Environment-friendly scouring agent and preparation method thereof

A scouring agent, an environmentally friendly technology, used in textiles, papermaking, fiber processing, etc., to achieve the effects of water saving, excellent emulsifying and dispersing, and excellent alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

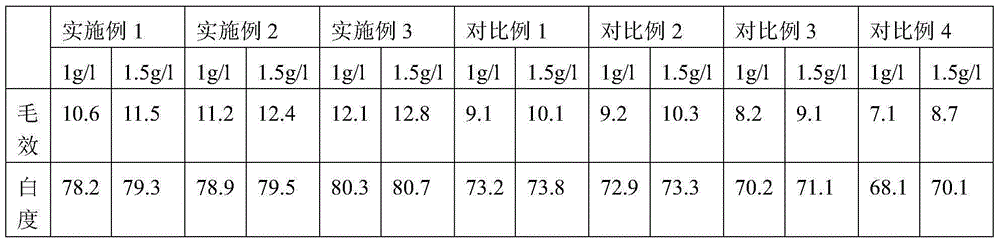

Examples

Embodiment 1

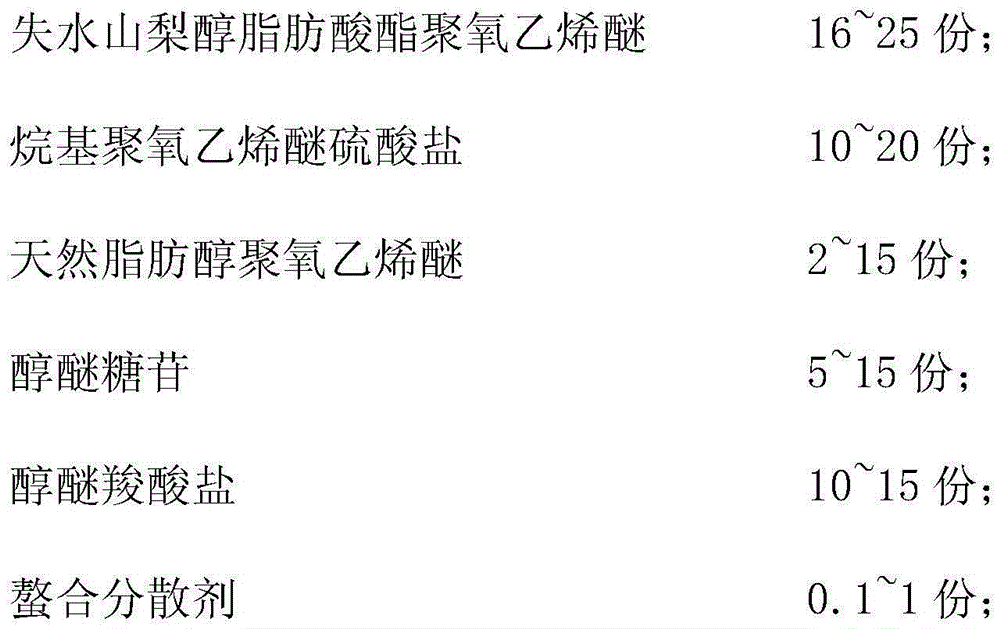

[0027] The components and parts by weight of the environment-friendly scouring agent are as follows:

[0028] 16 parts of mixture of Tween 21 and Tween 61 (saponification value 85-110 accounts for 85 mol); 10 parts of nonyl polyoxyethylene ether sulfate (HLB=13); 2 parts of natural fatty alcohol polyoxyethylene ether; alcohol ether glycoside 5 10 parts of isomeric C8 alcohol ether (6EO) carboxylate; 0.1 part of acrylic acid maleic acid graft; 1 part of urea; 0.1 part of silicone defoamer; 20 parts of water.

Embodiment 2

[0030] The components and parts by weight of the environment-friendly scouring agent are as follows:

[0031] 20 parts of Tween 21 and Tween 61 mixture (saponification value 85~110 accounts for 95% mol); 15 parts of lauryl polyoxyethylene ether sulfate (HLB=14); 8 parts of natural fatty alcohol polyoxyethylene ether; 10 parts of alcohol ether glycoside; 13 parts of isomeric C10 alcohol ether (2EO) carboxylate; 1 part of acrylic acid-maleic acid graft; 1 part of urea; 0.5 parts of silicone defoamer; 35 parts of water.

Embodiment 3

[0033] The components and parts by weight of the environment-friendly scouring agent are as follows:

[0034] 25 parts of mixture of Tween 21 and Tween 61 (saponification value 85-110 accounts for 90% mol); 20 parts of nonyl polyoxyethylene ether sulfate (HLB=12); 15 parts of natural fatty alcohol polyoxyethylene ether; alcohol ether 15 parts of glycosides; 15 parts of isomeric C8 alcohol ether (6EO) carboxylate; 0.5 parts of acrylic acid-maleic acid graft; 2 parts of urea; 0.3 parts of silicone defoamer; 55 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com