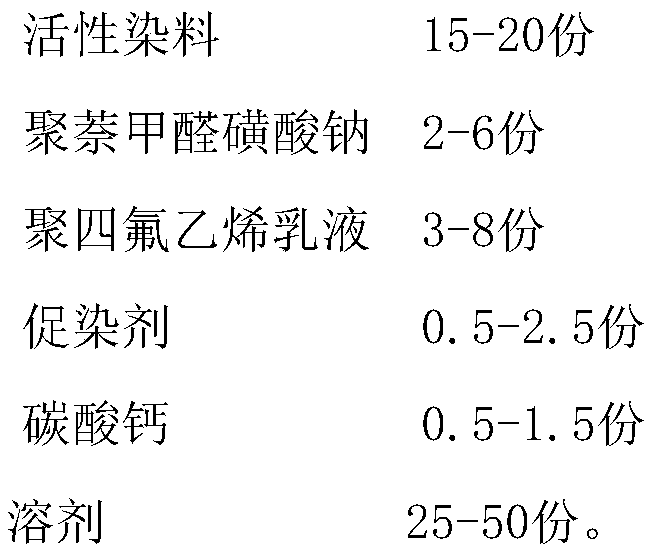

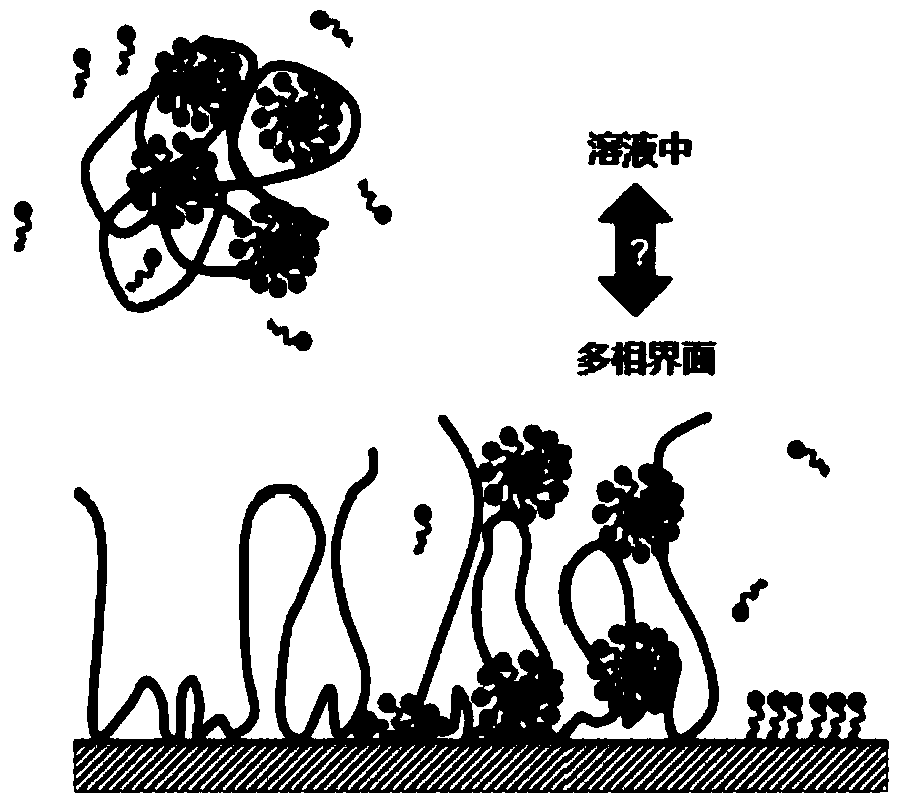

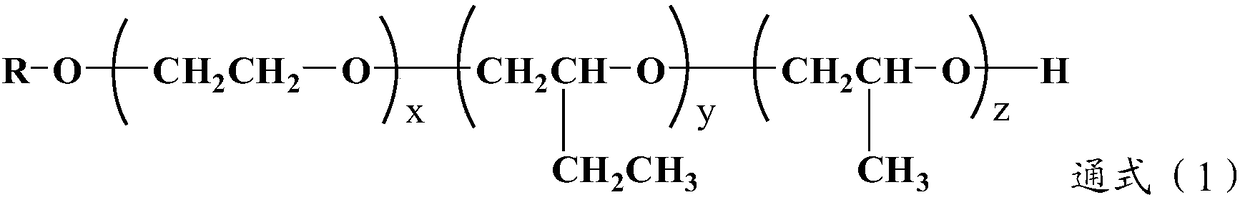

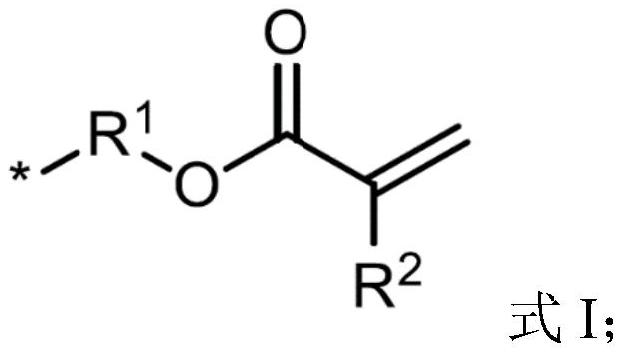

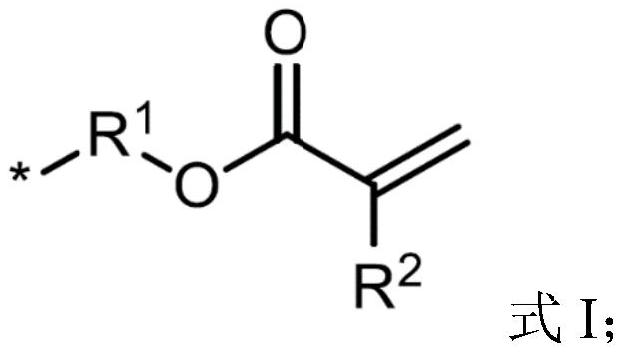

Preparation method and application of anionic nonionic reactive emulsifier

ActiveCN106750255AGood emulsification and dispersionLow foamSulfonic acids salts preparationEmulsionEmulsion polymerization

The invention discloses a preparation method and an application of an anionic nonionic reactive emulsifier. The structural formula of the anionic nonionic reactive emulsifier is as shown in the specification, wherein in the formula, n is 5-40. Meanwhile, the invention further discloses a preparation method of the anionic nonionic reactive emulsifier and an application of the anionic nonionic reactive emulsifier in preparation of polymers. The anionic nonionic reactive emulsifier disclosed by the invention has high spatial stability, high emulsifying dispersion ability, low foam, low surface tension, wetting and other excellent performances, and can be used in emulsion polymerization, especially in styrene-acrylic emulsion polymerization, to prepare a high-performance emulsion with high stability, high luster and small particle size.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

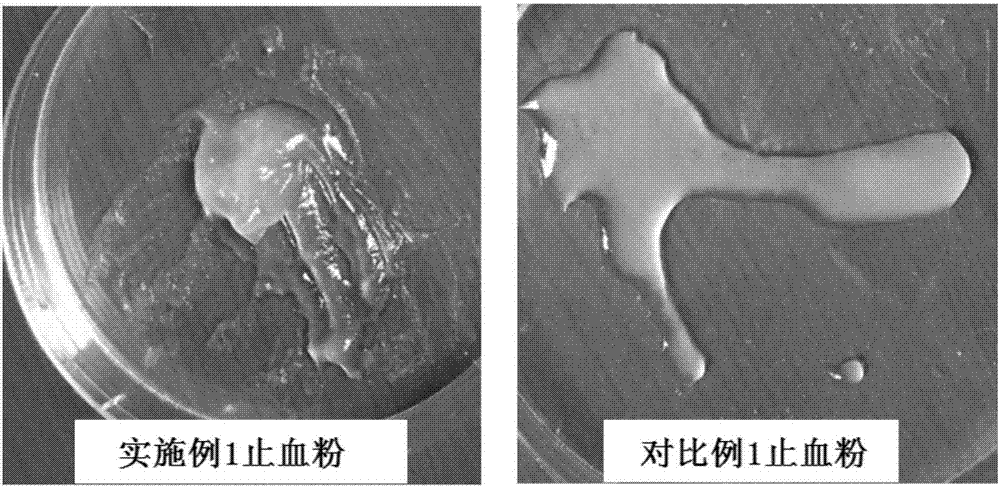

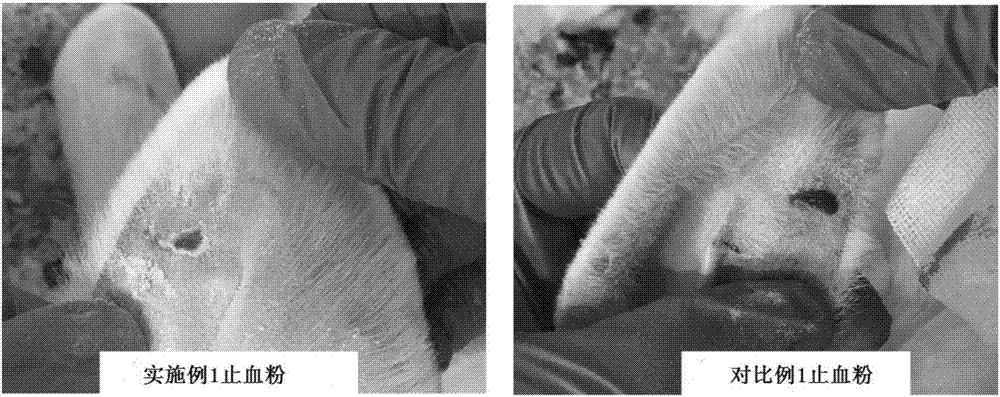

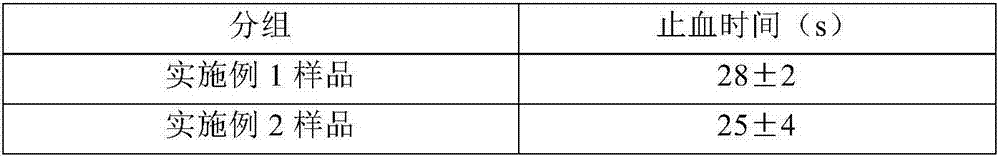

Styptic powder and preparation method thereof

ActiveCN107213509AEasy to prepareEasy to operate industriallySurgical adhesivesPharmaceutical delivery mechanismRaw materialStarch

The invention discloses a styptic powder and a preparation method thereof. The method comprises the following steps: dissolving a starch raw material in water, emulsifying and dispersing, performing cross-linking reaction, drying under reduced pressure, washing, drying, and sterilizing. The styptic powder prepared by the preparation method has the characteristics of rapid adhesion to wound, rapid water absorption, arresting bleeding, and biodegradable property. The invention also discloses the styptic powder prepared by the method of the invention.

Owner:深圳市和福汇生物科技有限公司

Table rose sauce and preparation method thereof

ActiveCN104055060ASmooth tasteRetain colorFood ingredient functionsFood preparationBiotechnologyGlucose-Fructose Syrup

The invention relates to table rose sauce and a preparation method thereof. The preparation method comprises the following steps: performing superfine grinding on edible rose petals to obtain rose powder; mixing the rose powder, glucose syrup, white granulated sugar and purified water, adjusting the pH value to be 1.8-2.2 by using citric acid to obtain a mixed solution, and heating the mixed solution to obtain a rose solution with sugar content of not less than 50%; adding pectin and salt into the rose solution, and boiling to obtain rose sauce; sterilizing the rose sauce in a water bath with temperature of 80-85 DEG C to obtain a finished product of rose sauce. According to the preparation method, the technical problems of instable quality and poor sensory quality of rose sauce in the prior art are solved, and the table rose sauce is stable in quality, bright in color, fragrant in smell, comfortable in mouth feel and wide in application range.

Owner:HUNAN AGRI PRODS PROCESSING INST

Stripping agent with complex formulation of mineral oil and emulsifying agent for drying cylinder as well as preparation method thereof

InactiveCN105970723AExtended service lifeReduce broken endsNon-fibrous pulp additionPaper coatingPerformance indexSpray forming

The invention discloses a stripping agent with complex formulation of mineral oil and an emulsifying agent for a drying cylinder. The stripping agent comprises mineral oil, the emulsifying agent and water. The mass ratio of the mineral oil to the emulsifying agent is 9-10:1, and the mass ratio of the total mass of the mineral oil and the emulsifying agent to water is 1:2-4. An externally spraying form is used for the stripping agent for the drying cylinder, so that a lubricating layer is formed on the contact interface of the drying cylinder and paper, breakage of drying parts is reduced, and smoothness, glossiness and other performance indices of paper sheets are greatly improved; at the same time, the drying cylinder and a drying net are protected, service life of the drying cylinder and the drying net is prolonged, production efficiency and product quality of a paper machine are improved, and the problem that overall performance is not ideal in the prior art is overcome.

Owner:SHAANXI UNIV OF SCI & TECH

Fireproof emulsion paint

InactiveCN105062264AGood weather resistanceImprove water resistanceFireproof paintsAnti-corrosive paintsPhosphateKetone

The invention discloses fireproof emulsion paint. The fireproof emulsion paint comprises acrylic acid emulsion, polyurethane emulsion, epoxy resin, a fire retardant, expanded perlite, titanium dioxide, nanometer silica sol, silicon powder, nanometer titanium dioxide, zinc trifluoroacetylacetonate, dodecafluoroheptyl methacrylate, a film forming auxiliary agent, sorbitan monopalmitate, lauric acid, an antifoaming agent, hydroxyethyl cellulose, methyl ethyl ketone, N-phenyl-N'-cyclohexyl p-phenylenediamine, potassium citrate, dimethyldiallylammonium chloride and water. The fire retardant comprises dimethyl phosphite, methylvinyldichlorosilane, 3-aminopropyltriethoxysilane, 5-ethyl-5-butyl-2-chloro-1,3,2-dioxaphosphorinane, potassium tripolyphosphate, cetyl pyridinium bromide, decabromodiphenyl ethane, aluminum dihydrogen phosphate, calcium borate, melamine and cyanuric acid. The fireproof emulsion paint has excellent flame resistance, good fire retardancy, good adhesion to a base material and good decorative effects.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Environmental-protection lubricating water-based cutting fluid

InactiveCN104327933AGood emulsification and dispersionGood dispersionLubricant compositionSolubilityWater based

The present invention discloses an environmental-protection lubricating water-based cutting fluid, which comprises the following raw materials by weight: 8-20 parts of sodium abietate, 15-25 parts of a rosin amine glucose ester surfactant, 5-10 parts of rosin amine polyoxyethylene ether, 12-18 parts of a polyaniline aqueous anti-corrosion agent, 5-15 parts of triethanolamine oleate, 3-8 parts of triethanolamine, 3-10 parts of diisopropanolamine, 10-15 parts of sodium carbonate, 5-15 parts of hydrophilic alcohol, 3-6 parts of a sterilization agent, 2-5 parts of a foaming agent, 3-10 parts of a stabilizer, and 80-100 parts of water. The environmental-protection lubricating water-based cutting fluid has functions of excellent cleaning, excellent lubrication, excellent corrosion resistance and excellent cooling, and further has characteristics of environmental protection, long service life, good water solubility, low cost, and high stability.

Owner:CHAOHU GUANGFENG METAL PROD

Fabric with low washing shrinkage rate and preparation process thereof

ActiveCN110774683AImprove wearing comfortGood skin affinitySynthetic resin layered productsGrip property fibresYarnPolymer science

The invention relates to the technical field of clothing fabrics, in particular to a fabric with low washing shrinkage rate and a preparation process thereof. The fabric is formed by weaving of a composite yarn, the composite yarn is formed by laminating a surface yarn, an elastic fiber yarn and a bottom yarn, after lamination shaping, the surface yarn forms a surface layer, the elastic fiber yarnforms an elastic middle layer, and the bottom yarn forms a base layer; the surface yarn is unshrinkable wool fiber with a metric number of 1 / 80Nm-1 / 60Nm and a count of 90S; the elastic fiber yarn islow-temperature spandex with Denier of 30-60D; and the base yarn is polypropylene fiber with Denier of 45-75D and a hole count of 45-75F. By adopting the three yarn fibers for blending weaving, the prepared fabric includes three sequentially formed yarn layers, and the middle layer has elasticity, thus improving the wearing comfort and skin friendliness of the fabric, and the fabric has the functions of environmental protection, warmth retention, machine washability, no ironing and the like, does not generate stuffiness and skin-sticky feel, is comfortable to wear, and low in washing shrinkagerate.

Owner:DONGGUAN SENLIN TEXTILE LTD

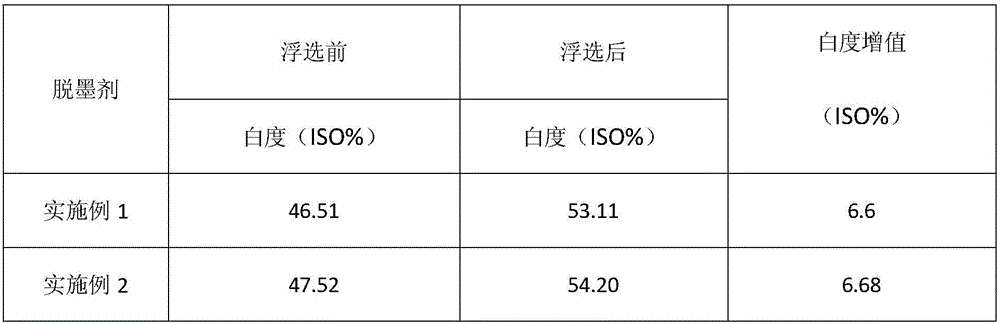

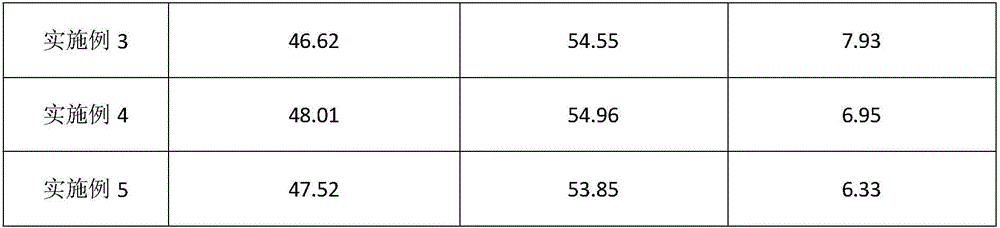

Biological deinking agent

ActiveCN105907162AReduce dosagePromote degradationChemical paints/ink removersDeinkingInorganic salts

The invention discloses a biological deinking agent. The biological deinking agent is prepared from, by weight, 8-25 parts of biomass raw materials, 2,000-150,000 U / g of biological enzymes, 15-40 parts of surface active agent, 1-5 parts of acid or alkali and 5-20 parts of inorganic salt electrolyte. The biological deinking agent is mainly formed by mixing the biomass raw materials, the biological enzymes and the surface active agent, a biological matrix is mainly adopted in the obtained biological deinking agent, the quantity of adopted chemical additives is small, the biological deinking agent is degradable, environmentally friendly and good in deinking effect, and the whiteness of paper obtained after deinking of the deinking agent is high.

Owner:苏州埃斯腾特生物科技有限公司

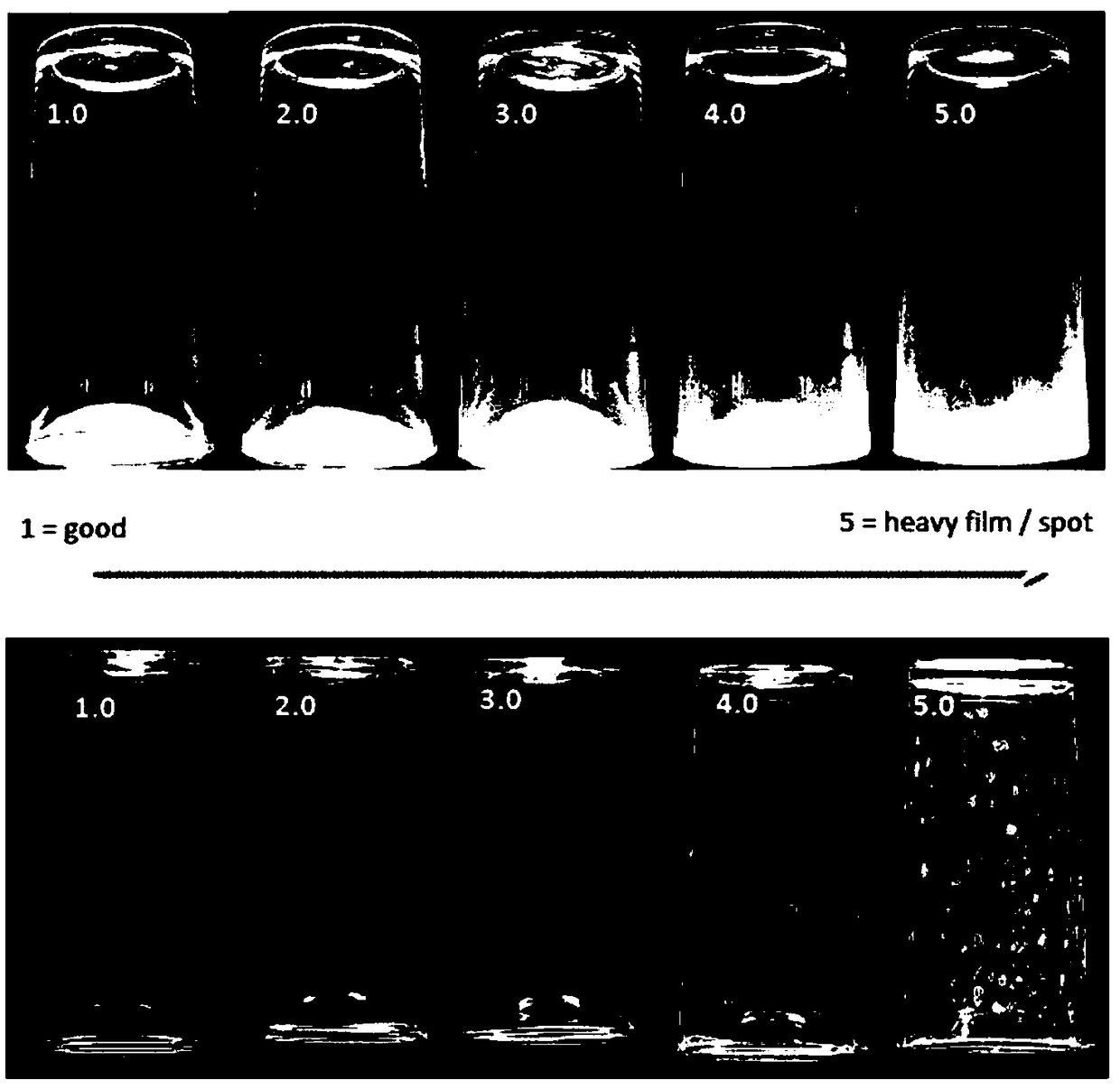

Detergent composition special for automatic dishwasher

ActiveCN108865480AImprove washing efficiencyGood emulsification and dispersionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsChemical industryFatty alcohol

The invention discloses a detergent composition special for an automatic dishwasher, relating to the technical field of daily chemical industry. The composition is prepared from 0.01 to 20 parts of apolyether surfactant, 0.01 to 20 parts of a nonionic surfactant, 0.01 to 20 parts of another surfactant, 0.1 to 30 parts of a copolymer dispersant, 0.1 to 40 parts of an amino acid derivative chelating agent, 0.1 to 10 parts of an enzyme preparation and 0 to 80 parts of an additive; wherein the nonionic surfactant at least contains two fatty alcohol alkoxylates, including a fast-emulsified fatty alcohol alkoxylate and a slow-emulsified fatty alcohol alkoxylate, and the weight ratio of the polyether surfactant to the fatty alcohol alkoxylates is 1: (0.1 to 1.5). The detergent composition for the automatic dishwasher, provided by the invention, has good emulsification and dispersion removal effects on oil stain and food dirt, effectively reduces foam in a washing process, and improves the cleaning ability of the detergent.

Owner:广州立涤科技有限公司

Cleaning method of wool fiber

InactiveCN103255610AEasy to emulsify and disperseIncrease profitDry-cleaning apparatus for textilesEnvironmental resistanceOrganic solvent

The invention relates to a cleaning method of wool fiber, which is mainly targeted at the cleaning of the wool fiber and pashm fiber. According to the cleaning method of the wool fiber provided by the invention, the wool fiber is subjected to circulated cleaning by a solution which is prepared by mixing an alcohol organic solvent in high proportion, a little water, and a wool washing agent, and oleophilic dirt on the wool fabric can be rapidly wetted and dissolved to clean the wool fiber more thoroughly. Not only is the loss of the wool fiber strength in the cleaning process greatly improved, but also the entanglement between the wool fibers is reduced, as well as the wool fiber cannot be puffed and felted, so that the yield of a combed wool strip is improved; the problems of incomplete wool cleaning, large wool fiber strength loss and high water consumption in a traditional wool fiber cleaning process are solved; the alcohol organic solvent used by the method provided by the invention is safe and nontoxic, and can be recycled; and the cleaning method greatly reduces water consumption, and is economical, energy-saving, safe and environment-friendly.

Owner:WUHAN TEXTILE UNIV

Tea-flavored low-fat Kefir fermented sausage and production method thereof

InactiveCN105211898AImprove flavorImprove the ability to resist fat oxidationFood preparationChemistryMonosodium glutamate

The invention discloses a tea-flavored low-fat Kefir fermented sausage and a production method thereof. The sausage is formed by filling a casing with meat paste. The meat paste comprises components in parts by weight as follows: 60 parts of pig lean meat, 5-7 parts of pig fat, 8-10 parts of inulin, 14.5-15.5 parts of a tea extract, 3-5 parts of starch, 2 parts of table salt, 0.002 parts of nitrite, 0.15 parts of sodium tripolyphosphate, 0.15 parts of sodium hexametaphosphate, 0.4 parts of white sugar, 0.5-1.5 parts of lactose, 0.01 parts of monosidum glutamate, 0.1 parts of carrageenan and 0.3-0.5 parts of a Kefir starter culture. The new fermented sausage has nutrition and healthcare functions, has the unique flavor, can be absorbed by human bodies easily and has better flavor and low fat content.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

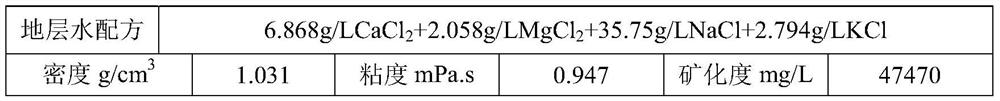

Imbibition oil displacement agent and preparation method thereof

ActiveCN113372896AEasy to manufactureImprove development efficiencyDrilling compositionHydrophilic monomerActive agent

The invention discloses an imbibition oil displacement agent and a preparation method thereof. The imbibition oil displacement agent comprises the following components: 20-60 parts by weight of a nano active agent material; and 10-40 parts by weight of a nonionic surfactant. The nano active agent material is obtained by polymerizing raw materials containing a double-bond modified lamellar nano material, a hydrophilic monomer and a hydrophobic monomer; the hydrophilic monomer is at least one of anhydride compounds; and the hydrophobic monomer is at least one of long-chain alkyl allyl quaternary ammonium salts. The nano active agent material is added into the imbibition oil displacement agent and combined with the non-ionic surface active agent to achieve a synergistic effect, the efficient imbibition oil displacement agent (system) which is easy to prepare and suitable for a low-permeability oil reservoir is obtained, and the efficient imbibition oil displacement agent has important significance and economic value for improving the development efficiency of the low-permeability oil reservoir.

Owner:NINGBO FENGCHENG NANOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com