Patents

Literature

118 results about "Saponification value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saponification value number represents the number of milligrams of potassium hydroxide required to saponify 1g of fat under the conditions specified. It is a measure of the average molecular weight (or chain length) of all the fatty acids present. As most of the mass of a fat/tri-ester is in the 3 fatty acids, the saponification value allows for comparison of the average fatty acid chain length. The long chain fatty acids found in fats have a low saponification value because they have a relatively fewer number of carboxylic functional groups per unit mass of the fat as compared to short chain fatty acids. If more moles of base are required to saponify N grams of fat then there are more moles of the fat and the chain lengths are relatively small, given the following relation...

Novel agents for treatment of ailments and dysfunctions

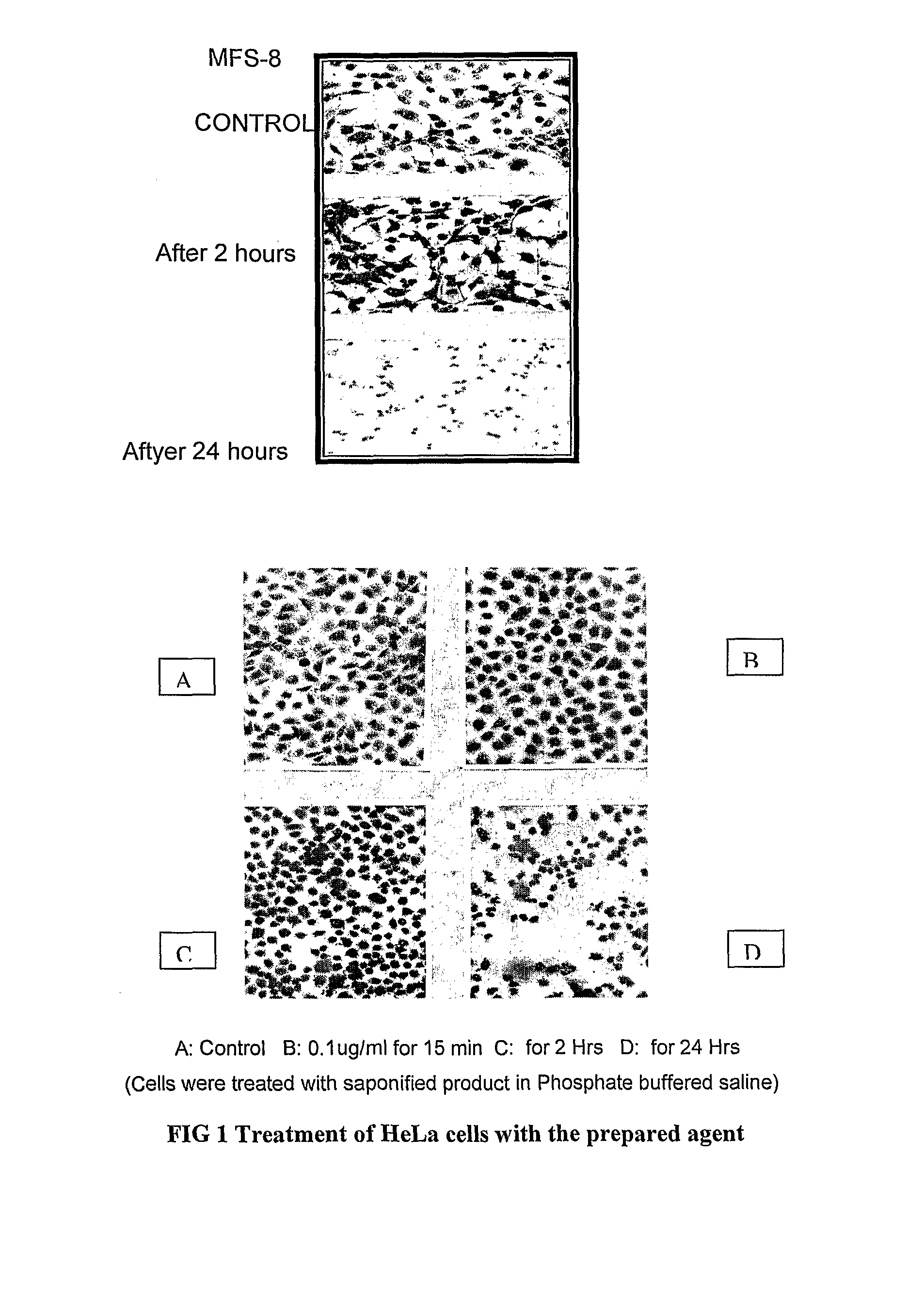

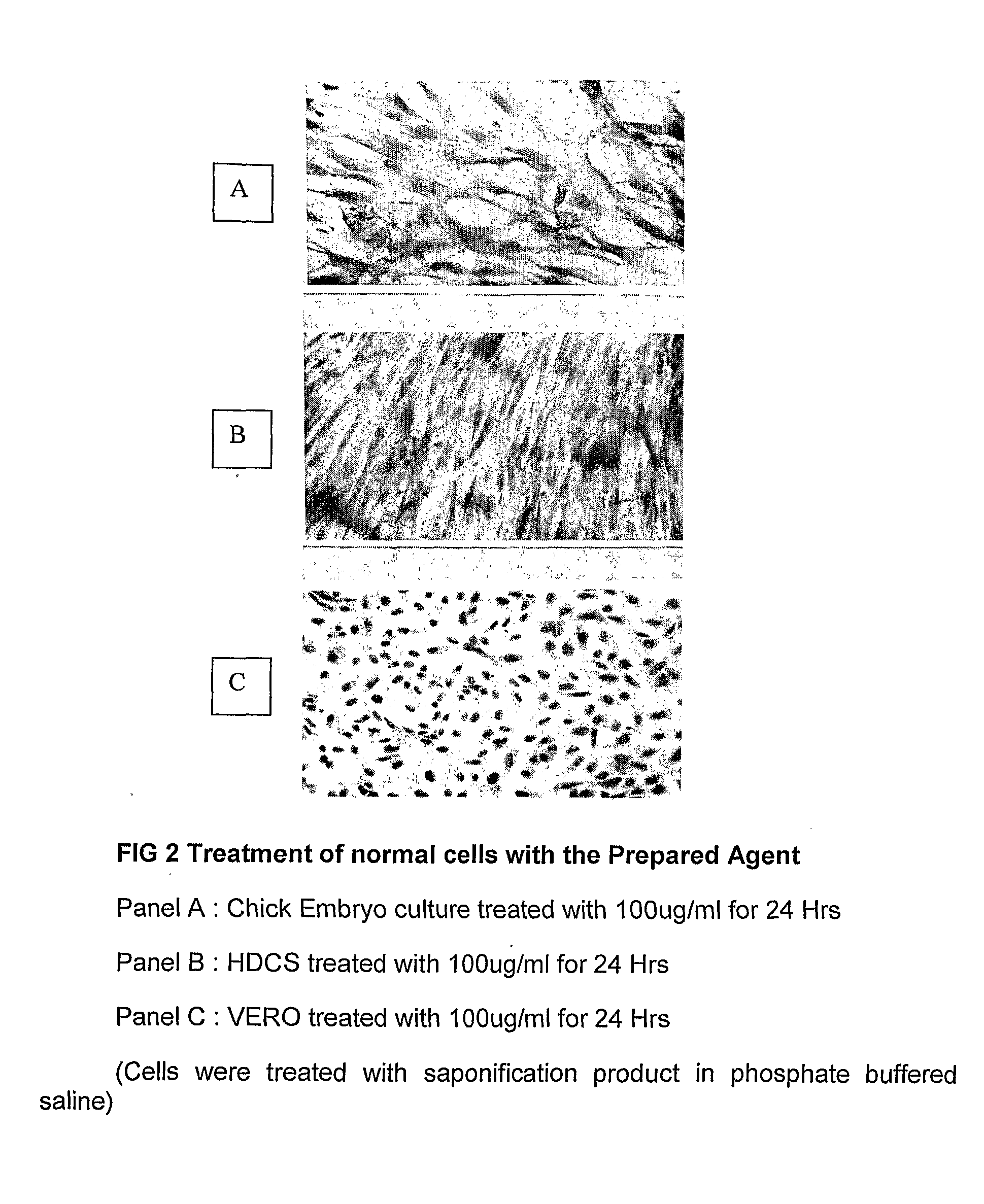

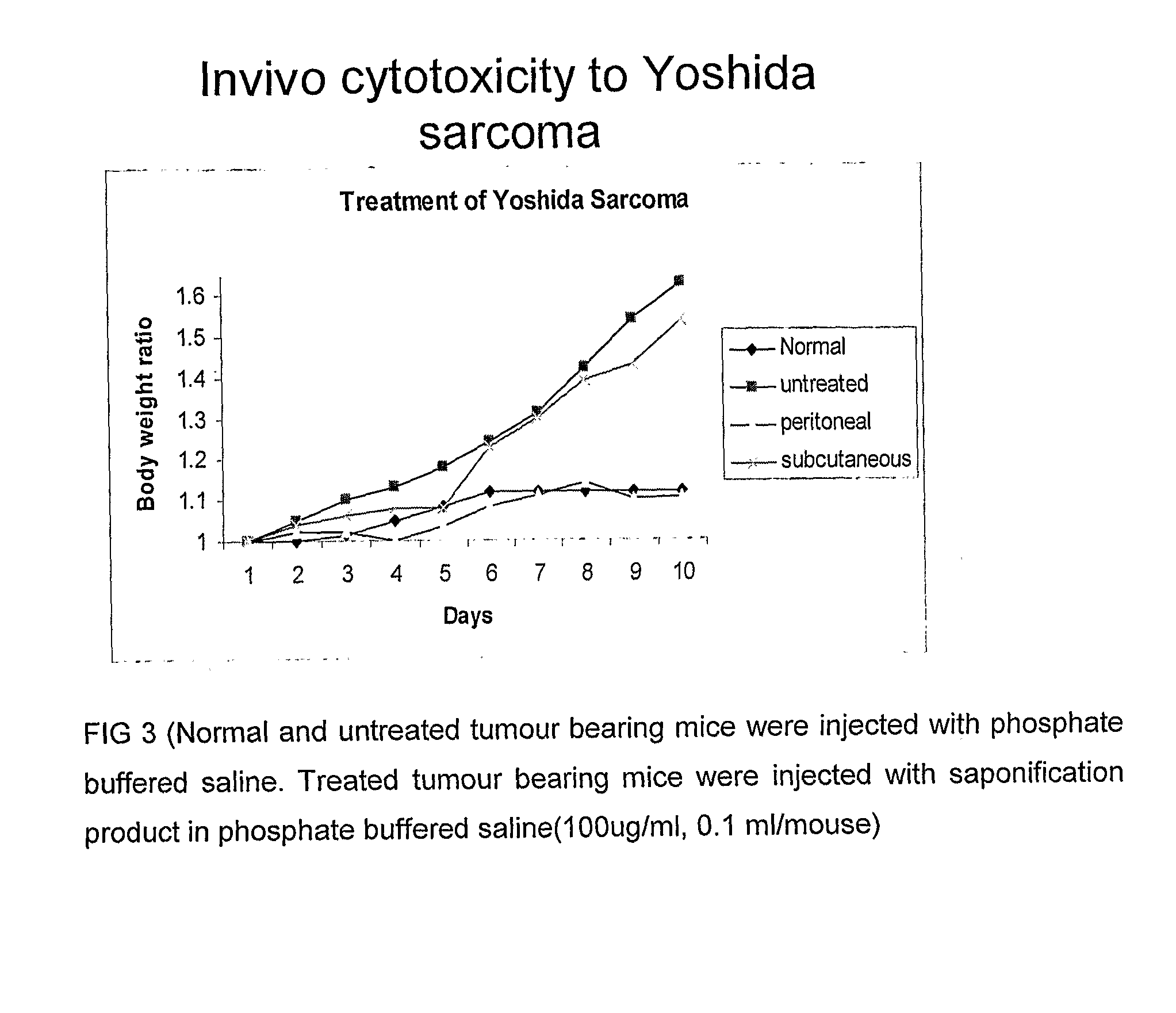

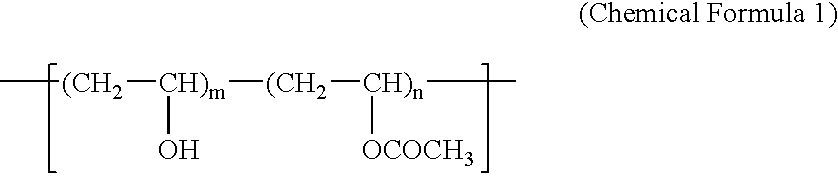

The present invention is related to the use of novel agents effective for differential killing of abnormal cells such as cancer cells without damaging or being toxic to normal cells. Further these agents may be used for treating a host of ailments including various types of cancers, skin diseases, prevention and reversal of ageing process, prevention of inflammatory reactions, cure of bacterial infections, cure of fungal infections, etc. The agents are prepared by air oxidation of natural oils optionally in the presence of a catalyst wherein the isolated agents have Iodine value 40-60% of the starting oil, Saponification value 20-60 higher than that of the starting oil, Peroxide value 2-3 times that of the starting oil. These agents on saponification and acidification yield free fatty acids and ether linked fatty acid dimmer wherein the dimmer also acts as an active.

Owner:REGAIN BIOTECH PVT

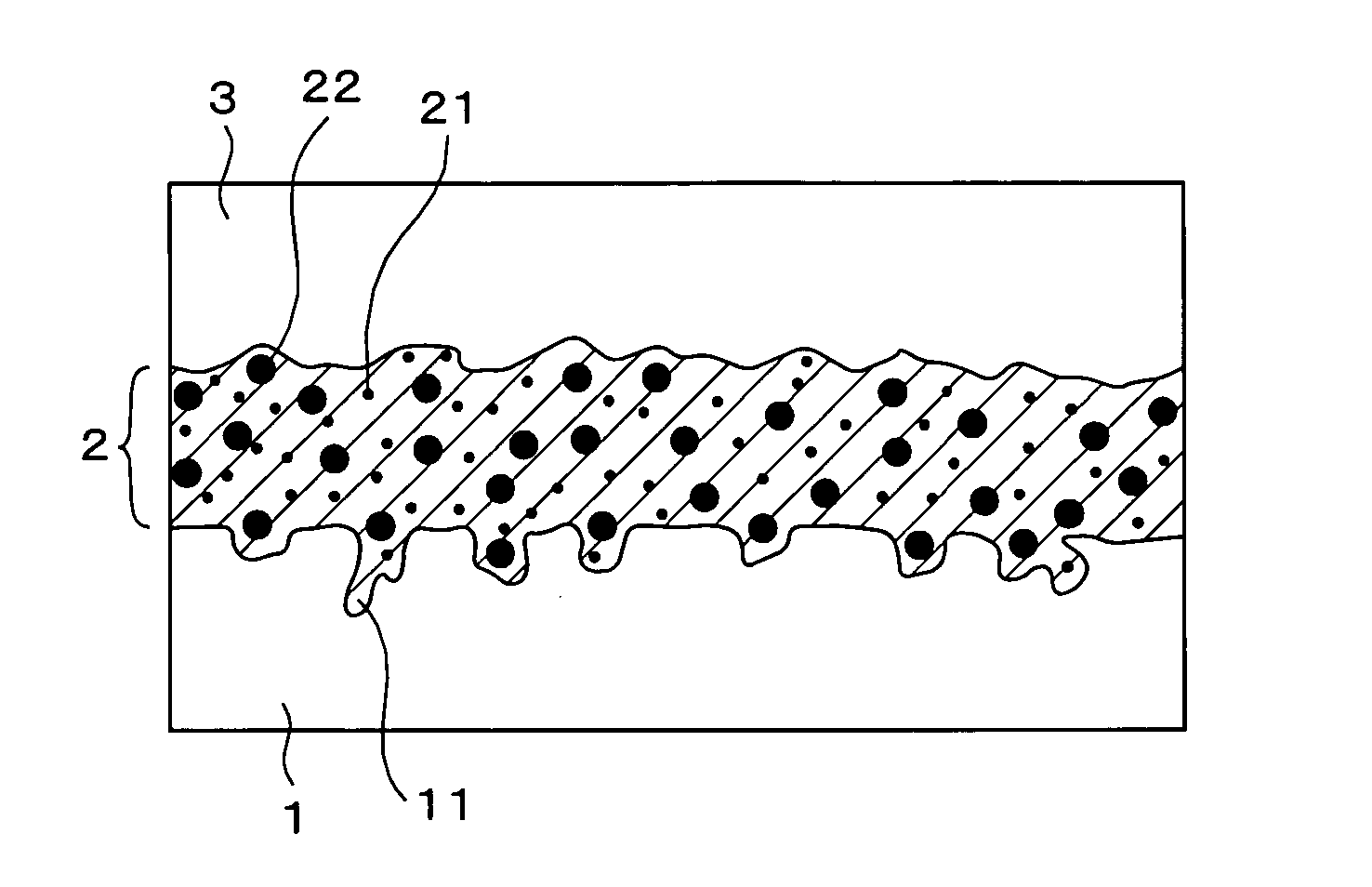

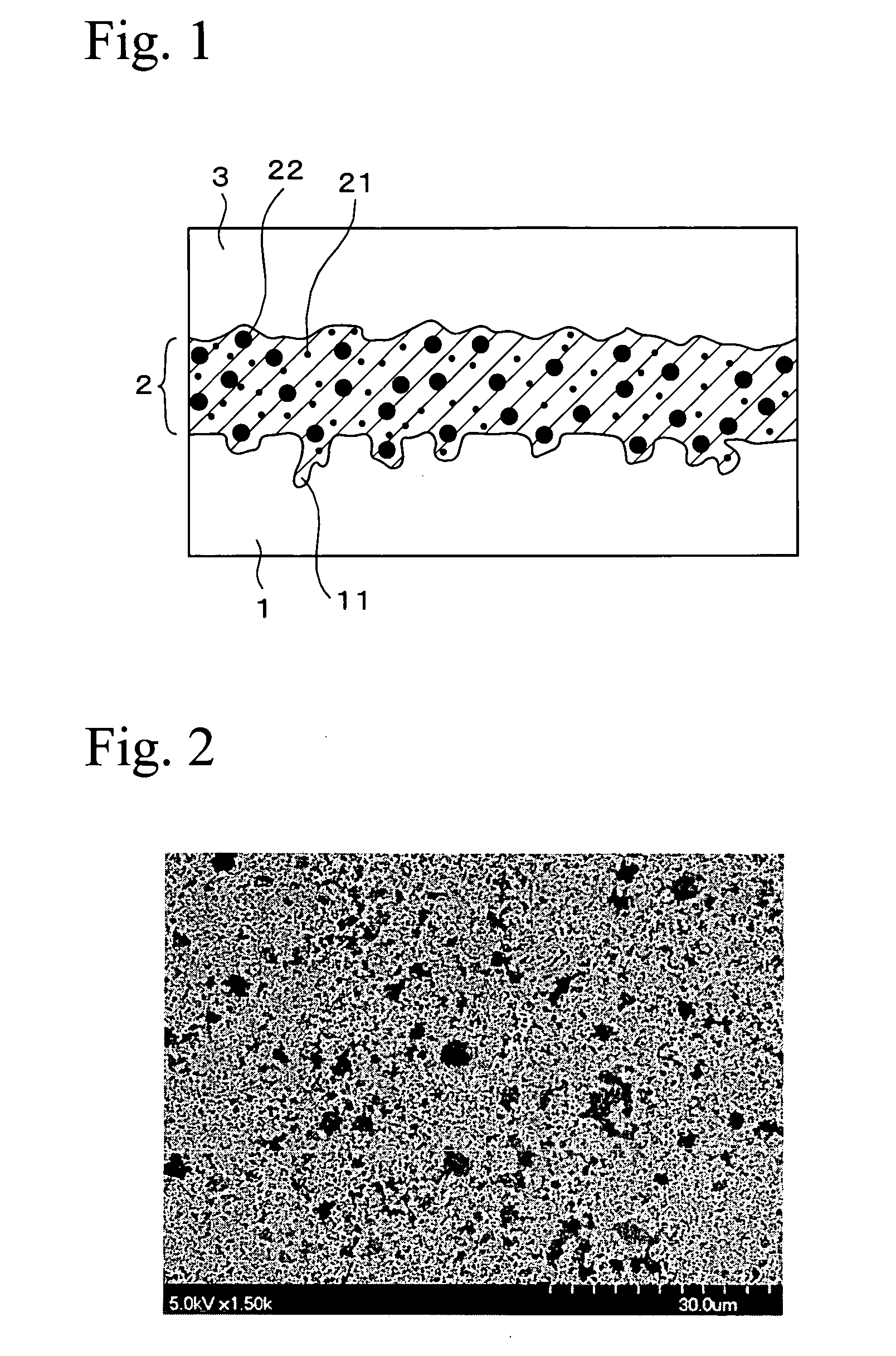

Electrode for electric double layer capacitor

InactiveUS20040130038A1Improve adhesionHigh resistivityLiquid electrolytic capacitorsSemiconductor/solid-state device detailsAdhesivePolyvinyl alcohol

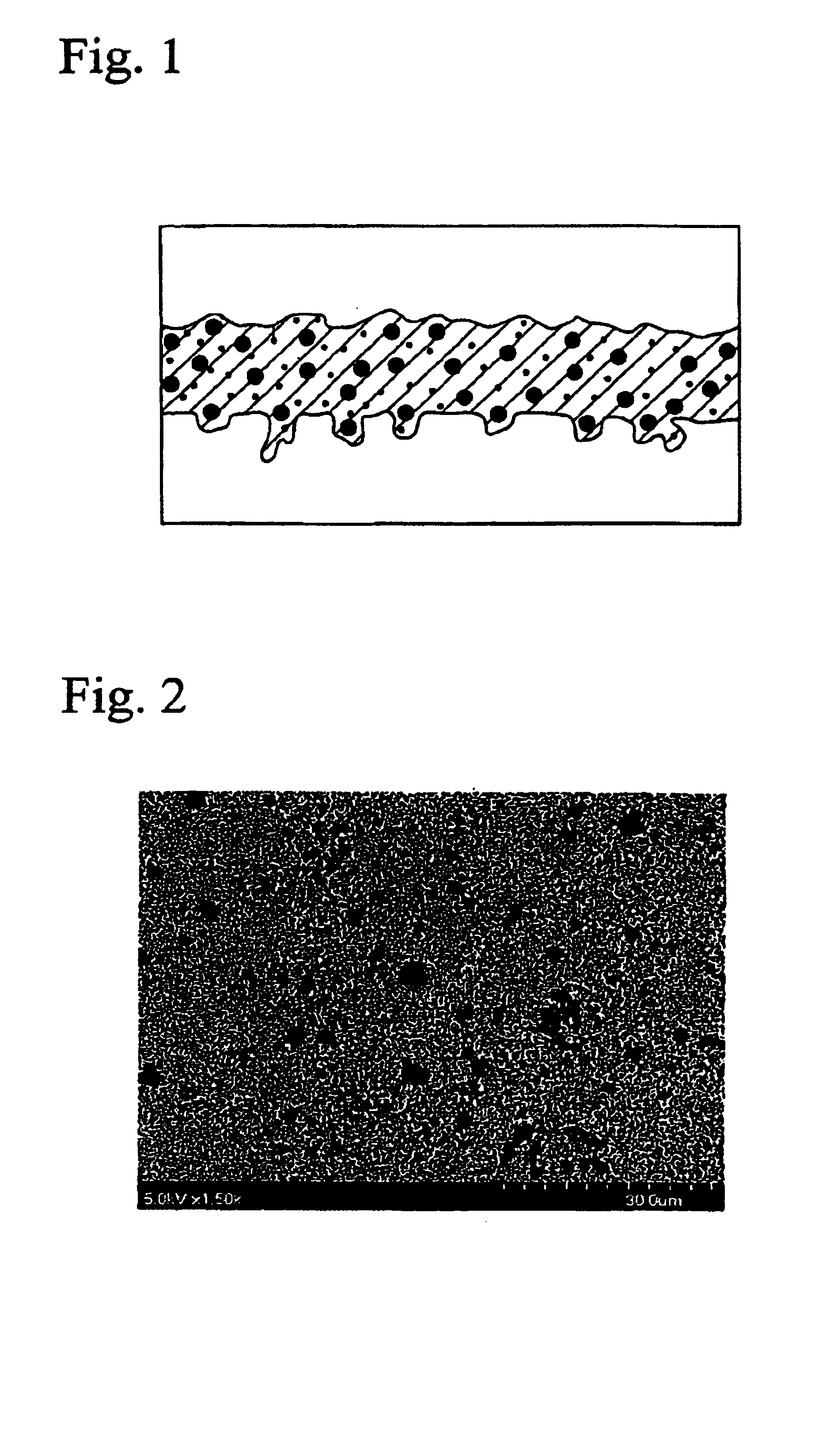

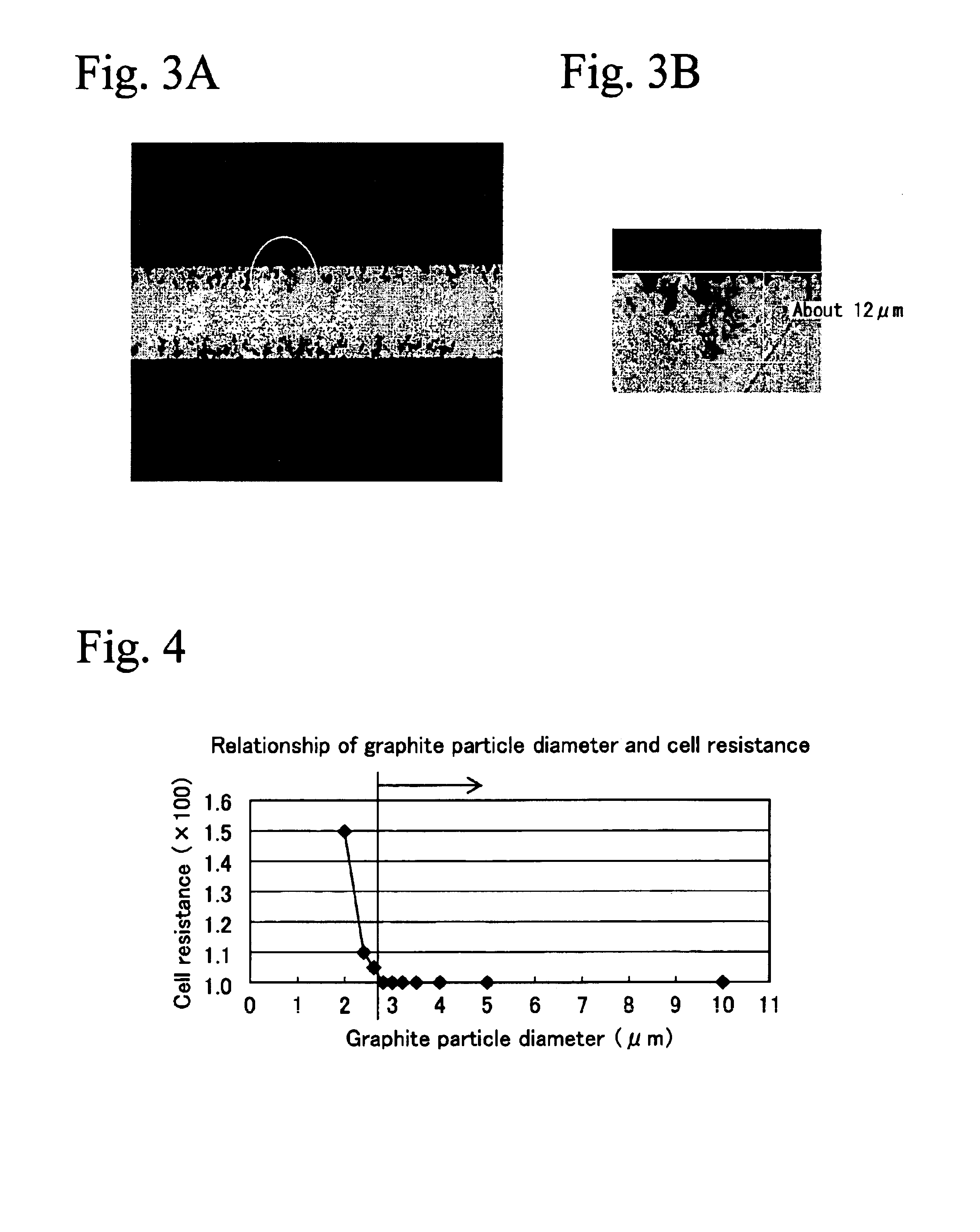

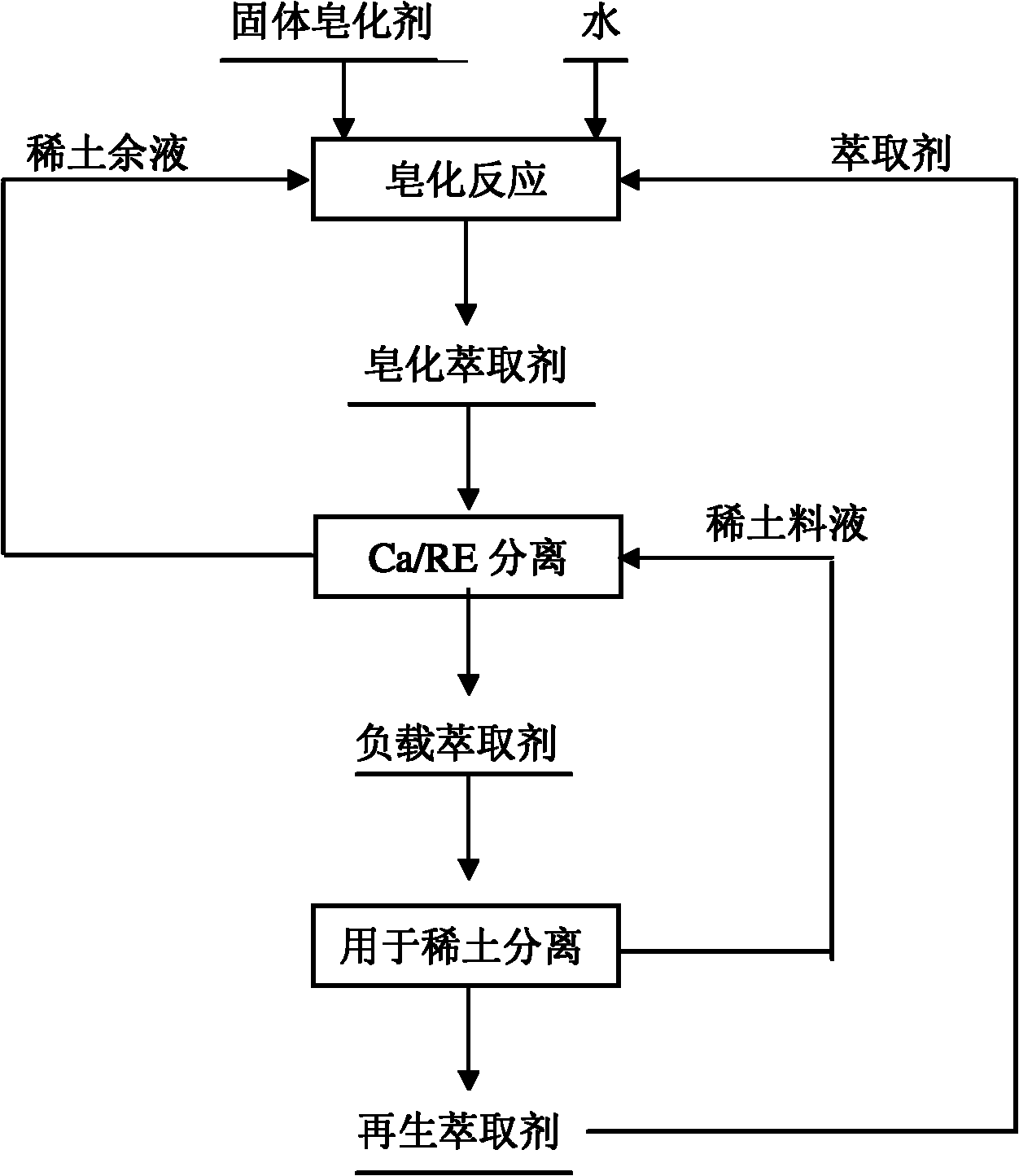

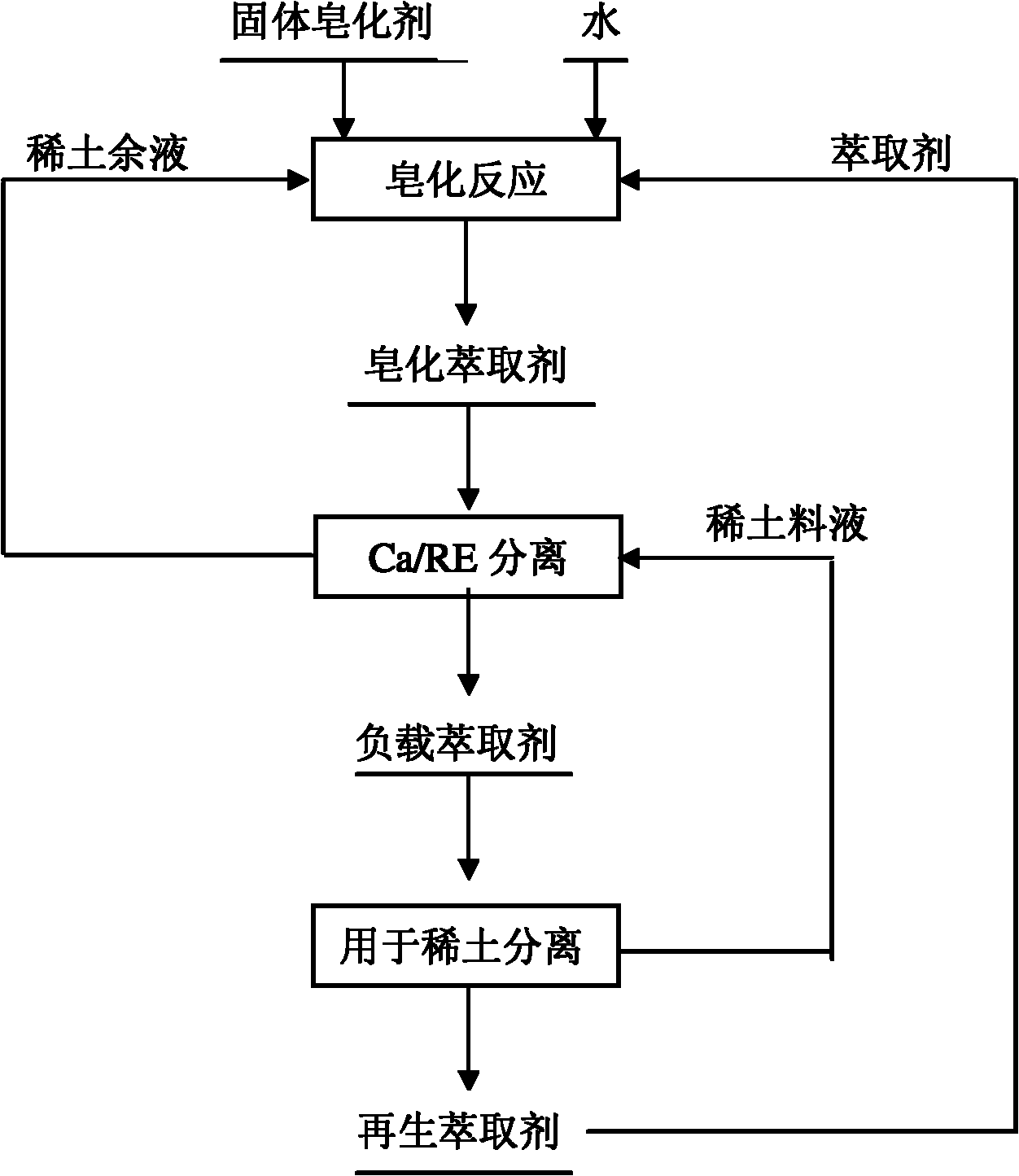

In an electrode for an electric double layer capacitor of the present invention, the peak value of particle size distribution of graphite particles added to a conductive adhesive is in a range of 2.6 to 3.2 mum, not less than 100,000 dimples having a largest outer diameter in a range of 4 to 10 mum and a depth in a range of 4 to 15 mum are formed on the surface of the collector sheet per 1 cm<2>, and the occupied area of the dimples to the entire surface area of the collector sheet is not more than 50%. By determining the saponification value of polyvinylalcohol which is used as a binder component of the conductive adhesive in a range of 90.0 to 98.5, adhesiveness of the collector sheet and the electrode forming sheet is improved. Furthermore, by substituting H atoms contained in the polyvinylalcohol with Si atoms, adhesiveness of the collector sheet and the electrode forming sheet can be further improved.

Owner:DAIDO METAL CO LTD

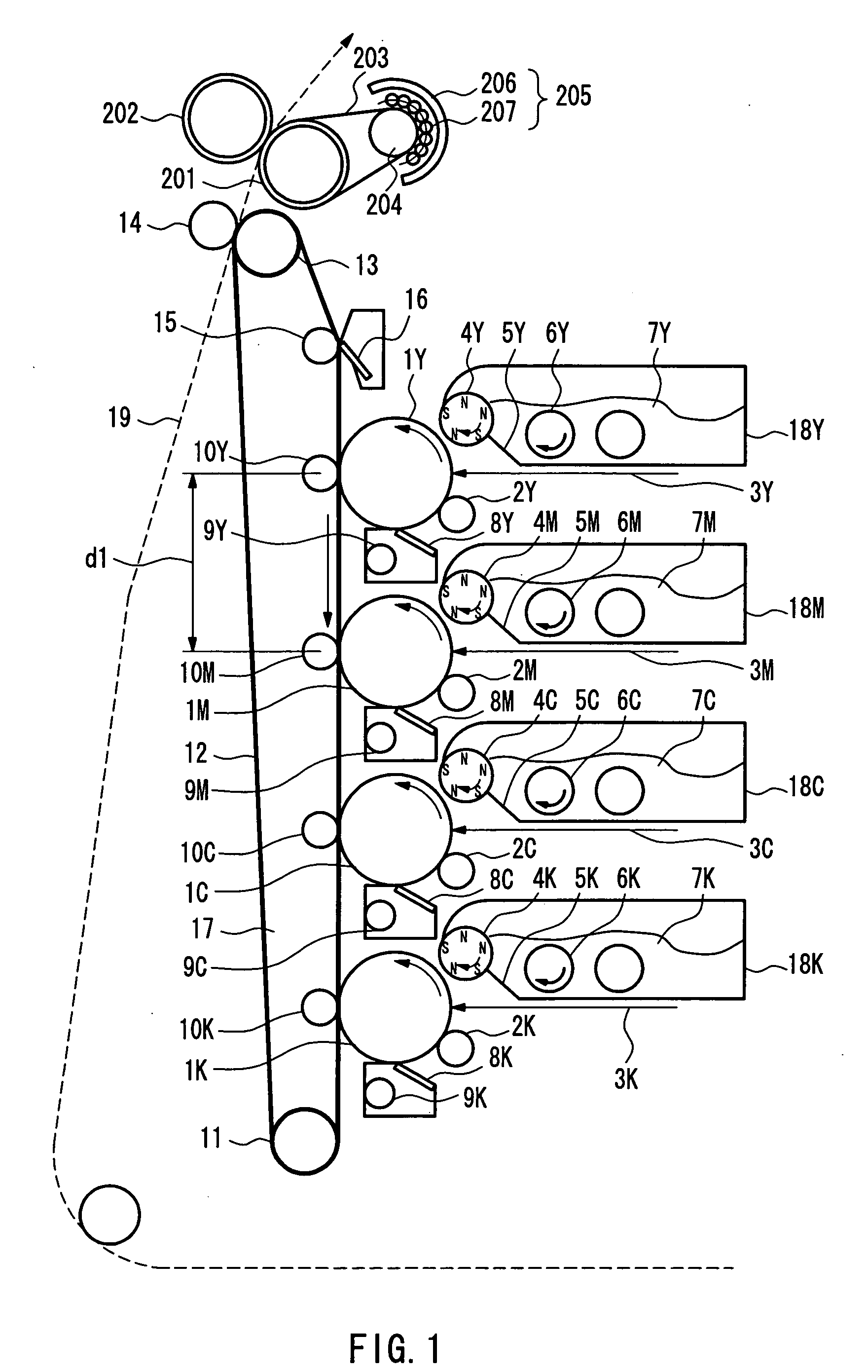

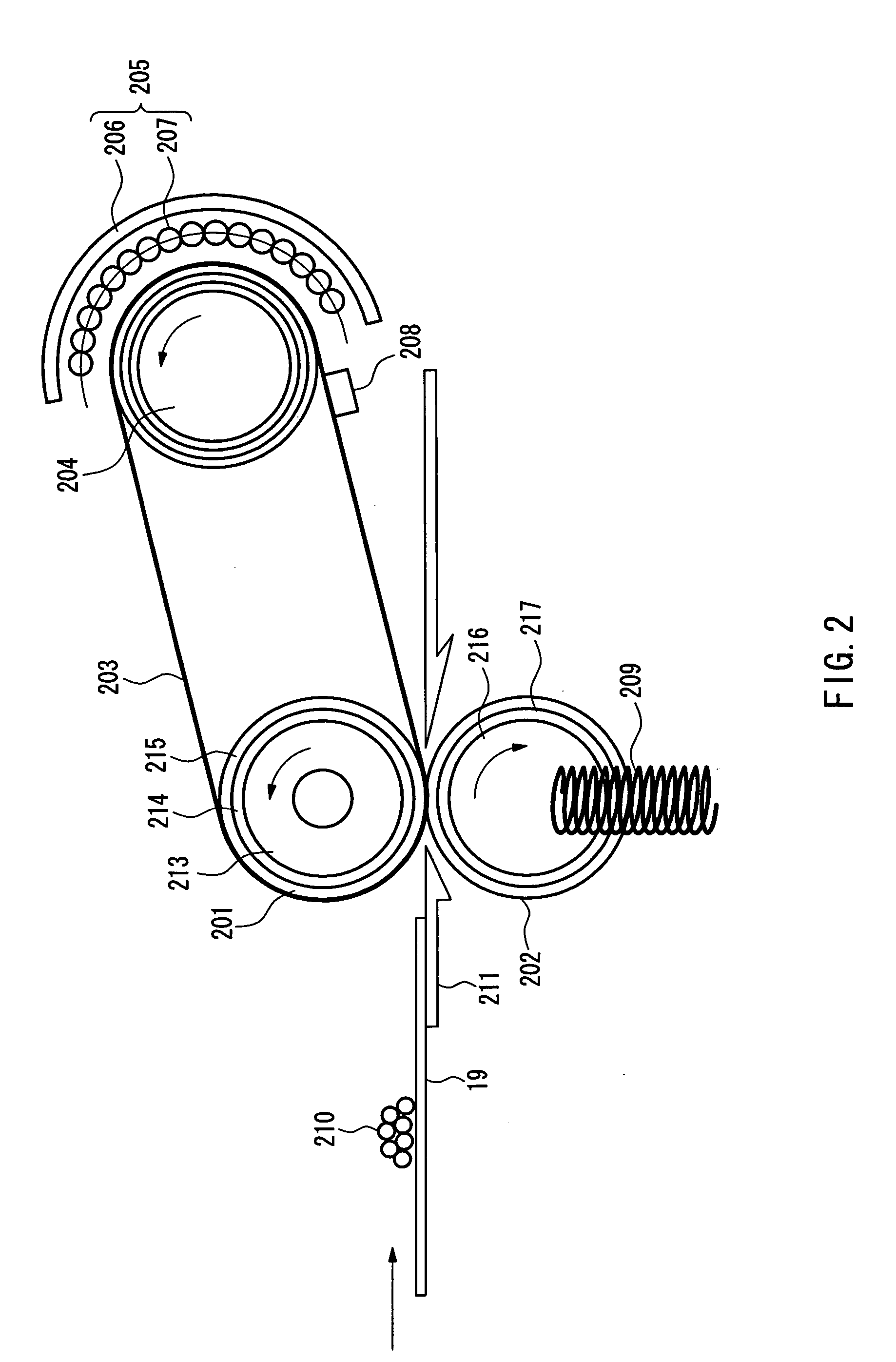

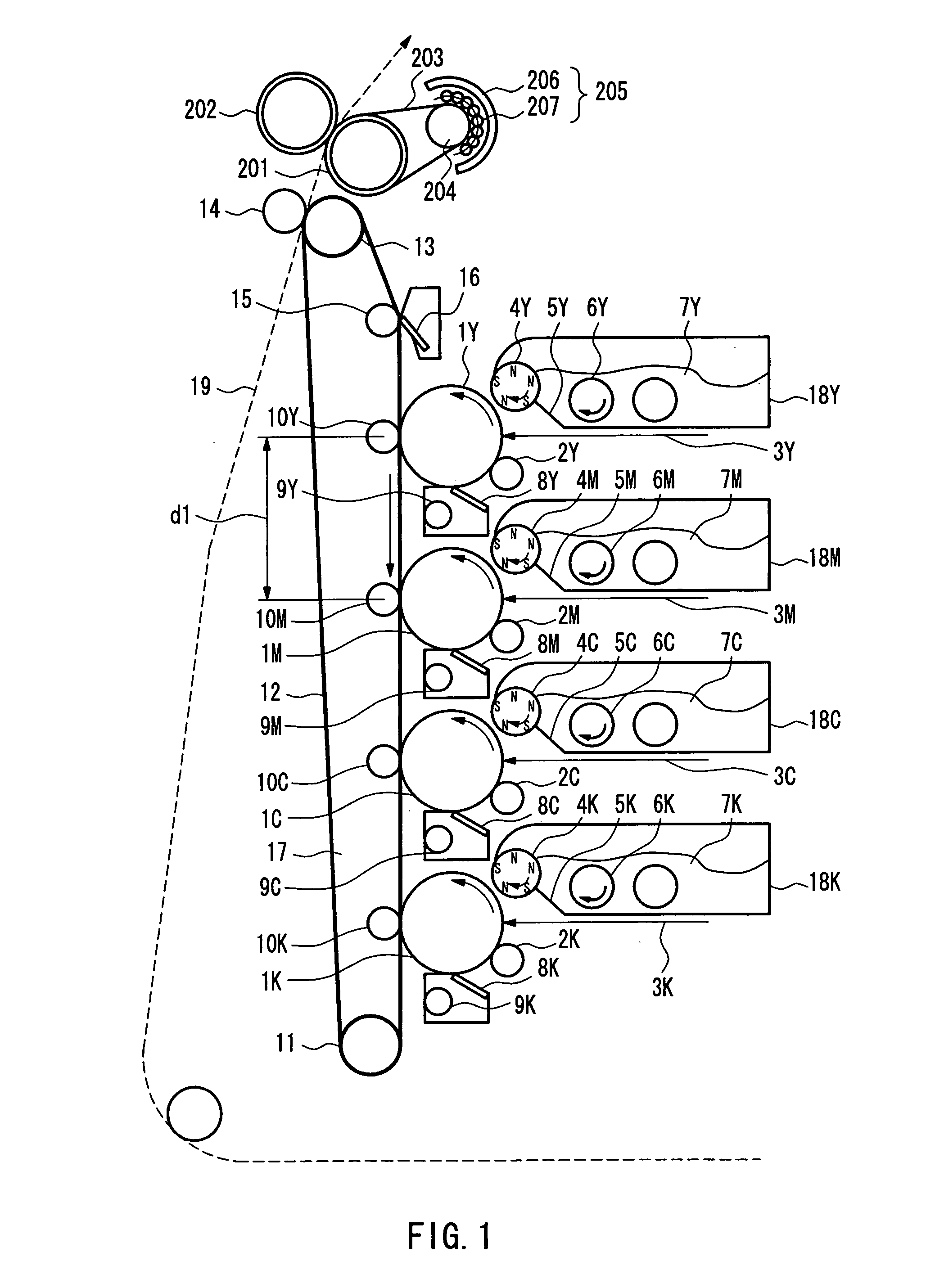

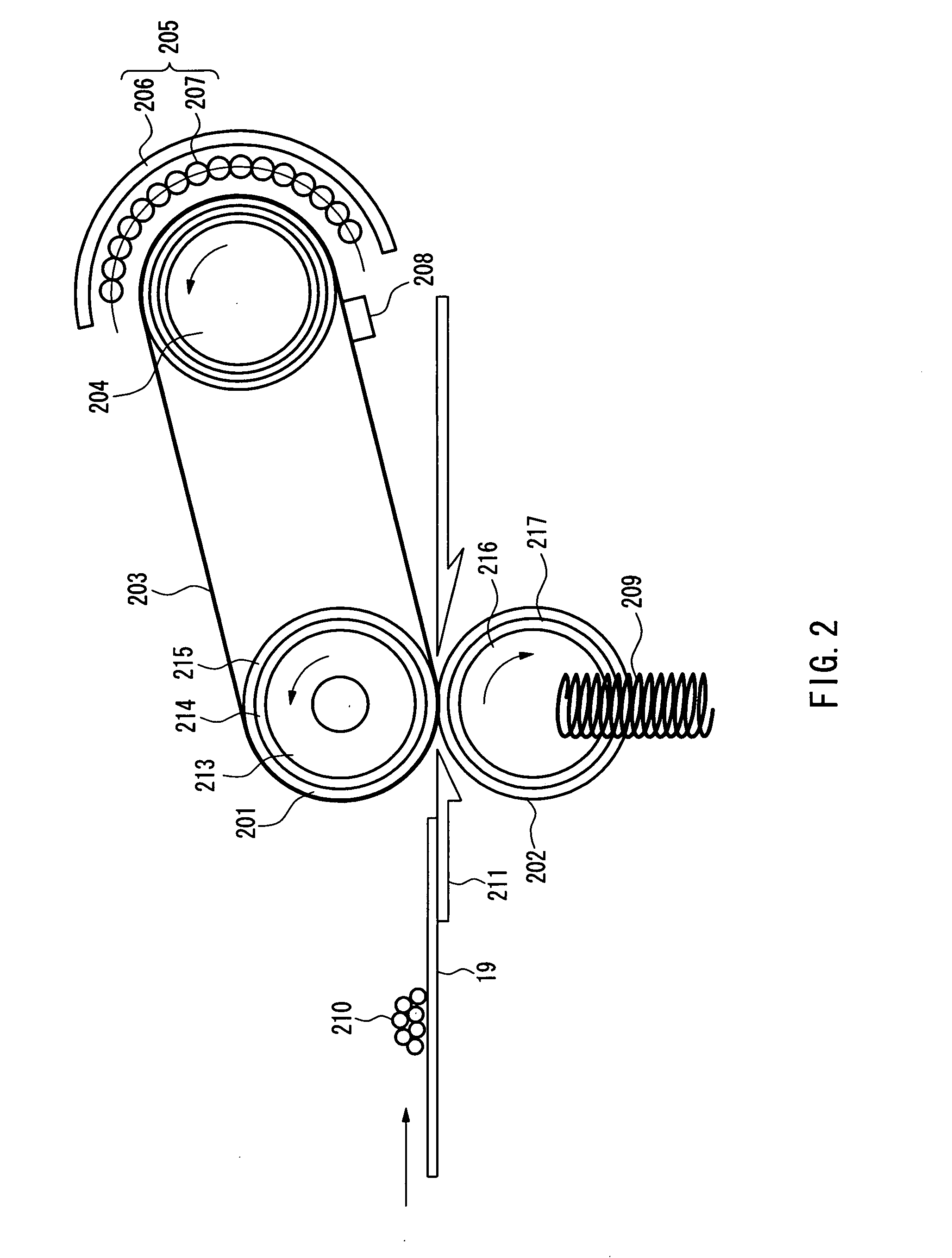

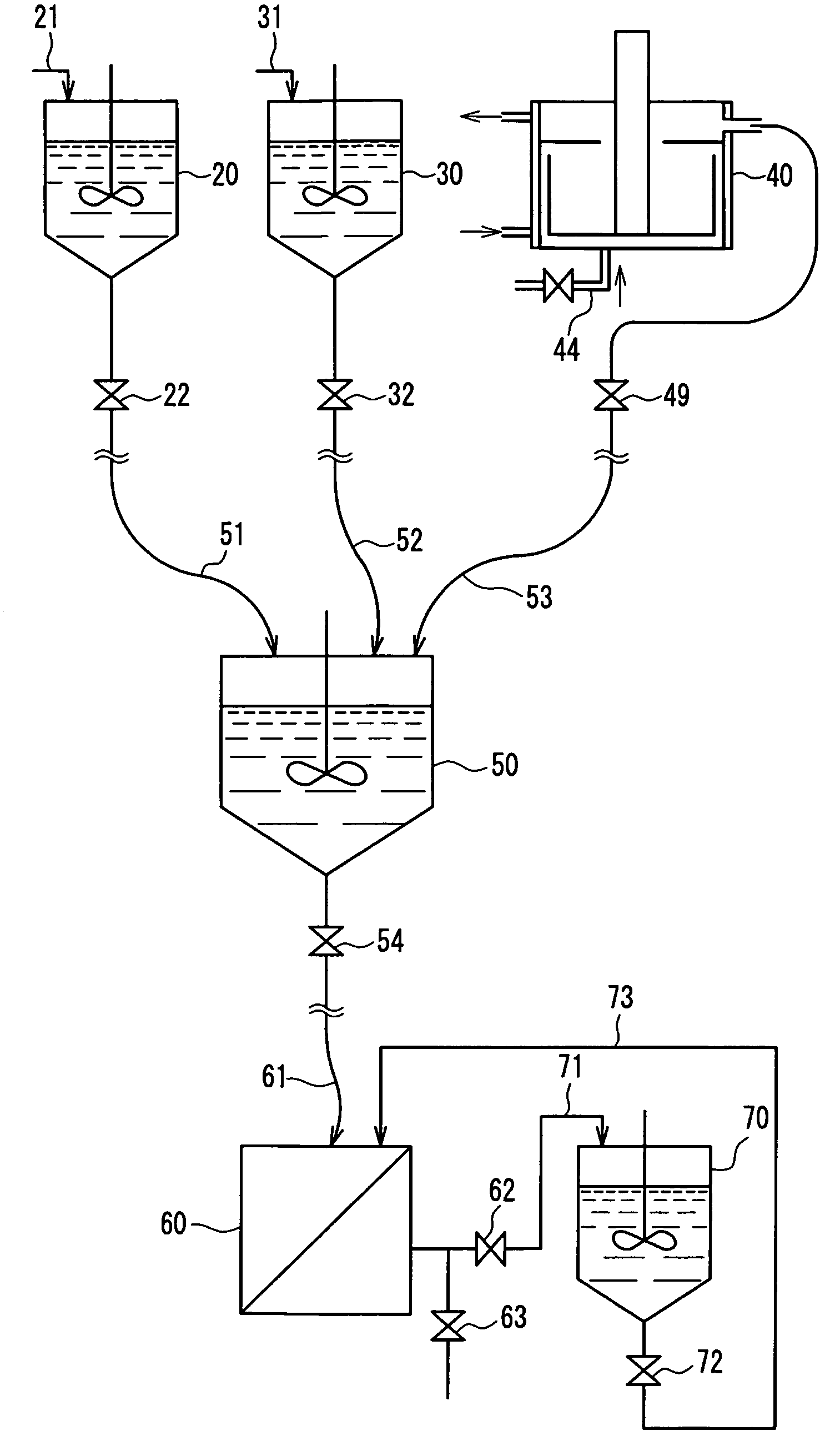

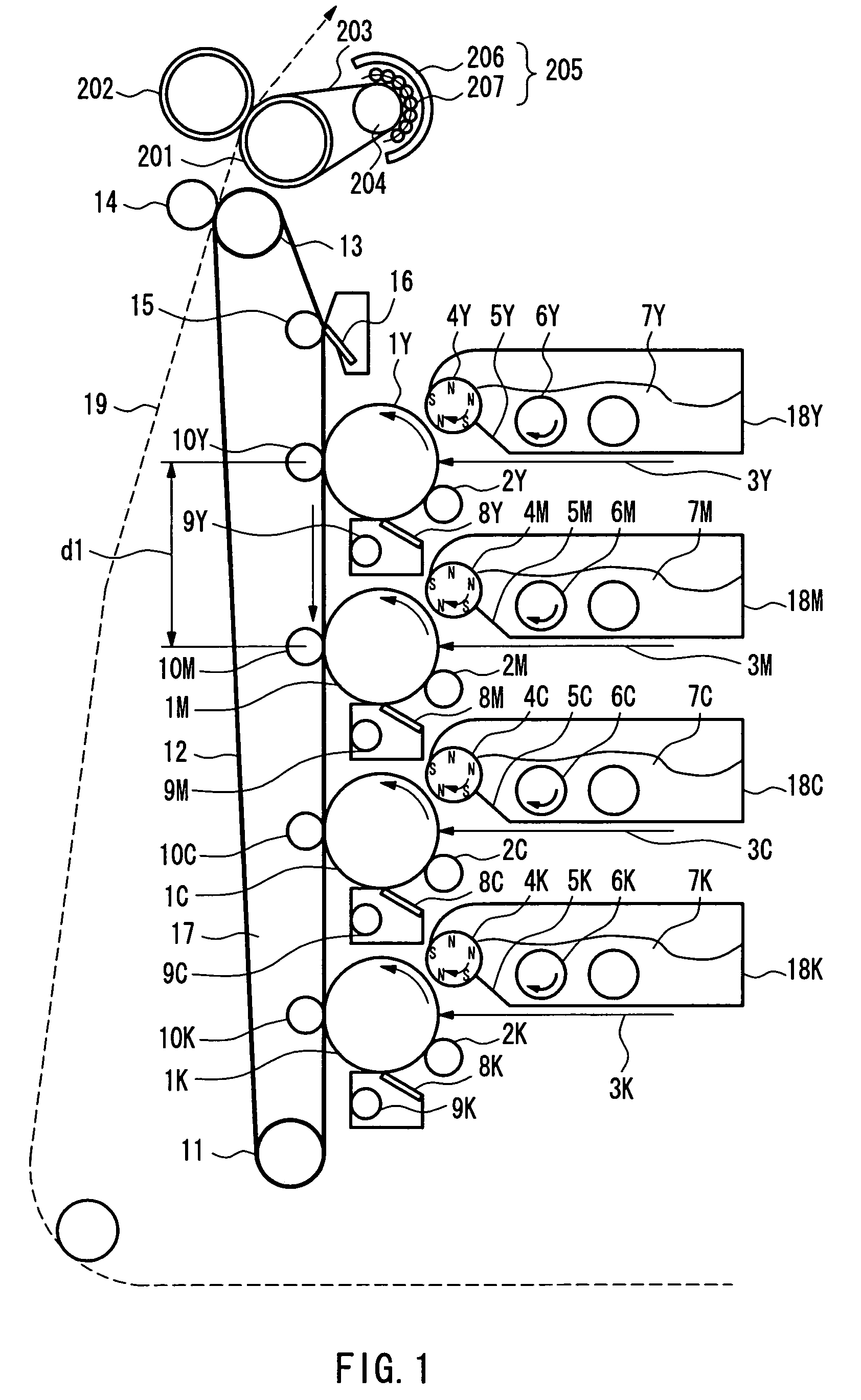

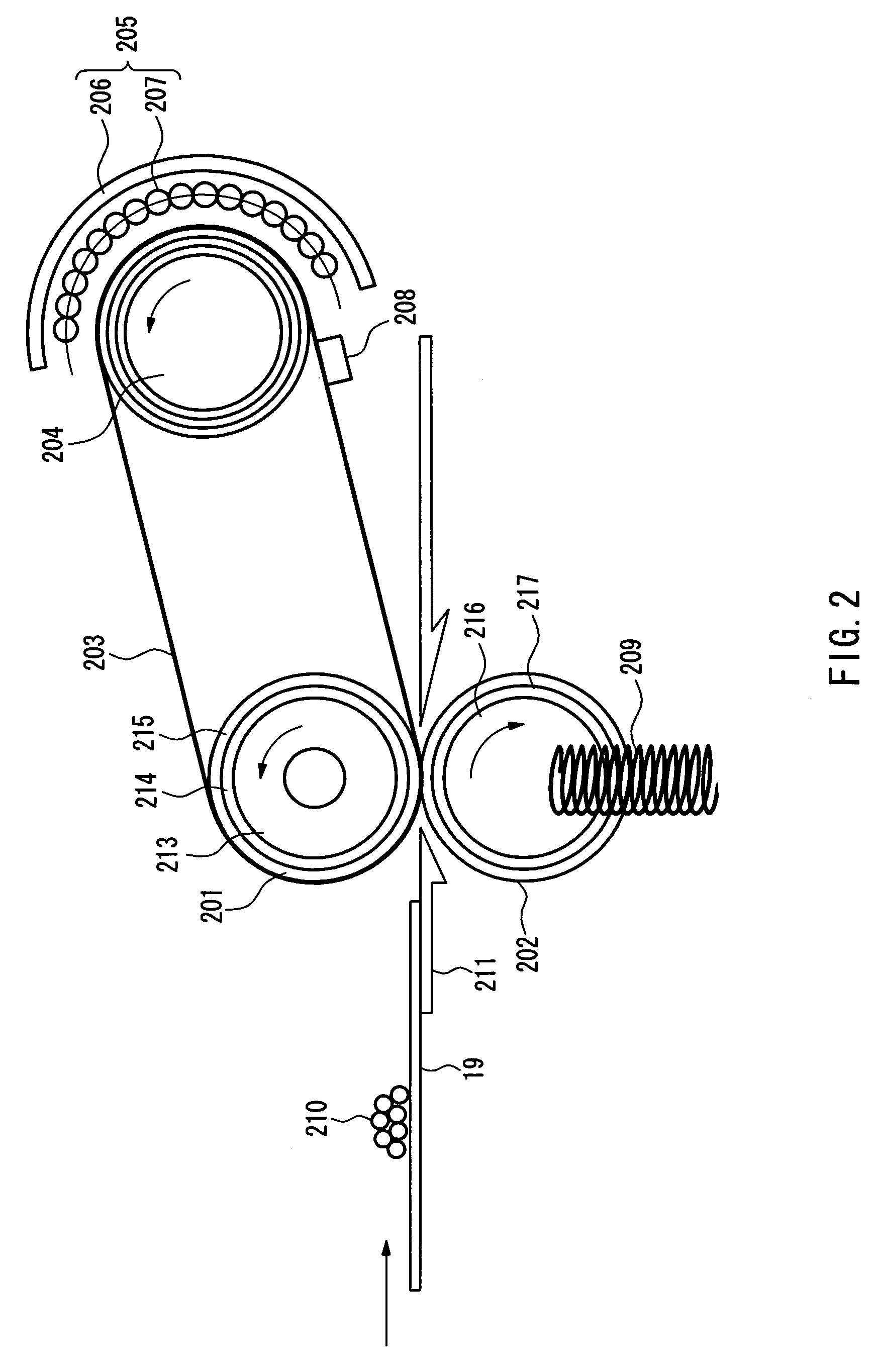

Two-component developer and method of forming image therewith

InactiveUS20060014094A1Increased durabilitySuitable negative chargeabilityDevelopersElectrographic process apparatusHydroxystearic AcidCarboxylic acid

The two-component developer of the present invention comprises a carrier coated with a resin composition containing an aminosilane coupling agent and a fluorine-modified silicone resin, and a toner that contains a wax selected from among the following A to D, which increases OHP light transmissivity, prevents offset, and prolongs service life. A) A synthetic wax with a DSC endothermic peak temperature of 80 to 120° C. and an acid value of 5 to 80 mgKOH / g, obtained by reacting a C4 to C30 long chain alkyl alcohol, an unsaturated polycarboxylic acid or anhydride thereof, and an unsaturated hydrocarbon wax B) An ester wax with a DSC endothermic peak temperature of 50 to 120° C., an iodine value of 25 or less, and a saponification value of 30 to 300 C) A fatty acid amide wax selected from among C16 to C24 aliphatic amide waxes and alkylene bis fatty acid amides of saturated, monounsaturated, or diunsaturated fatty acids D) A fatty acid ester wax selected from among hydroxystearic acid derivatives, glycerol fatty acid esters, glycol fatty acid esters, and sorbitan fatty acid esters.

Owner:PANASONIC CORP

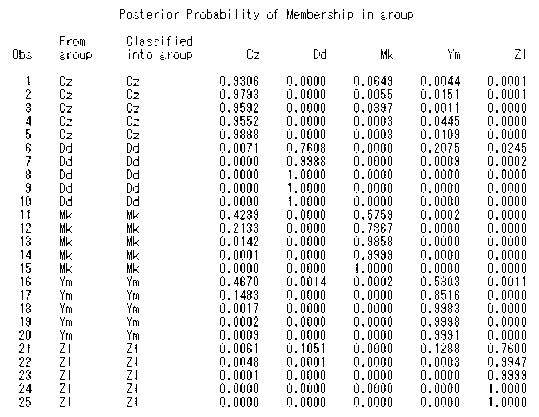

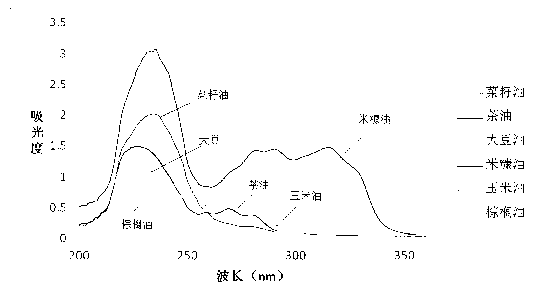

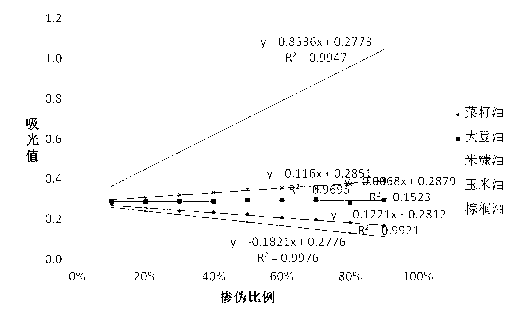

Detection method for adulterated tea oil

ActiveCN103217393APrevent impersonationProtect interestsColor/spectral properties measurementsFull waveRefractive index

The invention relates to the technical field of edible oil, and provides a method for detecting the adulterated tea oil. The method comprises the following steps of: firstly, establishing a refractive index, an iodine value, a saponification value and an oleic acid content adulteration detection model, determining the adulteration type by detecting the sample, then, determining an adulteration quantity model through ultraviolet spectrum full-wave scanning, and comparing the data to obtain the determined adulteration quantity. According to the method provided by the invention, not only can the adulteration type for the tea oil be identified, but also the adulteration quantity can be detected, so that cheap edible oil can be prevented from being used for personating expensive tea oil. The method provided by the invention has the characteristics of being economical and simple, excellent in repeatability and high in accuracy, and the like, can be practically used for the teal oil adulteration detection work, and can guarantee and safeguard the benefits of consumers.

Owner:SOUTH CHINA AGRI UNIV

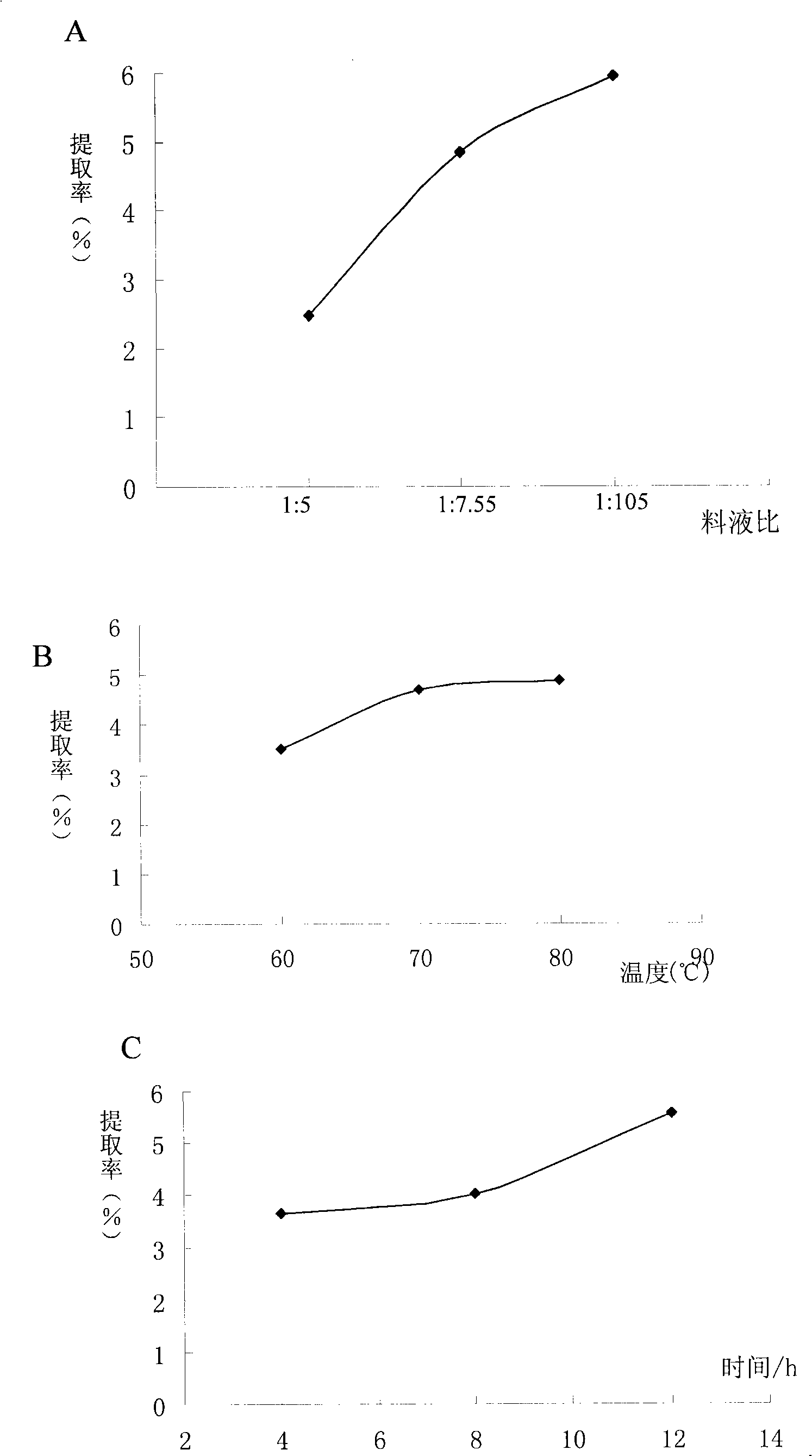

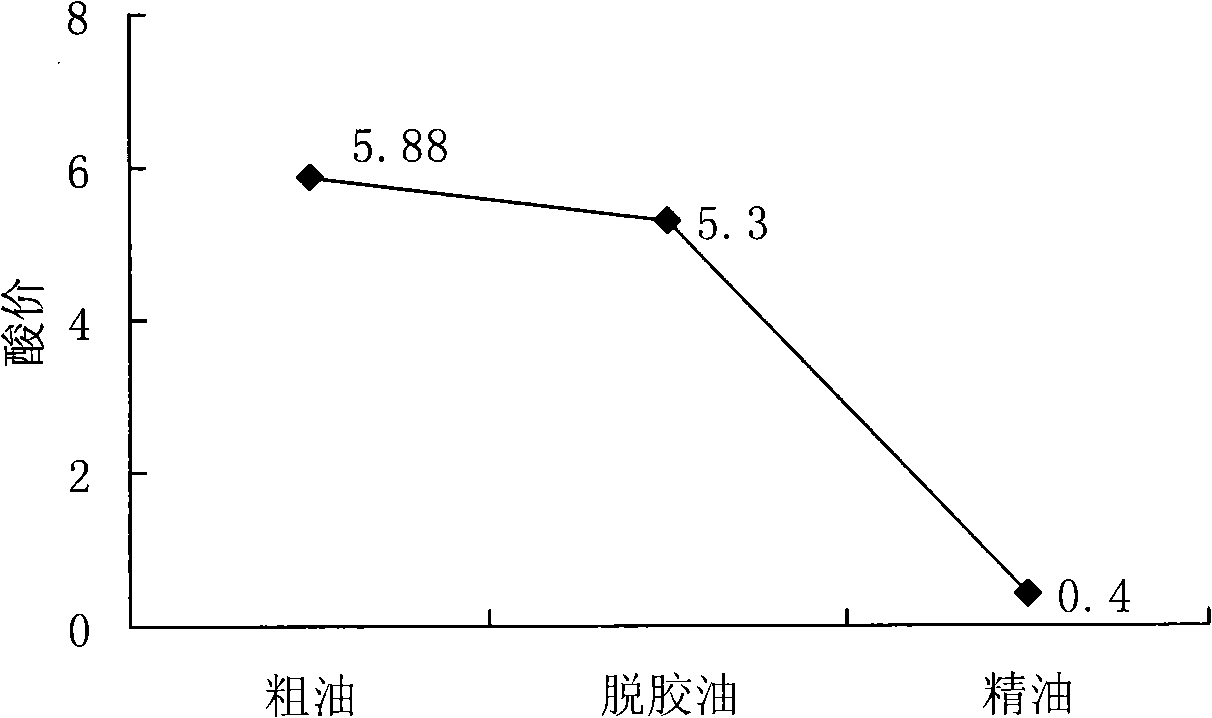

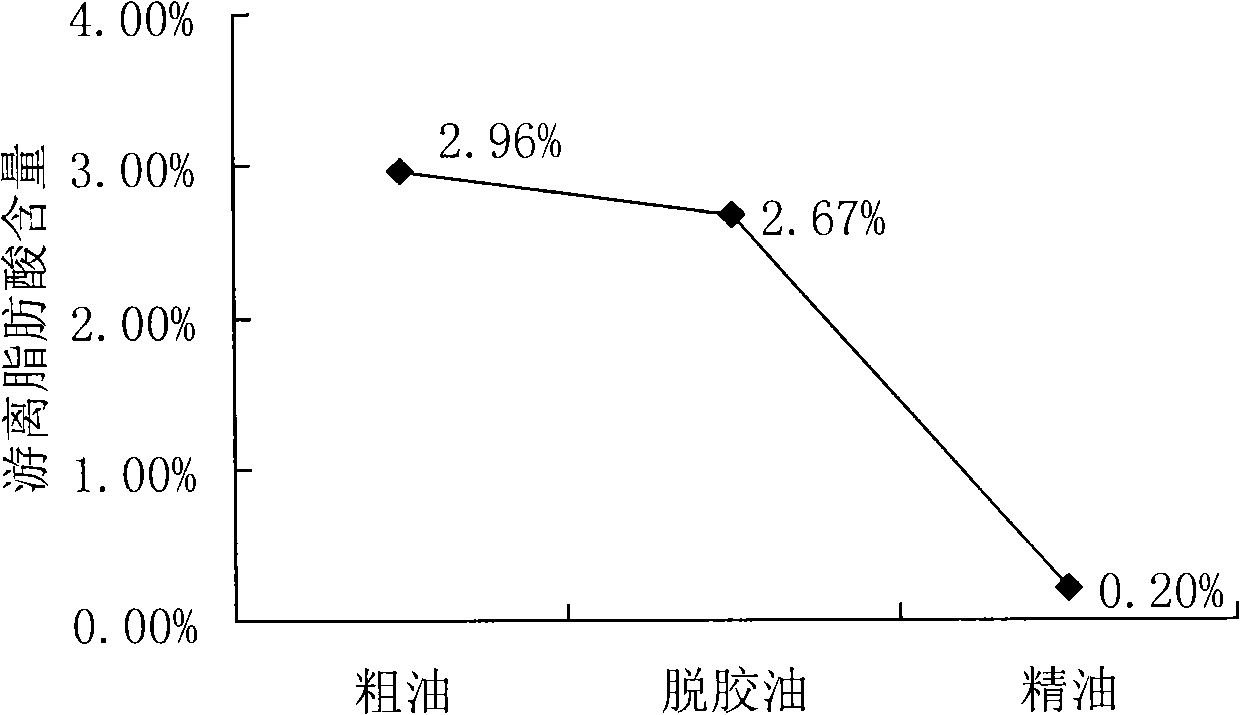

Oat oil, extracting process thereof and applications

The invention discloses an oat oil and an extraction method and application thereof. The oat oil is extracted by the following steps: firstly, the oat bran is added in petroleum ether and is reflux-extracted under 60-80 DEG C for 4-12 hours to get extraction liquid; secondly, oat oil crude oil is got by removing the residue in the extraction liquid and rotary evaporating to remove the petroleum ether. The method of the invention uses the bran which has the most oil content in the oat as raw material, uses the petroleum ether to extract, and has the unexampled advantages of little residual oil content, high oil extraction rate, low processing cost, good production conditions, and fully usage rate of oil plants and so on. The oat oil gained after being purified has the colors from yellowish green to brownish yellow, has good transparency, and has full-bodied natural oat fragrance. The physical and chemical indexes of acid valence, iodine valence and saponification value etc. have all met experimental design requirements, and the oat oil has the qualification to be taken as cosmetics additive.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

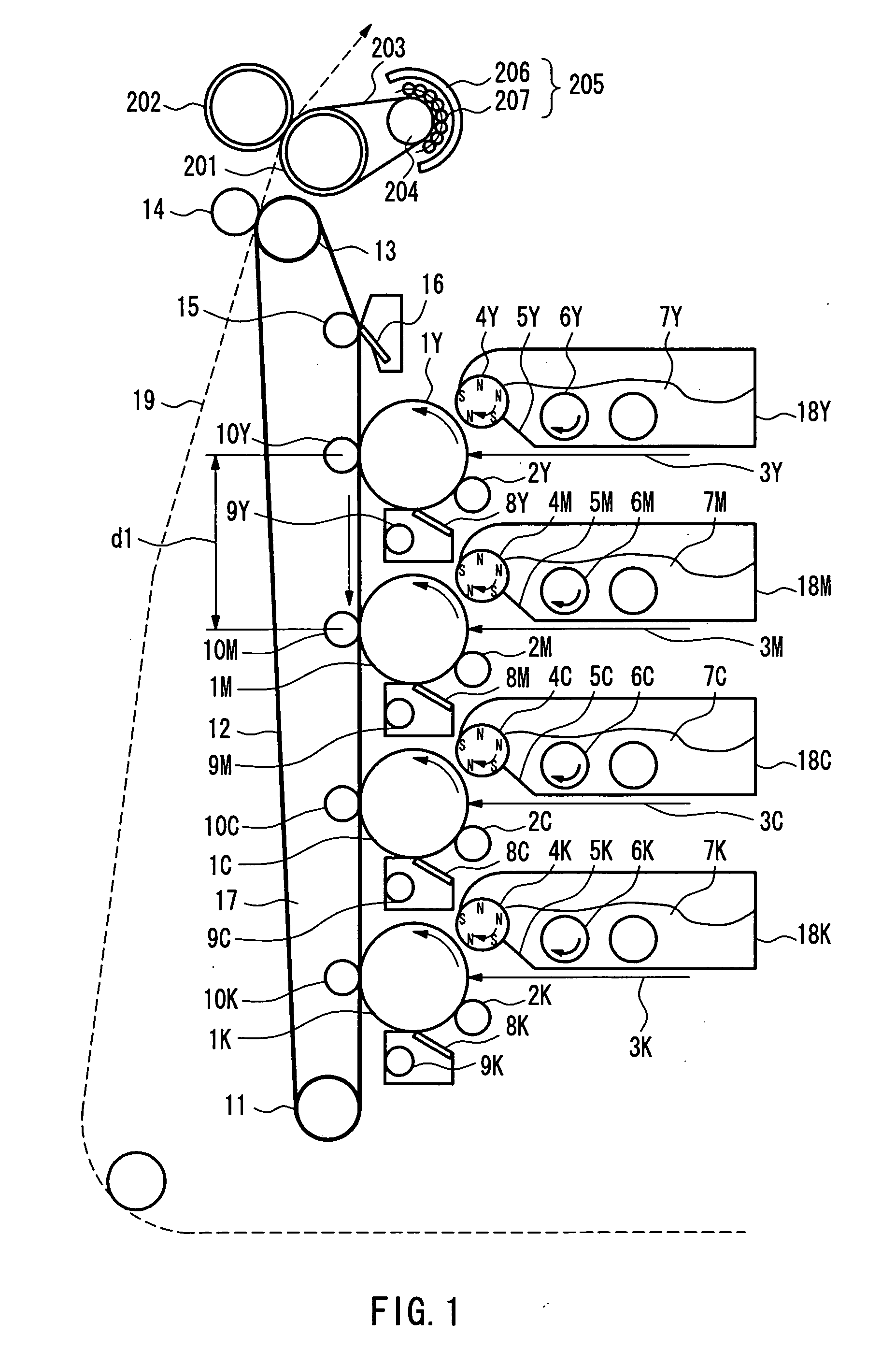

Toner, process for producing toner, two-component developing agent and image forming apparatus

InactiveUS20060263711A1Solution to short lifeHigh-temperature offset resistanceDevelopersCarbon numberCarboxylic acid

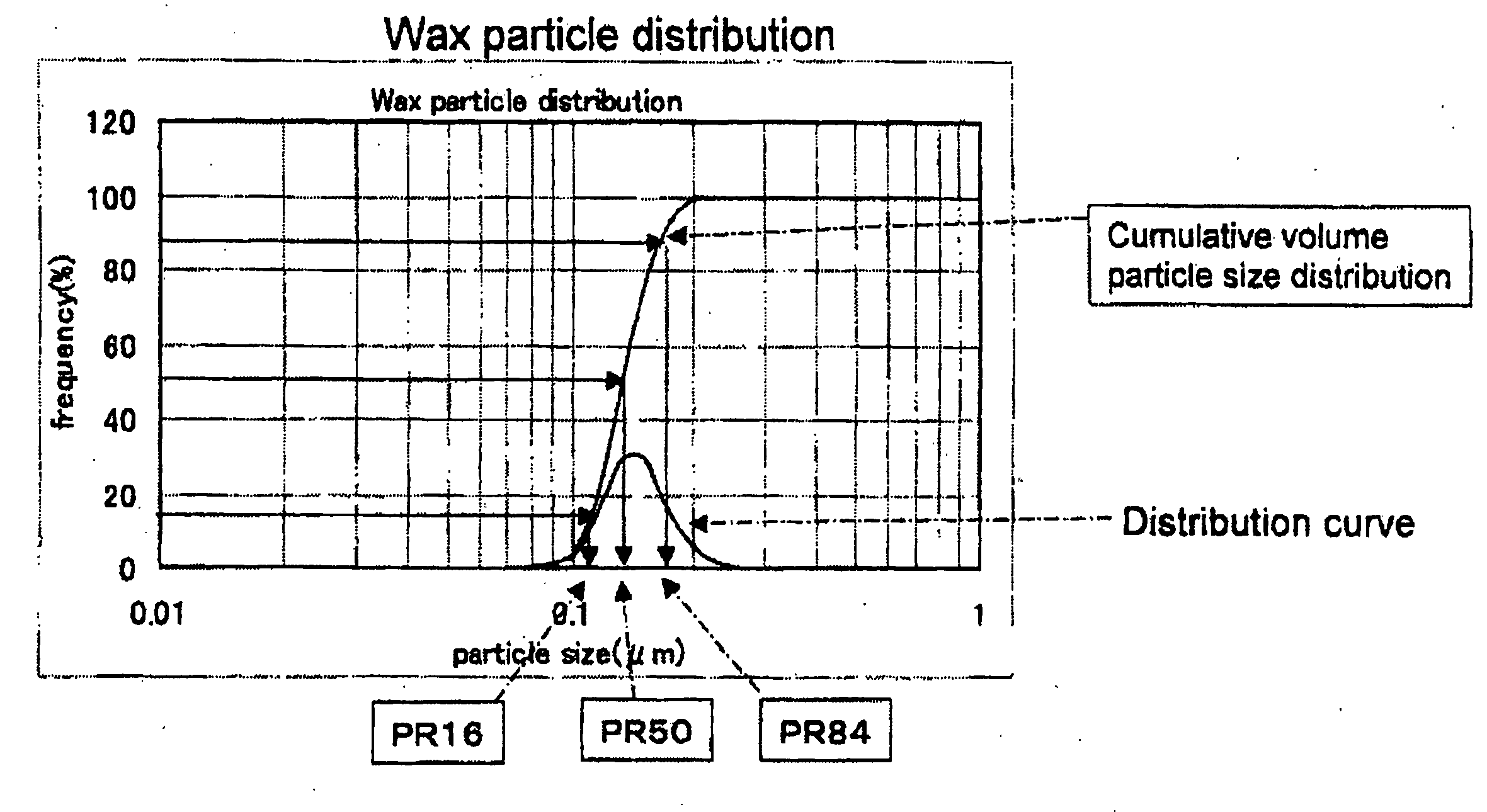

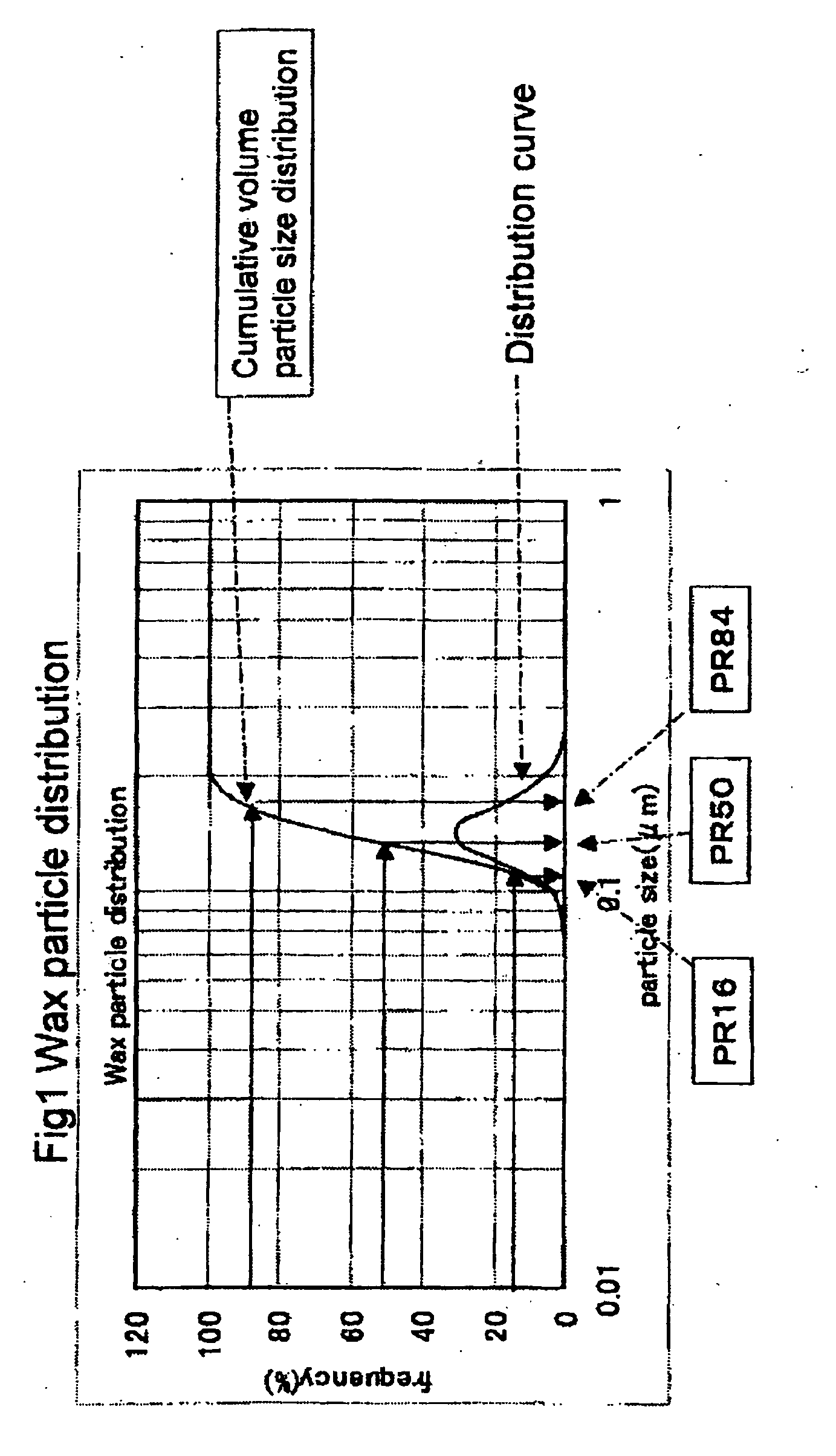

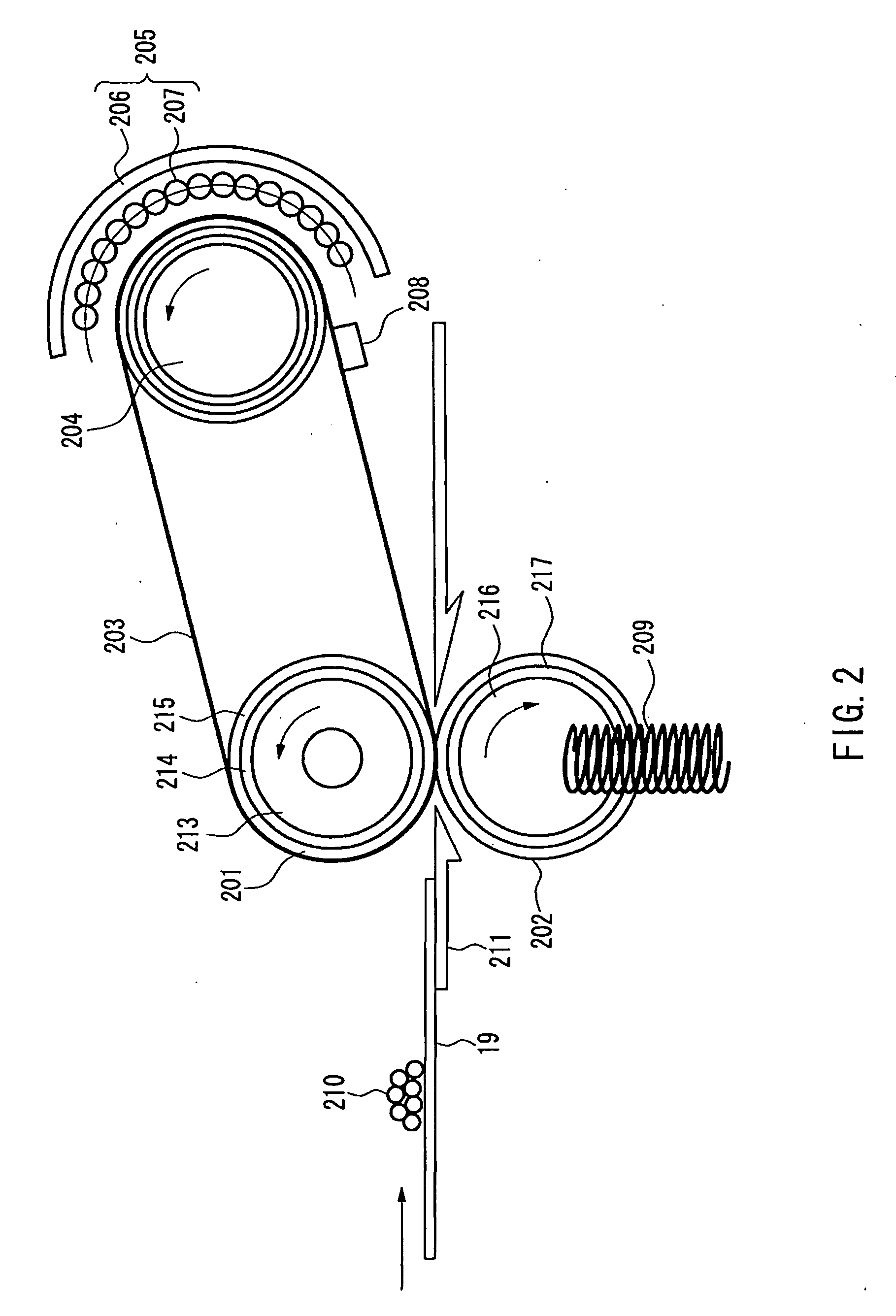

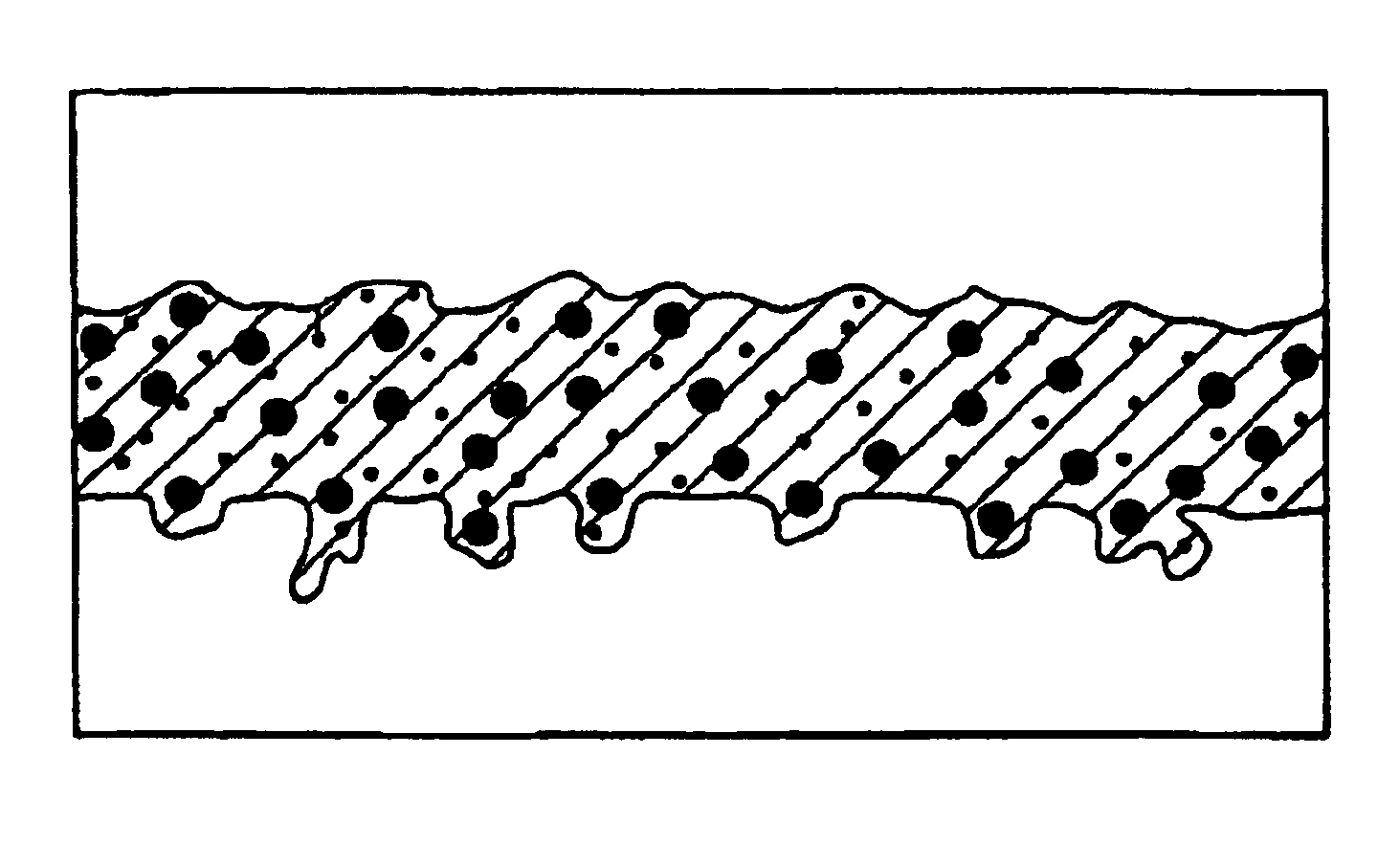

Toner of the present invention includes aggregated particles formed by aggregating at least resin particles, pigment particles, and wax particles in an aqueous medium in the presence of a water-soluble inorganic salt. The wax includes at least one selected from the following: ester wax that has an iodine value of not more than 25, a saponification value of 30 to 300, and an endothermic peak temperature (melting point) of 50° C. to 100° C. based on a DSC method; and wax that is obtained by a reaction of alkyl alcohol having a carbon number of 4 to 30, unsaturated polycarboxylic acid or its anhydride, and synthetic hydrocarbon wax, and has an acid value of 1 to 80 mgKOH / g and an endothermic peak temperature (melted point) of 50° C. to 120° C. based on the DSC method. The toner and a two-component developer can achieve oilless fixing that prevents offset without using oil while maintaining high OHP transmittance, can eliminate spent of the toner components on a carrier to make the life longer, and can ensure high transfer efficiency by suppressing transfer voids or scattering during transfer.

Owner:PANASONIC CORP

Method for preparing hydrocarbon fuel by using microwave-assisted catalytic soap decarboxylation method

InactiveCN102154023AEasy to purifyOxygen-containing compound preparationOrganic compound preparationBiodieselHydrocarbon mixtures

The invention relates to a method for preparing hydrocarbon fuel by using a microwave-assisted catalytic soap decarboxylation method. The method comprises the following steps of: (1) adding alkali liquor and low-carbon alcohol of which amounts are equal to or higher than a saponification value to waste animal fat or waste plant fat; (2) after saponification is ended, standing for demixing; (3) transferring fatty acid salt into a continuous type microwave cracking reactor; and (4) adding 40 percent by mass of phosphoric acid in a glycerol layer obtained in the step (2) while stirring. The invention has the technical effects that: (1) fatty acid salt hydrocarbon reaction is efficiently realized to finally obtain a hydrocarbon mixture; (2) various high-grade liquid fuels same as gasoline and aviation kerosene can be obtained through rectification, and various defects existing in the preparation of biodiesel by using the waste animal fat or the waste plant fat are overcome; and (3) glycerol which is a co-product obtained in the saponification reaction process is easier to purify than a co-product generated in the production of the biodiesel, and the commercial value of products is higher.

Owner:NANCHANG UNIV

Toner, process for producing the same, two-component developing agent and method of image formation

InactiveUS7413841B2Cutting costsHigh light transmittanceDevelopersElectrographic process apparatusCarbon numberWax

Toner includes aggregated particles including at least resin particles, pigment particles, and wax particles. A fused film of the resin is formed on the surface of the toner. The wax is at least one selected from A: ester wax that has an iodine value of not more than 25, a saponification value of 30 to 300, and an endothermic peak temperature (melting point) of 50° C. to 100° C. based on a DSC method; and B: wax that is obtained by a reaction of alkyl alcohol having a carbon number of 4 to 30, unsaturated polycarboxylic acid or its anhydride, and unsaturated hydrocarbon wax and has an acid value of 1 to 80 mgKOH / g and an endothermic peak temperature (melted point) of 50° C. to 120° C. based on the DSC method. The toner and a two-component developer can achieve oilless fixing that prevents offset without using oil while maintaining high OHP transmittance, can eliminate spent of the toner components on a carrier to make the life longer, and can ensure high transfer efficiency by suppressing transfer voids or scattering during transfer.

Owner:PANASONIC CORP

Sea cucumber oil product and method for preparing same

ActiveCN101530127ASeed preservation by heatingFood preparationCarbon numberBranched chain fatty acids

The invention relates to a sea cucumber oil product and a method for preparing the same. The sea cucumber oil is prepared by using sea cucumbers (in particular stichopus japonicus and internal organs thereof as well as cucumaria frondosa and the internal organs thereof) as raw materials through the processes of cleaning, freeze drying, pulverization and carbon dioxide supercritical extraction. The fatty acid component of the prepared finished product contains high-proportion branched-chain fatty acid, odd carbon number of fatty acid, as well as omega-3 fatty acid, wherein the branched-chain fatty acid accounts for 10 to 60 percent of the total fatty acids, and the content of 12-methyl-tetradecanoic-acid accounts for 2.5 to 30 percent of the total fatty acids. The sea cucumber oil is liquid state oil with colors from orange yellow to red and has stable property and sea fishy smell. The saponification value of the sea cucumber oil is between 150 and 190 mgKOH / g, and the iodine value thereof is between 70 and 100 g / 100 g.

Owner:DALIAN HAIYANTANG BIOLOGY

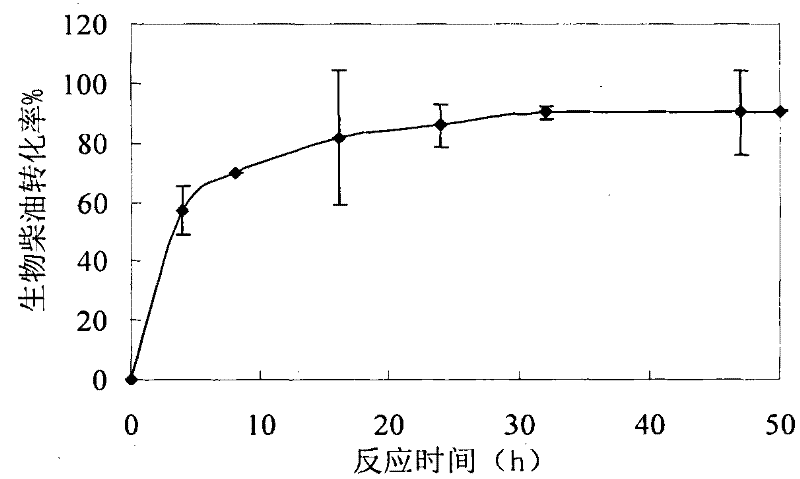

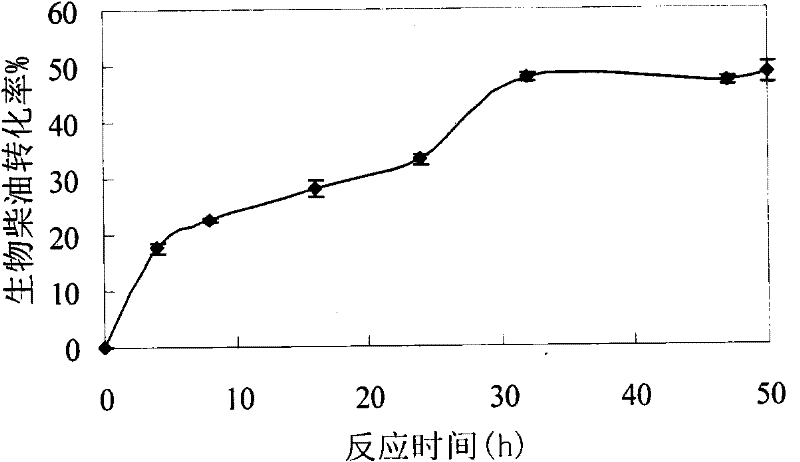

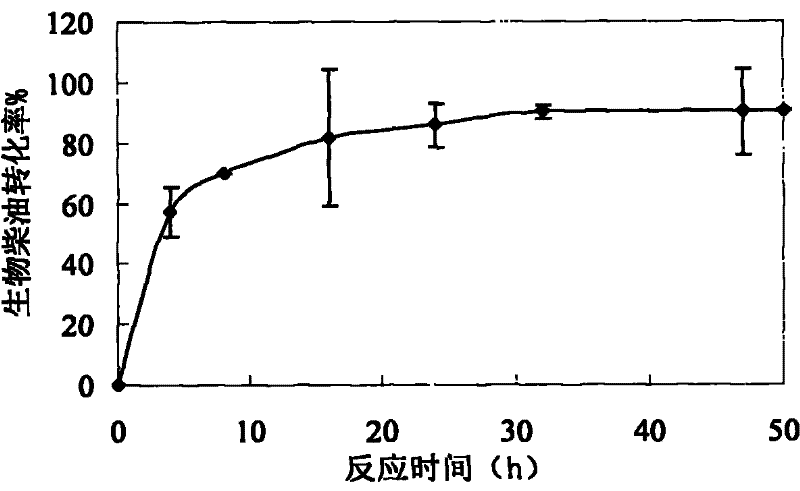

Preparation method of biodiesel from microalgal oil by enzyme method

InactiveCN102191126AImprove conversion rateEasy to separateFatty acid esterificationBiofuelsSaponification valueAlgae

Belonging to the biochemical field, the invention provides a preparation method of biodiesel from microalgal oil by enzyme method in a novel reaction medium. The method comprises the steps of: (1) providing algae powder made from dried microalgaes; (2) extracting microalgal oil from the algae powder; (3) characterizing the microalgal oil with physiochemical constants, and acquiring a saponification value so as to determine the amount of methanol needed; and (4) with ionic liquid (BMIm)(PF6) or tert-butyl alcohol as the reaction medium, adding methanol which contains alcohol and oil in a ratio ranging from 1:2 to 5:1 by mole into the microalgal oil, and adding 50-400mg penicillium expansum lipase for reaction, thus obtaining fatty acid methyl ester as the product.

Owner:SHENZHEN UNIV

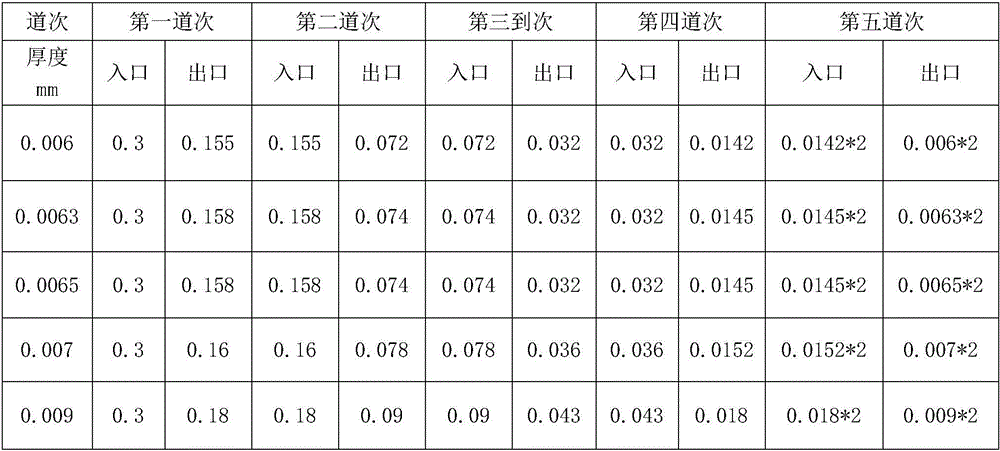

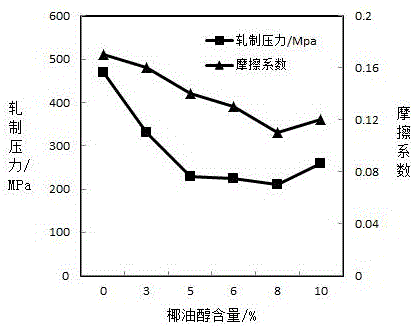

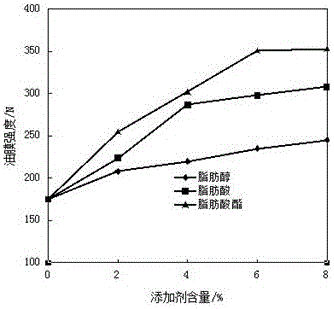

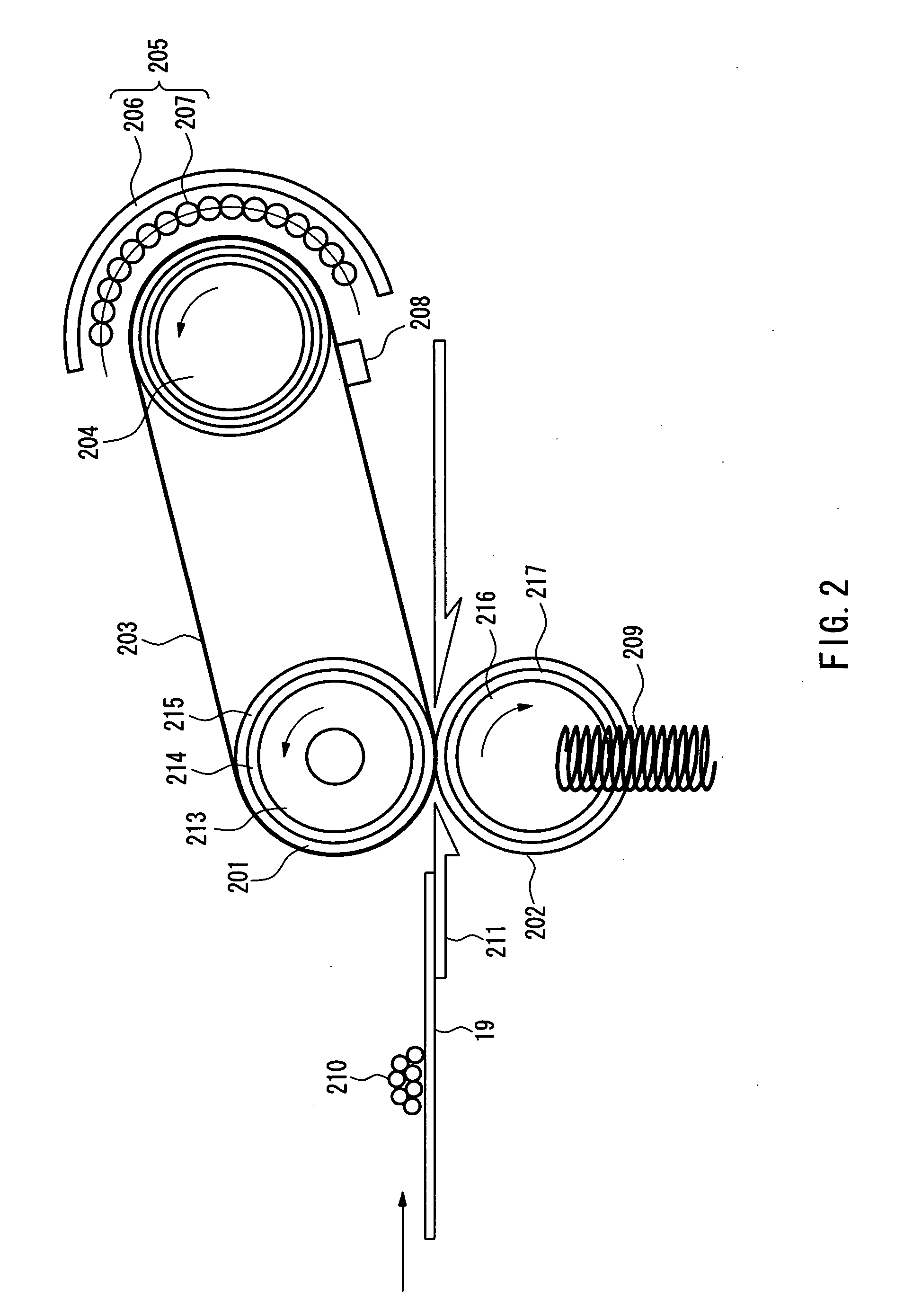

Method for rolling double-zero aluminum foil through 1850mm-width rolling mill

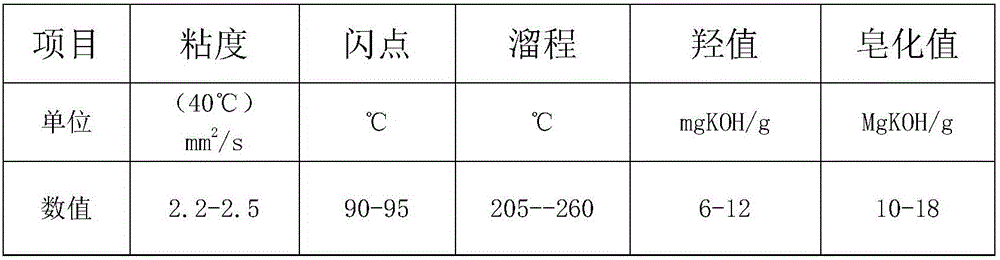

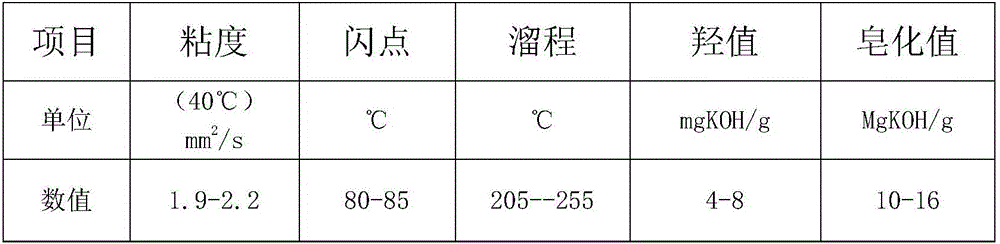

ActiveCN106825040ASolve the problem of more specification restrictionsAdd product specificationMetal rolling arrangementsDistillationHydroxyl value

The invention discloses a method for rolling a double-zero aluminum foil through a 1850mm-width rolling mill, and belongs to the technical field of aluminum foil machining. The method comprises the following step of carrying out three-pass rough rolling, one-pass intermediate rolling and one-pass finish rolling on a cast-rolled blank or a hot-rolled blank of which the thickness is 0.3mm on the 1850mm-width rolling mill to prepare the aluminum foil of which the thickness is 0.006-0.009mm and the width is 1,000-1650mm, wherein the roll diameter of a working roll of the rolling mill is phi260mm, 90# rolling oil is selected in the rough rolling procedure and the intermediate rolling procedure; 82# rolling oil is selected in the finish rolling procedure; an alcohol additive and / or ester additive is selected as the additive; and the rolling oil has the specifications after being prepared by using the additive at 40 DEG C as follows: the viscosity is 1.9-2.5mm<2> / s, the flash point is 80-95 DEG C, the distillation range is 205-260 DEG C, the hydroxyl value is 4-12mgKOH / g and the saponification value is 10-18MgKOH / g. The produced product is stable in quality and high in yield.

Owner:JIANGSU DAYA ALUMINUM

Non-Greasy Personal Care Compositions

An anhydrous personal care composition, comprising: (a) 45 to 60 weight % of at least one ester, selected from (i) triglycerides, (ii) diglycerides, (iii) monoglycerides, (iv) monoesters of diols, and (v) diesters of diols; (b) a first wax having a melting point of from 35° C. to 72° C. present in an amount of 5 to 25 weight %; (c) a second wax having a melting point of 73 to 90° C. present in an amount of 0.5 to 15 weight %; and (d) at least one plant oil having a saponification value of from 150 to 275 mg KOH / g present in an amount of 5 to 35 weight.

Owner:COLGATE PALMOLIVE CO

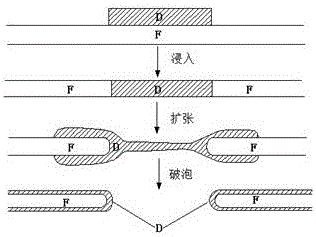

Cold rolling process capable of preventing broken edge wave defect of ultrathin steel strip

InactiveCN104550236AIncrease thermal convexityReduce cooling effectProfile control deviceMetal rolling arrangementsEmulsionStrip steel

The invention provides a cold rolling process capable of preventing a broken edge wave defect of an ultrathin steel strip. The process comprises the steps of a) setting the temperature of emulsion for lubricating a rolling unit to be 55 to 58 DEG C, setting the concentration to be 2.5 to 4.0%, and setting saponification value to be 160 to 180mgKOH / g; b) setting the chamfering width of a small head side of a medium roller body to be 50 to 55mm, setting the chamfering radian to be R2000 to R2100mm, setting the chamfering depth to be 0.8 to 1.1mm, rolling more than three volumes of boards being more than 0.25mm in thickness through a new arranged working roller, and then producing the steel strip being less than 0.25mm in thickness. According to the process, the temperature of the emulsion is increased, the molecular thermodynamic movement of rolling oil is increased and clean emulsion in a rolling seam is absorbed, so that the technical lubricating effect under extreme pressing can be improved, the frictional conditions in the roller seam can be improved, the rolling force per pass can be obviously reduced, and as a result, the broken edge wave defect can be prevented; the roller mechanism is optimized to ensure the uniform pressure of a chamfering contact area of the medium roller and the working roller, and therefore, harmful contact stress can be reduced, the thermal crown of the roller can be improved, the flatting capacity of two ends of the roller can be decreased, and the trend of broken edge wave can be prevented.

Owner:王乐 +2

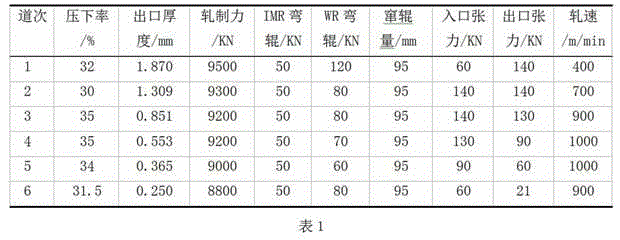

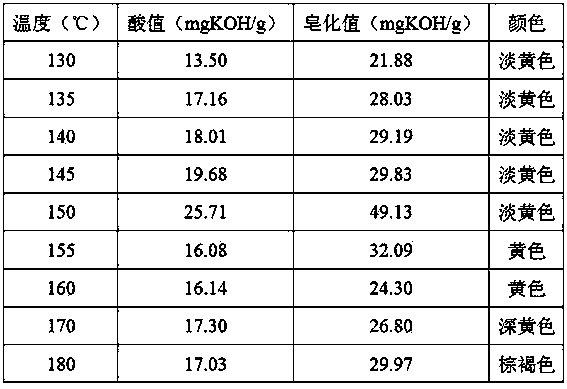

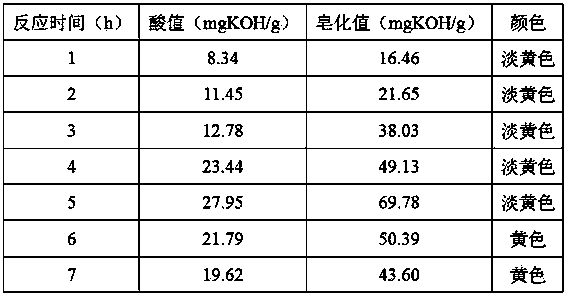

Preparation method of high-acid saponified oxidized wax

InactiveCN103468316ALight colorSmall smellPetroleum chemical modificationMANGANESE ACETATEParaffin wax

The invention discloses a preparation method of high-acid saponified oxidized wax, which comprises the following steps: heating paraffin and microcrystalline wax to completely melt the paraffin and microcrystalline wax, respectively adding a catalyst and an assistant, and introducing oxygen at constant flow rate to react, wherein the catalyst is manganese acetate or manganese sulfate, the assistant is stearic acid, the reaction temperature is 130-180 DEG C, the reaction time is 1-7 hours, and the flow rate of oxygen is 50-110 mL / min. The acid value of the oxidized wax is 27.95 mg KOH / g, and the saponification value is 69.78 mg KOH / g. The preparation method has the advantages of simple technique, short reaction time and low reaction temperature, and is convenient to operate; and the prepared oxidized wax product has the advantages of light color, light smell and high saponification value.

Owner:FUZHOU UNIV

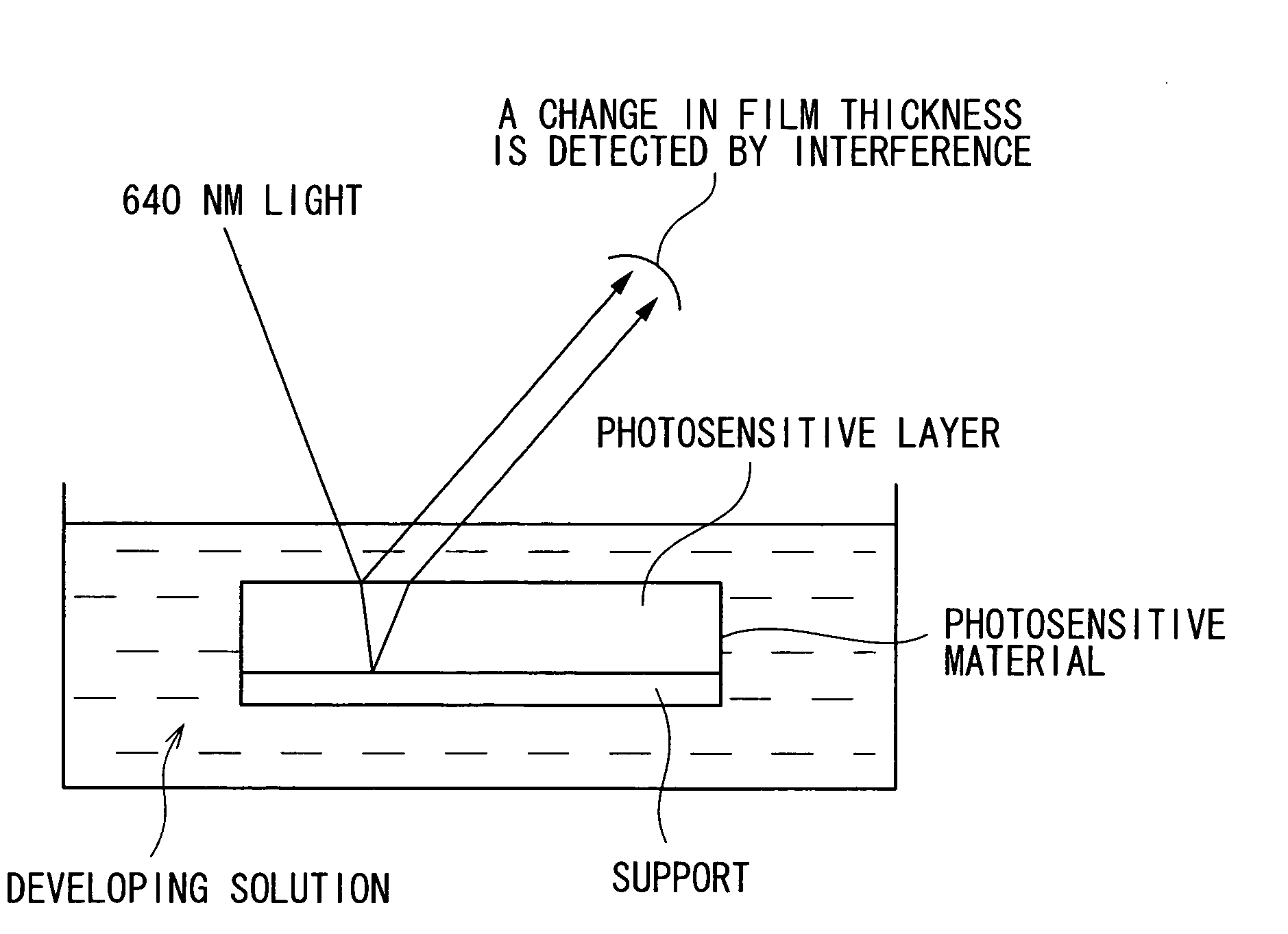

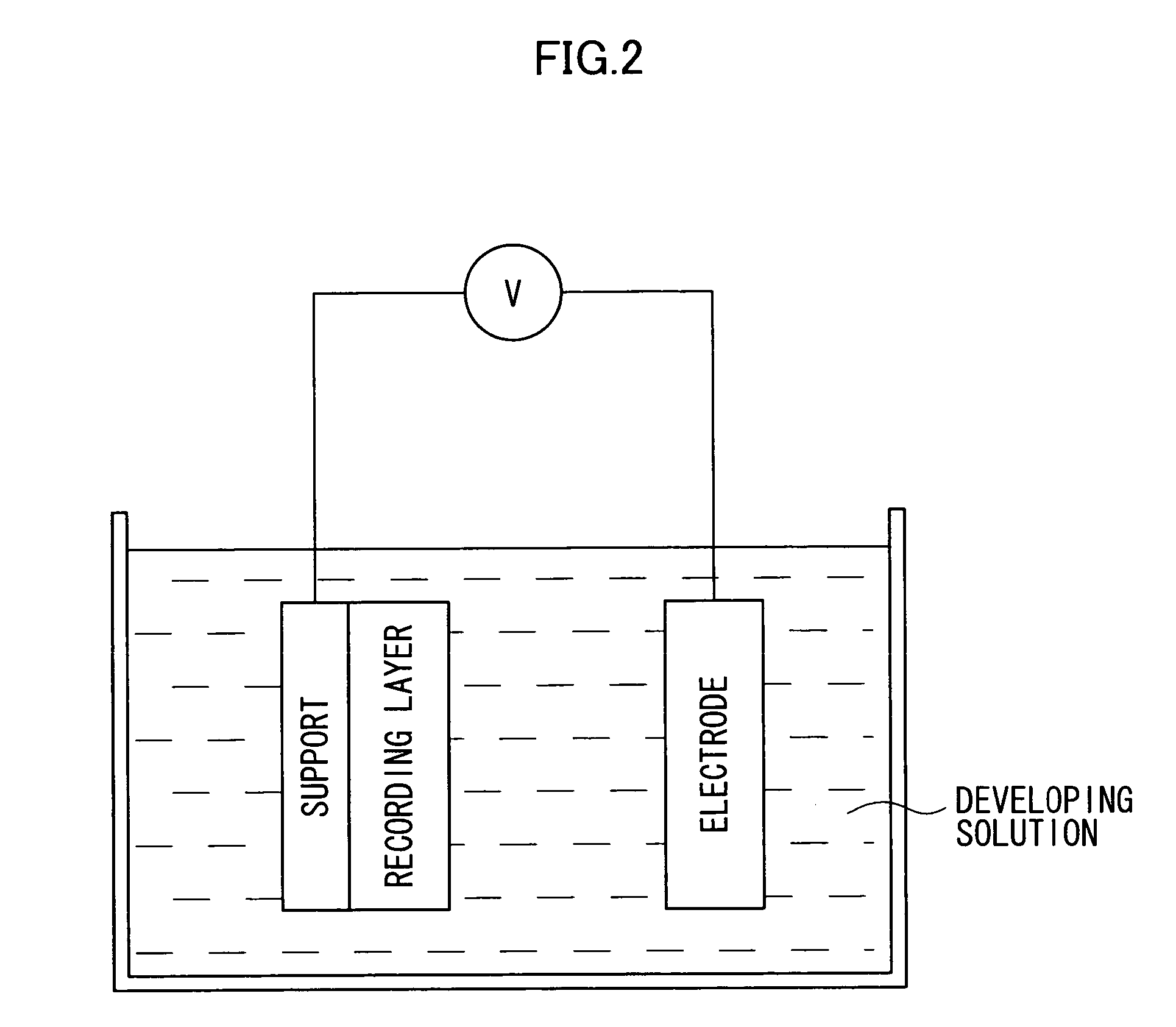

Planographic printing plate precursor and method of making planographic printing plate

InactiveUS20060046185A1High film strengthImprove removabilityPhotosensitive material auxillary/base layersLithographyPolyvinyl alcoholCompound (substance)

Disclosed is a planographic printing plate precursor including a photosensitive layer containing an infrared absorber, a polymerization initiator, a polymerizable compound and a binder polymer and a protective layer laminated on a support in this order, wherein the protective layer contains a mica compound and at least one polyvinyl alcohol selected from the group consisting of a polyvinyl alcohol having a saponification value of 90 mol % or less and an acid modified polyvinyl alcohol. Also disclosed is a method of making a planographic printing plate, the method including exposing the planographic printing plate precursor to light having a wavelength of 750 nm to 1400 nm and then carrying out developing step at a conveying speed of 1.25 m / min. or more with substantially no heat treatment and no water-washing treatment.

Owner:FUJIFILM HLDG CORP +1

Strip steel cold rolling emulsified oil containing boric acid ester and preparation method thereof

InactiveCN105733785AModerate viscosityIncrease relative volatilityLubricant compositionSurface finishSocial benefits

The invention relates to a strip steel cold rolling emulsified oil and a preparation method thereof.The strip steel cold rolling emulsified oil is prepared from 10%-40% of a component A, 15%-45% of a component B, 5%-20% of a component C, 3%-10% of a component D, 2%-8% of a component E, 2%-8% of a component F, 1.8%-7% of a component G and 1.5%-6% of other auxiliaries H.The cold rolling emulsified oil is appropriate in viscosity, good in volatility and moderate in saponification value; the emulsion particle size is moderate after the cold rolling emulsified oil is dissolved in water, so that rolled strip steel is good in surface finish and free of residues, which plays a key role in improving the galvanization quality of strip steel in a subsequent process; the rolling liquid is long in service life, low in cost and capable of prolonging the service life of rollers and reducing product cost; besides, the preparation method is simple and easy to apply and popularize on a large scale, so that good economic benefits and social benefits are brought.

Owner:TIANJIN JINHAILI GREASE CO LTD

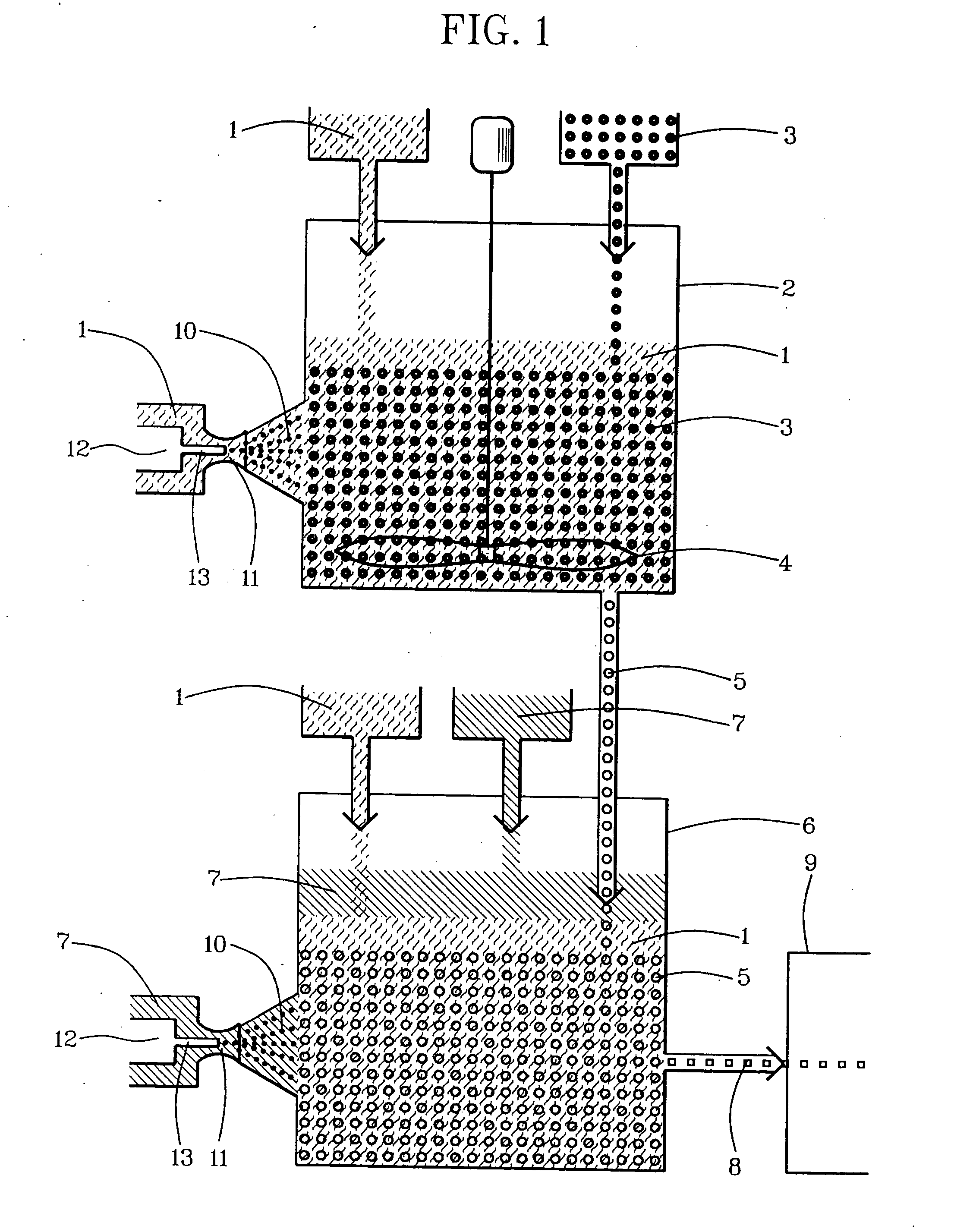

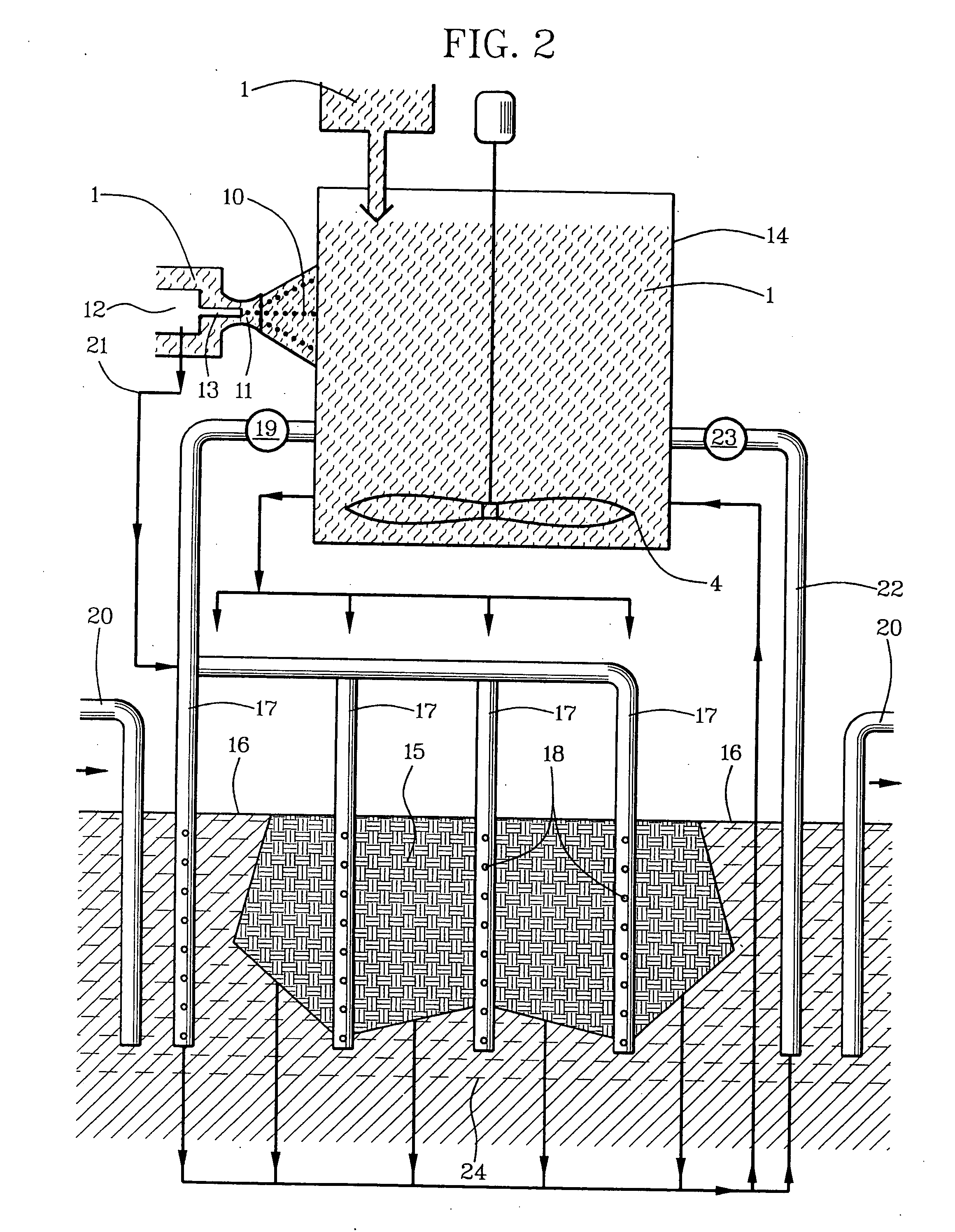

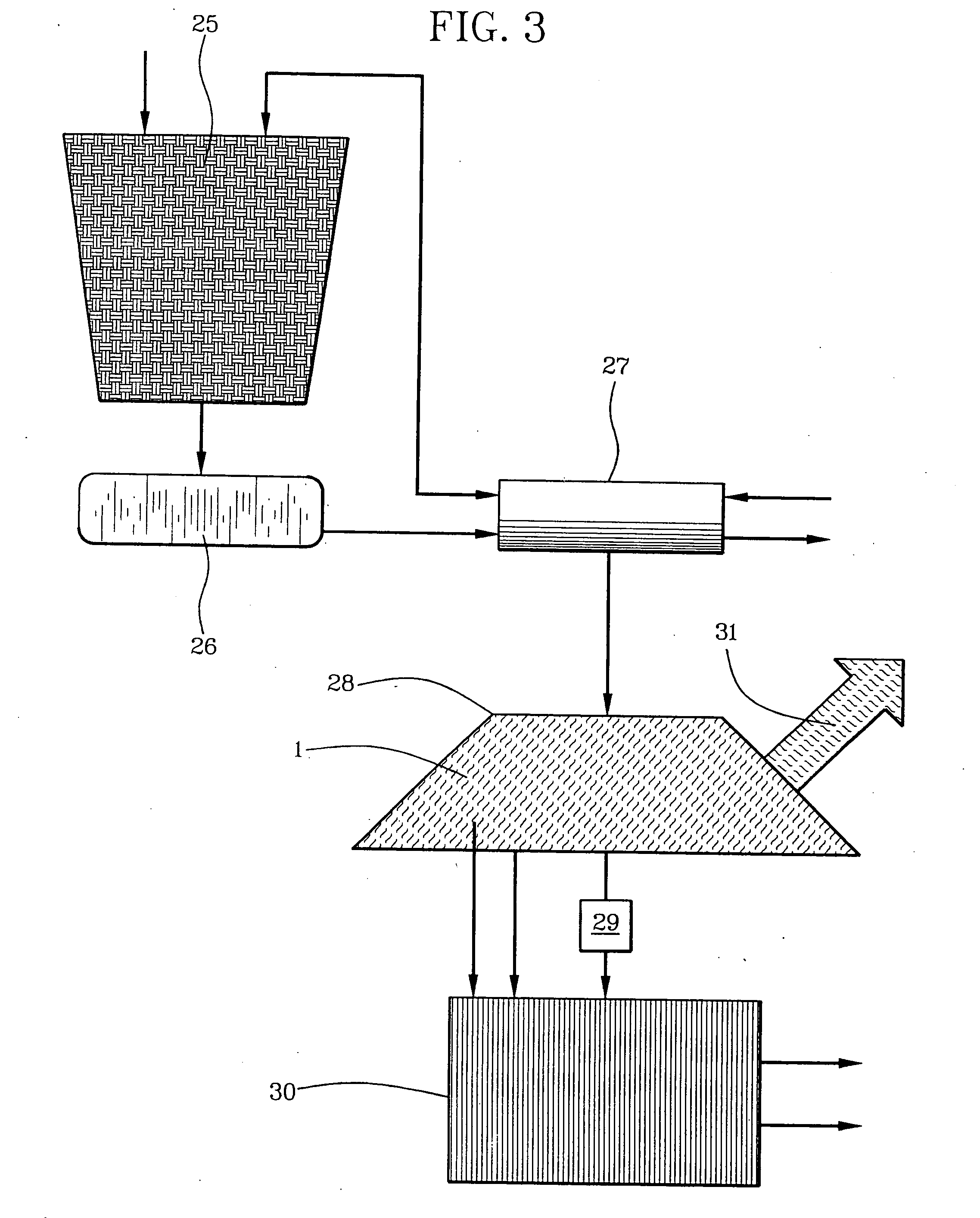

Contaminant eco-remedy and use method

A contaminant eco-remedy (1) has a colloid-active detergent with colloidal microspheres of a predetermined particle size in an alkanol amide. The alkanol amide is prepared by condensation of a predetermined vegetable fatty acid with an alkanol amine, ethanol, distilled water, and ethylene diamine tetraacetic acid in predetermined proportions. The vegetable fatty acid has a saponification value of about 271 and an acid value of about 269. The colloid-active detergent is diluted with specific concentration of water, nutrients and oxidative agents for degradation and enhanced bioremediation of organic compounds that are oxidation-reduced to non-contaminant mixtures containing nitrates, carbon dioxide, oxygen and water. From organic contaminants containing chlorine and sulphur groups, the non-contaminant mixtures may contain HCL, NACL, H2S, and SO3. A method for using the contaminant eco-remedy includes chemical degradation in a treatment tank (2), biodegradation by bacteria (aerobically or anaerobically) in a retention tank (6), degradation, soil flushing and bioremediation of contaminated targeted soil (15), a system tank (14) for the injection of the contaminant eco-remedy and the treated groundwater with injector tubes (17), extraction wells (20) and related circulation and handling equipment and a customized tank (28) that soil-washes organic compounds from contaminated soil with the contaminant eco-remedy to water phase eco-remediated wash waters.

Owner:DETORRES FERNANDO A

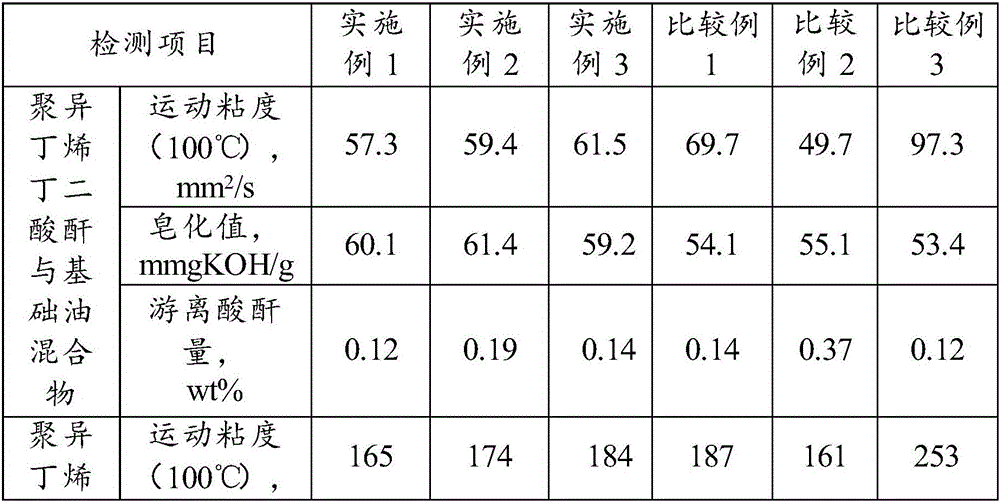

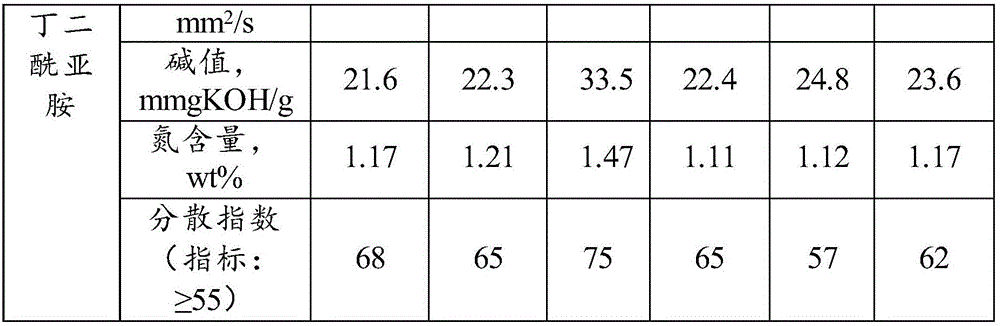

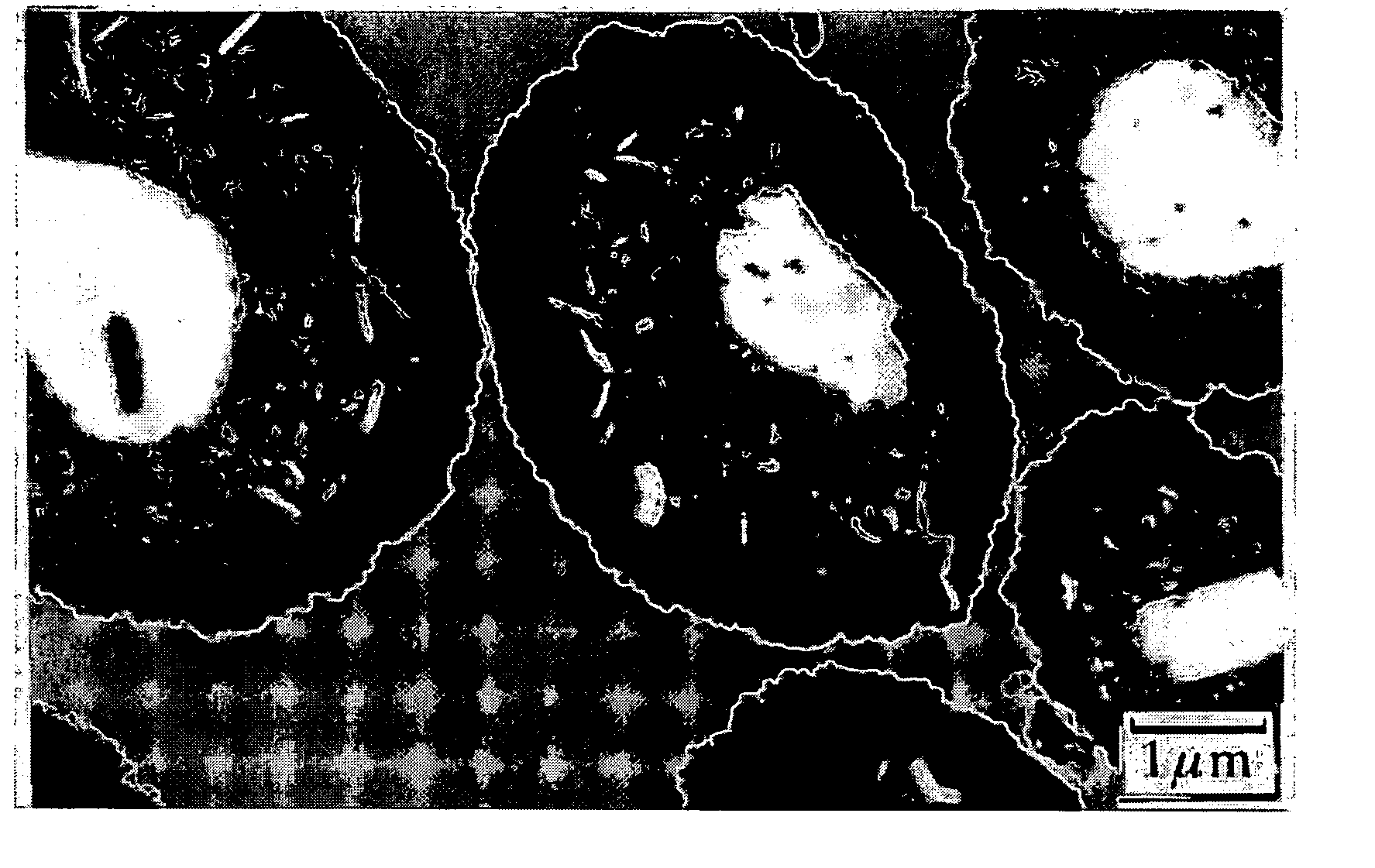

Preparation method for polyisobutylene succinimide

A provided preparation method for polyisobutylene succinimide comprises A) respectively dropwise adding a mixture of a radical initiator and base oil and maleic anhydride into polyisobutene for reaction, so as to obtain a mixture of polyisobutylene succinic anhydride and base oil; and B) mixing the mixture of polyisobutylene succinic anhydride and base oil, which is obtained in the step A), with polyethylene polyamine and second base oil, performing amination, so as to obtain polyisobutylene succinimide. The method reduces generation of byproducts such as autopolymer of maleic anhydride, polymer of polyisobutene and maleic anhydride and the like, reduces viscosity of the polyisobutylene succinic anhydride intermediate, and improves the effective utilization rate of maleic anhydride and saponification value of the polyisobutylene succinic anhydride intermediate. The dispersity of the prepared polyisobutylene succinimide is further improved.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

Toner, process for producing the same, two-component developing agent and method of image formation

InactiveUS20060147828A1Avoid offsetHigh light transmittanceElectrographic process apparatusDevelopersCarbon numberWax

Toner includes aggregated particles including at least resin particles, pigment particles, and wax particles. A fused film of the resin is formed on the surface of the toner. The wax is at least one selected from A: ester wax that has an iodine value of not more than 25, a saponification value of 30 to 300, and an endothermic peak temperature (melting point) of 50° C. to 100° C. based on a DSC method; and B: wax that is obtained by a reaction of alkyl alcohol having a carbon number of 4 to 30, unsaturated polycarboxylic acid or its anhydride, and unsaturated hydrocarbon wax and has an acid value of 1 to 80 mgKOH / g and an endothermic peak temperature (melted point) of 50° C. to 120° C. based on the DSC method. The toner and a two-component developer can achieve oilless fixing that prevents offset without using oil while maintaining high OHP transmittance, can eliminate spent of the toner components on a carrier to make the life longer, and can ensure high transfer efficiency by suppressing transfer voids or scattering during transfer.

Owner:PANASONIC CORP

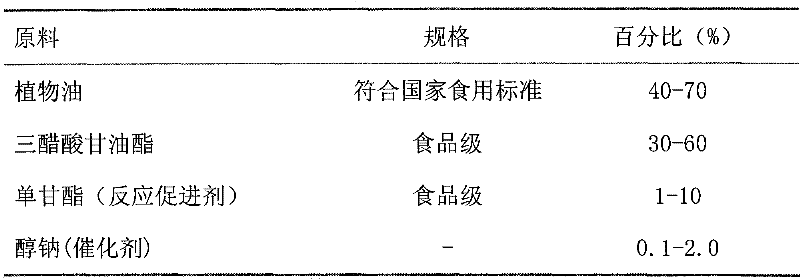

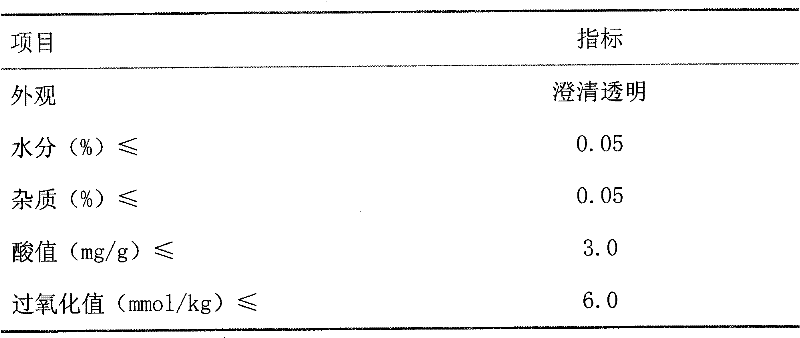

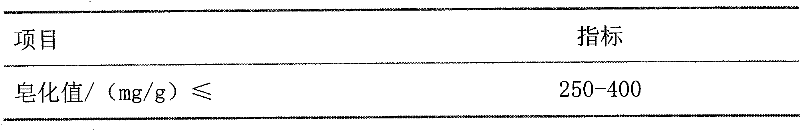

Low-calorie edible plant oil and preparation method thereof

InactiveCN102533452AReduce intakeReduce cardiovascular and cerebrovascular diseasesFatty acid esterificationEdible oils/fatsDiseaseOil and grease

The invention discloses a low-calorie edible plant oil and a preparation method thereof. According to the invention, the saponification value of the oil is between 250mg / g and 400mg / g; and compared with the traditional oil, the calorie of the plant oil disclosed by the invention is reduced by 2%-50%. The preparation method of the low-calorie edible plant oil comprises the following steps: weighing 40%-70% of edible oil; and adding 30%-60% of triacetin in the edible oil and then evenly mixing, and heating to obtain a mixture; adding a reaction accelerating agent monoglyceride and catalyst sodium alcoholate into the mixture for ester exchange reaction; after the reaction is finished, washing, distilling and filtering to obtain the low-calorie edible plant oil. The plant oil comprises all of the edible oils, such as common plant oils, such as soybean oil, colza oil, peanut oil, palm oil, cottonseed oil, corn oil, sunflower seed oil, tea seed oil, linseed oil, walnut oil, rice bran oil, acer truncatum oil and corn germ oil, or oil obtained by mixing the common plant oils in a proportion. By eating the low-calorie edible plant oil disclosed by the invention, the calorie intake amount of people can be effectively reduced, thereby reducing the probability of fat and reducing the generation of cardiovascular and cerebrovascular diseases.

Owner:COFCO GROUP +2

Fully-synthesized solid car wax

ActiveCN102363714AQuality improvementSmooth appearancePolishing compositionsSolventSaponification value

The invention relates to fully-synthesized solid car wax, which comprises the following components in percentage by mass: 6 to 8 percent of polyethylene wax, 3 to 4 percent of high alcohol wax, 1 to 2 percent of silicon wax, 5 to 7 percent of dimethyl silicon oil, 2 to 3 percent of amino silicone, 3 to 5 percent of slip agent, 0.3 to 0.5 percent of essence and the balance of solvent oil. The fully-synthesized solid car wax is made of a synthetic wax raw material completely, and therefore avoids offensive odor, toxicity and harm to human body and influences on the environment; and the indexes of properties of the synthetic wax raw material, such as acid value, saponification value, melting point and titer are stable, so the manufactured car wax product has a flat appearance, stable qualityand high brightness, can better protect car paint for a long time and is easy to construct.

Owner:JIANGXI CHEPU IND CO LTD

Toner, method for producing toner, two-component developer, and image forming apparatus

InactiveUS20080268368A1Solution to short lifeIncrease resistanceDevelopersCarbon numberCarboxylic acid

Toner of the present invention includes aggregated particles formed by aggregating at least resin particles, pigment particles, and wax particles in an aqueous medium in the presence of a water-soluble inorganic salt. The wax includes at least one selected from the following: ester wax that has an iodine value of not more than 25, a saponification value of 30 to 300, and an endothermic peak temperature (melting point) of 50° C. to 100° C. based on a DSC method; and wax that is obtained by a reaction of alkyl alcohol having a carbon number of 4 to 30, unsaturated polycarboxylic acid or its anhydride, and synthetic hydrocarbon wax, and has an acid value of 1 to 80 mgKOH / g and an endothermic peak temperature (melted point) of 50° C. to 120° C. based on the DSC method. The toner and a two-component developer can achieve oilless fixing that prevents offset without using oil while maintaining high OHP transmittance, can eliminate spent of the toner components on a carrier to make the life longer, and can ensure high transfer efficiency by suppressing transfer voids or scattering during transfer.

Owner:PANASONIC CORP

Electrode for electric double layer capacitor

InactiveUS6917094B2Increase resistanceImprove adhesionLiquid electrolytic capacitorsSemiconductor/solid-state device detailsAdhesiveEngineering

In an electrode for an electric double layer capacitor of the present invention, the peak value of particle size distribution of graphite particles added to a conductive adhesive is in a range of 2.6 to 3.2 μm, not less than 100,000 dimples having a largest outer diameter in a range of 4 to 10 μm and a depth in a range of 4 to 15 μm are formed on the surface of the collector sheet per 1 cm2, and the occupied area of the dimples to the entire surface area of the collector sheet is not more than 50%. By determining the saponification value of polyvinylalcohol which is used as a binder component of the conductive adhesive in a range of 90.0 to 98.5, adhesiveness of the collector sheet and the electrode forming sheet is improved. Furthermore, by substituting H atoms contained in the polyvinylalcohol with Si atoms, adhesiveness of the collector sheet and the electrode forming sheet can be further improved.

Owner:DAIDO METAL CO LTD

Process for preparing oxidized wax from coal wax

InactiveCN105087068AIncrease economic value addedAlleviate the pressure of resource shortageMineral wax recovery/refiningParaffin waxReaction temperature

The invention relates to a process for preparing oxidized wax from coal wax. The process comprises the following steps of preparing for a raw material, namely F-T coal wax, adding F-T coal wax into a three-neck flask, gradually heating to 100 DEG C and melting the F-T coal wax; then, adding a catalyst, wherein the weight of the catalyst accounts for 0.1-1.0% of the weight of the F-T coal wax; and introducing 0.2-0.8L / h oxygen gas to each gram of F-T coal wax, controlling the reaction temperature within 125-160 DEG C at the stage, reacting for 3-8 hours, then, taking out the product while the product is hot, sampling and analyzing. According to the process, the oxidized wax is prepared from the F-T coal wax instead of the traditional wax, so that the burden of petroleum resource shortage is relieved, and the economic additional value of the coal wax is increased; materials such as a heavy metal ionic catalyst, nitrogen shielding gases, a water-carrying agent and polymerization additives are not used; the reaction time is short, the process is simple and convenient to operate, the prepared oxidized wax product is light in color and smell, and the acid value and saponification value of the prepared oxidized wax product meet the requirements of the SASOLWAX A28 index of south Africa; and no special processing equipment is required in the process.

Owner:JIANGSU LANGFU PETROLEUM & CHEM CO LTD

Method for online saponification and Ca<2+> removal of extracting agent used for rare earth separation

ActiveCN102041383AReduce saponification costEliminate pollutionProcess efficiency improvementClosed loopRare earth

The invention relates to a method for online saponification and Ca<2+> removal of an extracting agent used for rare earth separation. The method comprises the following steps: firstly, adding an extracting agent and a solid saponifier and supplementing water in a saponification reaction tank, and carrying out an online downstream saponification reaction to saponify the extracting agent; and secondly, directly adding the saponified extracting agent into a tank for Ca<2+> removal, and carrying out a reverse flow exchange reaction with a continuously fed rare earth liquid to remove the Ca<2+> in the saponified extracting agent, wherein the remaining rare earth liquid containing Ca<2+> is returned to the saponification tank, and is not fed into the rare earth extraction process; and the loading extracting agent is fed into an extraction separation system and then is returned to the saponification tank for saponification after re-extraction and regeneration, and the extracting agent is subject to self-circulation in a closed loop in the extraction system. In the method, calcium oxide, calvital and calcium carbonate which are low in cost are used as raw materials, not only can the production cost be reduced, but also the pollution of ammonia-nitrogen waste water to the environment isavoided; and an online saponification method of directly adding the solid saponifier is adopted, thus the saponification process can be simple and continuous, and the cycle of the extracting agent and equipment and factories matched with saponification can be saved.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

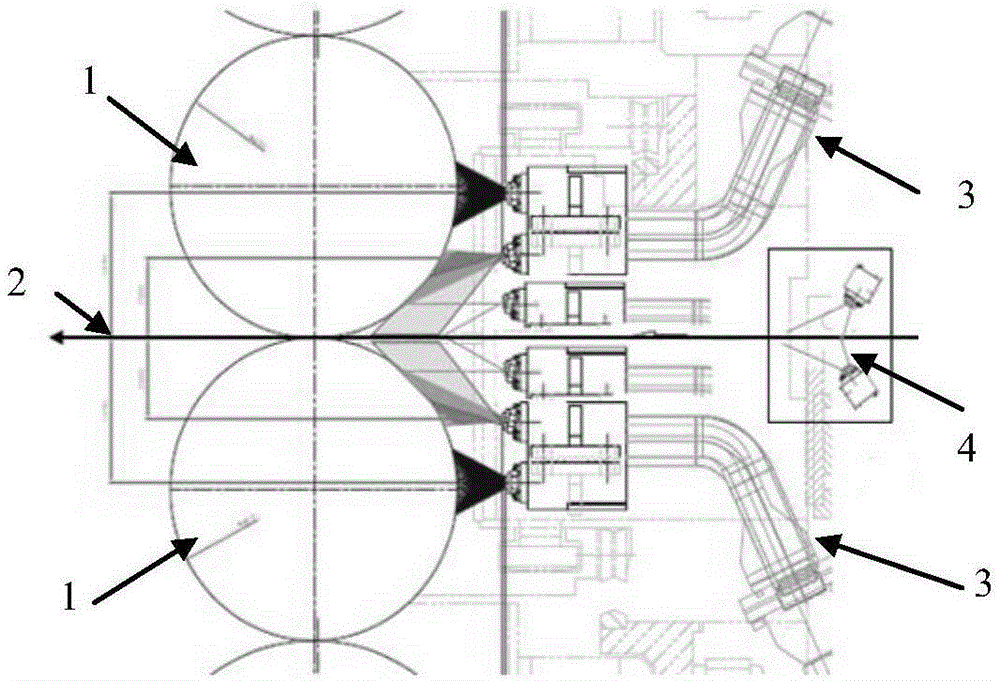

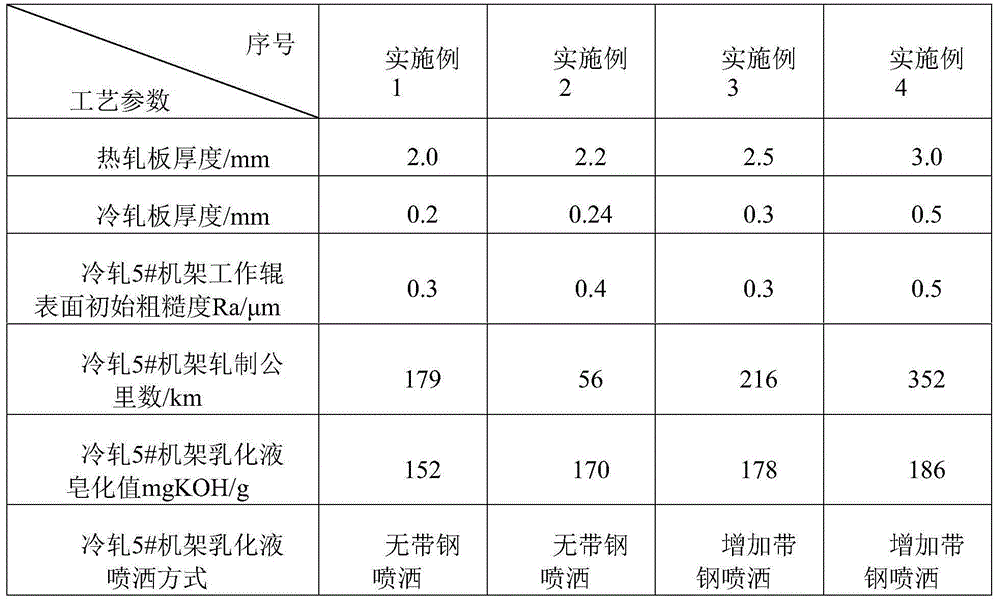

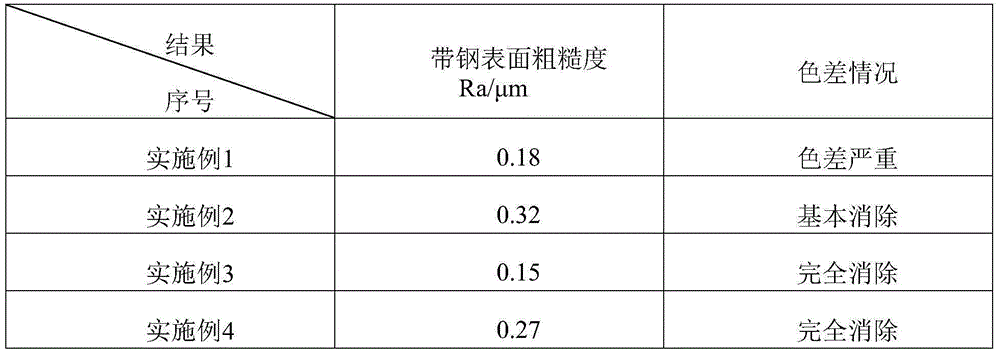

Production method for eliminating surface color difference of cold-rolled sheet

InactiveCN105234172AImprove chromatic aberration defectsStrong targetingRollsWork lubrication devicesSurface roughnessStrip steel

The invention provides a production method for eliminating the surface color difference of a cold-rolled sheet. According to the method, on the basis that reasons for the formation of the surface color difference of the cold-rolled sheet are analyzed systematically, a working mode of improving working rollers and emulsified liquid of a cold rolling 5# machine frame is provided to overcome the strip-shaped color difference defect on the surface of the cold-rolled sheet, and a set of process production method is formed. The production method mainly comprises the steps that the surface roughness Ra of the working rollers of the 5# machine frame is improved from original 0.2-0.3 [mu]m to 0.4-0.5 [mu]m; the saponification value (mgKOH / g) of the emulsified liquid of the cold rolling 5# machine frame is stabilized to be 180 + / - 10; and the amount of the emulsified liquid sprayed to the working rollers of the 5# machine frame and the surface of strip steel is improved. By the adoption of the measures, it is guaranteed that when the cold-rolled sheet is in a bright rolling state, the strip-shaped color difference on the surface of the cold-rolled sheet is avoided, and surface quality and product grade of the cold-rolled sheet are greatly improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

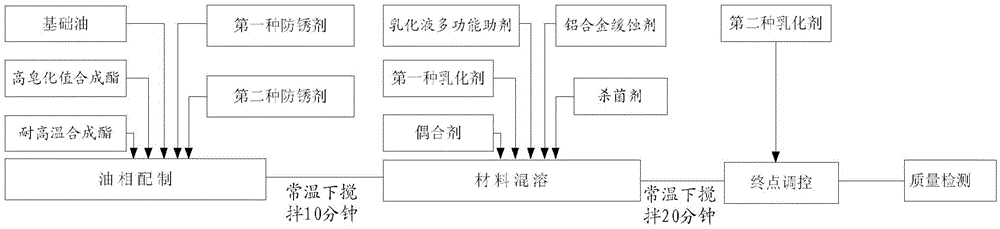

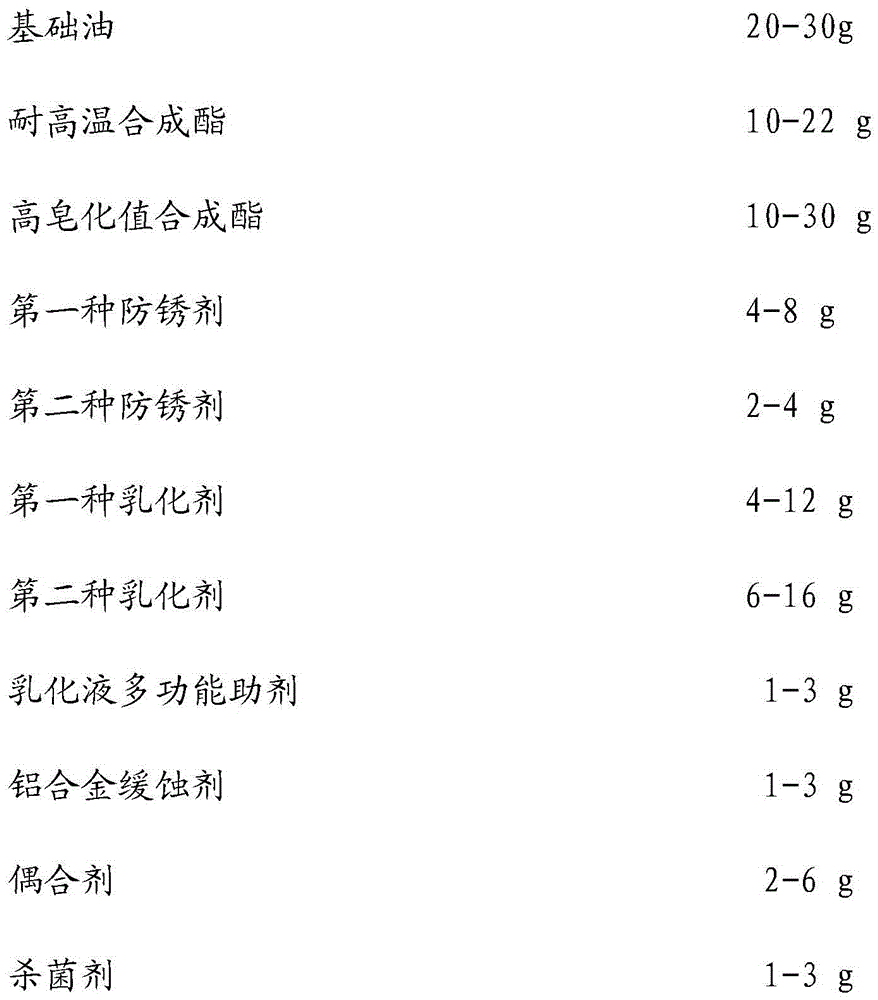

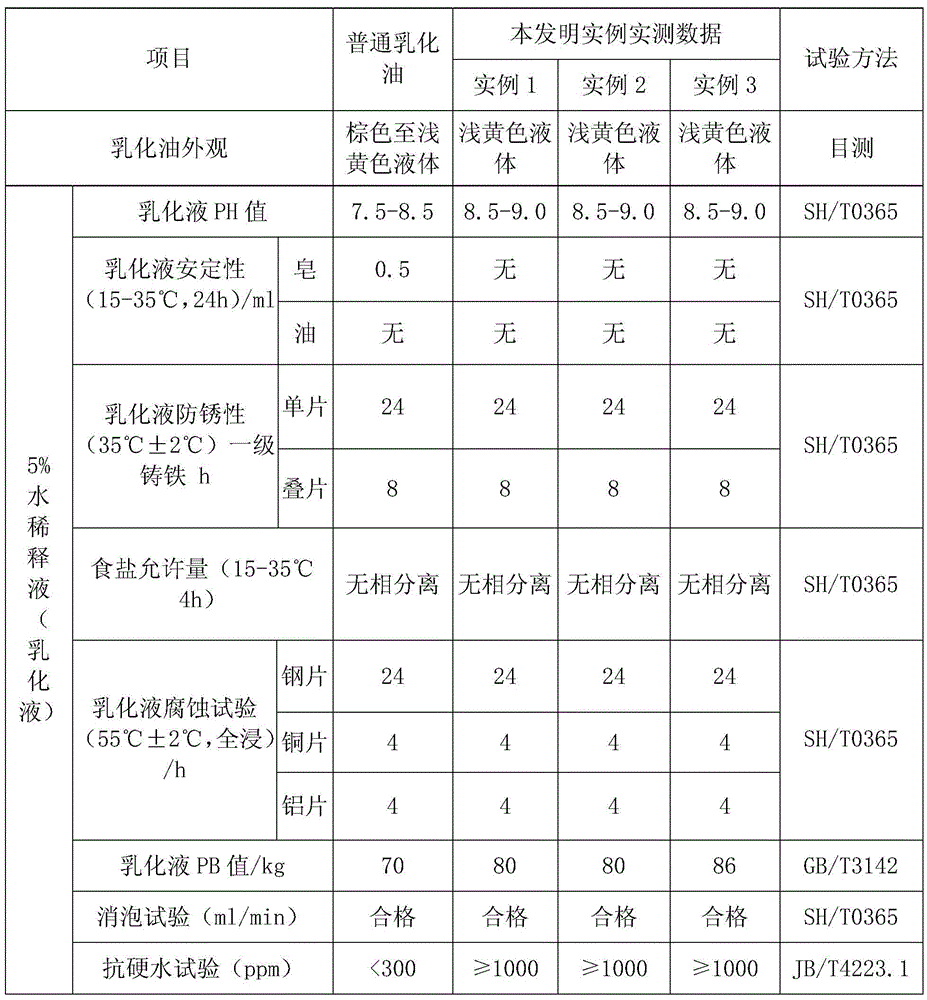

Synthetic ester environment-friendly type aluminum alloy cutting emulsified oil and preparing method thereof

ActiveCN105623809AImprove rust resistanceImprove hard water resistanceAdditivesEmulsionTemperature resistance

The invention relates to the field of cutting fluid for machining, in particular to synthetic ester environment-friendly type aluminum alloy cutting emulsified oil and a preparing method thereof. The synthetic ester environment-friendly type aluminum alloy cutting emulsified oil is prepared from, by weight, 20-30 g of base oil, 10-22 g of high-temperature resistance synthetic ester, 10-30 g of high-saponification value synthetic ester, 4-8 g of a first anti-rusting agent, 2-4 g of a second anti-rusting agent, 4-12 g of an emulsifying agent with the HLB value higher than or equal to 10, 6-16 g of an emulsifying agent with the HLB value lower than or equal to 6, 1-3 g of an emulsion multifunctional assistant, 1-3 g of an aluminum alloy corrosion inhibiting agent, 2-6 g of a coupling agent and 1-3 g of a sterilizing agent.

Owner:DONGGUAN PENGRUN CHEM PROD

Synthetic method for sorbitan octoate emulsifier

ActiveCN106588830AHigh selectivityHigh purityOrganic chemistryTransportation and packagingHydroxyl valueSaponification value

The invention discloses a synthetic method for a sorbitan octoate emulsifier. The synthetic method is characterized by being prepared from commercially available D-sorbitol, caprylic acid, a metal tin catalyst, a basic catalyst and a granular magnesium silicate adsorbent, which serve as raw materials, through processes of etherification, etherate refinement, esterification, deacidification, ester refinement and the like. According to the method, the metal tin catalyst is rationally selected and used; a product in the etherification process is subjected to adsorption and refinement treatment by utilizing the granular magnesium silicate adsorbent; unreacted caprylic acid is removed in vacuum at a high temperature; and a final product is subjected to adsorption and refinement treatment by utilizing the granular magnesium silicate adsorbent, so that the sorbitan octoate emulsifier which has the acid value less than 2.0 mgKOH / g, the color luster less than or equal to 100 Hazen, the hydroxyl value equal to 230-300 mgKOH / g and the saponification value equal to 180-210 mgKOH / g, is light in smell, high in transparency, low in fatty acid residue content, difficult in acid backflow and high in stability, and has good solubilizing, emulsification-facilitating, tackifying and anticorrosion-enhancing effects and safe and mild performance is obtained; and the method is suitable for the fields of daily chemicals and cosmetics, and the like.

Owner:ZHANGJIAGANG GREAT CHEM

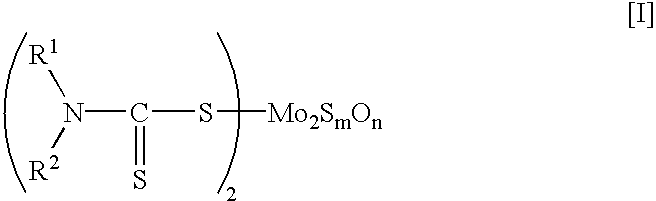

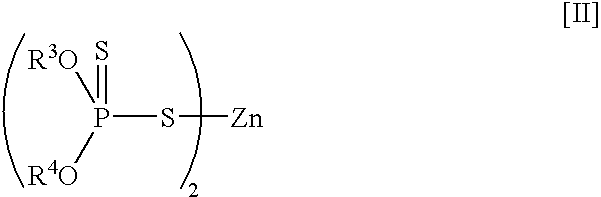

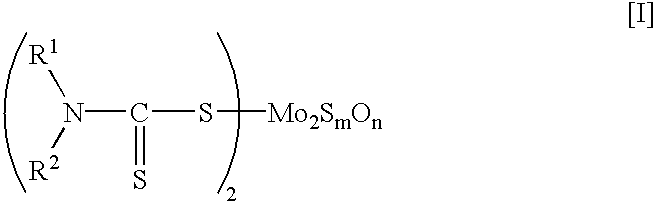

Lubricating oil composition for internal combustion engines (LAW651)

InactiveUS6605573B1Improve propertiesImprove performanceAdditivesBase-materialsChemical compositionCombustion

A synthetic lubricating oil composition for internal combustion engines, comprises an organomolybdenum compound, a zinc dithiophosphate and a base stock obtained by blending an ester having a kinematic viscosity of from 8 cSt to 35 cSt at 100° C. and a saponification value of 200 mg-KOH / g or smaller with a poly (alpha-olefin) and / or a highly-refined mineral oil.

Owner:KOGANEI KATSUYA +1

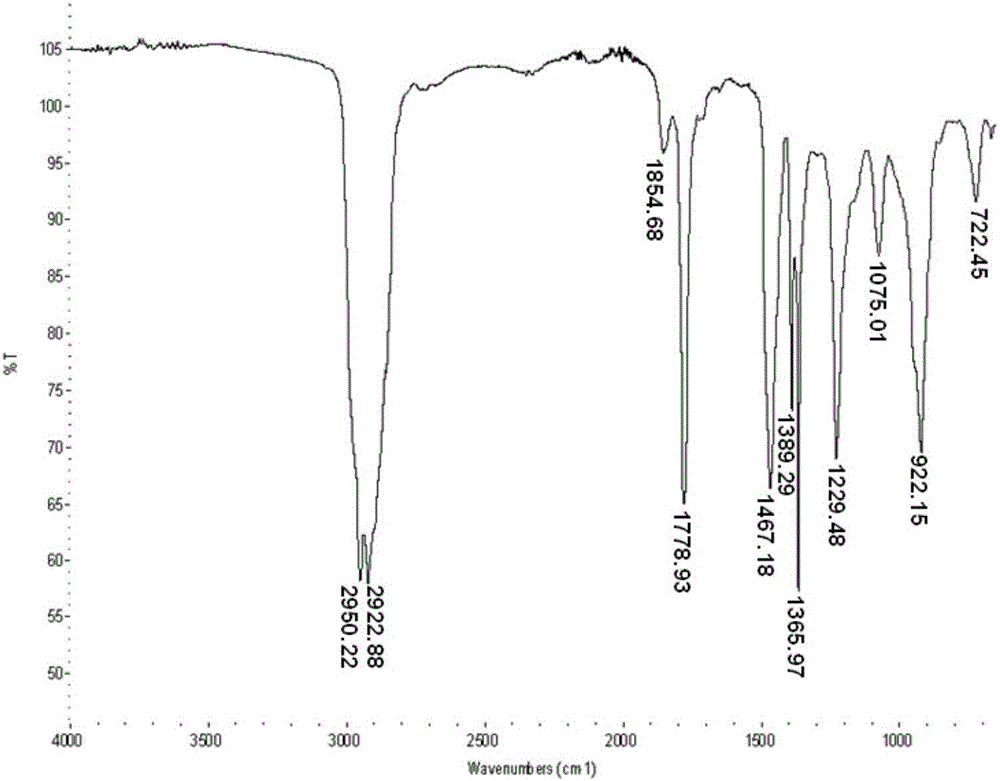

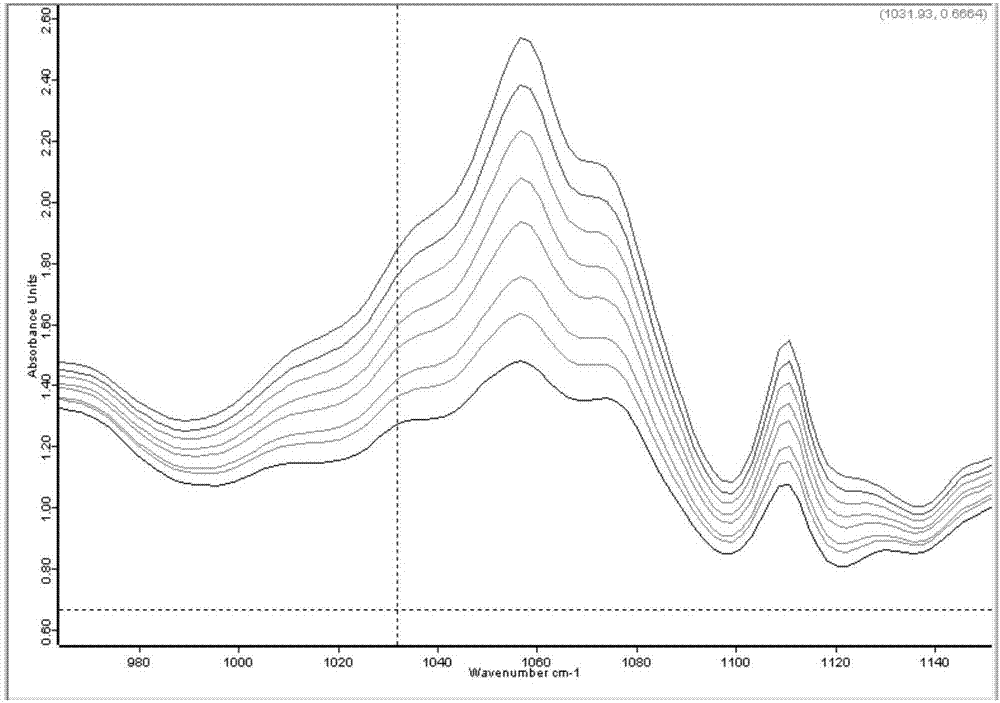

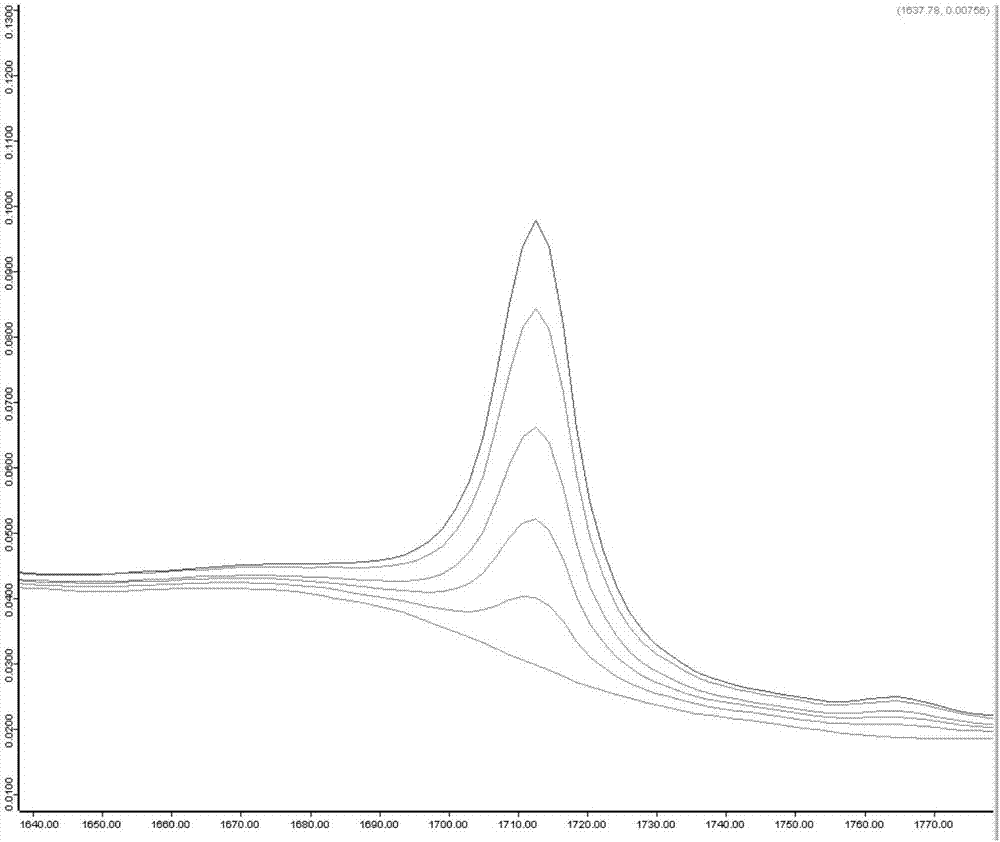

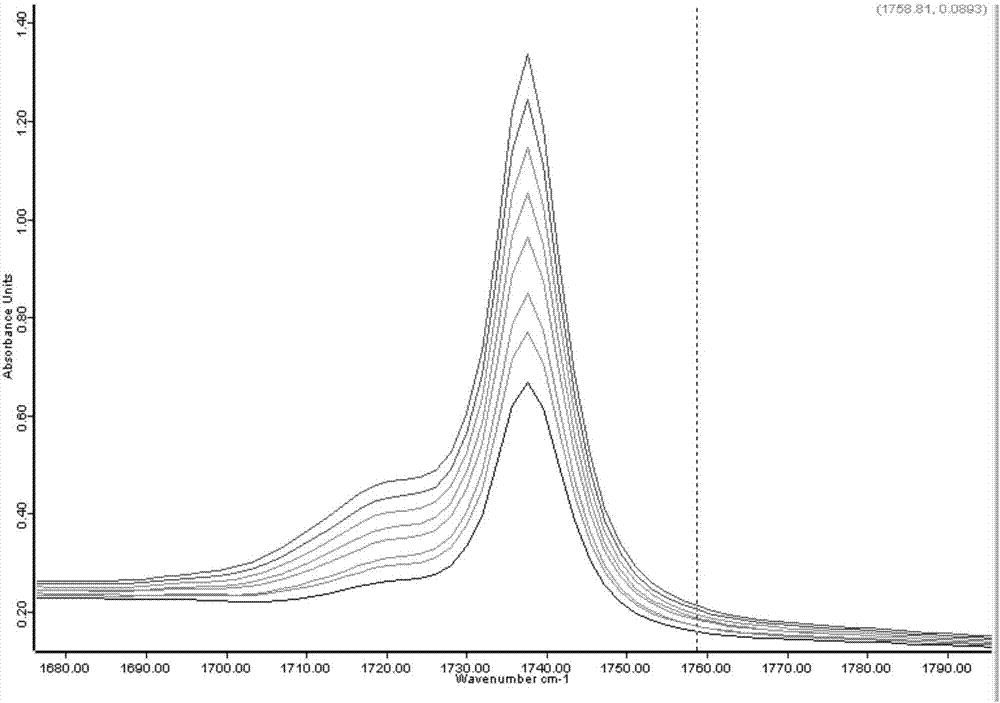

Infrared spectrum detection method for performance of rolling lubricating oil

InactiveCN107478596AReduce operational complexityImprove accuracyColor/spectral properties measurementsInfraredLinear regression

The invention provides an infrared spectrum detection method for performance of rolling lubricating oil. The infrared spectrum detection method comprises the following steps: (A) performing infrared spectrum analysis on a rolling lubricating oil standard sample, and recording peak intensity of alcohols, esters and acids of the sample; (B) by taking the peak intensity as a transverse coordinate and the content of components of the rolling lubricating oil as a longitudinal coordinate, performing linear fitting by using a least square method so as to obtain fitting linear regression equations of alcohol contents, acid contents, ester contents, hydroxyl values, acid values and saponification values, and performing performance detection. The infrared spectrum detection method for performance of the rolling lubricating oil, which is provided by the invention, has the advantages of convenience and rapidness that a conventional chemical analysis method does not have, in addition, the method needs no chemical reagent, the operation tediousness is remarkably reduced, related parameters of performance of the rolling lubricating oil can be tested by implementing the infrared spectrum detection method once, and thus the method is very applicable to wide popularization and application and is very worthy of use reference.

Owner:SHANDONG NANSHAN ALUMINUM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com