Infrared spectrum detection method for performance of rolling lubricating oil

A detection method, infrared spectroscopy technology, applied in the direction of color/spectral characteristic measurement, measuring device, material analysis through optical means, etc., can solve the problems of time-consuming, many reagents, and the change of process parameters cannot be fed back in time, and achieve operation The effect of reduced complexity and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Selection of Calibration Spectrum

[0038] According to the characteristics of lubricating oil in the cold rolling process, configure reasonable calibration data points, and establish a standard working curve. The specific performance data of each sample is shown in Table 1 below:

[0039] Table 1 The component values of each sample in the calibration spectrum

[0040]

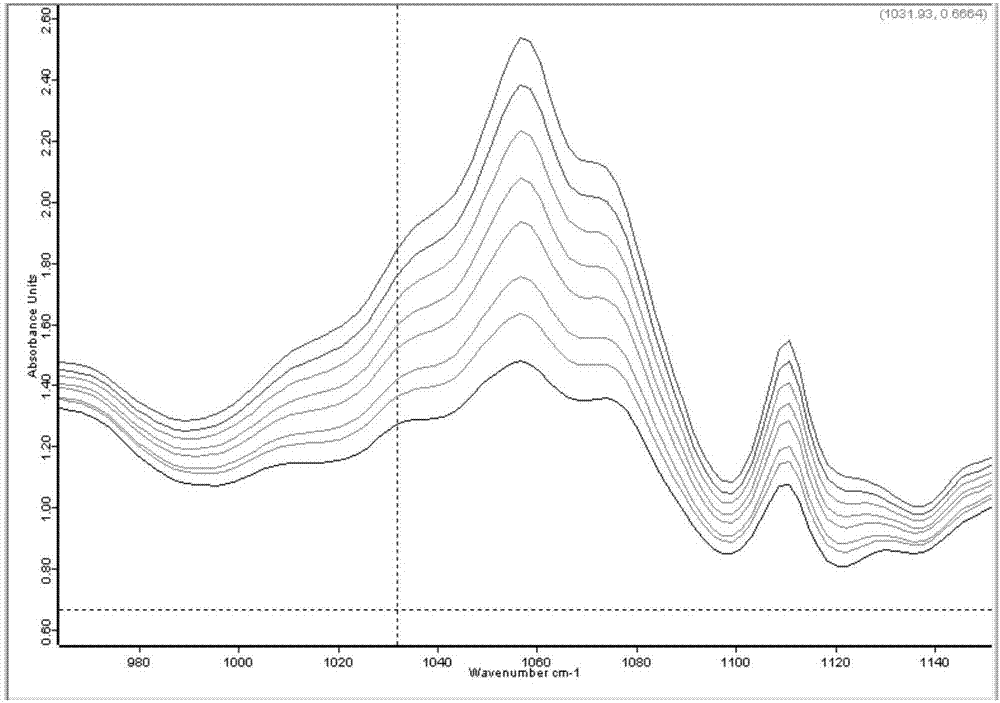

[0041] 2. Define the peak position of the spectrum

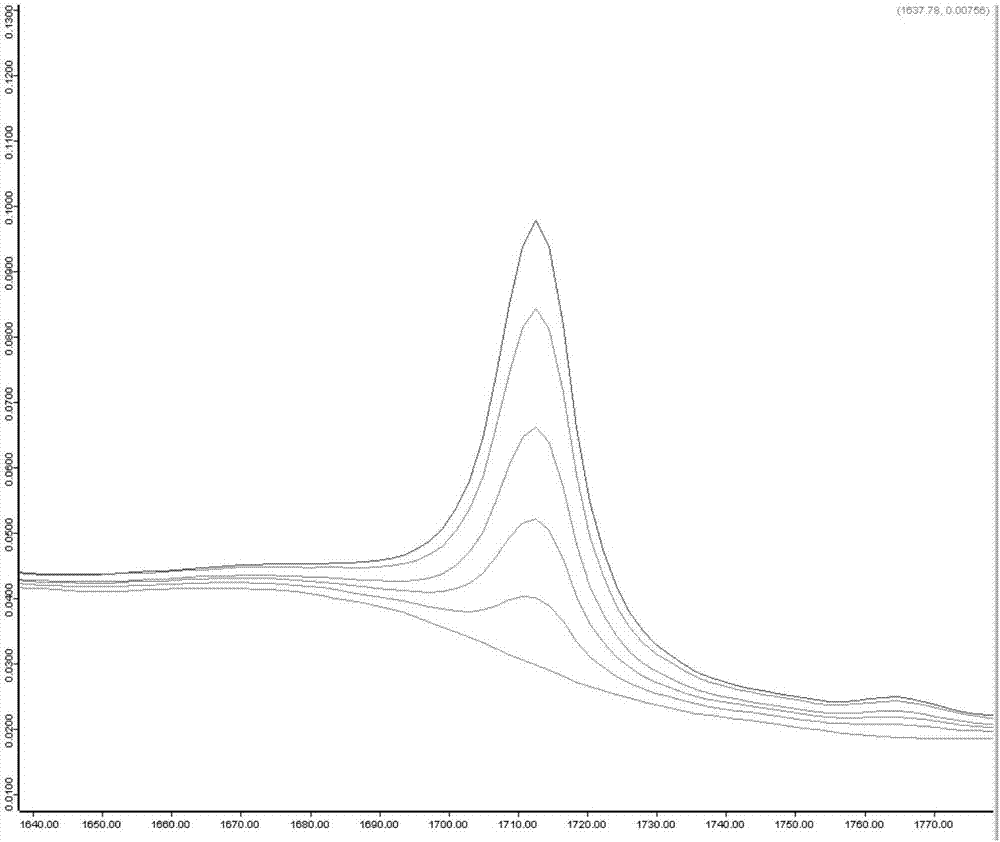

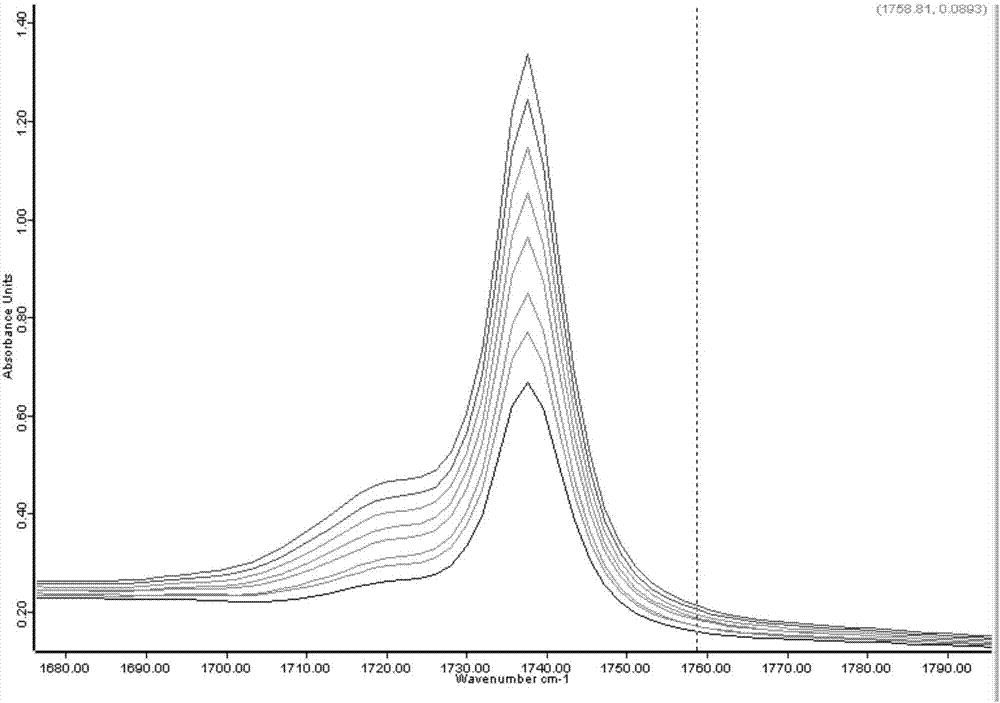

[0042] Use optical attenuator as compensation, record oil sample at 1043cm -1 ~1067cm -1 The infrared spectrum of the interval, the baseline method calculates the C-O stretching vibration absorption band of alcohols in the sample at 1057cm -1 Absorbance intensity at ; recorded at 1720cm -1 ~1770cm -1 The infrared spectrum of the interval, the baseline method calculates the ester stretching vibration absorption band in the sample at 1748cm -1 Absorbance intensity at ; recorded at 1705cm -1 ~1716cm -1The infrared spectrum of the interval...

Embodiment 2

[0061] Adopt the FTIR method of the embodiment of the present invention 1 and the chemical analysis method of prior art (acid value determination method (GB264), nonionic surfactant polyethoxylated derivative hydroxyl value determination (GB / T7384) and petroleum product saponification Value determination method (GB / T8021) these three kinds of methods), by detecting the rolling lubricating oil that alcohol content is 1wt%, the relative error between FTIR method and the chemical analysis method of prior art is below 3%.

Embodiment 3

[0063] Adopt the FTIR method of the embodiment of the present invention 1 and the chemical analysis method of prior art (acid value determination method (GB264), nonionic surfactant polyethoxylated derivative hydroxyl value determination (GB / T7384) and petroleum product saponification Value determination method (GB / T8021) these three methods), by detecting the rolling lubricating oil that alcohol content is 10wt%, the relative error between FTIR method and the chemical analysis method of prior art is below 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com